Tribological Properties of Aluminum–Silicon Alloy Cylinder Liners Paired with DLC and CKS Piston Rings

Abstract

1. Introduction

2. Experimental Materials and Methods

2.1. Experimental Materials

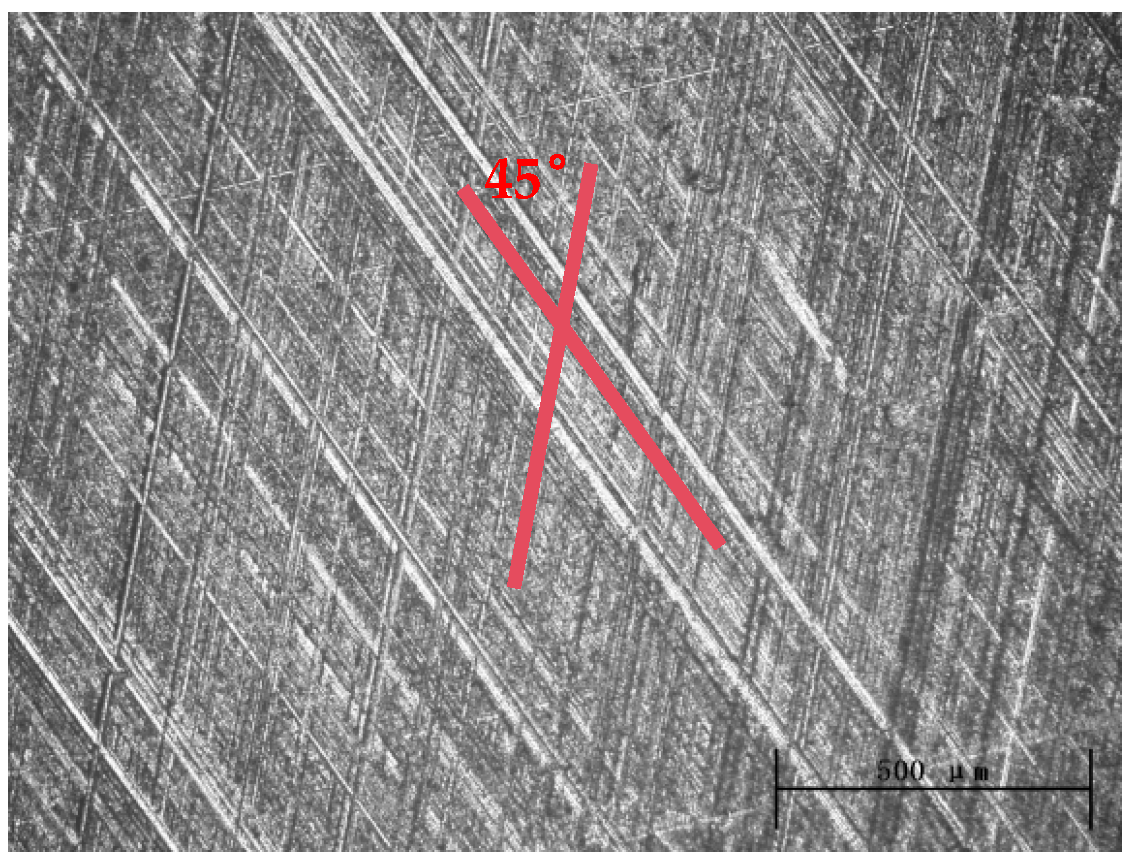

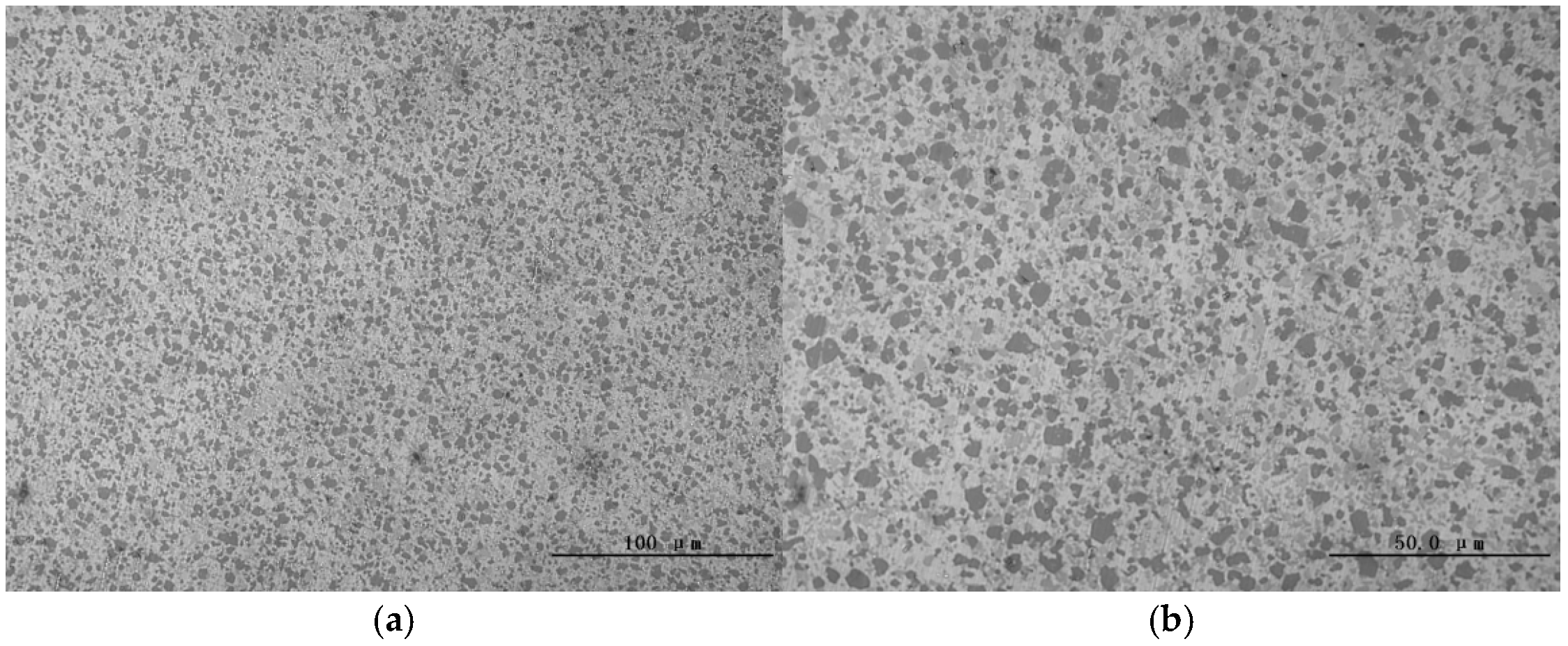

2.1.1. Aluminum–Silicon Alloy Cylinder Liner

2.1.2. Piston Rings

2.2. Experimental Methods

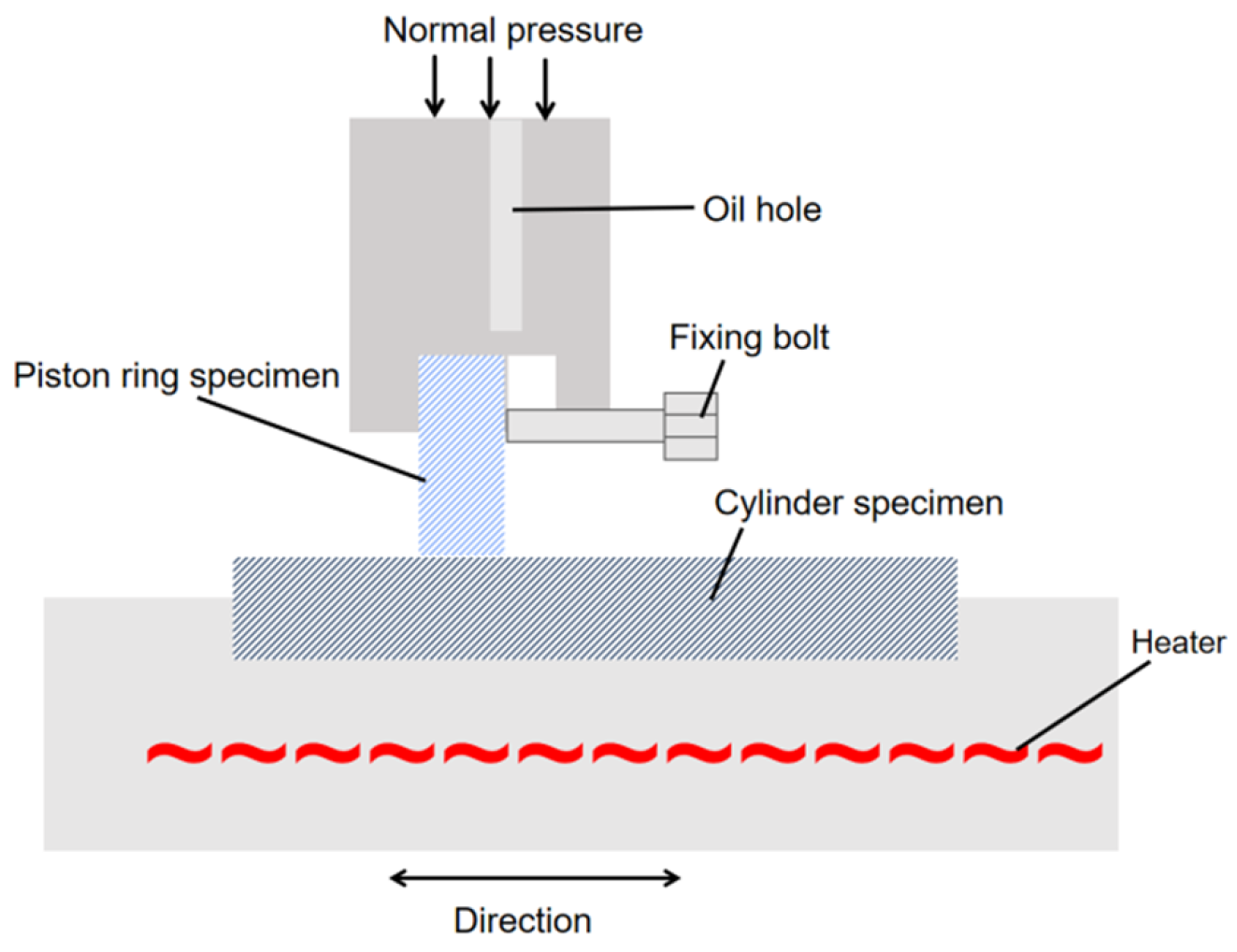

2.2.1. Experimental Equipment

2.2.2. Experimental Plan

- (a)

- Speed Selection:

- (b)

- Temperature Selection:

- (c)

- Load Selection:

- (d)

- Wear Test Duration:

| Test Stage | Test Parameters |

|---|---|

| Running-in Stage | 200 r/min 120 °C 5 MPa 1 h |

| 200 r/min 120 °C 10 MPa 1 h | |

| 200 r/min 120 °C 15 MPa 1 h | |

| Steady-State Wear Stage | 200 r/min 260 °C 20 MPa 21 h |

3. Results and Analysis

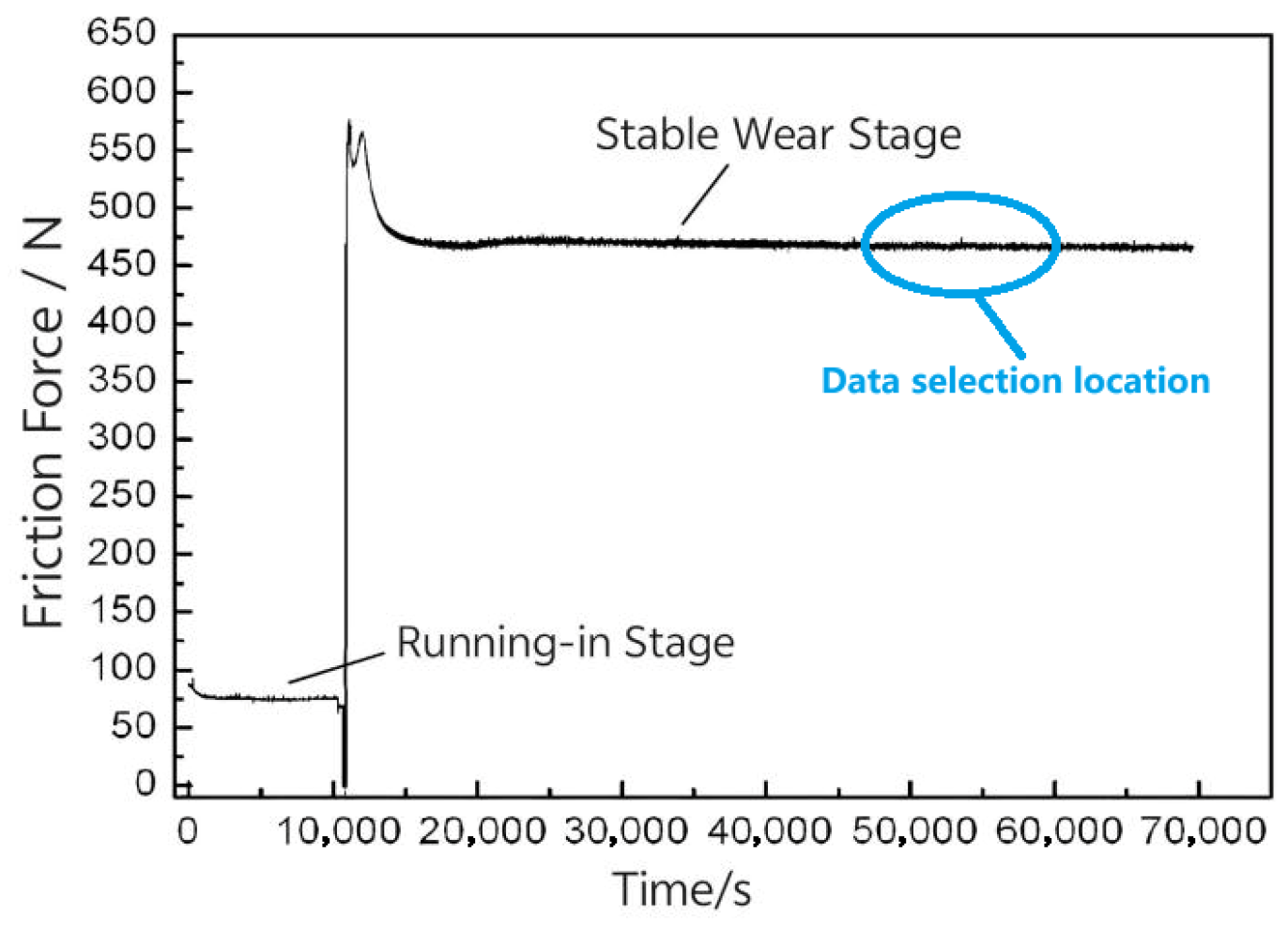

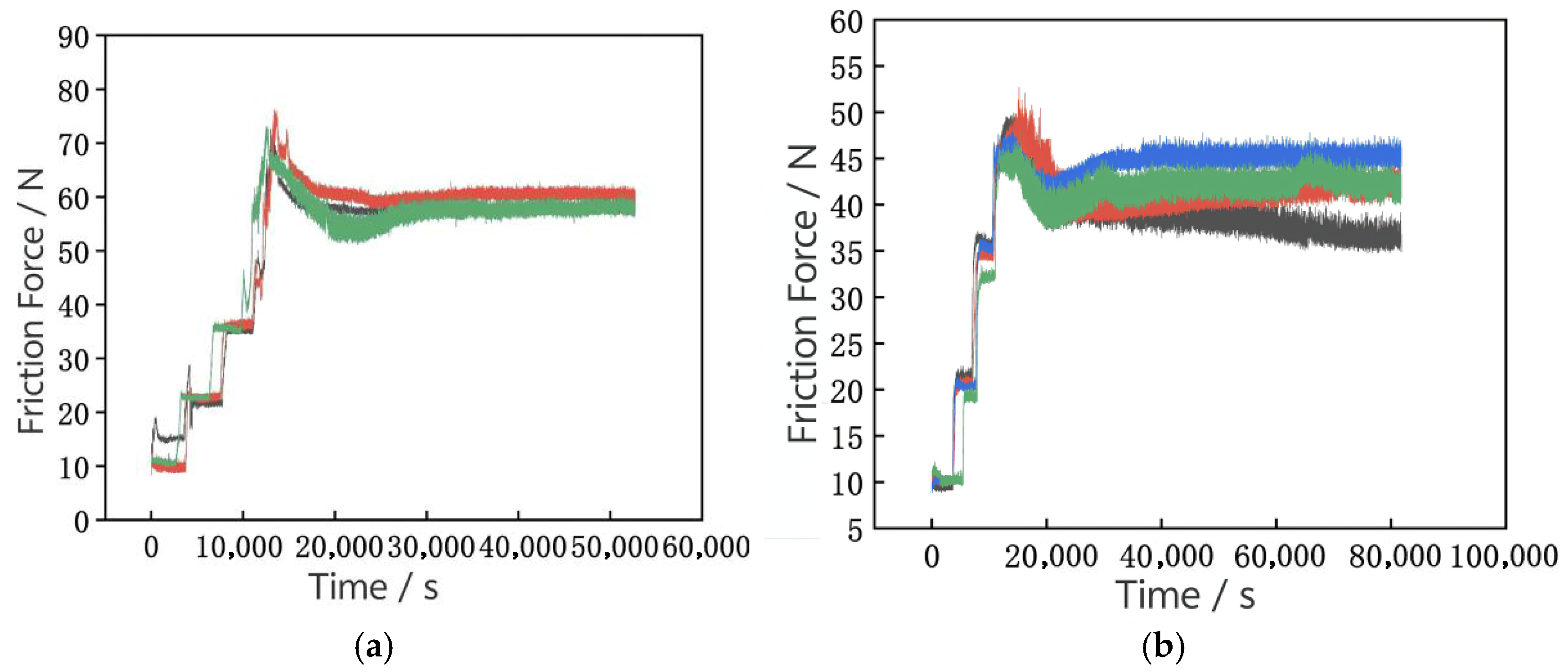

3.1. Friction Performance

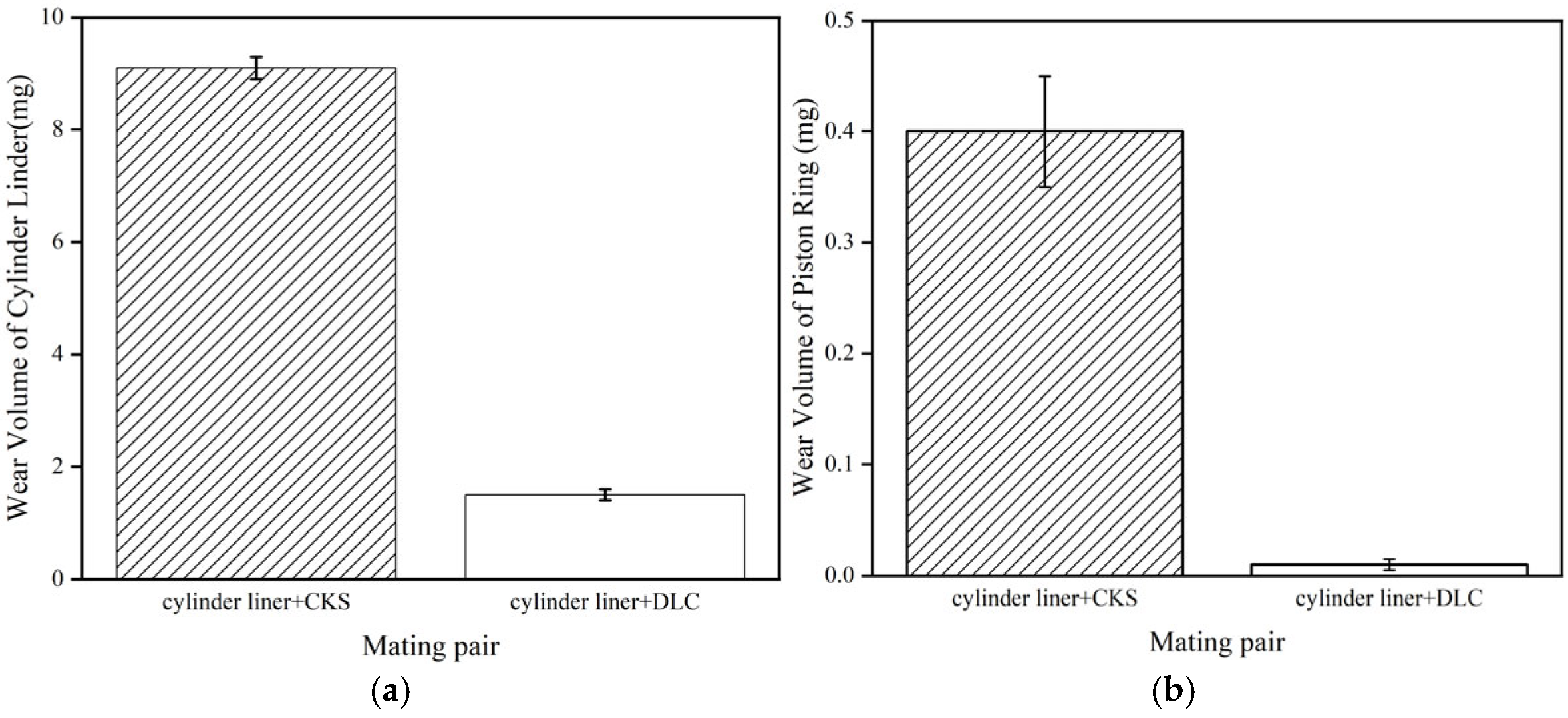

3.2. Wear Volume Analysis

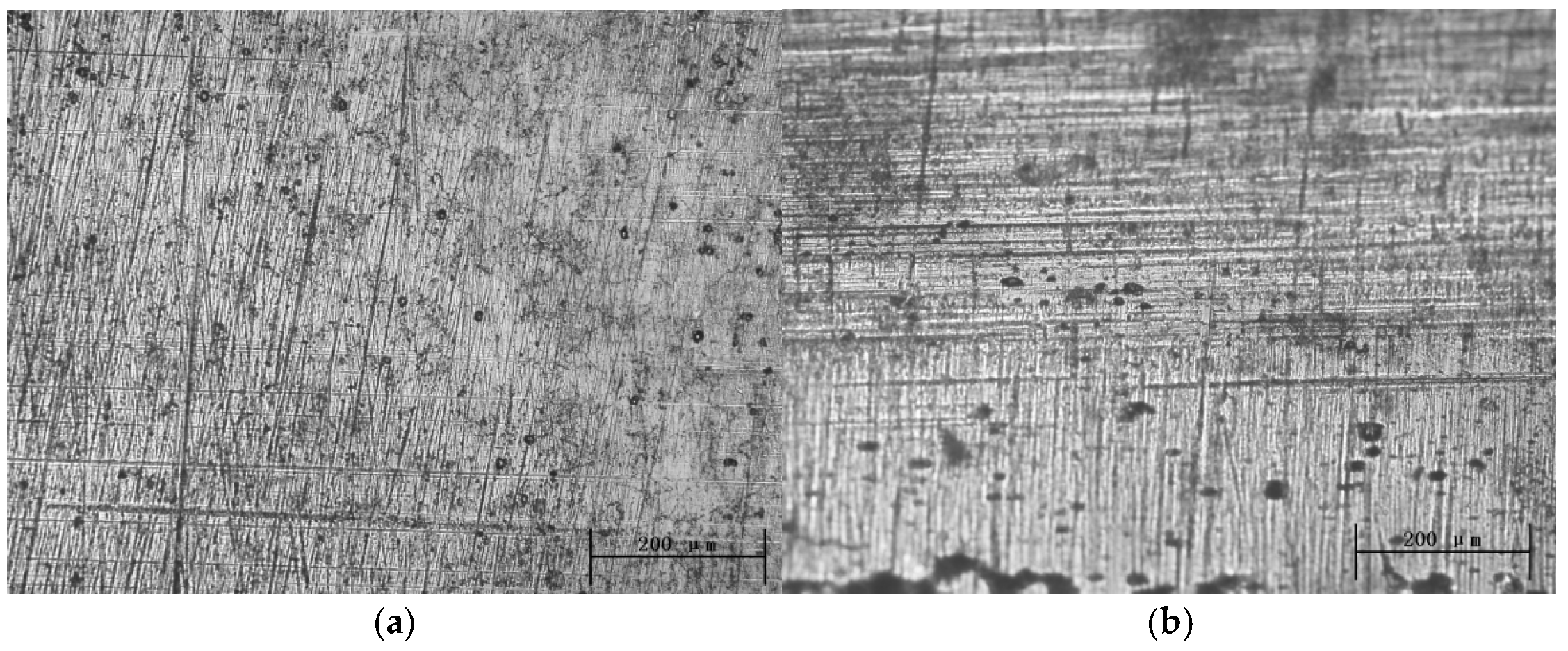

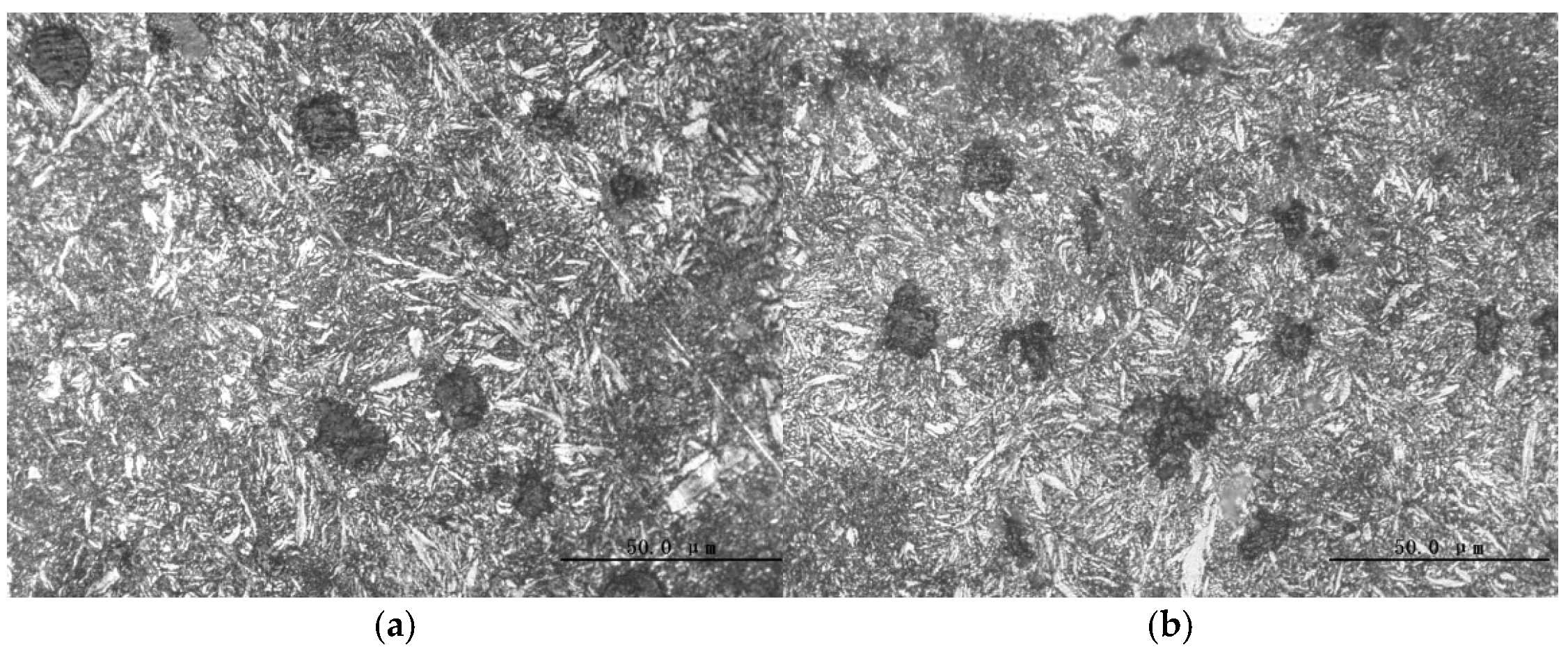

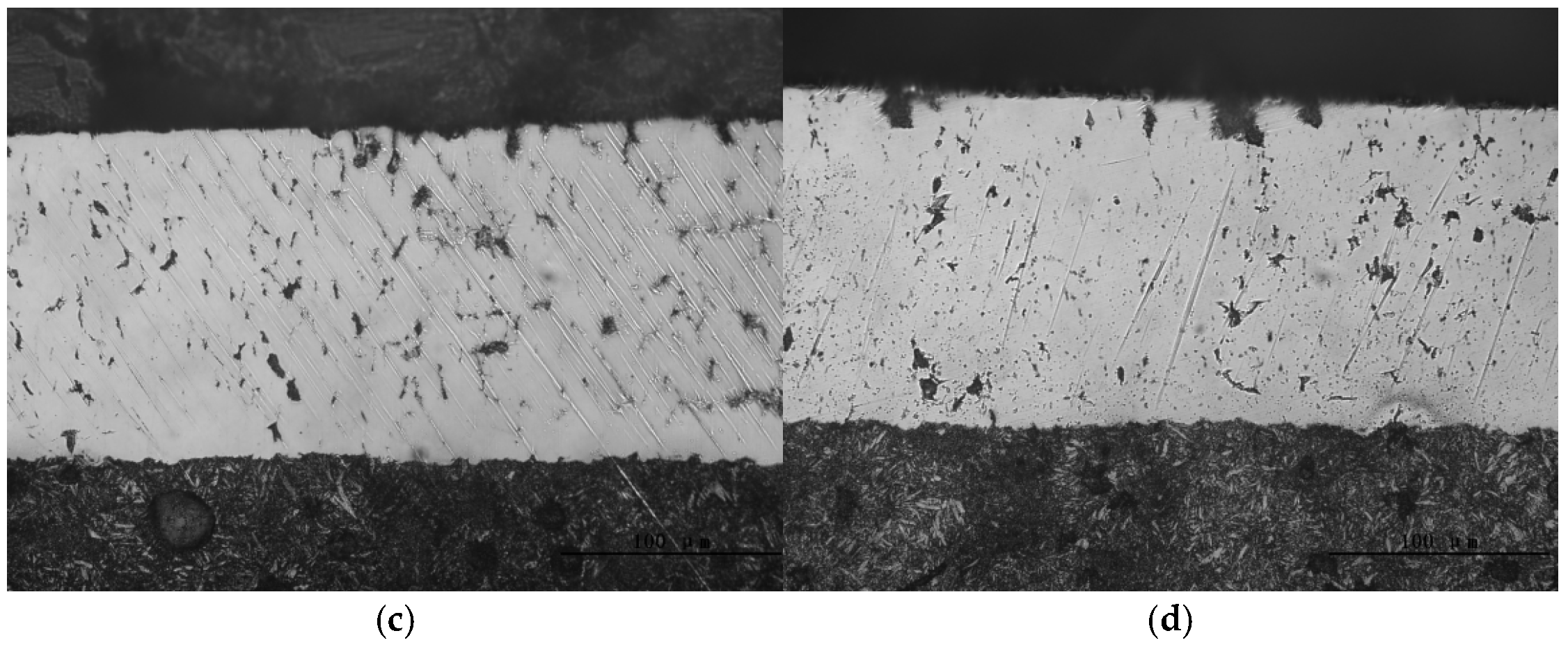

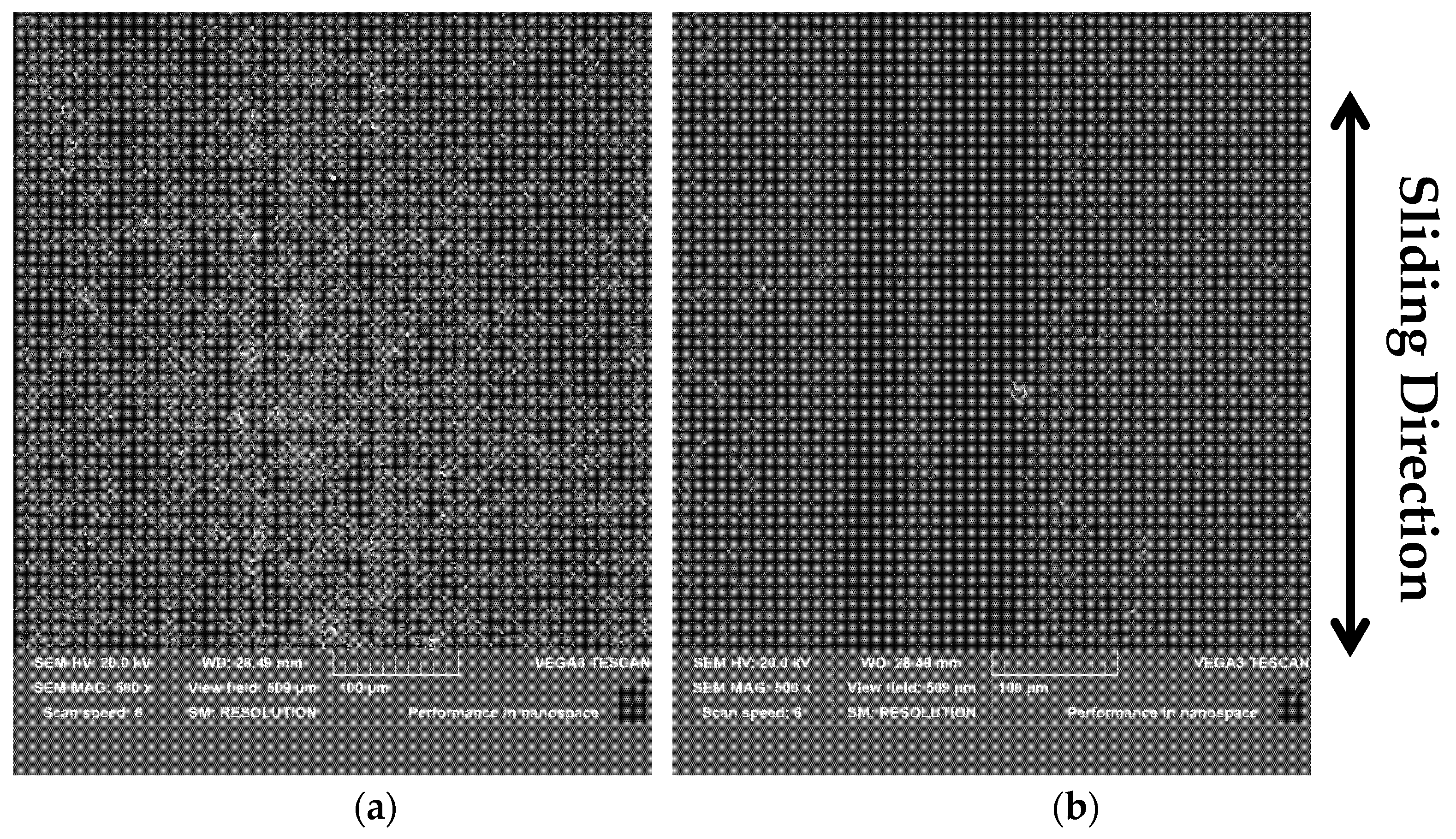

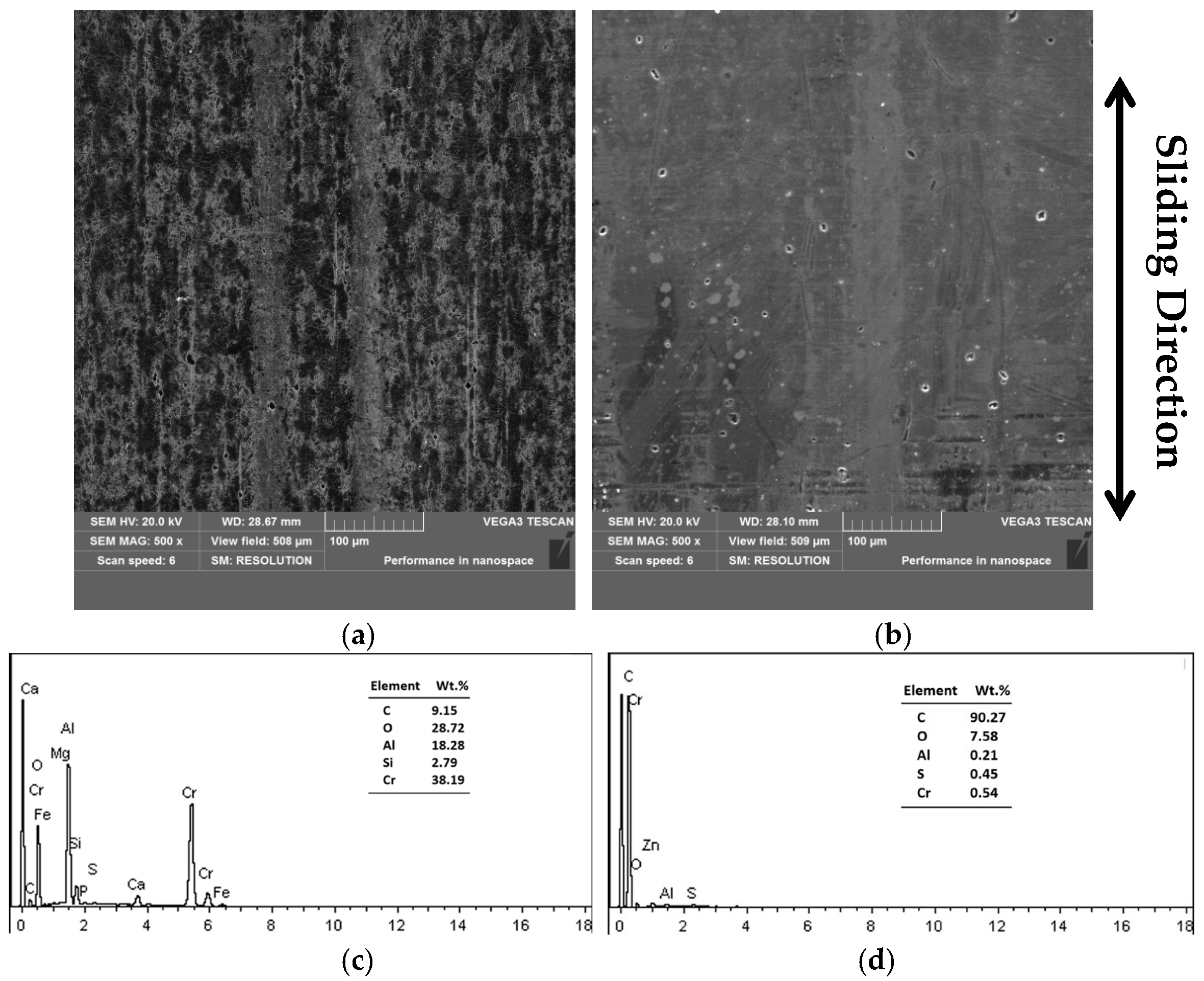

3.3. Worn Surface Morphology

3.4. Wear Mechanism

4. Conclusions

- (1)

- When the aluminum–silicon alloy cylinder liner is paired with the DLC piston ring, compared to pairing with the CKS piston ring, the friction coefficient is reduced by 27.82%, the wear volume of the cylinder liner is reduced by 83.52%, and the ear volume of the piston ring is reduced by 97.5%. This pairing exhibits lower friction coefficients and wear volumes, demonstrating superior tribological properties.

- (2)

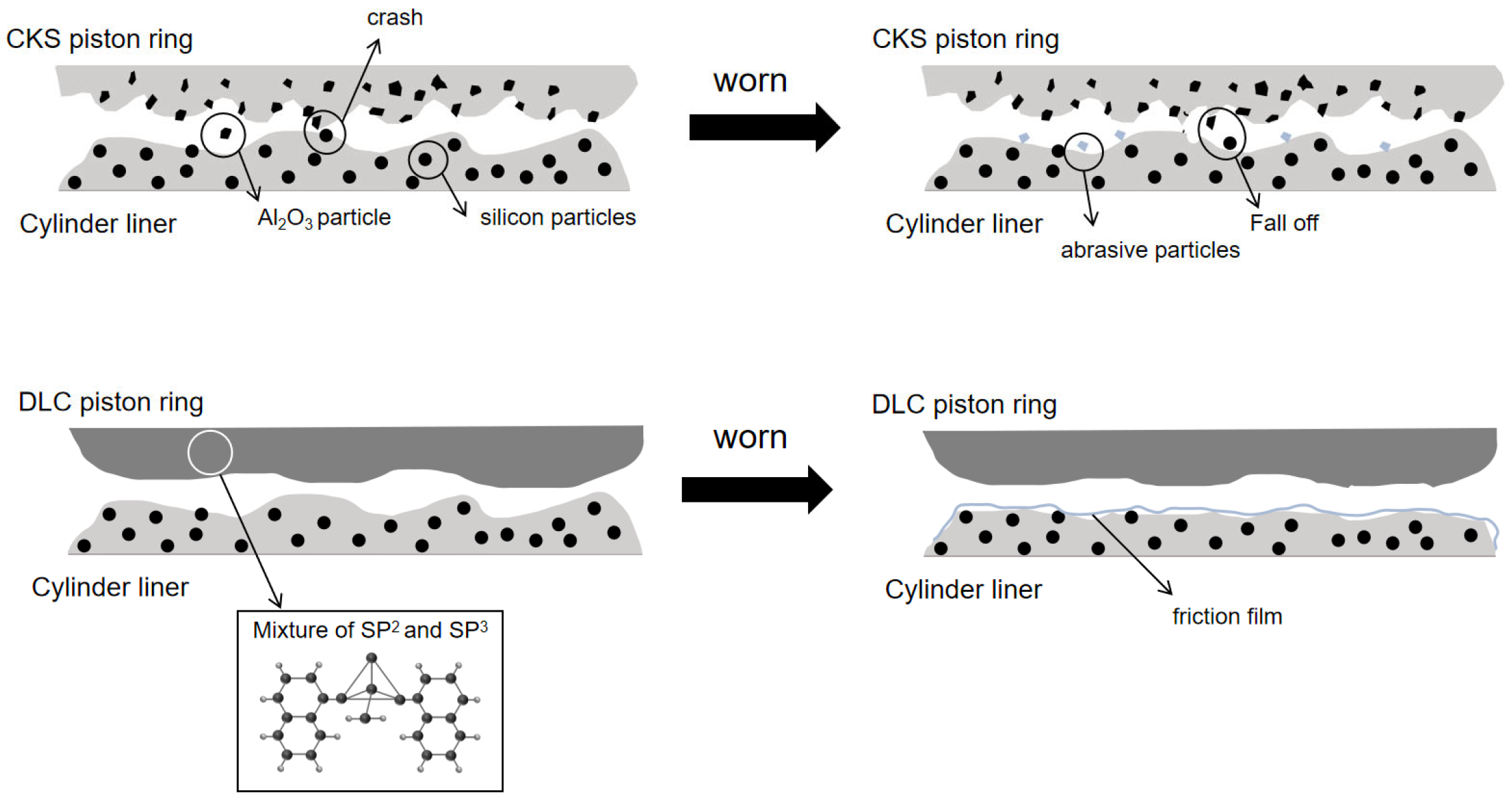

- When the aluminum–silicon alloy cylinder liner is paired with the CKS piston ring, distinct plowing marks are observed on the surface of the CKS piston ring after wear. Additionally, pits caused by the detachment of silicon particles are evident on the cylinder liner surface, indicating abrasive wear during the interaction between the cylinder liner and piston ring. In contrast, the surface of the DLC piston ring after wear remains relatively smooth, with minimal wear and retention of the original machining marks. Although scratches along the sliding direction are observed on the cylinder liner, the wear surface is smooth, and no abrasive wear is present.

- (3)

- The CKS piston ring coating, with fine ceramic particles in a chromium matrix, and the cylinder liner, containing uniformly distributed fine silicon particles, undergo particle detachment during wear. This generates abrasives that exacerbate frictional wear of the pair (higher friction coefficient, abrasive wear), leading to plowing marks on the CKS ring and particle detachment pits on the liner. In contrast, the DLC coating—with sp3-and sp2-hybridized carbon, combining diamond’s hardness and graphite’s lubricity—when paired with the Al-Si liner, exhibits a smooth surface without abrasive wear, as well as significantly lower friction and wear, thus showing superior performance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Markut, T.; Summer, F.; Pusterhofer, M.; Grün, F. Emergence of Coated Piston Ring Scuffing Behavior on an Application-Oriented Tribological Model Test System. Lubricants 2024, 12, 218. [Google Scholar] [CrossRef]

- Wong, V.W.; Tung, S.C. Overview of automotive engine friction and reduction trends–Effects of surface, material, and lubricant-additive technologies. Friction 2016, 4, 1–28. [Google Scholar] [CrossRef]

- Slattery, B.; Edrisy, A.; Perry, T. Investigation of wear induced surface and subsurface deformation in a linerless Al–Si engine. Wear 2010, 269, 298–309. [Google Scholar] [CrossRef]

- Li, C.; Chen, X.; Liu, H.; Dong, L.; Jian, H.; Wang, J.; Du, F. Tribological Performance and Scuffing Resistance of Cast-Iron Cylinder Liners and aluminum-silicon alloy cylinder liners. Coatings 2023, 13, 1951. [Google Scholar] [CrossRef]

- Li, C.D.; Chen, X.; Du, F.-M.; Shen, Y.; Xu, J.-J. The influence of protruding silicon particle shape on the friction performance of Al–Si alloy. Surf. Topogr. Metrol. Prop. 2020, 8, 025022. [Google Scholar] [CrossRef]

- Esser, J.; Linde, R.; Münchow, F. Diamantbewehrte Laufschicht für Kompressionsringe. MTZ-Mot. Z. 2004, 65, 582–585. [Google Scholar] [CrossRef]

- Kennedy, M.; Hoppe, S.; Esser, J. Piston ring coating reduces gasoline engine friction. MTZ Worldw. 2012, 73, 40–43. [Google Scholar] [CrossRef]

- Ma, S.; Chen, W.; Li, C.; Jin, M.; Huang, R.-X.; Xu, J.-J. Wear properties and scuffing resistance of the Cr–Al2O3 coated piston rings: The effect of convexity position on barrel surface. J. Tribol. 2019, 141, 021301. [Google Scholar] [CrossRef]

- Ohtake, N.; Hiratsuka, M.; Kanda, K.; Akasaka, H.; Tsujioka, M.; Hirakuri, K.; Hirata, A.; Ohana, T.; Inaba, H.; Kano, M.; et al. Properties and classification of diamond-like carbon films. Materials 2021, 14, 315. [Google Scholar] [CrossRef] [PubMed]

- Tyagi, A.; Walia, R.; Murtaza, Q.; Pandey, S.M.; Tyagi, P.K.; Bajaj, B. A critical review of diamond like carbon coating for wear resistance applications. Int. J. Refract. Met. Hard Mater. 2019, 78, 107–122. [Google Scholar] [CrossRef]

- Rajak, D.K.; Kumar, A.; Behera, A.; Menezes, P.L. Diamond-like carbon (DLC) coatings: Classification, properties, and applications. Appl. Sci. 2021, 11, 4445. [Google Scholar] [CrossRef]

- Moriguchi, H.; Ohara, H.; Tsujioka, M. History and applications of diamond-like carbon manufacturing processes. Sei Tech. Rev. 2016, 82, 52–58. [Google Scholar]

- Wan, S.H.; Li, D.S.; Zhang, G.A.; Tieu, A.K.; Zhang, B. Comparison of the scuffing behaviour and wear resistance of candidate engineered coatings for automotive piston rings. Tribol. Int. 2017, 106, 10–22. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, Z.; Huang, R.; Zhao, Z.; Zhang, W. Tribological Properties of Several Surface-Modified Piston Rings Under Extreme Conditions. ASME J. Tribol. 2024, 146, 011701. [Google Scholar] [CrossRef]

- Ferreira, R.; Almeida, R.; Carvalho, Ó.; Sobral, L.; Carvalho, S.; Silva, F. Influence of a DLC coating topography in the piston ring/cylinder liner tribological performance. J. Manuf. Process. 2021, 66, 483–493. [Google Scholar] [CrossRef]

- Bian, X.; Han, X.; Luo, J.; Li, C.; Hao, M. Effect of composite surface treatments on wear performance of Al-Si alloy cylinder liner. Ind. Lubr. Tribol. 2023, 75, 858–865. [Google Scholar] [CrossRef]

- Mabuchi, Y.; Higuchi, T.; Weihnacht, V. Effect of sp2/sp3 bonding ratio and nitrogen content on friction properties of hydrogen-free DLC coatings. Tribol. Int. 2013, 62, 130–140. [Google Scholar] [CrossRef]

- Kennedy, M.; Hoppe, S.; Esser, J. Lower friction losses with new piston ring coating. MTZ Worldw. 2014, 3, 30–35. [Google Scholar] [CrossRef]

- Dearnaley, G.; Arps, J.H. Biomedical applications of diamond-like carbon (DLC) coatings: A review. Surf. Coat. Technol. 2005, 200, 2518–2524. [Google Scholar] [CrossRef]

| Element | Si | Fe | Ni | Cu | Mn | Mg | V | Al |

|---|---|---|---|---|---|---|---|---|

| Mass Fraction | 20% | 5% | 2% | 3% | 2% | 1% | <1% | balanced |

| Experimental Order | 1 | 2 | 3 | 4 | 5 | Average |

|---|---|---|---|---|---|---|

| Microhardness (HV0.3) | 441.2 | 430.0 | 450.6 | 426.2 | 391.2 | 428.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guan, Y.; Li, C.-D.; Chen, X.; Zhu, S.-X.; Dong, L.-J.; Ye, P.; Deng, X.-F.; Zhou, L.-B.; Wu, L.-Y. Tribological Properties of Aluminum–Silicon Alloy Cylinder Liners Paired with DLC and CKS Piston Rings. Lubricants 2025, 13, 487. https://doi.org/10.3390/lubricants13110487

Guan Y, Li C-D, Chen X, Zhu S-X, Dong L-J, Ye P, Deng X-F, Zhou L-B, Wu L-Y. Tribological Properties of Aluminum–Silicon Alloy Cylinder Liners Paired with DLC and CKS Piston Rings. Lubricants. 2025; 13(11):487. https://doi.org/10.3390/lubricants13110487

Chicago/Turabian StyleGuan, Yong, Cheng-Di Li, Xiao Chen, Shuang-Xia Zhu, Lian-Jie Dong, Peng Ye, Xian-Feng Deng, Ling-Bo Zhou, and Lin-Ya Wu. 2025. "Tribological Properties of Aluminum–Silicon Alloy Cylinder Liners Paired with DLC and CKS Piston Rings" Lubricants 13, no. 11: 487. https://doi.org/10.3390/lubricants13110487

APA StyleGuan, Y., Li, C.-D., Chen, X., Zhu, S.-X., Dong, L.-J., Ye, P., Deng, X.-F., Zhou, L.-B., & Wu, L.-Y. (2025). Tribological Properties of Aluminum–Silicon Alloy Cylinder Liners Paired with DLC and CKS Piston Rings. Lubricants, 13(11), 487. https://doi.org/10.3390/lubricants13110487