Quantitative Study on the Friction of Different Types of Base Oils Based on Stribeck Curve and Traction Curve Characterization

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Materials

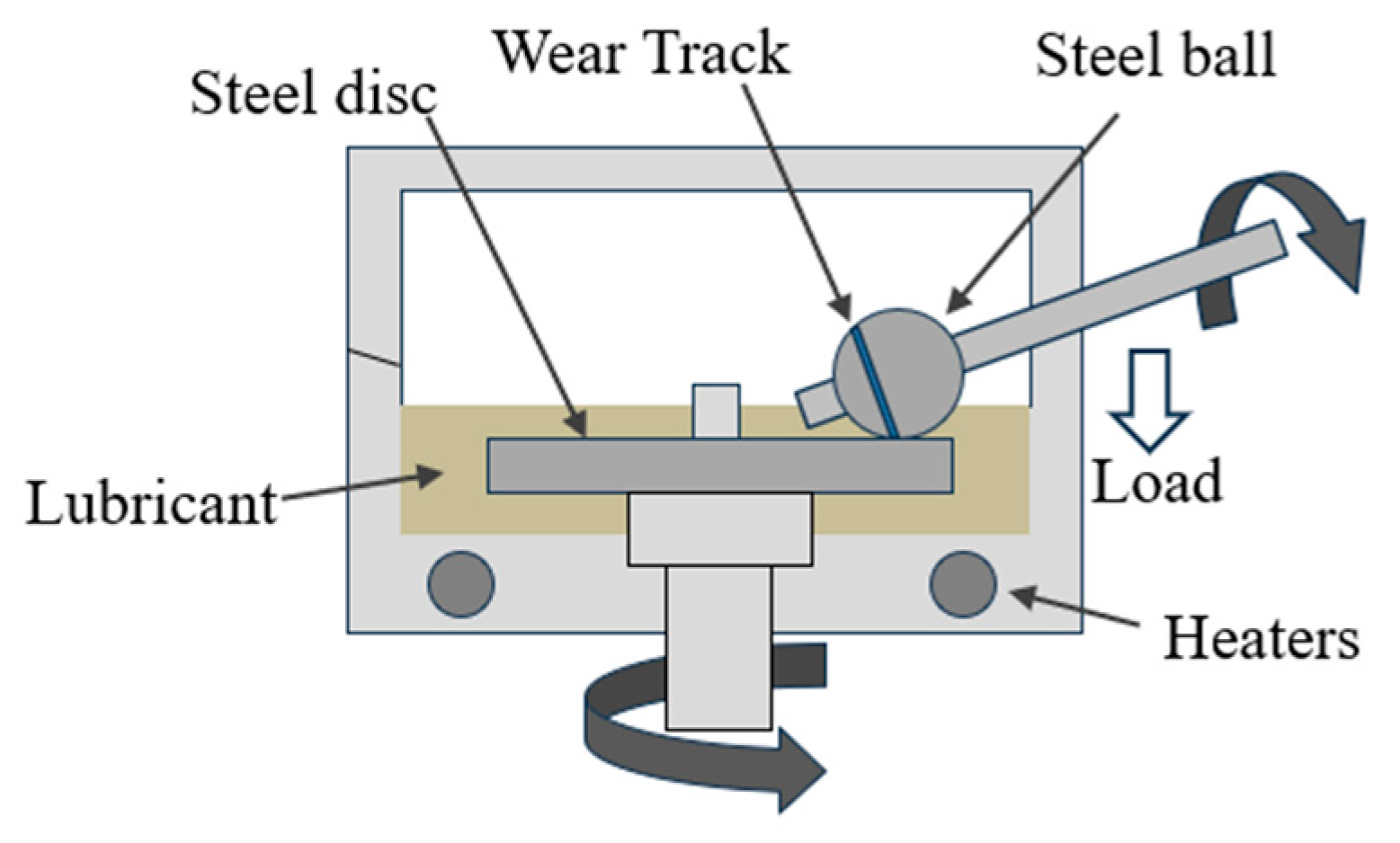

2.2. Test Rig

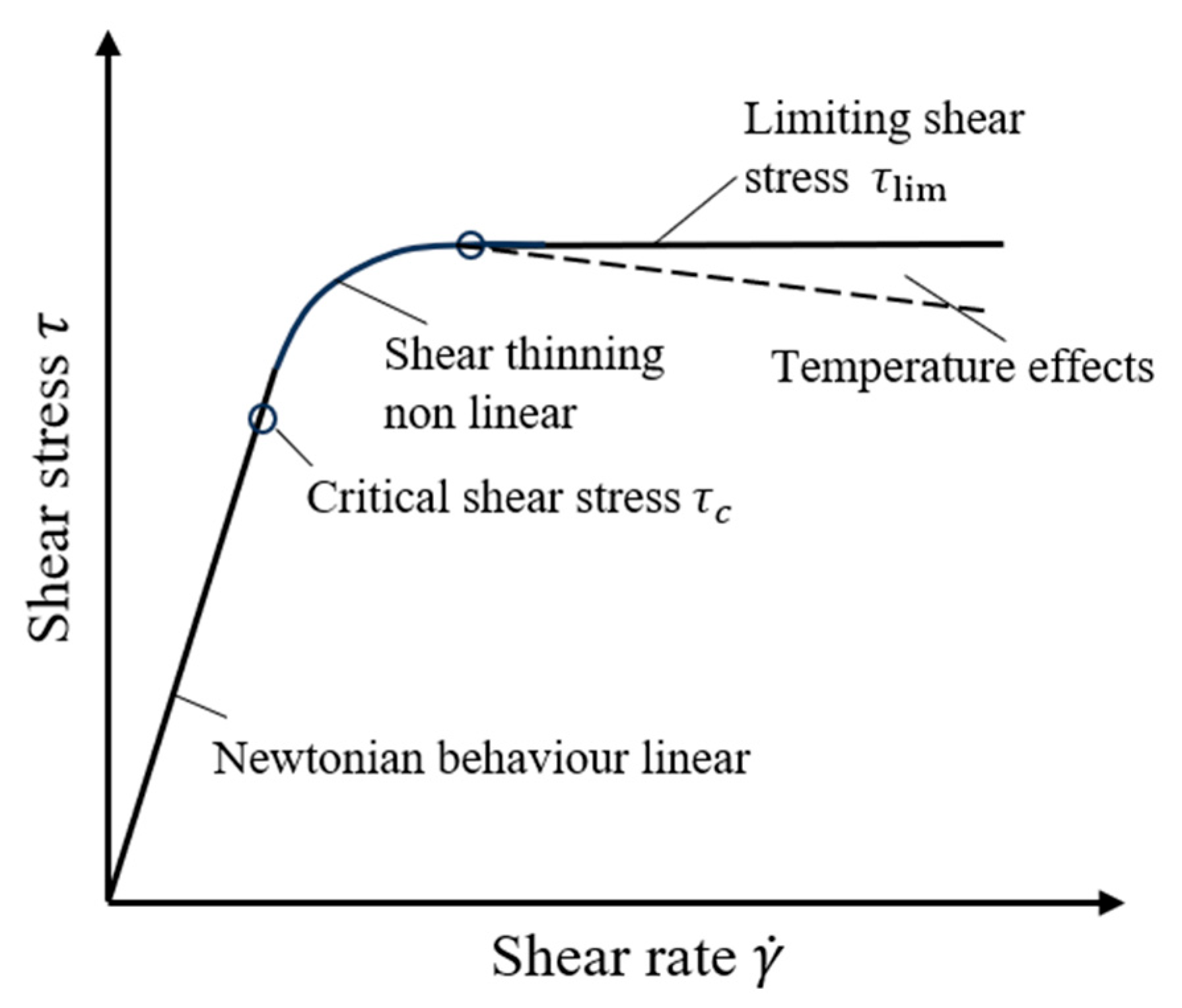

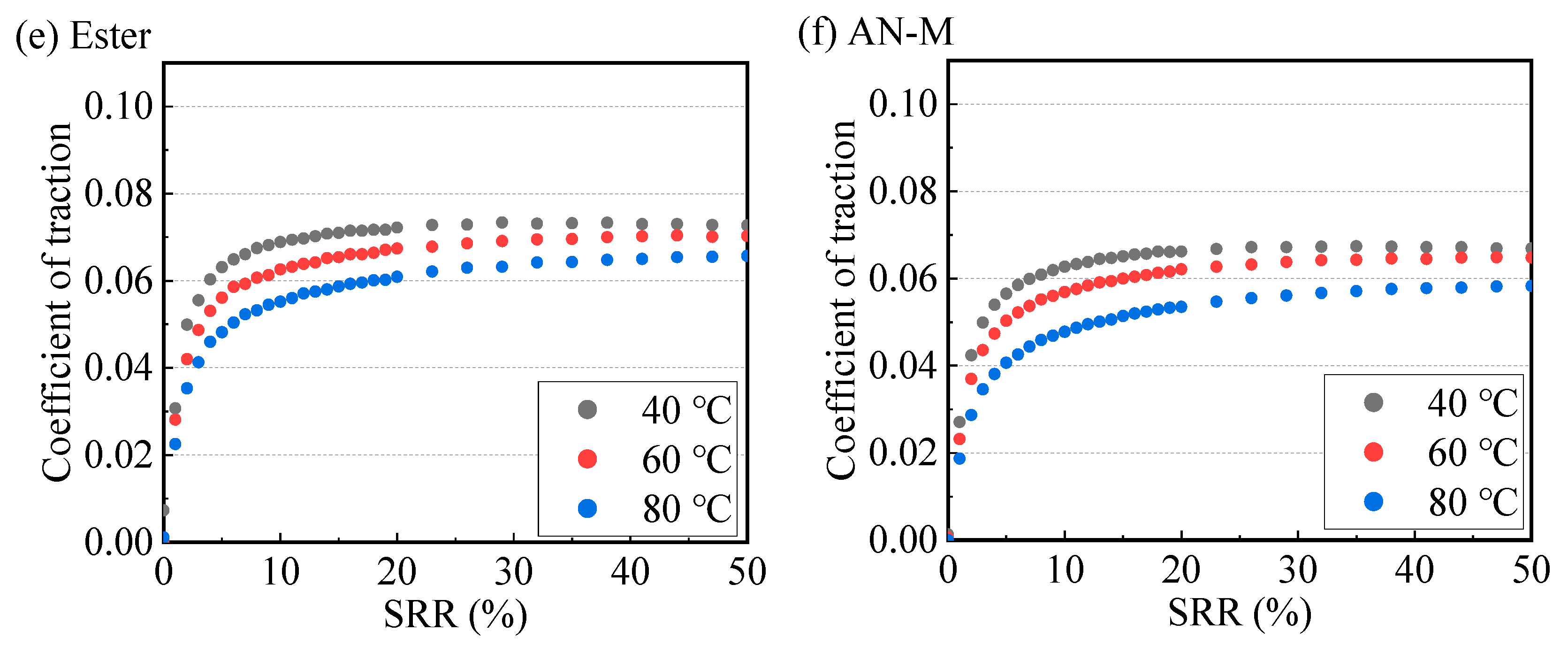

2.3. Calculation of Limiting Shear Stress

2.4. Experimental Conditions

3. Results and Discussion

3.1. Viscosity-Temperature Properties

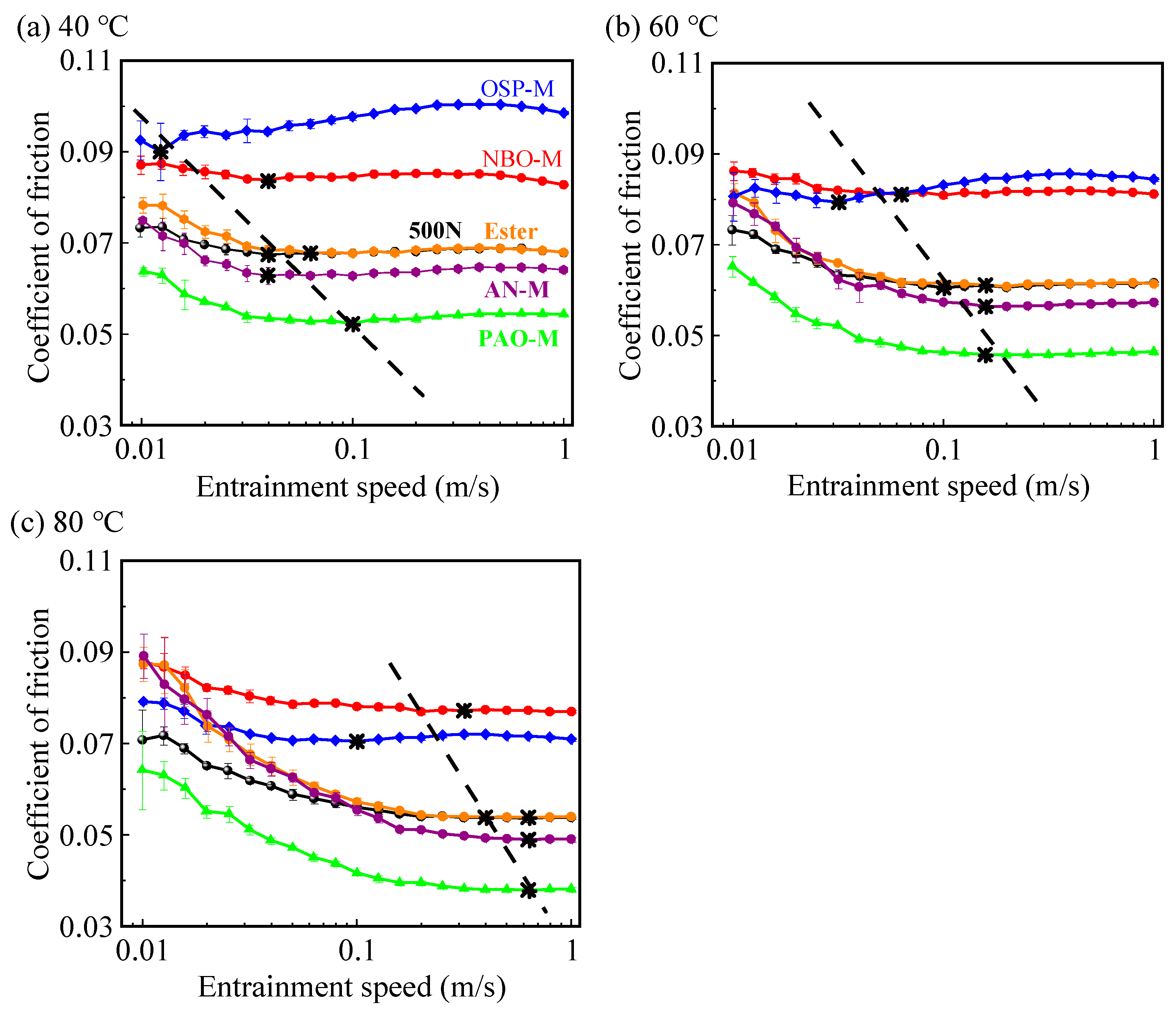

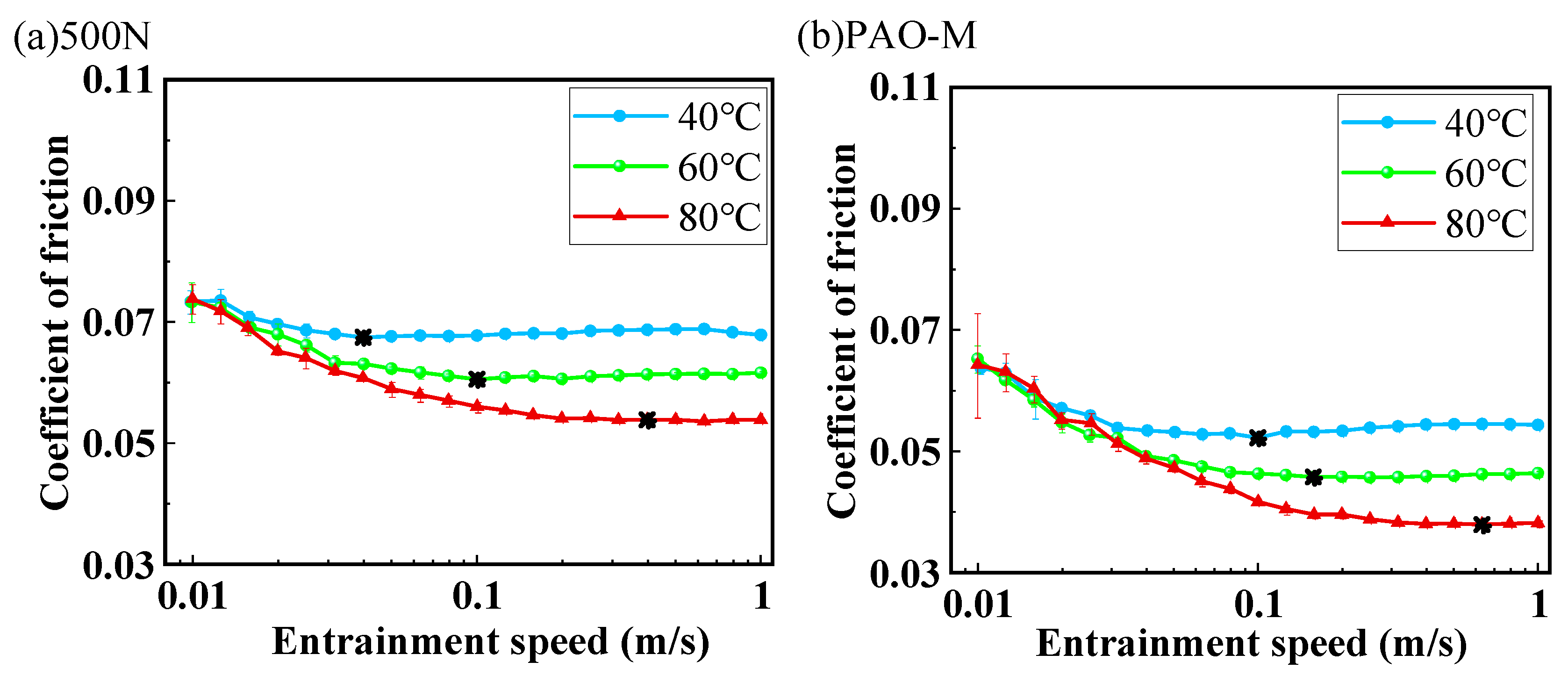

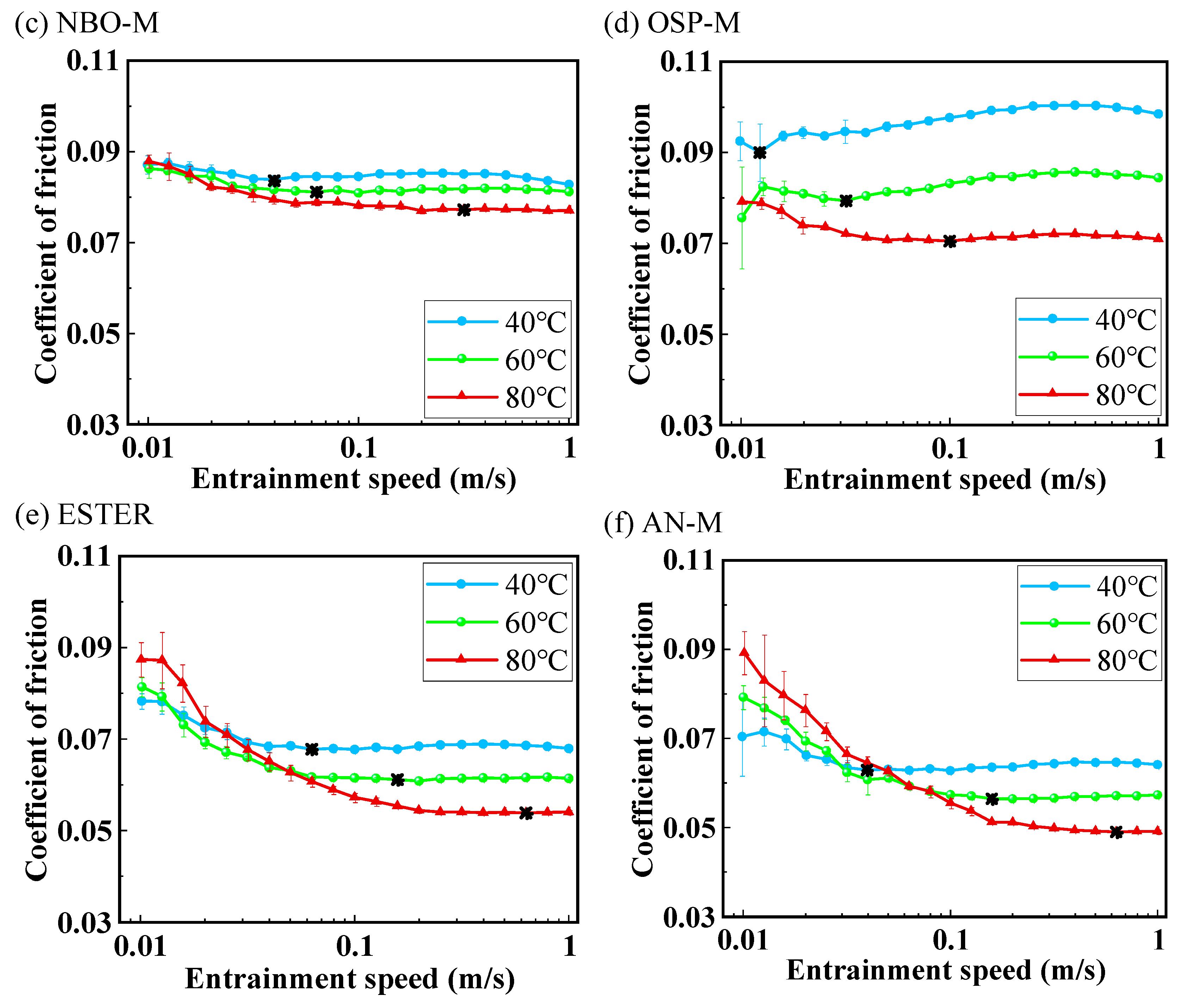

3.2. Comparison of Stribeck Curves for Different Types of Base Oils

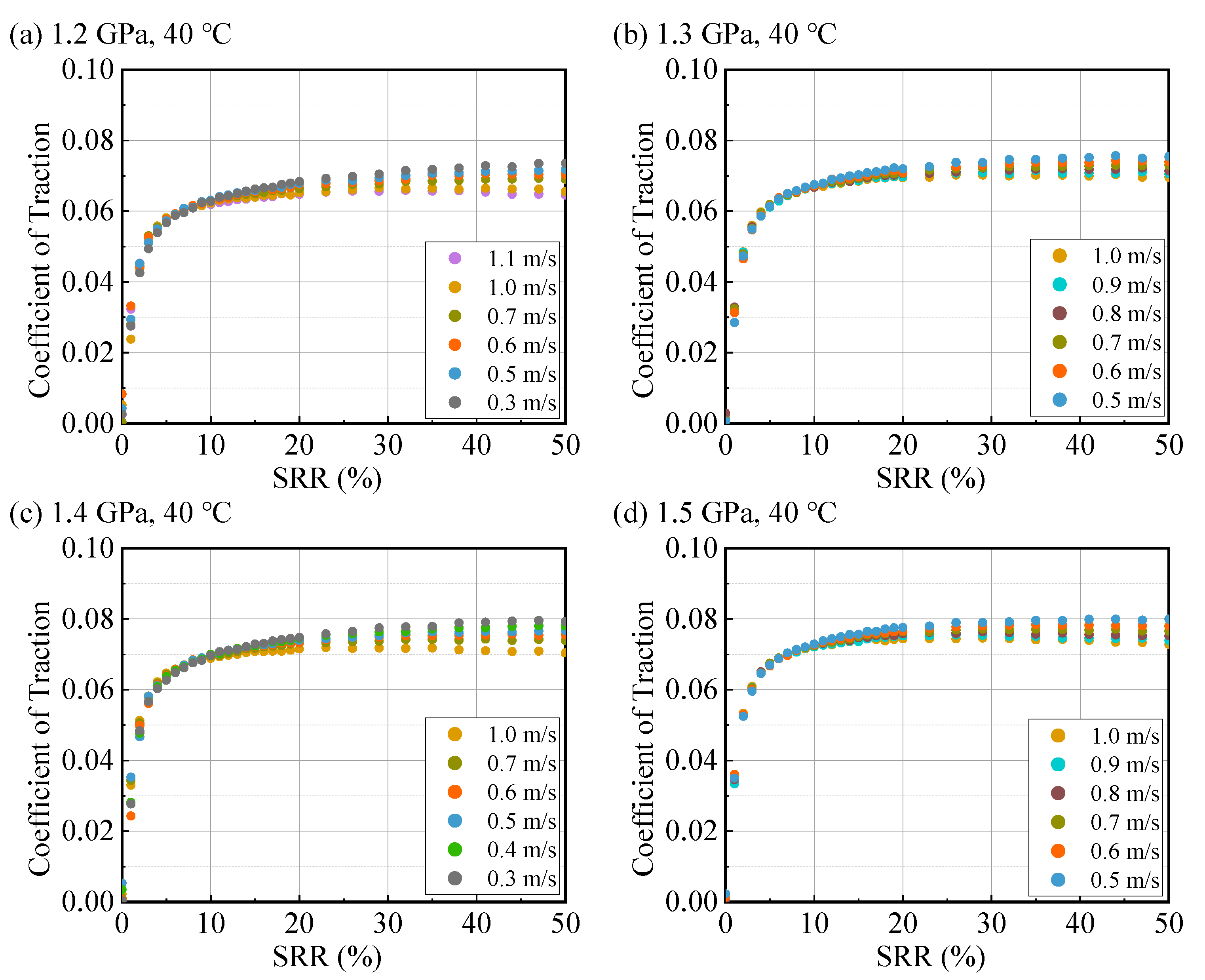

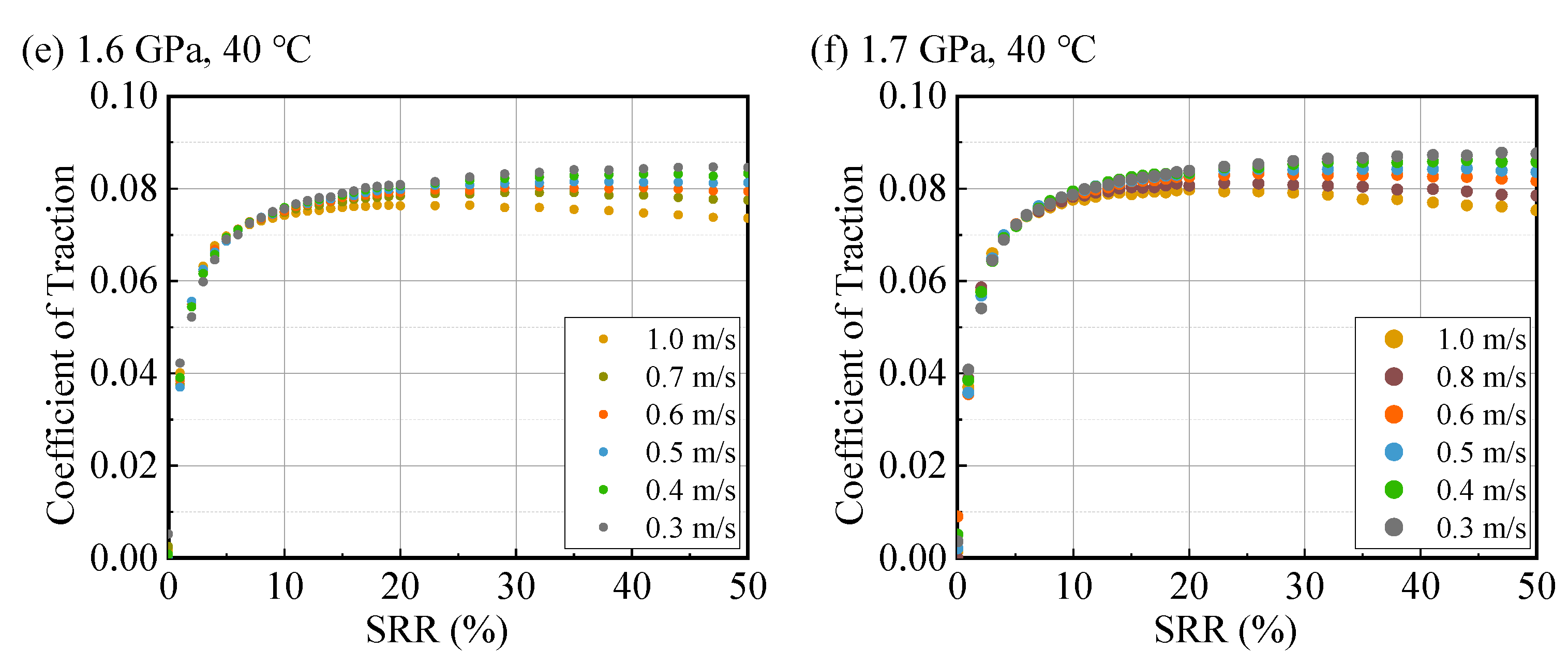

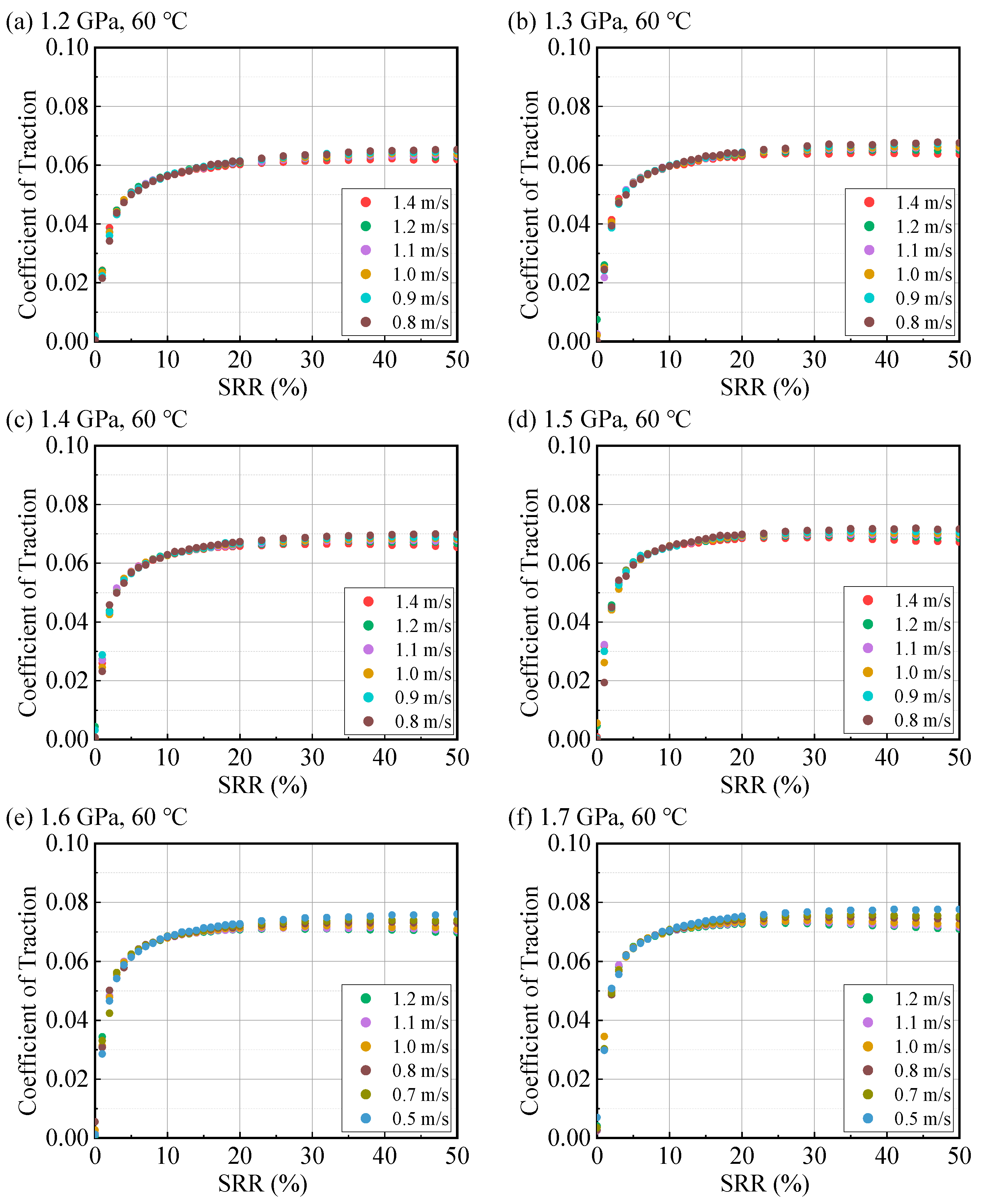

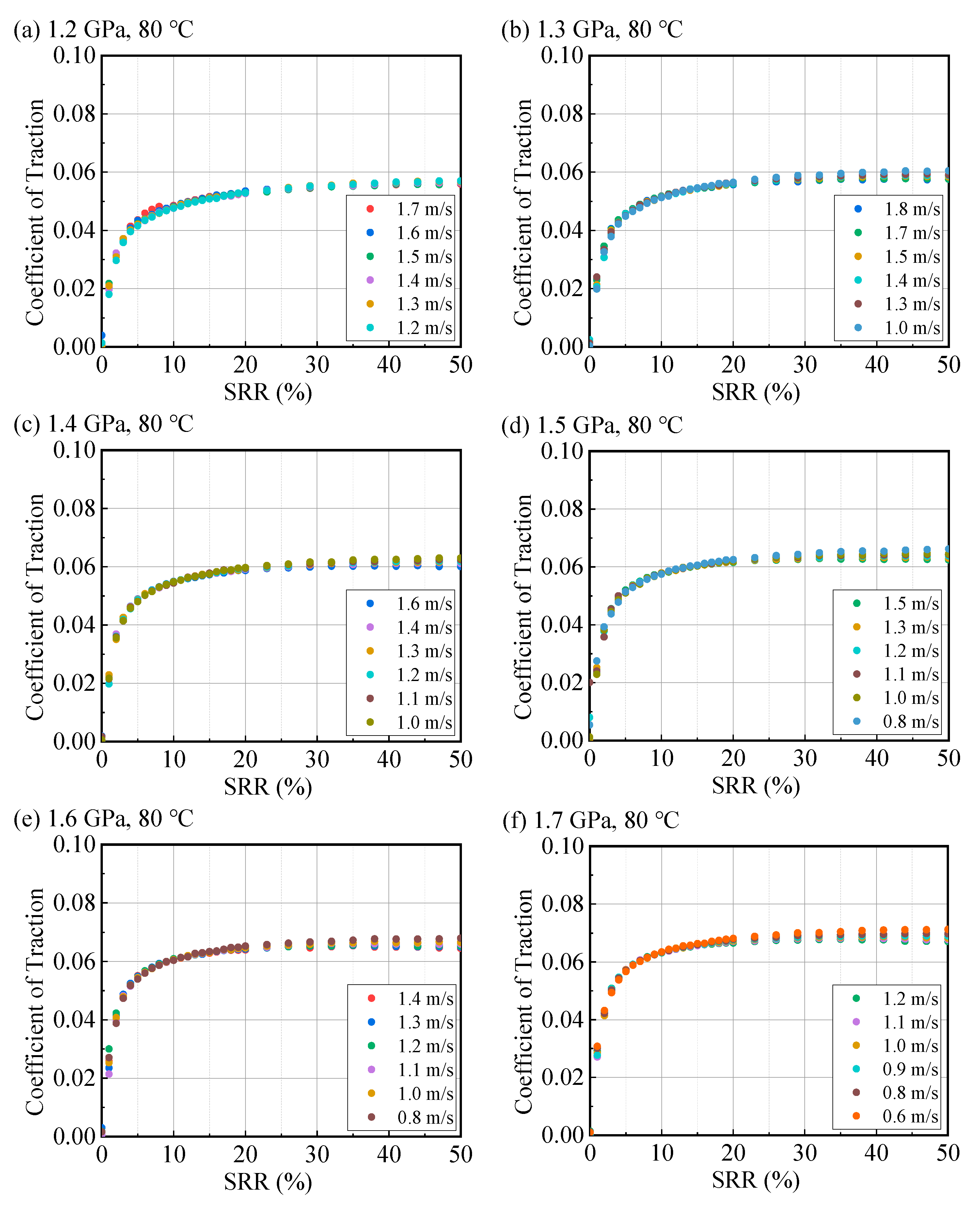

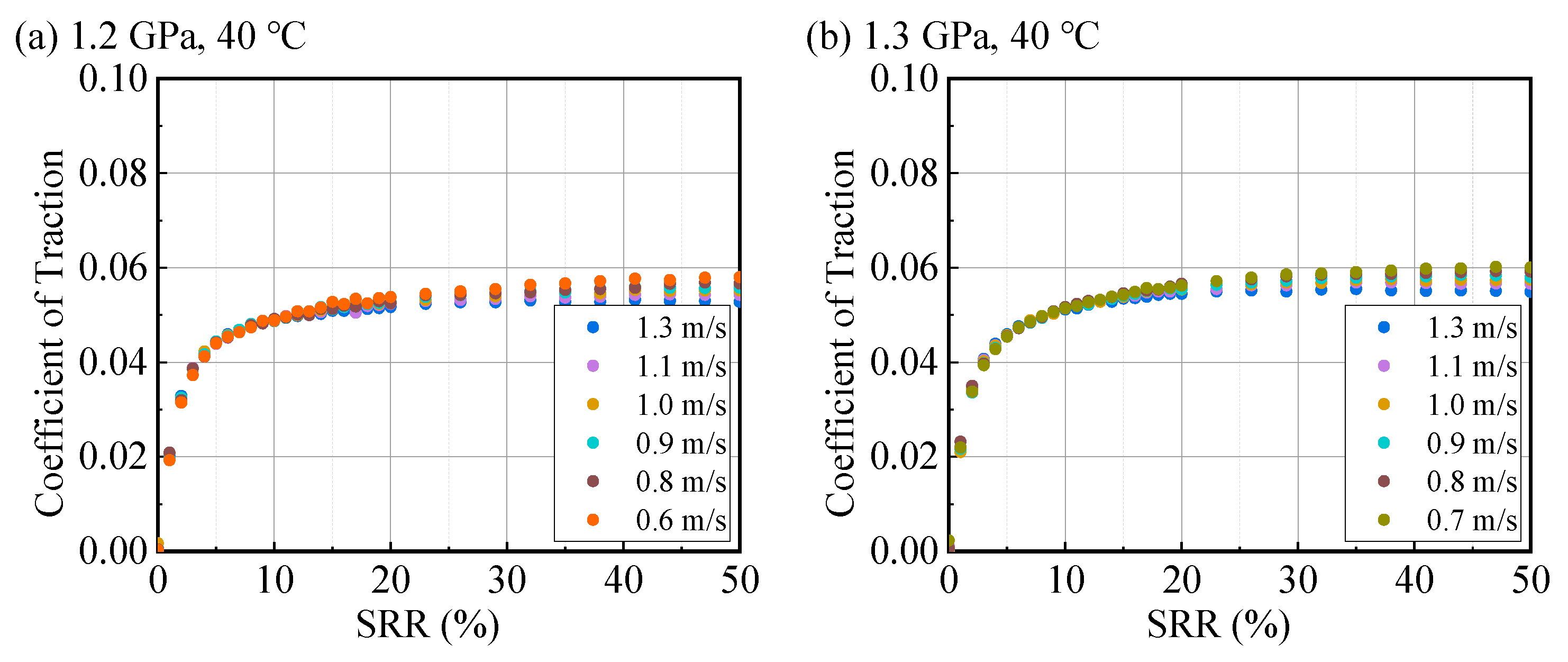

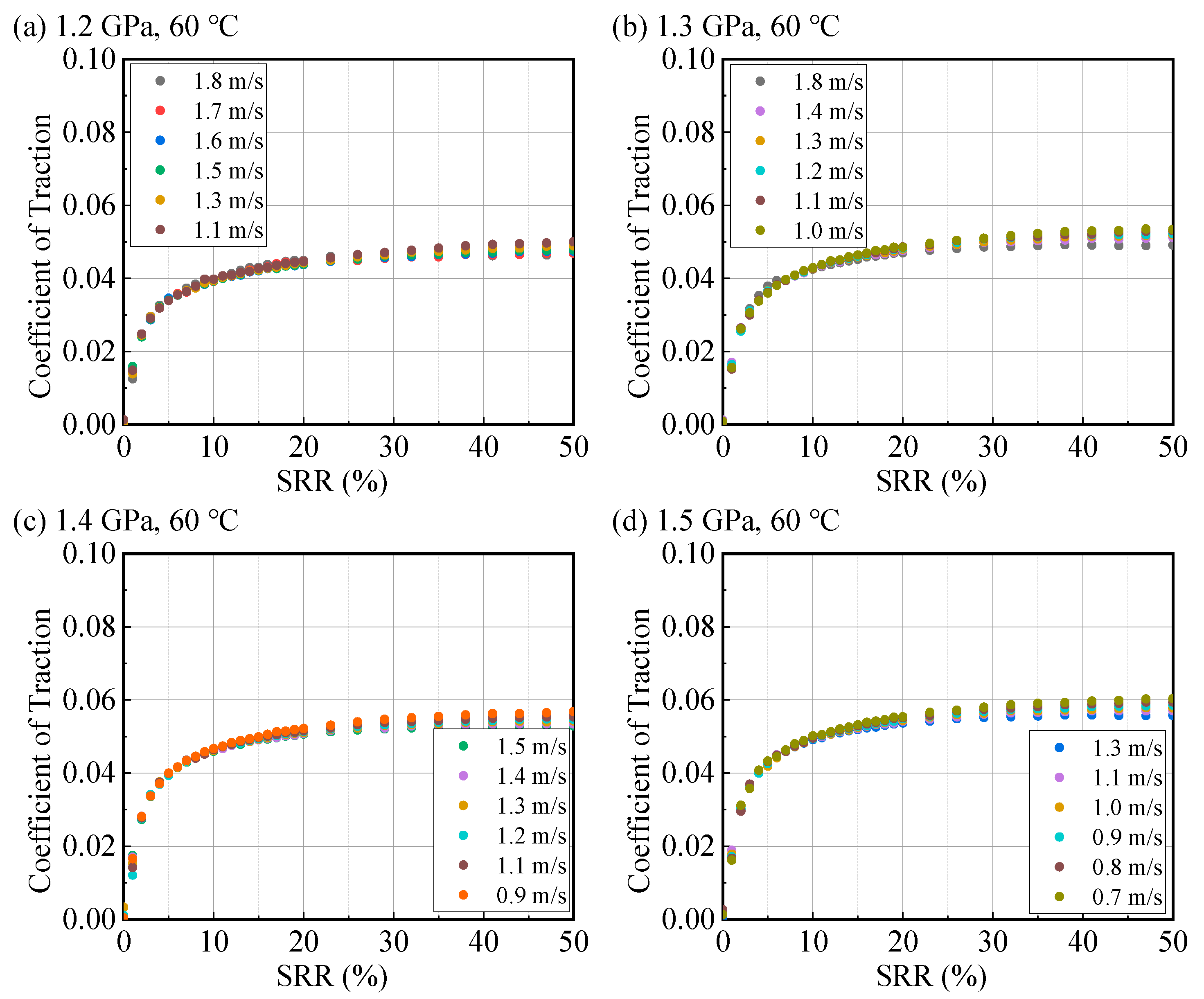

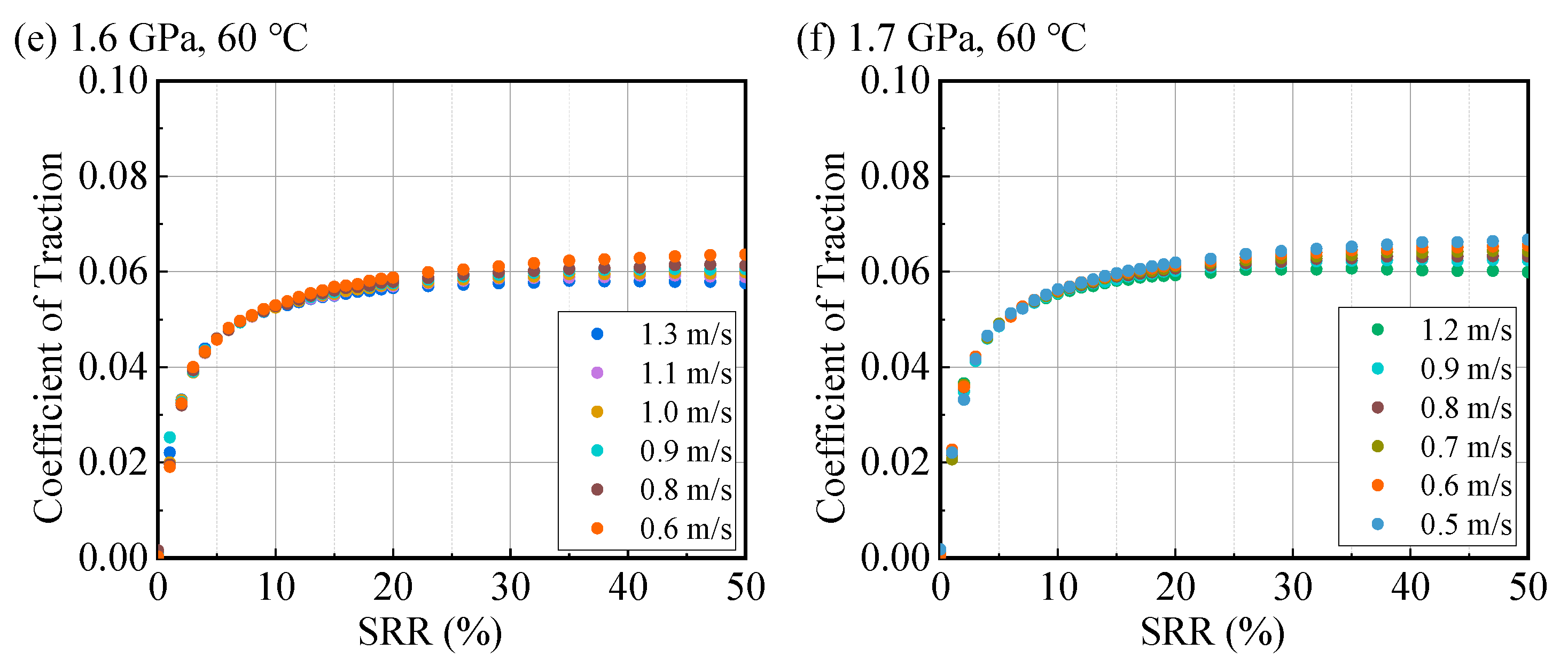

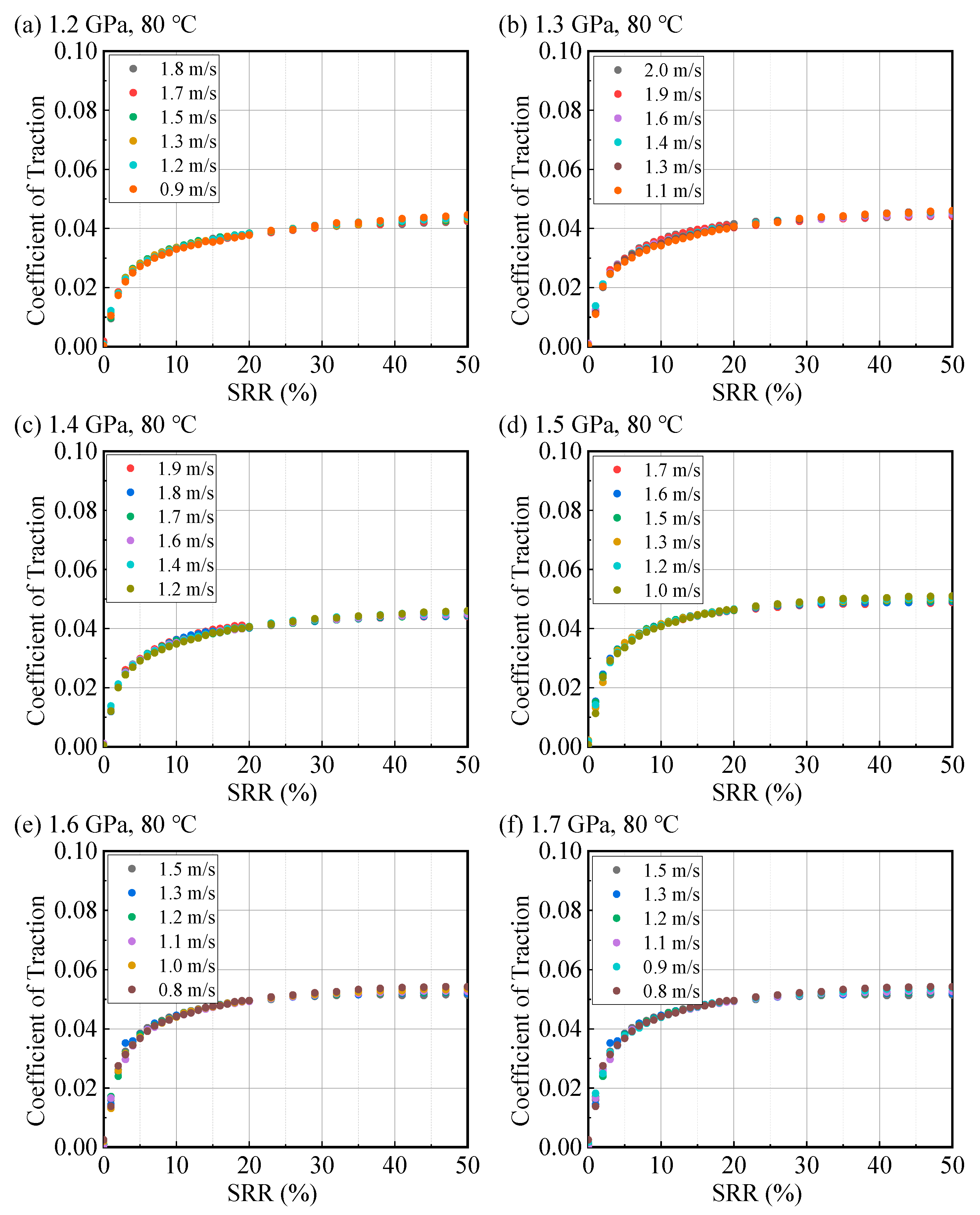

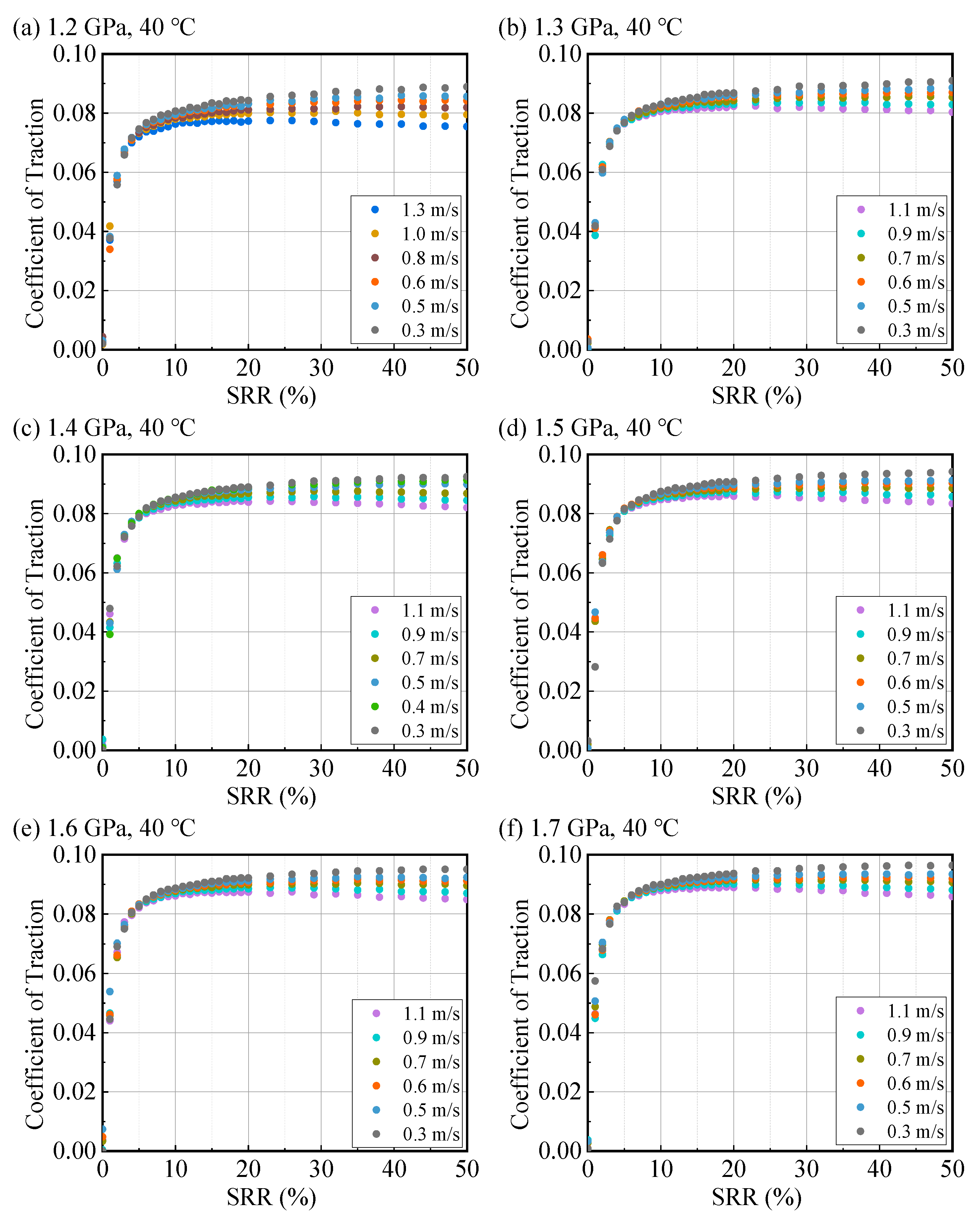

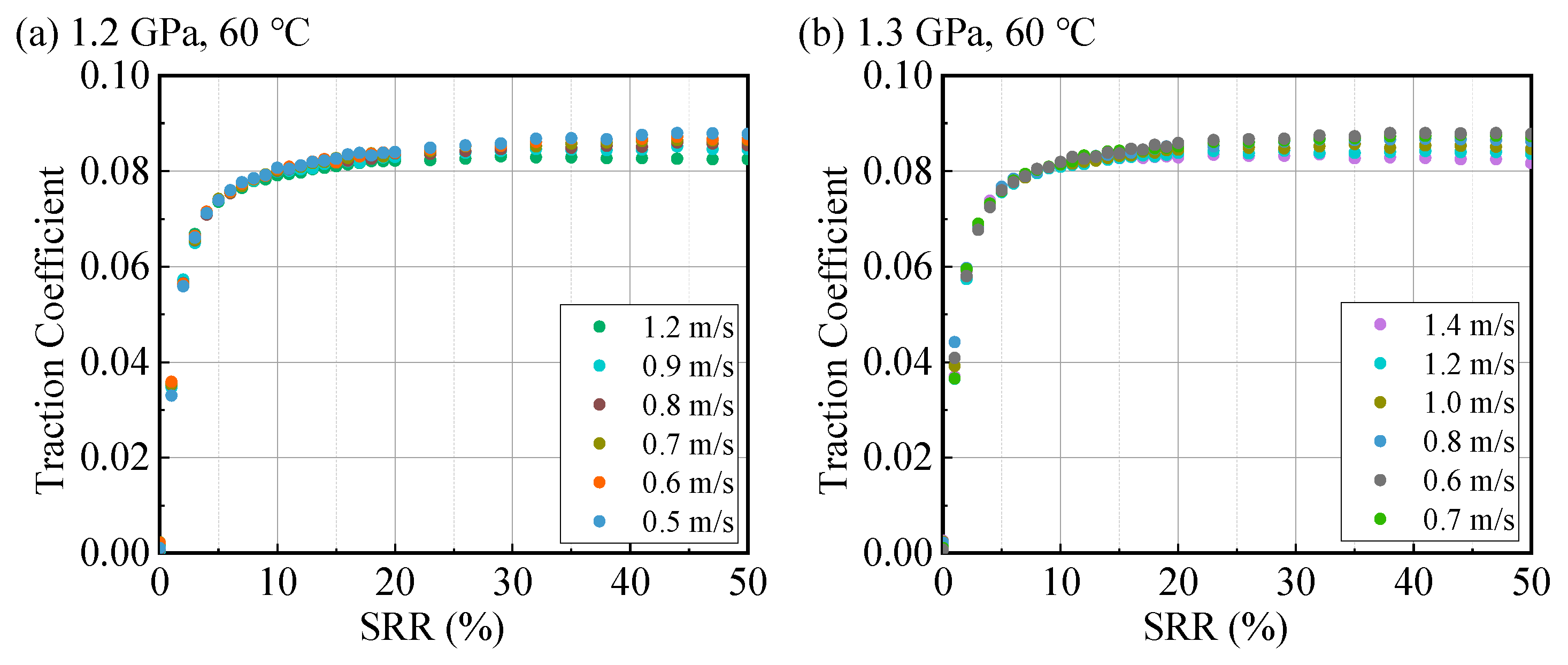

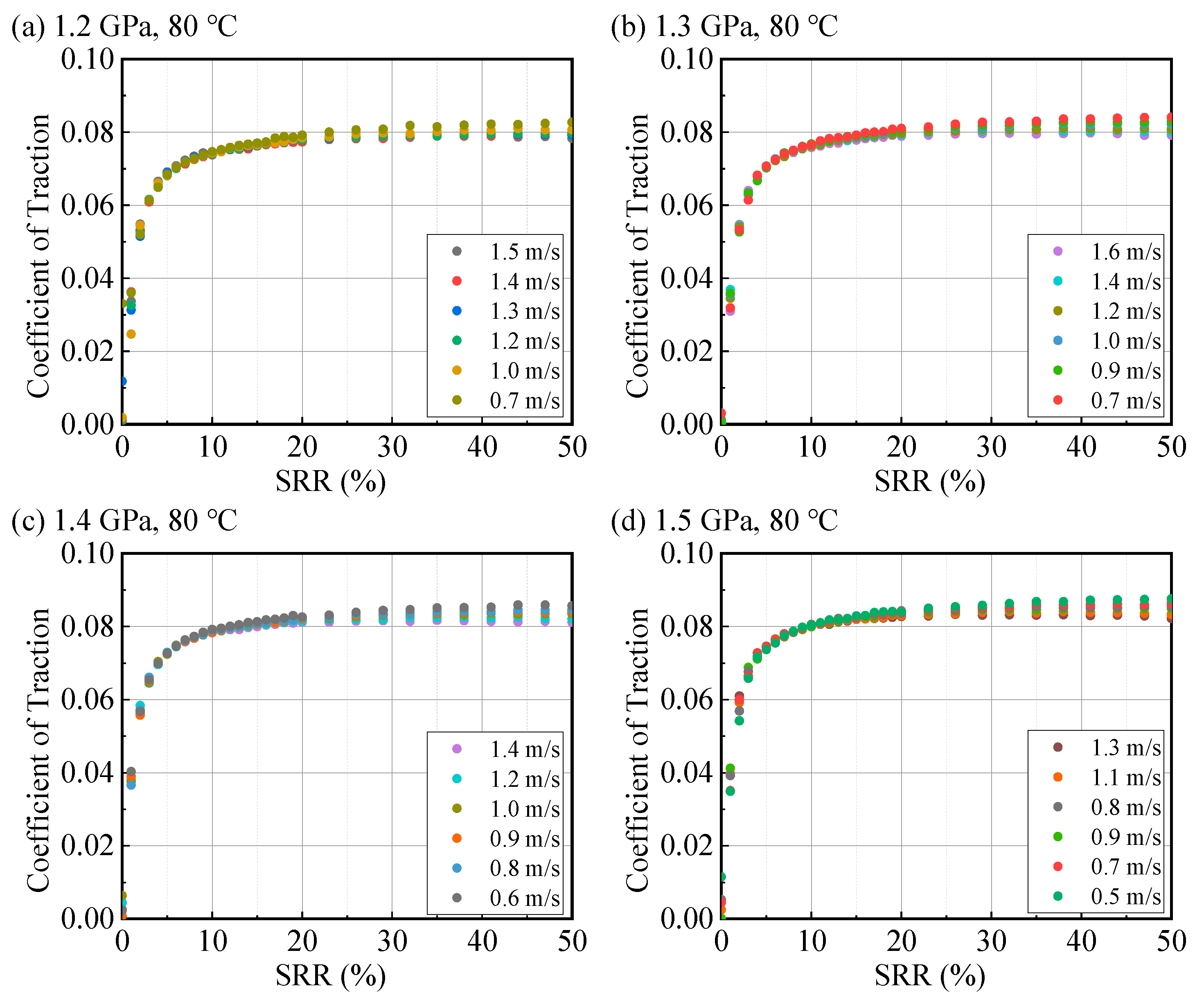

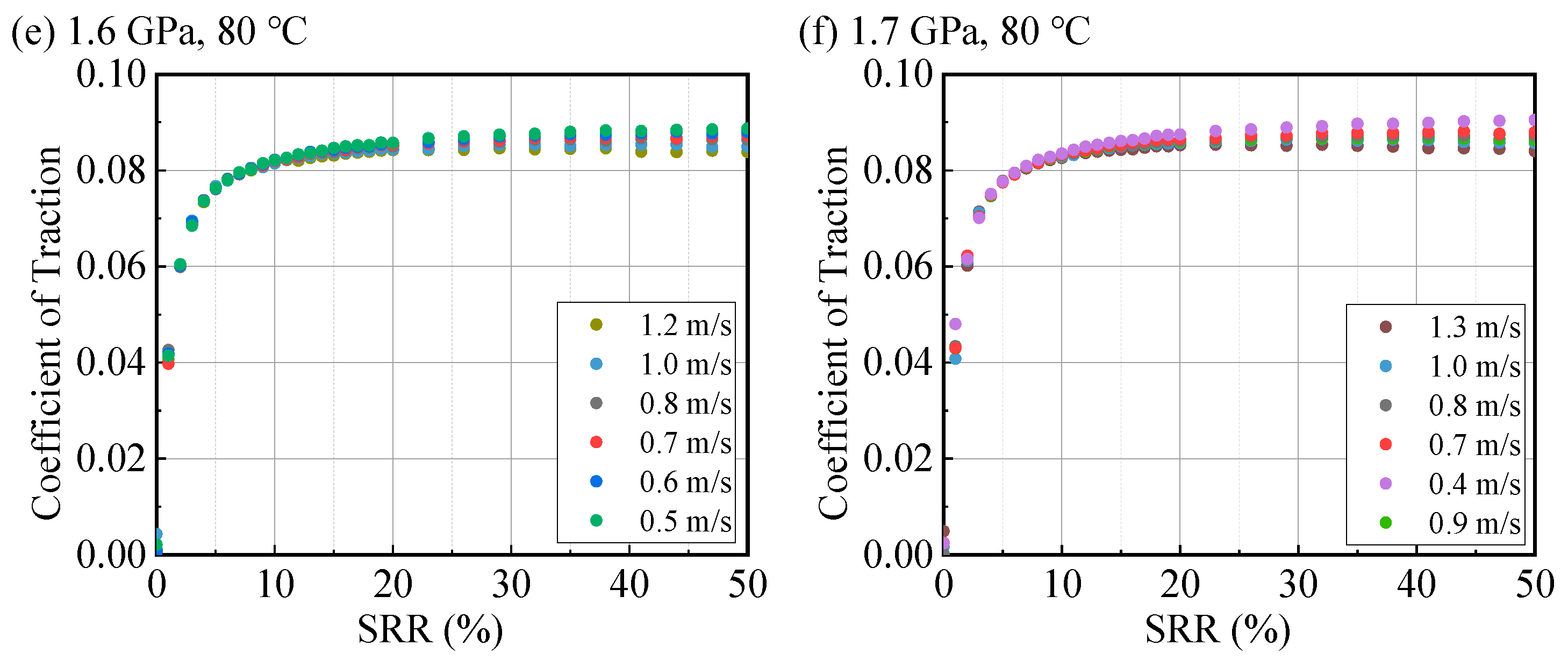

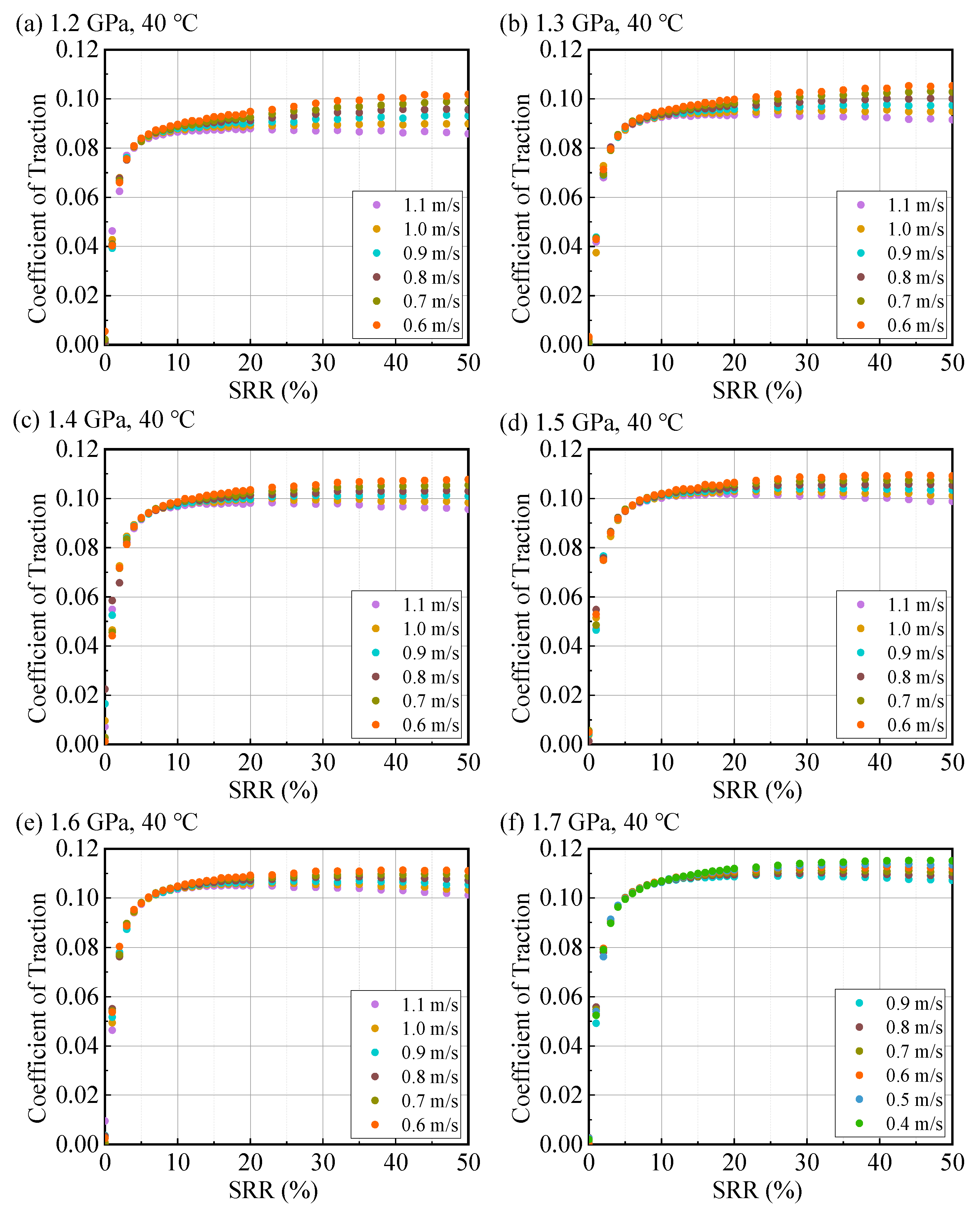

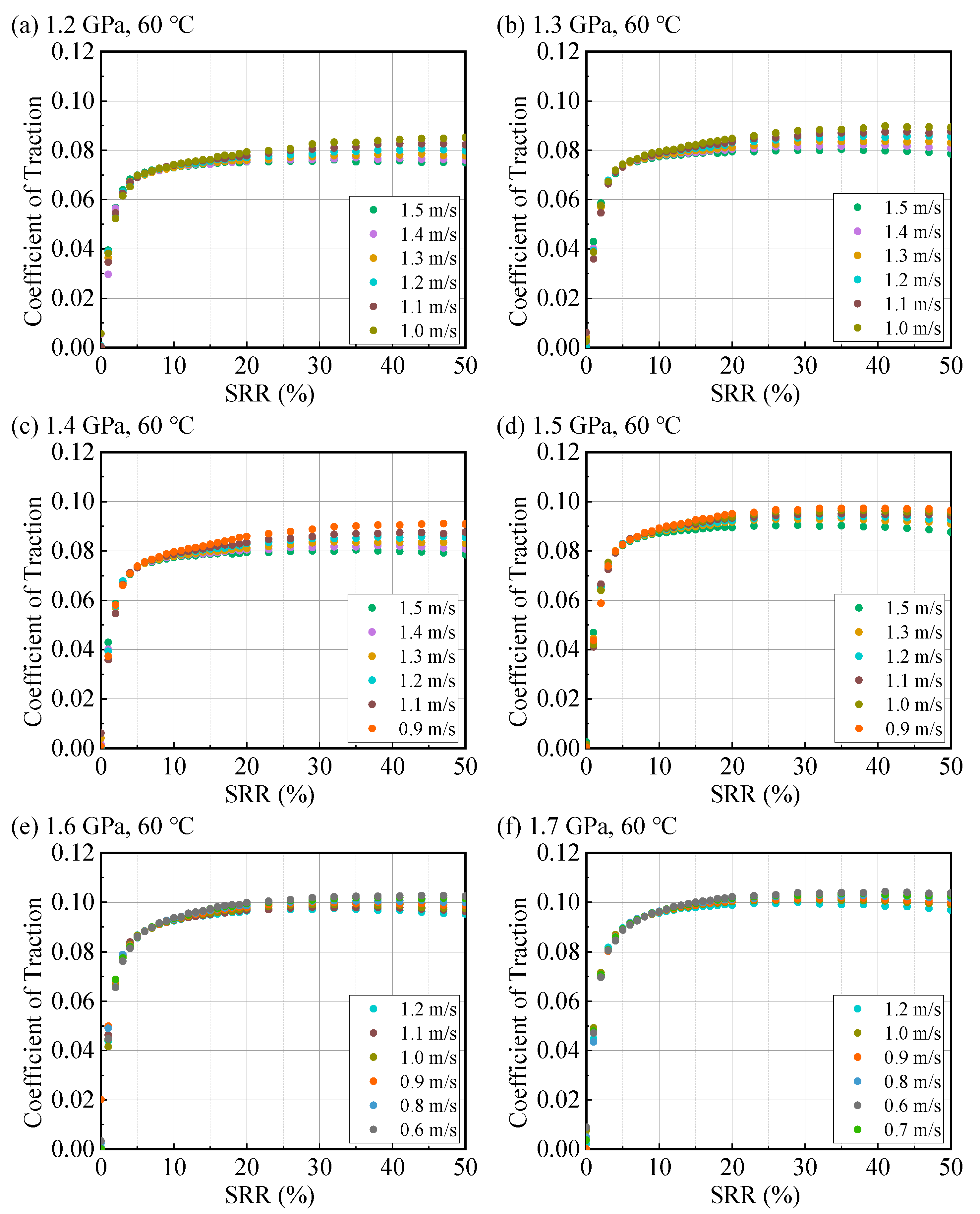

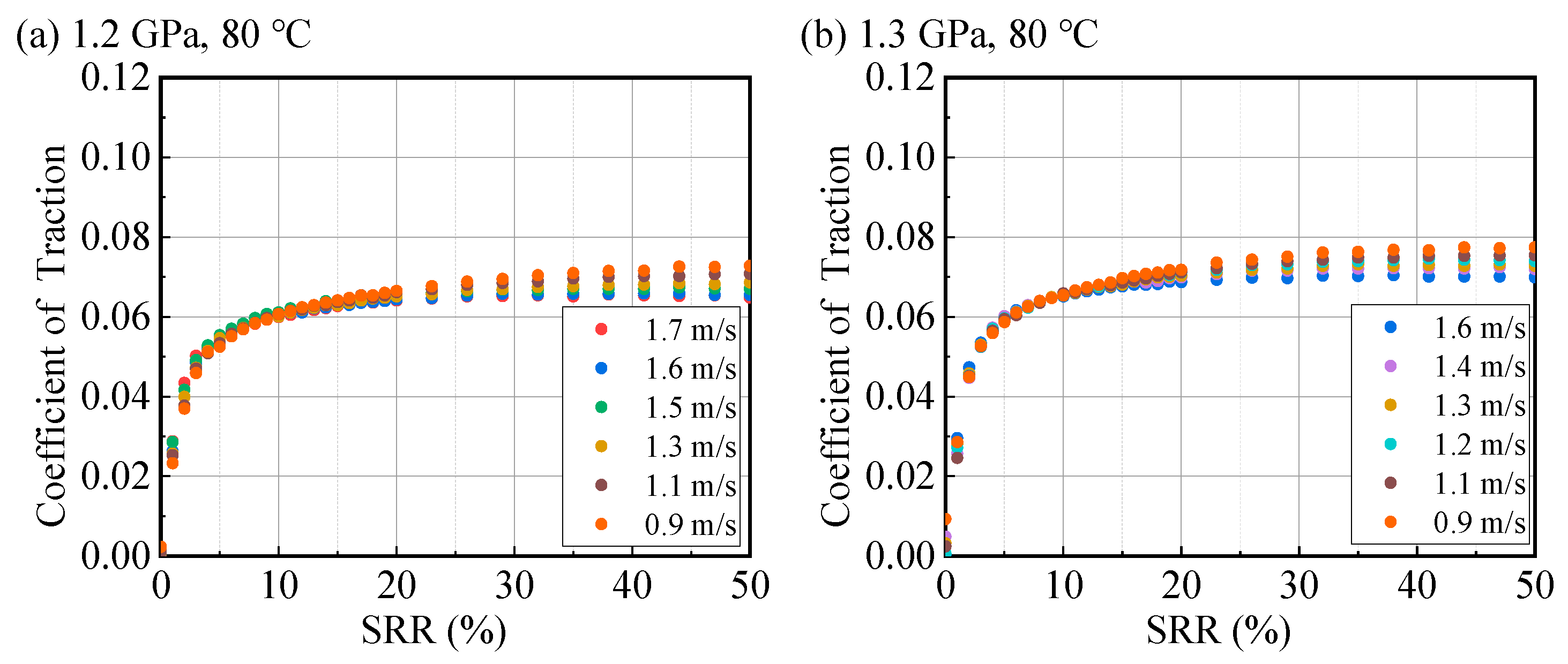

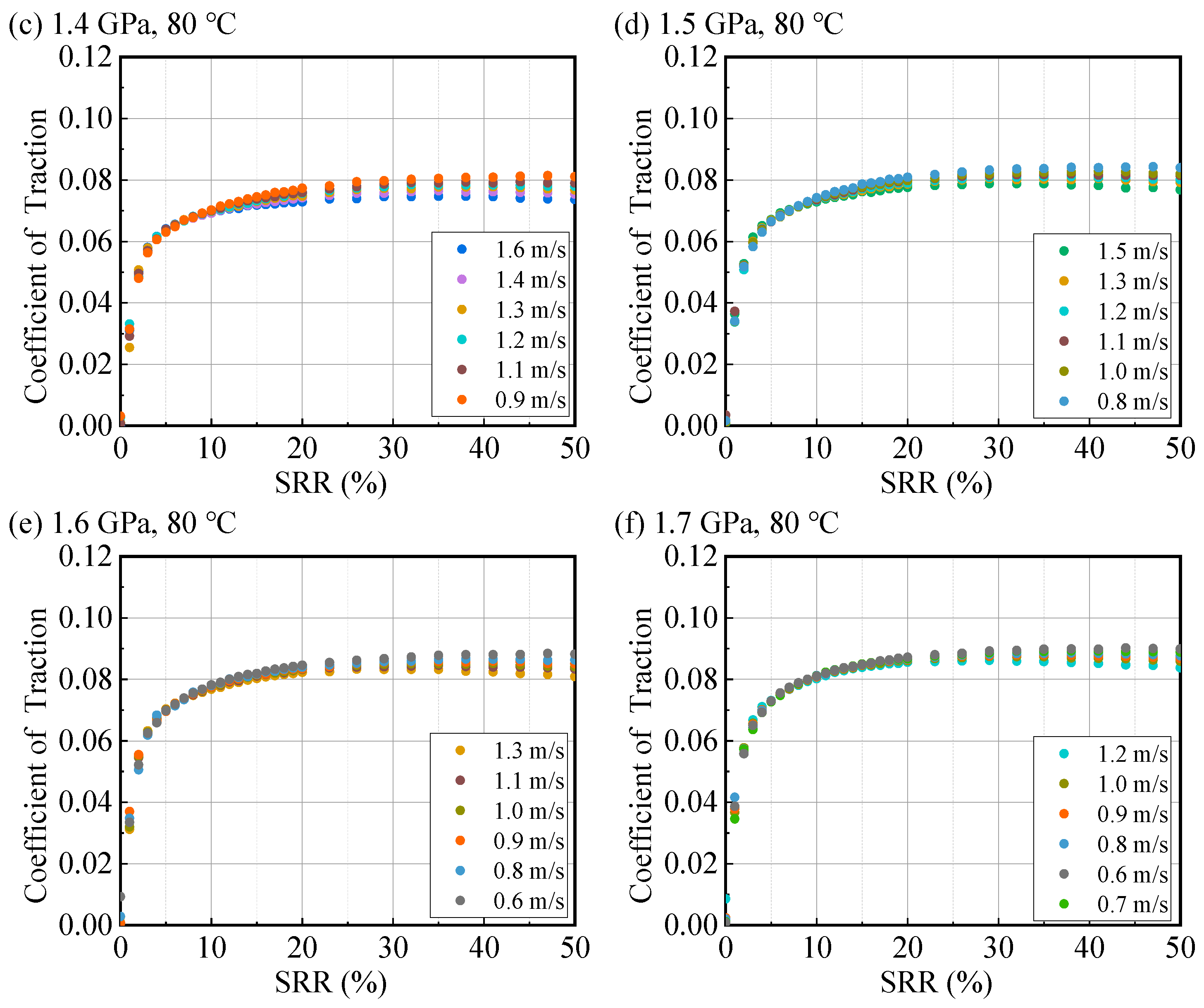

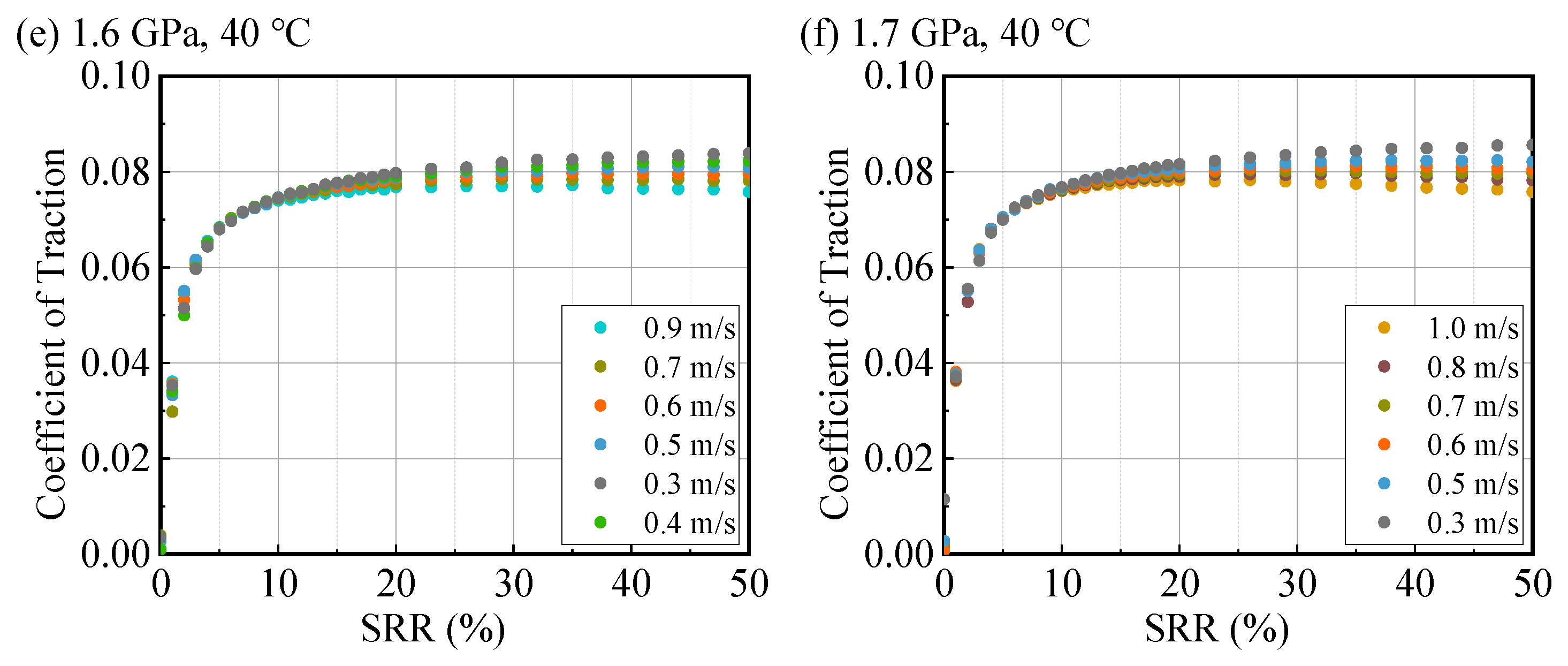

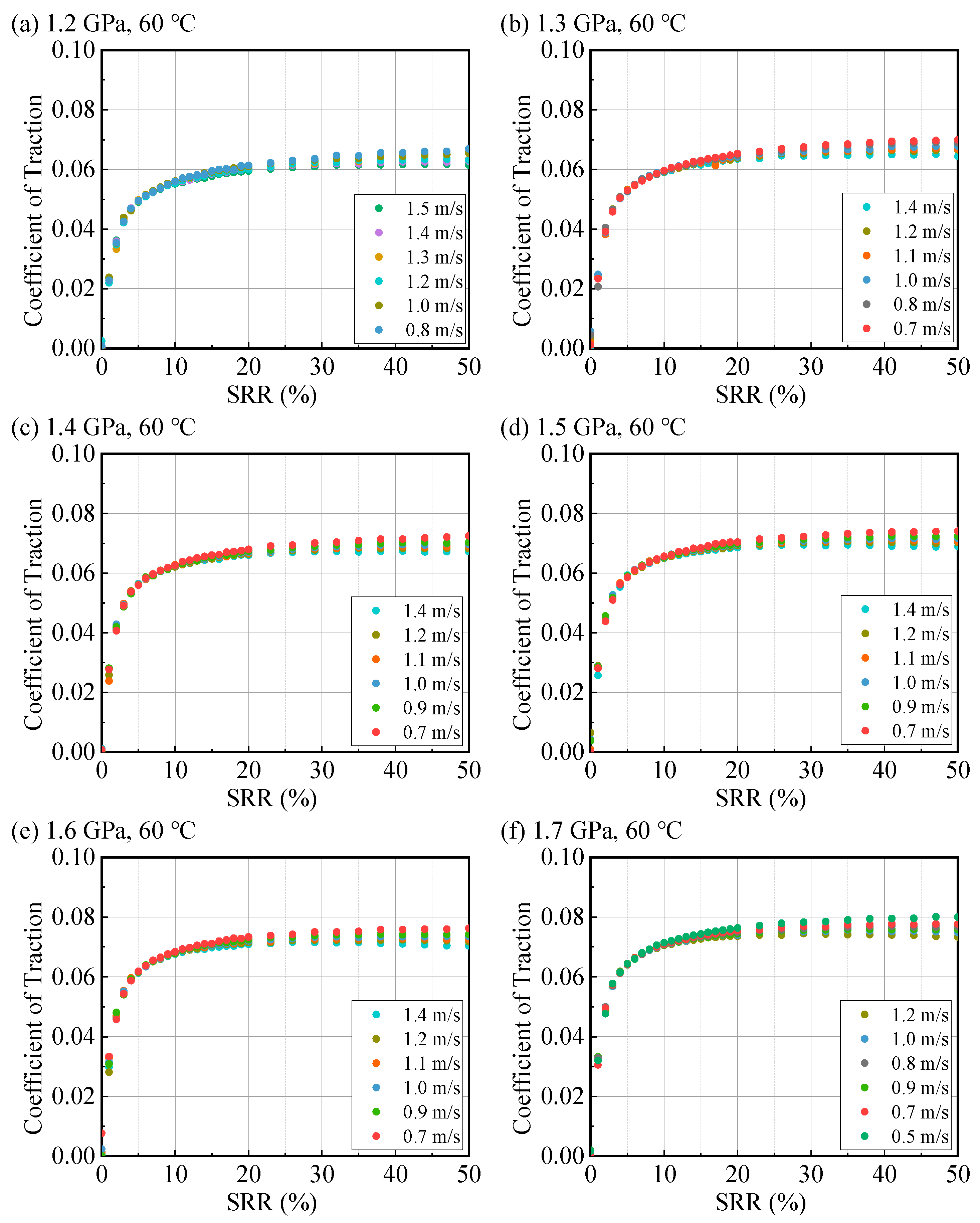

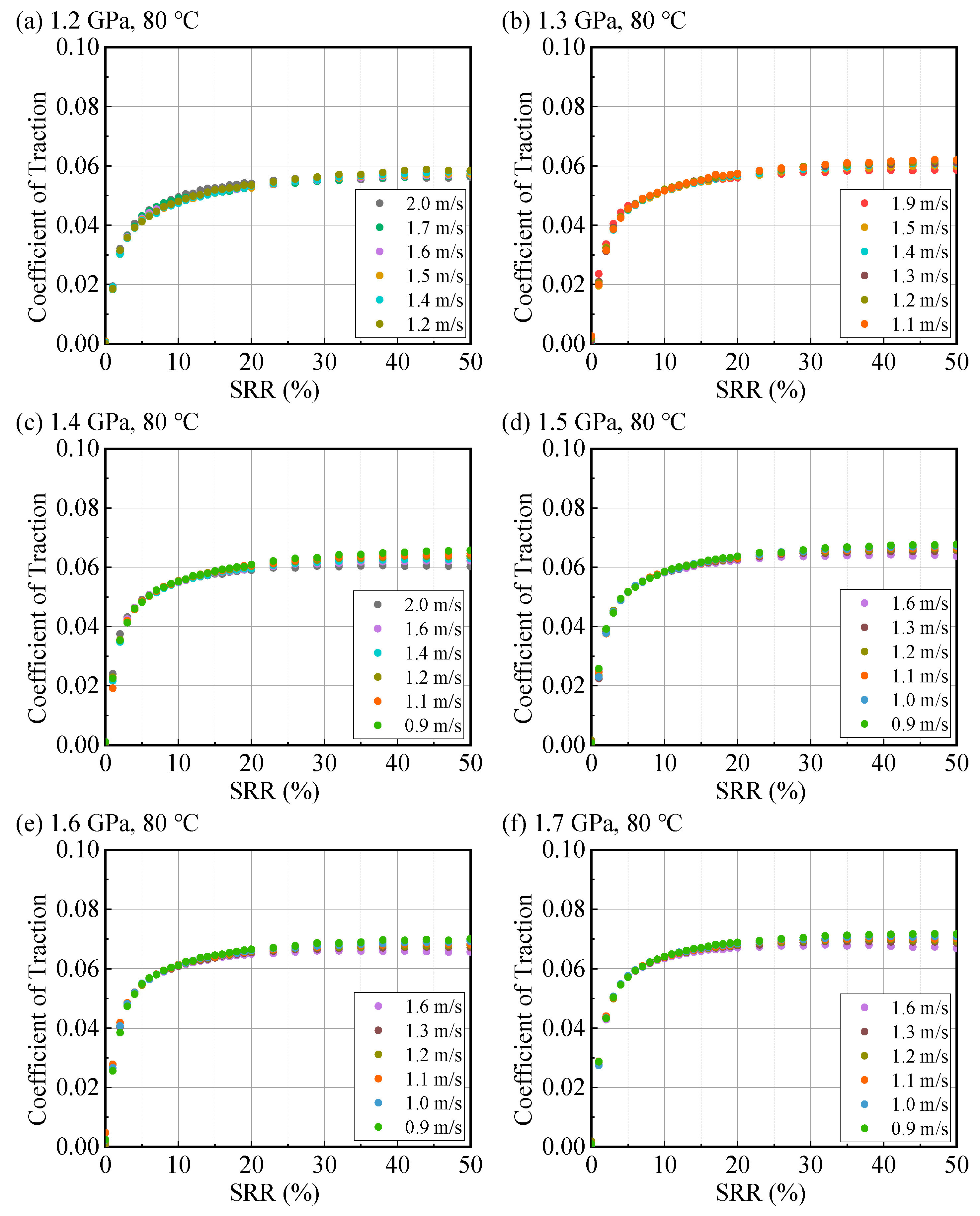

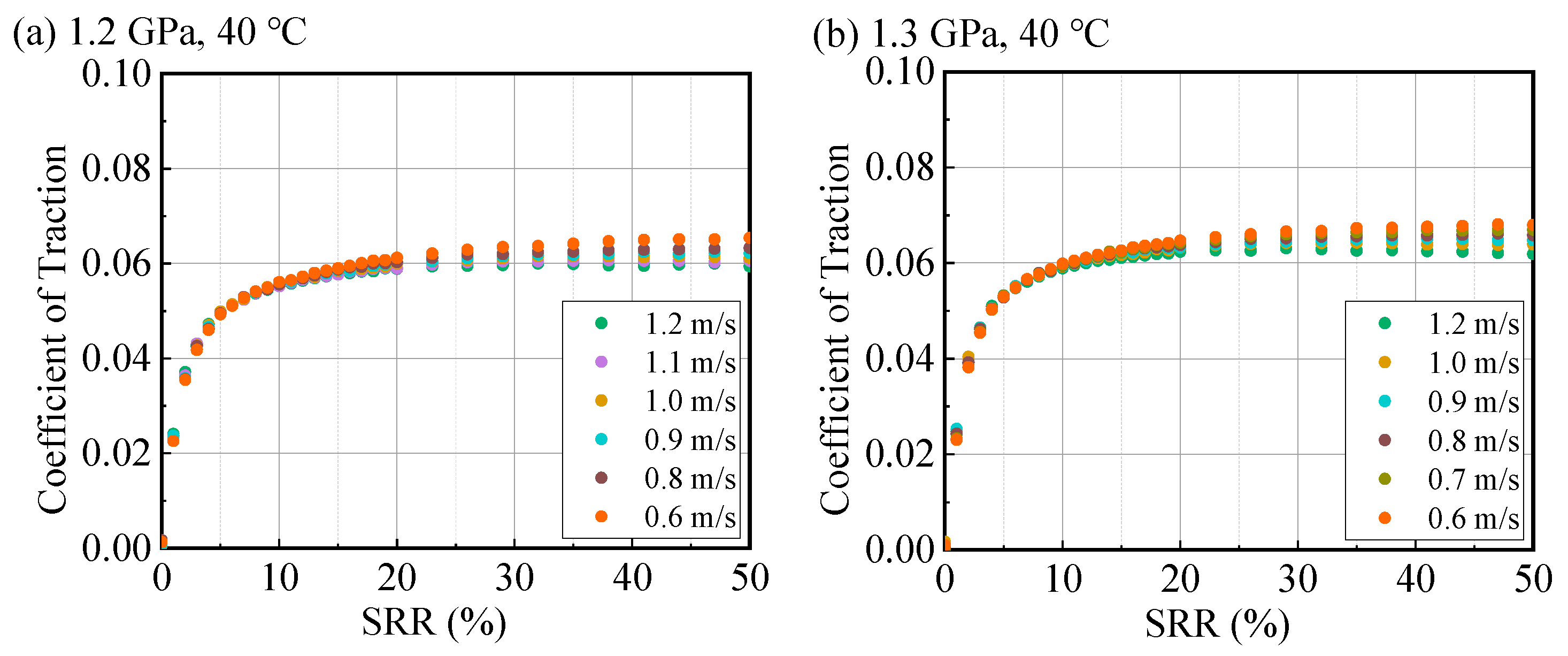

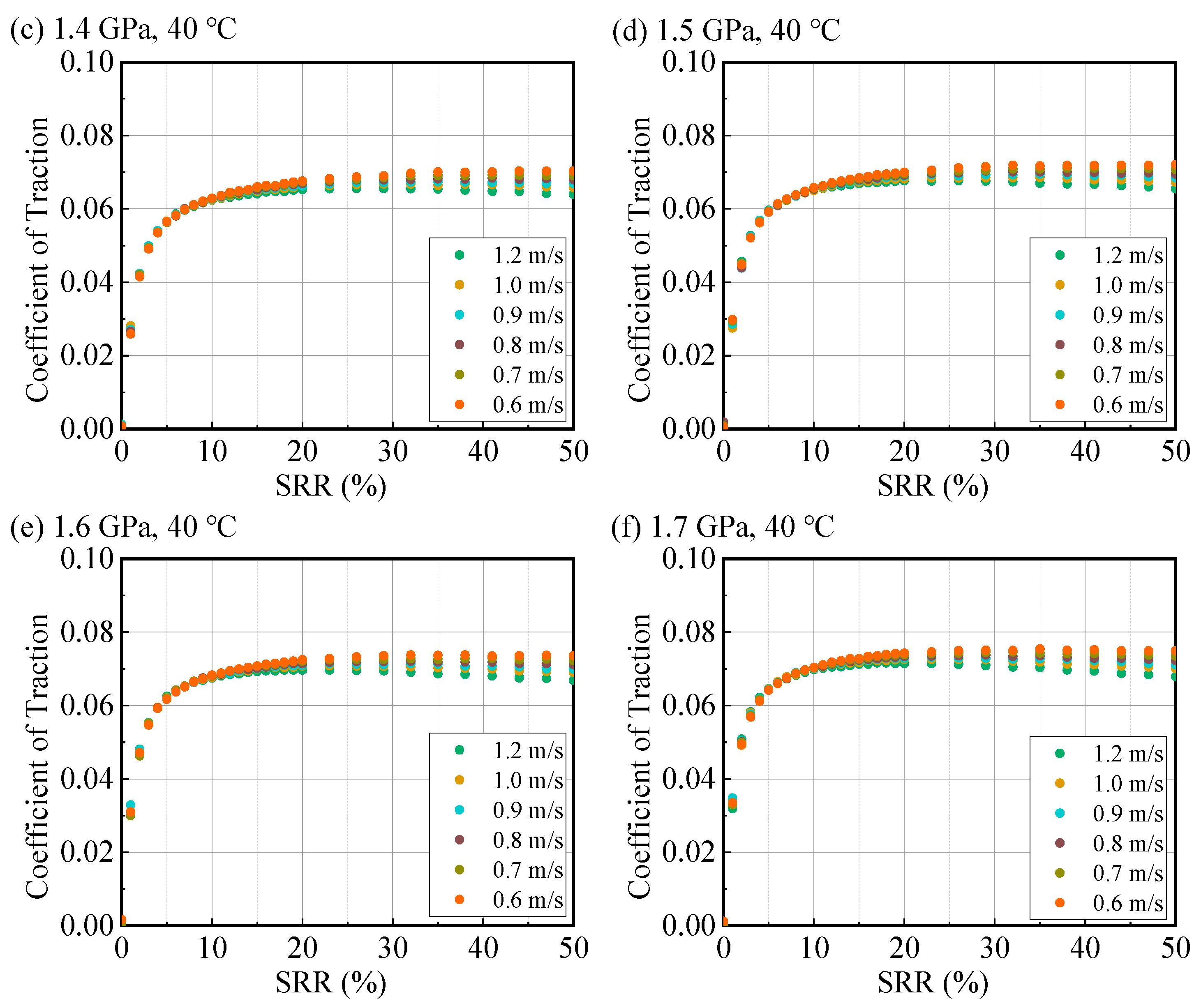

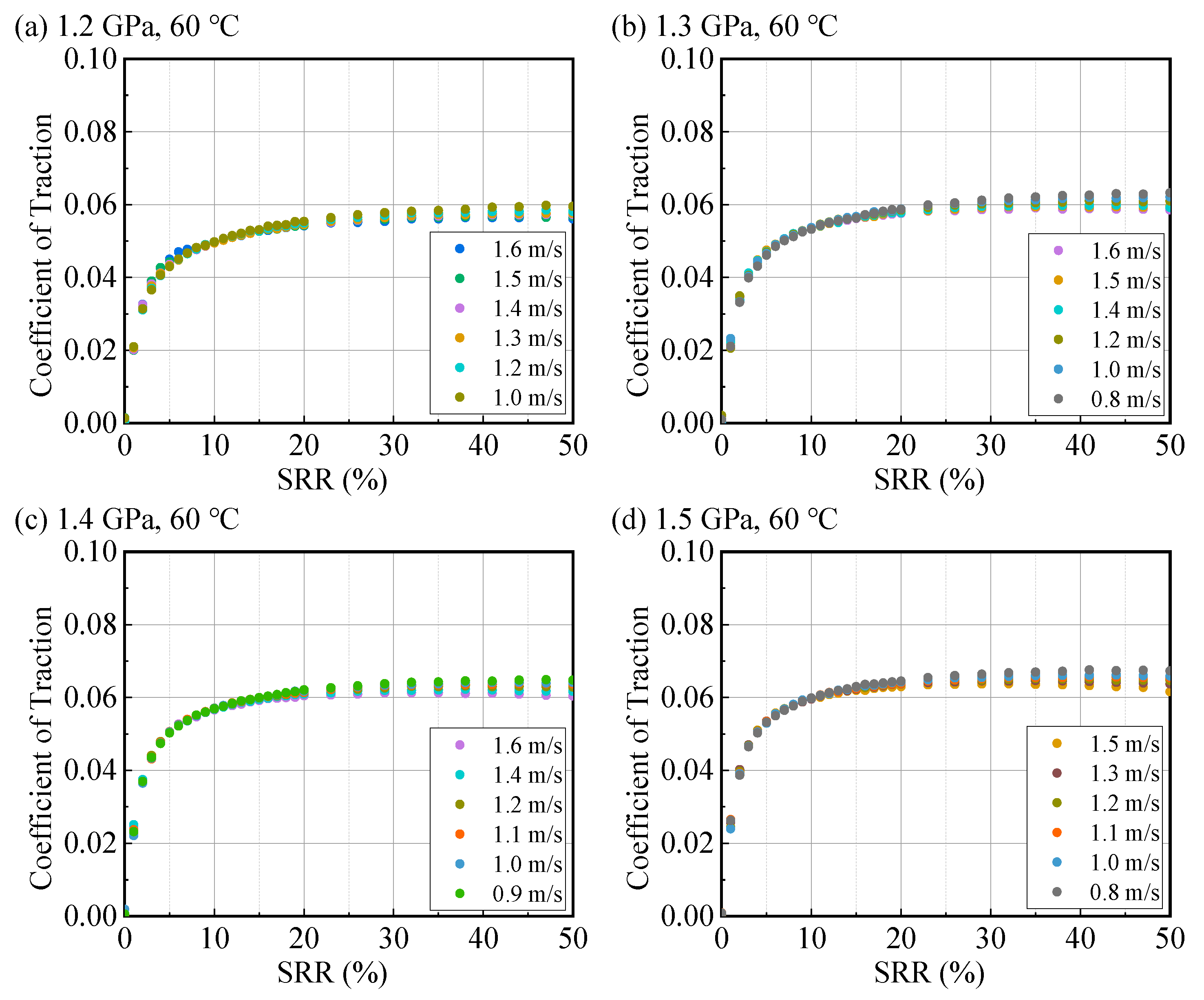

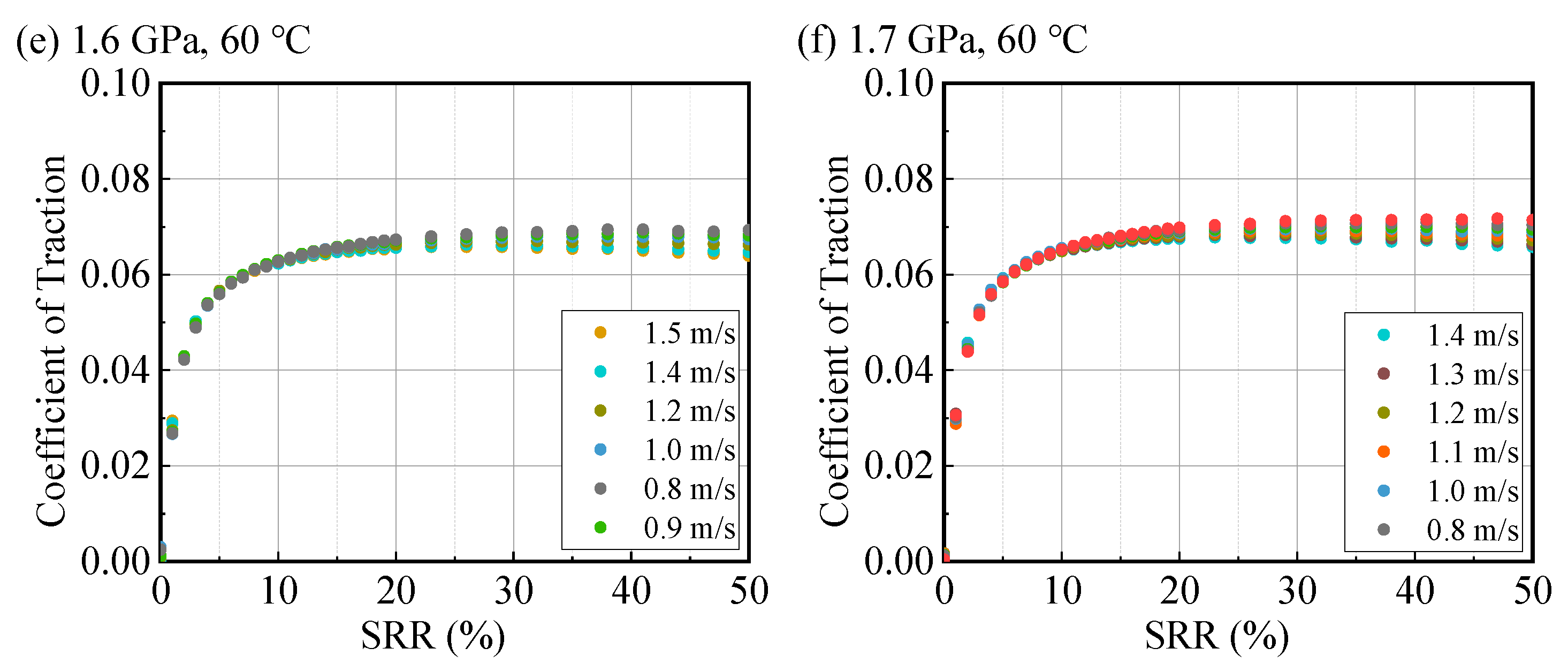

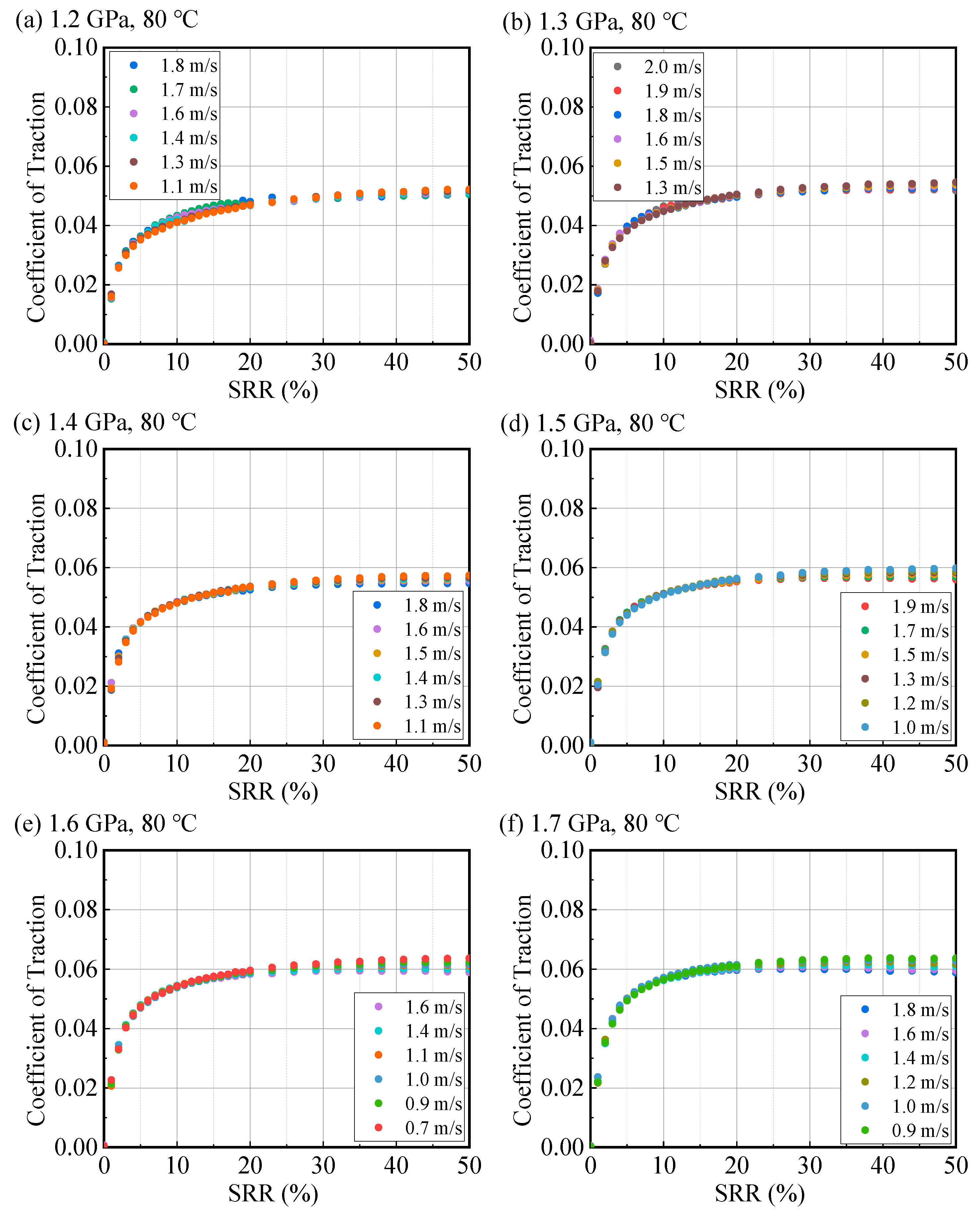

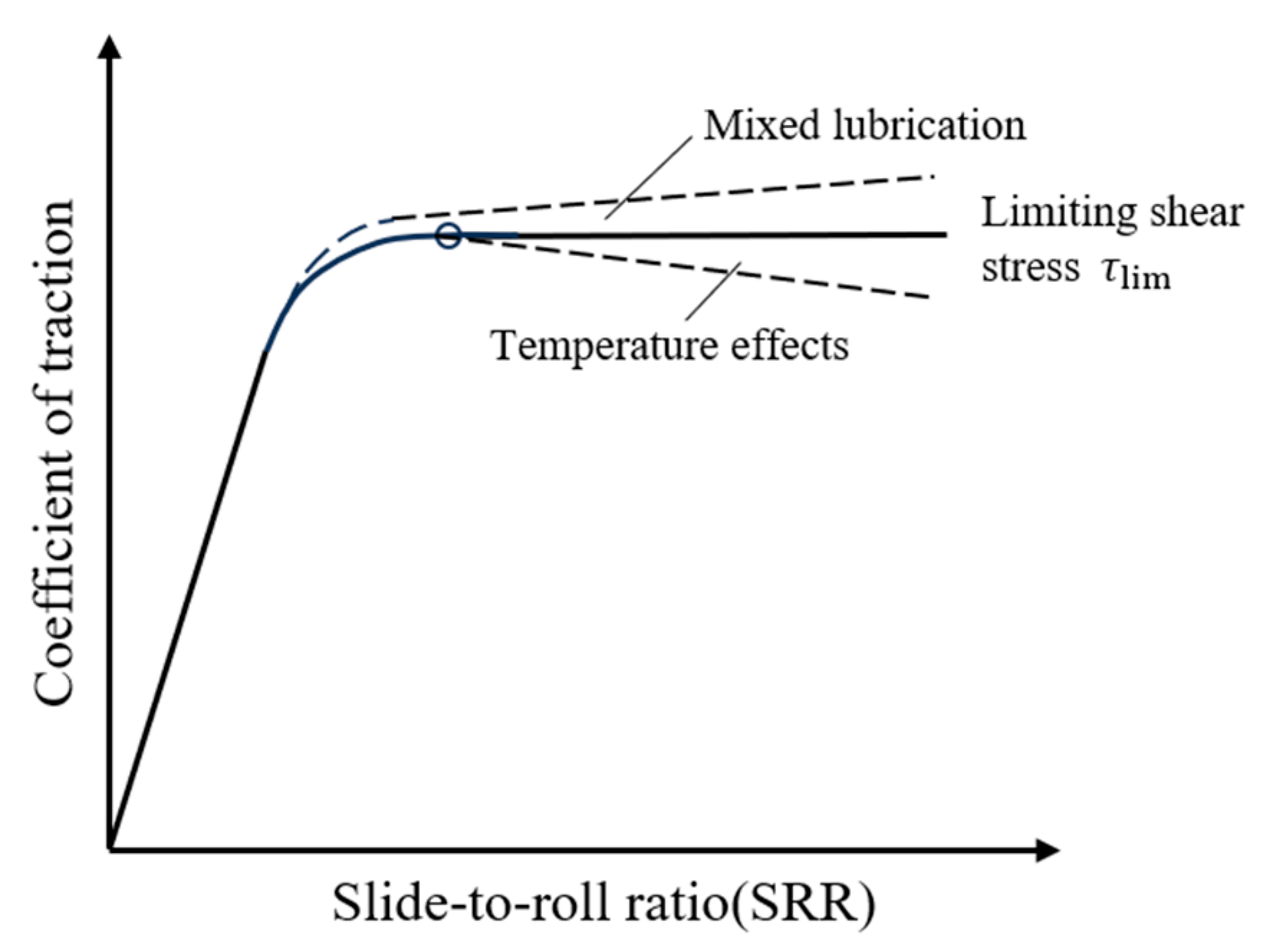

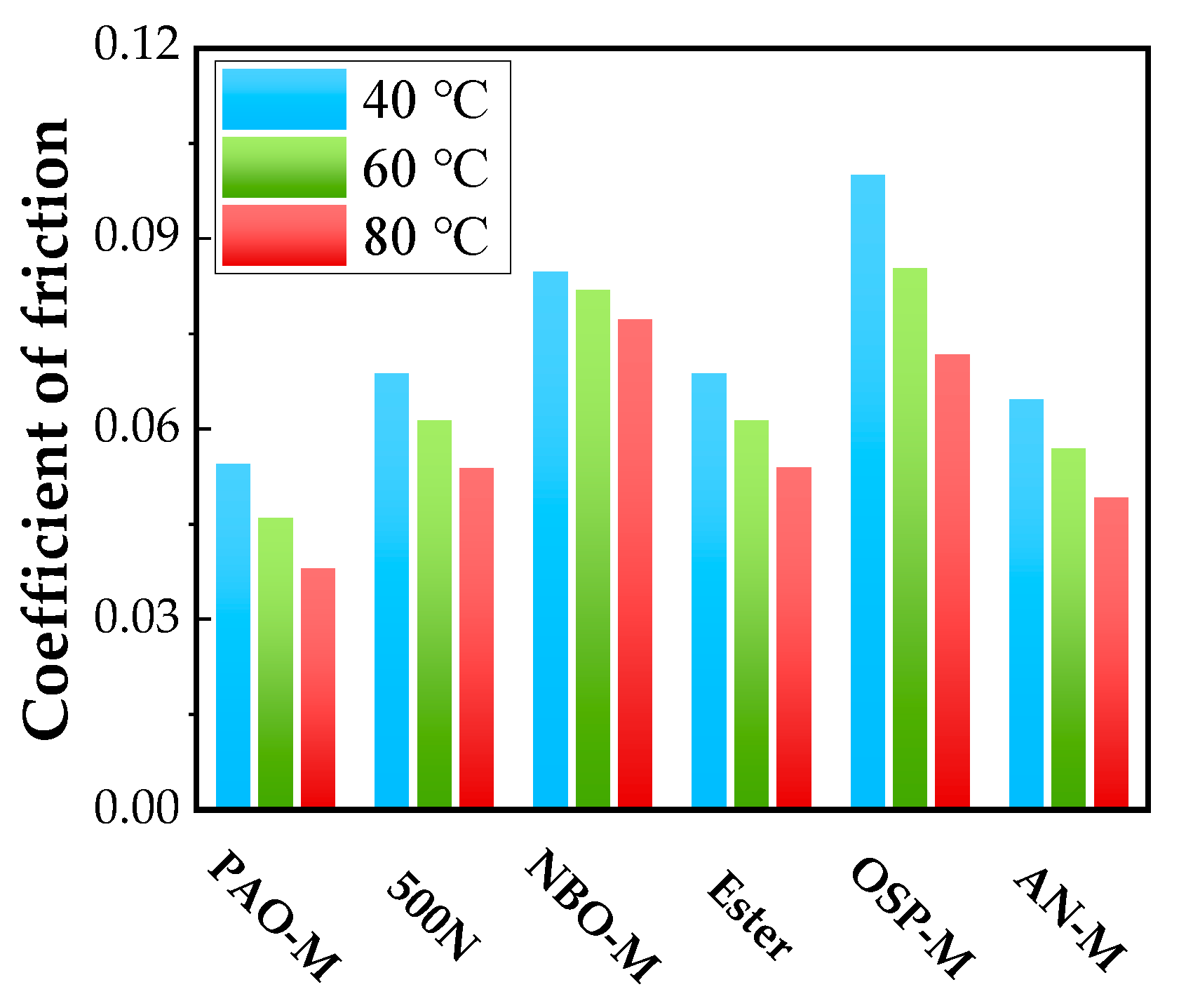

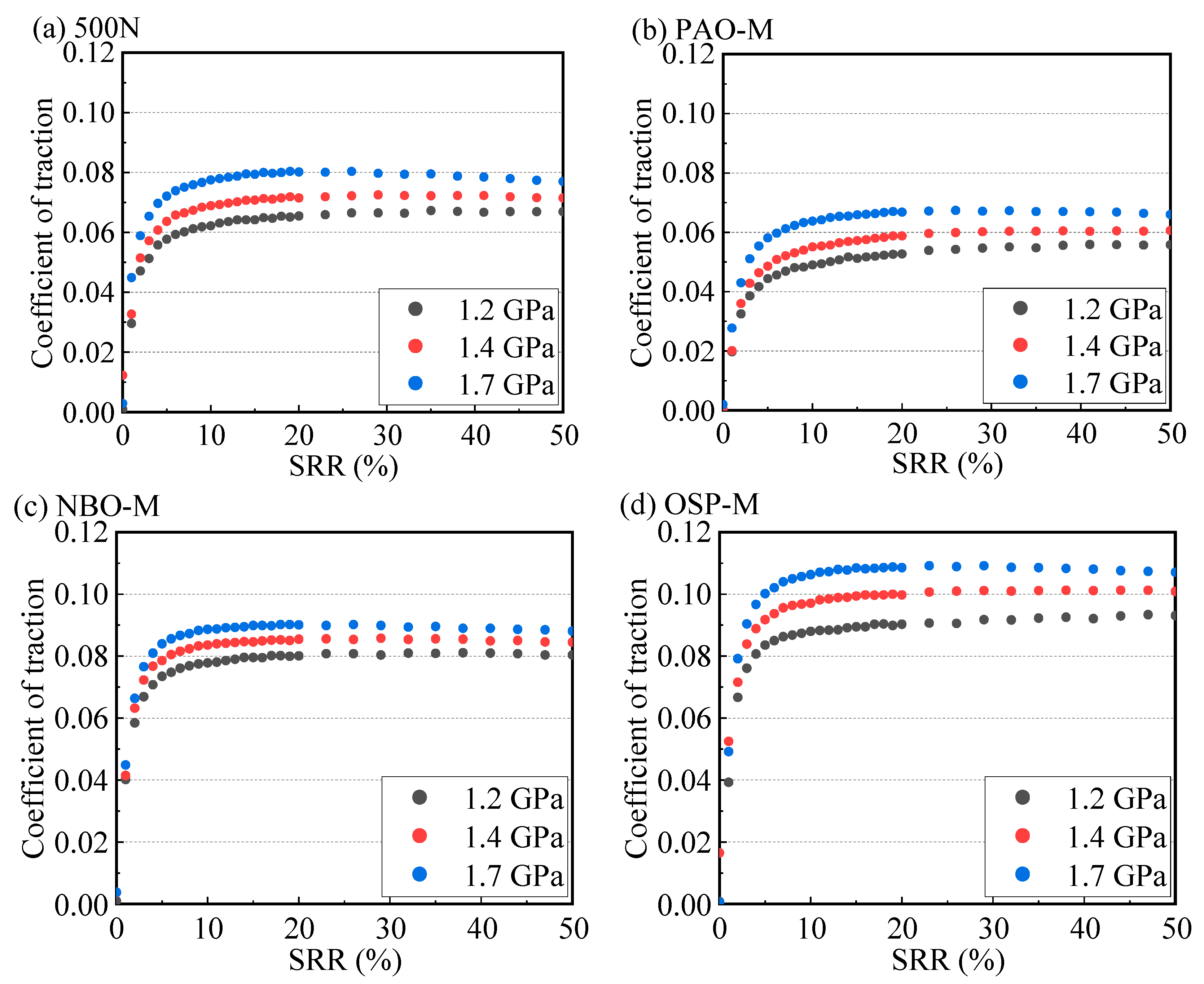

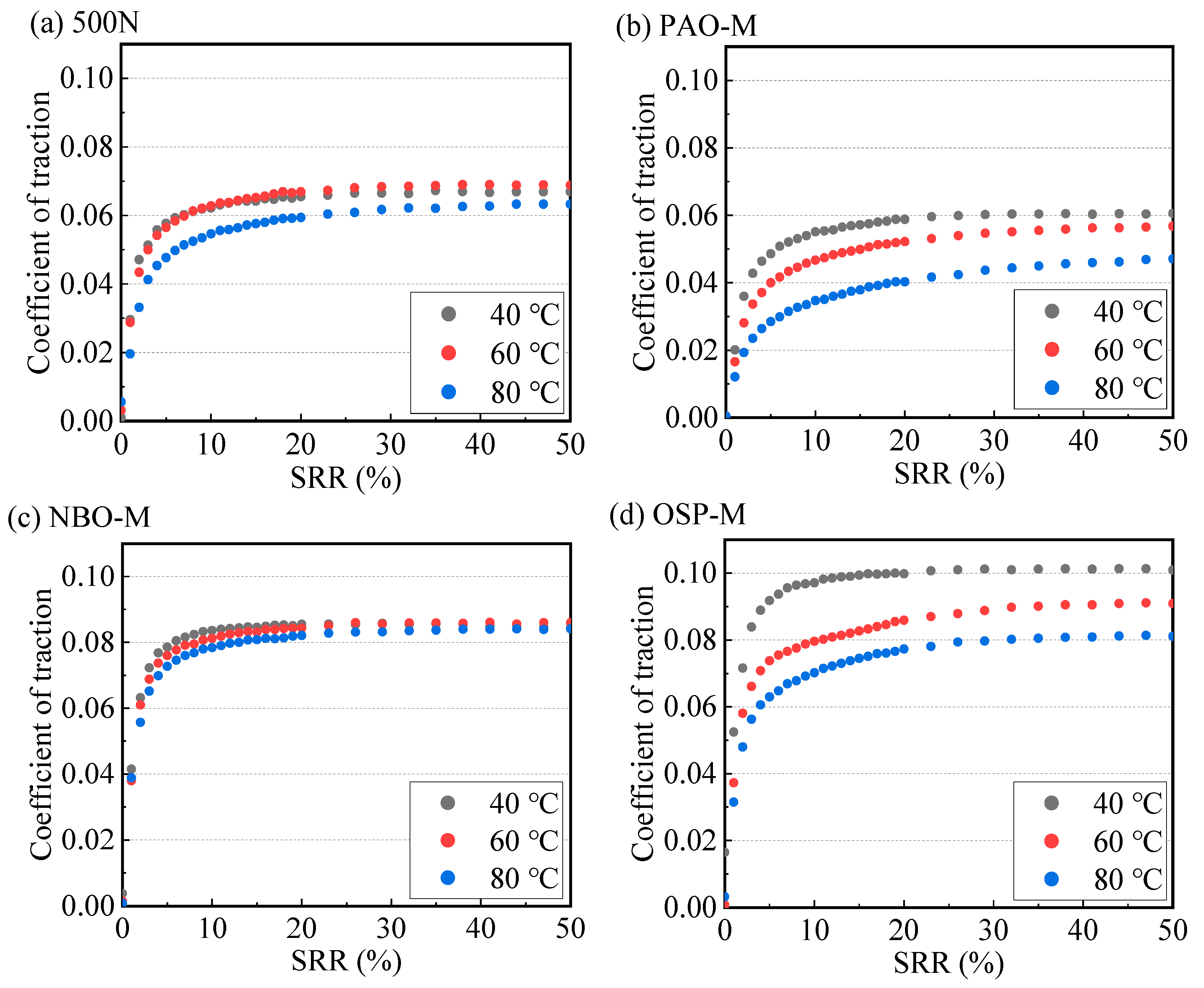

3.3. Comparison of Traction Curves for Different Types of Base Oils

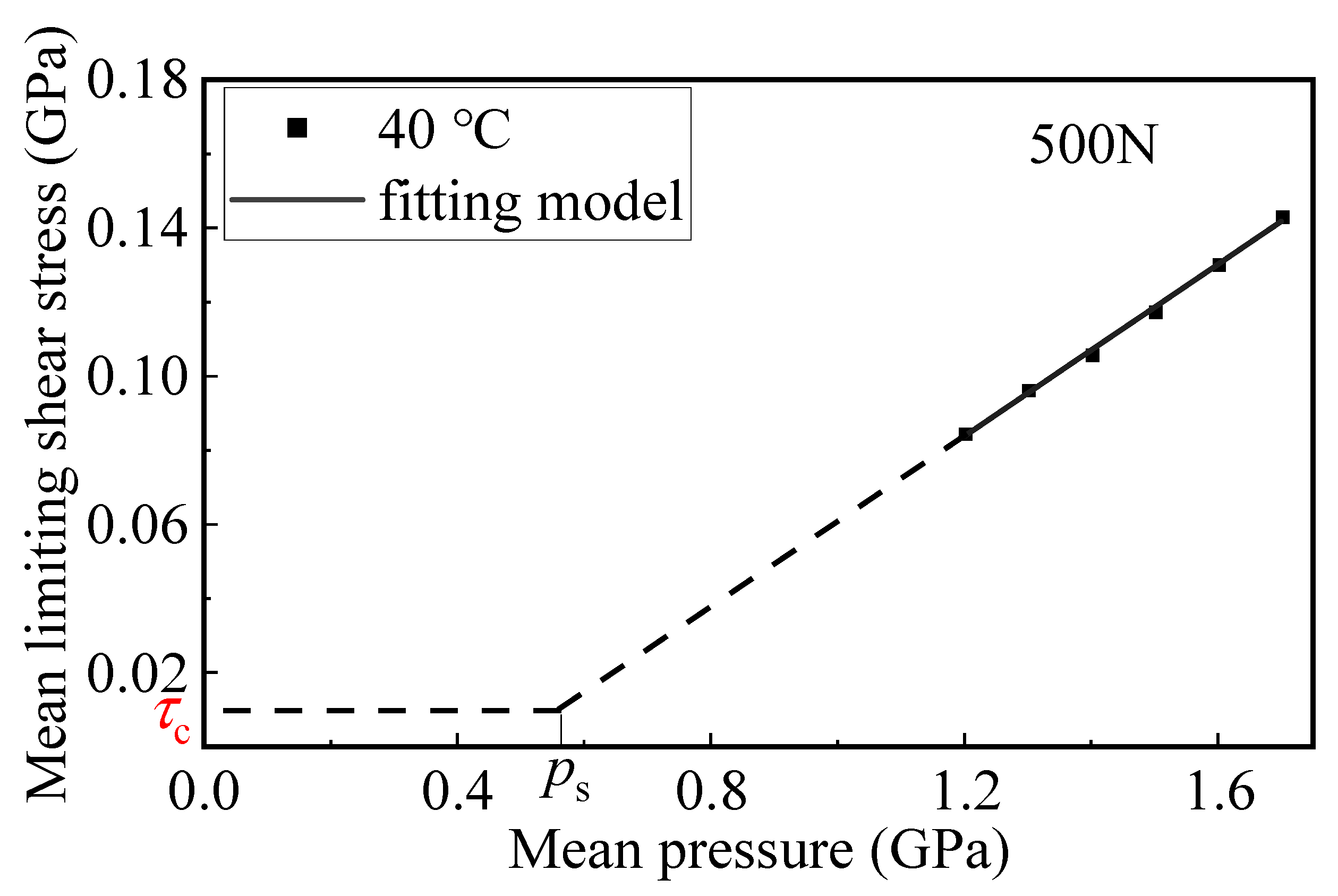

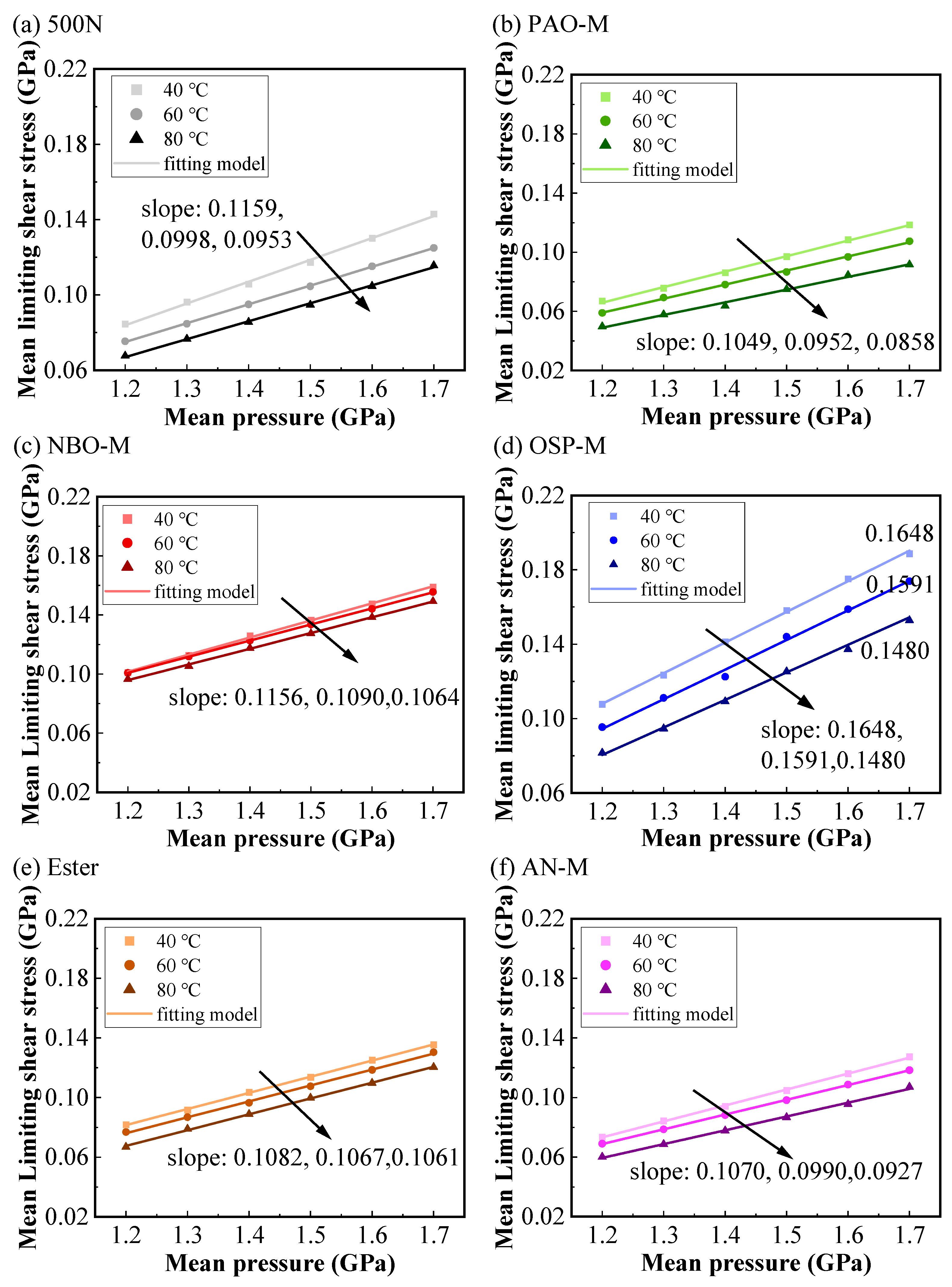

3.4. Comparative Analysis of Traction Curves Based on Limiting Shear Stress

4. Conclusions

- (a)

- At an experimental temperature of 40 °C, the six types of base oils with basically consistent viscosities exhibit different friction coefficients in both low-speed mixed lubrication and high-speed EHL regimes. In addition to viscosity, differences in the chemical structure, composition, and polarity of the base oils lead to variations in their adsorption at the contact interface, high-pressure rheological properties, and film-forming characteristics, thereby resulting in different mixed/EHL friction coefficients.

- (b)

- Influenced by the combination of non-Newtonian effects and thermal effects caused by high pressure and high shear in EHL contacts, the EHL friction coefficients of different types of base oils show a rapid linear increase, then remain basically constant, and finally gradually decrease with the increase in SRR. The LSS can quantitatively analyze the influences of base oil type, temperature, and contact pressure on the EHL friction in highly loaded rolling/sliding contacts, avoiding the influence of thermal effects and non-Newtonian shear thinning on viscosity changes. At a temperature of 40 °C, the LSS order for the six base oils within the experimental contact pressure range is OSP-M > NBO-M > 500N > Ester > AN-M > PAO-M. However, as the experimental temperature rises to 80 °C, the NBO-M gives a larger EHL friction coefficient than the OSP-M at contact pressures smaller than 1.6 GPa. This is attributed to the difference in the LSS coefficients of base oils.

- (c)

- Under the experimental temperatures of 40 °C, 60 °C, and 80 °C, the LSS of the six types of base oils are all linearly related to the mean contact pressure. In addition, as the temperature rises, the LSS decreases, and the temperature does not affect the LSS coefficient, i.e., the fitting slope between LSS and pressure, for a specific base oil. The effects of contact pressure and temperature on the LSS are relatively independent of each other. Moreover, if the fitting curves of the LSS-mean contact pressure at different temperatures are known, the LSS of the base oil at other temperatures can be obtained by interpolation of the known data. This method contributes to providing a rheological fluid model for the quantitative friction prediction in highly loaded lubricated rolling/sliding contacts.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| EHL | Elastohydrodynamic lubrication |

| LSS | Limiting shear stress |

| SRR | Slide-to-roll ratio |

Appendix A

Appendix B

| /GPa | 500N | PAO-M | NBO-M | ||||||

| ue, m/s | fmax | LSS, GPa | ue, m/s | fmax | LSS, GPa | ue, m/s | fmax | LSS, GPa | |

| 1.2 | 1.2 | 0.0628 | 0.07536 | 0.9 | 0.0831 | 0.1008 | |||

| 1.3 | 1.2 | 0.0651 | 0.08463 | 0.1 | 0.0533 | 0.06929 | 0.8 | 0.086 | 0.1118 |

| 1.4 | 1.1 | 0.0678 | 0.09492 | 0.1 | 0.0558 | 0.07812 | 0.7 | 0.0876 | 0.12264 |

| 1.5 | 1.1 | 0.0697 | 0.1045 | 0.1 | 0.0578 | 0.0867 | 0.7 | 0.0890 | 0.1335 |

| 1.6 | 1.0 | 0.0720 | 0.1152 | 0.9 | 0.0605 | 0.0968 | 0.7 | 0.0901 | 0.14416 |

| 1.7 | 1.0 | 0.0735 | 0.1250 | 0.8 | 0.0632 | 0.10744 | 0.6 | 0.0915 | 0.1556 |

| /GPa | Ester | OSP-M | AN-M | ||||||

| ue, m/s | fmax | LSS, GPa | ue, m/s | fmax | LSS, GPa | ue, m/s | fmax | LSS, GPa | |

| 1.2 | 1.1 | 0.0641 | 0.07692 | 1.2 | 0.0798 | 0.0954 | 1.3 | 0.0575 | 0.0690 |

| 1.3 | 1.1 | 0.0668 | 0.08684 | 1.2 | 0.0855 | 0.1111 | 1.3 | 0.0605 | 0.0786 |

| 1.4 | 1.1 | 0.0689 | 0.09646 | 1.2 | 0.0875 | 0.1225 | 1.2 | 0.0630 | 0.0882 |

| 1.5 | 1.0 | 0.0717 | 0.10755 | 1.1 | 0.096 | 0.1440 | 1.1 | 0.0655 | 0.0982 |

| 1.6 | 0.9 | 0.0741 | 0.11856 | 0.9 | 0.0988 | 0.1580 | 1.0 | 0.0679 | 0.1086 |

| 1.7 | 0.8 | 0.0767 | 0.13039 | 0.8 | 0.1023 | 0.1739 | 1.0 | 0.0696 | 0.1183 |

| /GPa | 500N | PAO-M | NBO-M | ||||||

| ue, m/s | fmax | LSS, GPa | ue, m/s | fmax | LSS, GPa | ue, m/s | fmax | LSS, GPa | |

| 1.2 | 1.0 | 0.0805 | 0.0966 | ||||||

| 1.3 | 1.4 | 0.0589 | 0.0765 | 1.2 | 0.0445 | 0.0578 | 1.0 | 0.0821 | 0.1053 |

| 1.4 | 1.4 | 0.0611 | 0.0855 | 1.2 | 0.0455 | 0.0637 | 0.9 | 0.0840 | 0.1176 |

| 1.5 | 1.3 | 0.0632 | 0.0947 | 1.2 | 0.050 | 0.075 | 0.9 | 0.0850 | 0.1275 |

| 1.6 | 1.2 | 0.0654 | 0.1046 | 1.1 | 0.0528 | 0.0845 | 0.8 | 0.0865 | 0.1384 |

| 1.7 | 1.2 | 0.0680 | 0.1156 | 1.0 | 0.0539 | 0.0926 | 0.7 | 0.0878 | 0.1493 |

| /GPa | Ester | OSP-M | AN-M | ||||||

| ue, m/s | fmax | LSS, GPa | ue, m/s | fmax | LSS, GPa | ue, m/s | fmax | LSS, GPa | |

| 1.2 | 0.0789 | 1.3 | 0.0680 | 0.0816 | 1.8 | 0.0501 | 0.0601 | ||

| 1.3 | 1.4 | 0.0607 | 0.0789 | 1.3 | 0.0728 | 0.09464 | 1.8 | 0.0528 | 0.0686 |

| 1.4 | 1.3 | 0.0635 | 0.0889 | 1.2 | 0.0780 | 0.1092 | 1.7 | 0.0555 | 0.0777 |

| 1.5 | 1.1 | 0.0665 | 0.0997 | 1.1 | 0.0815 | 0.1223 | 1.6 | 0.0578 | 0.0867 |

| 1.6 | 1.1 | 0.0686 | 0.1097 | 0.9 | 0.0858 | 0.1373 | 1.6 | 0.0597 | 0.0955 |

| 1.7 | 1.0 | 0.0708 | 0.1203 | 0.9 | 0.0899 | 0.1520 | 1.5 | 0.0630 | 0.1071 |

| Temperature | 40 °C | 60 °C | 80 °C | ||||||

|---|---|---|---|---|---|---|---|---|---|

| λ | (GPa) | R2 | λ | (GPa) | R2 | λ | R2 | ||

| 500N | 0.11593 ±0.00289 | 0.0553 ±0.00422 | 0.997 | 0.09980 ±0.000832 | 0.0447 ±0.00121 | 0.999 | 0.09532 ±0.00188 | 0.0474 ±0.00274 | 0.998 |

| PAO-M | 0.10487 ±0.00199 | 0.0599 ±0.00289 | 0.998 | 0.0952 ±0.00172 | 0.0551 ±0.00251 | 0.998 | 0.0858 ±0.00343 | 0.0540 ±0.00500 | 0.993 |

| NBO-M | 0.1156 ±0.00183 | 0.0371 ±0.00266 | 0.998 | 0.10905 ±0.000426 | 0.0300 ±0.000622 | 0.999 | 0.10643 ±0.00182 | 0.0318 ±0.00265 | 0.998 |

| Ester | 0.10822 ±0.00118 | 0.0483 ±0.00171 | 0.999 | 0.10674 ±0.00203 | 0.0519 ±0.00296 | 0.998 | 0.10606 ±0.00141 | 0.0597 ±0.00141 | 0.999 |

| OSP-M | 0.16476 ±0.00302 | 0.0897 ±0.00404 | 0.998 | 0.15914 ±0.00528 | 0.0964 ±0.00771 | 0.995 | 0.14803 ±0.00301 | 0.0971 ±0.00439 | 0.998 |

| AN-M | 0.10696 ±0.00139 | 0.05508 ±0.0020 | 0.999 | 0.09903 ±0.000669 | 0.05008 ±0.00097 | 0.999 | 0.09273 ±0.00226 | 0.05182 ±0.00329 | 0.997 |

References

- Holmberg, K.; Andersson, P.; Erdemir, A. Global energy consumption due to friction in passenger cars. Tribol. Int. 2012, 47, 221–234. [Google Scholar] [CrossRef]

- Liu, W.; Xu, J.; Feng, D.; Wang, X. The Research status and prospect of synthetic lubricating Oils. Tribology 2013, 33, 91–104. [Google Scholar]

- Shah, R.; Das, M.; Kabir, M.H.; Liang, H.; Salvi, L.; Bunting, T.L. Additive and base oil trends in electric vehicle applications. J. Tribol. 2025, 147, 051106. [Google Scholar] [CrossRef]

- Zou, S.; Xie, G.; Yang, R.; Hou, J.; Sun, F. Rehabilitation robot joint performance evaluation of a zero-spin traction drive with non-Newtonian fluid considered. Adv. Mech. Eng. 2024, 16, 16878132241266751. [Google Scholar]

- Bair, S.; Habchi, W. EHL Traction Coefficient Is Not a Property of the Liquid Alone. J. Tribol. 2025, 1–12. [Google Scholar] [CrossRef]

- Tsubouchi, T.; Hata, H.; Yoshida, Y. Optimisation of molecular structure for traction fluids. Lubr. Sci. 2004, 16, 393–403. [Google Scholar] [CrossRef]

- Rounds, F. Effects of Lubricant Composition on Friction as Measured with Thrust Ball Bearings. J. Chem. Eng. Data 1960, 5, 499–507. [Google Scholar] [CrossRef]

- Hammann, W.; Schisla, R.; Groenweghe, L.; Gash, V. Synthetic fluids for high capacity traction drives. ASLE Trans. 1970, 13, 105–116. [Google Scholar] [CrossRef]

- Wang, Y.; Qiu, Q.; Zhang, P.; Gao, X.; Zhang, Z.; Huang, P. Correlation between lubricating oil characteristic parameters and friction characteristics. Coatings 2023, 13, 881. [Google Scholar] [CrossRef]

- Zhang, J.; Tan, A.; Spikes, H. Effect of base oil structure on elastohydrodynamic friction. Tribol. Lett. 2017, 65, 13. [Google Scholar] [CrossRef]

- Hamrock, B.J.; Dowson, D. Isothermal elastohydrodynamic lubrication of point contacts: Part 1—Theoretical formulation. J. Lubr. Tech. 1976, 98, 223–228. [Google Scholar] [CrossRef]

- Martinie, L.; Vergne, P. Lubrication at extreme conditions: A discussion about the limiting shear stress concept. Tribol. Lett. 2016, 63, 21. [Google Scholar] [CrossRef]

- Ma, Z.; Zhao, Y.; Han, Y.; Lou, W.; Li, S.; Wang, X.; Guo, F.; Liu, H. Approach to Determine the Limiting Shear Stress of Lubricants at High Pressures Based on Traction Mapping. Lubricants 2024, 12, 128. [Google Scholar] [CrossRef]

- Bair, S.S. High Pressure Rheology for Quantitative Elastohydrodynamics; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Smith, F. Lubricant behavior in concentrated contact—Some rheological problems. ASLE Trans. 1960, 3, 18–25. [Google Scholar] [CrossRef]

- Bair, S. A traction (friction) curve is not a flow curve. Lubricants 2022, 10, 221. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, B.; Bader, N.; Venner, C.; Poll, G. Simplified traction prediction for highly loaded rolling/sliding EHL contacts. Tribol. Int. 2020, 148, 106335. [Google Scholar] [CrossRef]

- Fang, N.; Chang, L.; Webster, M.; Jackson, A. A non-averaging method of determining the rheological properties of traction fluids. Tribol. Int. 2000, 33, 751–760. [Google Scholar] [CrossRef]

- Ndiaye, S.-N.; Martinie, L.; Philippon, D.; Devaux, N.; Vergne, P. A quantitative friction-based approach of the limiting shear stress pressure and temperature dependence. Tribol. Lett. 2017, 65, 149. [Google Scholar] [CrossRef]

- Johnson, K.L.; Tevaarwerk, J. Shear behaviour of elastohydrodynamic oil films. Proc. R. Soc. Lond. A Math. Phys. Sci. 1977, 356, 215–236. [Google Scholar]

- Johnson, K.L. Contact Mechanics; Cambridge University Press: Cambridge, UK, 1987. [Google Scholar]

- Gangopadhyay, A.; Liu, Z.; Simko, S.; Peczonczyk, S.; Cuthbert, J.; Hock, E.; Erdemir, A.; Ramirez, G. Friction and wear reduction mechanism of polyalkylene glycol-based engine oils. Tribol. Trans. 2018, 61, 621–631. [Google Scholar] [CrossRef]

- Hirst, W.; Moore, A. Elastohydrodynamic lubrication at high pressures II. Non-Newtonian behaviour. Proc. R. Soc. Lond. A Math. Phys. Sci. 1979, 365, 537–565. [Google Scholar]

- Hamrock, B.J.; Dowson, D. Isothermal elastohydrodynamic lubrication of point contacts: Part II—Ellipticity parameter results. J. Lubr. Technol. 1976, 98, 375–381. [Google Scholar] [CrossRef]

- Hamrock, B.J.; Dowson, D. Isothermal elastohydrodynamic lubrication of point contacts: Part III—Fully flooded results. J. Lubr. Technol. 1977, 99, 264–275. [Google Scholar] [CrossRef]

- Airey, J.; Spencer, M.; Greenwood, R.; Simmons, M. The effect of gas turbine lubricant base oil molecular structure on friction. Tribol. Int. 2020, 146, 106052. [Google Scholar] [CrossRef]

- Wen, S.; Huang, P. Principle of Tribological; Tsinghua University Press Limited: Beijing, China, 2002. [Google Scholar]

- Liu, H.; Zhang, B.; Bader, N.; Venner, C.H.; Poll, G. Scale and contact geometry effects on friction in thermal EHL: Twin-disc versus ball-on-disc. Tribol. Int. 2021, 154, 106694. [Google Scholar] [CrossRef]

- Poll, G.; Wang, D. Fluid rheology, traction/creep relationships and friction in machine elements with rolling contacts. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2012, 226, 481–500. [Google Scholar] [CrossRef]

| No. | Name of the Base Oil | Viscosity at 40 °C, mPa·s | Viscosity at 100 °C, mPa·s | Viscosity Index, VI | Viscosity-Pressure Coefficient, GPa−1 |

|---|---|---|---|---|---|

| 1 | PAO-M | 86.3 | 12.9 | 126 | 18 |

| 2 | 500N | 86.1 | 11.26 | 122 | 24 |

| 3 | NBO-M | 86.3 | 8.6 | 62 | 32 |

| 4 | Ester | 86.0 | 11.2 | 113 | 16 |

| 5 | OSP-M | 86.7 | 16.1 | 199 | 19 |

| 6 | AN-M | 86.6 | 12.1 | 133 | 25 |

| Parameter | Traction Curve Measurement | Stribeck Curve Measurement |

|---|---|---|

| Temperature, T/°C | 40, 60, 80 | 40, 60, 80 |

| Mean contact pressure, pm/GPa | 1.2, 1.3, 1.4, 1.5, 1.6, 1.7 | 1.4 |

| Entrainment speed, ue/m/s | 0.4–2.0 | 0.01–1.0 |

| Slide-to-roll ratio, SRR/% | 0–50 | 10 |

| / GPa | 500N | PAO-M | NBO-M | ||||||

| ue, m/s | fmax | LSS, GPa | ue, m/s | fmax | LSS, GPa | ue, m/s | fmax | LSS, GPa | |

| 1.2 | 0.6 | 0.0704 | 0.0844 | 0.9 | 0.0558 | 0.0669 | 0.6 | 0.0842 | 0.1010 |

| 1.3 | 0.6 | 0.0740 | 0.0962 | 0.9 | 0.0582 | 0.0756 | 0.6 | 0.0868 | 0.1128 |

| 1.4 | 0.6 | 0.0755 | 0.1057 | 0.9 | 0.0615 | 0.0861 | 0.5 | 0.0900 | 0.126 |

| 1.5 | 0.6 | 0.0782 | 0.1173 | 0.7 | 0.0647 | 0.0970 | 0.5 | 0.0910 | 0.1365 |

| 1.6 | 0.5 | 0.0813 | 0.1300 | 0.6 | 0.0678 | 0.1084 | 0.5 | 0.0923 | 0.1476 |

| 1.7 | 0.5 | 0.0841 | 0.1429 | 0.6 | 0.0697 | 0.1184 | 0.5 | 0.0935 | 0.1589 |

| / GPa | Ester | OSP-M | AN-M | ||||||

| ue, m/s | fmax | LSS, GPa | ue, m/s | fmax | LSS, GPa | ue, m/s | fmax | LSS, GPa | |

| 1.2 | 0.9 | 0.0682 | 0.0818 | 1.0 | 0.0898 | 0.10776 | 1.0 | 0.0613 | 0.0735 |

| 1.3 | 0.9 | 0.0705 | 0.0916 | 1.0 | 0.0950 | 0.1235 | 0.9 | 0.0649 | 0.0843 |

| 1.4 | 0.8 | 0.0740 | 0.1036 | 0.9 | 0.1010 | 0.1414 | 0.9 | 0.0672 | 0.0940 |

| 1.5 | 0.8 | 0.0758 | 0.1137 | 0.8 | 0.1055 | 0.15825 | 0.8 | 0.0698 | 0.1047 |

| 1.6 | 0.7 | 0.0782 | 0.1251 | 0.7 | 0.1095 | 0.1752 | 0.7 | 0.0725 | 0.116 |

| 1.7 | 0.7 | 0.0797 | 0.1354 | 0.7 | 0.1110 | 0.1887 | 0.7 | 0.0749 | 0.1273 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, X.; Zhao, Y.; Lou, W.; Zhang, B.; Wang, X.; Guo, F.; Liu, H. Quantitative Study on the Friction of Different Types of Base Oils Based on Stribeck Curve and Traction Curve Characterization. Lubricants 2025, 13, 485. https://doi.org/10.3390/lubricants13110485

Guo X, Zhao Y, Lou W, Zhang B, Wang X, Guo F, Liu H. Quantitative Study on the Friction of Different Types of Base Oils Based on Stribeck Curve and Traction Curve Characterization. Lubricants. 2025; 13(11):485. https://doi.org/10.3390/lubricants13110485

Chicago/Turabian StyleGuo, Xinao, Yan Zhao, Wenjing Lou, Binbin Zhang, Xiaobo Wang, Feng Guo, and Haichao Liu. 2025. "Quantitative Study on the Friction of Different Types of Base Oils Based on Stribeck Curve and Traction Curve Characterization" Lubricants 13, no. 11: 485. https://doi.org/10.3390/lubricants13110485

APA StyleGuo, X., Zhao, Y., Lou, W., Zhang, B., Wang, X., Guo, F., & Liu, H. (2025). Quantitative Study on the Friction of Different Types of Base Oils Based on Stribeck Curve and Traction Curve Characterization. Lubricants, 13(11), 485. https://doi.org/10.3390/lubricants13110485