Thermal Characteristics Analysis of an Aerospace Friction Clutch Based on Thermal–Fluid–Solid Coupling

Abstract

1. Introduction

2. Theoretical Method

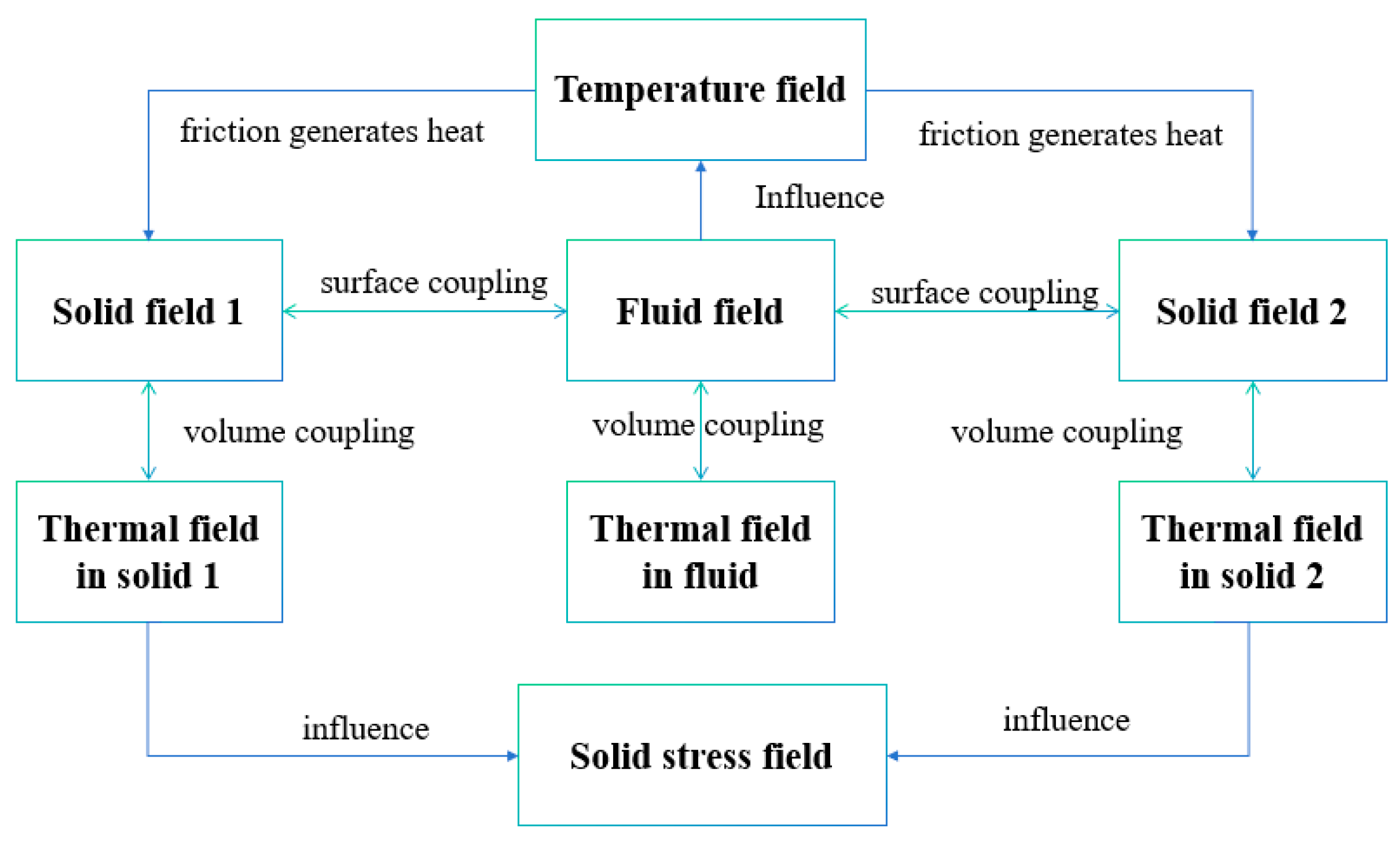

2.1. Thermo–Fluid–Solid Coupling Method

2.2. Heat Flux Calculation

3. Numerical Model

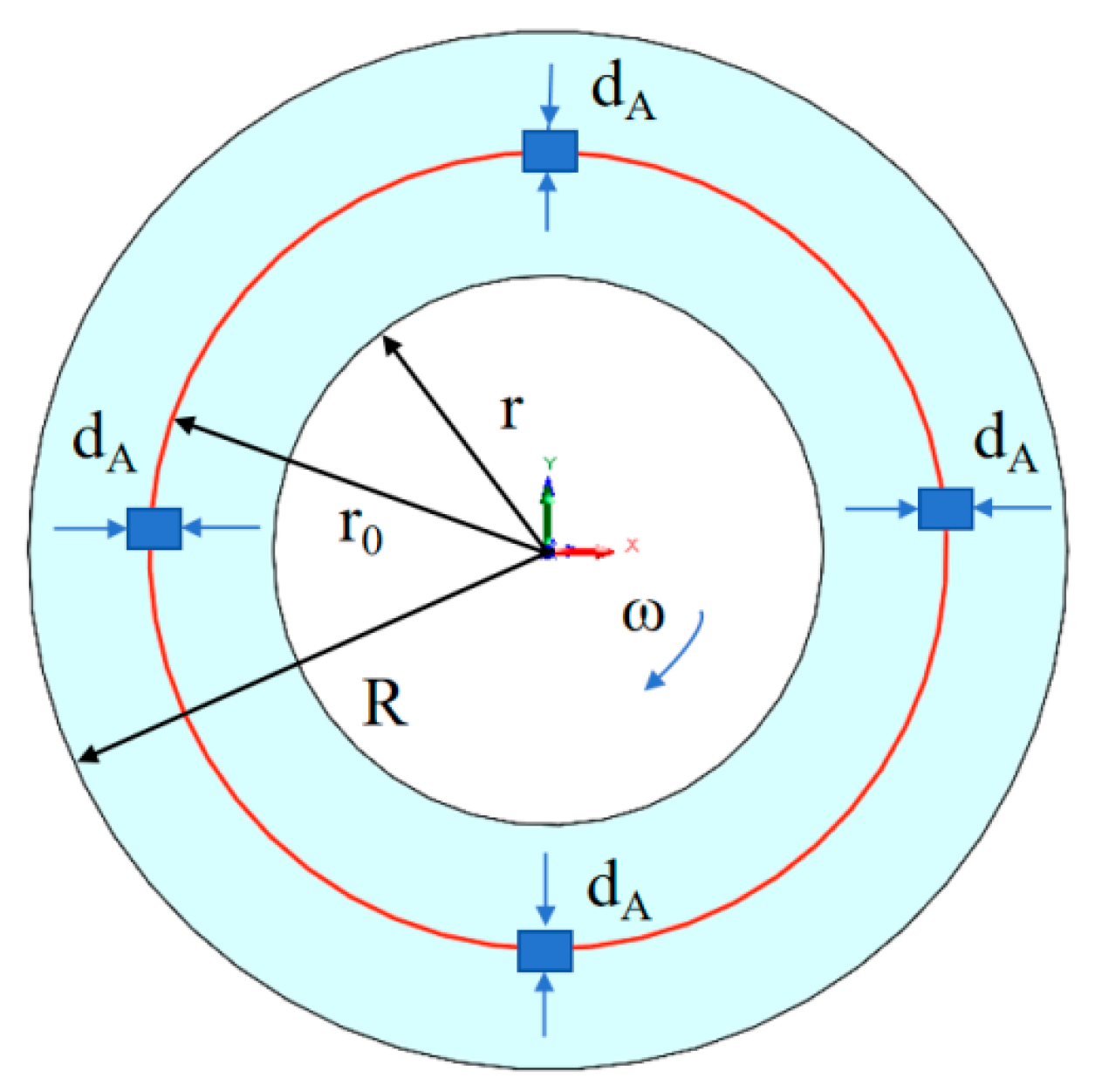

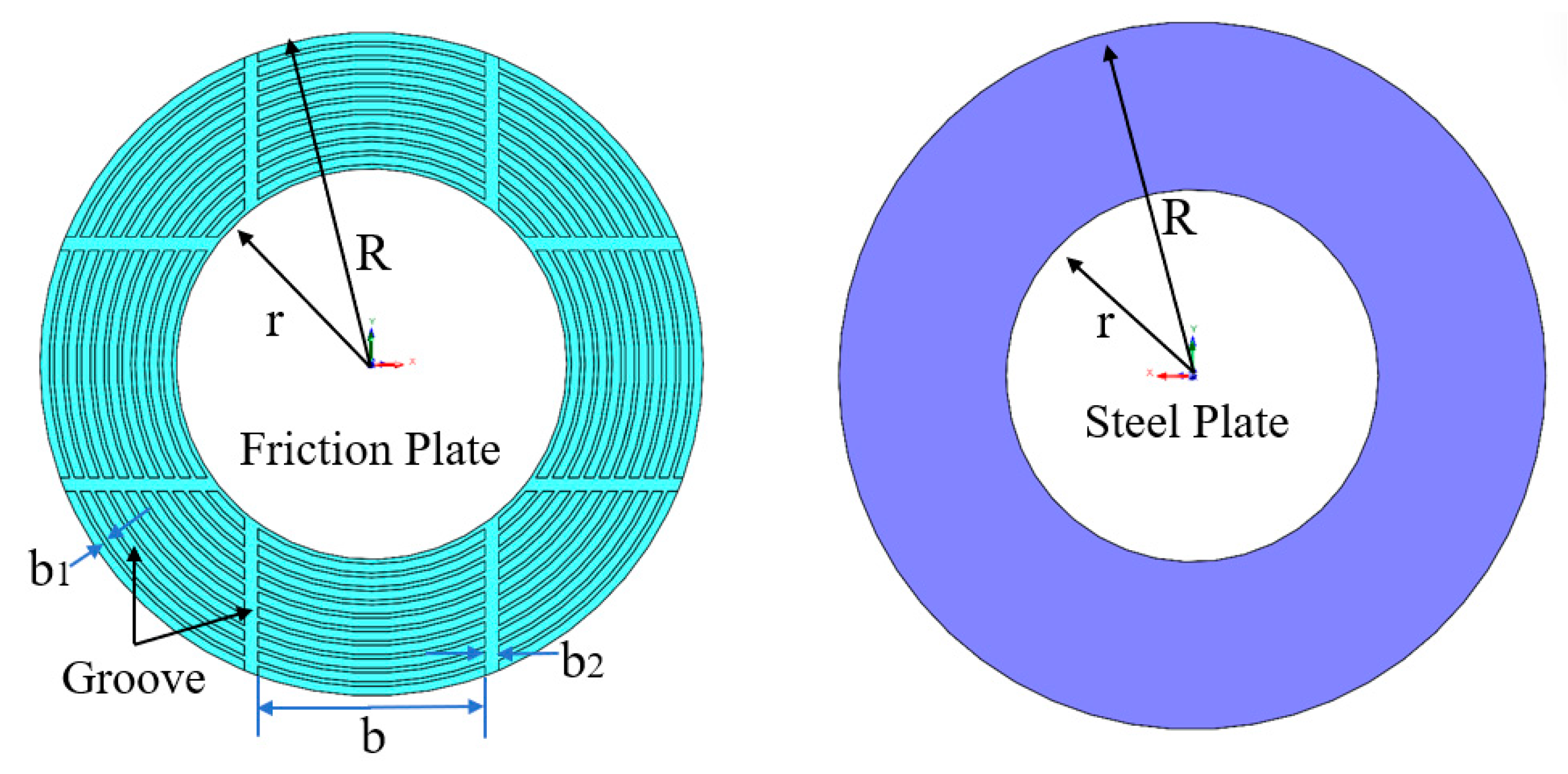

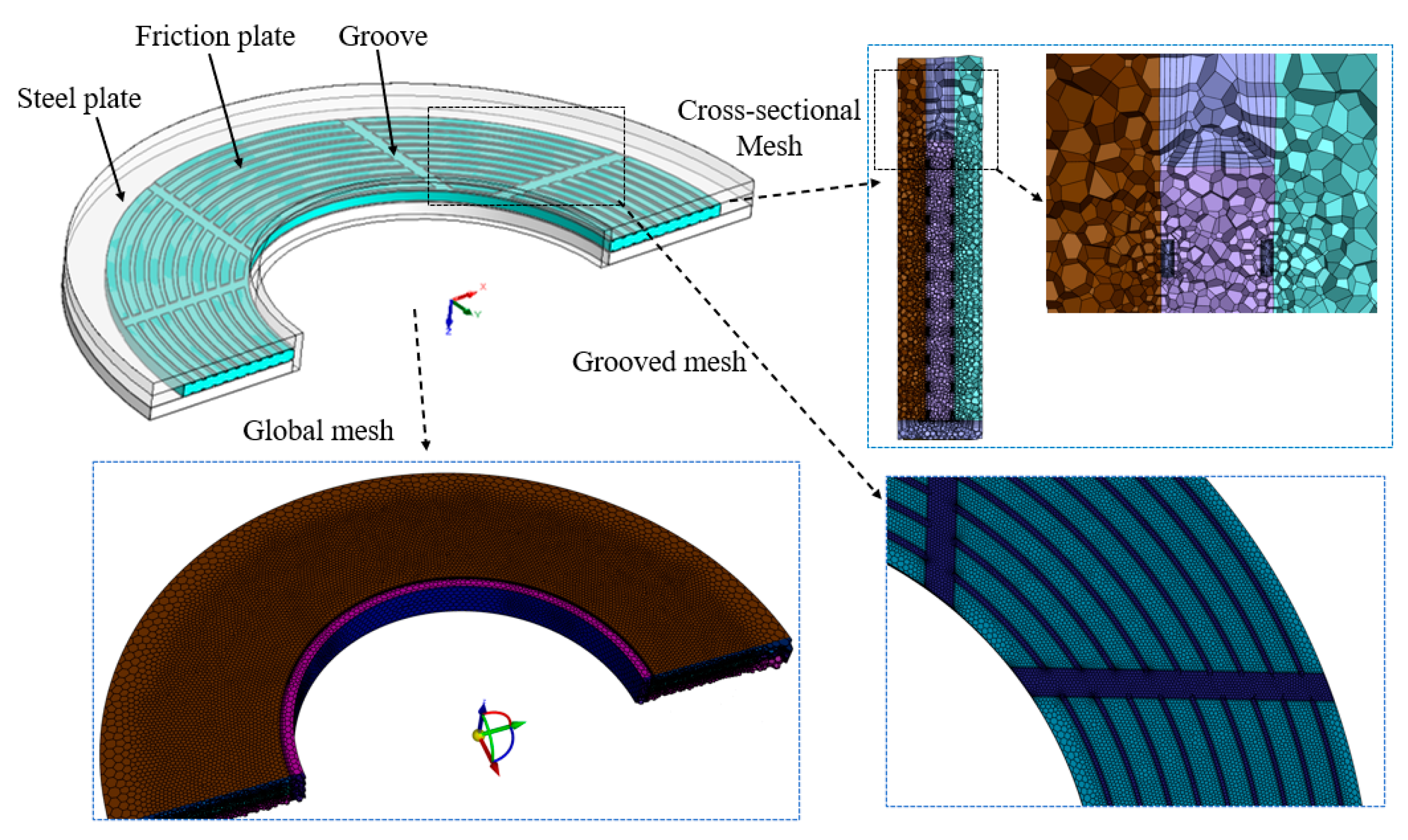

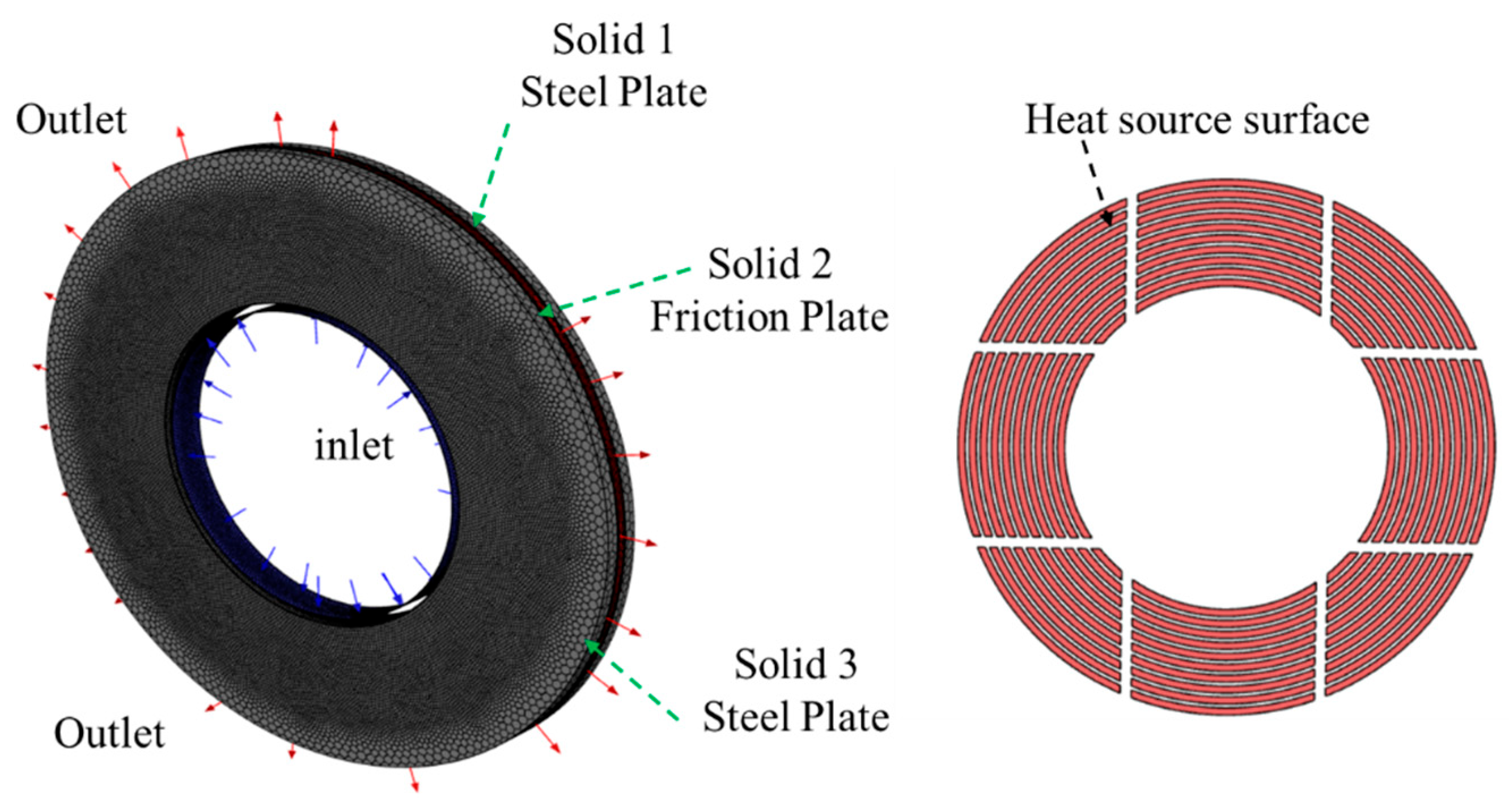

3.1. Geometric Model

3.2. Material Properties

3.3. Boundary Conditions

3.4. Turbulence Model

4. Results and Discussion

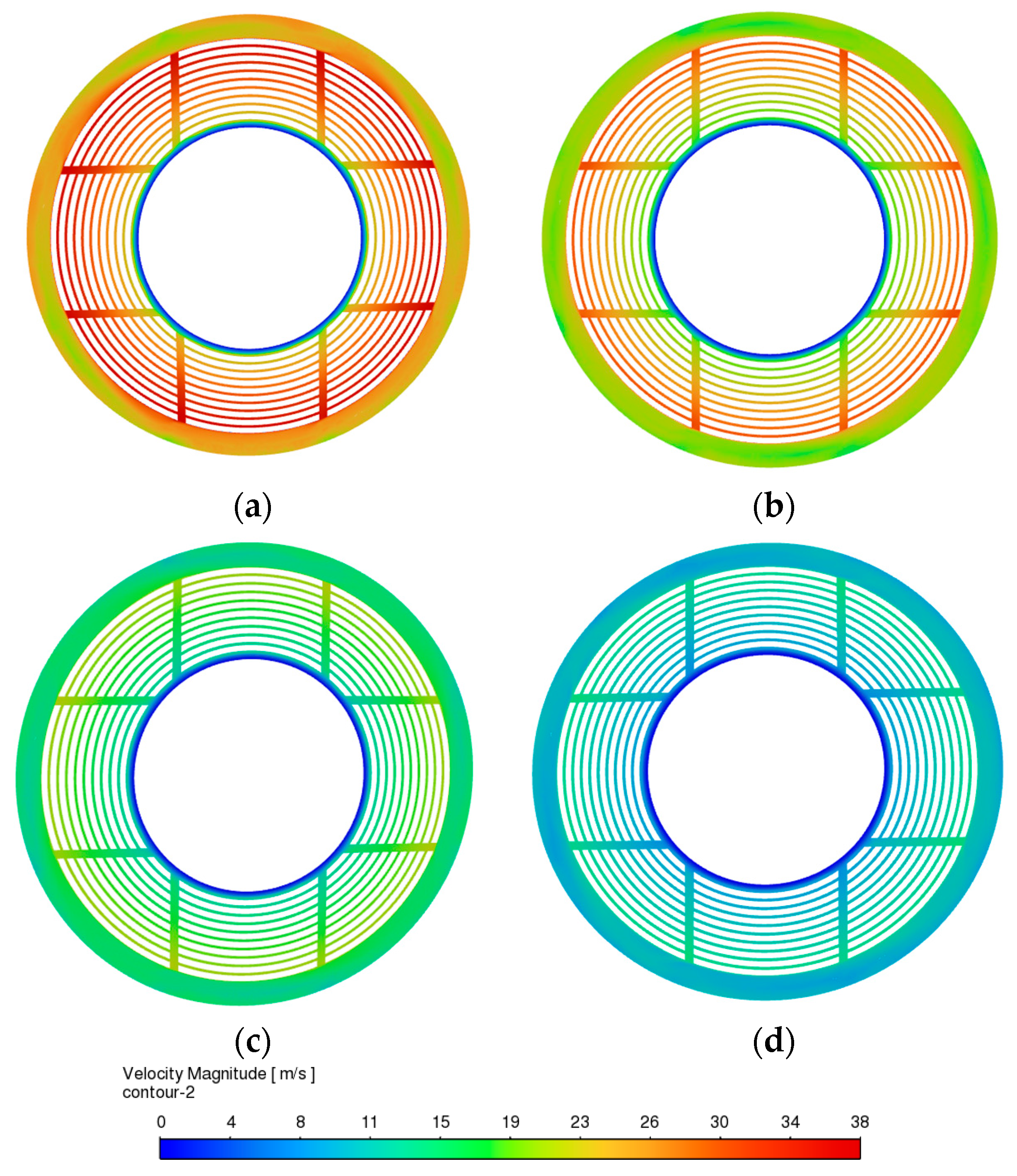

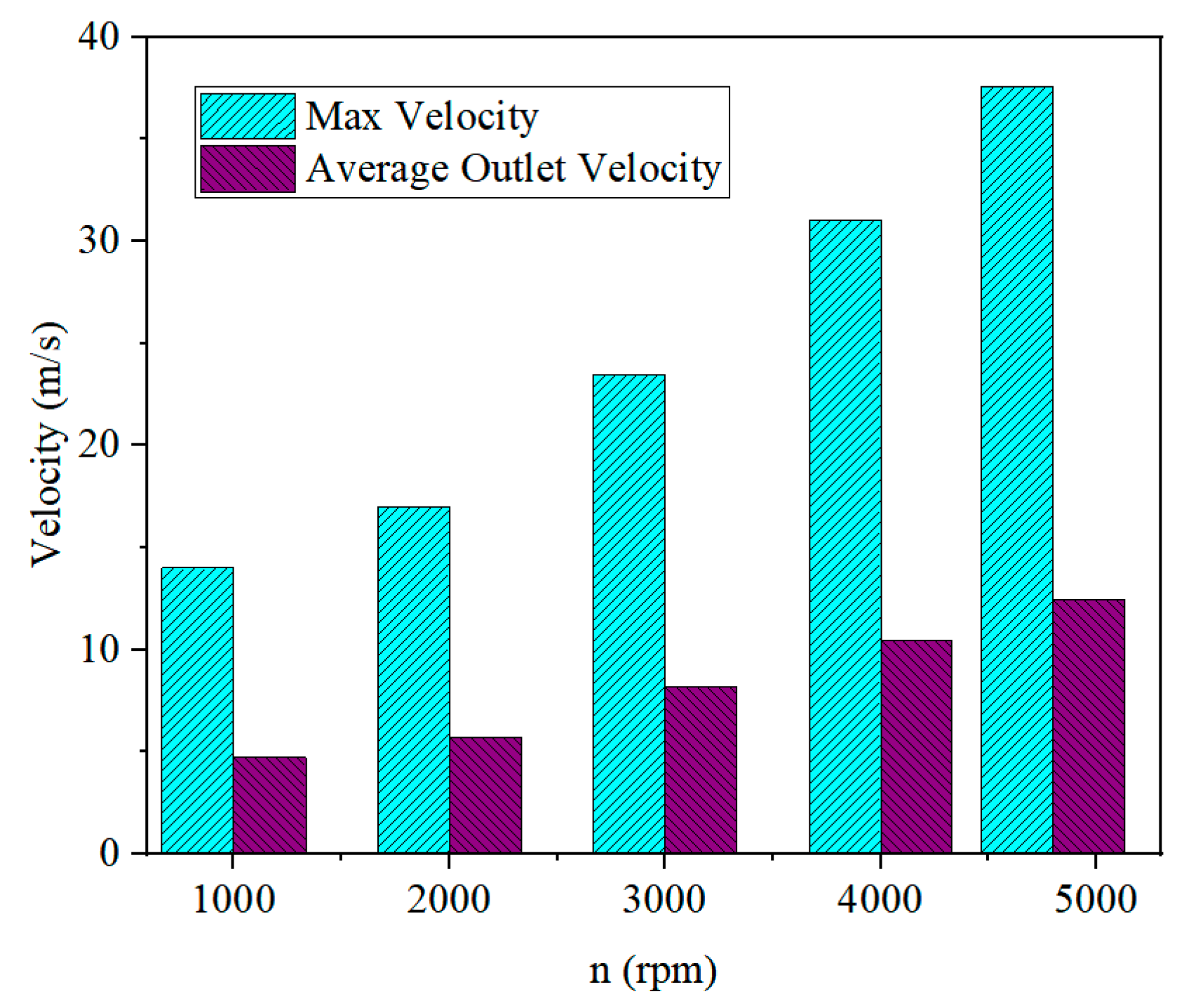

4.1. Flow Field Distribution at Different Rotational Speeds

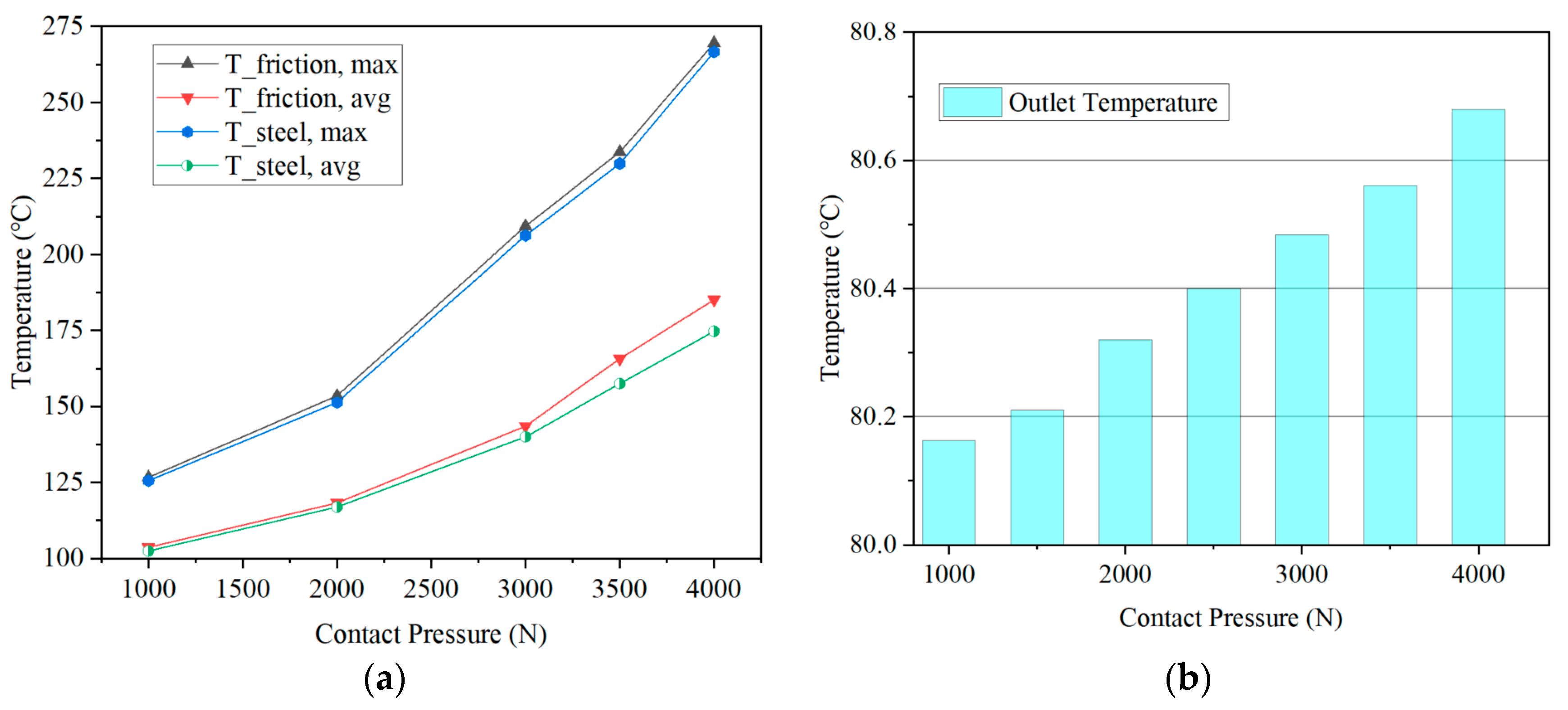

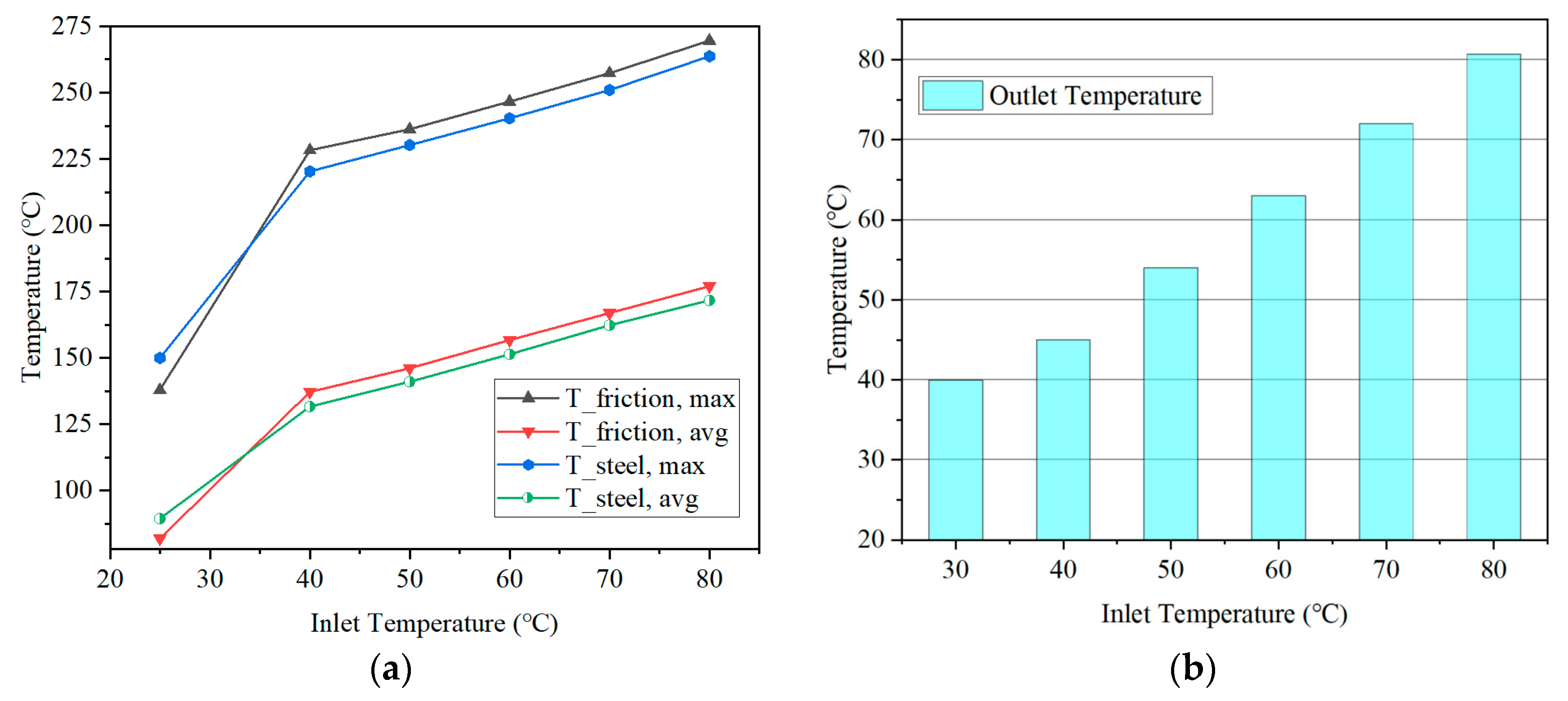

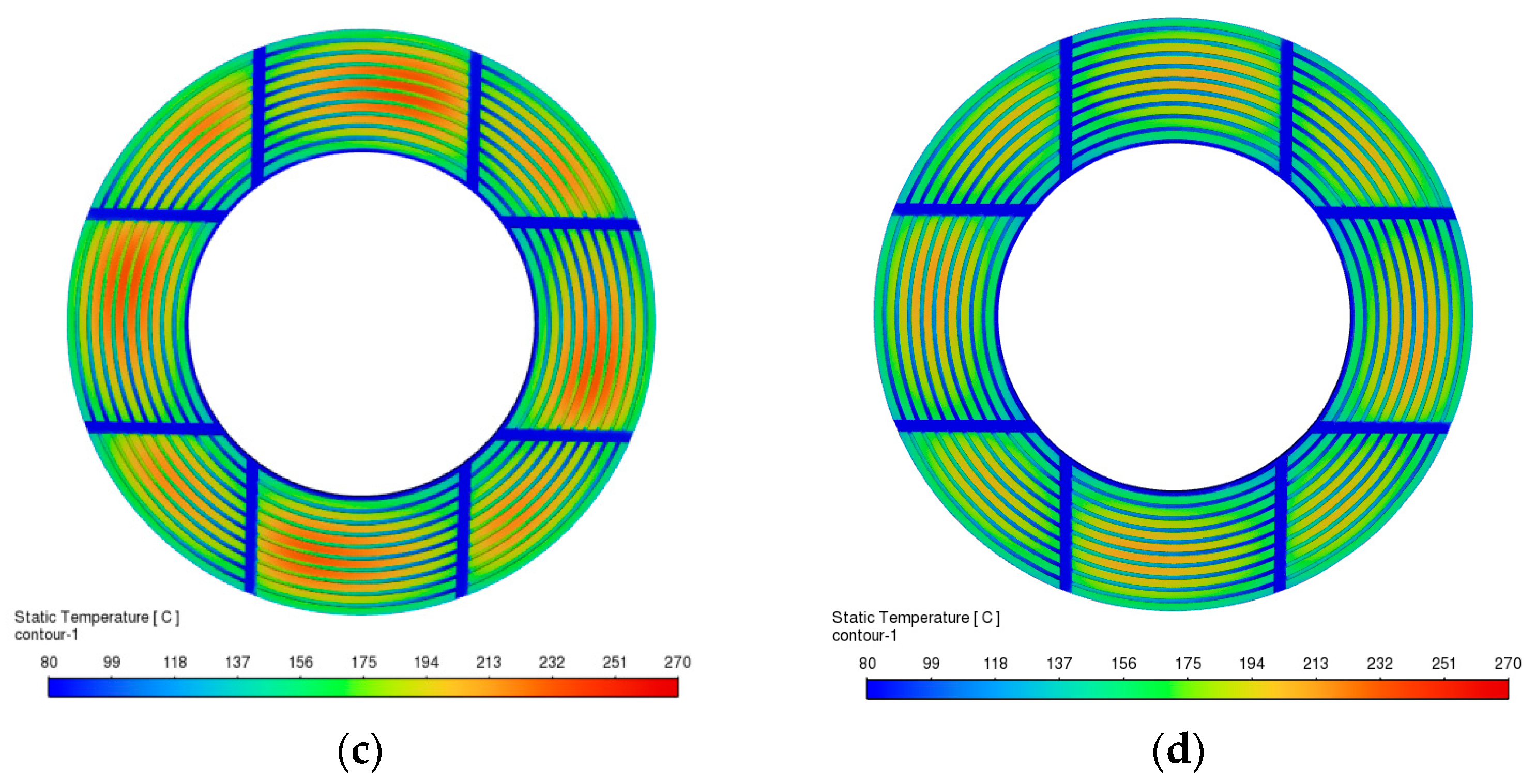

4.2. Temperature Field Distribution Under Different Engagement Pressures and Inlet Oil Temperatures

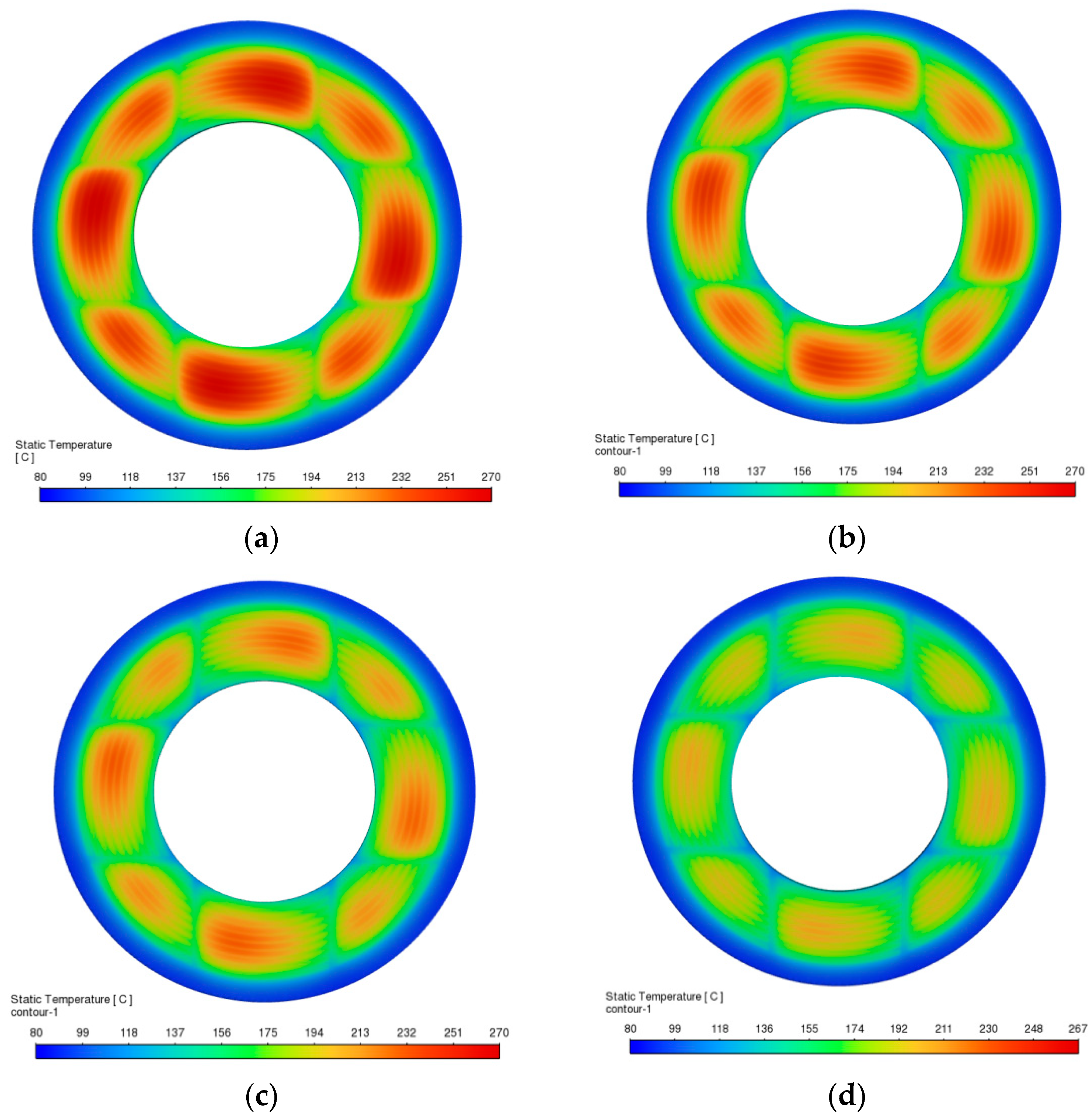

4.3. Distribution of the Temperature Field Under Different Rotational Speeds

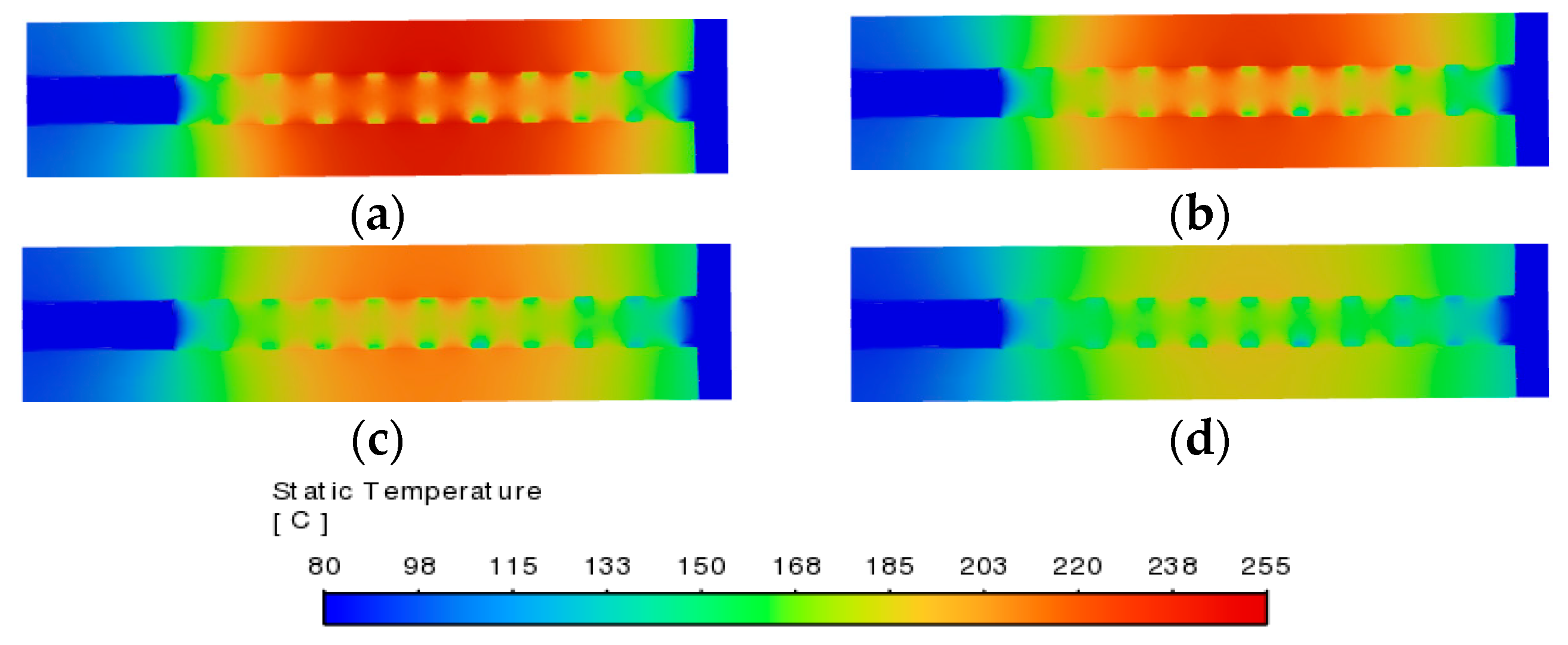

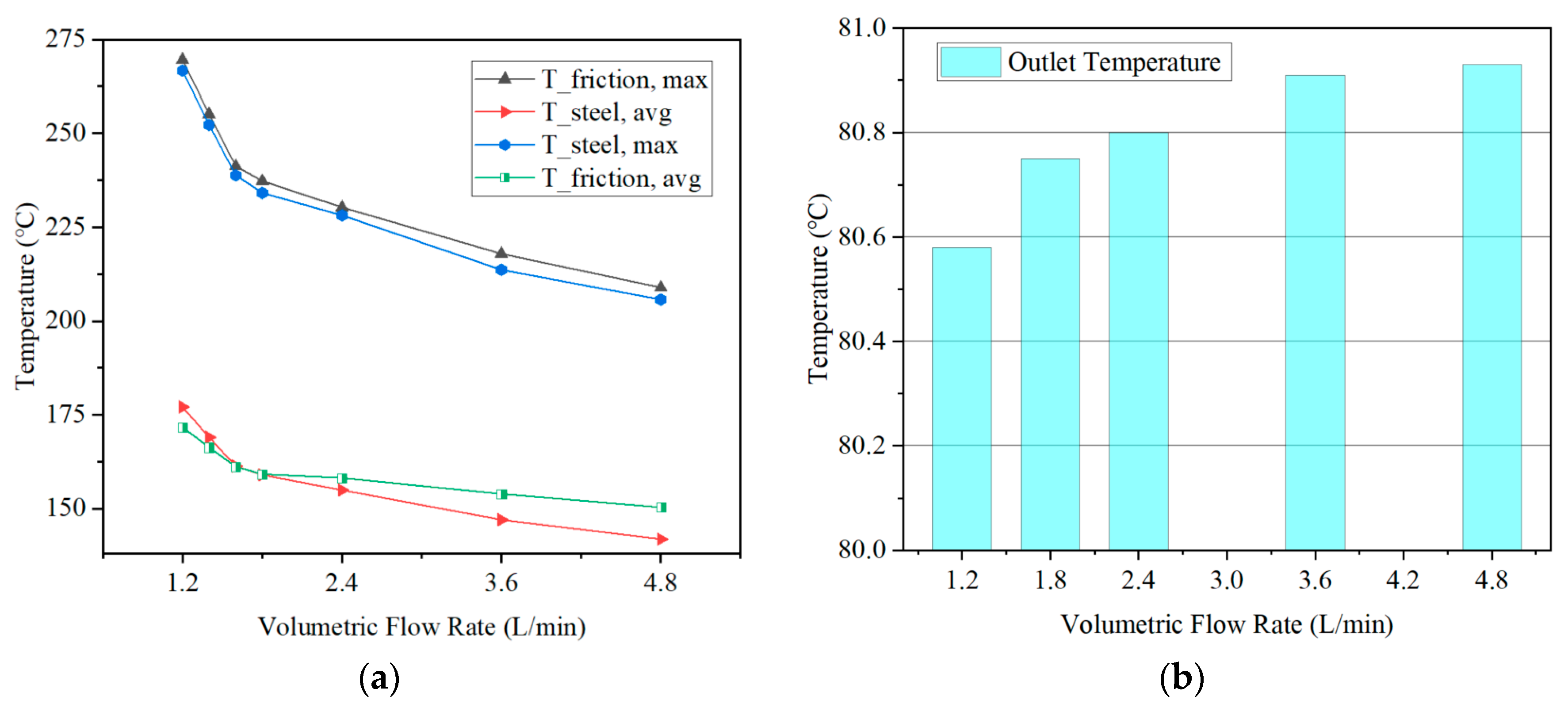

4.4. Temperature Field Distribution Under Different Inlet Flow Rates

5. Conclusions

- Engagement pressure is a key factor inducing local thermal failure. An increase in engagement pressure significantly elevates the peak temperature of the friction pair, while its effect on the overall average temperature remains relatively limited. This indicates that high pressure tends to generate localized hot spots in the contact region, which are the primary cause of friction material ablation and thermal spot formation, particularly for paper-based materials.

- A lower inlet oil temperature is an effective means of controlling thermal rise. Reducing the inlet oil temperature can markedly enhance heat dissipation. In particular, when the inlet temperature is below 40 °C, its suppression effect on the overall temperature field becomes more pronounced. This provides a clear direction for developing early-stage cooling strategies in the system.

- Increasing rotational speed nonlinearly intensifies the system’s thermal load. The frictional heat generation power increases sharply with rotational speed, especially in the high-speed range. The resulting rapid temperature rise not only poses a risk of thermal runaway but also serves as a dominant factor leading to local burning or failure of the friction pair.

- Flow optimization exhibits a yield inflection point, with material thermal management capability being the key constraint. Increasing the lubricant flow rate is an effective method for temperature regulation, but its effectiveness is limited by the flow channel structure, exhibiting a distinct critical point of diminishing returns. Blindly increasing the flow rate is not an economically efficient choice; design should instead target identifying this inflection point. Additionally, paper-based friction linings exhibit poor thermal conductivity and high heat storage capacity. This results in higher operating temperatures under identical conditions, making them a key focus in system thermal design.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Moodie, A.M.; Yeo, H. Design of a Cruise-Efficient Compound Helicopter. J. Am. Helicopter Soc. 2012, 57, 1–11. [Google Scholar] [CrossRef]

- Qiu, Y.; Li, Y.; Lang, J.; Wang, Z. Dynamics analysis and control of coaxial high-speed helicopter in transition flight. Aerosp. Sci. Technol. 2023, 137, 108278. [Google Scholar] [CrossRef]

- Xiao, Y.; Li, Q.; Liu, H. The Optimization and Control of the Engagement Pressure for a Helicopter Dry Clutch. Machines 2024, 12, 533. [Google Scholar] [CrossRef]

- Pointner-Gabriel, L.; Voelkel, K.; Stahl, K. Drag Losses of Wet Brakes and Clutches—A Scoping Review. Lubricants 2025, 13, 27. [Google Scholar] [CrossRef]

- Abdullah, O.I.; Schlattmann, J.; Majeed, M.H.; Sabri, L.A. The distribution of frictional heat generated between the contacting surfaces of the friction clutch system. Int. J. Interact. Des. Manuf. (IJIDeM) 2018, 13, 487–498. [Google Scholar] [CrossRef]

- Huang, Z.; Bao, H.; Xiao, Y.; Wei, Y. Transient thermal characteristic analysis and experimental validation of aviation wet friction clutch. J. Mech. Sci. Technol. 2025, 39, 2269–2283. [Google Scholar] [CrossRef]

- Jin, J.; Li, X.; Yang, S.; Sun, H.; Yi, H.; Hao, W. A temperature field model based on energy flow analysis of wet clutch sliding interface. Tribol. Int. 2024, 199, 109976. [Google Scholar] [CrossRef]

- Yu, L.; Zheng, C.; Wang, L.; Wu, J.; Jia, R. Influences of the Contact State between Friction Pairs on the Thermodynamic Characteristics of a Multi-Disc Clutch. Materials 2022, 15, 7758. [Google Scholar] [CrossRef]

- Liu, Y.; Sun, Y.; Gao, Z.; Ye, F.; Tang, P. Transient temperature characteristics of friction clutch disc considering thermal contact conductance under sliding conditions. Friction 2023, 11, 2253–2263. [Google Scholar] [CrossRef]

- Kong, J.; Jang, S. Temperature Analysis of Wet Clutch Surfaces During Clutch Engagement Processes Based on Friction Pad Patterns. Int. J. Automot. Technol. 2020, 21, 813–822. [Google Scholar] [CrossRef]

- Tan, W.; Chen, Z.; Li, Z.; Yan, H. Thermal-Fluid-Solid Coupling Simulation and Oil Groove Structure Optimization of Wet Friction Clutch for High-Speed Helicopter. Machines 2023, 11, 296. [Google Scholar] [CrossRef]

- Zhang, Z.; Mu, Z.; Yu, X. Mechanistic Study of Groove Parameters on the Thermoelastic Instability of Wet Clutch. Lubricants 2025, 13, 150. [Google Scholar] [CrossRef]

- Zheng, L.; Ma, B.; Chen, M.; Yu, L.; Wang, Q.; Xue, J. Study on the Temperature Rise Characteristics of Successive Clutch Shifting Considering the Disengaged Friction Pair Gaps. Machines 2022, 10, 576. [Google Scholar] [CrossRef]

- Saffar, I.Q.A.; Sultan, H.S.; Jweeg, M.J.; Abed, A.M.; Abdullah, O.I.; Schlattmann, J.; Sabri, L.A.; Alfilh, R.H.C. Investigation of the influence of sliding speed on thermoelastic problem in the frictional clutch system when applying a constant heat generation. Heat Transf. Res. 2023, 54, 19–40. [Google Scholar] [CrossRef]

- Jin, J.; Li, X.; Yang, S.; Yi, H.; Sun, H.; Hao, W. Calculation and analysis of wet clutch sliding torque based on fluid-solid coupling dynamic behavior. Tribol. Int. 2025, 202, 110363. [Google Scholar] [CrossRef]

- Wu, J.; Ding, A.; Yang, C.; Zhang, H.; Wang, L.; Li, H. Data-driven thermal safety threshold analysis of friction component based on macro-micro interaction model. Case Stud. Therm. Eng. 2025, 74, 106821. [Google Scholar] [CrossRef]

- Zhao, Q.; Ma, B.; Xiong, C.; Yu, L.; Fu, B.; Yan, S. Modeling of the Dynamics of Conical Separate Plates in a Wet Multi-Disc Clutch. Lubricants 2025, 13, 262. [Google Scholar] [CrossRef]

- Liang, X.; Chen, L.; Wang, Y.; Wan, L. A proposed torque calculation model for multi-plate clutch considering boundary lubrication conditions and heat transfer. Int. J. Heat Mass Transf. 2020, 157, 119732. [Google Scholar] [CrossRef]

- Gravemeier, V.; Civaner, S.M.; Wall, W.A. A partitioned-monolithic finite element method for thermo-fluid–structure interaction. Comput. Methods Appl. Mech. Eng. 2022, 401, 115596. [Google Scholar] [CrossRef]

- Abdullah, O.I.; Schlattmann, J.; Senatore, A.; Sabri, L.A.; Al-Sahb, W.S.A. Effect of Sliding Speed on the Thermal Stresses of Single-Disk Friction Clutches. J. Fail. Anal. Prev. 2020, 20, 1534–1540. [Google Scholar] [CrossRef]

- Wu, P.-h.; Zhou, X.; Yang, C.; Lv, H.; Lin, T.; Wu, X. Parametric analysis of the drag torque model of wet multi-plate friction clutch with groove consideration. Ind. Lubr. Tribol. 2018, 70, 1268–1281. [Google Scholar] [CrossRef]

- Abdullah, O.I.; Schlattmann, J.; Senatore, A.; Al-Shabibi, A.M. Investigation of thermoelastic problem of multiple-disc friction clutches applying different thermal loads. Heat Mass Transf. 2018, 54, 3461–3471. [Google Scholar] [CrossRef]

- Zhang, Z.; Zou, L.; Liu, H.; Chen, Y.; Zhang, B. Effects of operating and material parameters on the thermal characteristics of a wet clutch. Adv. Mech. Eng. 2021, 13, 16878140211034101. [Google Scholar] [CrossRef]

- Karaivanov, D.P.; Rogkas, N.; Almpani, D.; Vasileiou, G.; Tsolakis, E.; Vakouftsis, C.; Zalimidis, P.; Spitas, V. A comparative study on the effect of disks geometrical features on the drag torque of a wet friction clutch. MATEC Web Conf. 2020, 317, 04001. [Google Scholar] [CrossRef]

- Majeed, M.H.; Kadhim, D.E.; Abdullah, O.I.; Schlattmann, J. Numerical analysis of thermal problem in dry friction clutches based on the interactive design approach. Int. J. Interact. Des. Manuf. (IJIDeM) 2020, 14, 1091–1101. [Google Scholar] [CrossRef]

- Abdullah, O.I.; Schlattmann, J. Thermal behavior of friction clutch disc based on uniform pressure and uniform wear assumptions. Friction 2016, 4, 228–237. [Google Scholar] [CrossRef]

- Bao, H.; Kong, W.; Hou, X.; Zhu, R. Analysis on temperature field of friction pair of aviation friction clutch based on different groove shapes of friction disk. J. Mech. Sci. Technol. 2021, 35, 3735–3742. [Google Scholar] [CrossRef]

- Bao, H.; Huang, W.; Lu, F. Investigation of engagement characteristics of a multi-disc wet friction clutch. Tribol. Int. 2021, 159, 106940. [Google Scholar] [CrossRef]

- Wu, J.; Yan, H.; Liu, S.; Ni, D. Study on nonlinear dynamics characteristics of dual speed dual clutch transmission system based on bond graph. Heliyon 2023, 9, e20862. [Google Scholar] [CrossRef] [PubMed]

| Parameters | Friction Plate | Steel Plate |

|---|---|---|

| Outer radius (mm) | 73 | 81.75 |

| Inner radius (mm) | 43 | 44 |

| Thickness (mm) | 3 | 3 |

| Groove pitch (mm) | 50 | - |

| Groove width (mm) | 1 | - |

| Groove width (mm) | 3 | - |

| Groove depth (mm) | 0.35 | - |

| Groove angle (°) | 90 | - |

| Parameters | Paper Base | Steel |

|---|---|---|

| Density (kg·m−3) | 1200 | 7750 |

| Thermal conductivity (W·m−1·K−1) | 0.241 | 38 |

| Specific heat capacity (J·kg−1·K−1) | 1600 | 519 |

| Elastic modulus (GPa) | 1 | 210 |

| Poisson’s ratio | 0.25 | 0.3 |

| Thermal expansion (K−1) | 30 × 10−6 | 12 × 10−6 |

| Parameters | Value |

|---|---|

| Density (kg·m−3) | 850 |

| Thermal conductivity (W·m−1·K−1) | 0.12 |

| Specific heat capacity (J·kg−1·K−1) | 1950 |

| Dynamic viscosity 40 °C (kg·m−1·s−1) | 0.0227 |

| Dynamic viscosity 80 °C (kg·m−1·s−1) | 0.0085 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bian, J.; Wu, H.; Yang, X.; Ye, G.; Zhu, X.; Dai, Y. Thermal Characteristics Analysis of an Aerospace Friction Clutch Based on Thermal–Fluid–Solid Coupling. Lubricants 2025, 13, 469. https://doi.org/10.3390/lubricants13110469

Bian J, Wu H, Yang X, Ye G, Zhu X, Dai Y. Thermal Characteristics Analysis of an Aerospace Friction Clutch Based on Thermal–Fluid–Solid Coupling. Lubricants. 2025; 13(11):469. https://doi.org/10.3390/lubricants13110469

Chicago/Turabian StyleBian, Jianeng, Hongmei Wu, Xinyuan Yang, Guang Ye, Xiang Zhu, and Yu Dai. 2025. "Thermal Characteristics Analysis of an Aerospace Friction Clutch Based on Thermal–Fluid–Solid Coupling" Lubricants 13, no. 11: 469. https://doi.org/10.3390/lubricants13110469

APA StyleBian, J., Wu, H., Yang, X., Ye, G., Zhu, X., & Dai, Y. (2025). Thermal Characteristics Analysis of an Aerospace Friction Clutch Based on Thermal–Fluid–Solid Coupling. Lubricants, 13(11), 469. https://doi.org/10.3390/lubricants13110469