Oil Transport Simulation and Oil Consumption Prediction with a Physics-Based and Data-Driven Digital Twin Model for Internal Combustion Engines

Abstract

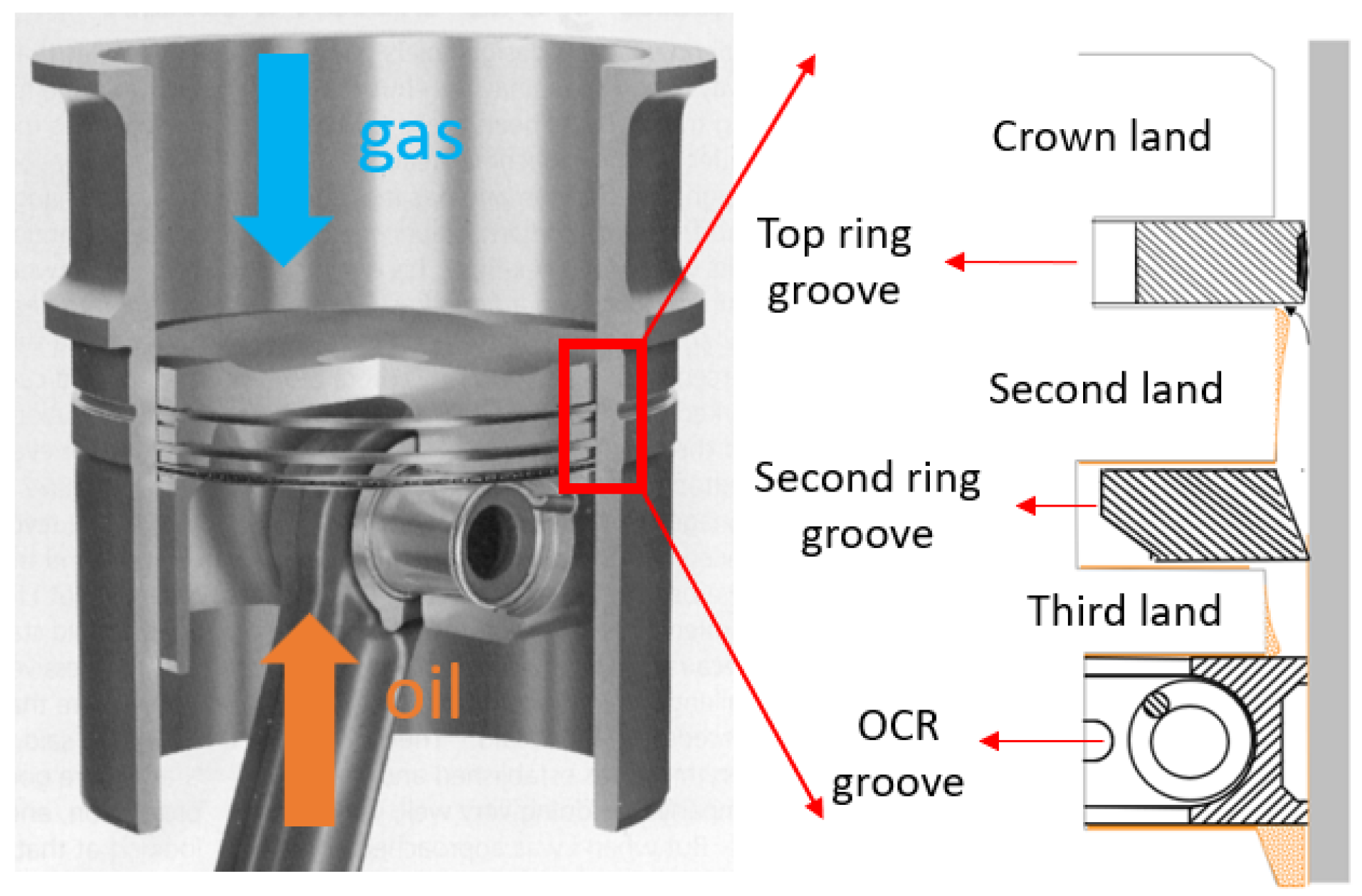

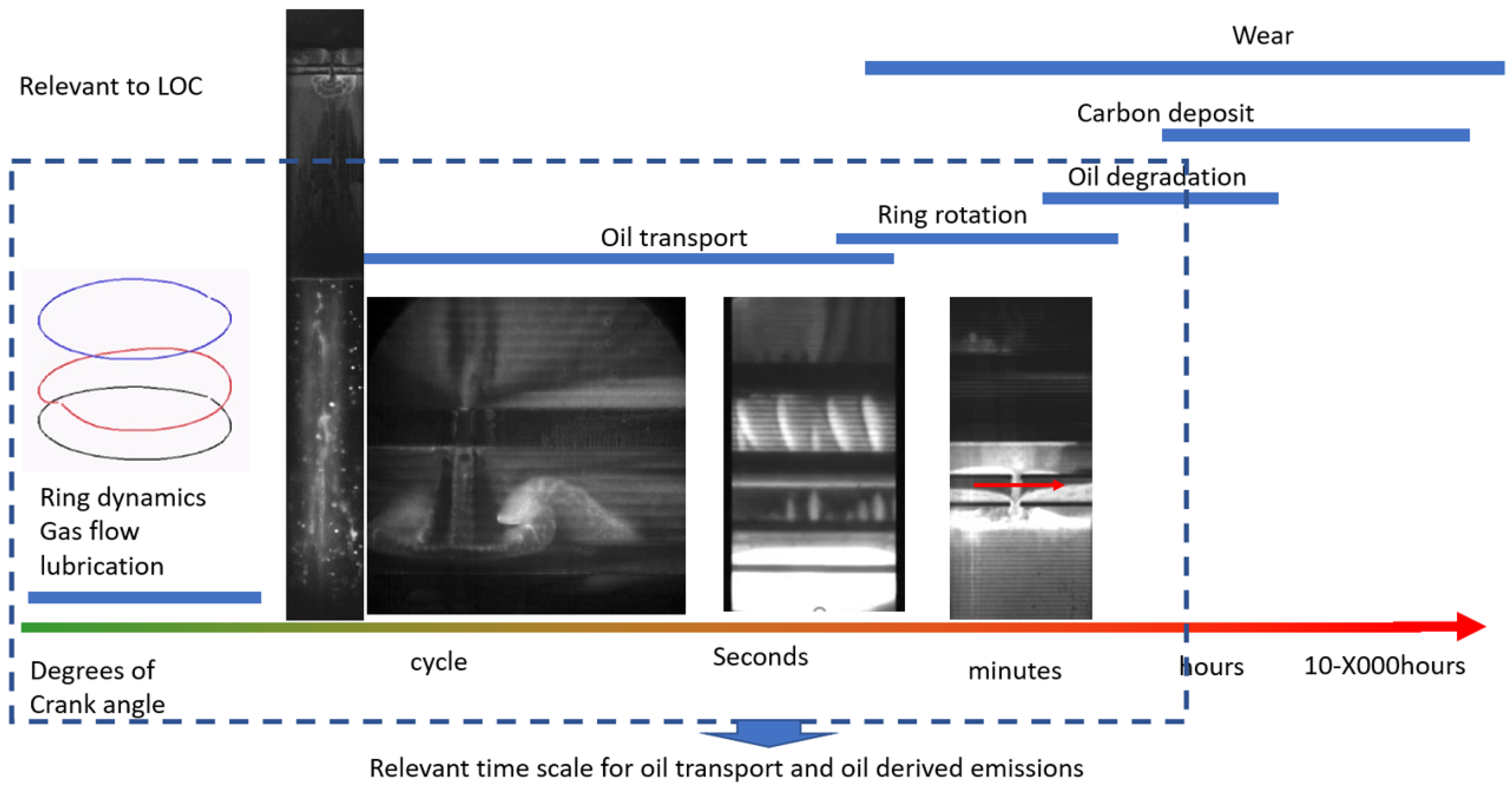

1. Introduction

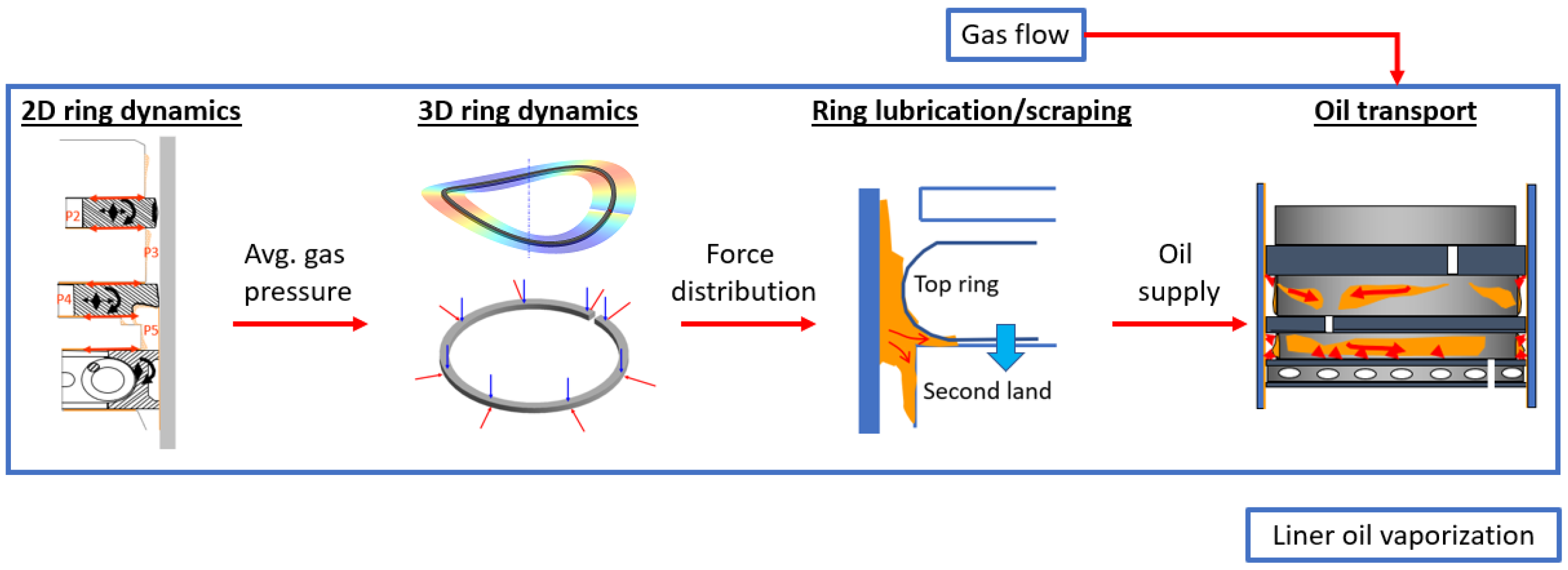

2. Modeling Methodology

3. Model Formulation

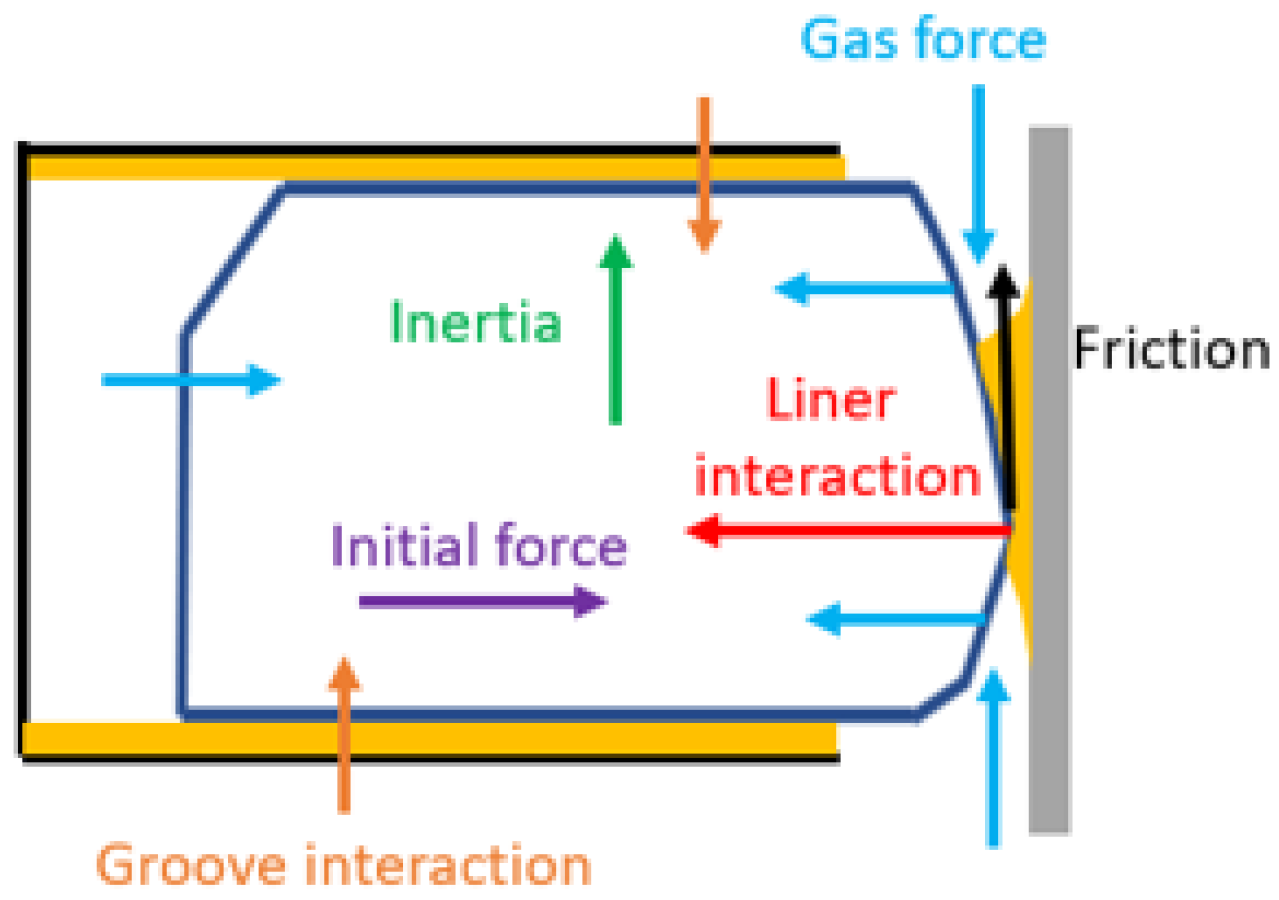

3.1. Three-Dimensional Ring Dynamics Model

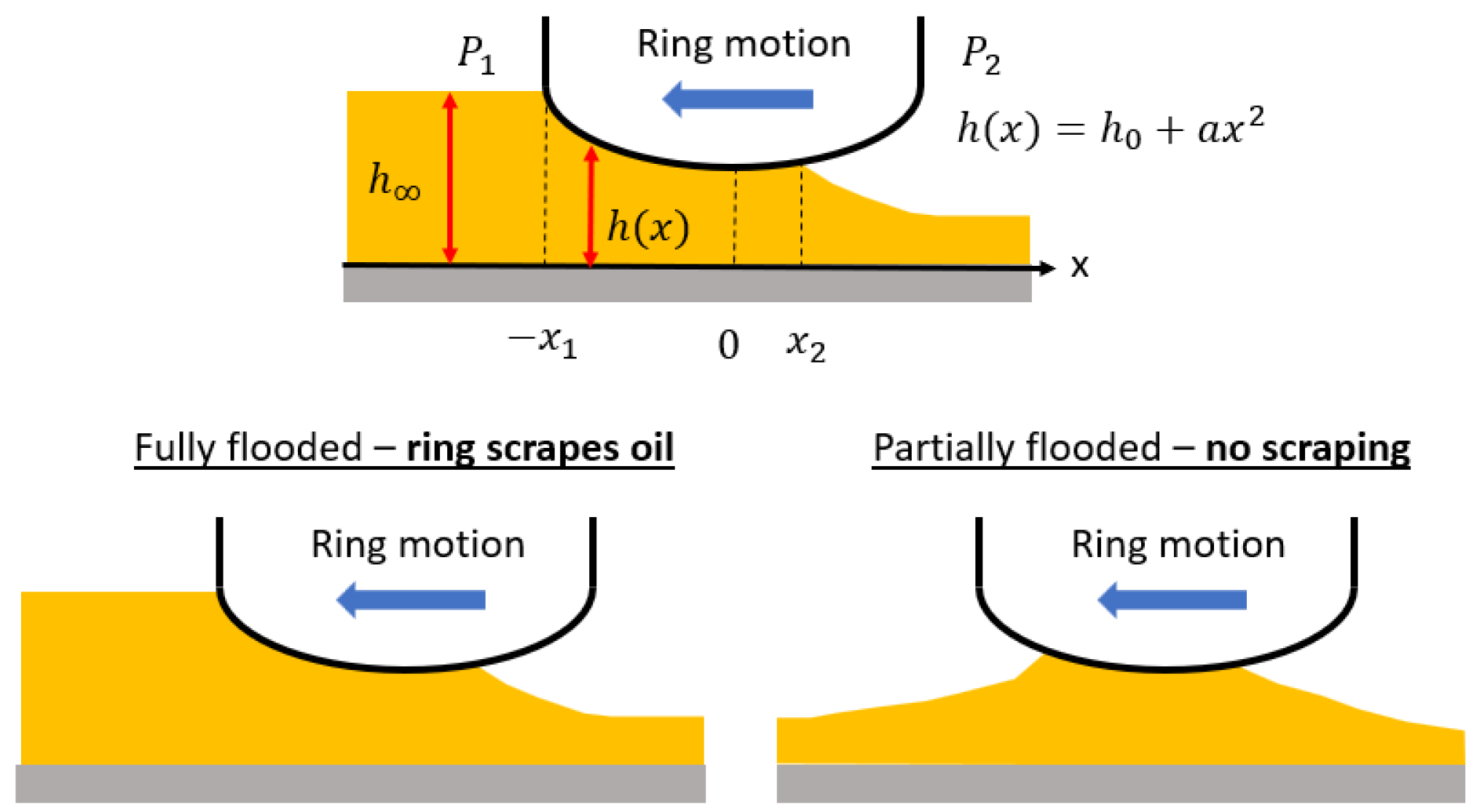

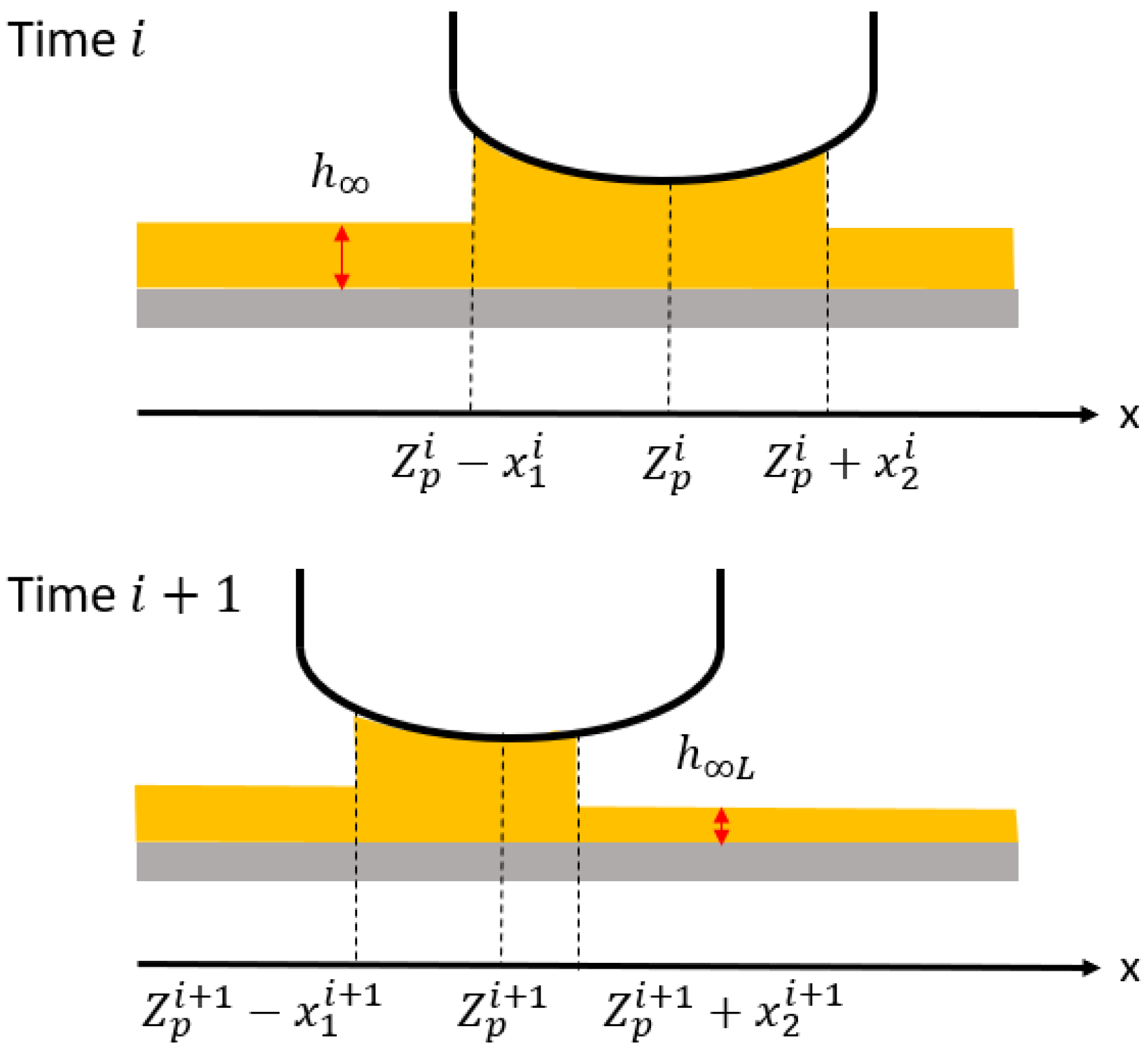

3.2. Mass-Conserved Ring–Liner Lubrication Model

3.3. Hybrid Gas Flow Model

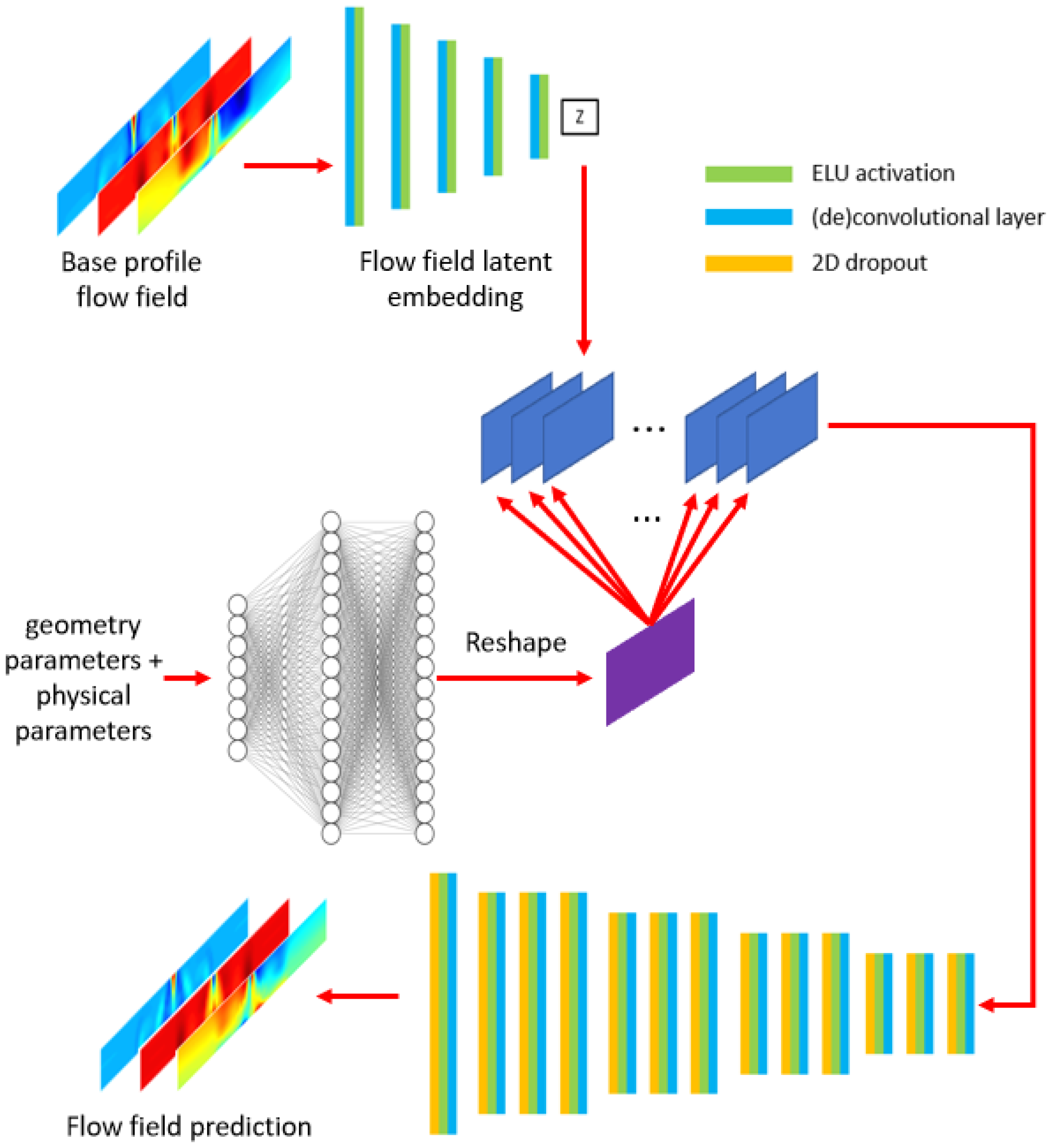

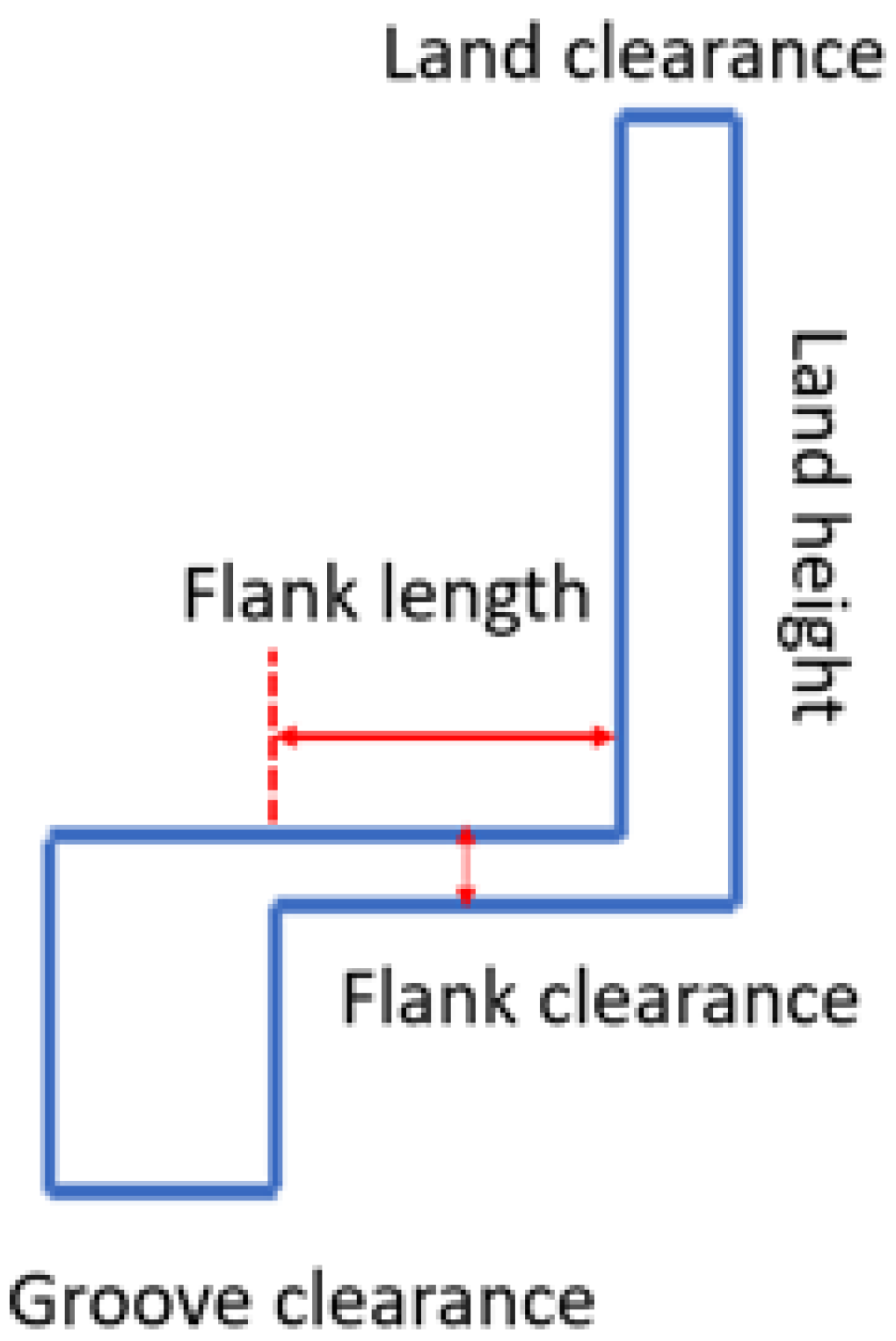

- Geometry parameters: the parameters that define the cross-section shape of the flow domain (Figure 11), the relative position between the inlet gap and the outlet gap, and the axial position of the second ring within the groove

- Physical parameters: pressure at the inlet gap and the outlet gap

- Base profile flow field: from the study performed in [21], compared to physical parameters, geometrical parameters have a more profound influence on the flow pattern. In other words, changing the shape of the cross-sectional geometry while holding pressure boundary conditions constant causes much more variation in the flow pattern than changing pressure boundary conditions while holding the cross-sectional geometry constant. Additionally, the various flow patterns resulting from different cross-section geometries within the design space can roughly be categorized into a predefined number of groups. A small number of “base geometries” are first sampled from the design space. The base flow field is generated by running CFD simulations on these geometries with the same inlet-outlet pressure combination. In predicting the flow field, the base profile for a particular set of input geometry is selected based on a similarity measure between the geometry parameters and the base profiles. The base profile flow field provides a rough estimation of the actual flow field to be predicted. A more detailed description can be found in [21].

- x is the predicted flow field and y the real flow field;

- and are the pixel means of x and y;

- and are the pixel standard deviation of x and y;

- is the pixel covariance of x and y;

- and are small constants for numerical stability.

3.4. Liquid Oil Transport Model

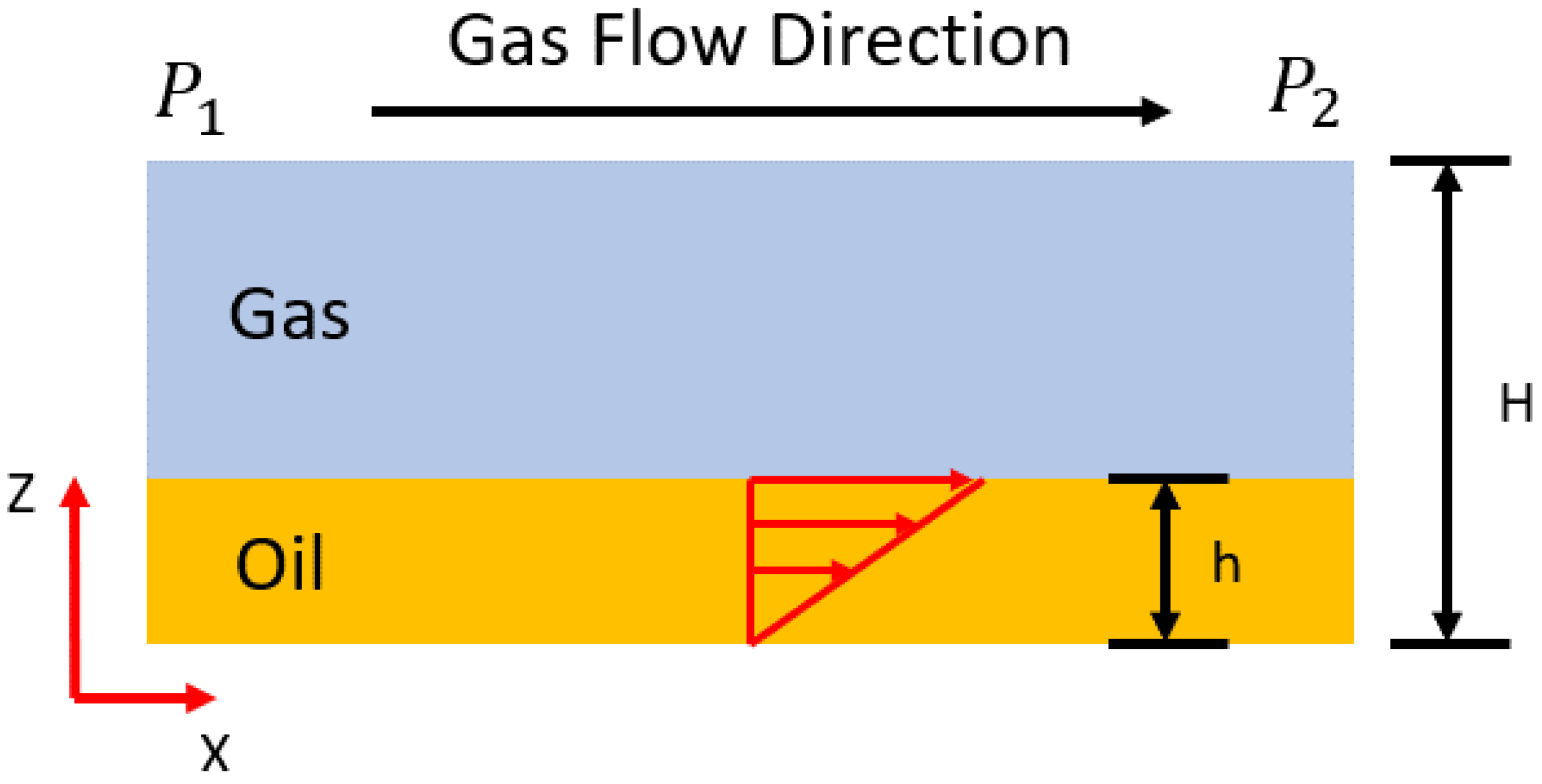

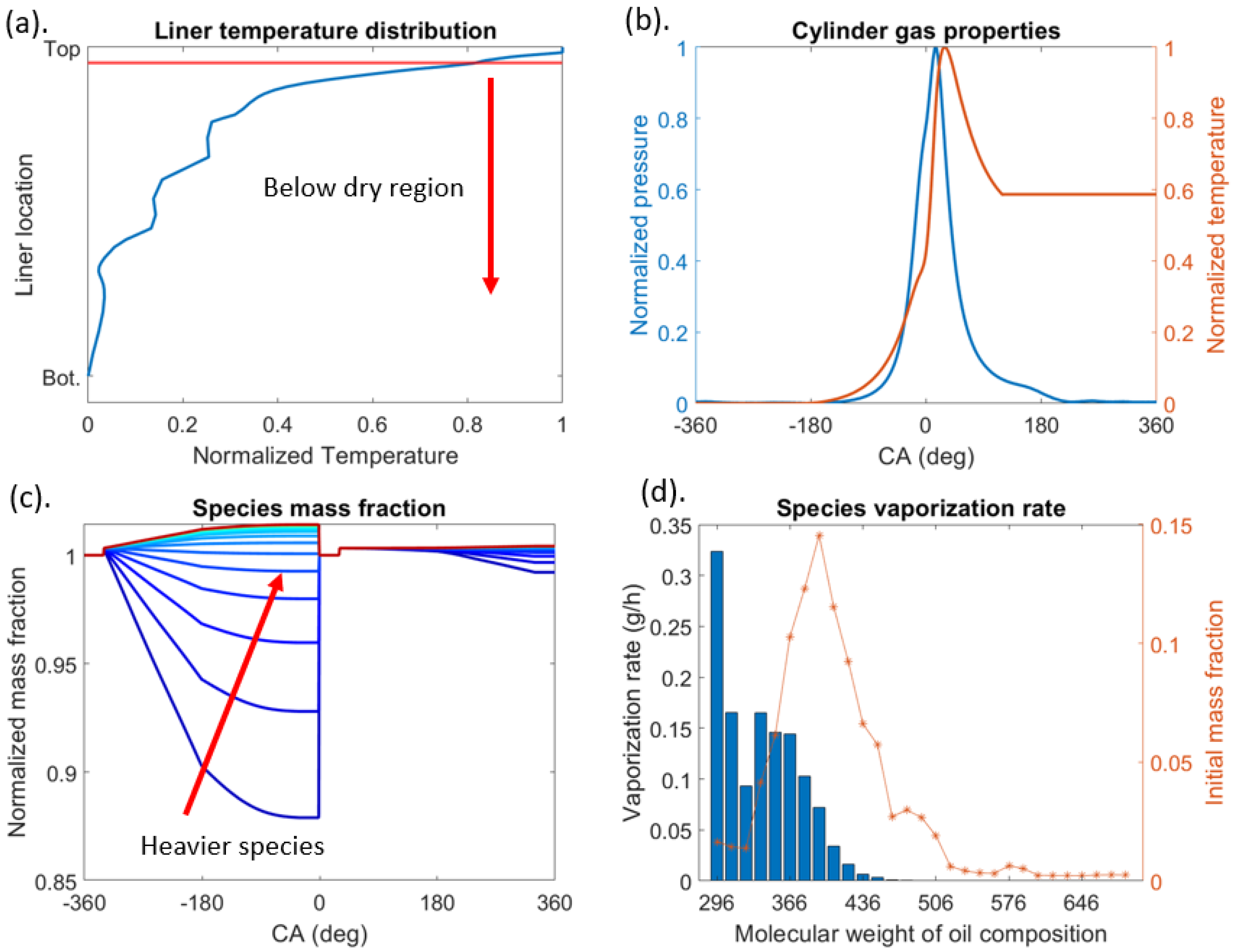

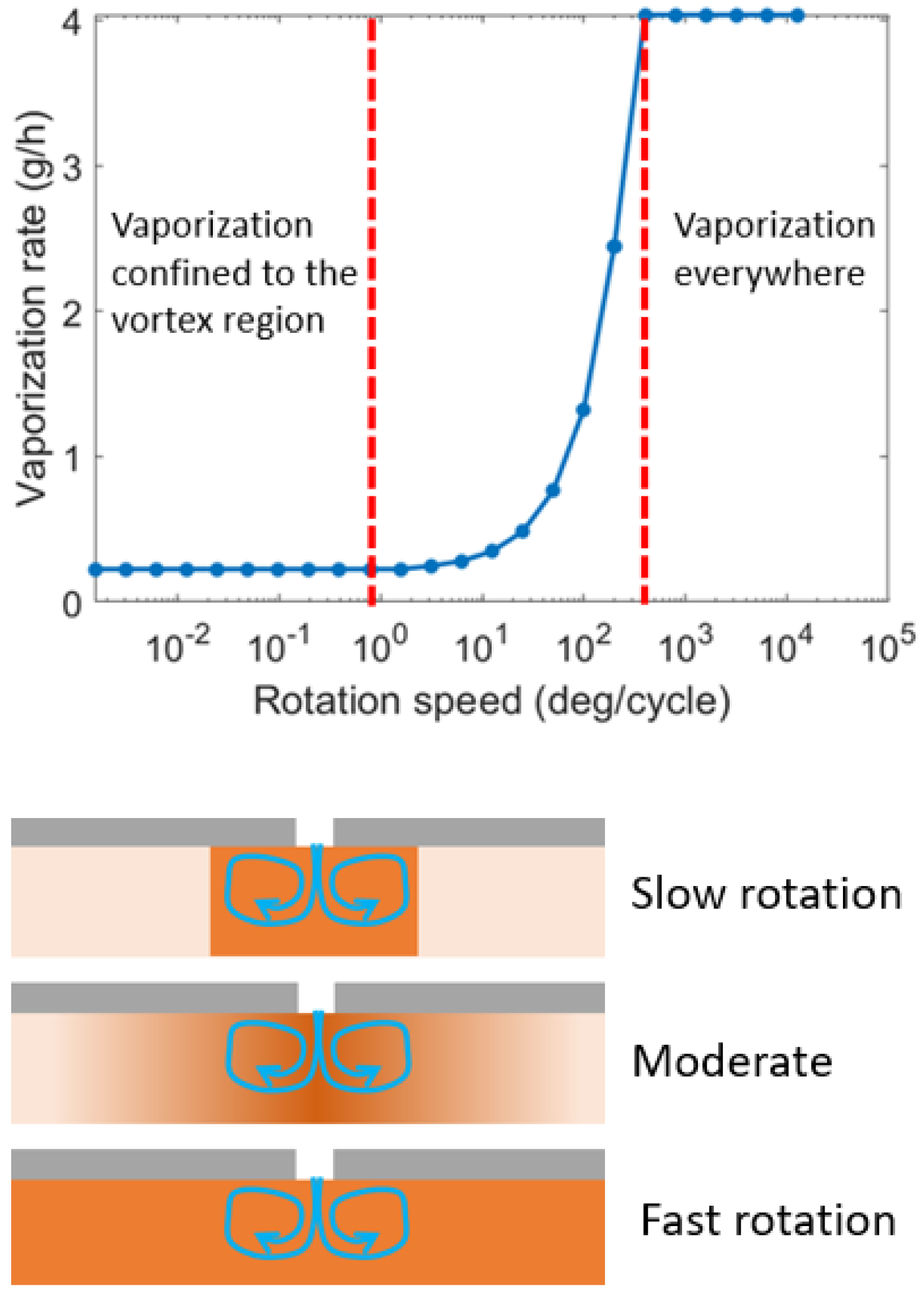

3.5. Liner Vaporization Model

4. Result Discussion

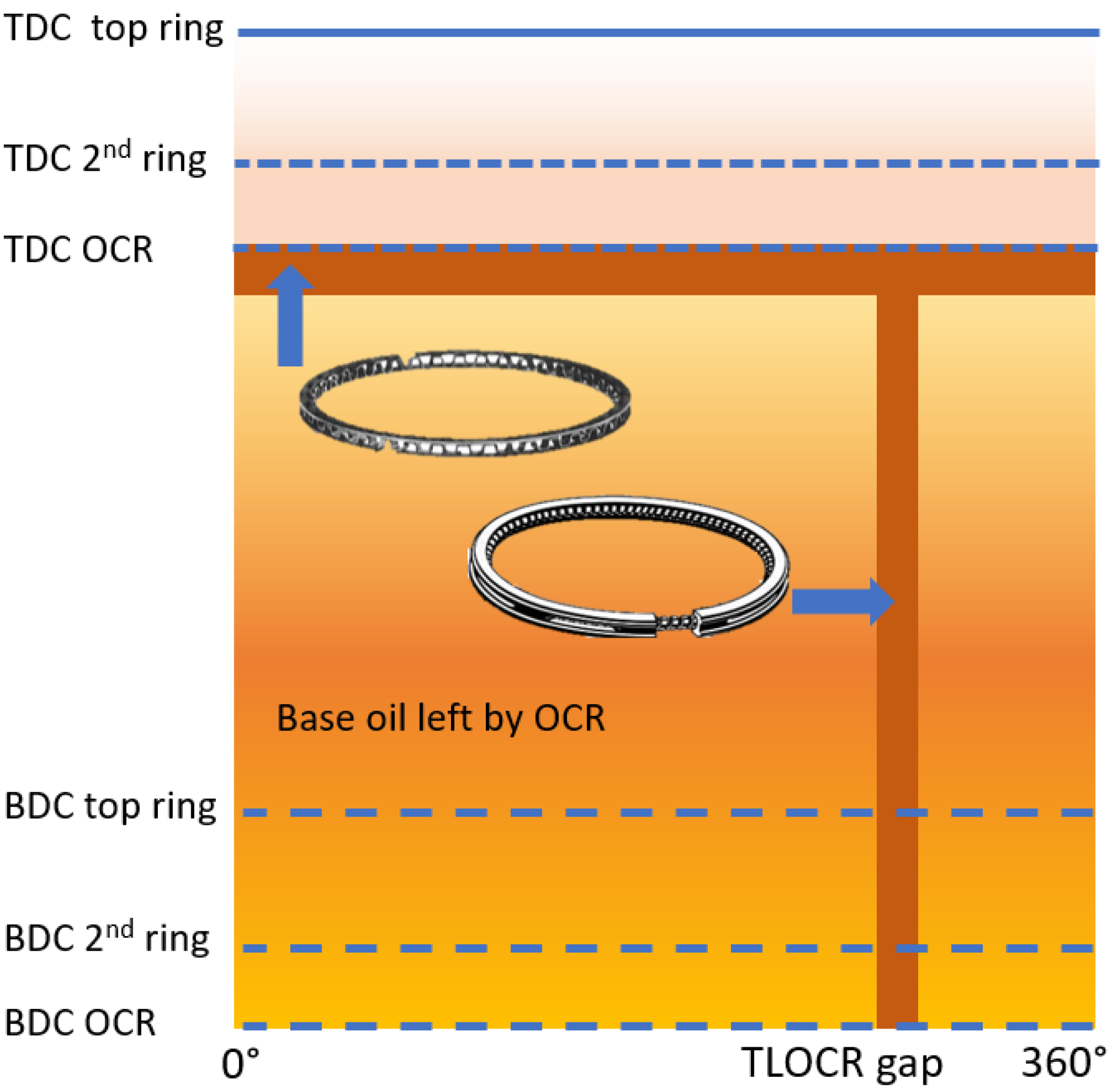

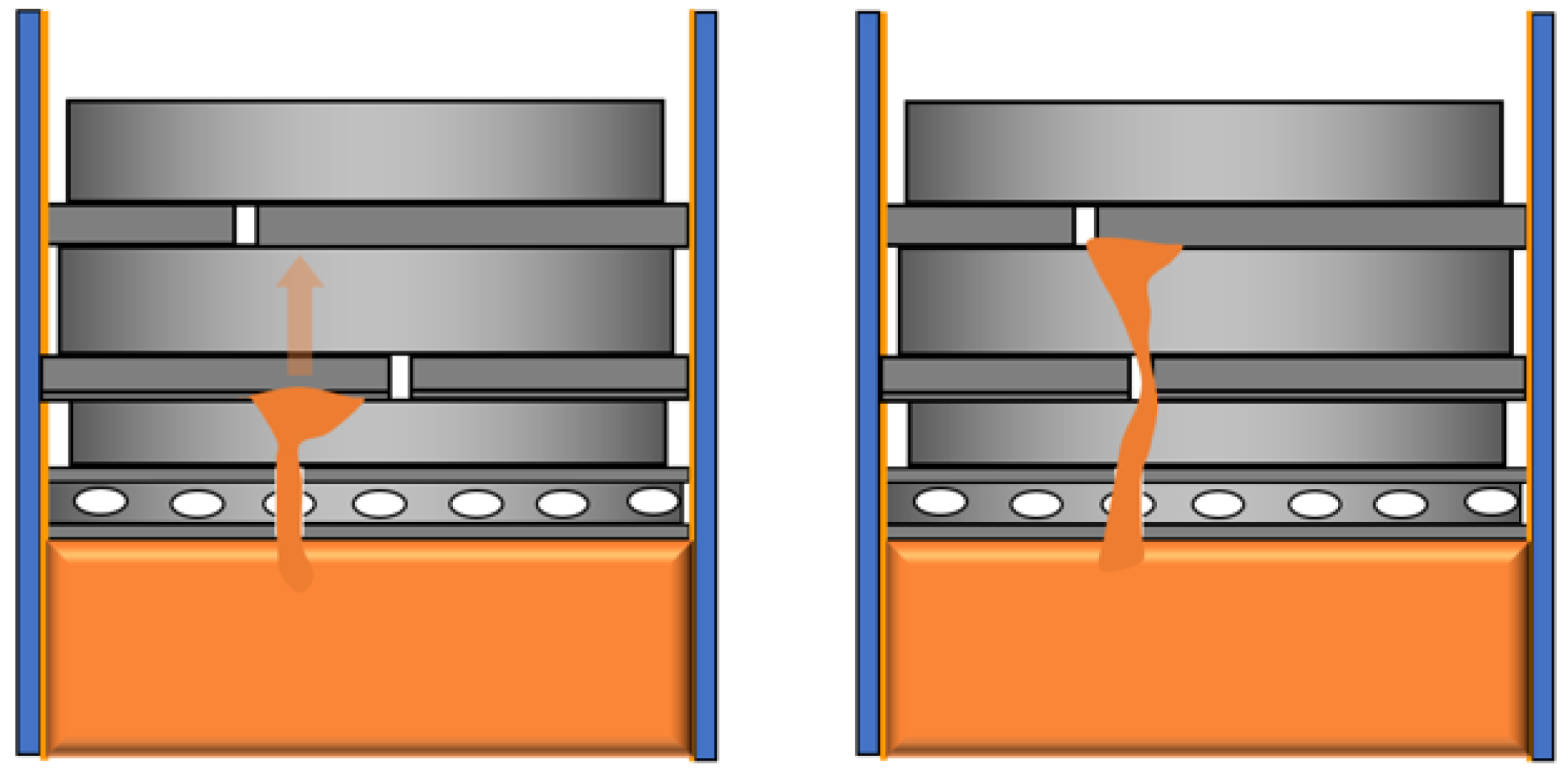

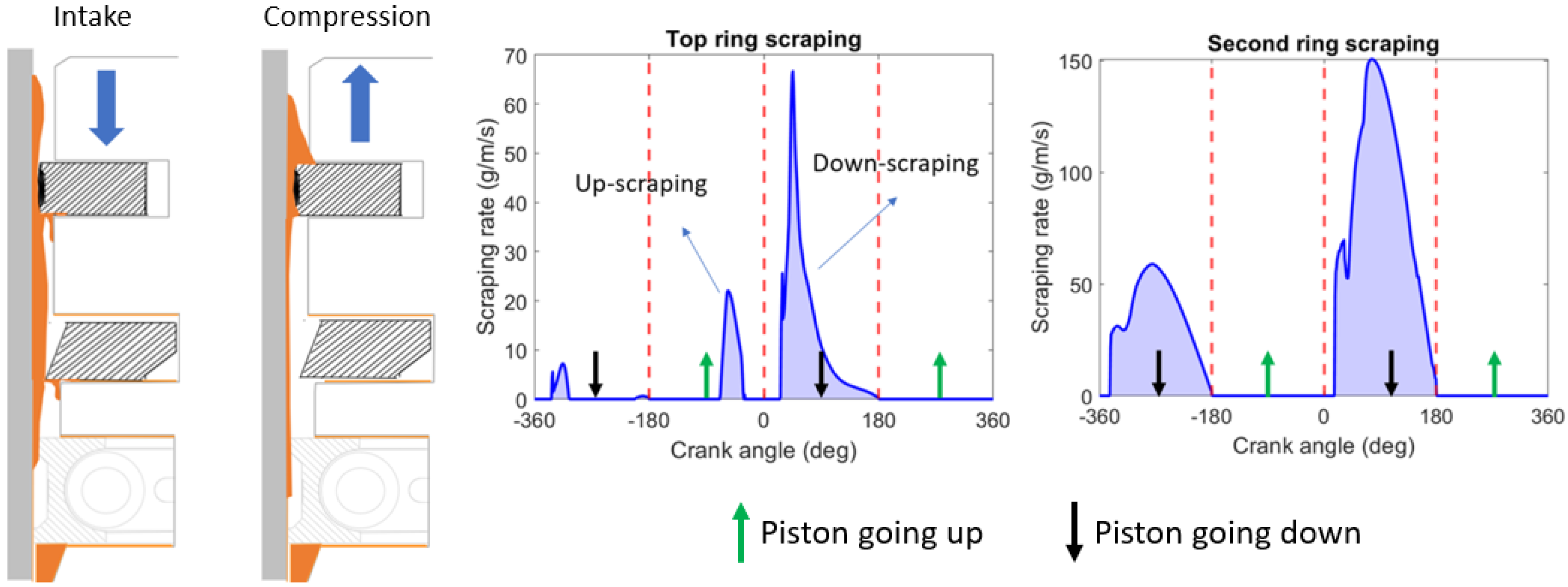

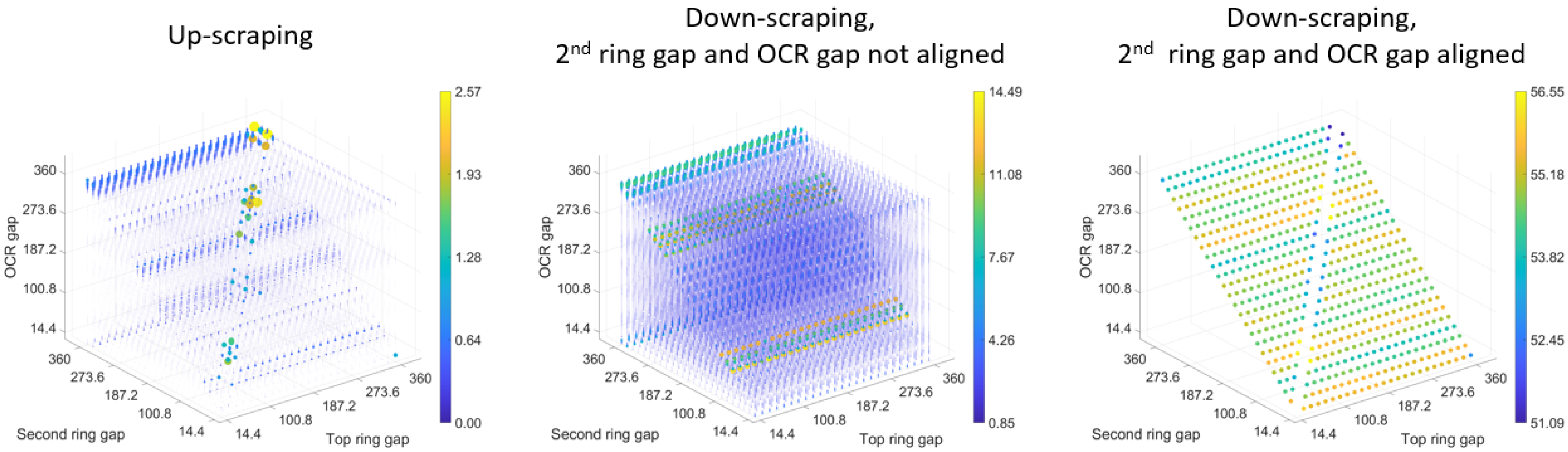

4.1. Ring Scraping Behavior

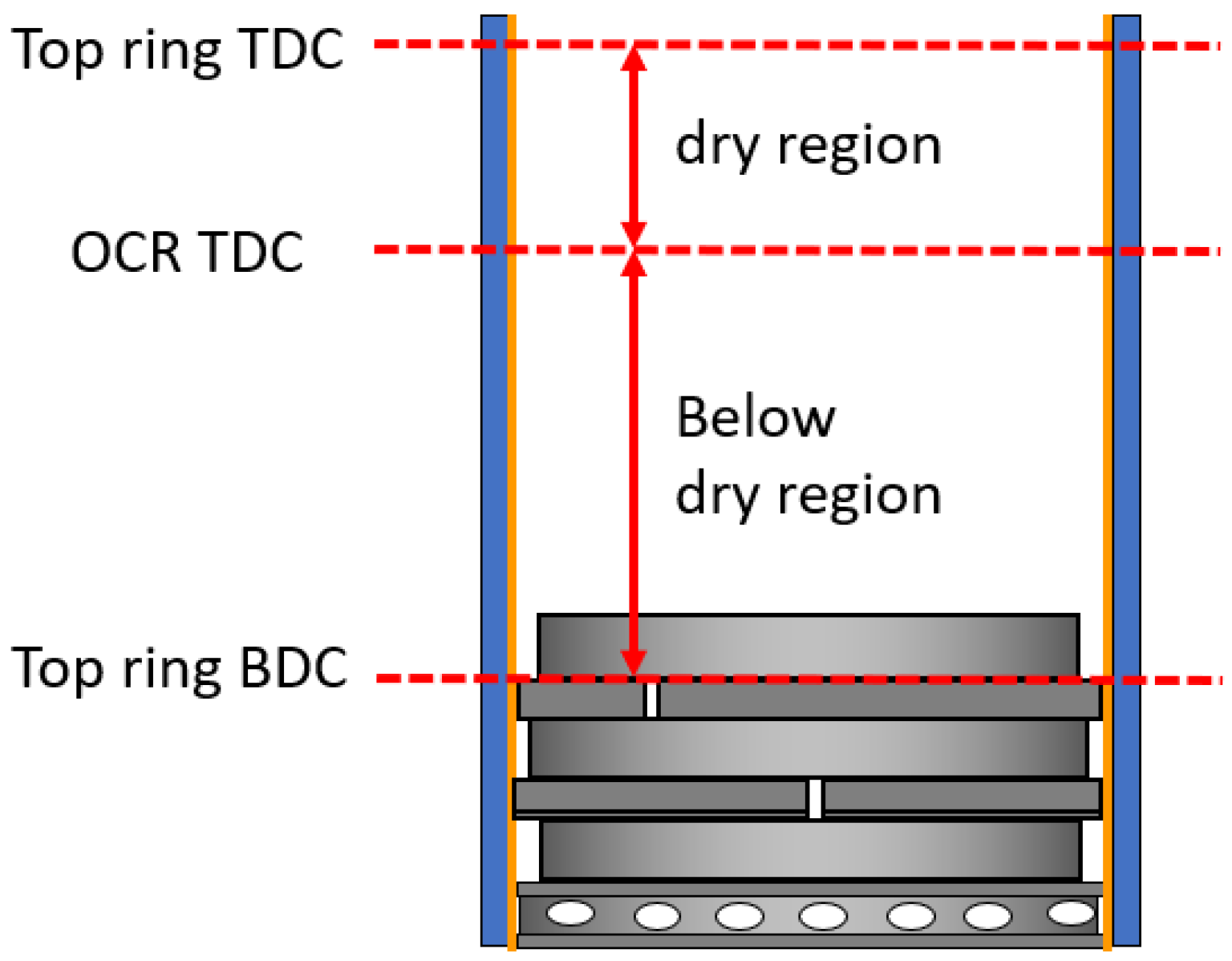

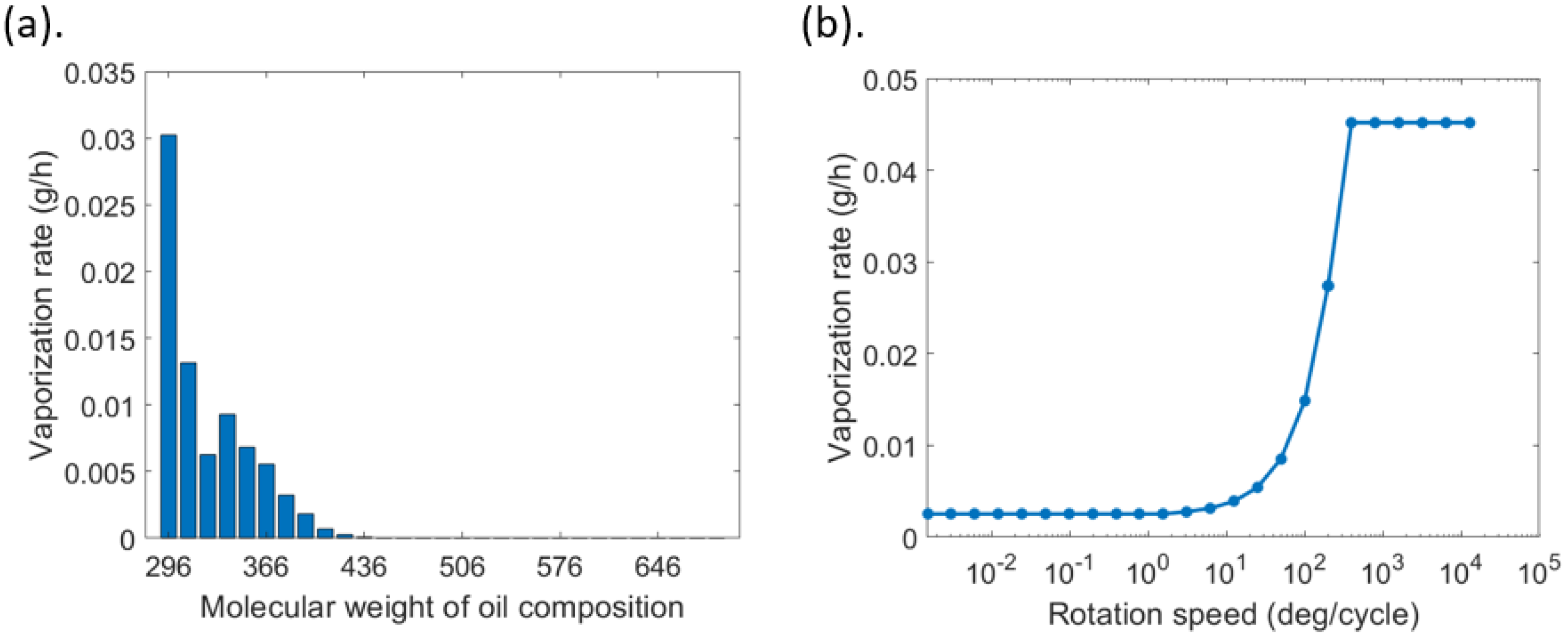

4.2. Liner Oil Vaporization

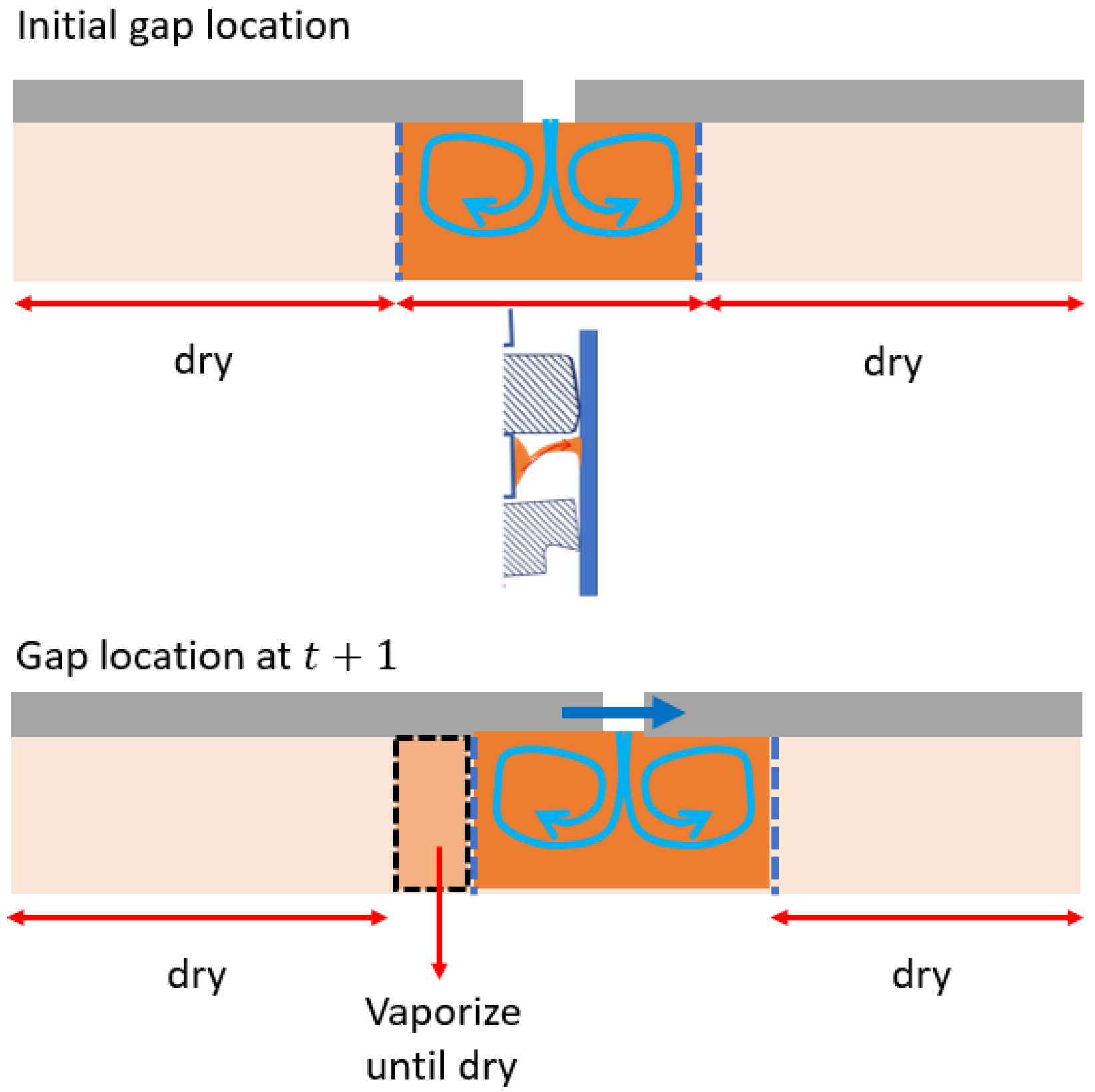

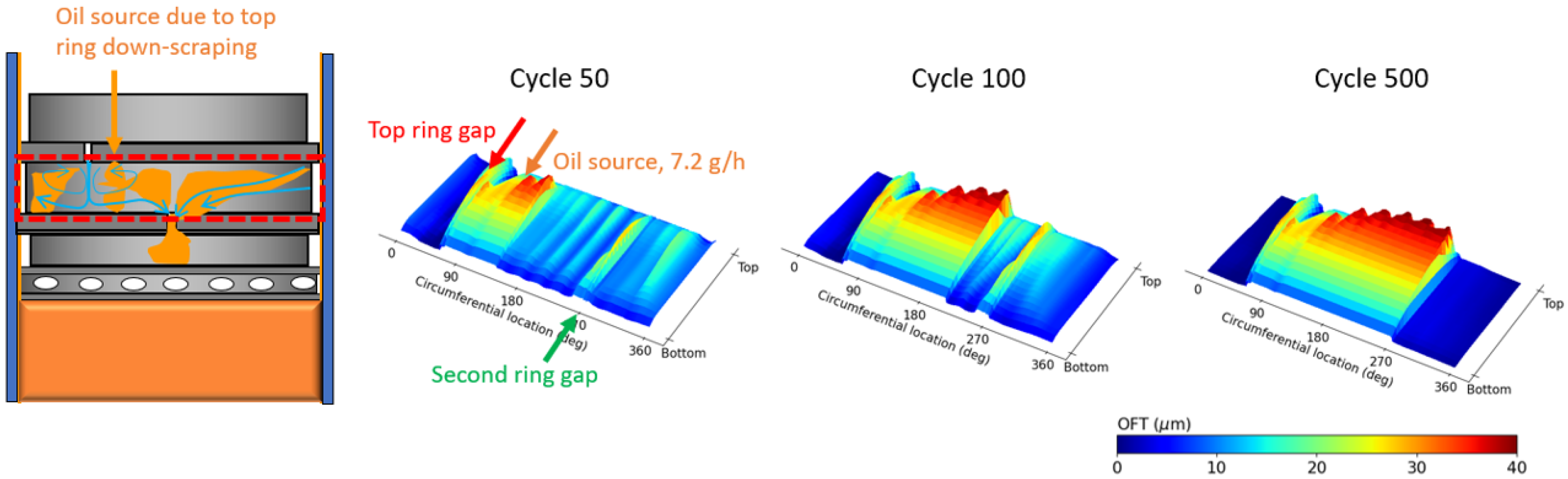

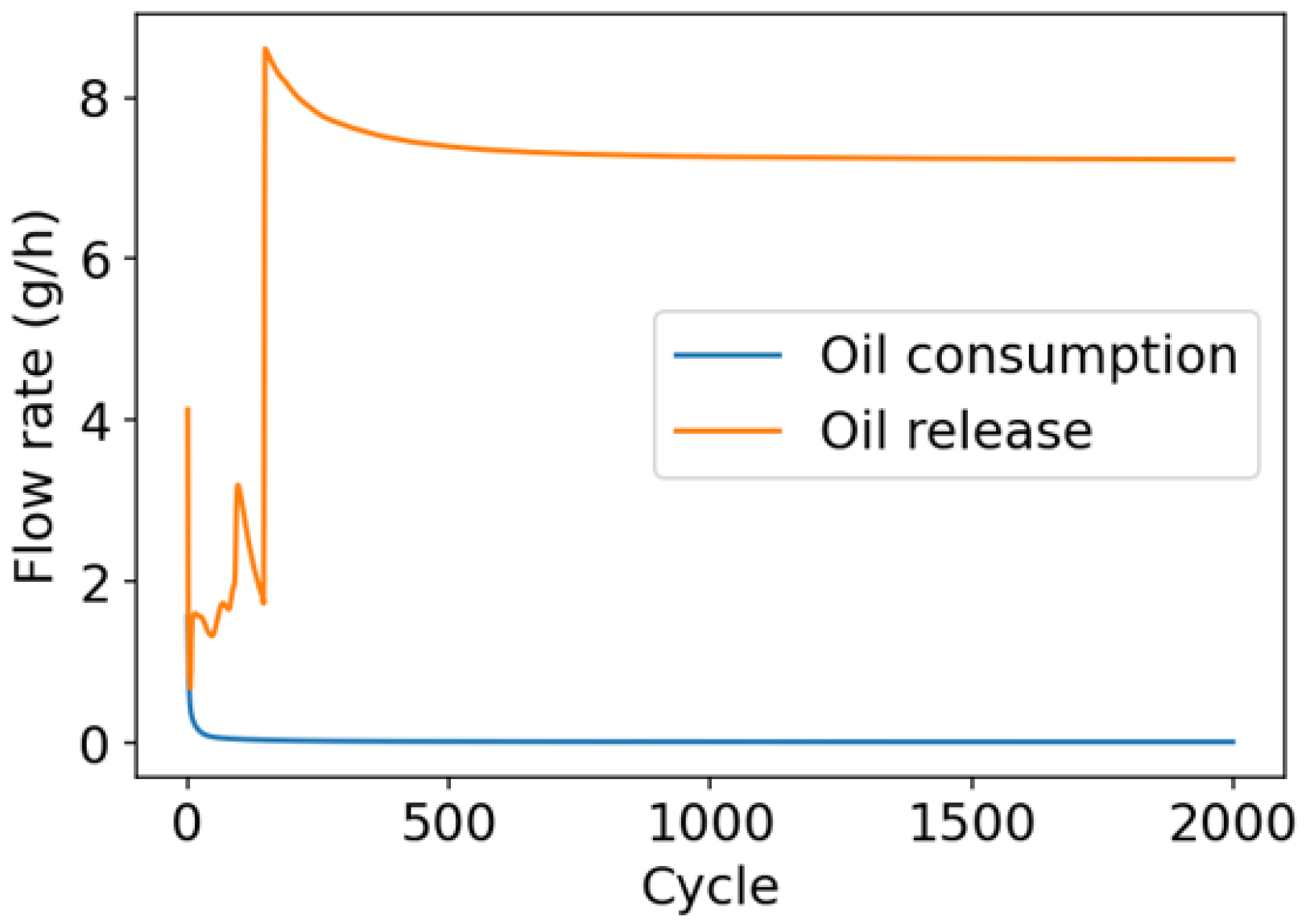

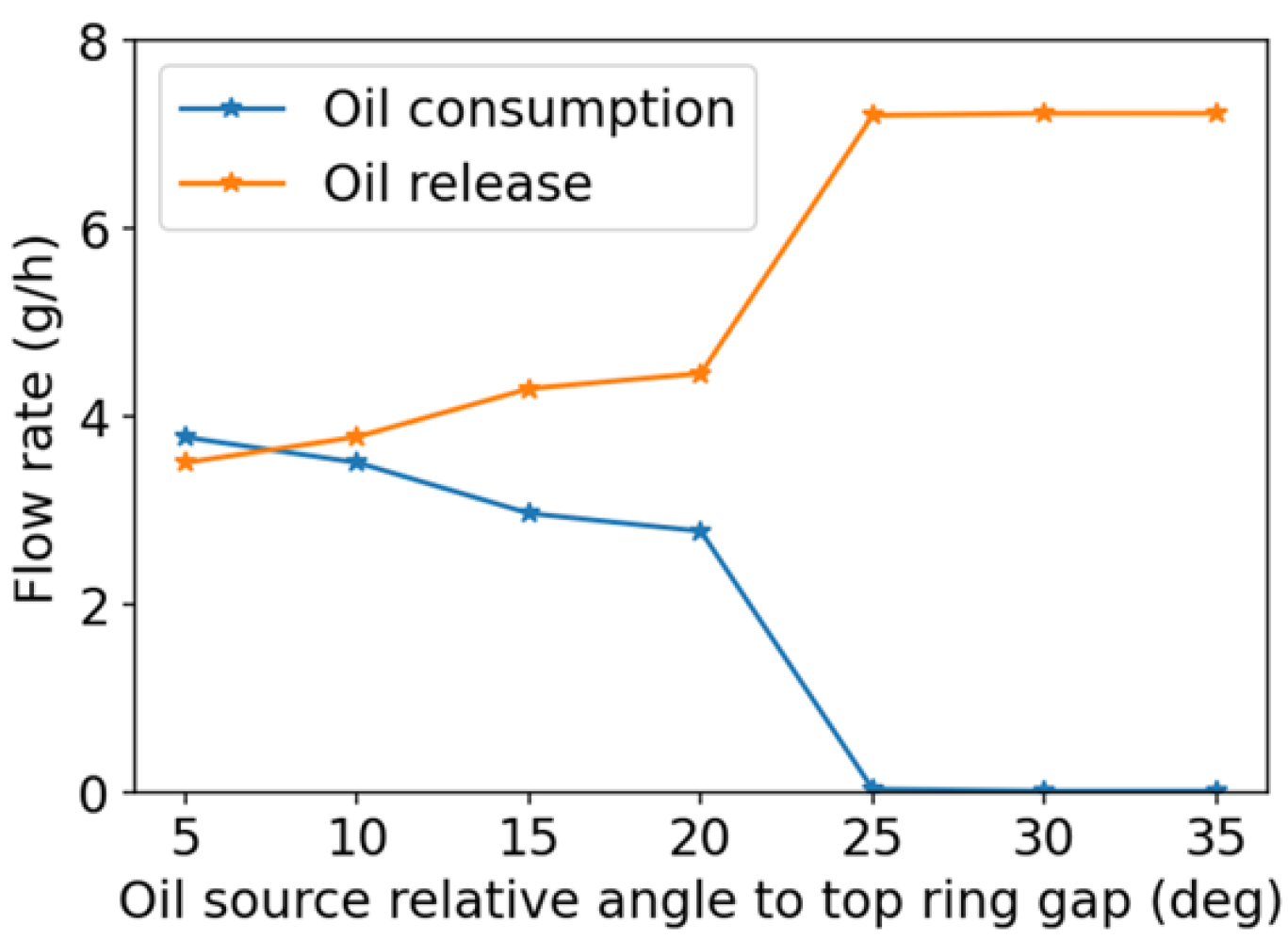

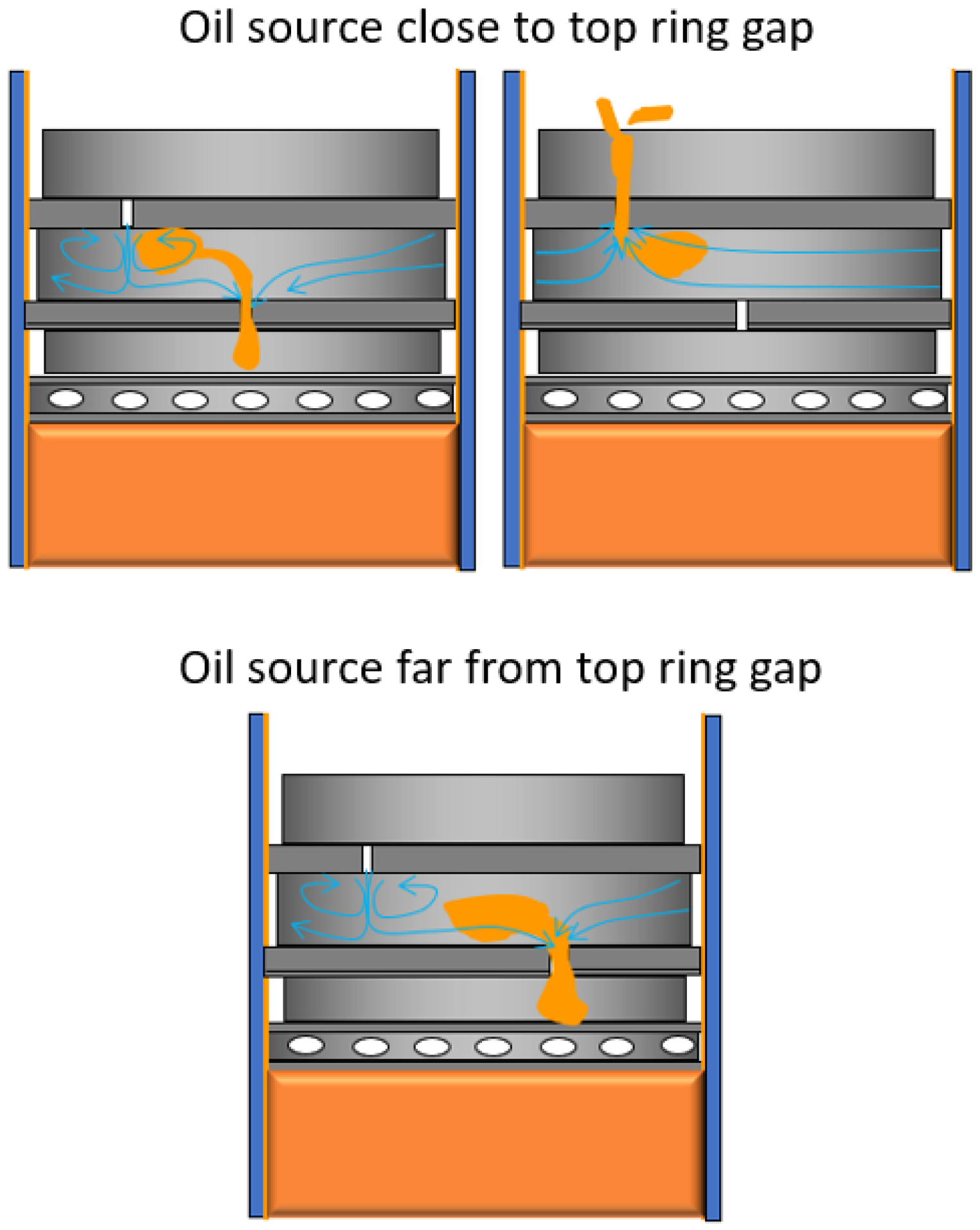

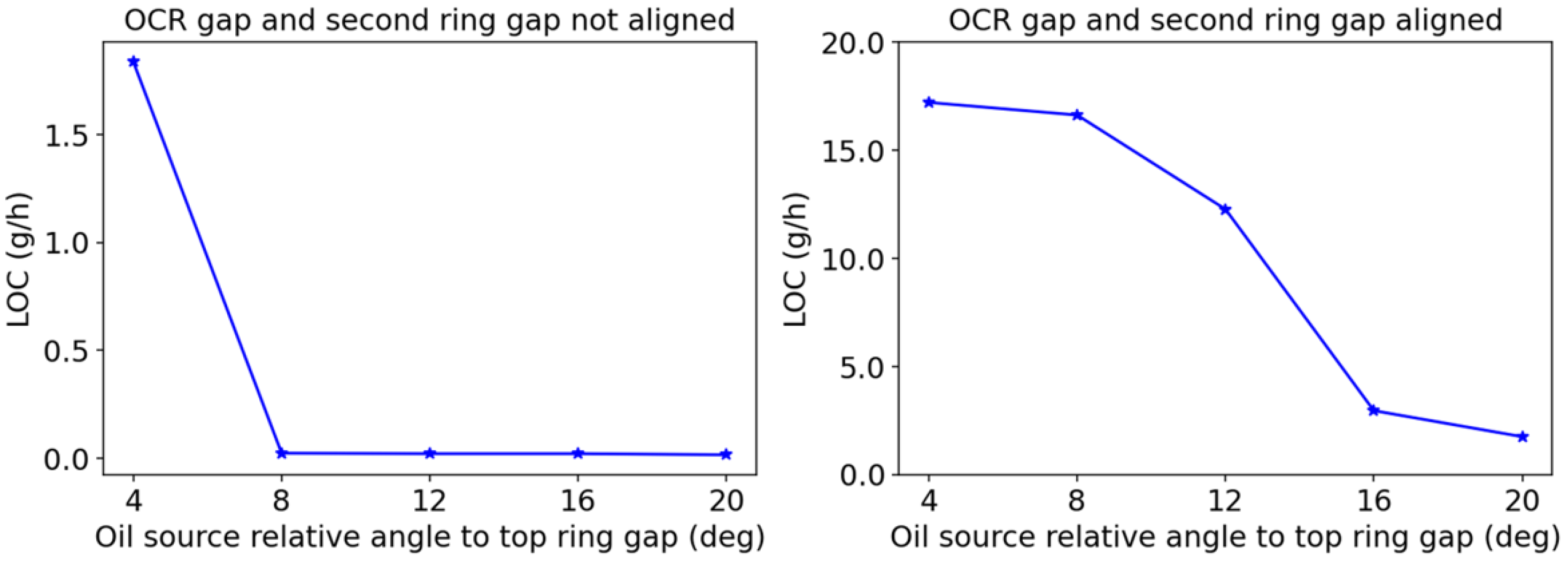

4.3. Oil Transport

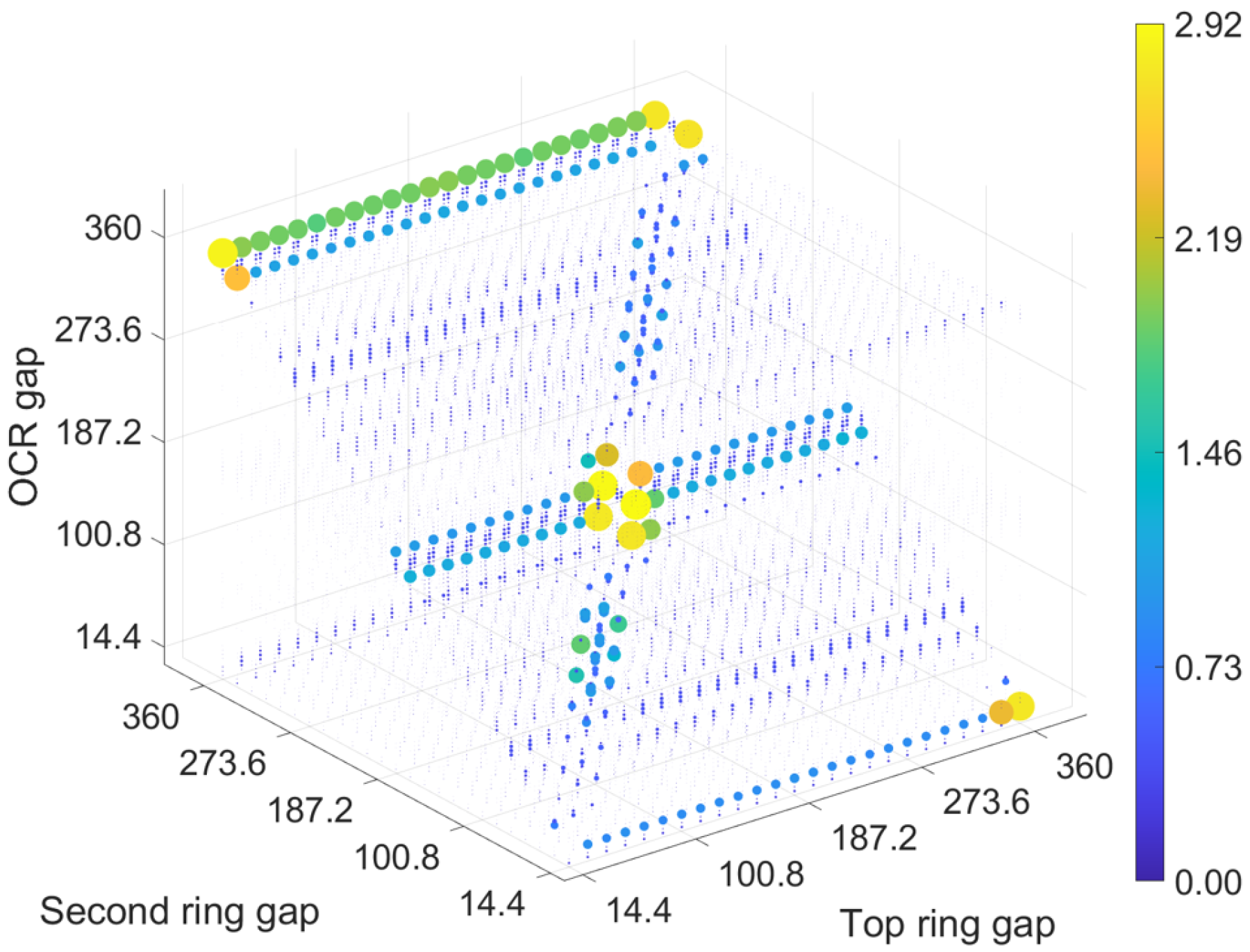

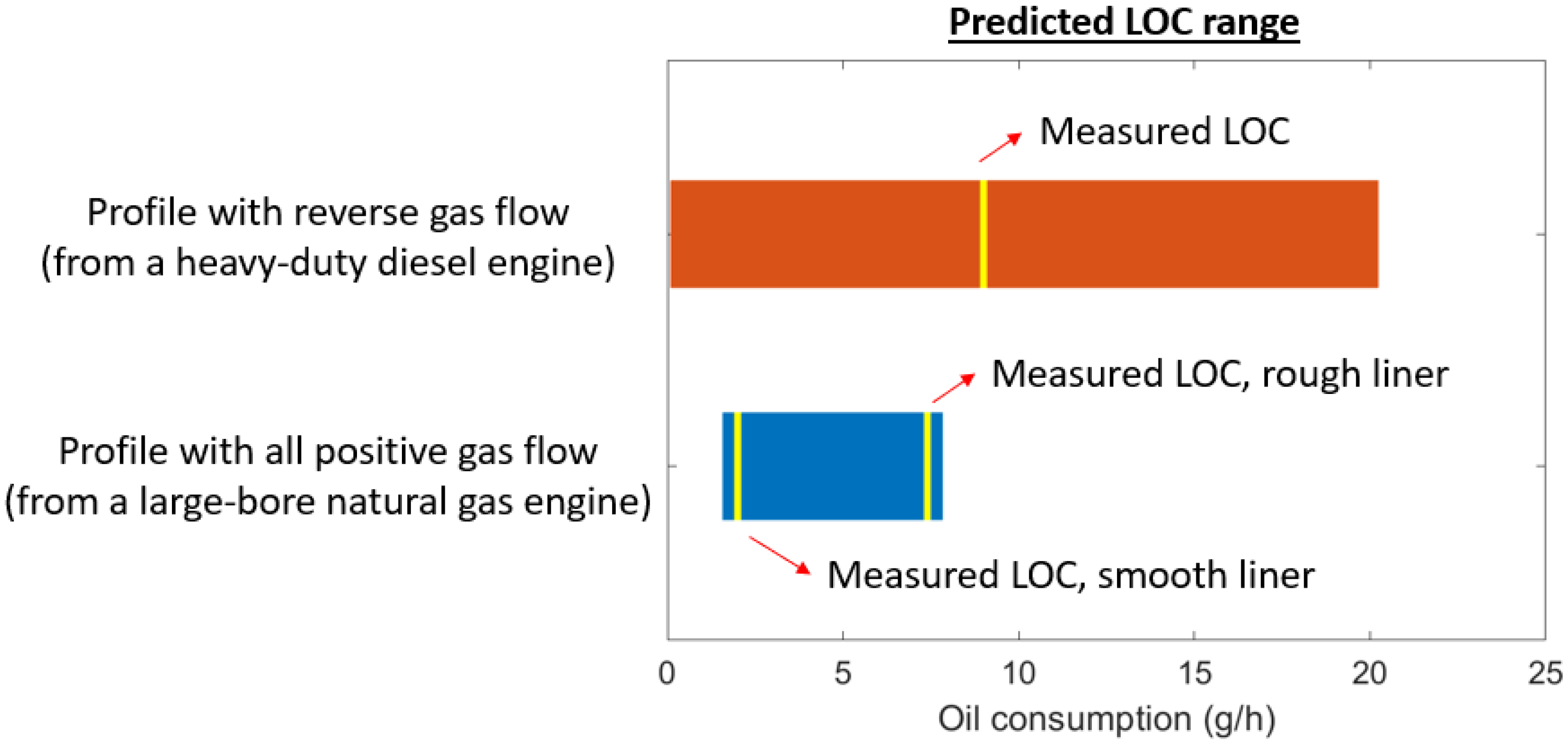

4.4. Overall LOC Prediction

- For all the possible ring gap arrangements, determine the top ring down-scraping rates using the ring–liner lubrication model with the assumption that the oil control ring gap leaves a 5 μm film thickness on the liner;

- Maintain the arrangements with a meaningful top ring down-scraping rate (>1 g/h);

- Run the oil transport model with the computed top ring down-scraping rate and the corresponding ring gap arrangement for each case to find the oil consumption rate due to reverse gas flow through the top ring gap.

5. Conclusions and Future Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| LOC | Lubrication oil consumption |

| OCR | Oil control ring |

| TDC | Top dead center |

| BDC | Bottom dead center |

| TLOCR | Twin-land oil control ring |

| TPOCR | Three-piece oil control ring |

| 2DLIF | 2D laser-induced fluorescence |

| IC | Internal combustion |

References

- Orrin, D.S.; Coles, B.W. Effects of Engine Oil Composition on Oil Consumption. SAE Trans. 1971, 80, 475–490. [Google Scholar]

- Min, B.S.; Kim, J.S.; Oh, D.Y.; Choi, J.K.; Jin, J.H. Dynamic Characteristics of Oil Consumption Relationship Between the Instantaneous Oil Consumption and the Location of Piston Ring Gap. SAE Trans. 1998, 107, 918–927. [Google Scholar]

- Rossegger, B.; Eder, M.; Vareka, M.; Engelmayer, M.; Wimmer, A. A novel method for lubrication oil consumption measurement for wholistic tribological assessments of internal combustion engines. Tribol. Int. 2021, 162, 107141. [Google Scholar] [CrossRef]

- Yilmaz, E.; Tian, T.; Wong, V.W.; Heywood, J.B. The Contribution of Different Oil Consumption Sources to Total Oil Consumption in a Spark Ignition Engine. SAE Trans. 2004, 113, 1622–1638. [Google Scholar] [CrossRef]

- Vokac, A. An Experimental Study of the Oil Evolution in Critical Piston Ring Pack Regions and the Effects of Piston and Ring Designs in an Internal Combustion Engine Utilizing Two-Dimensional Laser Induced Fluorescence and the Impact on Maritime Economics. Master’s Thesis, Massachusetts Institute of Technology, Department of Mechanical Engineering, Cambridge, MA, USA, 2004. [Google Scholar]

- Thirouard, B. Characterization and Modeling of the Fundamental Aspects of Oil Transport in the Piston Ring Pack of Internal Combustion Engines. Ph.D. Thesis, Massachusetts Institute of Technology, Department of Mechanical Engineering, Cambridge, MA, USA, 2001. [Google Scholar]

- Jay, A.; Ballard, H.; Ocerin Meñica, O.; Larralde Yoller, A.; Barcena Ortiz de Urbina, J. Using Analysis of the Ring Pack and Piston to Optimize Oil Consumption of Current and Future Engines. In Proceedings of the Energy and Propulsion Conference and Exhibition, Greenville, SC, USA, 7–9 November 2023; SAE International: Warrendale, PA, USA, 2023. [Google Scholar] [CrossRef]

- Ahling, S. Elements of Lubricant Transport Critical to Piston Skirt Lubrication and to Leakage into the Piston Ring Pack in Internal Combustion Engines. Ph.D. Thesis, Massachusetts Institute of Technology, Department of Mechanical Engineering, Cambridge, MA, USA, 2021. [Google Scholar]

- Li, M.; Zhong, X.; Ahling, S.; Tian, T. An Investigation of Oil Supply Mechanisms to the Top of the Liner in Internal Combustion Engines. SAE Int. J. Adv. Curr. Prac. Mobil. 2023, 6, 1459–1467. [Google Scholar] [CrossRef]

- Hitosugi, H.; Nagoshi, K.; Komada, M.; Furuhama, S. Study on Mechanism of Lubricating Oil Consumption Caused by Cylinder Bore Deformation. SAE Trans. 1996, 105, 147–156. [Google Scholar] [CrossRef]

- Iijima, N.; Sakurai, T.; Takiguchi, M.; Harigaya, Y.; Yamada, T.; Yoshida, H. An Experimental Study on Relationship between Lubricating Oil Consumption and Cylinder Bore Deformation in Conventional Gasoline Engine. SAE Int. J. Engines 2009, 2, 106–113. [Google Scholar] [CrossRef]

- Schneider, E.W.; Blossfeld, D.H.; Lechman, D.C.; Hill, R.F.; Reising, R.F.; Brevick, J.E. Effect of Cylinder Bore Out-of-Roundness on Piston Ring Rotation and Engine Oil Consumption. SAE Trans. 1993, 102, 1048–1069. [Google Scholar] [CrossRef]

- Tian, T. Modeling the Performance of the Piston Ring-Pack in Internal Combustion Engines. Ph.D. Thesis, Massachusetts Institute of Technology, Department of Mechanical Engineering, Cambridge, MA, USA, 1997. [Google Scholar]

- Liu, Y. A Multi-scale Model Integrating Both Global Ring Pack Behavior and Local Oil Transport in Internal Combustion Engines. Ph.D. Thesis, Massachusetts Institute of Technology, Department of Mechanical Engineering, Cambridge, MA, USA, 2017. [Google Scholar]

- Zhong, X.; Li, M.; Tian, T. Hybrid digital twin for conditional lubricant oil transport simulation and oil consumption prediction in internal combustion engines. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2023, 237, 1408–1429. [Google Scholar] [CrossRef]

- Oliva, A.; Held, S. Numerical multiphase simulation and validation of the flow in the piston ring pack of an internal combustion engine. Tribol. Int. 2016, 101, 98–109. [Google Scholar] [CrossRef]

- Chowdhury, S.S.; Kharazmi, A.; Atis, C.; Schock, H. Three-Dimensional Multi-phase Physics-Based Modeling Methodology to Study Engine Cylinder-kit Assembly Tribology and Design Considerations- Part I. SAE Int. J. Adv. Curr. Pract. Mobil. 2020, 3, 561–582. [Google Scholar] [CrossRef]

- Chowdhury, S.S.; Schock, H.; Kharazmi, A. The Effect of Ring-Groove Geometry on Engine Cylinder-Kit Assembly Using Three-Dimensional Multiphase Physics-Based Modeling Methodology-Part II; SAE International Technical Paper; SAE International: Warrendale, PA, USA, 2021. [Google Scholar] [CrossRef]

- McGrogan, S. Modeling and Simulation of Oil Transport for Studying Piston Deposit Formation in IC Engines. Master’s Thesis, Massachusetts Institute of Technology, Department of Mechanical Engineering, Cambridge, MA, USA, 2007. [Google Scholar]

- Fang, T. Fluid Mechanics of Lubricant Transport in Non-Contact Regions in the Piston Ring Pack in Internal Combustion Engines. Ph.D. Thesis, Massachusetts Institute of Technology, Department of Mechanical Engineering, Cambridge, MA, USA, 2019. [Google Scholar]

- Zhong, X. Physics-Based and Machine Learning Hybrid Modeling of Oil Transport and Oil Consumption in Internal Combustion Engines—A Digital Twin. Ph.D. Thesis, Massachusetts Institute of Technology, Department of Mechanical Engineering and Center for Computational Science and Engineering, Cambridge, MA, USA, 2025. [Google Scholar]

- Tian, T.; Ahling, S.; Liu, Y.; Zhang, W. Developing Healthy Piston Ring Pack Systems—Oil Control and Its Limit. In Proceedings of the Second World Internal Combustion Engine Conference, Jinan, China, 21–24 April 2021. [Google Scholar]

- Bhouri, M.A. Curved Beam Based Model for Piston-Ring Designs in Internal Combustion Engines. Master’s Thesis, Massachusetts Institute of Technology, Department of Mechanical Engineering, Cambridge, MA, USA, 2017. [Google Scholar]

- Li, M.; Tian, T. Sources and Destinations of Oil Leakage through TPOCR Based on 2D-LIF Observation and Modeling Analysis. Lubricants 2023, 11, 522. [Google Scholar] [CrossRef]

- Koeser, P. Novel Findings on Lube Oil Ignition and Piston Cylinder Unit for Future Fuel-Efficient Industrial Gas Engines. Ph.D. Thesis, Leibniz University Hannover, Institute for Technical Combustion, Hannover, Germany, 2021. [Google Scholar]

- Biboulet, N.; Lubrecht, A. Geometric Starvation of a One-Dimensional Parabolic Profile. Tribol. Lett. 2016, 61, 3. [Google Scholar] [CrossRef]

- Wang, Z.; Bovik, A.; Sheikh, H.; Simoncelli, E. Image quality assessment: From error visibility to structural similarity. IEEE Trans. Image Process. 2004, 13, 600–612. [Google Scholar] [CrossRef] [PubMed]

- Senzer, E. Oil Transport Inside the Oil Control Ring Groove and Its Interaction with Surrounding Areas in Internal Combustion Engines. Ph.D. Thesis, Massachusetts Institute of Technology, Department of Mechanical Engineering, Cambridge, MA, USA, 2012. [Google Scholar]

- Liu, L.; Tian, T.; Yilmaz, E. Modeling Oil Evaporation From the Engine Cylinder Liner With Consideration of the Transport of Oil Species Along the Liner. In Proceedings of the World Tribology Congress III, Washington, DC, USA, 12–16 September 2005; Volume 2, pp. 579–580. [Google Scholar] [CrossRef]

- Zhang, Q. Fast Modeling of Multi-Phase Mixture Transport in Piston/Ring/Liner System via GAN-Augmented Progressive Modeling. Ph.D. Thesis, Massachusetts Institute of Technology, Department of Mechanical Engineering, Cambridge, MA, USA, 2020. [Google Scholar]

- Woschni, G. A Universally Applicable Equation for the Instantaneous Heat Transfer Coefficient in the Internal Combustion Engine. SAE Trans. 1968, 76, 3065–3083. [Google Scholar] [CrossRef]

- Chilton, T.H.; Colburn, A.P. Mass Transfer (Absorption) Coefficients Prediction from Data on Heat Transfer and Fluid Friction. Ind. Eng. Chem. 1934, 26, 1183–1187. [Google Scholar] [CrossRef]

- Wilke, C.R.; Chang, P. Correlation of diffusion coefficients in dilute solutions. AIChE J. 1955, 1, 264–270. [Google Scholar] [CrossRef]

- Kudchadker, A.P.; Zwolinski, B.J. Vapor Pressure and Boiling Points of Normal Alkanes, C21 to C100. J. Chem. Eng. Data 1966, 11, 253–255. [Google Scholar] [CrossRef]

| Source | Range (g/h) | Range (g/kWh) |

|---|---|---|

| Top ring up-scraping | [0, 2.57] | [0, 0.02] |

| Liner vaporization | [1.57, 5.27] | [0.012, 0.04] |

| Reverse gas flow | N/A | N/A |

| Source | Range (g/h) | Range (g/kWh) |

|---|---|---|

| Top ring up-scraping | [0, 2.92] | [0, 0.04] |

| Liner vaporization | [0.085, 0.125] | [0.0013, 0.002] |

| Reverse gas flow | [0, 17.2] | [0, 0.26] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhong, X.; Tian, T. Oil Transport Simulation and Oil Consumption Prediction with a Physics-Based and Data-Driven Digital Twin Model for Internal Combustion Engines. Lubricants 2025, 13, 463. https://doi.org/10.3390/lubricants13100463

Zhong X, Tian T. Oil Transport Simulation and Oil Consumption Prediction with a Physics-Based and Data-Driven Digital Twin Model for Internal Combustion Engines. Lubricants. 2025; 13(10):463. https://doi.org/10.3390/lubricants13100463

Chicago/Turabian StyleZhong, Xinlin, and Tian Tian. 2025. "Oil Transport Simulation and Oil Consumption Prediction with a Physics-Based and Data-Driven Digital Twin Model for Internal Combustion Engines" Lubricants 13, no. 10: 463. https://doi.org/10.3390/lubricants13100463

APA StyleZhong, X., & Tian, T. (2025). Oil Transport Simulation and Oil Consumption Prediction with a Physics-Based and Data-Driven Digital Twin Model for Internal Combustion Engines. Lubricants, 13(10), 463. https://doi.org/10.3390/lubricants13100463