On the Film Stiffness Characteristics of Water-Lubricated Rubber Bearings in Deep-Sea Environments

Abstract

1. Introduction

2. Mathematical Model

2.1. Visco-Hyperelastic Contact Model

2.1.1. Fractional-Order Derivative Visco-Hyperelastic Model

2.1.2. Visco-Hyperelastic Contact Pressure

2.1.3. Visco-Hyperelastic Contact Load

2.2. Lubrication Model

2.3. Film Thickness Equation

2.4. Solution of Stiffness and Damping Coefficients of Water Film

2.5. Numerical Algorithm

3. Results and Discussion

3.1. Model Verification

3.1.1. Grid Independence Verification

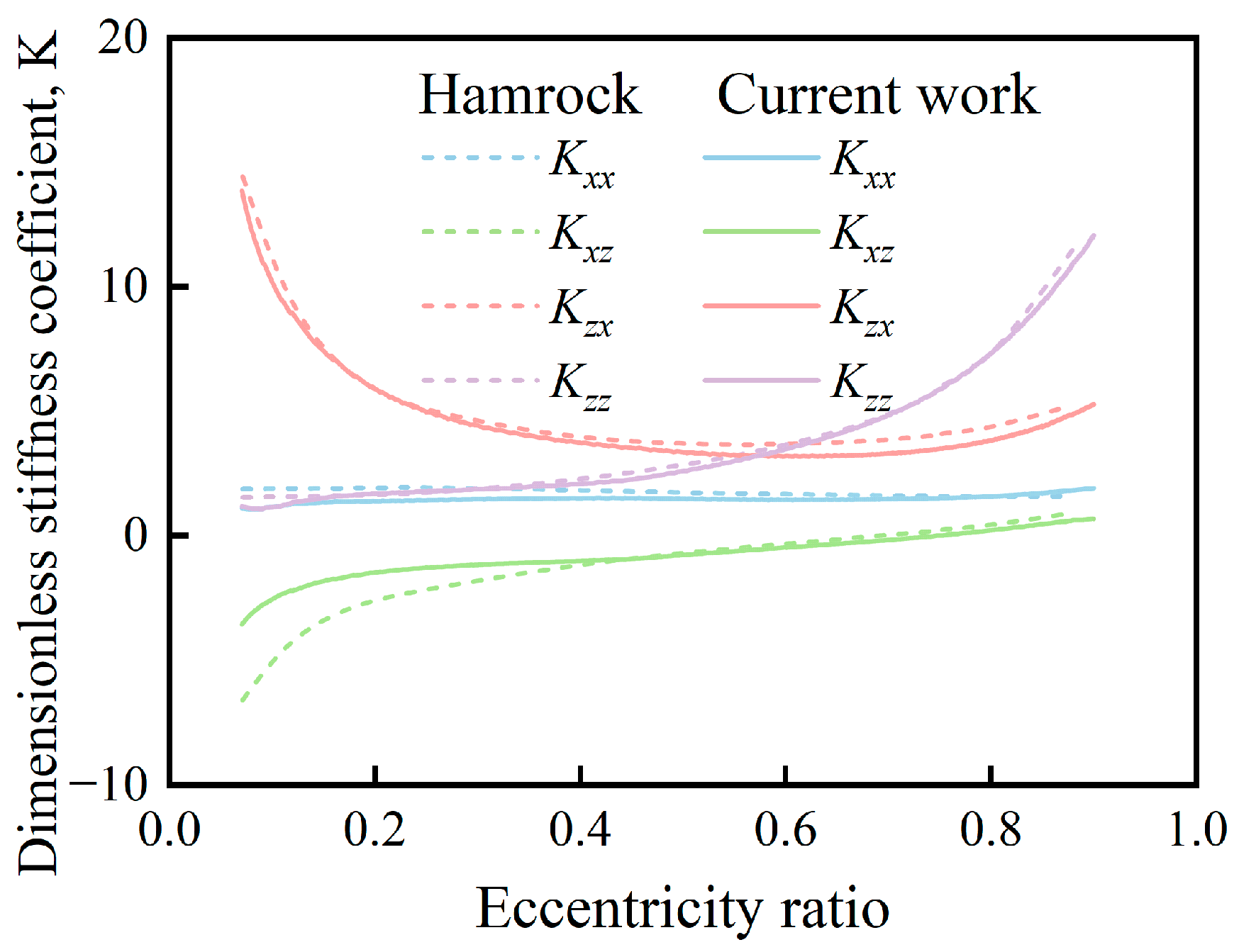

3.1.2. Verification of Water-Film Stiffness Coefficient

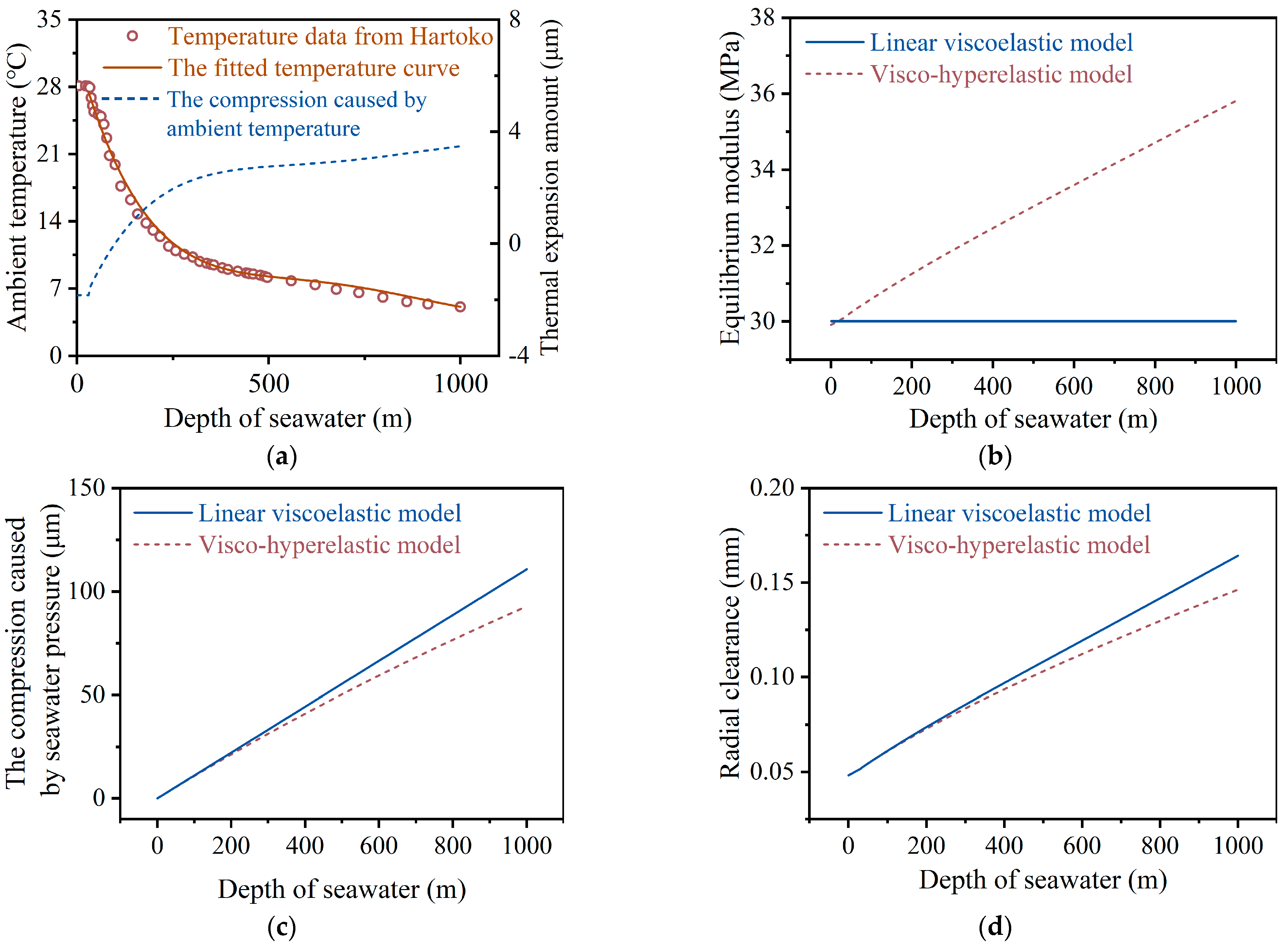

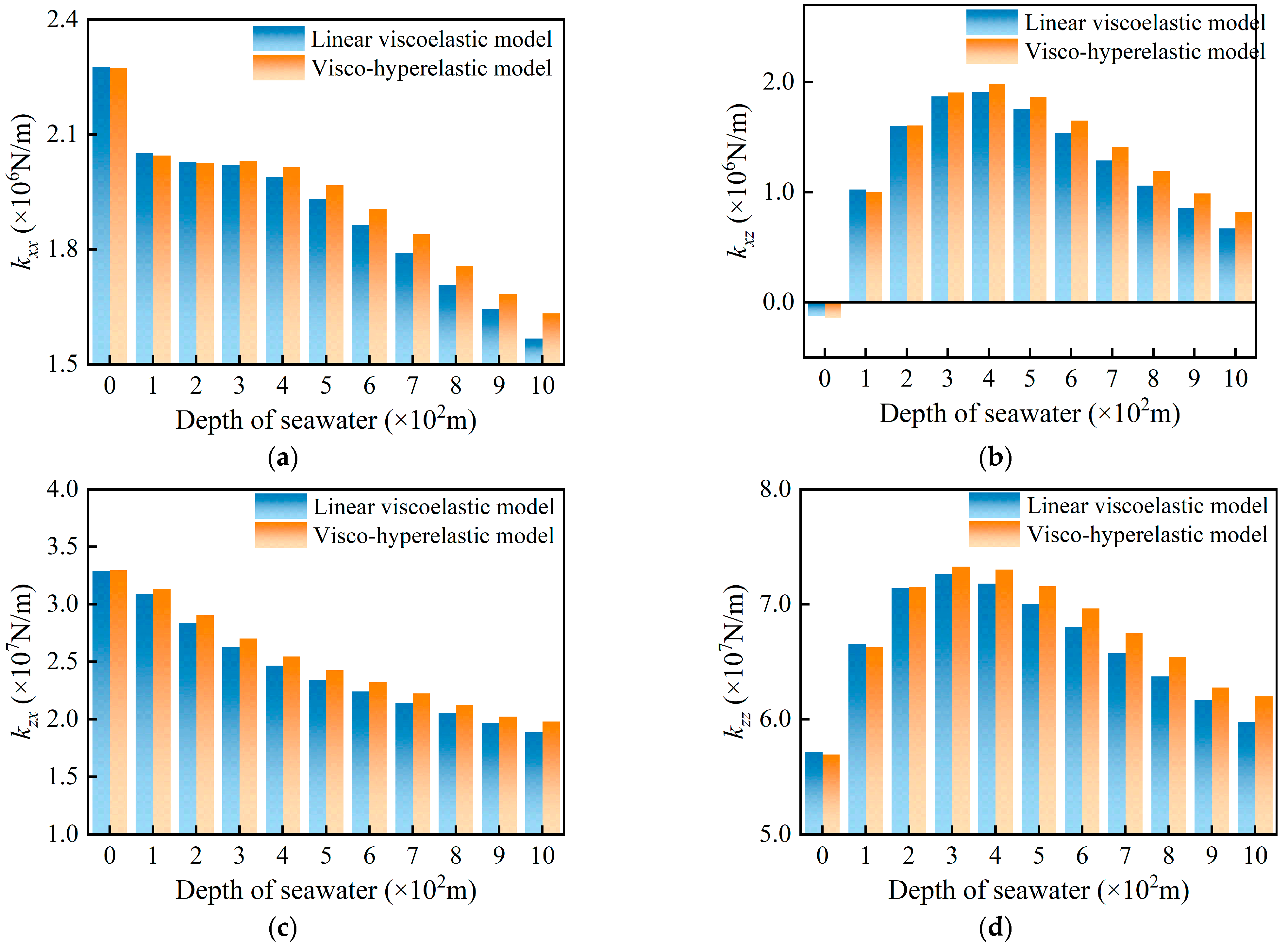

3.2. Comparative Analysis of Linear Viscoelastic and Visco-Hyperelastic Constitutive Models

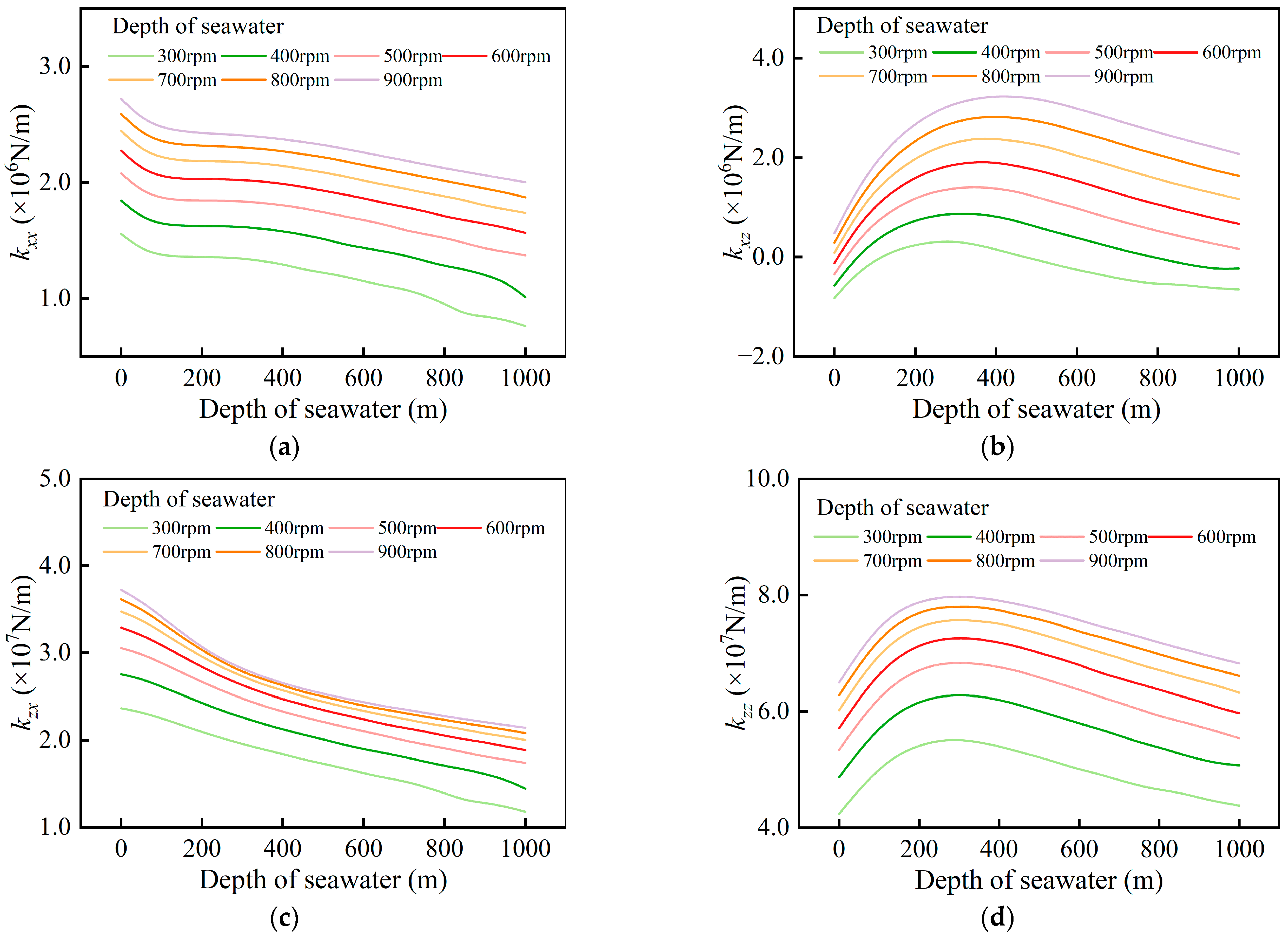

3.3. Effect of Rotational Speed on the Stiffness of Water Film

4. Conclusions

- (1)

- The water-film stiffness coefficients obtained from the linear viscoelastic and visco-hyperelastic models exhibit significant discrepancies, with the divergence increasing progressively with seawater depth. At a depth of 1000 m, the relative error in kxz between the two models reaches as high as 18.41%, underscoring the importance of accounting for visco-hyperelastic behavior in accurately predicting the dynamic characteristics of the water film in deep-sea applications.

- (2)

- Seawater depth has a pronounced effect on the water-film stiffness coefficient of water-lubricated rubber bearings. kxx and kzx decrease gradually with increasing depth, while kxz and kzz first increase and then decrease as depth increases. Therefore, the influence of depth should be considered when analyzing the water-film stiffness coefficient.

- (3)

- Increasing rotational speed strengthens the hydrodynamic effect and enhances the water-film stiffness coefficient. However, the influence of the rotational speed on the water-film stiffness coefficient is more significant at lower speeds and weaker at higher speeds.

- (4)

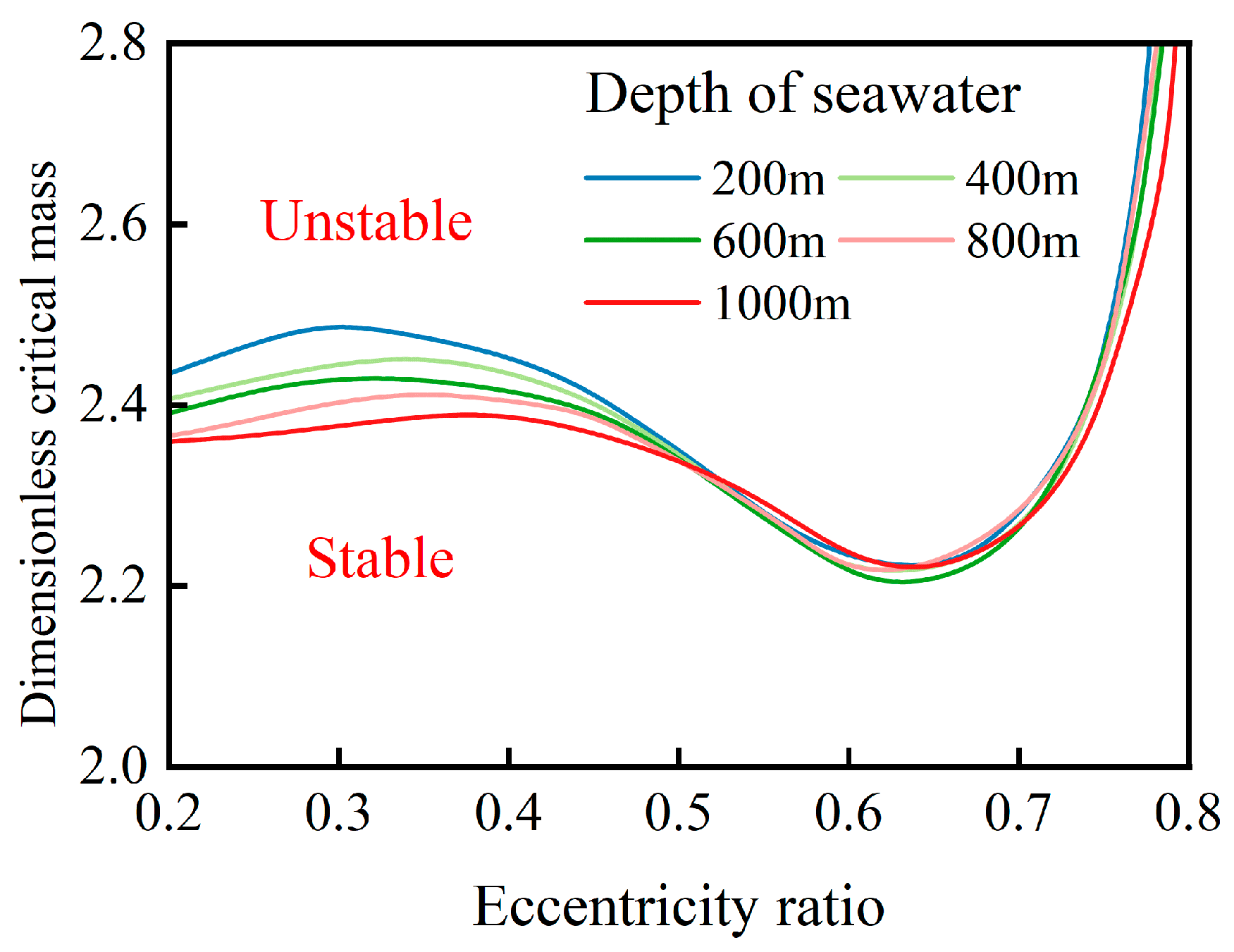

- Increasing seawater depth reduces the critical mass of water-lubricated rubber bearings at low eccentricity ratios, thereby degrading bearing stability.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, Z.; Liu, K.; Chen, X.; Ma, Z.; Lv, R.; Wei, C.; Ma, K. Deep-sea rock mechanics and mining technology: State of the art and perspectives. Int. J. Min. Sci. Technol. 2023, 33, 1083–1115. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, X.; Luan, L.; Sha, F.; Liu, X. Technology and equipment of deep-sea mining: State of the art and perspectives. Earth Energy Sci. 2025, 1, 65–84. [Google Scholar] [CrossRef]

- Zhou, G.W.; Wu, K.P.; Pu, W.; Li, P.; Han, Y.F. Tribological modification of hydrogenated nitrile rubber nanocomposites for water-lubricated bearing of ship stern shaft. Wear 2022, 504–505, 204432. [Google Scholar] [CrossRef]

- Litwin, W. Water-lubricated bearings of ship propeller shafts—Problems, experimental tests and theoretical investigations. Pol. Marit. Res. 2009, 16, 41–49. [Google Scholar] [CrossRef]

- Geng, T.; Meng, Q.; Wang, N.; Yuan, X.; Jia, Q. Experimental investigation of film pressure distribution in water-lubricated rubber journal bearings. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2013, 228, 397–406. [Google Scholar] [CrossRef]

- Litwin, W. Influence of main design parameters of ship propeller shaft water-lubricated bearings on their properties. Pol. Marit. Res. 2010, 4, 39–45. [Google Scholar] [CrossRef]

- Lun, W.; Zhou, X.C.; Zhu, H.H.; Huang, Q.P.; Zhou, Z.J.; Xing, S.P.; Liu, X.S. Fluid–Structure Interaction Mechanisms of Layered Thickness Effects on Lubrication Performance and Energy Dissipation in Water-Lubricated Bearings. Lubricants 2025, 13, 445. [Google Scholar] [CrossRef]

- Gong, J.; Jin, Y.; Liu, Z.; Jiang, H.; Xiao, M. Study on influencing factors of lubrication performance of water-lubricated micro-groove bearing. Tribol. Int. 2019, 129, 390–397. [Google Scholar] [CrossRef]

- Sander, D.E.; Allmaier, H.; Priebsch, H.H.; Witt, M.; Skiadas, A. Simulation of journal bearing friction in severe mixed lubrication—Validation and effect of surface smoothing due to running-in. Tribol. Int. 2016, 96, 173–183. [Google Scholar] [CrossRef]

- Deng, X.; Gates, H.; Fittro, R.; Wood, H. Methodology of Turbulence Parameter Correction in Water-Lubricated Thrust Bearings. J. Fluids Eng. 2019, 141, 071104. [Google Scholar] [CrossRef]

- Deng, X. Study of Temperature Drop Region in Transitional Region in Fluid-Film Thrust Bearings. J. Fluids Eng. 2024, 146, 121201. [Google Scholar] [CrossRef]

- Deng, X. A Mixed Zero-Equation and One-Equation Turbulence Model in Fluid-Film Thrust Bearings. J. Tribol. 2023, 146, 034101. [Google Scholar] [CrossRef]

- Lv, F.R.; Zhang, X.J.; Ji, C.C.; Rao, Z.S. Theoretical and experimental investigation on local turbulence effect on mixed-lubrication journal bearing during speeding up. Phys. Fluids 2022, 34, 113104. [Google Scholar] [CrossRef]

- Lv, F.R.; Shangguan, Y.; Zou, D.; Ji, A. Transient mixed-lubrication analysis of low-viscosity lubricated bearings under impact load with consideration of turbulence. Phys. Fluids 2022, 34, 033108. [Google Scholar] [CrossRef]

- Ouyang, W.; Zhang, Z.; Nie, Y.; Liu, B.; Vanierschot, M. Parametric modeling and collaborative optimization of a rim-driven thruster considering propeller-duct interactions. Ocean. Eng. 2025, 337, 121746. [Google Scholar] [CrossRef]

- Ouyang, W.; Liu, Q.; Li, J.; Jin, Y.; Dong, X. Semi-active control for transverse vibration of ship propulsion shafting with magnetorheological squeeze film damper. Mech. Syst. Signal Process. 2025, 233, 112763. [Google Scholar] [CrossRef]

- Xie, Z.; Zhang, Y.; Zhou, J.; Zhu, W. Theoretical and experimental research on the micro interface lubrication regime of water lubricated bearing. Mech. Syst. Signal Process. 2021, 151, 107422. [Google Scholar] [CrossRef]

- Xie, Z.; Liu, H. Experimental research on the interface lubrication regimes transition of water lubricated bearing. Mech. Syst. Signal Process. 2020, 136, 106522. [Google Scholar] [CrossRef]

- Han, Y.F.; Tang, T.; Xiang, G.; Jia, H. A Fluid–Solid–Heat Coupling Analysis for Water-Lubricated Rubber Stern Bearing Considering the Deflection of Propeller Shaft. Appl. Sci. 2021, 11, 1170. [Google Scholar] [CrossRef]

- Song, Y.; Xiao, K.; Xiang, G. Entropy-based fluid–solid–thermal coupled wear prediction of journal bearing during repeated starting and stopping. Wear 2024, 536–537, 205157. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhang, R. Theoretical and experimental analysis of a water-lubricated rubber journal bearing with a large aspect ratio. Ind. Lubr. Tribol. 2019, 72, 797–803. [Google Scholar] [CrossRef]

- Wu, C.; Wang, Y.; Chen, F.; Long, X. A mixed-lubricated friction model of water lubricated bearing based on fractal theory. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2023, 237, 1913–1929. [Google Scholar] [CrossRef]

- Ouyang, W.; Liu, Q.; Liang, X.; Zhang, X.; Wang, W. Data-Driven Model of the Distribution Lubrication on Water-Lubricated Bearing Under Severe Operating Conditions. J. Tribol. 2023, 237, 1913–1929. [Google Scholar] [CrossRef]

- Shen, Y.; Zhang, Y.; Zhang, X.; Zheng, H.; Wei, G.W.; Wang, M. A Fluid-Structure Interaction Method for the Elastohydrodynamic Lubrication Characteristics of Rubber-Plastic Double-Layer Water-Lubricated Journal Bearings. Lubricants 2023, 11, 240. [Google Scholar] [CrossRef]

- Kuang, F.; Mu, H.; Huang, J.; Wan, G.; Yuan, C.; Zhou, X. Theoretical and In Situ High Speed Measurement Study on Friction-Induced Vibration in Water Lubricated Rubber Bearing-Shaft System. Tribol. Trans. 2024, 67, 47–61. [Google Scholar] [CrossRef]

- Chen, R.; Zhao, B.; Xin, Q.; Niu, X.; Xie, Z.; Lu, X.; Zou, D. Analysis of transient lubrication and wear coupling behaviors considering thermal effect and journal misalignment for main bearings under dynamic load. Wear 2024, 554-555, 205478. [Google Scholar] [CrossRef]

- Shi, J.; Zhao, B.; Niu, X.; Xin, Q.; Xu, H.; Lu, X. Time-varying dynamic characteristic analysis of journal–thrust coupled bearings based on the transient lubrication considering thermal-pressure coupled effect. Phys. Fluids 2024, 36. [Google Scholar] [CrossRef]

- Xiang, G.; Goltsberg, R.; Etsion, I. Modeling static friction behavior of elastic–plastic spherical adhesive microcontact in full-stick condition. Friction 2024, 12, 2594–2610. [Google Scholar] [CrossRef]

- Yang, T.Y.; Xiao, K.; Xiang, G.; Wang, L.W.; Cai, J.L.; Wang, J.X. Effects of rotating microgroove on tribo-dynamic performance of coupled bearings. Int. J. Mech. Sci. 2024, 279, 109629. [Google Scholar] [CrossRef]

- Grosch, K.A. The relation between the friction and visco-elastic properties of rubber. Proc. R. Soc. London. Ser. A Math. Phys. Sci. 1963, 274, 21–39. [Google Scholar] [CrossRef]

- Schallamach, A. How Does Rubber Slide? Wear 1971, 17, 301–312. [Google Scholar] [CrossRef]

- Wang, L.; Xiang, G.; Han, Y.; Yang, T.; Zhou, G.; Wang, J. A mixed visco-hyperelastic hydrodynamic lubrication model for water-lubricated rubber bearings. Int. J. Mech. Sci. 2025, 286, 109887. [Google Scholar] [CrossRef]

- Wang, L.; Xiao, K.; Xiang, G.; Cai, J.; Yang, T.; Wang, J. Study on mixed thermal-visco-hyerelastic hydrodynamic lubrication performance of water-lubricated rubber bearings in deep-sea environment. Tribol. Int. 2025, 209, 110713. [Google Scholar] [CrossRef]

- Luo, W.-b.; Sheng, L.; Yong-jun, Z. Fractional Differential Constitutive Model for Dynamic Viscoelasticity of Asphalt Mixture. China J. Highw. Transp. 2020, 33, 34–43. [Google Scholar] [CrossRef]

- Persson, B. Theory of rubber friction and contact mechanics. J. Chem. Phys. 2001, 115, 3840–3861. [Google Scholar] [CrossRef]

- Persson, B.; Albohr, O.; Tartaglino, U.; Volokitin, A.; Tosatti, E. On the nature of surface roughness with application to contact mechanics, sealing, rubber friction and adhesion. J. Phys. Condens. Matter Inst. Phys. J. 2005, 17, R1–R62. [Google Scholar] [CrossRef]

- Carbone, G.; Mangialardi, L. Analysis of the adhesive contact of confined layers by using a Green’s function approach. J. Mech. Phys. Solids 2008, 56, 684–706. [Google Scholar] [CrossRef]

- Carbone, G.; Lorenz, B.; Persson, B.N.J.; Wohlers, A. Contact mechanics and rubber friction for randomly rough surfaces with anisotropic statistical properties. Eur. Phys. J. E 2009, 29, 275–284. [Google Scholar] [CrossRef] [PubMed]

- Carbone, G.; Putignano, C. A novel methodology to predict sliding and rolling friction of viscoelastic materials: Theory and experiments. J. Mech. Phys. Solids 2013, 61, 1822–1834. [Google Scholar] [CrossRef]

- Patir, N.; Cheng, H.S. An Average Flow Model for Determining Effects of Three-Dimensional Roughness on Partial Hydrodynamic Lubrication. J. Lubr. Technol. 1978, 100, 12–17. [Google Scholar] [CrossRef]

- Wu, C.; Zheng, L. An Average Reynolds Equation for Partial Film Lubrication With a Contact Factor. J. Tribol. 1989, 111, 188–191. [Google Scholar] [CrossRef]

- Dingcheng, X.; Yipan, D.; Zhengyao, W.; Tianhao, L.; Yinshui, L. Viscosity evolution of water glycol in deep-sea environment at high pressure and low temperature. J. Mol. Liq. 2023, 387, 122387. [Google Scholar] [CrossRef]

- Kuznetsov, E.; Glavatskih, S.; Fillon, M. THD analysis of compliant journal bearings considering liner deformation. Tribol. Int. 2011, 44, 1629–1641. [Google Scholar] [CrossRef]

- Skotheim, J.M.; Mahadevan, L. Soft lubrication. Phys. Rev. Lett. 2004, 92, 245509. [Google Scholar] [CrossRef]

- Skotheim, J.; Mahadevan, L. Soft lubrication: The elastohydrodynamics of nonconforming and conforming contacts. Phys. Fluids 2005, 17, 092101. [Google Scholar] [CrossRef]

- Bernard, J.; Hamrock, S.R. Fundamentals of Fluid Film Lubrication; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Hartoko, A. Spatial Distribution of Thunnus sp., Vertical and Horizontal Sub-Surface Multilayer Temperature Profiles of In-Situ Agro Float Data in Indian Ocean. J. Coast. Zone Manag. 2010, 14, 61–74. [Google Scholar]

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| Bearing inner radius, R1 | 22.5 mm | Relaxation time, τ | 5 × 10−8 s |

| Rubber thickness, hl | 2.5 mm | Bearing Poisson ratio, υp | 0.47 |

| Bearing length, L | 50 mm | Fractional order, α | 0.17 |

| Radial clearance, C0 | 0.1 mm | Fractional order, β | 0.77 |

| Specific pressure | 0.1 MPa | Seawater depth, hw | 0–1000 m |

| Shaft rotational speed, ωJ | 300~900 rpm | Ambient temperature, Ta | 5–28 °C |

| Equilibrium modulus, Ee,h | 30 MPa | Instantaneous modulus, Eg | 2.3 GPa |

| Modulus of spring pot, E0 | 3.0 GPa | Number of grooves | 8 |

| Groove depth, hgro | 1.0 mm | Groove width | 3.53 mm |

| Hyperelastic parameters, k1 | 1.47 MPa | Seawater density, ρ | 1050 kg/m3 |

| Hyperelastic parameters, k2 | 4.02 MPa | Reference temperature, T0 | 20 °C |

| Characteristic scale coefficient | 3.0 × 10−8 m | Fractal dimension, H | 1.5 |

| Constant, γ | 1.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Zhao, Q.; Feng, W.; Xiang, G. On the Film Stiffness Characteristics of Water-Lubricated Rubber Bearings in Deep-Sea Environments. Lubricants 2025, 13, 451. https://doi.org/10.3390/lubricants13100451

Wang L, Zhao Q, Feng W, Xiang G. On the Film Stiffness Characteristics of Water-Lubricated Rubber Bearings in Deep-Sea Environments. Lubricants. 2025; 13(10):451. https://doi.org/10.3390/lubricants13100451

Chicago/Turabian StyleWang, Liwu, Qilong Zhao, Wei Feng, and Guo Xiang. 2025. "On the Film Stiffness Characteristics of Water-Lubricated Rubber Bearings in Deep-Sea Environments" Lubricants 13, no. 10: 451. https://doi.org/10.3390/lubricants13100451

APA StyleWang, L., Zhao, Q., Feng, W., & Xiang, G. (2025). On the Film Stiffness Characteristics of Water-Lubricated Rubber Bearings in Deep-Sea Environments. Lubricants, 13(10), 451. https://doi.org/10.3390/lubricants13100451