Abstract

Magnesium alloys are widely used in automotive and aerospace applications due to their light weight but suffer from poor tribological performance. This study investigates the effects of base oil (SAE 5W-30) with 100% hBN, 100% ZnO, and various ratios of hBN/ZnO hybrid nanoparticles on the tribological performance of AZ91D magnesium alloy. Pin-on-disk tribometer tests were conducted on AZ91D magnesium alloy under loads of 10–60 N and a sliding distance of 1000 m. Dry sliding produced the highest coefficient of friction (COF, ~0.30) and the greatest wear. Base oil lubrication reduced COF to ~0.14 and improved wear resistance by more than 50%. The 100% hBN nanolubricant provided the lowest wear and a COF of ~0.114, while the 75hBN/25ZnO hybrid achieved the lowest COF (~0.110) with wear values close to hBN. Surface analyses confirmed that hBN formed a lamellar tribofilm that minimized metal-to-metal contact, and ZnO contributed to the formation of load-bearing oxide layers that enhanced surface stability. Overall, the results demonstrate that hBN and ZnO, in single or hybrid form, can significantly reduce friction and wear, showing strong potential for applications in automotive, aerospace, defense, and industrial systems.

1. Introduction

Light weight, high strength, and energy efficiency are fundamental factors that guide material selection in advanced sectors, including automotive, aerospace, transportation, and defense. Magnesium (Mg) and its alloys are particularly attractive because their low density and high specific strength reduce vehicle weight, improve fuel efficiency, and lower carbon emissions [1,2,3,4]. Mg alloys also possess favorable properties, including excellent castability, high machinability, thermal conductivity, dimensional stability, vibration-damping capacity, and recyclability. These characteristics give them broad application potential in sectors such as automotive, aerospace, electronics, medical, and household industries [5,6,7,8].

Pure magnesium has limited mechanical strength and poor corrosion resistance, which restricts its industrial applications. These shortcomings can be largely overcome by alloying with elements such as aluminum (Al), zinc (Zn), and manganese (Mn). Al improves the hardness and castability of Mg alloys, while Zn enhances their performance through a strengthening effect [9,10,11]. Among the commercial Mg alloys developed for structural applications, AZ91D, AM50A, and AM60B are widely used, where AZ91D is commonly employed in automotive engine blocks and transmission housings due to its excellent castability and strength [12,13,14,15], AM50A is preferred in safety components such as instrument panels and seat frames because of its superior ductility and energy absorption capacity [14,16,17], and AM60B finds extensive application in aerospace and automotive parts requiring a balance of strength and corrosion resistance [13,14,16]. The AZ91D magnesium alloy contains about 9% Al, 1% Zn, and the balance Mg. It is notable for its excellent castability, mechanical strength, and low cost. These properties make it a preferred material for structural components in automotive and aerospace applications, including engine blocks, transmission housings, and electronic casings. Despite these favorable attributes, certain key properties of Mg alloys, including wear resistance, corrosion resistance, creep resistance, and fatigue life, still require improvement [11,18,19]. In applications subjected to high mechanical loads, typically in the range of 1–3 GPa, and elevated temperatures between 600 and 1300 K, contact between surfaces and other materials is inevitable [20,21,22]. Under such operating conditions, surface wear emerges as a critical factor limiting the service life of Mg alloys. Wear, a type of mechanical damage resulting from relative motion between surfaces, leads to both material loss and performance degradation, and is widely recognized as one of the most critical tribological phenomena influencing the service life of engineering components [23,24]. Therefore, the systematic investigation of the wear behavior of Mg alloys under various loading and environmental conditions is of great importance for extending their service life and broadening their application areas. The direct use of Mg alloys in components such as bearings, gears, or other friction-exposed surfaces is often not suitable. However, their interaction with different materials makes tribological performance a critical factor. Therefore, surface engineering techniques and nanoadditive lubricant systems have gained significant attention as promising approaches to improve the friction and wear performance of Mg alloys [11,23].

The addition of micro and nanoscale solid particles to lubricants significantly reduces friction and wear, thereby extending the service life of mechanical components while simultaneously lowering costs, maintenance requirements, and material losses [25,26]. Various materials such as graphene [27], graphene oxide [28], graphite [29], carbon nanotubes [30,31], polytetrafluoroethylene (PTFE) [32], hexagonal boron nitride (hBN) [11,26,33], molybdenum disulfide (MoS2) [34,35,36], silicon dioxide (SiO2), copper oxide (CuO) [37,38], zinc oxide (ZnO) [30,39], titanium dioxide (TiO2) [31], and soft metals [40] have been increasingly employed in recent years as lubricant additives to reduce friction and wear. Among these materials, nanoparticles, typically with diameters in the range of 20–100 nm, possess a high surface area and can generate a three-body rolling effect that fills the asperities on contact surfaces, thereby minimizing friction and wear [25,41]. Among nanoparticles, hBN, also referred to as white graphite due to its hexagonal crystal structure, has attracted considerable attention in lubricants in recent years [34,42]. In each layer of hBN, strong sp2-type B-N covalent bonds with an average bond energy of approximately 389 kJ.mol−1 are present, while weak van der Waals interactions of about 15–20 kJ.mol−1 exist between the layers, indicating that the interlayer covalent bonds are nearly twenty times stronger than the interlayer interactions [43,44,45]. This structural characteristic allows the hBN layers to easily slide over one another in the direction of shear, thereby reducing frictional resistance and wear losses. Furthermore, hBN possesses excellent chemical inertness and high thermal stability, and its high thermal conductivity enables rapid dissipation of heat, preventing wear. Due to these superior properties, the addition of hBN nanoparticles to lubricants at an appropriate concentration leads to a reduction in both the coefficient of friction (COF) and wear [26,35,42,46,47]. On the other hand, ZnO nanoparticles, with their high surface energy and good dispersibility, have been widely investigated in recent years as lubricant additives. ZnO nanoparticles contribute to the effective reduction in friction by forming a thin and stable tribofilm layer on the surfaces in mutual contact. This beneficial effect is often attributed to the ability of ZnO particles to transform sliding friction into rolling motion through a three-body “rolling” mechanism in the contact regions, thereby limiting surface deformation [25,39]. Furthermore, the tribofilm formed by ZnO prevents direct contact between surfaces, reducing wear rates and enhancing lubrication performance. In this context, ZnO not only acts as a physical protective barrier but also serves as an effective nanoadditive for improving tribological efficiency in systems operating under mechanical load [25,39,48,49,50].

In recent years, solid nanoparticle-based lubricants have become an important area of research in engineering applications due to their enhanced tribological properties. Hybrid additive lubricant systems were developed to address the limited performance of single-type nanoparticle additives. They combine two or more nanoparticles with different structures and properties to achieve improved lubrication effects. Hybrid nanoparticles combine lubrication effects that act through different mechanisms. They reduce the coefficient of friction, decrease wear rates, increase load-carrying capacity, and improve thermo-chemical stability. The combined use of additives with different sizes, shapes, surface energies, and crystal structures promotes the formation of denser and more durable tribofilms on the surface. These films provide more effective protection under both boundary and hydrodynamic lubrication conditions. Hybrid systems also improve the rheological and chemical properties of lubricants, including viscosity index, thermal conductivity, oxidation resistance, and high-temperature stability. These improvements extend lubricant service life and increase system reliability. Compared to base oils and single-type additives, hybrid nanoparticle lubricants not only reduce friction but also enhance heat transfer, enabling more stable operating temperatures. Therefore, the hybrid nanoadditive strategy emerges as a promising approach for achieving high-performance, energy-efficient, and environmentally friendly lubrication in advanced engineering systems [31,34,35,49,51].

Jiang and Ling investigated the friction and wear behavior of AZ91D magnesium alloy against GCr15 steel using vegetable-based lubricants containing sulfur-modified rapeseed oil (SRO) as an additive. In this study, the effects of environmentally friendly oil bases on the formation of protective films on the surface and on tribological performance were evaluated [52]. In another study, Wang et al. investigated the sliding contact between AZ31B magnesium alloy and steel at high temperatures under open-air conditions using a silicone oil-based nanolubricant with Al2O3 nanoparticles and evaluated the effects of different temperatures and concentrations [53]. Yin et al. evaluated the friction and wear performance of AZ91D magnesium alloy under various loads and sliding frequencies in systems containing serpentine structured magnesium silicate hydroxide (MSH) nanotubes [54]. In another study, Wang et al. investigated the high-temperature oxidation behavior of the AZ31B alloy using a commercial silicone oil. They evaluated the data obtained from pin-on-disk tests conducted at different temperatures [55]. Zhou et al. investigated the friction and wear behaviors of AZ91D magnesium alloy matrix nanocomposites reinforced with various ratios of hybrid additives consisting of multi walled carbon nanotubes (CNTs) and nano-SiC particles, which were produced using ultrasonic cavitation-assisted semi solid stirring followed by hot extrusion [56]. In another study, wear data obtained from AZ91D magnesium alloy under dry, oil, and hBN-added lubrication conditions were predicted using a hybrid artificial intelligence model called golden jackal optimizer–multi-layer perceptron (GJO-MLP), in which the golden jackal optimizer algorithm is employed to optimize the weights and biases of the neural network. In this approach, the input parameters were wear condition, load, sliding speed, and sliding distance, while the output was the predicted wear loss, and the model demonstrated higher accuracy than other metaheuristic-based MLP method [11]. Huang et al. investigated the effects of various nitrogen-containing compounds (e.g., propylamine, ethylenediamine, triethylenetetramine, acetamide, and acrylamide) on tribological behavior in a liquid paraffin-based oil medium, examining their influence in relation to their molecular structures [57]. In a study by Xie et al., different ratios of SiO2/MoS2 hybrid nanoparticles were incorporated into an environmentally friendly engine oil, and the tribological performance of these lubricants was then evaluated on AZ31 alloy against steel surfaces [58]. In a study examining the friction and wear behaviors of SiC reinforced hybrid composites based on AZ91D alloy under different lubrication conditions, the SiC content of the nanofluids was formulated at varying ratios [59]. In the study by Yao et al., slippery liquid infused porous surface (SLIPS) structures containing SiO2 nanoparticles were utilized, and evaluations were conducted on MgAl layered structures formed on the surfaces of AZ31 magnesium alloy [60]. In another study, Xie et al. developed water-based nanostructured lubricants containing graphene and graphene oxide, and examined the surface behaviors of these systems under different concentrations and conditions [61]. Nagarajan et al. incorporated MoS2 and hBN hybrid nanoparticles at specific ratios into a diesel-based SAE 20W40 engine oil and evaluated their effects on the oil’s friction, wear, and oxidation resistance [35]. Azman et al. investigated the comparative tribological performance of biolubricants obtained by adding layered nanoparticles such as graphite, hBN, and MoS2 to palm kernel oil (PKO)-based systems [34]. In another study, hybrid nanoparticles composed of 45% TiO2 and 55% multi-walled carbon nanotubes (MWCNTs) were added to 10W40 engine oil to prepare nanolubricants. Their rheological behavior was examined under different temperatures and shear rates, and the experimental results were further analyzed using an artificial neural network model B [31]. Finally, Alghani et al. (2020) evaluated the tribological performance of nanolubricants formulated by adding ZnO, graphene, and their hybrid form to an API Group II base oil and examined in detail the effects of these oil systems on surface interactions and film formation [49]. In addition to experimental approaches, molecular dynamics (MD) simulations have become powerful tools for understanding the tribological behavior of lubricants across different spatio-temporal scales. All-atom MD simulations are widely used to study lattice-resolved friction and the role of confined molecules at sliding contacts. These studies provide atomistic insight into stick–slip dynamics and the effect of water entrapment at interfaces. Reactive MD simulations, in contrast, enable the investigation of chemical reactions and structural changes under shear. For example, they have been applied to vanadium oxides, where tribological properties were evaluated at elevated temperatures and pressures. At larger scales, coarse-grained MD simulations have been employed to model ionic liquid lubricants in automotive contacts. These studies capture confinement effects, layering transitions, and velocity-dependent friction behavior under realistic loading conditions [62,63,64]. Together, these computational strategies complement experimental findings by revealing the fundamental mechanisms of lubrication, film stability, and additive performance, thereby broadening the understanding of tribological processes across multiple length and time scales.

Studies show that the wear behavior of Mg and Mg alloys under dry conditions and different experimental parameters has been widely investigated, and their tribological response under various lubricants has also been examined. Previous studies have mainly focused on single-type nanoparticle additives such as hBN, ZnO, MoS2, graphene, Al2O3, and SiO2, which have each demonstrated the ability to reduce friction and improve wear resistance to some extent. Although these works provided valuable insights, their effects were generally restricted to specific mechanisms or operating conditions. In addition, a number of investigations have explored hybrid additives, including MoS2-hBN, SiO2-MoS2, and TiO2-MWCNT, but these studies were mostly directed toward other alloy systems or different lubricating environments and therefore did not comprehensively evaluate the tribological performance of magnesium alloys under hybrid nanolubrication. There is still a clear research gap regarding the systematic evaluation of magnesium alloys, particularly AZ91D, with hybrid nanoparticle-based lubricants. The novelty of the present study lies in filling this gap through a detailed comparative assessment of ZnO and hBN nanoparticles used together in a hybrid form within an SAE 5W-30 base oil. Unlike previous works that predominantly examined single nanoparticle systems, this study investigates different hybrid ratios under a wide range of applied loads at a constant sliding speed and supports these experiments with SEM and EDX analyses to clarify the underlying wear mechanisms. By combining friction and wear data with morphological and compositional evidence, the study provides a new understanding of how complementary mechanisms, such as the lamellar tribofilm formation of hBN and the load-bearing and rolling effects of ZnO, can act together to enhance lubrication performance. This contribution highlights the originality of the present work by demonstrating for the first time in a systematic manner that hybrid hBN/ZnO nanolubricants can simultaneously reduce the coefficient of friction and improve wear resistance in AZ91D magnesium alloys. Beyond addressing the identified research gap, the study also emphasizes the importance of hybrid nanolubricant strategies as a promising approach to extend the service life of lightweight magnesium components and to develop advanced lubrication solutions for critical applications in automotive, aerospace, and other high-performance engineering sectors.

In this study, nanolubricants containing pure hBN, pure ZnO, and hybrid ZnO/hBN nanoparticles at different ratios (25–75%, 50–50%, and 75–25%) with a total additive concentration of 1 wt.% were prepared using SAE 5W-30 base oil, which was selected due to its wide commercial availability, well-established viscosity-temperature characteristics, and common use in automotive engines, making it a suitable and representative reference lubricant for tribological evaluations. The nanoparticles were characterized prior to use to confirm their structural and morphological integrity. Tribological tests were performed on AZ91D magnesium alloy samples under dry, base oil, and nanoparticle-enhanced lubrication conditions using a pin-on-disk tribometer. The COF was continuously recorded throughout the tests, and wear losses were determined gravimetrically. Worn surface morphologies and elemental compositions were examined using field emission scanning electron microscopy (FE-SEM) and energy-dispersive X-ray spectroscopy (EDX) to evaluate tribofilm formation and to identify dominant wear mechanisms under different lubrication conditions.

2. Materials and Methods

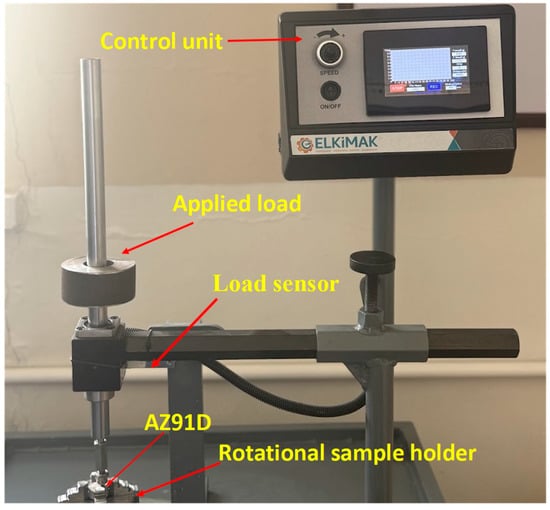

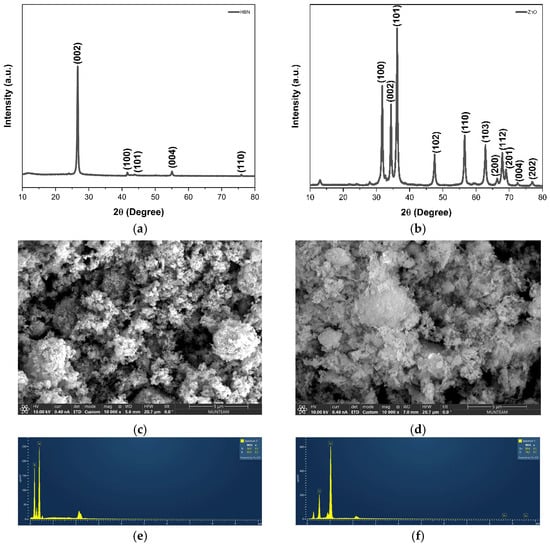

In the present study, cylindrical specimens with dimensions of Ø 20 mm × 10 mm were prepared from commercially available AZ91D magnesium alloy with a microhardness of 70 HV0.1. The nominal chemical composition of the alloy is Mg 88–90.5 wt.%, Al 8.5–9.5 wt.%, Zn 0.45–0.9 wt.%, Mn 0.17–0.4 wt.%, Si ≤ 0.050 wt.%, and Cu ≤ 0.025 wt.%, with the remainder consisting of trace elements such as Fe, Ni, Ca, and Cr. The AZ91D pins were examined in detail using a Zeiss EVO MA10 (Carl Zeiss, Oberkochen, Germany) scanning electron microscope, and the EDX analysis of the commercially obtained alloy indicated the presence of Mg (92.08 wt.%), Al (2.42 wt.%), Zn (1.39 wt.%), and O (2.64 wt.%), along with a minor C signal (1.47 wt.%) that is most likely related to surface contamination or carbon tape used during sample preparation, with magnesium being the dominant element. The density of the alloy is presented in Table 1. The pin-on-disk tests were conducted in accordance with the ASTM G99 standard. As the abrasive material, 2 mm diameter AISI 52100 steel balls were used, with a new ball installed before each test. The specimen surfaces were sequentially ground using SiC abrasive papers with grit sizes ranging from 400 to 1200, followed by polishing with a felt cloth and a 3 µm diamond suspension. After polishing, the Mg alloy specimens were subjected to ultrasonic cleaning in an alcohol bath for 5 min and then dried with hot air. Wear tests were conducted on a pin-on-disk apparatus (Figure 1) at room temperature, with a constant sliding speed of 30 mm s−1 and a total sliding distance of 1000 m. The sliding speed was selected based on reference studies in the literature related to hybrid nanolubricants [58]. Since the acceleration period required to reach the preset sliding speed was very short and identical for all specimens, this initial stage was neglected in the measurements, and data recording commenced once the constant sliding speed was established. The applied normal loads were 10, 20, 30, 40, 50, and 60 N. Three different lubrication conditions were evaluated in the study: the first was unlubricated (dry) tests conducted to reveal absolute contact conditions, the second was reference tests using pure 5W-30 engine oil, and the third was a nanoadditive 5W-30 formulation prepared by adding 1 wt.% solid nanoparticles to the same base oil. The nanoparticle concentration was selected based on the amount reported in the literature to achieve low wear loss [65]. The properties of the Shell Helix 5W-30 (Shell Global, London, UK) lubricant and the Nanografi brand (Nanografi Nano Technology, Ankara, Türkiye) hBN and ZnO nanoparticles are presented in Table 1. Figure 2a–f shows the X-ray diffraction (XRD) patterns, FE-SEM images, and EDX results of the hBN and ZnO nanoparticles. XRD analyses were carried out using a PANalytical Empyrean diffractometer (Malvern Panalytical, Malvern, UK) equipped with Cu Kα radiation (λ = 1.5406 Å). The measurements were performed with a scan step of 0.0262° operating at 45 kV and 45 mA, within the 2θ range of 10–80°. The surface morphology of the nanoparticles was examined using a field emission scanning electron microscope (FE-SEM, Thermo Scientific Scios 2, Thermo Fisher Scientific, Waltham, MA, USA). Elemental composition analyses were performed with an energy-dispersive X-ray spectroscopy (EDS) system (Oxford Instruments AZtec EDS, Oxford Instruments, Abingdon, Oxfordshire, UK) integrated into the same microscope. It was observed from the XRD patterns that the ZnO nanoparticles used in the experiments exhibited the hexagonal wurtzite structure, which is the most stable polymorph of ZnO under ambient conditions, while the hBN nanoparticles showed the typical hexagonal layered phase consistent with their lamellar nature. To further validate the phase and purity, EDX analyses were performed, confirming that the hBN sample consisted mainly of B (45.5 wt.%) and N (54.5 wt.%), whereas the ZnO sample contained Zn (80.8 wt.%) and O (19.2 wt.%) without significant impurity peaks. In addition, the manufacturer’s specifications indicated a purity level above 99.5%, with an average ZnO particle size of 30–50 nm, a spherical morphology, and only trace amounts of elements such as Cu, Mn, and Pb. These results confirm that both ZnO and hBN nanoparticles are of high purity and structurally consistent with literature reports, while the minor small-angle reflections in the diffraction pattern are attributed to trace element impurities at levels far below 0.01% [66,67,68,69]. Additionally, the morphology of hBN exhibits a sheet-like form, while ZnO shows a spherical form. In the nanoadditive system, individual hBN and ZnO, as well as hBN/ZnO hybrid mixtures with different weight ratios (75/25, 50/50, and 25/75), were used to investigate the synergistic effect of the two phases. While stirring the base oil with a magnetic stirrer, the additive nanoparticles were gradually introduced, followed by continuous mixing at room temperature for 30 min. The mixture was then subjected to ultrasonic agitation for 30 min to ensure homogeneous dispersion of the nanoparticles in the oil. Finally, to further enhance the uniform distribution of nanoparticles within the oil, the mixtures were sonicated for 30 min using a Sonopuls HD 4200 (Bandelin Electronic, Berlin, Germany) probe sonicator. After confirming the absence of any visible sedimentation or agglomeration, the single and hybrid nanolubricants were used directly in the experiments. To quantitatively verify the dispersion stability, UV-Vis absorbance measurements were performed using a Shimadzu UV-1800 spectrophotometer (Shimadzu Corporation, Kyoto, Japan). The maximum absorbance wavelength of the base oil was determined as 293 nm, with an absorbance value of 0.451 at this wavelength. In comparison, the nanolubricants containing 100% hBN, 100% ZnO, 75hBN/25ZnO, 50hBN/50ZnO, and 25hBN/75ZnO all exhibited absorbance values of approximately 4 at the same wavelength. The similarity of these absorbance values among the nanoparticle-containing formulations, and their considerably higher magnitude compared to the base oil, clearly demonstrates the homogeneous dispersion of the nanoparticles and the absence of sedimentation, confirming the stability of the prepared nanolubricants during the tests. The nanolubricants used in the experiments were designated as hBN nanolubricant, ZnO nanolubricant, 75hBN/25ZnO nanolubricant, 50hBN/50ZnO nanolubricant, and 25hBN/75ZnO nanolubricant. Within the wear testing protocol, the specimens were removed every time the sliding distance reached 100 m, cleaned with alcohol, dried with a hot air stream, and weighed using an analytical balance with a resolution of 10−5 g. The total sliding distance of 1000 m was thus completed in ten equal increments, with a new specimen used at each intermediate measurement to eliminate wear effects originating from previous test cycles. In oil lubricated and nanolubricated experiments, 10 µL of oil was applied to the wear surface with a micropipette at the beginning of the test and every 10 m thereafter. For each load level, tests were carried out in triplicate, and the mean values were reported. Separate pin specimens were used for the coefficient of friction (COF) and wear measurements in order to avoid any mutual influence between the two evaluations. The COF values were continuously recorded without interruption throughout the entire sliding distance of 1000 m, while the wear losses were determined at the end of the tests. At the end of the experiments, the wear tracks and morphological changes on the surfaces of the AZ91D pins were examined in detail using FE-SEM-EDX analysis. Prior to the examination, the specimens were cleaned in an ultrasonic bath with alcohol for 10 min and subsequently dried with hot air to remove any loosely attached debris and ensure reliable surface characterization. For the observation of worn surfaces after tribological tests, the pin samples were examined directly without any additional preparation. Following the tests, the specimens were carefully removed from the tribometer, cleaned gently with a stream of compressed air to eliminate loose wear debris, and then mounted on aluminum stubs using conductive carbon tape. Since the AZ91D alloy is conductive, no additional coating was required for FE-SEM or EDX analysis. The worn surfaces were therefore directly placed in the FE-SEM chamber, and imaging and compositional analyses were carried out under these conditions.

Table 1.

Physical and chemical properties of the materials utilized in the experimental study.

Figure 1.

Schematic representation of the pin-on-disc wear test setup used in this study.

Figure 2.

XRD patterns of (a) hBN and (b) ZnO, FE-SEM images of (c) hBN, (d) ZnO, and EDX results of (e) hBN and (f) ZnO.

3. Results

3.1. Friction

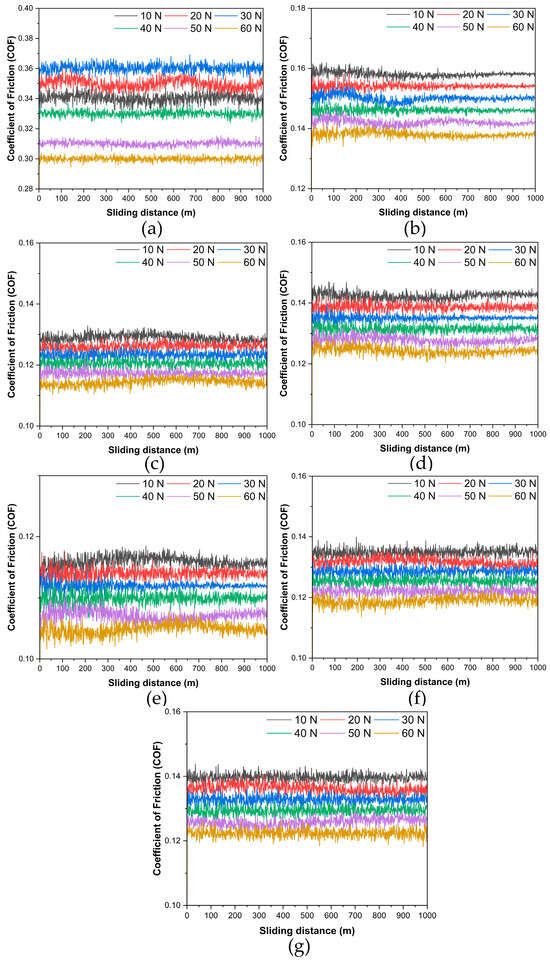

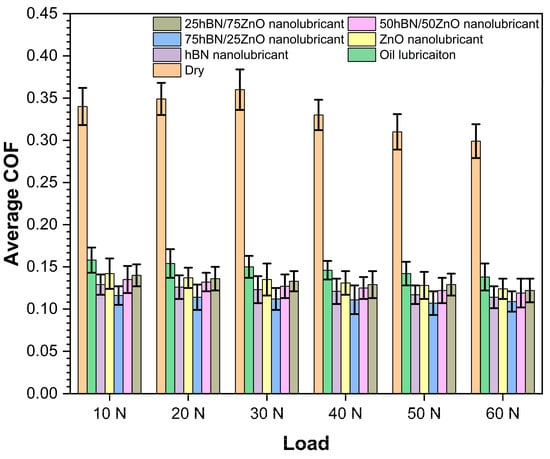

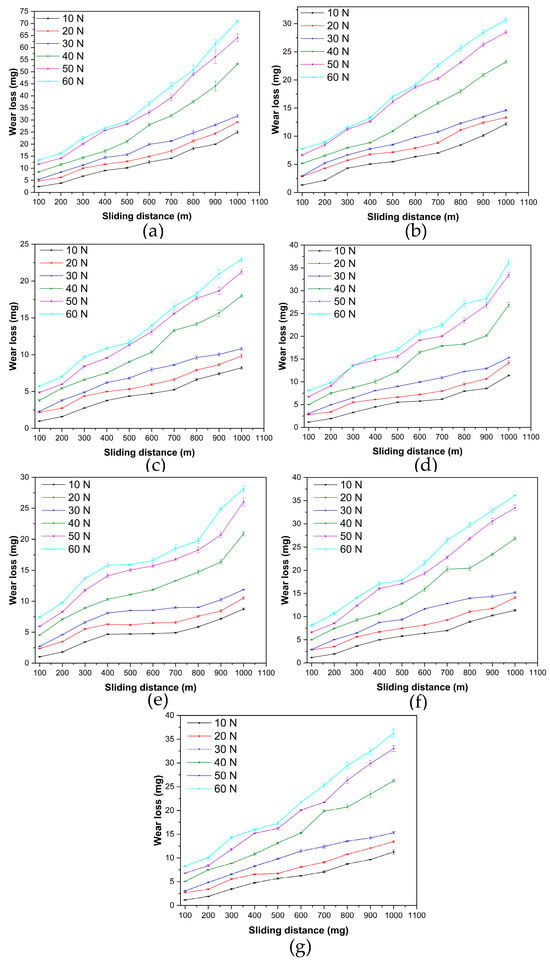

Figure 3a–g illustrate the evolution of the COF for AZ91D as a function of sliding distance under various loads and lubrication conditions. Correspondingly, Figure 4 presents the average COF values obtained for each load and lubrication scenario, providing a clear comparison of the overall frictional performance. The results of the tribological experiments comparatively reveal the effects of different lubrication conditions and loads on the friction behavior of the AZ91D magnesium alloy. According to the experimental results, the dry condition exhibited the highest COF, with average values ranging from approximately 0.299 to 0.360 depending on the applied load. When lubricated with pure 5W-30 motor oil, the COF decreased significantly to values between 0.138 and 0.158. The use of nanolubricants containing hBN or ZnO provided further reductions, yielding COF values of 0.114–0.129 and 0.124–0.142, respectively. Hybrid formulations demonstrated even lower friction, with 75hBN/25ZnO, 50hBN/50ZnO, and 25hBN/75ZnO nanolubricants achieving ranges of 0.109–0.116, 0.119–0.135, and 0.122–0.140, respectively. To ensure repeatability and statistical reliability, all tests were performed in triplicate, and the mean COF values were reported together with error bars representing the standard deviations. The error bars, ranging approximately between ±0.011 and ±0.024 depending on load and lubrication condition, demonstrate the reproducibility of the measurements and confirm that the slight variations in COF with nanoparticle addition are statistically meaningful. This reduction shows that adding hBN and ZnO nanoadditives to lubricants effectively decreases friction between surfaces. The friction-reducing effect of nanoadditives is well documented in the literature. Nanoparticles fill the asperity valleys of opposing surfaces, improve contact conditions, and, through a “third-body rolling” effect, transform sliding friction into rolling friction. As a result, overall friction is significantly reduced [25,70,71]. Under dry sliding conditions, the COF was by far the highest among all test conditions and exhibited a characteristic “U-shaped” variation, increasing initially with load and then decreasing. At 10 N, the COF was approximately 0.34, reaching its peak value of about 0.360 at 30 N, and then decreasing to around 0.30 at 60 N. At low loads, the rise in normal force increases the real contact area and adhesion. Plastic deformation of asperities and the accumulation of abrasive debris further intensify, leading to higher friction. At high loads, however, severe plastic flow and surface polishing effects flatten the asperities, which reduces friction [72,73,74,75,76]. In addition, the combination of high load and temperature may contribute to the renewal of a thin MgO layer on the surface, forming a lubricating barrier. In this case, the formation of a “tribo-oxide” film on the surface prevents metal-to-metal contact under high pressure and reduces sliding resistance [76,77,78]. On surfaces lubricated with pure 5W-30 motor oil, the COF was significantly lower compared to the dry condition (approximately 0.16 at 10 N and about 0.14 at 60 N) and remained relatively stable with changes in load. This behavior is attributed to the oil film maintaining at least its minimum thickness even in the boundary lubrication regime, thereby preventing metal-to-metal contact [79,80]. This is considered to be the reason why the COF remains lower and more stable than in the dry condition, even under varying and high loads [81]. In friction tests conducted on AZ91D magnesium alloy, lubricants enriched with hBN, ZnO, and their hybrid nanoadditives at different ratios exhibited distinct friction behaviors in the load range of 10–60 N. Under all nanolubricated conditions, the COF gradually decreased as the load increased. For instance, in the 75hBN/25ZnO hybrid oil, the COF declined from about 0.116 at 10 N to 0.105 at 60 N. At every load level, the lubricant with pure hBN produced lower COF values than that with pure ZnO, confirming the superior effectiveness of hBN in reducing friction [34,42,82]. The hybrid lubricant with the highest hBN content (75hBN/25ZnO) provided the lowest COF values at all loads, surpassing even the pure hBN-containing lubricant. Notably, the COF of 0.105 recorded at 60 N was the lowest value observed in the experiments and was lower than that obtained with pure hBN at the same load (approximately 0.114). The 50hBN/50ZnO hybrid additive lubricant reduced the COF from around 0.135 at 10 N to 0.119 at 60 N, showing better friction-reducing performance than the pure ZnO additive, although remaining slightly above the low friction level achieved with pure hBN. Similarly, in the hybrid lubricant with the lowest hBN content (25hBN/75ZnO), the COF values (about 0.139 at 10 N and 0.122 at 60 N) were slightly lower than those for the pure ZnO additive but did not reach the minimum levels achieved with pure hBN. In the literature, the friction-reducing effect of nanoadditives is explained by several mechanisms. These include the formation of a protective tribofilm on sliding surfaces and the filling or repairing of asperity valleys with nanoparticles, which smooths the contact area. Spherical nanoparticles may also act as miniature ball bearings, known as the “ball effect,” that transform sliding friction into rolling friction. In addition, the micro-abrasive action of hard particles polishes the surfaces, which further reduces friction [83,84,85,86,87,88]. At a low load of 10 N, all nanoadditive lubricants achieved similar COF values (approximately 0.12–0.13), whereas at 60 N, the hybrid formulations demonstrated a clear advantage. In particular, the 75hBN/25ZnO mixture produced the lowest average COF of 0.105 at 60 N, which was lower than that of both the pure hBN (0.114) and pure ZnO (0.124) lubricants. This performance ranking can be explained by the synergy arising from the complementary properties of the two nanoparticles. Lamellar hBN forms a low shear resistance film that spreads easily over the contact surface due to the weak interlayer bonds, while spherical, hard ZnO particles exhibit rolling behavior in the same region and, under high pressure, form a zinc-rich tribofilm that prevents metal-to-metal contact. In this way, the slippery film effect of hBN combines with the rolling-and-film contribution of ZnO [89,90,91,92]. These findings clarify the COF ranking according to load and lubrication conditions as follows: 75hBN/25ZnO < hBN < 50hBN/50ZnO < 25hBN/75ZnO < ZnO < pure oil < dry. In the present experimental results, the hybrid mixture at the highest load was found to activate three mechanisms simultaneously, namely slippery lamellar film formation, rolling effect, and the development of a thick tribofilm, which together produced the lowest COF. Therefore, the 75hBN/25ZnO formulation emerges as the optimum nanolubricant composition for AZ91D magnesium alloy under high-load, low-friction conditions. Moreover, the results indicate that nanoadditive lubricant engineering holds substantial potential for friction control in heavily loaded magnesium alloy applications.

Figure 3.

Coefficients of friction according to sliding distance at different loads for conditions: (a) dry, (b) oil lubrication, (c) hBN nanolubricant, (d) ZnO nanolubricant, (e) 75hBN/25ZnO nanolubricant, (f) 50hBN/50ZnO nanolubricant, and (g) 25hBN/75ZnO nanolubricant.

Figure 4.

Average coefficients of friction against loads at different wear conditions.

3.2. Wear

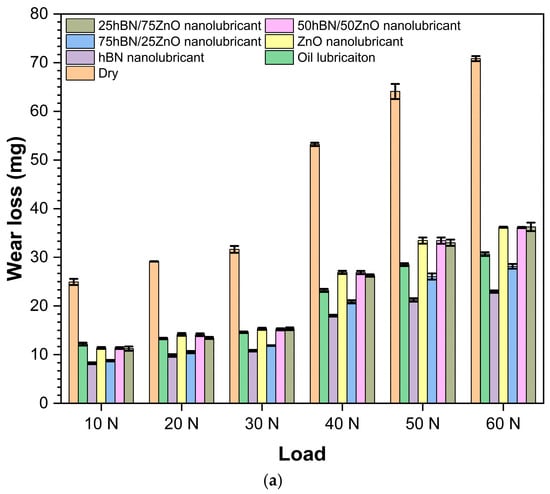

Pin-on-disk wear tests conducted on the AZ91D magnesium alloy revealed that, under all lubrication conditions, the amount of wear increased systematically with sliding distance (Figure 5a–g). As shown, the cumulative material loss accumulated in each 100 m sliding interval reached significant levels by the end of 1000 m. This cumulative increase accelerated with the applied normal load. Higher loads produced greater contact pressure and a larger real contact area, which promoted surface deformation and particle detachment [93,94,95,96]. Particularly under the maximum load of 60 N, the total wear volume obtained was significantly higher compared to that at a lower load level, such as 10 N. This indicates that, with increasing load, adhesive and abrasive wear mechanisms become simultaneously more active and the surfaces are subjected to more severe mechanical stress [97,98]. Increased contact stress causes more intense plastic deformation of the surface asperities. It also intensifies the mechanical interaction with the counter surface and leads to the detachment of microscopic particles. As the load increases, this process disrupts the morphological integrity of the contact surface. The accumulation of detached debris then establishes the conditions for the development of a new contact regime [99,100,101,102,103,104]. Particularly at high loads, when the accumulation of deformation energy in the surfaces exceeds a certain threshold, microstructural degradation accelerates. This leads to a weakening of surface film stability and causes more aggressive adhesive and abrasive wear modes to become dominant in the friction pair [24,105,106,107]. This behavior challenges the local hardness and toughness of the surface, making it more brittle and susceptible to degradation. As a result, its tribological resistance is weakened. The wear volumes measured after 1000 m of sliding are influenced not only by the lubrication conditions but also by the mechanical stresses and microstructural changes caused by the applied load. With increasing load, stress concentrations intensify and plastic flow becomes more complex, directly affecting the overall wear resistance of the tribological system [76,108,109,110,111].

Figure 5.

Wear loss according to sliding distance at different loads for conditions: (a) dry, (b) oil lubrication, (c) hBN nanolubricant, (d) ZnO nanolubricant, (e) 75hBN/25ZnO nanolubricant, (f) 50hBN/50ZnO nanolubricant, and (g) 25hBN/75ZnO nanolubricant.

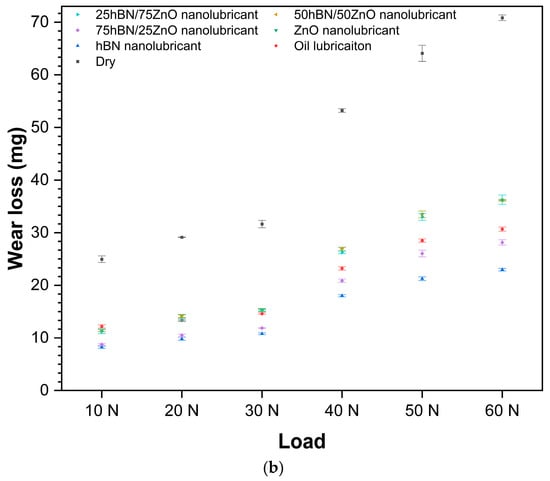

For each condition, the total mass losses measured at the end of 1000 m are presented in Figure 6 as mean values with ± error bars representing standard deviations. In terms of the repeatability of the wear results, the error bars were generally small under oil-lubricated and nanoadditive-lubricated conditions, indicating stable and predictable wear behavior. The standard deviations for the nanoadditive oils varied between approximately ±0.07 and ±0.87 mg, depending on the load and formulation. The relatively low scatter in most cases is attributed to the continuous regeneration of the protective tribofilm, which led to a similar wear mechanism across repeated tests [49,112,113,114]. In contrast, under dry friction conditions, the error bars were noticeably larger, particularly at high loads. This may be attributed to the irregular nature of wear in the dry condition, the occurrence of severe localized surface damage, and variations in the size and amount of detached debris between measurements [115,116,117]. Therefore, in tests conducted without lubrication, the scatter among the wear values was greater, indicating lower system stability. In general, the minimal overlap of error bars for all conditions suggests that the differences in the measured wear values are statistically significant. Among all conditions, the highest wear loss was observed under dry friction. In the absence of a lubricant film, direct metal-to-metal contact occurred, activating severe adhesion and abrasion mechanisms that resulted in substantial material loss [118,119]. In the case of base oil lubrication (SAE 5W-30), the formation of a lubricant film between the sliding surfaces led to a significant reduction in wear loss compared to the dry condition. The reduction was approximately 47% at 10 N, 54% at 20 N, 54% at 30 N, 56% at 40 N, 55% at 50 N, and 57% at 60 N, showing a consistent improvement in wear resistance across increasing load levels. Even though the lubricant film was relatively thin, it effectively prevented direct asperity contact, thereby lowering both friction and wear [120,121]. Thus, lubrication with base oil exhibited much better wear performance than dry friction. The addition of hBN nanoparticles to the base oil provided further improvement. Wear was reduced relative to base oil by about 17% at 10 N, 26% at 20 N, 19% at 30 N, 23% at 40 N, 21% at 50 N, and 25% at 60 N. This confirms that the hBN-based nanolubricant consistently outperformed the base oil at all load levels. Among all test conditions, this formulation provided the lowest wear losses, demonstrating the best overall tribological performance. The superior effectiveness of hBN is attributed to its lamellar structure, which promotes tribofilm formation and acts as a lubricating barrier at the asperity contacts, even under high load [42,122]. As a result, wear reached its lowest level under 100% hBN lubrication. In the case of the 75hBN/25ZnO hybrid nanolubricant, wear was also exceptionally low. The measured wear loss was approximately 8.3% lower than that with base oil and exhibited a wear performance very close to that achieved with pure hBN oil. In other words, the hybrid nano oil containing 75% hBN was able to minimize wear almost as effectively as the pure hBN additive. This suggests that the addition of a small amount of ZnO nanoparticles does not significantly diminish the anti-wear effect of hBN, on the contrary, it may contribute to wear protection through different mechanisms, such as ZnO particles filling surface asperities to act as micro-bearings or aiding in the formation of an enhanced tribofilm [25,123,124]. The lowest wear value was obtained with the pure hBN oil. The hybrid oil showed a performance close to this result but produced slightly higher wear while achieving better friction behavior. Lubrication with only ZnO nanoparticles resulted in wear losses that were intermediate between the best case with pure hBN and the worst case under dry sliding. At 10 N load, ZnO additives showed a slight reduction in wear compared to base oil, indicating some beneficial effect under light loading. However, at higher loads (20–60 N), the ZnO nanolubricant consistently produced greater wear losses than base oil, demonstrating that its effectiveness is limited and cannot be generalized across all load conditions. The hybrid formulations exhibited intermediate performance between pure hBN and pure ZnO. Although the 50hBN/50ZnO oil improved tribological behavior compared to pure ZnO, its wear losses remained significantly higher than those of pure hBN at all loads, including 60 N. Similarly, the 25hBN/75ZnO blend performed slightly better than pure ZnO but was also clearly inferior to hBN. These findings emphasize that a higher proportion of hBN is critical for minimizing wear, while ZnO is not effective under medium and high load conditions. Among all lubricated cases, pure hBN consistently provided the best wear resistance, with reductions of approximately 17–26% compared to base oil, depending on the applied load. The superior performance of hBN is attributed to its lamellar crystal structure, which promotes tribofilm formation and provides a lubricating barrier at asperity contacts even under severe loading [25,124,125]. The lowest wear values were obtained under nanolubricant conditions containing high fractions of hBN. In particular, hBN nanoparticles form a highly effective solid lubricating film on the sliding surfaces and thereby minimize wear [126,127]. ZnO nanoparticles, in contrast, exhibited only a limited wear-reducing effect. Through their spherical morphology, they partially lowered friction via a rolling effect and formed oxide-based tribofilms, but at medium and high loads, their performance was inferior to that of base oil [49,128,129]. In hybrid systems (hBN + ZnO), the combined attributes of both additives contributed to intermediate performance. However, Figure 6 shows that ZnO, 25hBN/75ZnO, and 50hBN/50ZnO produced nearly identical wear values within error, indicating that hBN contents up to 50% do not provide a substantial improvement over ZnO alone. In contrast, the 75hBN/25ZnO formulation exhibited markedly lower wear, approaching the performance of pure hBN. This finding suggests the presence of a critical threshold in hBN concentration, above which the lamellar mechanism of hBN dominates and leads to significantly better wear resistance. Overall, the results demonstrate that oils with high hBN content offer the most effective wear protection, while ZnO by itself is not efficient except at very low loads. Nevertheless, ZnO can play a supporting role in hybrid formulations, but only when the proportion of hBN is sufficiently high. By reinforcing the lubrication film with hBN-rich nanolubricants, wear losses can be significantly reduced even under severe loading conditions such as 60 N.

Figure 6.

(a) Total wear loss at 1000 m for different wear conditions with error bars; (b) error bars.

A strong inverse relationship was also observed between COF and wear loss. In general, an increase in frictional resistance at the contact surfaces is a factor that intensifies wear, whereas conditions with a lower COF significantly reduce material loss [122,130]. Indeed, in the experiments, the highest COF and the most irregular friction behavior were observed under dry friction conditions without a lubricant film, and this resulted in the greatest wear loss. Metal-to-metal adhesion and microwelding occurring in unlubricated contact increased friction and generated high shear stresses on the surfaces, leading to large particle detachment and severe surface damage [131,132,133]. In contrast, lubrication with base oil significantly reduced the coefficient of friction, and the thin oil film between the surfaces prevented direct contact, lowering frictional resistance and resulting in approximately 57% less wear compared to the dry condition. At this point, lower COF values lead to less energy dissipation and reduced heating in the tribological system, which prevents surface damage and consequently slows down wear [130,134,135]. Solid lubricant nanoadditives not only further reduced the coefficient of friction, thereby minimizing sliding resistance, but also formed protective films that lowered wear to its minimum level. For example, the addition of hBN nanoparticles, as an excellent solid lubricant with a lamellar structure, enabled extremely low COF values on the contact surfaces, resulting in the lowest wear loss among all conditions. The slippery tribofilm formed by hBN is thought to have reduced interfacial shear resistance even under high load and prevented direct metal contact, thereby minimizing material detachment. ZnO nanoparticles likewise reduced the COF compared to the base oil, although this effect was not as pronounced as with hBN. The spherical morphology of ZnO particles is believed to facilitate sliding motion through a “micro-bearing” effect and to reduce friction by forming an oxide-based tribofilm on the surface [34,42,85,136,137,138,139]. ZnO-containing lubrication reduced the COF due to the rolling effect of its spherical particles and the formation of an oxide-based tribofilm. However, despite this reduction in COF, the wear losses with ZnO alone were generally higher than those of base oil, particularly at medium and high loads, indicating that ZnO is not effective in improving wear resistance on its own. Hybrid nanolubricants (hBN + ZnO) combined the attributes of both additives and provided intermediate performance. Oils containing up to 50% hBN showed wear values comparable to ZnO-rich systems, confirming that a moderate hBN content does not markedly enhance wear protection. In contrast, the hybrid oil containing 75% hBN exhibited wear behavior much closer to pure hBN, while also maintaining very low COF. Although its wear remained slightly higher than that of pure hBN, this formulation demonstrated that a sufficiently high hBN fraction is critical for achieving significant improvement. Overall, the results show that while ZnO primarily contributes to lowering COF, substantial wear reduction is only achieved with hBN-rich oils. By suppressing adhesive and abrasive mechanisms through tribofilm formation and smoother sliding, such nanolubricants significantly enhance tribological performance even under high loads [130,131,140,141]. Conversely, high and fluctuating COF values are indicative of severe mechanical interactions and unstable contact at the surface, which in turn result in higher wear rates and variable wear values even between repeated tests [101,131,142]. The relationship between friction and wear shows that selecting the right lubrication and nanoadditives can improve both parameters at the same time, thus enhancing the tribological performance of the AZ91D alloy. The improvement in wear resistance provided by nanoadditive lubricants is directly linked to the specific mechanisms of hBN and ZnO. hBN nanoparticles, with their lamellar crystal structure, act as a solid lubricating film between surfaces. Known as “white graphite,” hBN contains strong sp2-hybridized B-N covalent bonds within each layer, while the layers themselves are held together by weak van der Waals interactions. This structure allows the hBN layers to stack and easily slide over one another in the direction of shear. As a result, hBN provides low shear resistance between contact surfaces, reducing friction and the associated wear damage [25,143,144]. hBN nanoparticles are chemically inert and have high thermal conductivity. These properties allow them to dissipate frictional heat quickly, limiting local temperature rise on the surface. As a result, they help prevent softening or oxidative wear on the Mg alloy and reduce material loss [43,44,122,145,146]. The contribution mechanism of ZnO nanoparticles can be broadly summarized as surface barrier formation and a third body rolling effect. With their high surface energy and good dispersibility, ZnO nanoparticles form a thin and stable tribofilm layer on the surfaces in mutual contact during friction, preventing direct metal-to-metal contact. In this way, adhesion-induced wear and microfractures on the surface are significantly reduced. Additionally, ZnO particles that remain free in the contact regions act like nanoscale ball bearings, providing a third body rolling mechanism. In this mechanism, also referred to in the literature as the “ball effect,” the particles transform sliding friction between two surfaces into rolling motion, thereby reducing frictional forces and shear stresses on the surface [147,148]. The lower COF values observed with ZnO addition are a result of this rolling effect. Considering both the tribofilm layer formed by ZnO and the bearing effect together, it can be stated that this nanoadditive has a dual positive impact on wear. It reduces abrasive wear by limiting surface deformation and minimizes adhesive wear by preventing direct metal-to-metal contact [49,149,150]. Within the scope of this study, the superior performance of the hybrid nanolubricants arises from the synergistic combination of the complementary effects of hBN and ZnO. In particular, the formulation containing 75% hBN minimized the COF and reduced the wear loss to a low level close to that of the pure hBN formulation by combining the low friction contribution of lamellar hBN layers with the surface protective effect of ZnO particles.

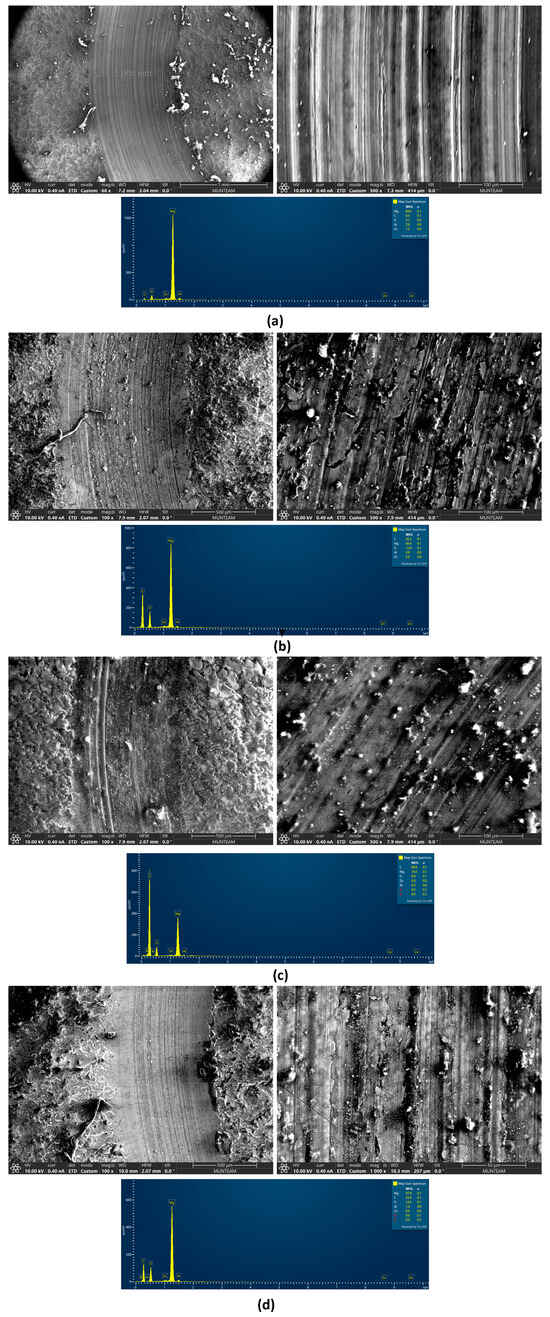

Figure 7 displays the worn surface morphologies and corresponding EDX analyses of AZ91D samples tested under 60 N load for three lubrication conditions: dry, oil, hBN nanolubricated, and 75hBN/25ZnO hybrid nanolubricated. These specific conditions were selected for detailed surface characterization as the 100% hBN formulation exhibited the lowest wear rate, while the 75hBN/25ZnO nanolubricant demonstrated the lowest COF among all tested conditions. Among all abraded samples tested under different lubrication conditions, the hBN nanoadditive oil condition exhibits the most surface morphology and minimal material removal, indicating the highest wear resistance and the lowest wear loss. This study demonstrates that the superior performance of hybrid nanolubricants is due to the synergistic combination of the complementary effects of hBN and ZnO. The formulation containing 75% hBN achieved the lowest COF and a wear loss close to that of the pure hBN formulation by uniting the low friction contribution of lamellar hBN layers with the surface protective effect of ZnO particles [151,152]. Under dry sliding, the surface showed severe abrasive and adhesive wear, with deep grooves and heavy debris. The EDX spectrum revealed strong oxygen peaks together with Mg, Al, and Zn, indicating oxidation due to frictional heating. As expected, this condition gave the highest COF (approximately 0.30), due to the absence of a protective film layer. This high friction value can be explained by the combined effects of adhesive and abrasive components resulting from direct metal-to-metal contact, as well as the contribution of the oxides formed [119,153]. With base oil, scratches and debris were still evident, and oxygen peaks confirmed partial oxidation. The oil film reduced wear compared to dry sliding but did not form a durable protective layer, resulting in intermediate tribological performance. The 100% hBN sample exhibited the shallowest wear tracks and the smoothest surface, reflecting the highest wear resistance among all conditions. This performance is attributed to the lamellar structure of hBN, which acts as a nano-bearing and reduces three-body abrasion by capturing or fragmenting wear debris and preventing their accumulation on the surface [154]. As a result, less wear debris was observed on the worn track compared to the dry and base oil conditions, producing a more uniform surface. The presence of hBN nanoparticles also promoted the formation of a solid lubricating tribofilm that acted as a barrier between the metal surfaces, thereby minimizing wear while maintaining low friction [35,59,155]. Indeed, under hBN-lubricated conditions, a low average COF was obtained (~0.114), consistent with the ability of hBN platelets to slide easily between asperities due to their high intrinsic lubricity and lamellar structure [35,59,136]. The corresponding EDX spectrum showed weak N and C peaks in addition to the main alloy elements, consistent with the incorporation of some hBN residues and oil decomposition products into the contact region [156,157]. Boron was not detected because of its low atomic number, and N signals were weak, suggesting that the hBN nanoparticles did not remain strongly adhered to the worn track [158,159,160,161]. This can be explained by the dynamic behavior of the lubricant system: under high load, the oil’s cooling and lubricating effect likely promoted the circulation and transfer of hBN particles away from the worn surface rather than their permanent deposition. Consequently, the spectra were dominated by the alloy’s intrinsic elements (Mg, Al, Zn) and oxygen from tribo-oxidation. Despite these limitations in post-test detection, the tribological results confirmed that hBN lubrication produced the lowest wear and friction due to the combined effects of debris scavenging, lamellar sliding, and the formation of a thin but effective protective tribofilm. For the 75hBN/25ZnO hybrid lubrication, the worn surface morphology revealed partial film formation with a non-uniform topography. The FE-SEM images showed relatively smooth areas alternating with localized shallow grooves and fine wear debris. This indicates that a thin tribofilm was formed intermittently across the wear track instead of a continuous layer. Patchy regions with compacted material suggested local deposition of reaction products and nanoparticle residues, while the adjacent smoother areas reflected the polishing and sliding effect of hBN platelets [25,35,135,150]. Despite these morphological indications, the EDX spectra did not show pronounced Zn enrichment compared to the base alloy. This can be explained by the weak adhesion of ZnO particles to the worn track and their transfer by the lubricant during sliding. Consequently, the spectra mainly reflected the intrinsic elements of the alloy (Mg, Al, Zn) and oxygen from tribo-oxidation products. These results indicate that ZnO contributed indirectly by influencing frictional behavior in the lubricant rather than forming a durable tribofilm detectable by EDX. Nevertheless, the hybrid condition produced the lowest COF of all cases, while wear resistance remained close to that of pure hBN. This shows that hBN and ZnO acted in a complementary manner, hBN reducing shear stresses and ZnO contributing to surface stabilization. In addition, the worn surface morphology of the hybrid condition displayed a patchy and clustered appearance, which explains why wear remained slightly higher than in the pure hBN case. Nevertheless, in terms of friction, this composition was the most advantageous, producing the lowest coefficient of friction. Surface morphology and EDX analyses under a 60 N load confirmed that the hBN-containing nanolubricant offered the highest wear resistance and the lowest mass loss for the AZ91D magnesium alloy. The dry condition was characterized by a thick oxidative layer, deep grooves, and a high coefficient of friction. In contrast, under hBN lubrication, the surface was significantly smoother, wear tracks were shallower, and debris accumulation was reduced by the protective effect of a lamellar tribofilm. This film, although thin and only weakly detected in the EDX spectrum by a weak N signal due to limited nanoparticle adhesion, still provided an effective barrier against direct metal-to-metal contact. In the 75hBN/25ZnO hybrid formulation, the worn track exhibited a discontinuous morphology with localized compacted regions and smoother zones, suggesting partial film formation. However, the EDX spectra did not show pronounced Zn or N enrichment compared to the base alloy, which indicates that the nanoparticles did not remain firmly attached to the surface but were instead circulated and transferred by the lubricant film during sliding. Despite this, the hybrid condition still achieved the lowest COF, highlighting its advantage in friction performance, even though its wear resistance was slightly lower than that of pure hBN.

Figure 7.

FE-SEM images and EDX results of the worn surfaces obtained at a high load of 60 N under different lubrication conditions: (a) dry, (b) oil, (c) hBN nanoadditive oil, and (d) 75hBN/25ZnO nanoadditive oil.

The findings of this study revealed that both the 100% hBN nanolubricant, with its superior wear resistance, and the 75hBN/25ZnO hybrid formulation, with its low friction performance, stand out prominently. The advantages provided by these two formulations hold significant potential to extend the service life and reduce maintenance requirements of magnesium alloy components operating under high load and repetitive sliding conditions. Their applicability is particularly notable in areas such as engine and transmission components in the automotive sector, lightweight and high-strength structural elements in the aerospace industry, precision moving systems in the defense sector, and connection points exposed to corrosion and wear in the maritime field. Furthermore, due to their ability to form a tribofilm layer that remains stable under high temperature and pressure, these lubricants can also be effectively used in rotating shafts, gears, bearings, and sliding surfaces found in heavy machinery, wind turbines, railway systems, and industrial production lines. In this way, by extending component life and improving energy efficiency, they can contribute to sustainable and environmentally friendly engineering solutions.

Although the present study provides a comprehensive evaluation of the tribological performance of AZ91D magnesium alloy under hybrid hBN/ZnO nanolubrication, certain limitations should be acknowledged. The experiments were conducted at room temperature and under controlled laboratory conditions, which do not fully represent the thermal and mechanical complexities encountered in real operating environments. In addition, while the stability of the nanolubricants was supported, long-term oil aging and high-temperature stability were not investigated in this work. Furthermore, the validation of the findings was limited to pin-on-disk tribometer tests, and the performance of the formulated nanolubricants on actual mechanical components, such as engines or transmission systems, has not yet been addressed. Future research should therefore extend the present findings by exploring the high-temperature durability of hybrid nanolubricants, assessing their long-term stability under oil aging conditions, and verifying their applicability in real components and systems. These directions will be essential to translate the laboratory-scale outcomes into practical, large-scale engineering applications.

4. Conclusions

The experimental results obtained in this study comprehensively demonstrate that nanoadditive lubrication significantly enhances the wear resistance, frictional performance, and surface integrity of the AZ91D magnesium alloy. Systematic pin-on-disk tests supported by FE-SEM and EDX analyses demonstrated that lubrication conditions had a decisive influence on the tribological behavior of AZ91D magnesium alloy. Among all cases, dry sliding produced the highest wear, base oil lubrication reduced wear by more than half, and the incorporation of nanoparticle additives, particularly hBN and hBN-rich hybrids, further minimized wear and friction, leading to the best overall performance. Some of the key findings obtained from this study are summarized below:

- The incorporation of solid nanoparticle additives into SAE 5W-30 motor oil consistently reduced the coefficient of friction (from 0.34 in the dry condition at 10 N to as low as 0.109 with the 75hBN/25ZnO hybrid at 60 N) and wear loss across all tested loads, demonstrating a strong correlation between friction reduction and enhanced wear resistance.

- The pure hBN formulation exhibited the highest wear resistance among all tested lubricants. In this condition, the worn surface displayed smooth morphology with shallow grooves and minimal debris accumulation, while a low average COF of about 0.114 was obtained, confirming the combined effects of lamellar sliding, debris scavenging, and tribofilm protection.

- The 75hBN/25ZnO hybrid formulation achieved the lowest COF of the study (0.116 at 10 N and 0.109 at 60 N) while maintaining wear resistance close to that of pure hBN, indicating a pronounced synergistic effect between the lamellar nanolubricant properties of hBN and the rolling and film-forming capabilities of ZnO.

- FE-SEM observations confirmed that nanoadditive conditions, particularly hBN-rich and optimized hybrid formulations, produced more uniform and continuous tribofilms, while EDX analyses revealed the presence of protective nanolubricant and oxide phases that contributed to improved load-bearing capacity and surface stability.

- A clear inverse relationship between friction and wear was observed, highlighting the critical role of friction control in extending component service life under high-load, repetitive sliding conditions.

These findings indicate that hBN and ZnO nanoadditive lubricants, particularly 100% hBN and 75hBN/25ZnO formulations, have strong potential for use in automotive engine and transmission components, aerospace structural parts, defense industry precision mechanisms, and marine connection points exposed to severe loading and sliding. Their ability to form thermally and mechanically stable tribofilms also makes them suitable for heavy machinery, wind turbines, railway systems, and industrial rotating equipment, where they can extend component life, reduce maintenance requirements, and improve overall energy efficiency. Future research should focus on extending the present findings by investigating the high-temperature stability of hybrid nanolubricants to ensure reliable performance under severe thermal conditions. Long-term oil aging studies are also required to assess the durability and dispersion stability of the nanoparticles during extended service life. In addition, validation on real mechanical components such as engine or transmission parts will be essential to confirm the practical applicability of these nanolubricants in automotive, aerospace, and other high-performance systems.

Funding

The APC was funded by Firat University Research Fund (grant number FUBAP-TEKF.24.20).

Data Availability Statement

The data presented in this study are available upon request from the corresponding author.

Acknowledgments

The author would like to thank the Firat University Research Fund (FÜBAP, grant number FUBAP-TEKF.24.20) for providing material and equipment support for this research study.

Conflicts of Interest

The author declares no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| Al | Aluminium |

| COF | Coefficient of friction |

| EDX | Energy-dispersive X-ray spectroscopy |

| hBN | Hexagonal boron nitride |

| HV | Vickers hardness |

| Mg | Magnesium |

| Mn | Manganese |

| MWCNTs | Multi-walled carbon nanotubes |

| SEM | Scanning electron microscopy |

| SiO2 | Silicon dioxide |

| SLIPS | Slippery liquid-infused porous surface |

| SRO | Sulfur-modified rapeseed oil |

| TiO2 | Titanium dioxide |

| XRD | X-ray diffraction |

| ZnO | Zinc oxide |

References

- Chen, D.; Wang, R.; Huang, Z.; Wu, Y.; Zhang, Y.; Wu, G.; Li, D.; Guo, C.; Jiang, G.; Yu, S. Evolution processes of the corrosion behavior and structural characteristics of plasma electrolytic oxidation coatings on AZ31 magnesium alloy. Appl. Surf. Sci. 2018, 434, 326–335. [Google Scholar] [CrossRef]

- Gurgenc, T.; Altay, O. Surface roughness prediction of wire electric discharge machining (WEDM)-machined AZ91D magnesium alloy using multilayer perceptron, ensemble neural network, and evolving product-unit neural network. Mater. Test. 2022, 64, 350–362. [Google Scholar] [CrossRef]

- Rakoch, A.; Monakhova, E.; Khabibullina, Z.; Serdechnova, M.; Blawert, C.; Zheludkevich, M.; Gladkova, A. Plasma electrolytic oxidation of AZ31 and AZ91 magnesium alloys: Comparison of coatings formation mechanism. J. Magnes. Alloys 2020, 8, 587–600. [Google Scholar] [CrossRef]

- Padhee, C.K.; Masanta, M.; Mondal, A. Feasibility of Al-TiC coating on AZ91 magnesium alloy by TIG alloying method for tribological application. Trans. Nonferrous Met. Soc. China 2020, 30, 1550–1559. [Google Scholar] [CrossRef]

- Gurgenc, T. Microstructure, mechanical properties and ELM based wear loss prediction of plasma sprayed ZrO2-MgO coatings on a magnesium alloy. Mater. Test. 2019, 61, 787–796. [Google Scholar] [CrossRef]

- Nam, D.; Lim, D.; Kim, S.-D.; Seo, D.; Shim, S.E.; Baeck, S.-H. The fabrication of a conversion film on AZ31 containing carbonate product and evaluation of its corrosion resistance. J. Alloys Compd. 2018, 737, 597–602. [Google Scholar] [CrossRef]

- Luo, X.-P.; Wang, X.; Li, Q.-S. Microstructure and mechanical properties of shear-extruded Mg-Sn-Y-Zr alloys. Emerg. Mater. Res. 2016, 5, 74–80. [Google Scholar]

- Srinivas, M.; Pandey, D.; Prasad, T.; Purushothaman, S.; Sankar, M. Comparative tribological studies of additive manufactured as-built and chemically polished AlSi10Mg alloy surfaces. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2025, 239, 789–806. [Google Scholar]

- Zhu, B.; Cui, Y.; Xu, K.; Liu, X.; Ye, F.; Liu, W.; Guo, P.; Wu, Y.; Li, X. Hard-soft-hard layered structure for enhanced mechanical properties in corrugated rolled AZ31 magnesium alloy sheets. J. Mater. Res. Technol. 2025, 35, 3205–3216. [Google Scholar] [CrossRef]

- Sun, X.; Xie, Y.; Meng, X.; Zhang, Z.; Tian, H.; Dong, W.; Dong, J.; Ma, X.; Wang, N.; Huang, Y. Wire-based friction stir additive manufacturing of AZ31B magnesium alloy: Precipitate behavior and mechanical properties. J. Magnes. Alloys 2025, in press. [CrossRef]

- Altay, O.; Gurgenc, T. GJO-MLP: A novel method for hybrid metaheuristics multi-layer perceptron and a new approach for prediction of wear loss of AZ91D magnesium alloy worn at dry, oil, and H-BN nanoadditive oil. Surf. Rev. Lett. 2024, 31, 2450048. [Google Scholar]

- Senthilkumar, N. Characterization of Graphene and Titanium Carbide Reinforced Magnesium Alloy Composite for Transmission Housings in Automobile; Technical Paper; SAE: Warrendale, PA, USA, 2024. [Google Scholar]

- Kanaginahal, G.M.; Kiran, M.; Shahapurkar, K.; Mahale, R.S.; Kakkamari, P. Automobile Applications of Mechanically Alloyed Magnesium and Titanium Material. In Mechanically Alloyed Novel Materials: Processing, Applications, and Properties; Springer: Berlin/Heidelberg, Germany, 2024; pp. 379–406. [Google Scholar]

- Wang, G.G.; Weiler, J. Recent developments in high-pressure die-cast magnesium alloys for automotive and future applications. J. Magnes. Alloys 2023, 11, 78–87. [Google Scholar] [CrossRef]

- Jouini, N.; Ruslan, M.S.M.; Ghani, J.A.; Che Haron, C.H. Sustainable high-speed milling of magnesium alloy AZ91D in dry and cryogenic conditions. Sustainability 2023, 15, 3760. [Google Scholar]

- Okoth, G.H.; Ndeda, R.; Raghupatruni, P.; Olakanmi, E.O. Trends in Lightweighting for Automotive Applications: A Case Study. J. Sustain. Res. Eng. 2024, 8, 50–67. [Google Scholar]

- Sevvel, P.; Gunasekaran, J.; Roy, J.V.; Sivaramakrishnan, A.; Choudri, V.; Murugan, M.A. Multi-Objective Optimization of Parameters during Friction Stir Welding of AM50A Mg Alloy Using Genetic Algorithm and Desirability Function Approach for Maximizing Tensile Strength and Hardness. J. Mater. Eng. Perform. 2025, 1–20. [Google Scholar] [CrossRef]

- Yue, X.; Sha, L. Corrosion resistance of AZ91D magnesium alloy modified by rare earths-laser surface treatment. J. Rare Earths 2007, 25, 201–203. [Google Scholar] [CrossRef]

- Vignesh, R.V.; Padmanaban, R. Forecasting tribological properties of wrought AZ91D magnesium alloy using soft computing model. Russ. J. Non-Ferr. Met. 2018, 59, 135–141. [Google Scholar] [CrossRef]

- Shah, R.; Chen, R.; Woydt, M.; Baumann, C.; Jurs, J.; Iaccarino, P. High temperature tribology under linear oscillation motion. Lubricants 2020, 9, 5. [Google Scholar] [CrossRef]

- Beake, B.D. Elevated temperature nanomechanics of coatings for high-temperature applications: A review. Emergent Mater. 2021, 4, 1531–1545. [Google Scholar] [CrossRef]

- Koly, F.A.; Bhattacharjee, A.; Murthy, N.; Gould, B.; Ajayi, O.; Walck, S.; Martin, C.L.; Berkebile, S.; Burris, D.L. Methods to observe tribological failures in self-mated steel contacts. Tribol. Lett. 2025, 73, 35. [Google Scholar] [CrossRef]

- Holmberg, K.; Erdemir, A. Influence of tribology on global energy consumption, costs and emissions. Friction 2017, 5, 263–284. [Google Scholar] [CrossRef]

- Zhai, W.; Bai, L.; Zhou, R.; Fan, X.; Kang, G.; Liu, Y.; Zhou, K. Recent progress on wear-resistant materials: Designs, properties, and applications. Adv. Sci. 2021, 8, 2003739. [Google Scholar]

- Waqas, M.; Zahid, R.; Bhutta, M.U.; Khan, Z.A.; Saeed, A. A review of friction performance of lubricants with nano additives. Materials 2021, 14, 6310. [Google Scholar] [CrossRef]

- Orman, R.Ç. Effect of Adding Hexagonal Boron Nitride (hBN) Nano-Powder to Lubricant on Performance and Emissions in a Two-Stroke Gasoline Engine. Sustainability 2023, 15, 14605. [Google Scholar] [CrossRef]

- Alqahtani, B.; Hoziefa, W.; Abdel Moneam, H.M.; Hamoud, M.; Salunkhe, S.; Elshalakany, A.B.; Abdel-Mottaleb, M.; Davim, J.P. Tribological Performance and Rheological Properties of Engine Oil with Graphene Nano-Additives. Lubricants 2022, 10, 137. [Google Scholar] [CrossRef]

- Ranjbarzadeh, R.; Chaabane, R. Experimental study of thermal properties and dynamic viscosity of graphene oxide/oil nano-lubricant. Energies 2021, 14, 2886. [Google Scholar] [CrossRef]

- Lee, C.-G.; Hwang, Y.-J.; Choi, Y.-M.; Lee, J.-K.; Choi, C.; Oh, J.-M. A study on the tribological characteristics of graphite nano lubricants. Int. J. Precis. Eng. Manuf. 2009, 10, 85–90. [Google Scholar] [CrossRef]

- Dinesh, R.; Prasad, M.G.; Kumar, R.R.; Santharaj, N.J.; Santhip, J.; Raaj, A.A. Investigation of tribological and thermophysical properties of engine oil containing nano additives. Mater. Today Proc. 2016, 3, 45–53. [Google Scholar]

- Esfe, M.H.; Rostamian, H.; Sarlak, M.R.; Rejvani, M.; Alirezaie, A. Rheological behavior characteristics of TiO2-MWCNT/10w40 hybrid nano-oil affected by temperature, concentration and shear rate: An experimental study and a neural network simulating. Phys. E Low-Dimens. Syst. Nanostruct. 2017, 94, 231–240. [Google Scholar] [CrossRef]

- Saini, V.; Bijwe, J.; Seth, S.; Ramakumar, S. Role of base oils in developing extreme pressure lubricants by exploring nano-PTFE particles. Tribol. Int. 2020, 143, 106071. [Google Scholar] [CrossRef]

- Liu, J.; Xiang, S.; Zhou, X.; Lin, S.; Dong, K.; Liu, Y.; He, D.; Fan, Y.; Liu, Y.; Xiong, B. Lubrication performance promotion of GTL base oil by BN nanosheets via cascade centrifugation-assisted liquid-phase exfoliation. Lubricants 2025, 13, 281. [Google Scholar]

- Azman, N.F.; Samion, S.; Paiman, Z.; Hamid, M.K.A. Tribological performance and mechanism of graphite, hBN and MoS2 as nano-additives in palm kernel oil-based lubricants: A comparative study. J. Mol. Liq. 2024, 410, 125616. [Google Scholar]

- Nagarajan, T.; Sridewi, N.; Wong, W.P.; Walvekar, R.; Khanna, V.; Khalid, M. Synergistic performance evaluation of MoS2–hBN hybrid nanoparticles as a tribological additive in diesel-based engine oil. Sci. Rep. 2023, 13, 12559. [Google Scholar] [CrossRef]

- Mobarhan, G.; Zolriasatein, A.; Ghahari, M.; Jalili, M.; Rostami, M. The enhancement of wear properties of compressor oil using MoS2 nano-additives. Adv. Powder Technol. 2022, 33, 103648. [Google Scholar] [CrossRef]

- Thottackkad, M.V.; Perikinalil, R.K.; Kumarapillai, P.N. Experimental evaluation on the tribological properties of coconut oil by the addition of CuO nanoparticles. Int. J. Precis. Eng. Manuf. 2012, 13, 111–116. [Google Scholar] [CrossRef]

- Farbod, M. Morphology dependence of thermal and rheological properties of oil-based nanofluids of CuO nanostructures. Colloids Surf. A Physicochem. Eng. Asp. 2015, 474, 71–75. [Google Scholar] [CrossRef]

- Sepyani, K.; Afrand, M.; Esfe, M.H. An experimental evaluation of the effect of ZnO nanoparticles on the rheological behavior of engine oil. J. Mol. Liq. 2017, 236, 198–204. [Google Scholar] [CrossRef]

- Guo, Z.; Zhang, Y.; Wang, J.; Gao, C.; Zhang, S.; Zhang, P.; Zhang, Z. Interactions of Cu nanoparticles with conventional lubricant additives on tribological performance and some physicochemical properties of an ester base oil. Tribol. Int. 2020, 141, 105941. [Google Scholar] [CrossRef]

- Chen, Y.; Renner, P.; Liang, H. Dispersion of nanoparticles in lubricating oil: A critical review. Lubricants 2019, 7, 7. [Google Scholar] [CrossRef]

- Thachnatharen, N.; Khalid, M.; Arulraj, A.; Sridewi, N. Tribological performance of hexagonal boron nitride (hBN) as nano-additives in military grade diesel engine oil. Mater. Today Proc. 2022, 50, 70–73. [Google Scholar] [CrossRef]

- Bu, H.; Zheng, H.; Zhou, H.; Zhang, H.; Yang, Z.; Liu, Z.; Wang, H.; Xu, Q. The role of sp 2 and sp 3 hybridized bonds on the structural, mechanical, and electronic properties in a hard BN framework. RSC Adv. 2019, 9, 2657–2665. [Google Scholar]

- Vats, P.; Khanna, N.; Kumar, A.; Gajrani, K.K. Tribological performance of hBN and graphene-enriched hybrid nanofluids on tool wear and hole surface quality in drilling: A comparative study on WAAM and wrought Inconel 625. Wear 2025, 574–575, 206090. [Google Scholar] [CrossRef]

- Honglin, M.; Haichao, Z.; Honggang, T.; Guozheng, M.; Ming, L.; Haidou, W.; Fengkuan, X.; Zhihai, C. Effects of hBN content and particle size on microstructure, mechanical and tribological properties of NiCr-Cr3C2-hBN coatings. Surf. Coat. Technol. 2024, 478, 130330. [Google Scholar]

- Senyk, S.; Chodkiewicz, A.; Gocman, K.; Szczęśniak, B.; Kałdoński, T. Hexagonal nano and micro boron nitride: Properties and lubrication applications. Materials 2022, 15, 955. [Google Scholar] [CrossRef]

- Abdullah, M.I.H.C.; Abdollah, M.F.B.; Amiruddin, H.; Tamaldin, N.; Nuri, N.R.M. Optimization of tribological performance of hBN/AL2O3Nanoparticles as engine oil additives. Procedia Eng. 2013, 68, 313–319. [Google Scholar] [CrossRef]

- Gara, L.; Zou, Q. Friction and wear characteristics of oil-based ZnO nanofluids. Tribol. Trans. 2013, 56, 236–244. [Google Scholar] [CrossRef]

- Alghani, W.; Karim, M.; Bagheri, S.; Zaharinie, T.; Gulzar, M. Formulation, tribological performance, and characterization of base oil with ZnO, graphene, and ZnO/graphene nanoparticles additives. Mater. Werkst. 2020, 51, 1515–1532. [Google Scholar]

- Bhaumik, S.; Maggirwar, R.; Datta, S.; Pathak, S. Analyses of anti-wear and extreme pressure properties of castor oil with zinc oxide nano friction modifiers. Appl. Surf. Sci. 2018, 449, 277–286. [Google Scholar] [CrossRef]

- Esfe, M.H.; Arani, A.A.A.; Esfandeh, S. Improving engine oil lubrication in light-duty vehicles by using of dispersing MWCNT and ZnO nanoparticles in 5W50 as viscosity index improvers (VII). Appl. Therm. Eng. 2018, 143, 493–506. [Google Scholar]

- Jiang, W.; Ling, D. Friction and wear performances of magnesium alloy against steel under lubrication of rapeseed oil with S-containing additive. Trans. Nonferrous Met. Soc. China 2011, 21, 2649–2653. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, L.; Liu, A.; Wu, C.; Li, W. Tribological performance of silicone oil based Al2O3 nano lubricant for an Mg alloy subjected to sliding at elevated temperatures. Tribol. Int. 2022, 175, 107779. [Google Scholar] [CrossRef]

- Yin, Y.; Yu, H.; Wang, H.; Ji, X.; Song, Z.; Zhou, X.; Wei, M.; Shi, P.; Zhang, W.; Zhao, C. Tribological behaviors of AZ91D magnesium alloy under the lubrication of oil suspended synthetic magnesium silicate hydroxide nanotubes. J. Magnes. Alloys 2025, 13, 379–397. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, L.; Wu, C. Experimental evaluation of a silicone oil as an oxidation inhibitor for magnesium alloy under contact sliding at elevated temperatures. Wear 2022, 506, 204451. [Google Scholar] [CrossRef]

- Zhou, X.; Li, L.; Wen, D.; Liu, X.; Wu, C. Effect of hybrid ratio on friction and wear behavior of AZ91D matrix nanocomposites under oil lubricated conditions. Trans. Nonferrous Met. Soc. China 2018, 28, 440–450. [Google Scholar] [CrossRef]

- Huang, W.; Du, C.; Li, Z.; Liu, M.; Liu, W. Tribological characteristics of magnesium alloy using N-containing compounds as lubricating additives during sliding. Wear 2006, 260, 140–148. [Google Scholar] [CrossRef]

- Xie, H.; Jiang, B.; Liu, B.; Wang, Q.; Xu, J.; Pan, F. An investigation on the tribological performances of the SiO2/MoS2 hybrid nanofluids for magnesium alloy-steel contacts. Nanoscale Res. Lett. 2016, 11, 329. [Google Scholar] [CrossRef]

- Kharb, S.S.; Khatkar, S.K.; Charak, A.; Thakur, A. Tribological investigation of AZ91/SiC magnesium hybrid composite under dry, oil and nanofluids lubricating conditions. Silicon 2021, 13, 1313–1323. [Google Scholar] [CrossRef]

- Yao, W.; Qin, J.; Chen, Y.; Wu, L.; Jiang, B.; Pan, F. SiO2 nanoparticles-containing slippery-liquid infused porous surface for corrosion and wear resistance of AZ31 Mg alloy. Mater. Des. 2023, 227, 111721. [Google Scholar] [CrossRef]