The Effect of In Situ Boron Reinforcement on the Microstructure and Tribological Performances of a Biocompatible Ti-30Zr-10Ta Alloy Fabricated by Powder Metallurgy

Abstract

1. Introduction

2. Materials and Methods

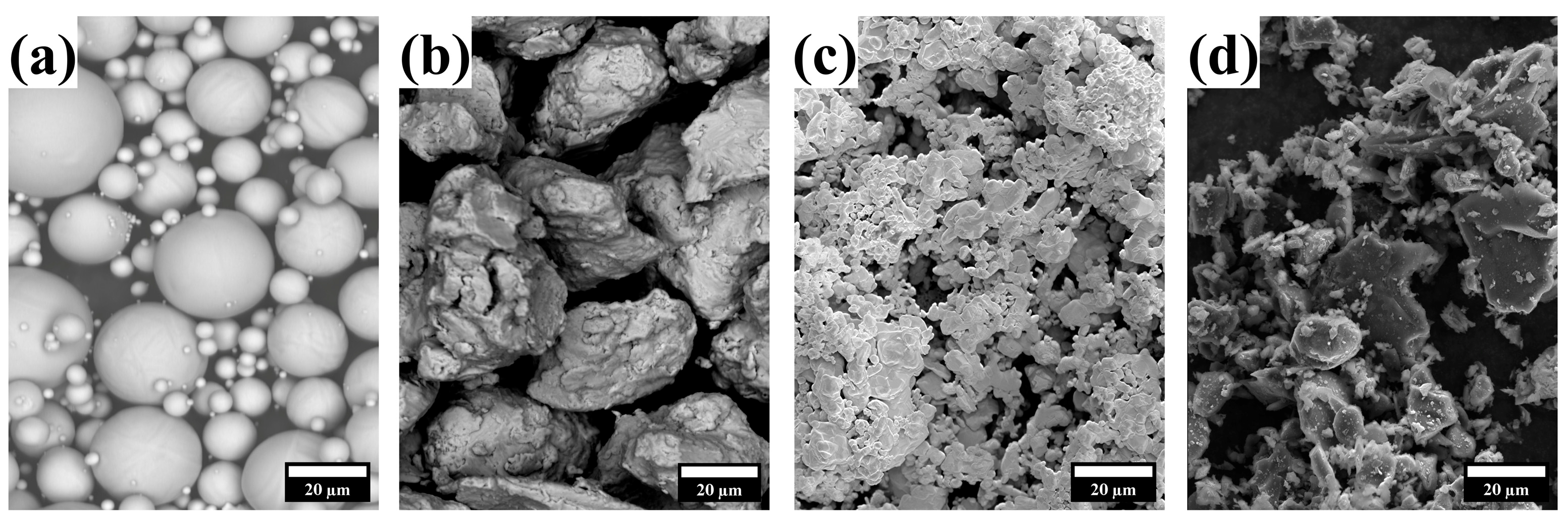

2.1. Sample Preparation

2.2. Microstructural and Hardness Characterization

2.3. Tribological Tests

3. Results and Discussion

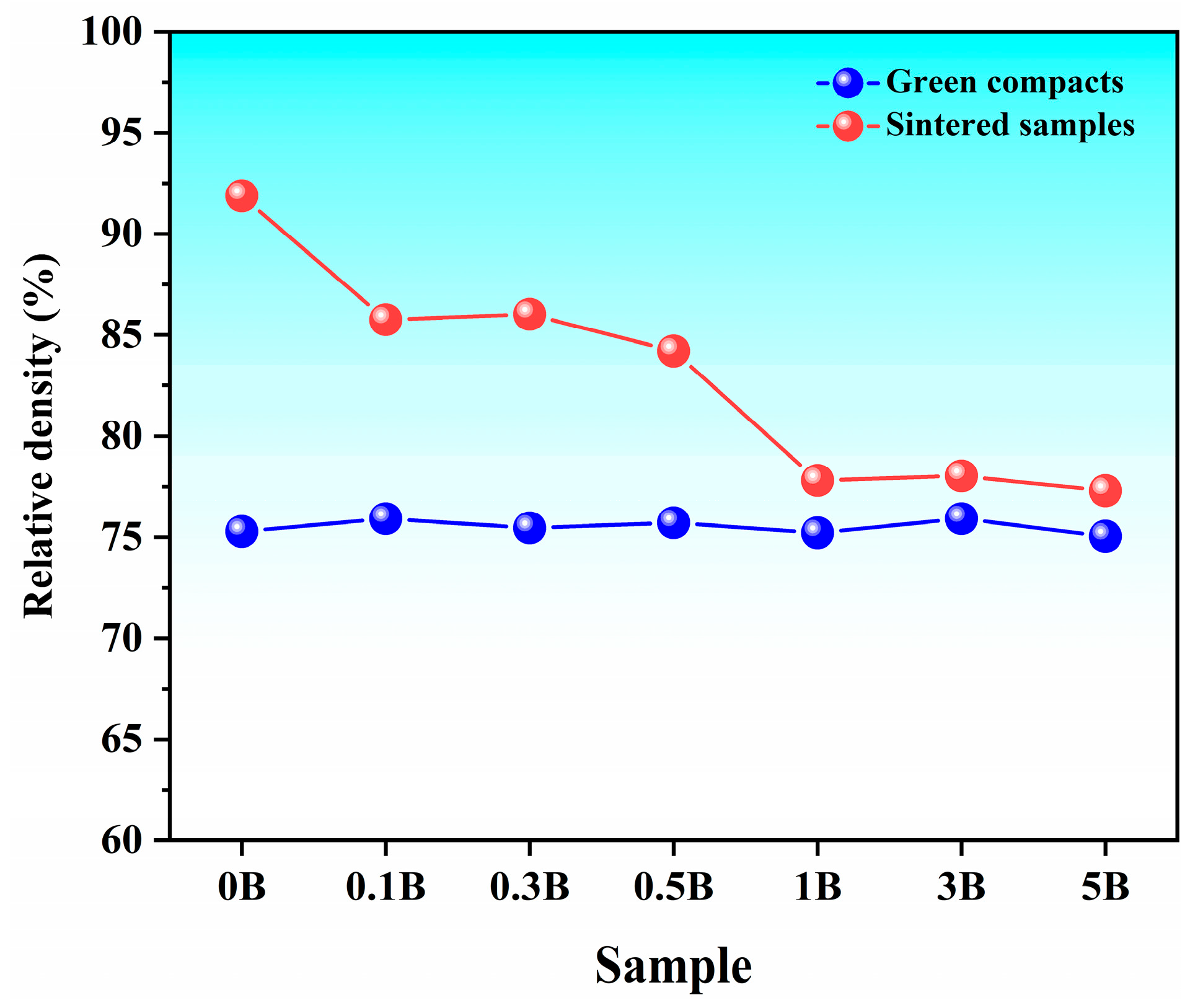

3.1. Densification of Samples

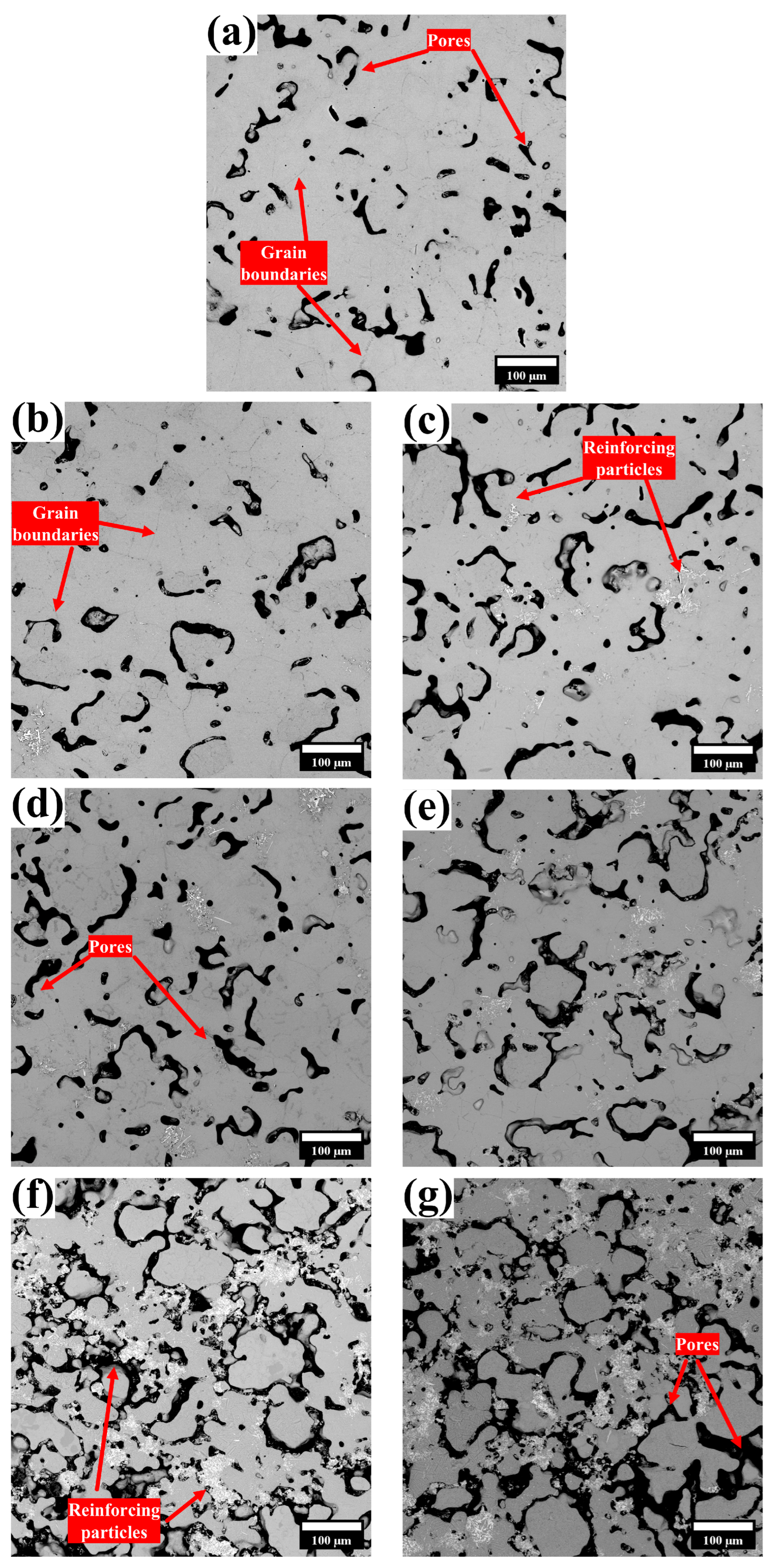

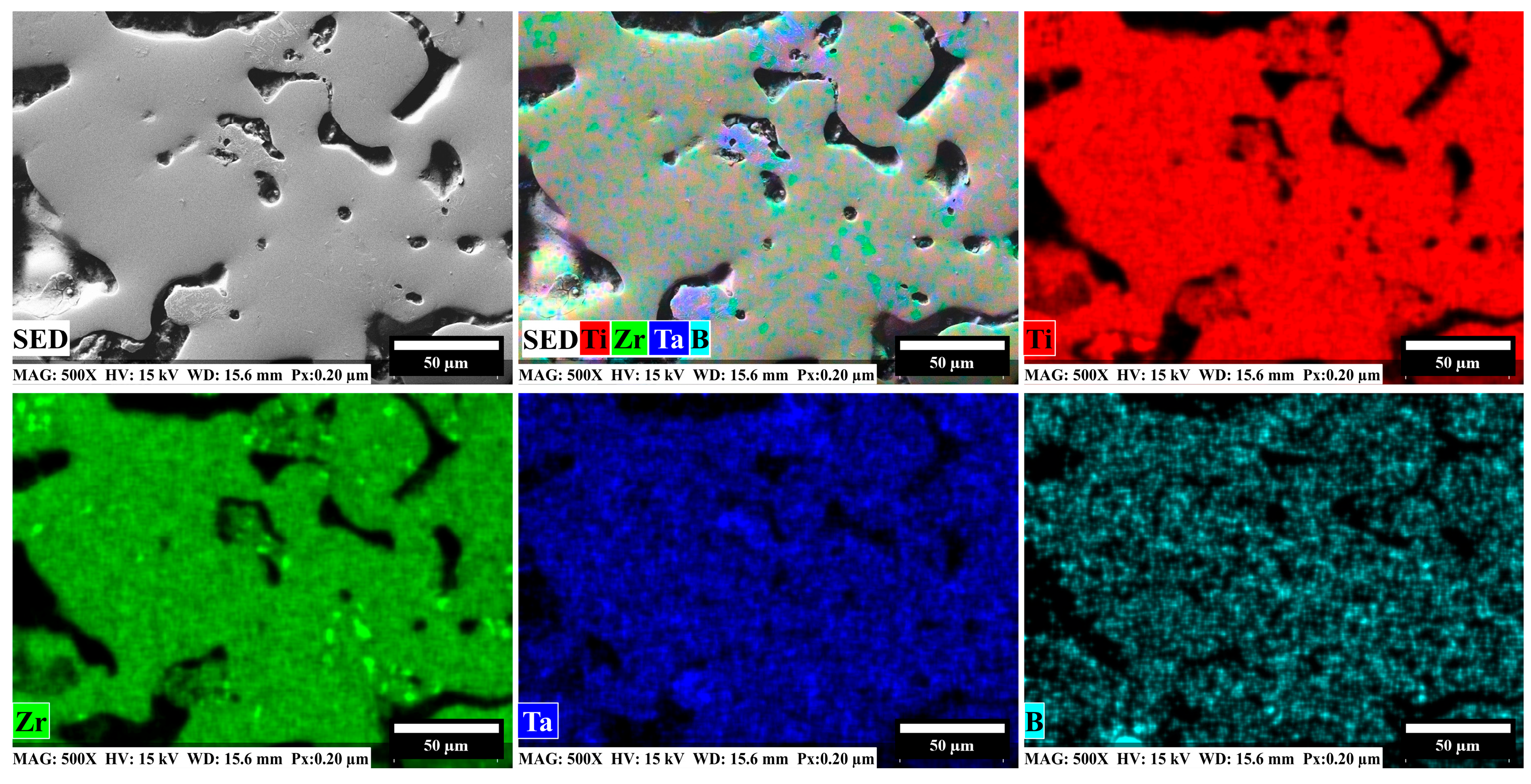

3.2. Microstructural Analysis

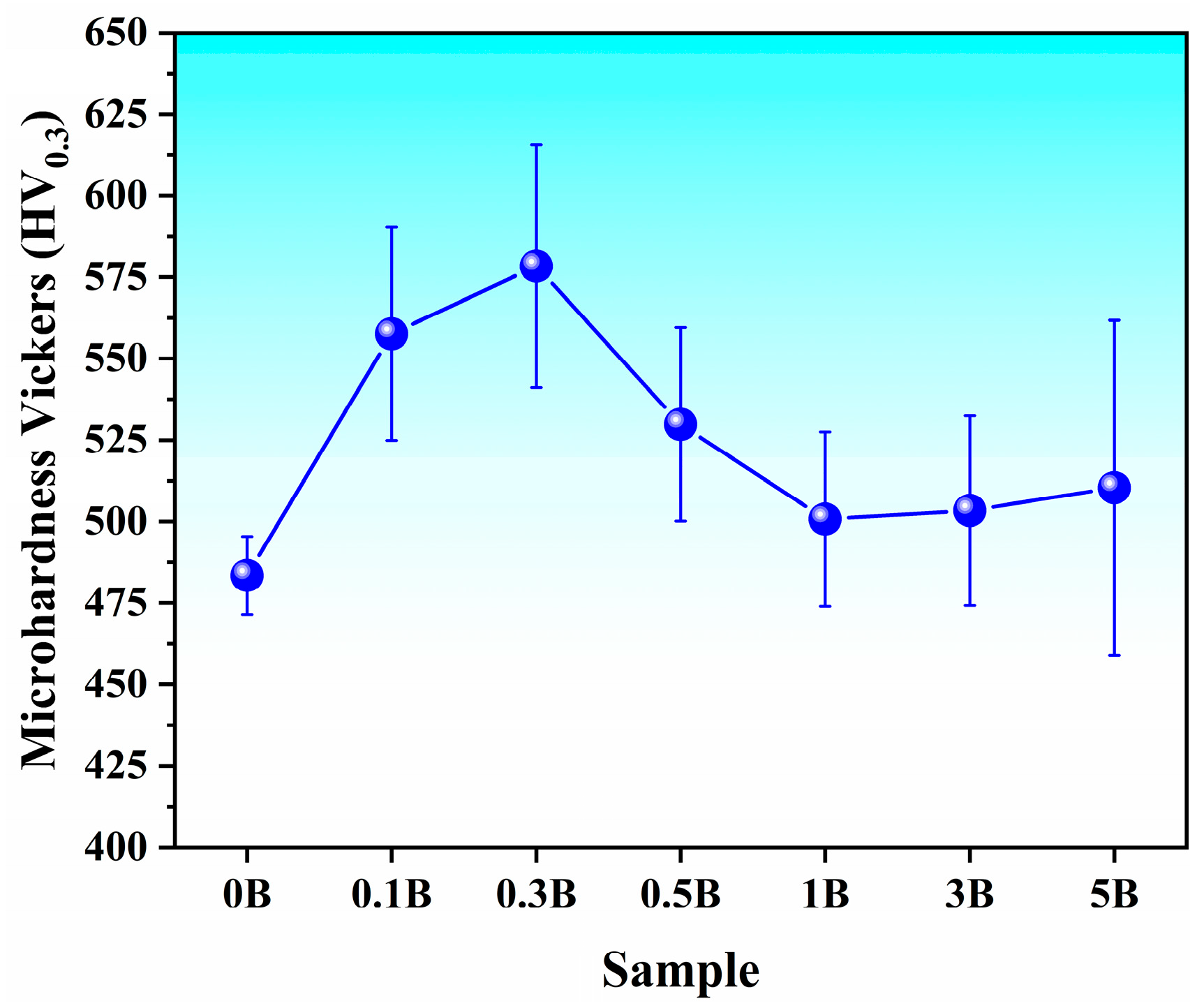

3.3. Microhardness Evaluation

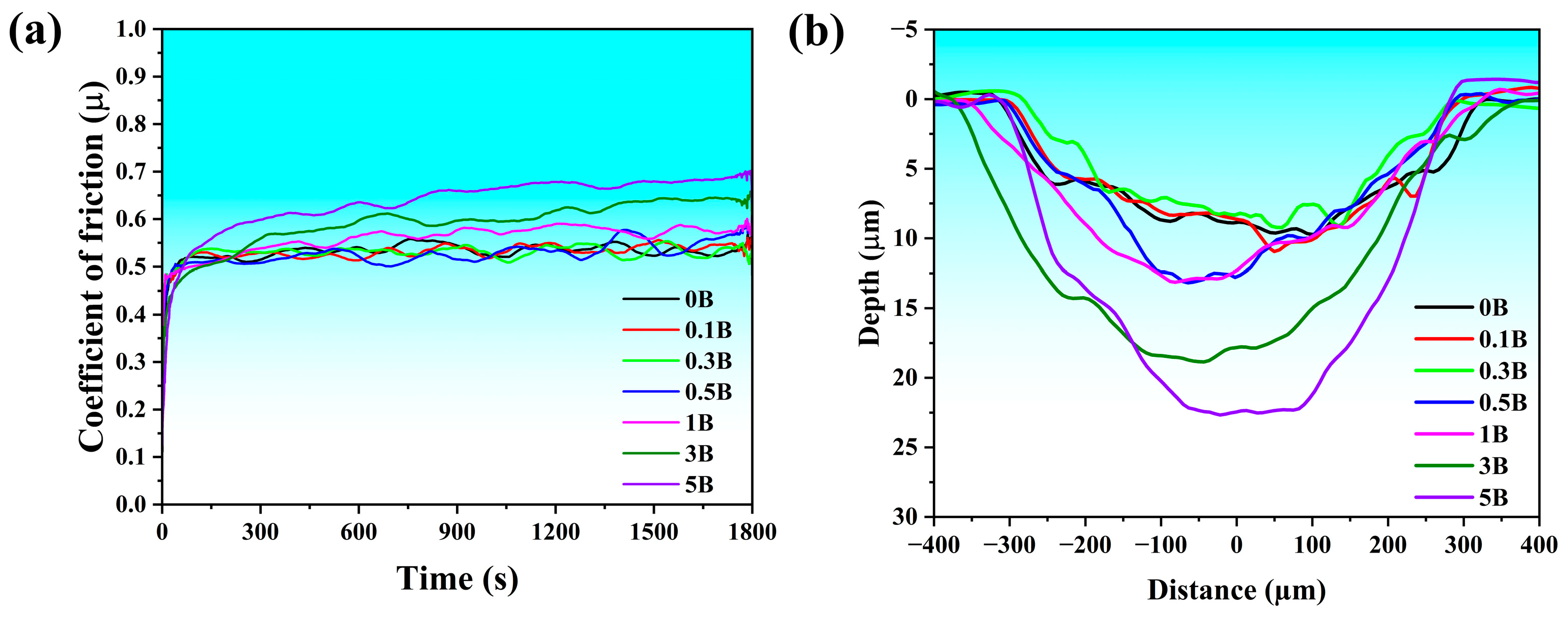

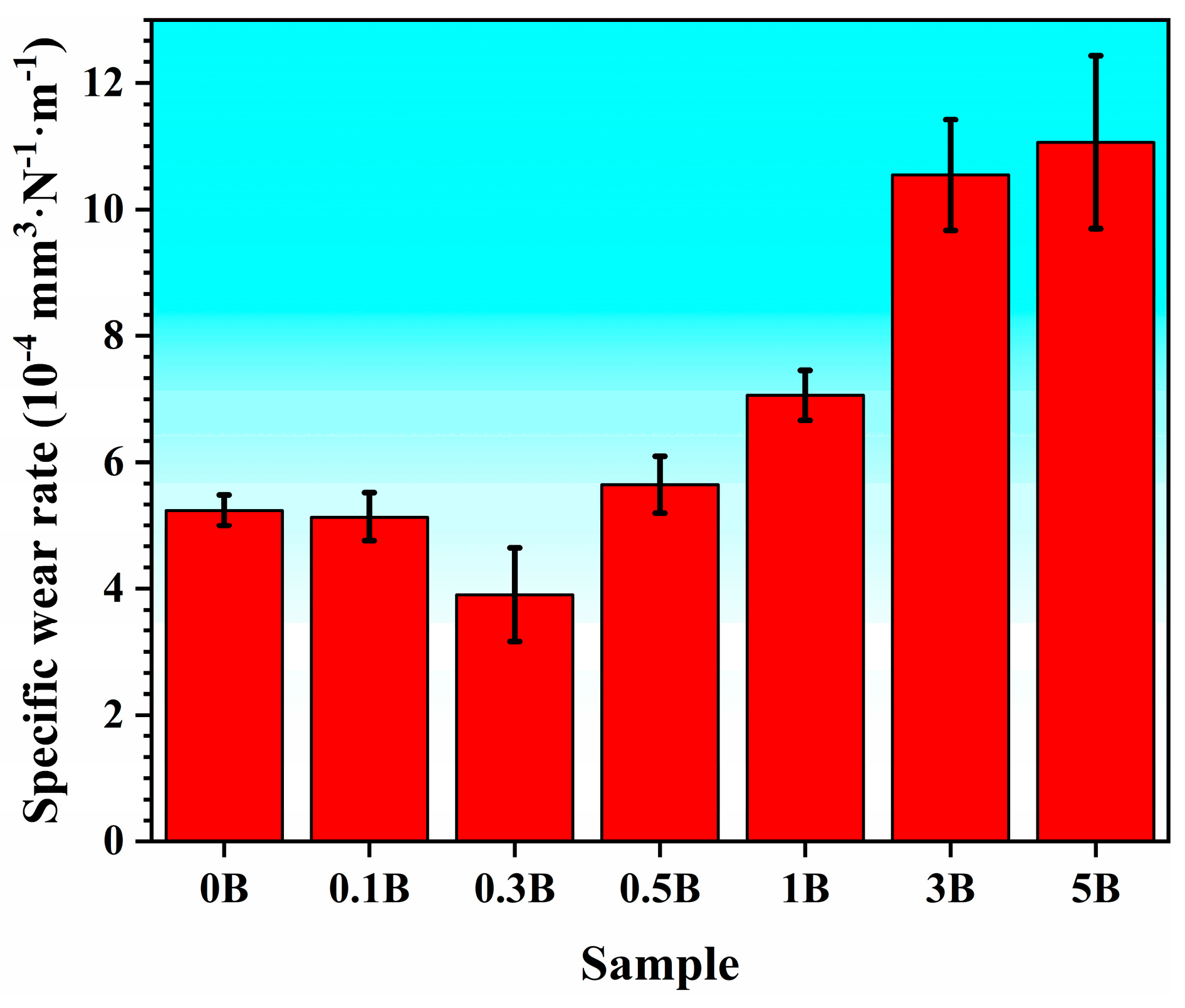

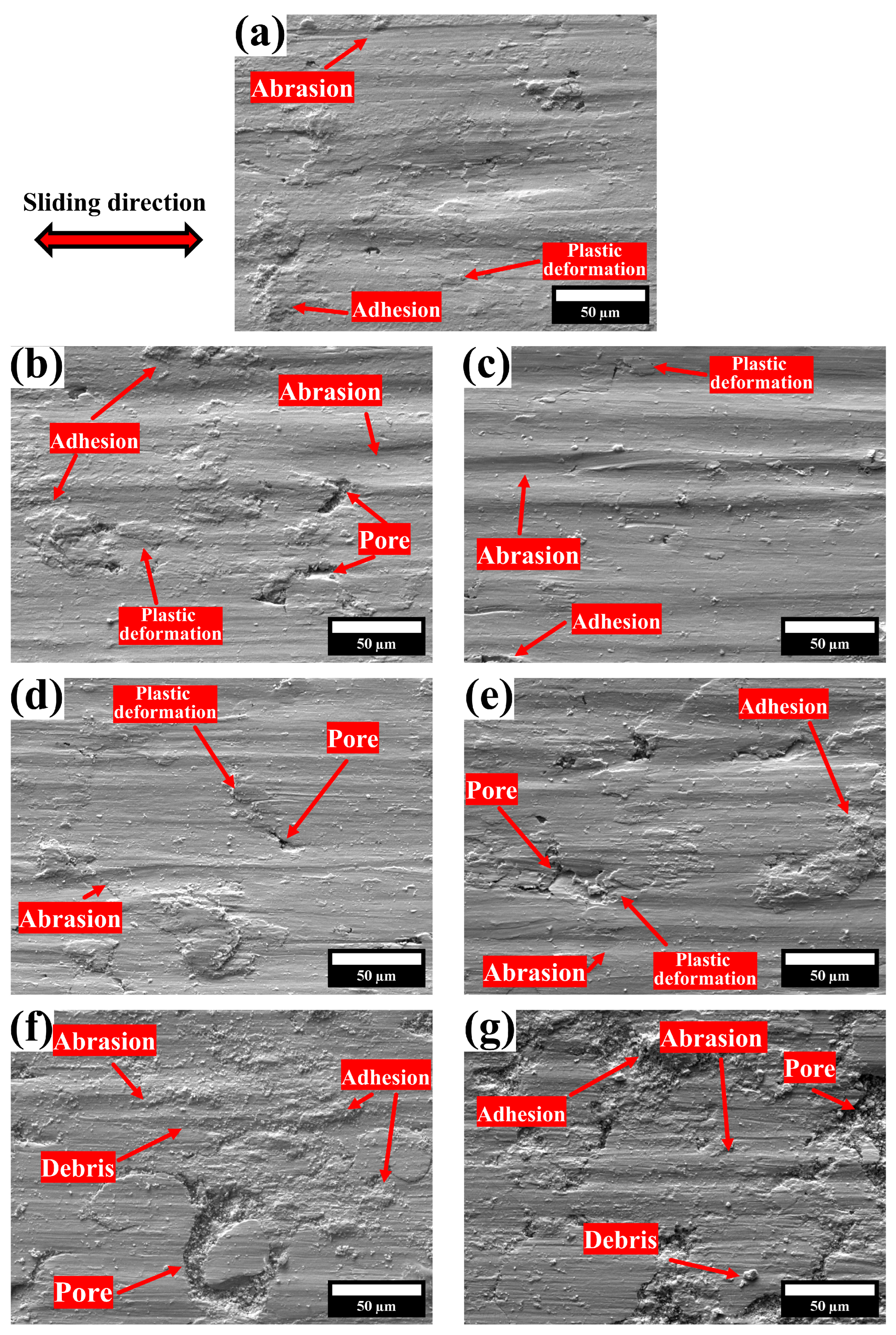

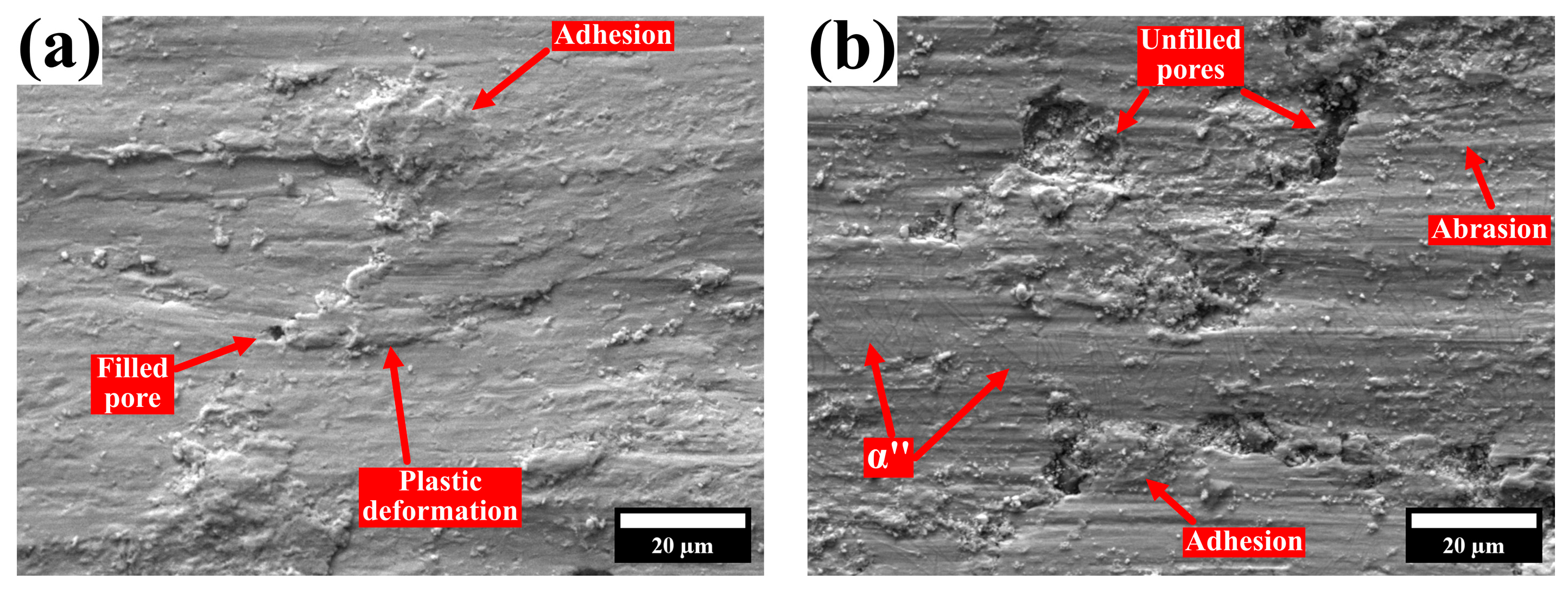

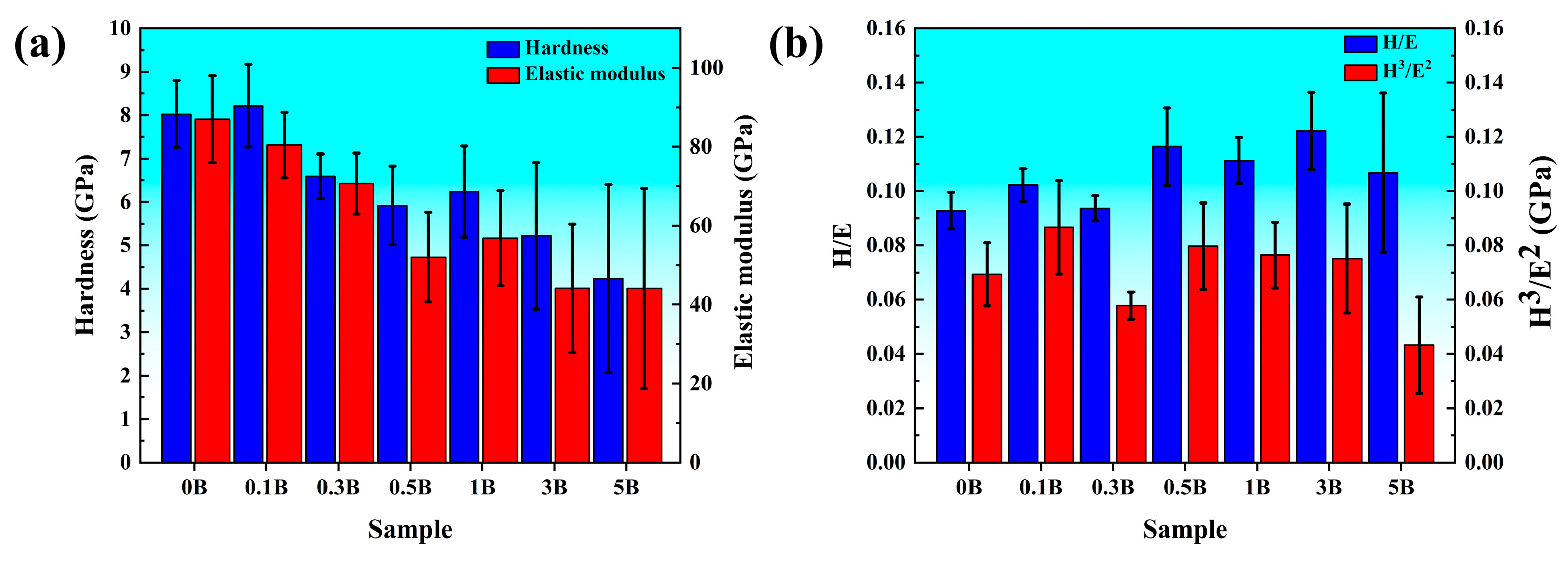

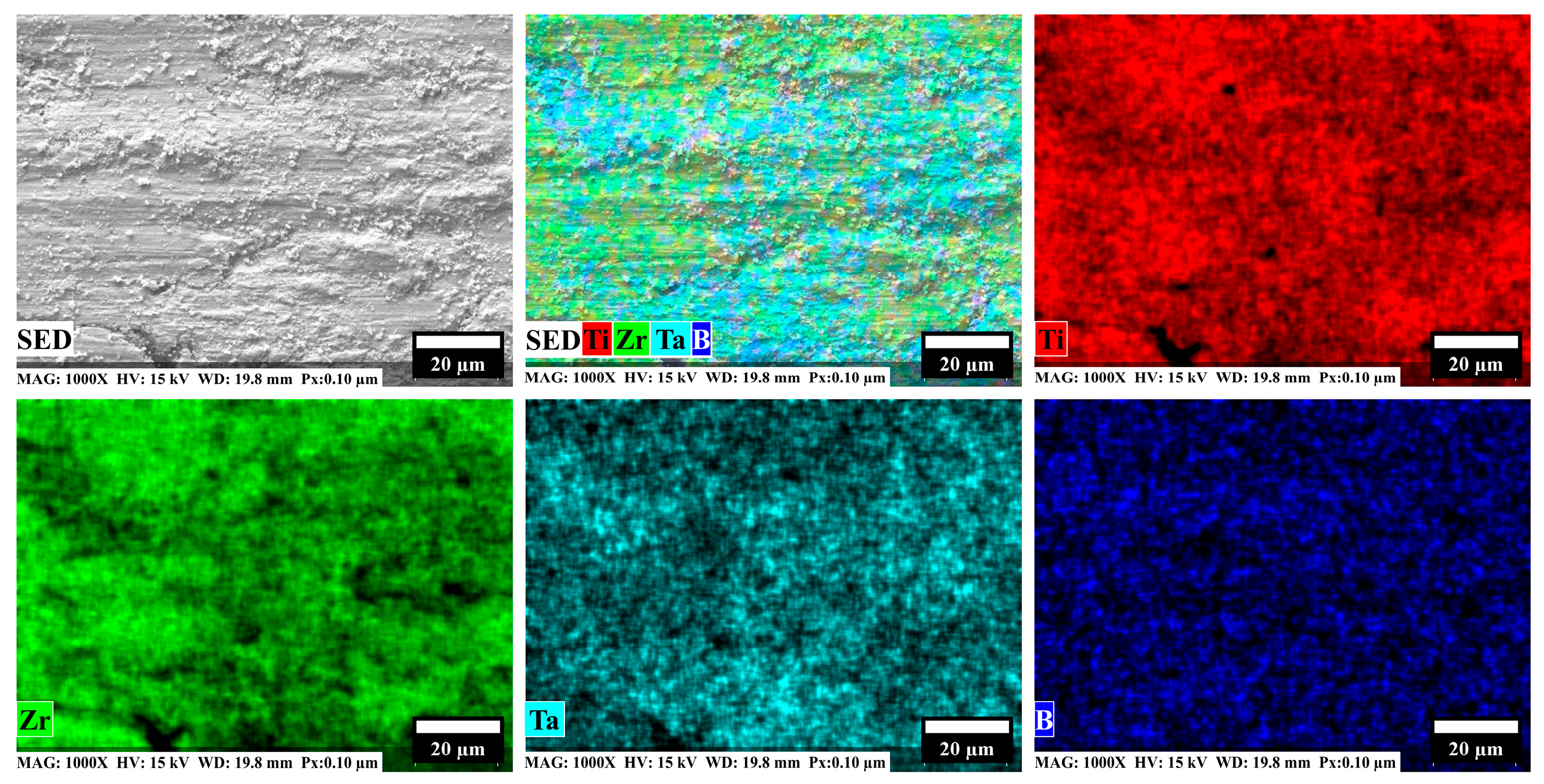

3.4. Tribological Behavior

4. Conclusions

- XRD and SEM analysis demonstrated that the Ti-30Zr-10Ta alloy mainly comprised β-Ti and the α″ phases. Additionally, the boron additions resulted in both the increase in the martensitic α″ phase amount and the in situ precipitation of intermetallic phases such as TiB, TaB, and TaB2, mainly configured as whiskers.

- Boride formation progressively reduced the relative density of the sintered samples due to the hindrance of sinterable contacts. Despite the density decrease, the solid solution of boron in the matrix caused the alloy to harden by up to 19.63% with lower boron additions (0.3 wt.%); however, this trend diminished with further additions due to increased porosity and the consumption of Ta to form borides.

- Instrumented indentation confirmed a consistent decrease in both hardness and elastic modulus as the boron content increased, which was attributed to the increase in a softer martensitic α″ phase with higher boron levels. Furthermore, the H/E ratio indicated a more elastic contact with the increase in martensite, and the H3/E2 parameter showed higher wear resistance in samples with lower boron addition, which declined with greater reinforcement.

- The Ti-30Zr-10Ta alloy with 0.3 wt.% boron exhibited the highest wear resistance, demonstrating a 25.5% reduction in wear rate compared to the unreinforced alloy. For samples with higher boron content (1, 3, and 5 wt.%), the wear rate and coefficient of friction increased, as the in situ formed boride particles acted as a three-body abrasive, causing more severe wear.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Baskaran, P.; Muthiah, B.; Uthirapathy, V. A systematic review on biomaterials and their recent progress in biomedical applications: Bone tissue engineering. Rev. Inorg. Chem. 2025. [Google Scholar] [CrossRef]

- Nouri, A.; Hodgson, P.; Wen, C. Biomimetic Porous Titanium Scaffolds for Orthopedic and Dental Applications; Mukherjee, A., Ed.; Biomimetics Learning from Nature, Chapter 21; InTech: Rijek, Croatia, 2010. [Google Scholar]

- Li, S.; Kang, S.W.; Kim, J.H.; Nam, T.-H.; Yeom, J.-T. Superelastic metastable Ti-Mo-Sn alloys with high elastic admissible strain for potential bio-implant applications. J. Mater. Sci. Technol. 2023, 163, 45–58. [Google Scholar] [CrossRef]

- Abdel-Hady, M.; Fuwa, H.; Hinoshita, K.; Kimura, H.; Shinzato, Y.; Morinaga, M. Phase stability change with Zr content in β-type Ti–Nb alloys. Scr. Mater. 2007, 57, 1000–1003. [Google Scholar] [CrossRef]

- Si, K.; Wang, X.; Yin, Z.; Yang, Y.; Wu, S.; Li, G.; Zhang, K.; Wang, H.; Huang, A. Influence of Oxygen and Zirconium Contents on the Mechanical Properties of Ti-23Nb-0.7Ta-Zr-O Alloys. Metals 2022, 12, 1018. [Google Scholar] [CrossRef]

- Gonzalez, E.D.; Fukumasu, N.K.; Afonso, C.R.M.; Nascente, P.A.P. Impact of Zr content on the nanostructure, mechanical, and tribological behaviors of β-Ti-Nb-Zr ternary alloy coatings. Thin Solid Film. 2021, 721, 138565. [Google Scholar] [CrossRef]

- Musi, M.; Kardos, S.; Hatzenbichler, L.; Holec, D.; Stark, A.; Allen, M.; Güther, V.; Clemens, H.; Spoerk-Erdely, P. The effect of zirconium on the Ti-(42-46 at.%)Al system. Acta Mater. 2022, 241, 118414. [Google Scholar] [CrossRef]

- Sharma, A.; Waddell, J.N.; Li, K.C.; Sharma, L.A.; Prior, D.J.; Duncan, W.J. Is titanium–zirconium alloy a better alternative to pure titanium for oral implant? Composition, mechanical properties, and microstructure analysis. Saudi Dent. J. 2021, 33, 546–553. [Google Scholar] [CrossRef]

- Kim, K.M.; Kim, H.Y.; Miyazaki, S. Effect of Zr Content on Phase Stability, Deformation Behavior, and Young’s Modulus in Ti–Nb–Zr Alloys. Materials 2020, 13, 476. [Google Scholar] [CrossRef]

- Franzone, J.M.; Sargent, B.M.; Do, A.N.D.; Knue, M.; Marini, J.C.; Kruse, R.W. Stress Shielding in the Setting of Osteogenesis Imperfecta and the Effect of Downsizing an Intramedullary Rod: A Case Report. JBJS Case Connect. 2021, 11, e20. [Google Scholar] [CrossRef]

- Li, H.; Yao, Z.; Zhang, J.; Cai, X.; Li, L.; Liu, G.; Liu, J.; Cui, L.; Huang, J. The progress on physicochemical properties and biocompatibility of tantalum-based metal bone implants. SN Appl. Sci. 2020, 2, 671. [Google Scholar] [CrossRef]

- Wang, C.; Cai, Q.; Liu, J.; Yan, X. Strengthening mechanism of lamellar-structured Ti–Ta alloys prepared by powder metallurgy. J. Mater. Res. Technol. 2022, 21, 2868–2879. [Google Scholar] [CrossRef]

- Lauhoff, C.; Nobach, M.; Medvedev, A.; Arold, T.; Torrent, C.; Elambasseril, J.; Krooß, P.; Stenzel, M.; Weinmann, M.; Xu, W.; et al. Electron beam powder bed fusion of Ti-30Ta high-temperature shape memory alloy: Microstructure and phase transformation behaviour. Virtual Phys. Prototyp. 2024, 19, e2358107. [Google Scholar] [CrossRef]

- Chávez, J.; Alemán, O.J.; Martínez, M.F.; Vergara-Hernández, H.J.; Olmos, L.; Garnica-González, P.; Bouvard, D. Characterization of Ti6Al4V–Ti6Al4V/30Ta Bilayer Components Processed by Powder Metallurgy for Biomedical Applications. Met. Mater. Int. 2020, 26, 205–220. [Google Scholar] [CrossRef]

- Kuroda, P.A.B.; dos Santos, R.F.M.; Grandini, C.R.; Afonso, C.R.M. Unveiling the effect of Nb and Zr additions on microstructure and properties of β Ti-25Ta alloys for biomedical applications. Mater. Charact. 2024, 207, 113577. [Google Scholar] [CrossRef]

- Dercz, G.; Matuła, I.; Zubko, M.; Kazek-Kęsik, A.; Maszybrocka, J.; Simka, W.; Dercz, J.; Świec, P.; Jendrzejewska, I. Synthesis of porous Ti–50Ta alloy by powder metallurgy. Mater. Charact. 2018, 142, 124–136. [Google Scholar] [CrossRef]

- Zhao, D.; Han, C.; Li, Y.; Li, J.; Zhou, K.; Wei, Q.; Liu, J.; Shi, Y. Improvement on mechanical properties and corrosion resistance of titanium-tantalum alloys in-situ fabricated via selective laser melting. J. Alloys Compd. 2019, 804, 288–298. [Google Scholar] [CrossRef]

- Zhang, R.; Lin, A. First principles study of Ti-Zr-Ta alloy phase stability and elastic properties. Mater. Res. Express 2023, 10, 026503. [Google Scholar]

- Biesiekierski, A.; Ping, D.; Li, Y.; Lin, J.; Munir, K.S.; Yamabe-Mitarai, Y.; Wen, C. Extraordinary high strength Ti-Zr-Ta alloys through nanoscaled, dual-cubic spinodal reinforcement. Acta Biomater. 2017, 53, 549–558. [Google Scholar] [CrossRef]

- Hussein, M.A.; Mohammed, A.S.; Al-Aqeeli, N. Wear Characteristics of Metallic Biomaterials: A Review. Materials 2015, 8, 2749–2768. [Google Scholar] [CrossRef]

- Pooja, K.; Tarannum, N.; Chaudhary, P. Metal matrix composites: Revolutionary materials for shaping the future. Discov. Mater. 2025, 5, 35. [Google Scholar] [CrossRef]

- Gonçalves, V.R.M.; Corrêa, D.R.N.; Sousa, T.d.S.P.d.; Pintão, C.A.F.; Grandini, C.R.; Afonso, C.R.M.; Lisboa-Filho, P.N. Promising composites for wear resistant load-bearing implant applications: Low elastic moduli of β Ti–Nb alloy reinforced with TiC particles and/or TiB whiskers. J. Mater. Res. Technol. 2024, 30, 879–889. [Google Scholar] [CrossRef]

- An, Q.; Huang, L.; Bao, Y.; Zhang, R.; Jiang, S.; Geng, L.; Xiao, M. Dry sliding wear characteristics of in-situ TiBw/Ti6Al4V composites with different network parameters. Tribol. Int. 2018, 121, 252–259. [Google Scholar] [CrossRef]

- Otte, J.A.; Zou, J.; Patel, R.; Lu, M.; Dargusch, M.S. TiB Nanowhisker Reinforced Titanium Matrix Composite with Improved Hardness for Biomedical Applications. Nanomaterials 2020, 10, 2480. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Sun, B.; Imai, H.; Kondoh, K. Powder metallurgy Ti–TiC metal matrix composites prepared by in situ reactive processing of Ti-VGCFs system. Carbon 2013, 61, 216–228. [Google Scholar] [CrossRef]

- Chen, K.; Zhu, C.; He, J.; Zhang, X.-Y.; Zhou, K. Unexpected strengthening and toughening effects of B minor alloying in a new low-density near-α titanium alloy. Scr. Mater. 2025, 254, 116318. [Google Scholar] [CrossRef]

- Sousa, L.; Alves, A.; Costa, N.; Gemini-Piperni, S.; Rossi, A.; Ribeiro, A.; Simões, S.; Toptan, F. Preliminary tribo-electrochemical and biological responses of the Ti-TiB-TiCx in-situ composites intended for load-bearing biomedical implants. J. Alloys Compd. 2022, 896, 162965. [Google Scholar] [CrossRef]

- Verma, P.K.; Warghane, S.; Nichul, U.; Kumar, P.; Dhole, A.; Hiwarkar, V. Effect of boron addition on microstructure, hardness and wear performance of Ti-6Al-4 V alloy manufactured by laser powder bed fusion additive manufacturing. Mater. Charact. 2021, 172, 110848. [Google Scholar] [CrossRef]

- ASTM 384-22; Standard Test Method for Microindentation Hardness of Materials. ASTM Committee: West Conshohocken, PA, USA, 2022.

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Dantas, P.; Grenho, A.; Mascarenhas, V.; Martins, J.; da Silva, M.T.; Gonçalves, S.B.; Consciência, J.G. Hip joint contact pressure and force: A scoping review of in vivo and cadaver studies. Bone Jt. Res. 2023, 12, 712–721. [Google Scholar] [CrossRef]

- Murray, J.L. The Ti-Zr (Titanium-Zirconium) system. Bull. Alloy Phase Diagr. 1981, 2, 197–201. [Google Scholar] [CrossRef]

- Murray, J.L. The Ta-Ti (Tantalum-Titanium) system. Bull. Alloy Phase Diagr. 1981, 2, 62–66. [Google Scholar] [CrossRef]

- Fernández Guillermet, A. Phase diagram and thermochemical properties of the Zr–Ta system. An assessment based on Gibbs energy modelling. J. Alloys Compd. 1995, 226, 174–184. [Google Scholar] [CrossRef]

- Amigó-Mata, A.; Haro-Rodriguez, M.; Vicente-Escuder, Á.; Amigó-Borrás, V. Development of Ti–Zr alloys by powder metallurgy for biomedical applications. Powder Metall. 2022, 65, 31–38. [Google Scholar] [CrossRef]

- Murray, J.L.; Liao, P.K.; Spear, K.E. The B−Ti (Boron-Titanium) system. Bull. Alloy Phase Diagr. 1986, 7, 550–555. [Google Scholar] [CrossRef]

- Franke, P.; Neuschütz, D.; Scientific Group Thermodata Europe (SGTE). Introduction: Thermodynamic Properties of Inorganic Materials. In Binary Systems. Part 5: Binary Systems Supplement 1: Phase Diagrams, Phase Transition Data, Integral and Partial Quantities of Alloys; Springer: Berlin/Heidelberg, Germany, 2007; pp. 1–13. [Google Scholar]

- Sobolev, A.S.; Kuz’MA, Y.B.; Soboleva, T.E.; Fedorov, T.F. Phase equilibria in tantalum—Titanium—Boron and tantalum—Molybdenum—Boron systems. Sov. Powder Metall. Met. Ceram. 1968, 7, 48–51. [Google Scholar] [CrossRef]

- Hulka, I.; Mirza-Rosca, J.C.; Buzdugan, D.; Saceleanu, A. Microstructure and Mechanical Characteristics of Ti-Ta Alloys before and after NaOH Treatment and Their Behavior in Simulated Body Fluid. Materials 2023, 16, 1943. [Google Scholar] [CrossRef] [PubMed]

- Lütjering, G.; Williams, J.C. Titanium; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Dobromyslov, A.V. Nature and Regularities of the Orthorhombic α″-Phase Formation in Binary Titanium Alloys. Alloys 2023, 2, 148–156. [Google Scholar] [CrossRef]

- Dobromyslov, A.V.; Taluts, N.I. Regularities of Orthorhombic α″ Phase Formation in Binary Zirconium Alloys. Metall. Mater. Trans. A 2025, 56, 3961–3971. [Google Scholar] [CrossRef]

- Guo, S.; Zhang, J.; Cheng, X.; Zhao, X. A metastable β-type Ti–Nb binary alloy with low modulus and high strength. J. Alloys Compd. 2015, 644, 411–415. [Google Scholar] [CrossRef]

- Saunders, N.; Miodownik, A.P. (Eds.) Chapter 3—Basic Thermodynamics. In Pergamon Materials Series; Pergamon Press: Oxford, UK, 1998; pp. 33–57. [Google Scholar]

- Takeuchi, A.; Inoue, A. Classification of Bulk Metallic Glasses by Atomic Size Difference, Heat of Mixing and Period of Constituent Elements and Its Application to Characterization of the Main Alloying Element. Mater. Trans. 2005, 46, 2817–2829. [Google Scholar] [CrossRef]

- Horiuchi, Y.; Inamura, T.; Kim, H.Y.; Wakashima, K.; Miyazaki, S.; Hosoda, H. Effect of Boron Concentration on Martensitic Transformation Temperatures, Stress for Inducing Martensite and Slip Stress of Ti-24 mol%Nb-3 mol%Al Superelastic Alloy. Mater. Trans. 2007, 48, 407–413. [Google Scholar] [CrossRef]

- Mei, W.; Sun, J.; Wen, Y. Martensitic transformation from β to α′ and α″ phases in Ti–V alloys: A first-principles study. J. Mater. Res. 2017, 32, 3183–3190. [Google Scholar] [CrossRef]

- Fang, H.; Xu, X.; Zhang, H.; Sun, Q.; Sun, J. Alloying Effect on Transformation Strain and Martensitic Transformation Temperature of Ti-Based Alloys from Ab Initio Calculations. Materials 2023, 16, 6069. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.-J.; Ma, S.-Y.; Wang, S.-Q. The Nucleation and the Intrinsic Microstructure Evolution of Martensite from 332 〈113〉 β Twin Boundary in β Titanium: First-Principles Calculations. Metals 2019, 9, 1202. [Google Scholar] [CrossRef]

- Kayani, S.H.; Cui, M.; Ahmed, R.T.M.; Cho, Y.-H.; Lee, J.-M.; Park, N.-K.; Ajmal, H.M.S.; Euh, K. Pore formation mechanism and intermetallic phase transformation in Ti–Al alloy during reactive sintering. J. Mater. Res. Technol. 2023, 22, 1878–1887. [Google Scholar] [CrossRef]

- Hu, X.; Liu, C.; Wu, Z.; Song, M. Formation mechanism of β precipitate within α′ martensite in α+β titanium alloys. Scr. Mater. 2025, 262, 116632. [Google Scholar] [CrossRef]

- Motyka, M. Martensite Formation and Decomposition during Traditional and AM Processing of Two-Phase Titanium Alloys—An Overview. Metals 2021, 11, 481. [Google Scholar] [CrossRef]

- Angel, D.A.; Mikó, T.; Kristály, F.; Benke, M.; Gácsi, Z. Development of TiB and nanocrystalline Ti-reinforced novel hybrid Ti nanocomposite produced by powder metallurgy. J. Mater. Sci. 2022, 57, 4130–4144. [Google Scholar] [CrossRef]

- Rundora, N.R.; Klenam, D.E.P.; Polat, S.; Mathabathe, N.M.; van der Merwe, J.; Bodunrin, M.O. Dry Sliding Wear Behavior of Experimental Low-Cost Titanium Alloys. Tribol. Trans. 2024, 67, 560–572. [Google Scholar] [CrossRef]

- Chávez, J.; Jimenez, O.; Olmos, L.; Farias, I.; Flores-Jimenez, M.; Suárez-Martínez, R.; Cabezas-Villa, J.; Lemus-Ruiz, J. Tribocorrosion behavior of Ti64-xTa alloys fabricated through powder metallurgy. Mater. Lett. 2020, 280, 128590. [Google Scholar] [CrossRef]

- Avcu, Y.Y.; Iakovakis, E.; Guney, M.; Çalım, E.; Özkılınç, A.; Abakay, E.; Sönmez, F.; Koç, F.G.; Yamanoğlu, R.; Cengiz, A.; et al. Surface and Tribological Properties of Powder Metallurgical Cp-Ti Titanium Alloy Modified by Shot Peening. Coatings 2023, 13, 89. [Google Scholar] [CrossRef]

- Vinod, B.; Suresh, S.; Reddy, S.S.K. Tribological and Fatigue Behaviour of Ti-Nb-Zr-Sn Alloy through Powder Compacting: Novel Performance of High Niobium Alloys for Bone Tissue Compatibility. Arch. Metall. Mater. 2024, 69, 1543–1554. [Google Scholar] [CrossRef]

- Samuel, S.; Nag, S.; Scharf, T.W.; Banerjee, R. Wear resistance of laser-deposited boride reinforced Ti-Nb–Zr–Ta alloy composites for orthopedic implants. Mater. Sci. Eng. C 2008, 28, 414–420. [Google Scholar] [CrossRef]

- Mantri, S.A.; Torgerson, T.; Ivanov, E.; Scharf, T.W.; Banerjee, R. Effect of boron addition on the mechanical wear resistance of additively manufactured biomedical titanium alloy. Metall. Mater. Trans. A 2018, 49, 806–810. [Google Scholar] [CrossRef]

- Jiang, X.; Jing, R.; Ma, M.; Liu, R. The orthorhombic α″ martensite transformation during water quenching and its influence on mechanical properties of Ti-41Zr-7.3Al alloy. Intermetallics 2014, 52, 32–35. [Google Scholar] [CrossRef]

- Ji, P.; Chen, B.; Li, B.; Tang, Y.; Zhang, G.; Zhang, X.; Ma, M.; Liu, R. Influence of Nb addition on microstructural evolution and compression mechanical properties of Ti-Zr alloys. J. Mater. Sci. Technol. 2021, 69, 7–14. [Google Scholar] [CrossRef]

- Ehtemam-Haghighi, S.; Cao, G.; Zhang, L.-C. Nanoindentation study of mechanical properties of Ti based alloys with Fe and Ta additions. J. Alloys Compd. 2017, 692, 892–897. [Google Scholar] [CrossRef]

- Majumdar, P.; Singh, S.; Chakraborty, M. The role of heat treatment on microstructure and mechanical properties of Ti–13Zr–13Nb alloy for biomedical load bearing applications. J. Mech. Behav. Biomed. Mater. 2011, 4, 1132–1144. [Google Scholar] [CrossRef]

- Zysset, P.K.; Guo, X.E.; Hoffler, C.E.; E Moore, K.; A Goldstein, S. Elastic modulus and hardness of cortical and trabecular bone lamellae measured by nanoindentation in the human femur. J. Biomech. 1999, 32, 1005–1012. [Google Scholar] [CrossRef]

- Beake, B.D. The influence of the H/E ratio on wear resistance of coating systems—Insights from small-scale testing. Surf. Coat. Technol. 2022, 442, 128272. [Google Scholar] [CrossRef]

- Finkin, E. Examination of abrasion resistance criteria for some ductile metals. J. Lubr. Technol. 1974, 96, 210–214. [Google Scholar] [CrossRef]

- Tsui, T.Y.; Pharr, G.M.; Oliver, W.C.; Bhatia, C.S.; White, R.L.; Anders, S.; Anders, A.; Brown, I.G. Nanoindentation and Nanoscratching of Hard Carbon Coatings for Magnetic Disks. MRS Online Proc. Libr. 1995, 383, 447–452. [Google Scholar] [CrossRef]

| Pairs | ∆Hmix (kJ·mol−1) | ∆Gmix (kJ·mol−1) |

|---|---|---|

| Zr-Ta | 3 | −2.7628 |

| Ti-Ta | 1 | −4.7628 |

| Ti-Zr | 0 | −5.7628 |

| Ta-B | −54 | −59.763 |

| Ti-B | −58 | −63.763 |

| Zr-B | −71 | −76.763 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chávez, J.; Cruz-Gómez, Y.; López-Arámburo, L.; García-Carrillo, A.M.; Jiménez, O.; Olmos, L.; Bravo-Barcenas, D.; Flores, M. The Effect of In Situ Boron Reinforcement on the Microstructure and Tribological Performances of a Biocompatible Ti-30Zr-10Ta Alloy Fabricated by Powder Metallurgy. Lubricants 2025, 13, 431. https://doi.org/10.3390/lubricants13100431

Chávez J, Cruz-Gómez Y, López-Arámburo L, García-Carrillo AM, Jiménez O, Olmos L, Bravo-Barcenas D, Flores M. The Effect of In Situ Boron Reinforcement on the Microstructure and Tribological Performances of a Biocompatible Ti-30Zr-10Ta Alloy Fabricated by Powder Metallurgy. Lubricants. 2025; 13(10):431. https://doi.org/10.3390/lubricants13100431

Chicago/Turabian StyleChávez, Jorge, Yadira Cruz-Gómez, Lorena López-Arámburo, Armando M. García-Carrillo, Omar Jiménez, Luis Olmos, David Bravo-Barcenas, and Martín Flores. 2025. "The Effect of In Situ Boron Reinforcement on the Microstructure and Tribological Performances of a Biocompatible Ti-30Zr-10Ta Alloy Fabricated by Powder Metallurgy" Lubricants 13, no. 10: 431. https://doi.org/10.3390/lubricants13100431

APA StyleChávez, J., Cruz-Gómez, Y., López-Arámburo, L., García-Carrillo, A. M., Jiménez, O., Olmos, L., Bravo-Barcenas, D., & Flores, M. (2025). The Effect of In Situ Boron Reinforcement on the Microstructure and Tribological Performances of a Biocompatible Ti-30Zr-10Ta Alloy Fabricated by Powder Metallurgy. Lubricants, 13(10), 431. https://doi.org/10.3390/lubricants13100431