1. Introduction

Internal combustion engines constitute a significant component of global fuel consumption, generating substantial costs across commercial and defense sectors, while contributing considerably to greenhouse gas emissions. Enhanced engine efficiency through reduced friction, minimized wear, and improved thermal heat transfer capabilities presents a viable solution to these challenges. Such improvements yield dual benefits of addressing the economic implications of fuel logistics while simultaneously reducing carbon emissions. This optimization strategy particularly benefits both commercial and defense operations, where fuel consumption represents a critical operational parameter. The resultant increase in engine efficiency not only mitigates environmental impact through reduced carbon emissions but also promotes sustainable operational practices across sectors.

Engine oils undergo oxidation and degradation due to the high temperature and high load operating conditions in combustion engines, leading to the deterioration of the friction and wear-reducing properties [

1,

2]. Friction and wear-modifying additives are introduced to engine oil to provide sufficient lubrication [

3]. Commonly used additives include zinc dialkydithiophosphates (ZDDPs) [

4,

5], metal oxides, amorphous carbon [

6,

7], and two-dimensional (2D) materials such as molybdenum disulfide (MoS

2) [

8,

9], graphene [

10,

11], and hexagonal boron nitride (BN) [

12]. These nanomaterials significantly reduce the friction and wear of engine parts by filling in the imperfections and minimizing direct contact between moving parts [

13]. In addition, 2D materials like MoS

2 are known for friction reducing for their ability to provide sliding effects. Recently, hybrid nano additives have drawn increased attention due to their synergistic effects [

14,

15]. For example, a MoS

2–graphene hybrid nano additive was reported to have synergistic effects in reducing friction and wear due to the layered structure of MoS

2, which provides exceptional lubrication, and the high shear strength and chemical stability of graphene, which further improves lubrication, thermal conductivity, and oxidation resistance [

16].

Building on the team’s early studies on carbon nanotubes (CNTs) in improving the lubricating and heat transfer properties of nanofluids and greases, Novum Nano has developed and patented a nano-based engine oil additive that reduces engine friction and wear and increases torque, horsepower, and fuel efficiency [

17]. This nano oil additive contains functionalized CNTs and BN nanosheets that are dispersed in a base engine oil using a proprietary ultrasonication process. Previous studies on engine oil additives focused on either CNTs or BN as the sole nano additive material [

18]. For example, Thachnatharen et al. studied the tribological performance of BN-based 20W-50 oil for diesel engines and demonstrated a 20.5% reduction in friction and a 9.47% reduction in wear compared to the base oil [

19]. Researchers also reported nano-based engine oil using MoS

2 and CNTs as hybrid nanostructures [

20]. Meanwhile, in this work, the functionalized CNTs and BN form a unique sandwich-like configuration by sonication and hydrogen bonding interactions. The combined use of hybrid nanomaterials showed improved dispersion and stability in the base oil suspension due to hydrogen bonding and the long tube structure of the nanotubes [

21,

22,

23]. The improved engine efficiency leads to prolonged engine life expectancy and will significantly improve global environmental sustainability.

Most engine oil additive studies in the literature have focused on analysis of the engine oil itself, such as tribology, viscosity, emissions, and used oil composition studies, etc. [

24,

25]. For example, Kashefi et al. reported a silica-based nano lubricant and studied the optimum concentration of silica by evaluating the tribological and rheological properties of the treated oil [

26]. Ali et al. studied the mechanical efficiency and fuel economy of a gasoline engine with nano-based lubricant oil under the New European Driving Cycle [

27]. However, the research on oil additives that involves comprehensive engine performance analysis, including engine power and fuel economy, is limited.

The present study extends beyond these conventional parameters to establish direct correlations between oil properties improvement and quantifiable engine performance metrics. This comprehensive evaluation encompasses both laboratory analysis of oil properties and practical engine performance assessment following the introduction of the novel nano oil additive. Specifically, the investigation examines the tribological properties, thermal stability, and oil filter differential pressure of the treated engine oil. Furthermore, the study incorporates extensive field testing across diverse engine configurations to quantify efficiency improvements through precise measurements of torque, horsepower, and fuel economy parameters.

2. Materials and Methods

2.1. Oil Sample Preparation

The oil additive being evaluated in this work is a commercial product developed by Novum Nano, LLC. The product contains functionalized carbon nanotubes and hexagonal boron nitride nanosheets that are dispersed in a base oil using a proprietary ultrasonication process. The formulation details of the product remain protected as trade secrets. Test samples were prepared through direct incorporation of the additive into manufacturer-recommended base engine oils, specific to each test engine configuration. A mixing ratio of 44:1 (base oil:nano additive) in volume was determined as one dose.

2.2. Friction and Wear Test

Friction and wear performance was evaluated by the Falex Corporation and H.F. Webster Engineering Services using the ASTM D2714: Standard test [

28] method for calibration and operation of the Falex block-on-ring test machine. Testing temperature and speed were set at 43.3 °C and 72 rpm, respectively, and a 150 lb load was used. At least three tests were performed on each sample by each facility to ensure repeatability. A total of nine oil samples were prepared (denoted by S1 to S9) and evaluated by the Falex Corporation laboratory. Sample S1 represents the pure base oil as the control sample, while samples S2–S9 contain one dose of oil additive with incrementally increasing CNT to BN ratios (specific concentration parameters remain proprietary).

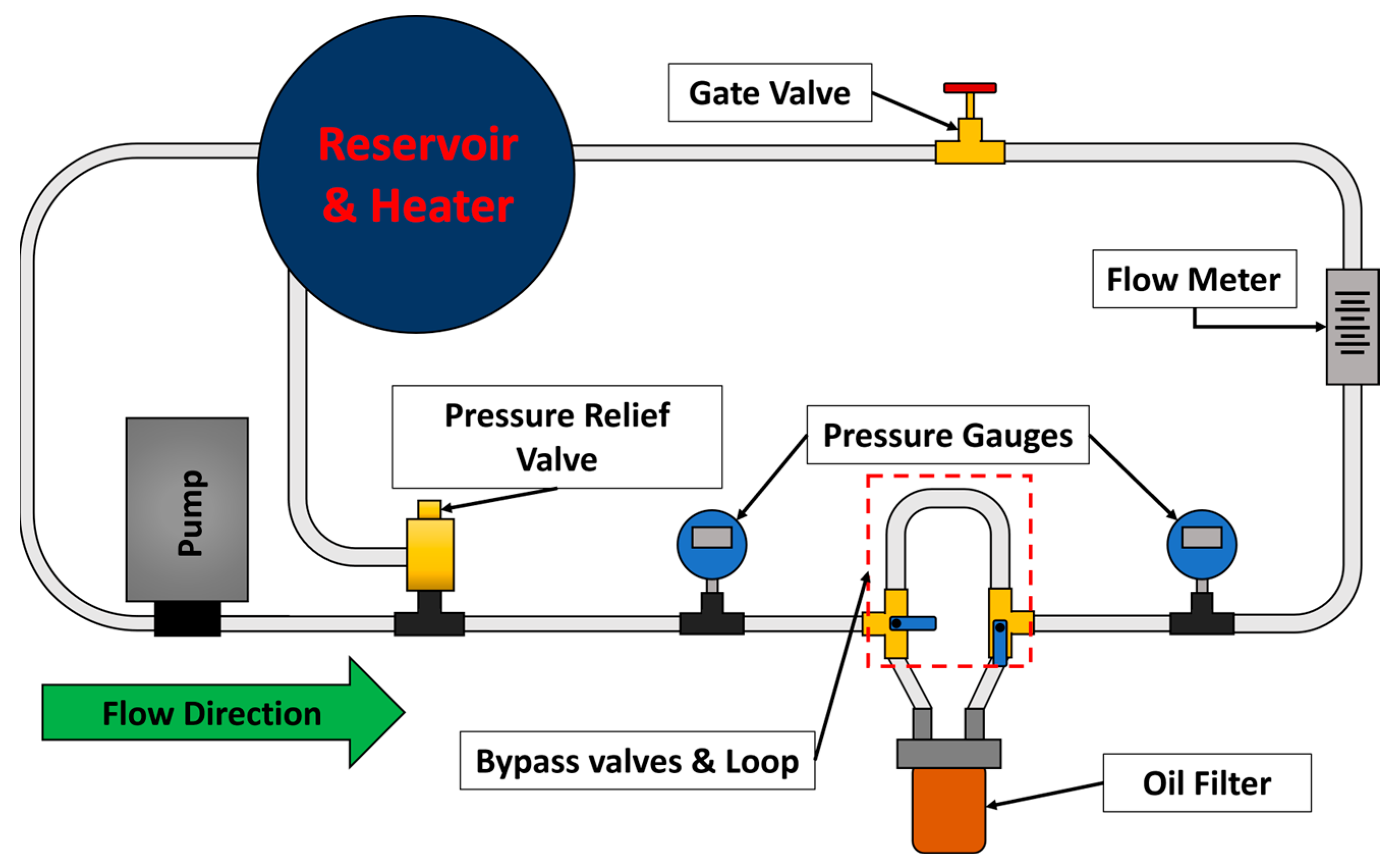

2.3. Oil Filter Test

Figure 1 shows the diagram of the oil filter pressure test setup. This test rig simulates the pressures in a typical engine and monitors the pressure difference across the filter element. It allows for testing of a wide variety of filter types while collecting quantitative data about the performance. A standardized amount of base engine oil was added to the reservoir, and multiple baseline tests were performed to determine the most appropriate test parameters. During a 90 min test duration, the controlled heating gradually increased the oil temperature to 150 °F (65.6 °C) near the end of the test. System pressure was calibrated to 75 psi (517 kPa) under bypass configuration through precise gate valve adjustment. Oil was then directed through the filter rather than the bypass, and the differential pressure was recorded over time. High-performance K&N HP-2002 filters (K&N Filters, Riverside, CA, USA), rated for 10 µm particle filtration, were used throughout the evaluation protocol.

2.4. Engine Performance Evaluation

Comprehensive performance evaluation of the nano oil additive encompassed multiple testing protocols. Thermal stability characteristics were assessed through thermogravimetric analysis of treated oil samples. Performance metrics, including torque and horsepower, were quantified using dynamometer testing across diverse engine configurations, including six Harley-Davidson motorcycles representing various engine specifications, operational ages, and accumulated mileages (detailed specifications provided in

Table 1). Additionally, performance evaluation extended to a Chevrolet crate engine and multiple pickup truck configurations. The test trucks comprised a 2020 Toyota Tundra (Toyota Motor Manufacturing, San Antonio, TX, USA) (5.7 L gasoline engine, 3000 miles (4828 km)) and a 2020 RAM 1500 (Stellantis Automotive Corporation, Sterling Heights Assembly Plant, Sterling Heights, MI, USA) (5.7 L Hemi gasoline engine, 2300 miles (3701 km)). Dynamometer testing on all vehicles with any of the samples was repeated at least three times to ensure data reliability. The fuel economy assessment incorporated a broad spectrum of engine types, ranging from small-displacement lawn mower engines to heavy-duty diesel applications, including light tower generators, a pickup truck (2019 Chevrolet Duramax (DMAX Ltd., Moraine, OH, USA) 6.6 L), and four commercial semi-truck fleet vehicles. The semi-trucks information is as follows: truck 1 was a Freightliner Cascadia (Daimler Truck North America, Cleveland, OH, USA) with a DD15 engine (Detroit Diesel Corporation, Redford, MI, USA), truck 2 was a Peterbilt (PACCAR Inc., Denton, TX, USA) with a Cummins ISX15 engine (Cummins Jamestown Engine Plant, Lakewood, CO, USA), and trucks 3 and 4 were Mack trucks equipped with MP8-TC engines (Mack Trucks, Hagerstown, MD, USA). The DD15 engine took 44 quarts (41.6 L) of oil, the Cummins engine used 40 quarts (37.9 L) of oil and the Macks used 38 quarts (36.0 L) of oil. The fuel economy of the small lawn mower engine was measured by the runtime of the engine based on a predetermined amount of fuel. The fuel economy of the light tower generator was calculated based on the runtime and the fuel consumed. For both the small lawn mower engine and the light tower generator, at least ten parallel tests were performed to establish data reliability, and the average results and standard deviation were obtained. The fuel economy of the Chevrolet pickup truck and commercial fleet trucks were calculated based on a substantial number of distances driven and the fuel consumed.

3. Results

3.1. Friction and Wear

Initial development of the nano oil additive concentrated on evaluating friction and wear-reduction capabilities. Multiple testing facilities, including Novum Nano’s laboratory, the H.F. Webster Engineering Services laboratory, and the Falex Corporation laboratory, conducted comprehensive block-on-ring tests on various sample preparations.

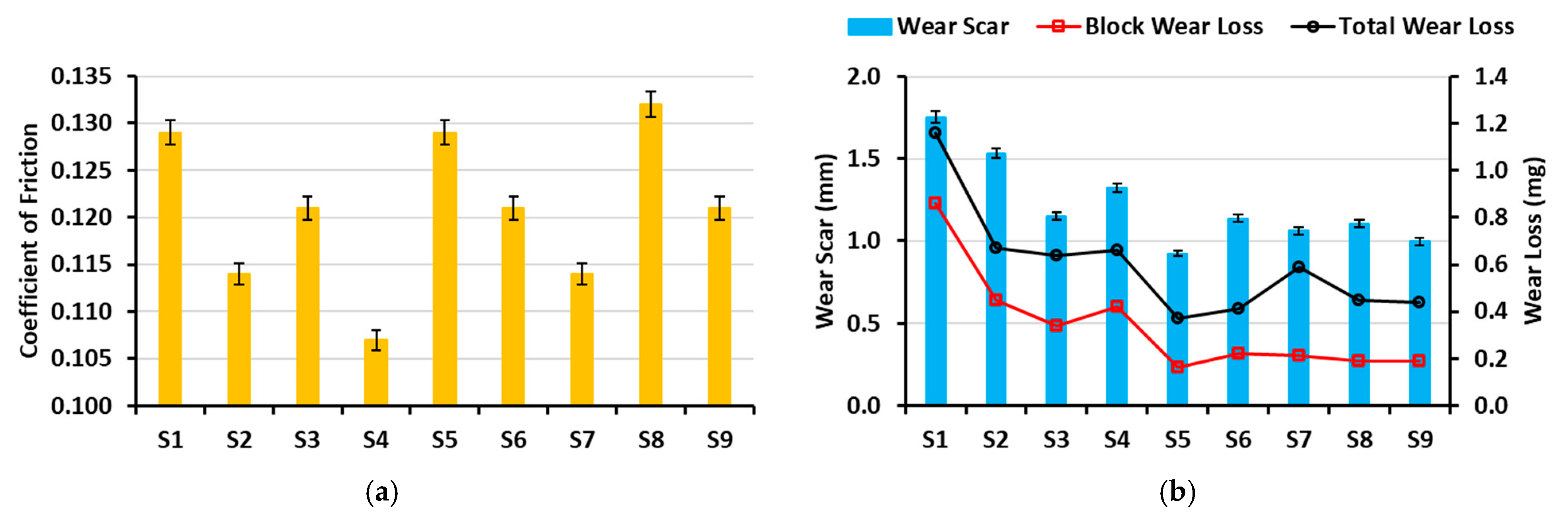

Figure 2 presents the coefficient of friction (CoF) results (a) and wear measurements (b) for oil samples S1–S9, as evaluated by the Falex Corporation laboratory. The majority of the treated samples demonstrated a reduced CoF compared to pure base oil (0.129), with samples S2, S4, and S7 achieving reductions of up to 17% (minimum CoF of 0.107). Exceptions included S5, showing equivalent CoF, and S8, displaying marginally higher values.

The wear analysis results, illustrated in

Figure 2b, demonstrate consistently superior performance of treated samples compared to the base oil control. The data presents wear scars, block wear losses, and total wear losses (block and ring combined). An inverse correlation emerged between CNT-to-BN ratio and wear measurements, with the rate of improvement diminishing at higher CNT concentrations. Sample S5 achieved optimal performance, with a 47% reduction in wear scar compared to the base oil, while samples S6–S9 demonstrated comparable wear characteristics.

Notably, the relationship between CoF and wear performance exhibited complex behavior. Lower average CoF values did not consistently correlate with reduced wear measurements, as exemplified by sample S4. Additionally, samples S5 and S8 demonstrated significantly reduced wear despite CoF values similar to the base oil. This phenomenon is attributed to the complex surface interactions of the entangled CNT structures in forming protective lubricating films of varying durability and robustness.

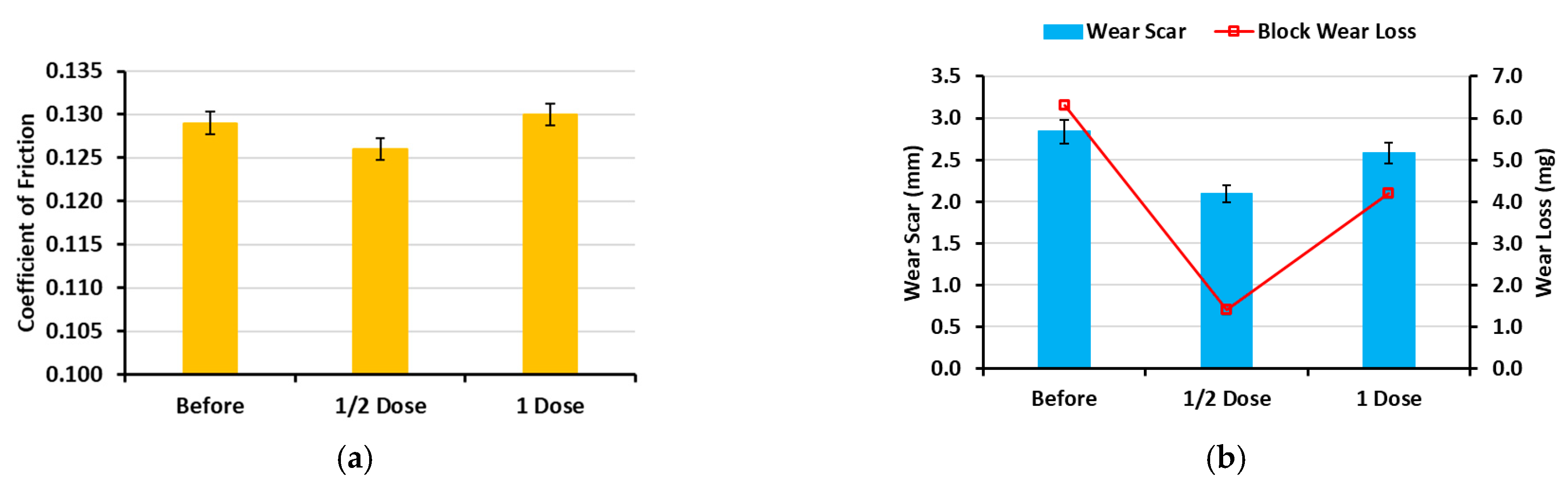

Figure 3 presents comparative analysis of coefficient of friction (CoF) measurements (a) and wear characteristics (b) for oil samples evaluated under varying additive concentrations, utilizing block-on-ring testing protocols at H.F. Webster Engineering Services. Testing methodology incorporated minimum triplicate measurements to ensure statistical validity. The implementation of S25 rings, notably harder than the S10 rings employed in Falex testing, resulted in substantially increased block wear measurements.

Analysis revealed comparable CoF values across the base oil and treated samples. However, wear reduction was observed in treated samples, with the half-dose formulation demonstrating an optimal performance of a 26.4% reduction in wear scar dimensions and a 78% reduction in mass loss compared to baseline measurements. This indicates that the nanomaterials reduced the friction and wear by filling in the imperfections of the metal surfaces and forming a durable and robust lubricating film. While the full-dose sample exhibited higher wear loss than the half-dose formulation, it maintained substantially improved wear characteristics relative to the untreated base oil.

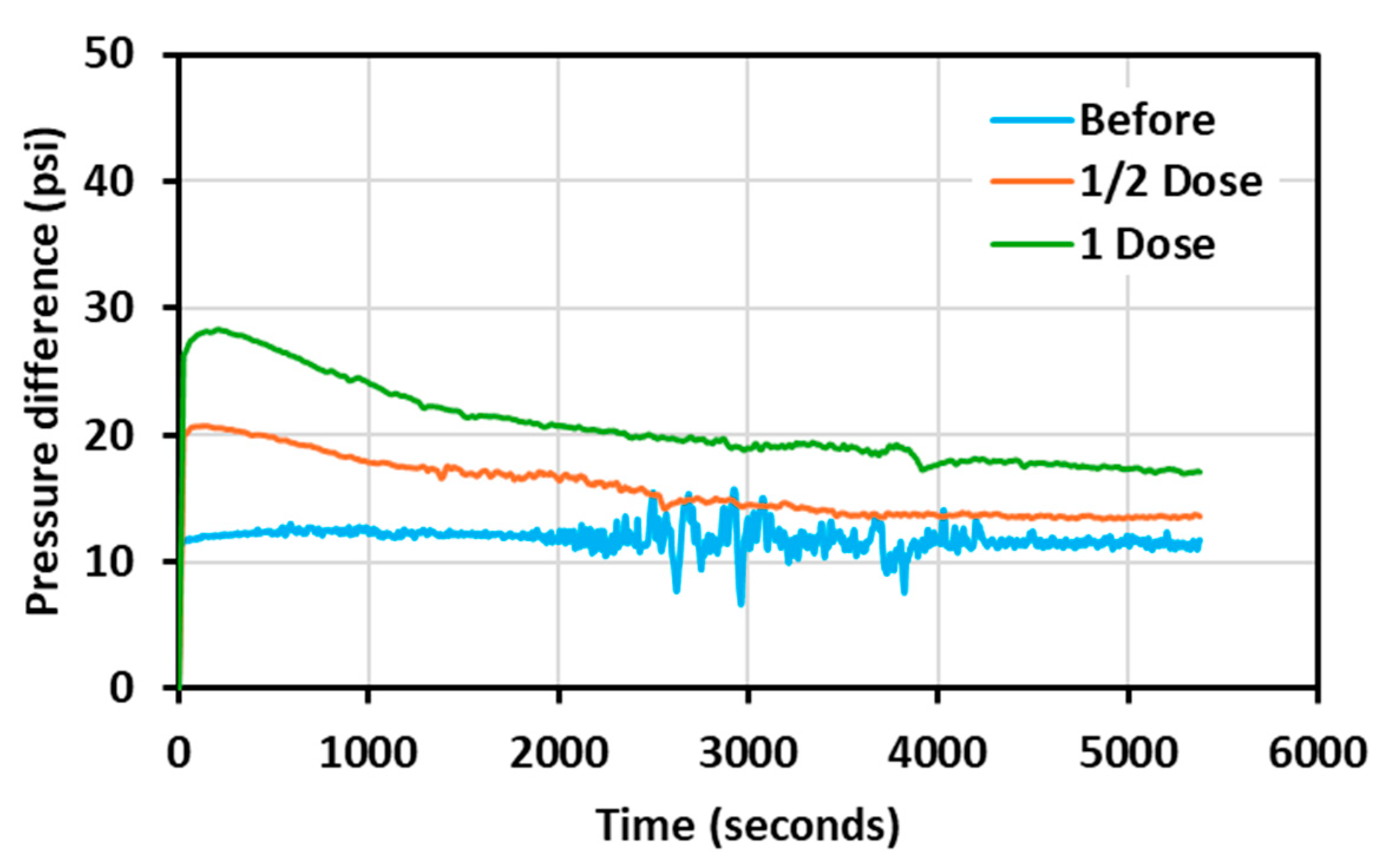

3.2. Oil Filter Pressure

Figure 4 illustrates the differential pressure characteristics across oil filters for untreated and nano-additive-treated oil samples. The baseline measurements with untreated oil demonstrated consistent differential pressure of approximately 11 psi (76 kPa) throughout temperature and temporal variations.

Upon introduction of nano additives (both half- and full-dose concentrations), initial pressure differentials exhibited modest elevation during cold-start conditions. These differentials subsequently stabilized as operating temperatures approached 150 °F (65.6 °C). The experimental protocol deliberately excluded pre-mixing or pre-heating procedures to simulate real-world application conditions.

The observed initial pressure differential elevation can be attributed to the direct introduction methodology, where concentrated additive dispersion through the filter medium generated temporary pressure increases. At elevated temperatures, the differential pressure characteristics of treated oils demonstrated convergence toward baseline values, attributable to improved additive dispersion dynamics as well as reduced viscosity by elevated temperature.

Specifically, the half-dose treatment maintained equivalent pressure differential to the baseline, while the full-dose treatment exhibited moderately elevated differentials (approximately 17 psi, or 117 kPa). This pressure differential increase correlates with viscosity enhancement from nano-additive incorporation rather than filtration effects, as the nanomaterial dimensions remain substantially below filter media specifications.

3.3. Oil Thermal Performance

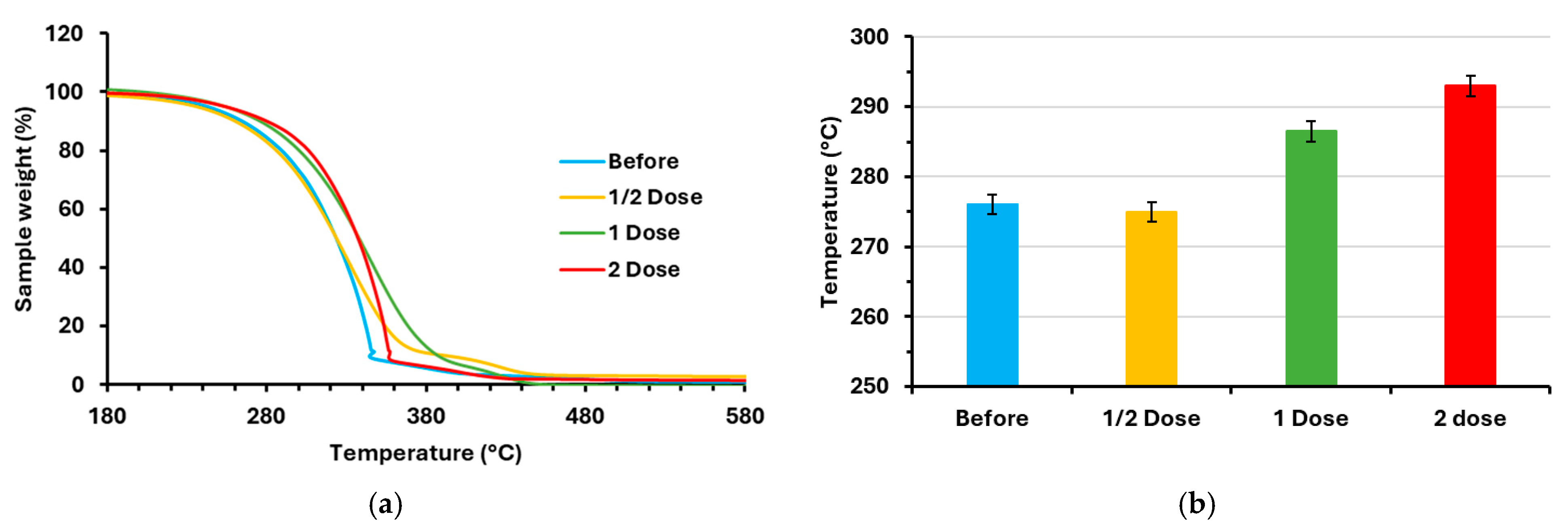

Figure 5 shows the thermal stability of oil samples before and after the addition of nano oil additive measured by thermogravimetric analysis (TGA).

Figure 5a shows the percentage weight of the oil samples compared to temperature, and

Figure 5b demonstrates the calculated decomposition temperature that is determined as the onset temperature (T

o) on the TGA curves. The base oil before the addition of the nano additive had an extrapolated onset temperature of 276 °C, while the T

o for the oil samples treated with half a dose, one dose, and two doses of the nano additive are 275 °C, 286.5 °C, and 293 °C, respectively. The decomposition of the oils treated with one or two doses of the nano additive showed an improvement of 3.8% and 6.2%, respectively. These results demonstrate progressive enhancement of thermal stability characteristics with increasing nano-additive concentration, particularly evident in the single and double dose treatments. The systematic improvement in decomposition temperatures suggests successful modification of the oil’s thermal characteristics through nano-additive incorporation.

The nano oil additive demonstrated thermal management benefits beyond basic thermal stability enhancement. Initial evaluation utilizing a 2010 Peterbilt straight truck equipped with a Paccar PX8 engine (PACCAR, Columbus, OH, USA) revealed substantial turbo temperature reduction under load conditions, decreasing from 740 °F (393 °C) to 720 °F (382 °C) post-additive introduction. This temperature reduction potentially derives from the improved engine efficiency through friction and wear reduction. Another possible mechanism is that the incorporation of CNT and BN enhanced the heat transfer coefficient of the oil.

Further validation was conducted during a 14 h endurance race at Daytona International Speedway using a BMW test vehicle (BMW Manufacturing Co., Spartanburg, SC, USA). During the race, the oil temperature dropped down to 224.7 °F (107 °C) from a normal temperature of 230 °F (110 °C). This oil temperature decrease resulted in the water temperature dropping from a baseline of 206 °F (96.7 °C) to an average of 201.3 °F (94 °C) across the entire 14 h race. According to the race team, this is a significant drop of both engine oil and water temperature. These thermal improvements are particularly significant considering the baseline measurements were established during less demanding qualifying conditions, suggesting potentially greater benefits under controlled testing protocols. The sustained temperature reduction throughout the high-stress endurance race environment demonstrates robust thermal management capabilities.

Alternatively, while temperature reductions are significant, the relative contribution of each proposed mechanism (enhanced heat transfer versus improved efficiency) requires further investigation.

3.4. Torque and Horsepower

3.4.1. Harley-Davidson Bikes

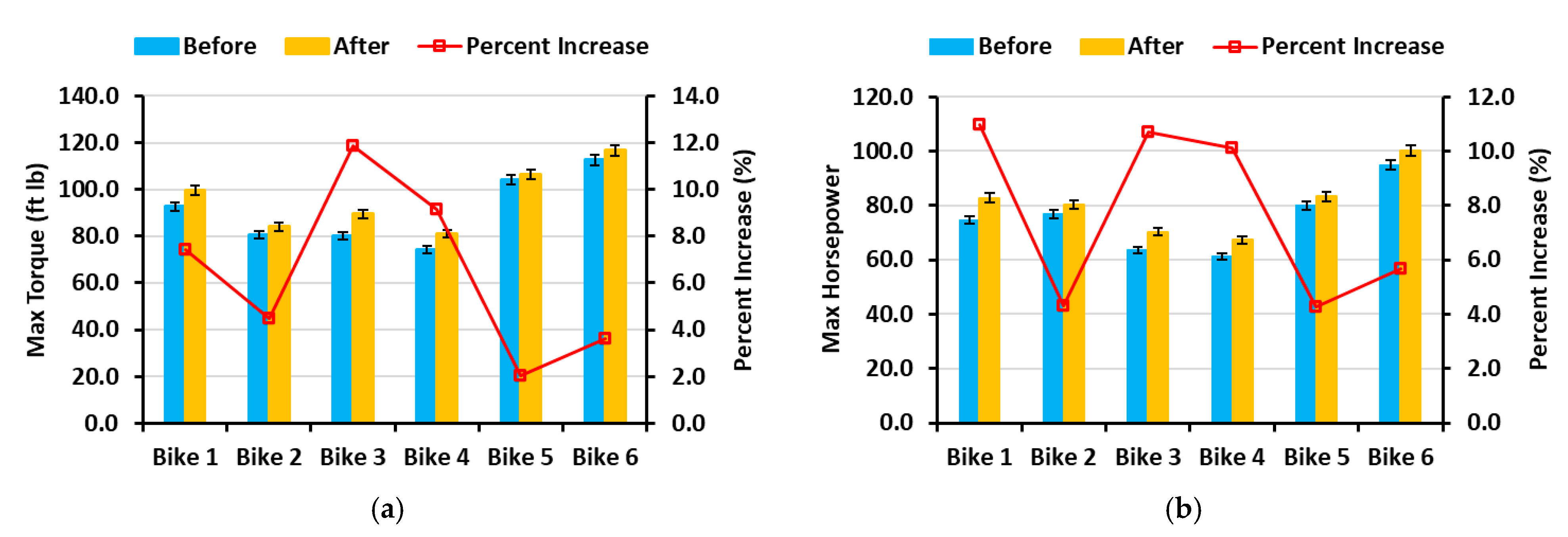

Performance evaluation was conducted on six Harley-Davidson motorcycles of varying age and mileage utilizing dynamometer testing protocols. The nano oil additive was administered incrementally in 0.25 dose intervals, ranging from 0.75 to 2 doses, with minimum triplicate dynamometer pulls performed at each dosage level.

Figure 6 presents maximum torque (a) and horsepower (b) results across the test fleet. All vehicles demonstrated performance improvements, with peak increases of 12% in torque and 11% in horsepower. While not all bikes showed such high improvements, the overall torque and horsepower increase averaged at 6.4% and 7.7%, respectively. Analysis revealed a correlation between vehicle age/mileage and performance enhancement. Bikes 2, 5, and 6, representing newer vehicles with lower mileage, demonstrated below-average improvements, suggesting that higher-mileage applications may gain more benefits than lower-mileage or less-worn applications. While there seems to be a correlation between vehicle age/mileage and performance, a solid conclusion cannot be drawn at this point due to the complexity of engine conditions and the small sample size in this test. In addition, optimal dosage analysis indicated maximum performance improvements typically occurred at or below 1.5 doses, with only one exception (Bike 6) requiring 1.75 doses. Additional dosing beyond these thresholds did not yield further performance benefits.

3.4.2. Chevrolet Crate Engine

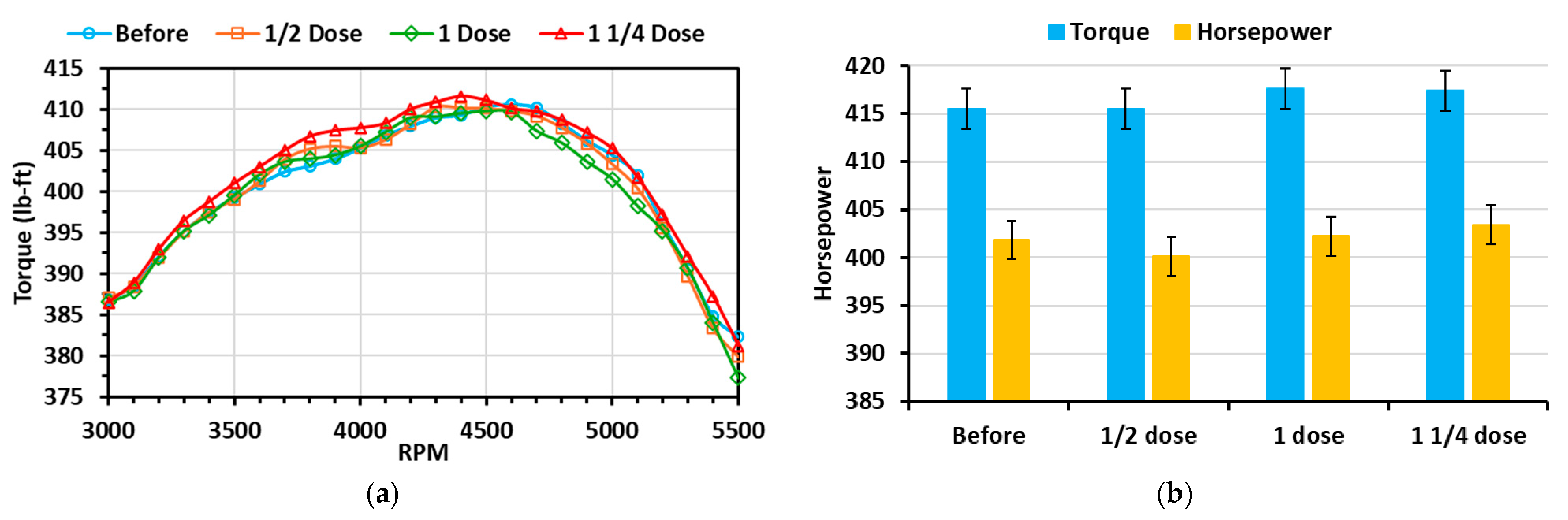

The performance evaluation of the nano oil additive was conducted on a new Chevrolet 5.7 L crate engine at the University of Northwestern Ohio to assess torque and horsepower benefits in modern engine applications.

Figure 7 illustrates the relationship between torque and RPM (a) and presents maximum torque and horsepower measurements (b) across multiple additive concentrations (0, 0.5, 1, and 1.25 doses).

Analysis of the data revealed performance improvements following the introduction of both 1 dose and 1.25 doses of the nano additive. While the percentage improvements appear modest compared to baseline measurements, these gains represent absolute power increases in high-output modern engines. A notable characteristic of the nano additive treatment was its ability to modify the torque curve profile, specifically in enhancing torque production at lower RPM ranges and progressive torque curve displacement with increased dosage.

3.4.3. Pickup Trucks

Extended dosage evaluation was conducted utilizing two new pickup trucks to assess performance characteristics with nano additive concentrations up to three doses.

Table 2 presents comparative torque and horsepower measurements, with each data point representing the average of minimum triplicate dynamometer pulls. Under continuous dosing conditions, Truck 1 demonstrated peak performance characteristics at two doses, with negligible improvements observed at three doses. Similarly, Truck 2 achieved maximum torque (312.63, representing a 1.37% increase) at intermediate dosage levels, though subsequent dosing resulted in torque reduction despite continued horsepower increases.

This performance plateau suggests the existence of an optimal dosage threshold, beyond which additional nano additive administration provides diminishing returns. Notably, the post-cooling cycle testing of Truck 1 revealed performance enhancement, with both torque and horsepower increasing more than 3.5% compared to baseline measurements. This temperature-dependent behavior suggests complex interaction mechanisms warranting further investigation.

3.5. Fuel Economy

3.5.1. Small Lawn Mower Engine

A 173-cc (0.173 L) gasoline 10 horsepower lawn mower engine was tested for maximum run time on a predetermined fuel volume, performed in a controlled laboratory environment. For each test, the same predetermined quantity of fuel was added to the fuel tank. The engine was allowed to run at 2700 rpm until all the fuel was consumed.

Baseline measurements established an average runtime of 23 min and 54 s without additive treatment. Following nano oil additive administration, the average runtime extended to 24 min and 36 s, representing a 3% improvement in fuel efficiency. This unloaded testing protocol provides insight into efficiency gains under idle conditions, where parasitic losses typically dominate energy consumption.

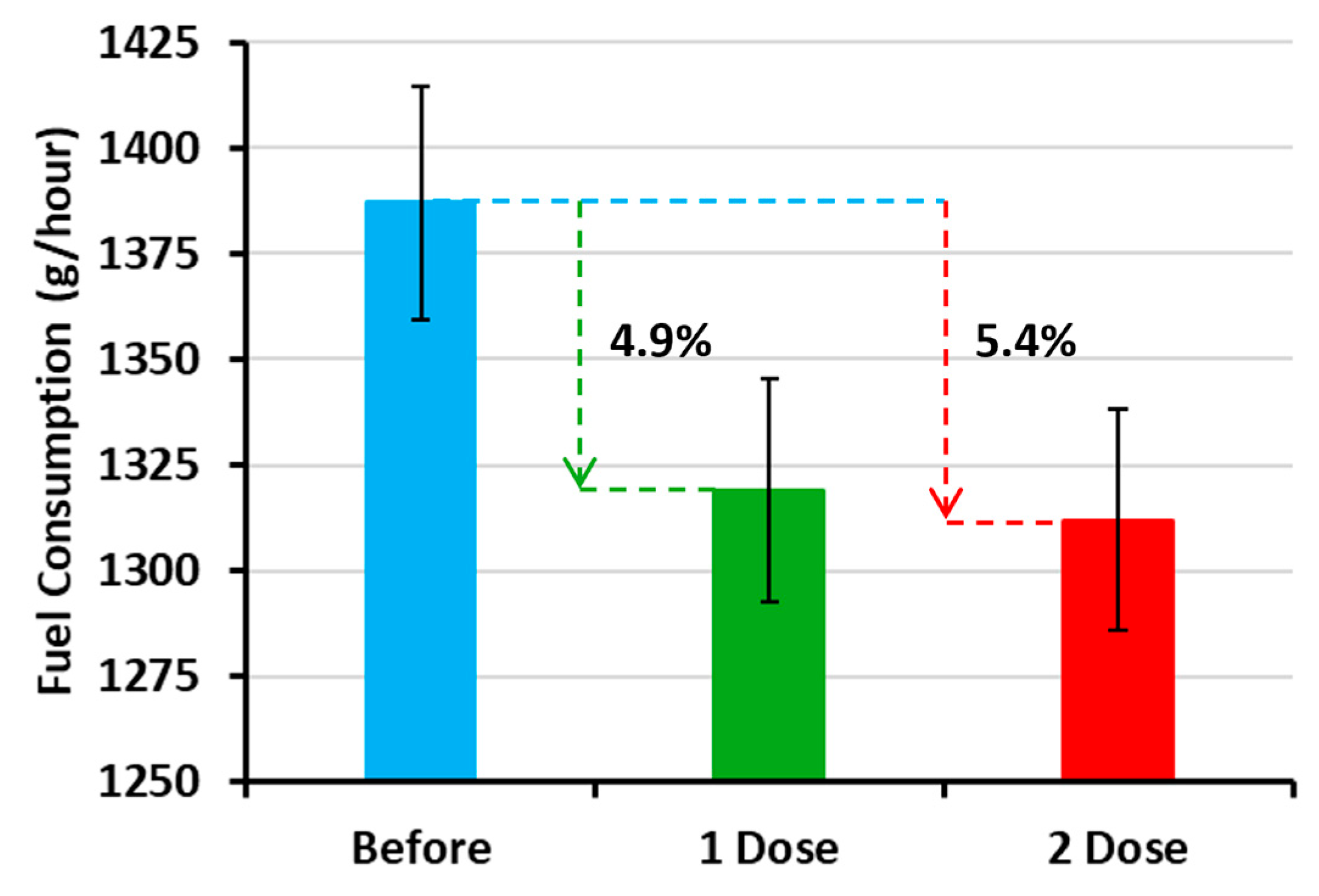

3.5.2. Light Tower Generator

Fuel economy evaluation was conducted utilizing a Kubota non-turbo diesel engine in a light tower generator configuration, selected for its representative low-RPM characteristics and constant load operation typical of industrial diesel applications. To account for environmental variables, particularly ambient temperature fluctuations, comprehensive baseline testing preceded additive evaluation.

Baseline testing was performed for over twenty hours over a period of four days. Once a single dose of nano oil additive was added to the engine, testing was performed over several days, as with the baseline. Nineteen total baseline runs were used to obtain an average fuel usage of 1387 g per hour. A single dose of nano oil additive was added, and over twenty total tests were run to obtain an average of 1319 g per hour. This yielded a 4.9% improvement in fuel economy for the diesel-powered light tower equipped generator. With the addition of a second dose of nano oil additive, a 0.5% incremental improvement was recorded over six total tests, yielding a total improvement of over 5% compared to the use of standard engine oil (see

Figure 8).

3.5.3. Pickup Truck Field Test

To further test the oil additive in a realistic experiment, a 2019 Chevrolet Duramax 6.6 L was selected for testing before and after dosing with the additive. This truck was tested across two distinct driving routes. Route one was the freeway (85 mph or 136.8 km/h) and route two was lower-speed roads. Prior to testing, the vehicle was fully serviced, with new engine oil added, to establish accurate baselines for each route. Fuel economy was calculated based on a hundred miles driven and the fuel consumed. On route one, a baseline fuel economy of 14.4 mpg (16.3 L/100 km) was obtained based on over 100 miles (160.9 km) driven. After one dose of the nano oil additive was added, the fuel economy over 325 miles (523.0 km) increased to 15.5 mpg (15.2 L/100 km), which was an 8% increase compared to the fuel economy before adding the additive. For route two, an average fuel economy of 18.1 mpg (13.0 L/100 km) was obtained after nearly 300 miles (482.8 km) driven. This resulted in a 16.5% increase compared to the baseline fuel economy of 15.5 mpg (15.2 L/100 km) on 88 miles (141.6 km) driven. Additional field test results are documented in the

Appendix A.

3.5.4. Semi-Truck Field Test

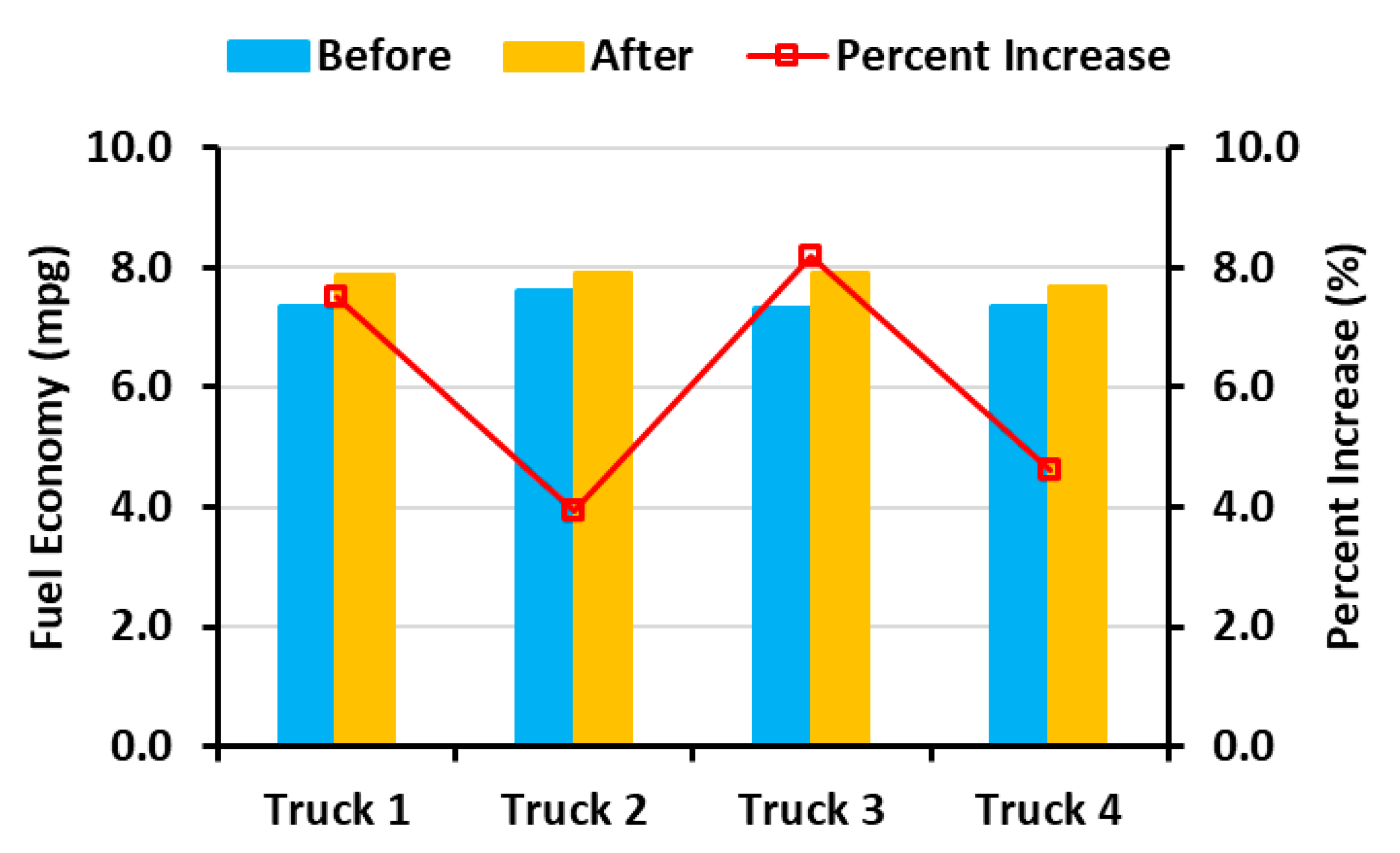

The nano oil additive was tested in a commercial truck fleet where each truck was routinely monitored and serviced. A total of four trucks were selected with similar age and mileage but different types of engines, and each truck had a designated route. The testing protocol incorporated standard maintenance intervals (45,000-mile/3-month oil change cycles) and established routes. Historical fuel economy data provided baseline measurements. Following scheduled oil changes, nano additive treatment was administered (single dose for trucks 1–3, double dose for truck 4) without driver notification to minimize operational variables.

After 60 days of service, the fuel economy of each truck within the 60-day period was calculated by the monitoring system based on miles driven and fuels consumed. The total mileage driven for each truck within this 60-day period was averaged at 30,000 miles (48,280 km).

Figure 9 shows the fuel economy of the four selected semi-trucks before and after dosing with the nano oil additive. It is observed that all four trucks showed significant improvements, with the highest exceeding 8%. The average fuel economy increases for these four trucks reached 6%. Similarly to the trend in torque and horsepower increases, the smallest increase in fuel economy (4.6%) goes to the newest truck (truck 2, 2024) with the least mileage on it. The results suggest that there may be a correlation between vehicle age/mileage and performance improvement, which can be validated by further testing on a larger sample size with various engine conditions. It is also interesting that truck 4, with two doses of the additive, did not show as high an increase in fuel economy as the other three trucks. This also aligns with other tests and indicates that excess addition of the oil additive does not necessarily improve the engine performance any further.

4. Discussions

This work encompasses both laboratory analysis of oil properties and practical engine performance assessment following the introduction of the nano oil additive. While the ultimate goal was to develop a nano oil additive formulation that increases vehicle fuel economy, especially for large/heavy duty diesel engines, a variety of laboratory tests were performed on treated oil, including friction and wear tests, thermal stability measurements, and oil filter differential pressure tests. The laboratory test results demonstrated the benefits provided by the nano oil additive in friction and wear reduction and thermal stability improvements. Combined with oil filter differential pressure results, it was noticed that an excess amount of the nano additive may negatively impact the nano oil performance by increasing the oil viscosity and potentially increasing the differential pressure across the filter. To gain further understanding of the impact of oil additive dosage, engine performance tests on dynamometers were conducted across a variety of engines, including motorcycles, pickup trucks, and a large diesel crate engine, with incremental additive dosages. The results indicated that there might be an optimal dosage that provided the most efficiency benefits to the engines, and an excess amount of the nano additive does not necessarily provide further benefits in torque and horsepower improvements. Additionally, it was noticed that performance benefits varied across different engines and might be correlated with engine conditions such as age and wear characteristics. Results suggest that an excess amount of the nano additive may affect engine performance, potentially due to increased oil viscosity, which leads to higher differential pressure across the oil filter. Fuel economy assessments demonstrated increases in fuel economy on various engines/vehicles but also indicated a potential correlation between fuel economy improvements and the nano additive dosage or engine conditions. Further testing on a larger sample size with a variety of engines is required to understand the correlation between engine type/conditions and performance benefits.

Despite the promising engine efficiency improvements, this work demonstrated a few limitations that may have affected the results considerably. One key limitation is the variety of engines being tested in this work, including engine types and conditions (age and mileage). While a broad engine type helps the development process in broader applications, focusing on one engine type could provide more insights into understanding the mechanism of nano additive benefiting engine performance improvements. Current results indicated that an “optimal” dosage that provided the maximum performance improvements was engine/vehicle-dependent. Another key limitation is the lack of a large sample size for engine performance assessments. The torque, horsepower, and fuel economy tests on a variety of engines and vehicles were limited to a small sample size due to availability, resulting in a lack of statistical significance of the performance improvements. Based on current results, a correlation could exist between engine conditions (age and mileage) and performance improvements. It is believed that older and more worn engines may benefit more from the nano additive than new and less worn engines; however, this would require a much larger sample size to be statistically proven.

As the development of this nano oil additive continues, future work will focus on engine performance tests on a large sample size with a variety of engine types and engine conditions. This will provide insights into validating data reliability and statistical significance of the performance improvements as well as analyzing the “optimal” dosing concentration of the nano additive. Secondly, it will be interesting to further explore the mechanisms that provide the thermal benefits of the engines. It is believed that both improved efficiency and heat transfer properties contribute to the thermal benefits. Control experiments by isolating these two mechanisms can provide more insights into engine performance. Another interesting area is the impact of an excess amount of nano additive dosing on modern engines with tight tolerance on viscosity and filter pressure. Lastly, it is essential to study the dispersibility of the nano additive in different base oil groups as the nanomaterial dispersion can vary depending on viscosity characteristics and specific dispersants in the oil formula.

5. Conclusions

This investigation evaluates a patented nano oil additive developed by Novum Nano, demonstrating enhanced engine efficiency. Comprehensive testing revealed improvements in multiple performance metrics including friction and wear reduction, thermal stability, torque and horsepower, and fuel economy.

Coefficient of friction reductions up to 17% and wear reductions up to 78% were obtained by block-on-ring tests on oils treated with the nano oil additive. Increases of up to 17 °C in oil decomposition temperature were obtained, indicating the increased thermal stability after dosing with the nano additive. Additionally, the improved engine efficiency, combined with the anticipated increase in heat transfer properties of the oil by the addition of CNT and BN, resulted in lower engine oil and water temperature.

Dynamometer testing across multiple vehicles demonstrated improvements in torque and horsepower, with enhancement magnitude potentially correlating to engine age and wear characteristics. Notably, increasing the amount of nano additive dosage does not necessarily provide benefits in torque or horsepower. Performance assessments on a variety of engines demonstrated increased fuel economy, with laboratory tests reporting 3–5% increases and practical field tests on commercial semi-trucks reporting an average of a 6% increase.

6. Patents

Bailey et al., US 12122975B2, Lubricant with Nanoparticulate Additive [

17].

Author Contributions

Conceptualization, G.C. and C.B.; methodology, D.L. and J.M.; investigation, D.L. and J.M.; writing—original draft preparation, D.L.; writing—review and editing, G.C., R.G., and A.N.; visualization, D.L.; supervision, C.B., A.N., and R.H.; funding acquisition, G.C. and C.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the United States Air Force, grant number FA8649-20-9-9046.

Data Availability Statement

Data presented in this work is available upon request from the corresponding author.

Acknowledgments

The authors would like to acknowledge the testing support from the South Dakota School of Mines and Technology, Georgia Institute of Technology, and H.F. Webster Engineering Services.

Conflicts of Interest

Authors Ding Lou, Jordan Morrison, Greg Christensen, Craig Bailey, Aaron Nardi, and Rob Hrabe are employed by Novum Nano, LLC. Authors Rose Gerani, Aaron Nardi, and Rob Hrabe are employed by VRC Metal Systems, which is the majority shareholder of Novum Nano LLC.

Abbreviations

The following abbreviations are used in this manuscript:

| BN | Boron nitride |

| CNT | Carbon nanotube |

| CoF | Coefficient of friction |

| TGA | Thermogravimetric analysis |

| ZDDP | Zinc dialkydithiophosphates |

Appendix A

A Utah company known to the researcher for their careful data collection of their fleet vehicles was selected for further testing with both a Mercedes diesel Sprinter van and two Ram heavy duty trucks, all equipped with high-output Cummins diesel engines. These vehicles were tested with one dose of nano oil additive.

The nano oil additive was added at an odometer reading of 14,515 miles (23,360 km) to the Sprinter, 2016 3.0 V6 diesel, 1 ton dually 4 × 4. Before the addition of the oil additive, its overall average fuel economy was 17.2 mpg (13.7 L/100 km), with the worst fuel economy recorded as 14.6 mpg (16.1 L/100 km). This vehicle often worked hard as it was required to travel on steep mountain roads. About 1000 miles (1609 km) before the nano oil additive was evaluated, a K&N air filter was added to the vehicle, increasing the average fuel economy to 18.2 mpg (12.9 L/100 km). The addition of the nano oil additive brought the average up to 19.27 mpg (12.2 L/100 km) under all conditions, with a peak of 21.1 mpg (11.1 L/100 km).

Testing with this Sprinter van also included towing a trailer on a 70-mile (112.7 km) round trip from Logan, Utah to Perry, UT. On this trip, the average fuel economy increased from 12.1 mpg (19.4 L/100 km) to 16.2 mpg (14.5 L/100 km). The company stated that the highest improvements were noticed while pulling trailers through the mountain canyon. It should be noted that this 34% increase in fuel economy includes both the performance increase from the K&N air filter and the nano oil additive.

The nano oil additive was added at an odometer reading of 11,283 miles (18,158 km) to a 2017 RAM high-output diesel (920 ft. lbs. torque in this year) with the Aisin transmission. This truck averaged 11.6 mpg (20.3 L/100 km) pulling a heavy trailer loaded with a tractor from Utah to South Dakota. On trips from Perry, Utah to Logan, Utah, pulling 7000–8000 lbs. on average, it was noted that after traveling 185 miles (297.7 km) with the nano oil additive, the average was up to 14.7 mpg (16.0 L/100 km), demonstrating a 26.7% increase.

The nano oil additive was added at an odometer reading of 36,019 miles (57,967 km) to a 2014 RAM high-output diesel with the Aisin transmission. The previous average fuel economy was 14.6 mpg, pulling trailers weighing 4500 lbs. on average. After the addition of the oil additive, the average fuel economy increased to 17.3 mpg (13.6 L/100 km) on the first day, pulling trailers with a total of 526 miles (846.5 km). After another 210 miles (338.0 km) of this same route pulling trailers, the average fuel economy increased up to 18.6 mpg (12.6 L/100 km), noting that the improvement increased over time.

References

- Golebiowski, W.; Krakowski, R.; Zajac, G. Degradation of anti-wear additives and tribological properties of engine oils at extended oil change intervals in city buses. Sci. Rep. 2025, 15, 27238. [Google Scholar] [CrossRef]

- Kumara, C.; Speed, L.; Viola, M.B.; Luo, H.; Qu, J. Using ionic liquid additive to enhance lubricating performance of low-viscosity engine oil. ACS Sustain. Chem. Eng. 2021, 9, 7198–7205. [Google Scholar] [CrossRef]

- Dubey, M.K.; Chaudhary, R.; Emmandi, R.; Seth, S.; Mahapatra, R.; Harinarain, A.K.; Ramakumar, S.S.V. Tribological evaluation of passenger car engine oil: Effect of friction modifiers. Results Eng. 2022, 16, 100727. [Google Scholar] [CrossRef]

- Agocs, A.; Besser, C.; Brenner, J.; Budnyk, S.; Frauscher, M.; Dorr, N. Engine oils in the field: A comprehensive tribological assessment of engine oil degradation in a passenger car. Tribol. Lett. 2022, 70, 28. [Google Scholar] [CrossRef]

- Huynh, K.K.; Tieu, K.A.; Pham, S.T. Synergistic and competitive effects between zinc dialkyldithiophosphates and modern generation of additives in engine oil. Lubricants 2021, 9, 35. [Google Scholar] [CrossRef]

- Omar, A.A.S.; Salehi, F.M.; Farooq, U.; Morina, A.; Neville, A. Chemical and physical assessment of engine oils degradation and additive depletion by soot. Tribol. Int. 2021, 160, 107054. [Google Scholar] [CrossRef]

- Chen, X.; Li, J. Superlubricity of carbon nanostructures. Carbon 2020, 158, 1–23. [Google Scholar] [CrossRef]

- Makowski, L.; Bojarska, Z.; Rozen, A. Rheological properties of engine oil with nano-additives based on MoS2 materials. Nanomaterials 2022, 12, 581. [Google Scholar] [CrossRef]

- Wu, H.; Wang, L.; Dong, G. Origin of the tribofilm from MoS2 nanoparticle oil additives: Dependence of oil film thickness on particle aggregation in rolling point contact. Friction 2020, 9, 1436–1449. [Google Scholar] [CrossRef]

- Alqahtani, B.; Hoziefa, W.; Moneam, H.M.A.; Hamoud, M.; Salunkhe, S.; Elshalakany, A.B.; Mottaleb, M.A.; Davim, J.P. Tribological performance and rheological properties of engine oil with graphene nano-additives. Lubricants 2022, 10, 137. [Google Scholar] [CrossRef]

- Kaleli, H.; Demirtas, S.; Uysal, V.; Karnis, I.; Stylianakis, M.M.; Anastasiadis, S.H.; Kim, D.E. Tribological performance investigation of a commercial engine oil incorporating reduced graphene oxide as additive. Nanomaterials 2021, 11, 386. [Google Scholar] [CrossRef]

- Nagarajan, T.; Sridewi, N.; Wong, W.P.; Walvekar, R.; Khanna, V.; Khalid, M. Synergistic performance evaluation of MoS2-hBN hybrid nanoparticles as a tribological additive in diesel-based engine oil. Sci. Rep. 2023, 13, 12559. [Google Scholar] [CrossRef]

- Tonk, R. The science and technology of using nano-materials in engine oil as lubricant additives. Mater. Today Proc. 2021, 37, 3475–3479. [Google Scholar] [CrossRef]

- Bojarska, Z.; Kopytowski, J.; Pawlicka, M.M.; Bazarnik, P.; Gierlotka, S.; Rozen, A.; Makowski, L. Molybdenum disulfide-based hybrid materials as new types of oil additives with enhanced tribological and rheological properties. Tribol. Int. 2021, 160, 106999. [Google Scholar] [CrossRef]

- Markandan, K.; Nagarajan, T.; Walvekar, R.; Chaudhary, V.; Khalid, M. Enhanced Tribological Behaviour of Hybrid MoS2@Ti3C2 MXene as an Effective Anti-Friction Additive in Gasoline Engine Oil. Lubricants 2023, 11, 47. [Google Scholar]

- Nagarajan, T.; Sridewi, N.; Wong, W.P.; Walvekar, R.; Khalid, M. Enhanced tribological properties of diesel-based engine oil through synergistic MoS2-graphene nanohybrid additive. Sci. Rep. 2023, 13, 17424. [Google Scholar] [CrossRef] [PubMed]

- Bailey, C.; Christensen, G.; Hong, H. Lubricant with Nanoparticulate Additive. US12122975B2, 22 October 2024. [Google Scholar]

- Kałużny, J.; Merkisz-Guranowska, A.; Giersig, M.; Kempa, K. Lubricating performance of carbon nanotubes in internal combustion engines—Engine test results for CNT enriched oil. Int. J. Automot. Technol. 2017, 18, 1047–1059. [Google Scholar] [CrossRef]

- Thachnatharen, N.; Khalid, M.; Arulraj, A.; Sridewi, N. Tribological performance of hexagonal boron nitride (hBN) as nano-additives in military grade diesel engine oil. Mater. Today Proc. 2022, 50, 70–73. [Google Scholar] [CrossRef]

- Bojarska, Z.; Goławska, W.; Mazurkiewicz-Pawlicka, M.; Makowski, Ł. Reducing particulate emissions by using advanced engine oil nanoadditives based on molybdenum disulfide and carbon nanotubes. Sci. Rep. 2023, 13, 13621. [Google Scholar] [CrossRef]

- Younes, H.; Mao, M.; Murshed, S.M.S.; Lou, D.; Hong, H.; Peterson, G.P. Nanofluids: Key parameters to enhance thermal conductivity and its applications. Appl. Therm. Eng. 2022, 207, 118202. [Google Scholar] [CrossRef]

- Xia, R.; Lou, D.; Younes, H.; Haiston, J.; Chen, H.; Hong, H. Synergistic effect of hexagonal boron nitride and carbon nanofibers on tribological behavior of nanolubricant. Tribol. Int. 2023, 177, 107957. [Google Scholar] [CrossRef]

- Lou, D.; Grablander, T.; Mao, M.; Hong, H.; Peterson, G.P. Improved thermal conductivity of PEG-based fluids using hydrogen bonding and long chain of nanoparticle. J. Nanopart. Res. 2021, 23, 98. [Google Scholar] [CrossRef]

- Cyriac, F.; Yi, T.X.; Poornachary, S.K.; Chow, P.S. Influence of base oil polarity on the tribological performance of surface-active engine oil additives. Tribol. Lett. 2021, 69, 87. [Google Scholar] [CrossRef]

- Akbiyik, T.; Kahraman, N.; Taner, T. Investigation of the effect of boron additive to lubricating oil on engine performance, exhaust, and emissions. Fuel 2022, 312, 122931. [Google Scholar] [CrossRef]

- Kashefi, M.H.; Saedodin, S.; Rostamian, S.H. Effect of silica nano-additive on flash point, pour point, rheological and tribological properties of lubricating engine oil: An experimental study. J. Therm. Anal. Calorim. 2021, 147, 4073–4086. [Google Scholar] [CrossRef]

- Mohamed, K.A.A.; Peng, F.; Younus, H.A.; Mohamed, A.A.A.; Essa, F.A.; Elagouz, A.; Hou, X. Fuel economy in gasoline engines using Al2O3/TiO2 nanomaterials as nanolubricant additives. Appl. Energy 2018, 211, 461–478. [Google Scholar]

- ASTM D2714-94(2019); Standard Test Method for Calibration and Operation of the Falex Block-on-Ring Friction and Wear Testing Machine. ASTM International: Conshohocken, PA, USA, 2019.

Figure 1.

Schematic diagram of oil filter pressure test.

Figure 1.

Schematic diagram of oil filter pressure test.

Figure 2.

Coefficient of friction (a) and wear analysis (b) of dosed oil samples S1–S9 by block-on-ring tests. S1 is pure base oil; S2–S9 contain one dose of oil additive with increasing CNT to BN ratio.

Figure 2.

Coefficient of friction (a) and wear analysis (b) of dosed oil samples S1–S9 by block-on-ring tests. S1 is pure base oil; S2–S9 contain one dose of oil additive with increasing CNT to BN ratio.

Figure 3.

Coefficient of friction (a) and wear analysis (b) of oil samples with 0 doses (before), 0.5 doses, and 1 dose of nano oil additive by block-on-ring tests.

Figure 3.

Coefficient of friction (a) and wear analysis (b) of oil samples with 0 doses (before), 0.5 doses, and 1 dose of nano oil additive by block-on-ring tests.

Figure 4.

Oil filter pressure difference changes over time for oil samples with 0 doses (before), 0.5 doses, and 1 dose of nano oil additive.

Figure 4.

Oil filter pressure difference changes over time for oil samples with 0 doses (before), 0.5 doses, and 1 dose of nano oil additive.

Figure 5.

Percent weight over temperature (a) and the decomposition temperature (b) of oil samples with 0 doses (before), 0.5 doses, 1 dose, and 2 doses of nano oil additive by thermogravimetric analysis.

Figure 5.

Percent weight over temperature (a) and the decomposition temperature (b) of oil samples with 0 doses (before), 0.5 doses, 1 dose, and 2 doses of nano oil additive by thermogravimetric analysis.

Figure 6.

Max torque (a) and horsepower (b) of six Harley-Davidson motorcycles with different ages and mileages. Required doses to achieve the maximum torque and horsepower: bike 1: 1.25 doses; bike 2: 1.5 doses; bike 3: 1 dose; bike 4: 1.5 doses; bike 5: 1.25 doses; bike 6: 1.75 doses.

Figure 6.

Max torque (a) and horsepower (b) of six Harley-Davidson motorcycles with different ages and mileages. Required doses to achieve the maximum torque and horsepower: bike 1: 1.25 doses; bike 2: 1.5 doses; bike 3: 1 dose; bike 4: 1.5 doses; bike 5: 1.25 doses; bike 6: 1.75 doses.

Figure 7.

Torque over RPM curves (a) and maximum torque and horsepower results (b) of oil samples with 0 doses (before), 0.5 doses, 1 doses, and 1.25 doses of nano oil additive tested in a Chevy Crate engine.

Figure 7.

Torque over RPM curves (a) and maximum torque and horsepower results (b) of oil samples with 0 doses (before), 0.5 doses, 1 doses, and 1.25 doses of nano oil additive tested in a Chevy Crate engine.

Figure 8.

Fuel consumption of a light tower generator with oils containing 0 doses (before), 1 dose, and 2 doses of nano oil additive.

Figure 8.

Fuel consumption of a light tower generator with oils containing 0 doses (before), 1 dose, and 2 doses of nano oil additive.

Figure 9.

Fuel economy of four semi-trucks with different ages and mileages. Trucks 1–3 were single dosed and truck 4 was double-dosed.

Figure 9.

Fuel economy of four semi-trucks with different ages and mileages. Trucks 1–3 were single dosed and truck 4 was double-dosed.

Table 1.

Details of the six selected Harley-Davidson motorcycles.

Table 1.

Details of the six selected Harley-Davidson motorcycles.

| | Year | Model | Mileage (Miles) | Oil Capacity (Qts) |

|---|

| Bike 1 | 2002 | FXDL Dyna Low Rider | 10,338 (16,637 km) | 3 (2.8 L) |

| Bike 2 | 2005 | FXDL Dyna Low Rider | 18,188 (29,271 km) | 3 (2.8 L) |

| Bike 3 | 2009 | FXSTB Night Train | 25,322 (40,782 km) | 3 (2.8 L) |

| Bike 4 | 1998 | FLHR Road King | 56,985 (91,708 km) | 4 (3.8 L) |

| Bike 5 | 2017 | FLTRXS Road Glide | 6925 (11,145 km) | 5 (4.7 L) |

| Bike 6 | 2009 | Dyna Fat Bob | 54,578 * (87,835 km) | 3 (2.8 L) |

Table 2.

Torque and horsepower (HP) of pickup trucks before and after dosing with the additive.

Table 2.

Torque and horsepower (HP) of pickup trucks before and after dosing with the additive.

| | Before | After Dosing | Max Increase |

|---|

| 1 Dose | 1.5 Doses | 2 Doses | 3 Doses | Cool Down |

|---|

| Truck 1 | HP | 295.76 | 295.96 | / | 300.35 | 300.54 | 307.06 | 3.80% |

| Torque | 323.61 | 324.53 | / | 328.51 | 328.55 | 335.24 | 3.60% |

| Truck 2 | HP | 293.61 | / | 294.43 | / | 296.20 | / | 0.88% |

| Torque | 308.42 | / | 312.63 | / | 309.92 | / | 1.37% |

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).