Molecular Dynamics Study on the Tribological Characteristics of Grain Boundary-Containing Graphene/h-BN Heterostructure Films

Abstract

1. Introduction

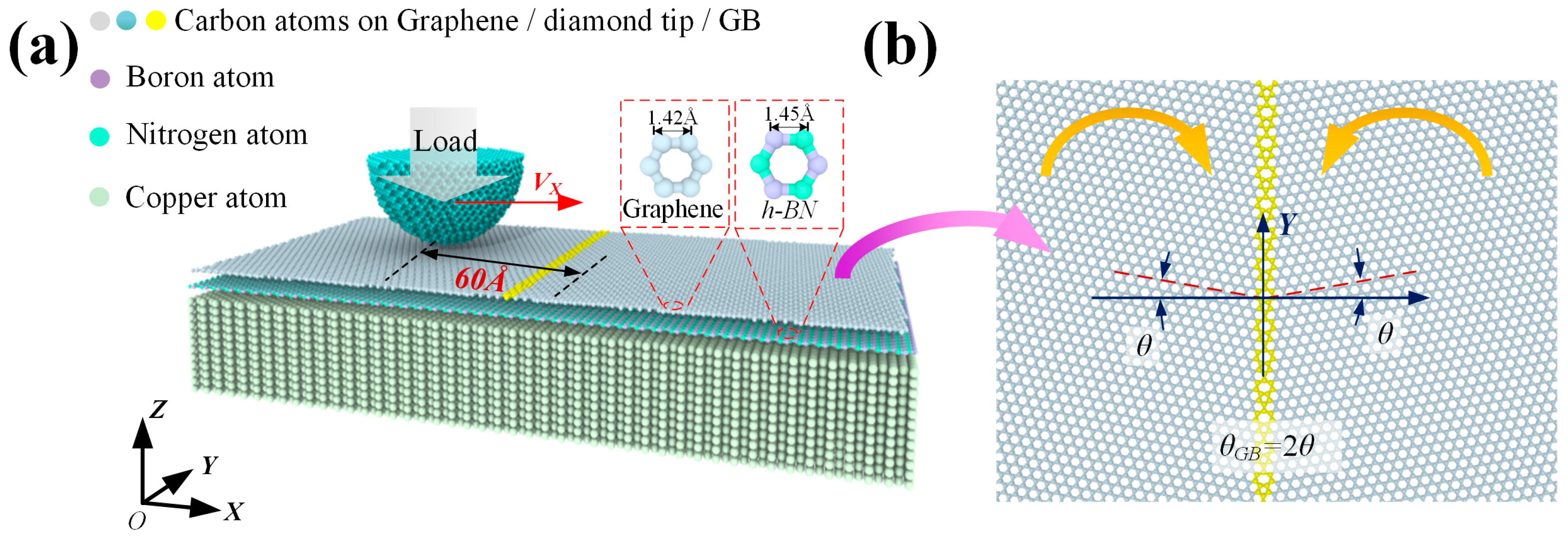

2. Molecular Dynamics Modeling

3. Results and Discussion

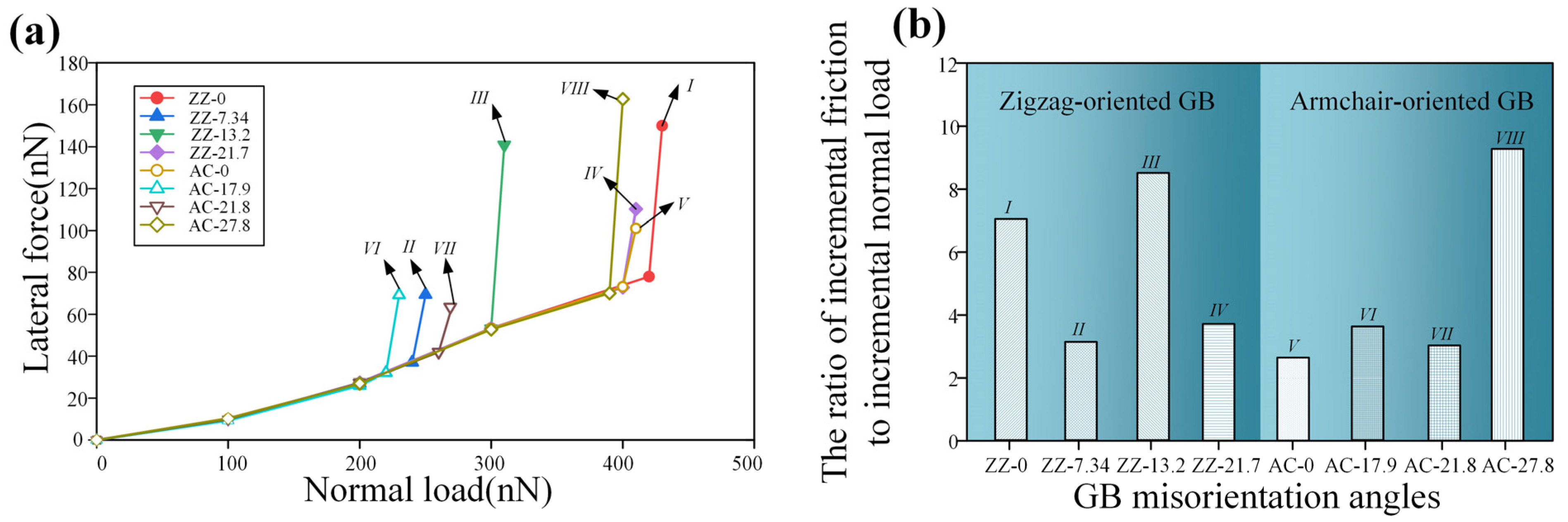

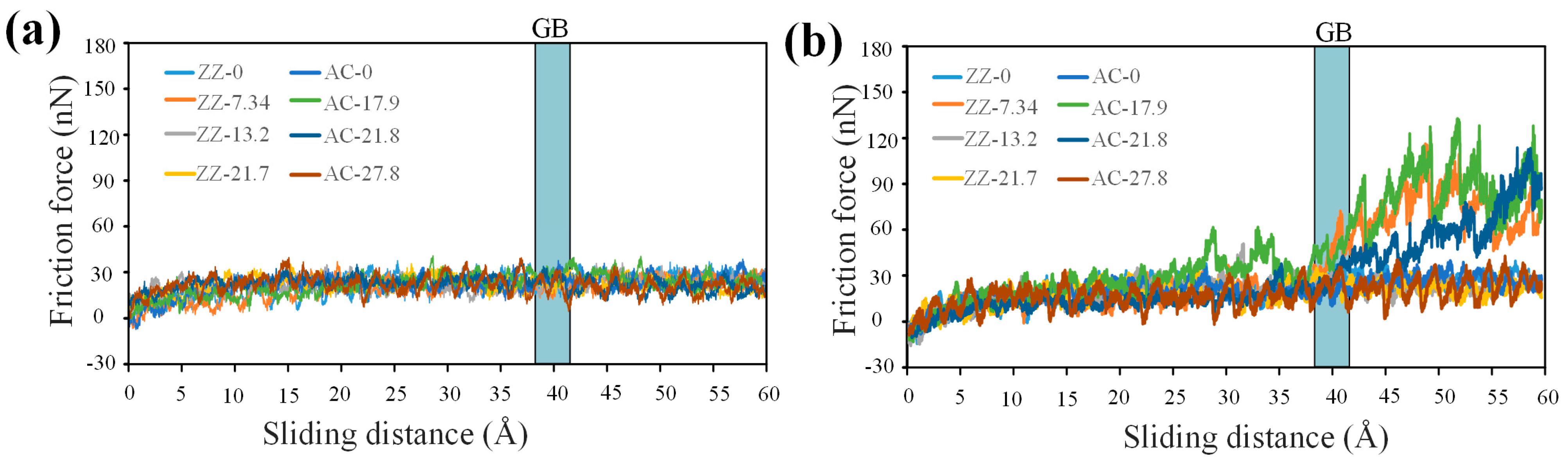

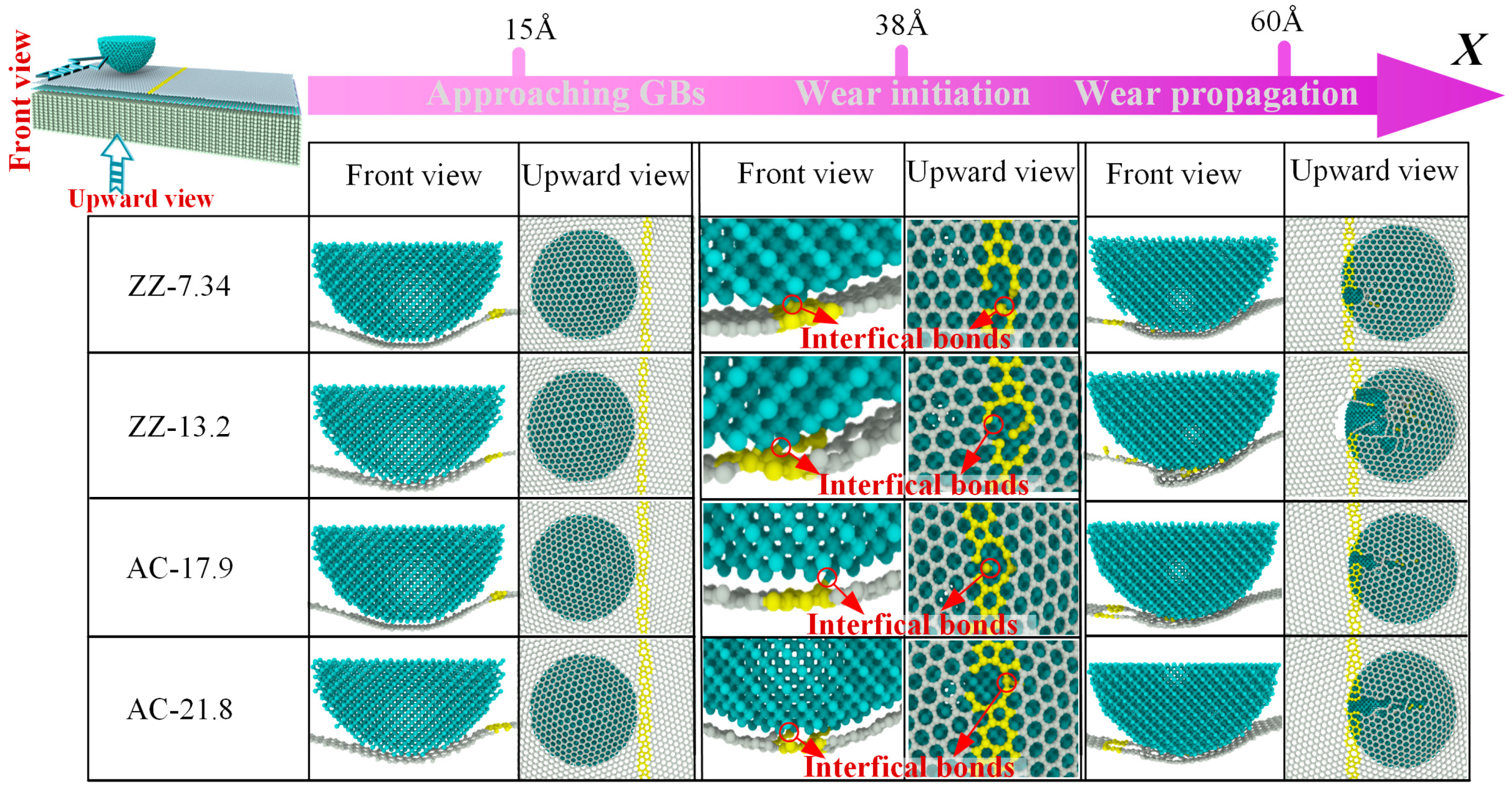

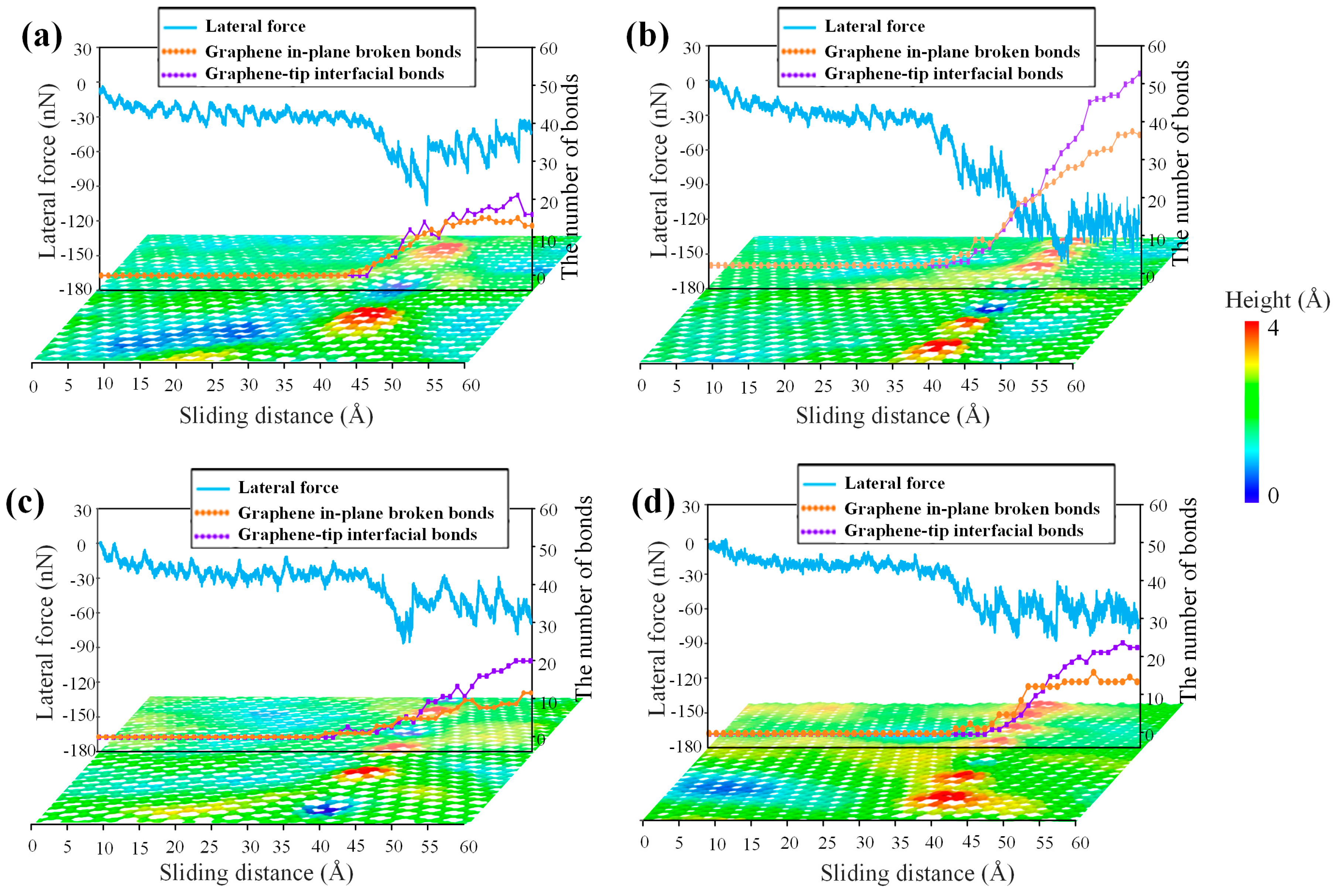

3.1. Effects of GBs with Different Misorientation Angles on the Tribological Performances of the Heterostructure Film

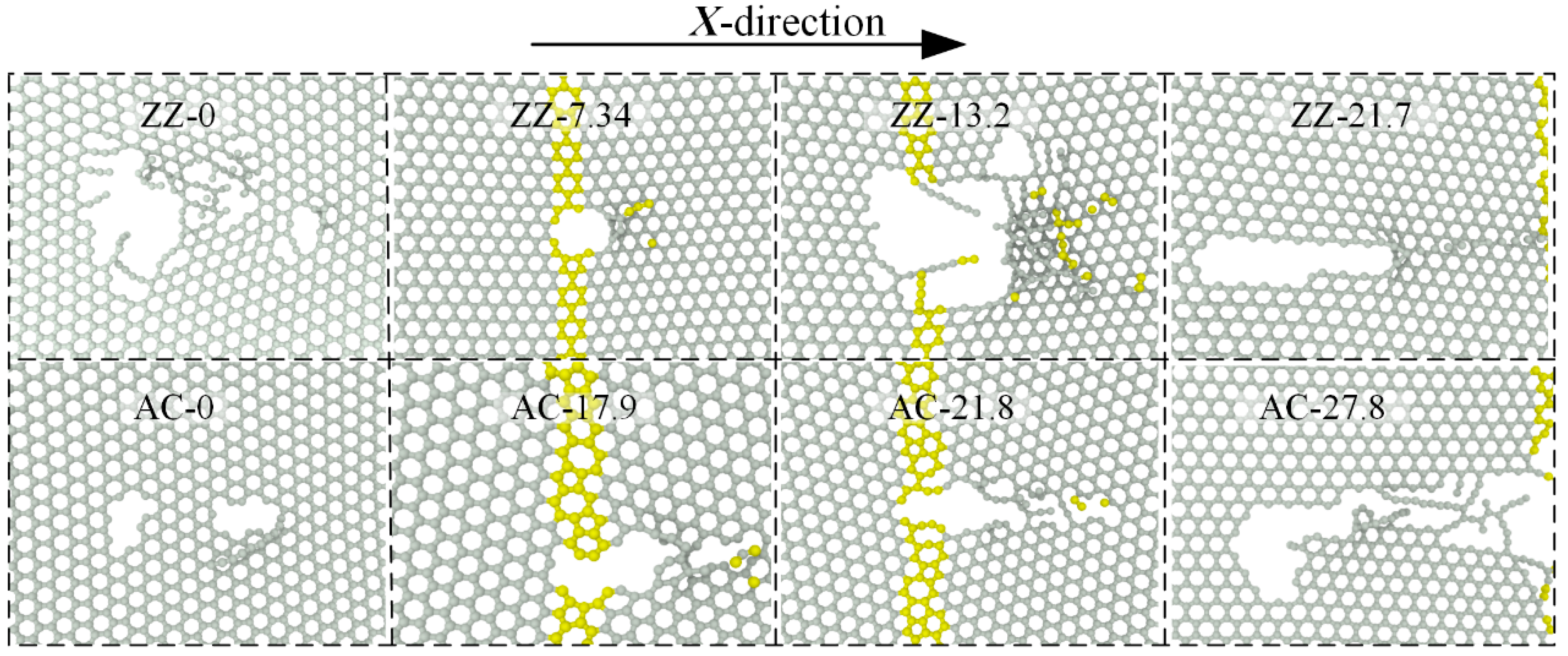

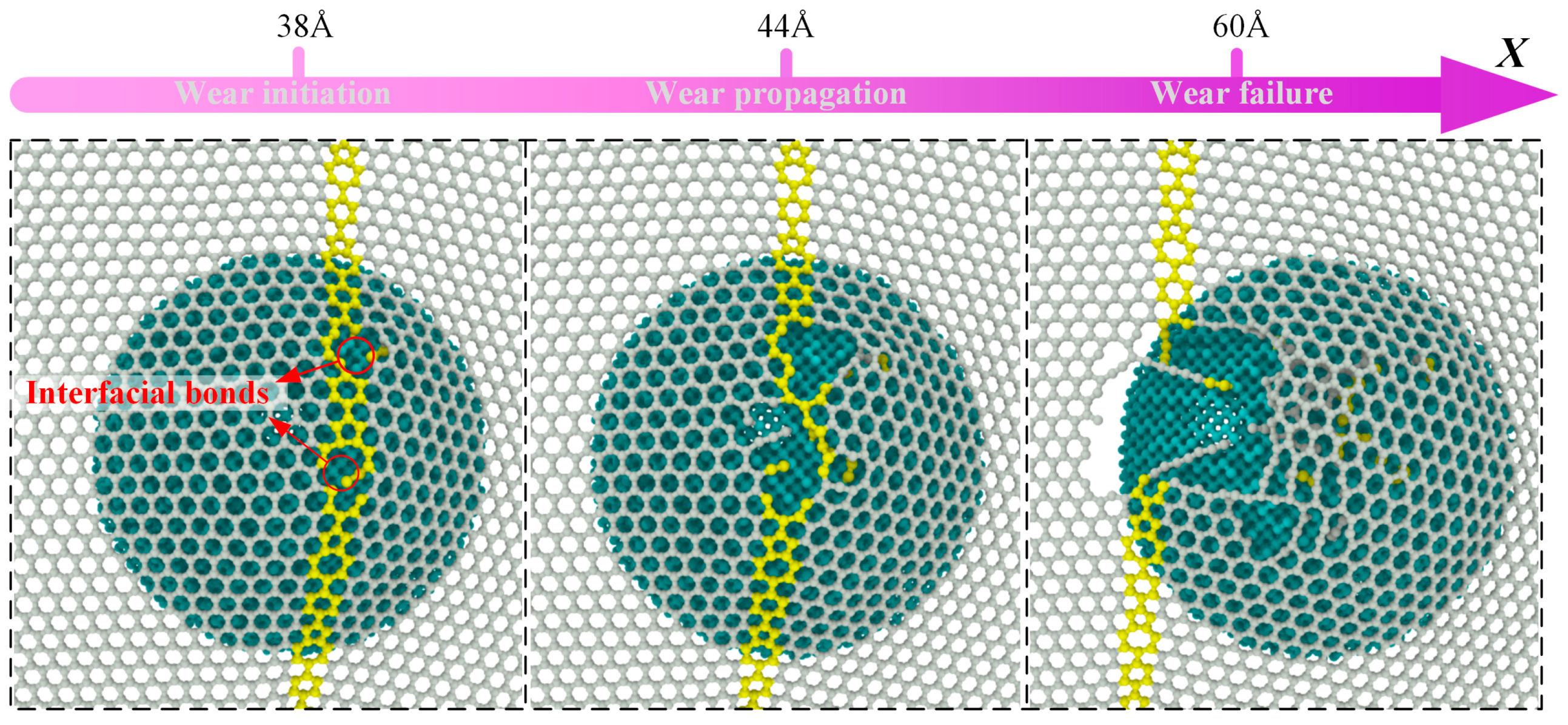

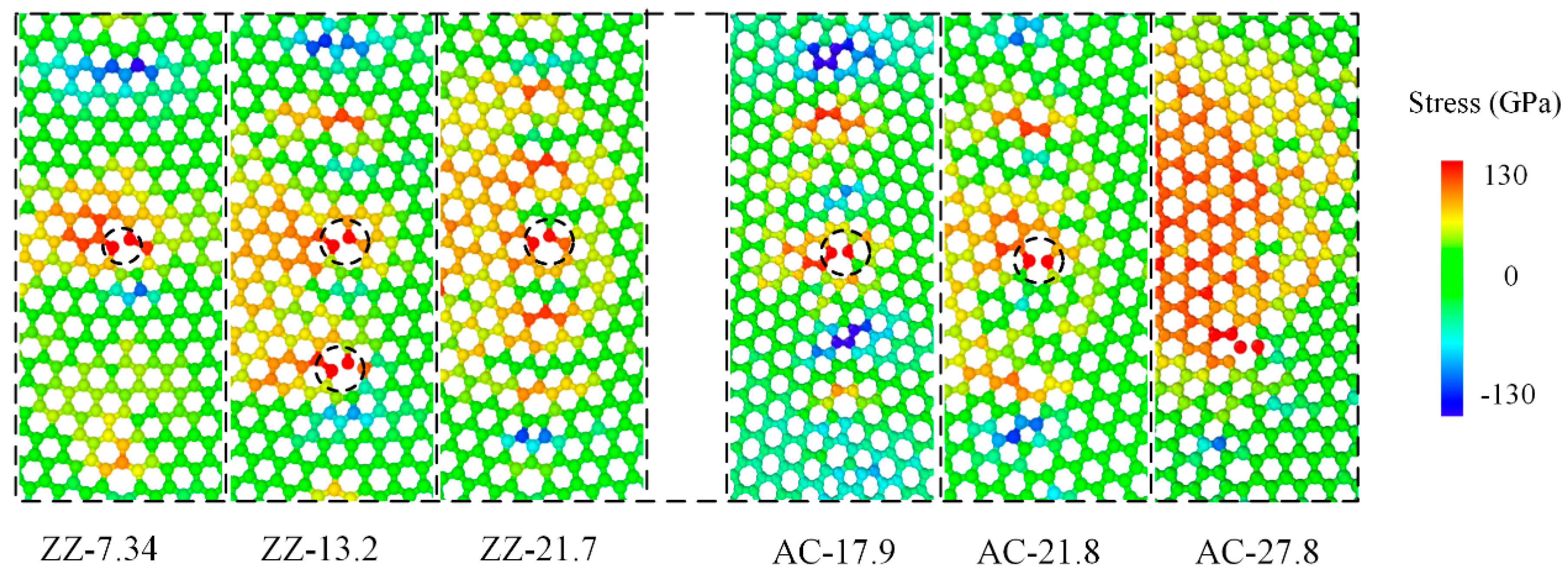

3.2. Weakening Mechanism of GBs on the Wear Resistance of Heterostructure Films

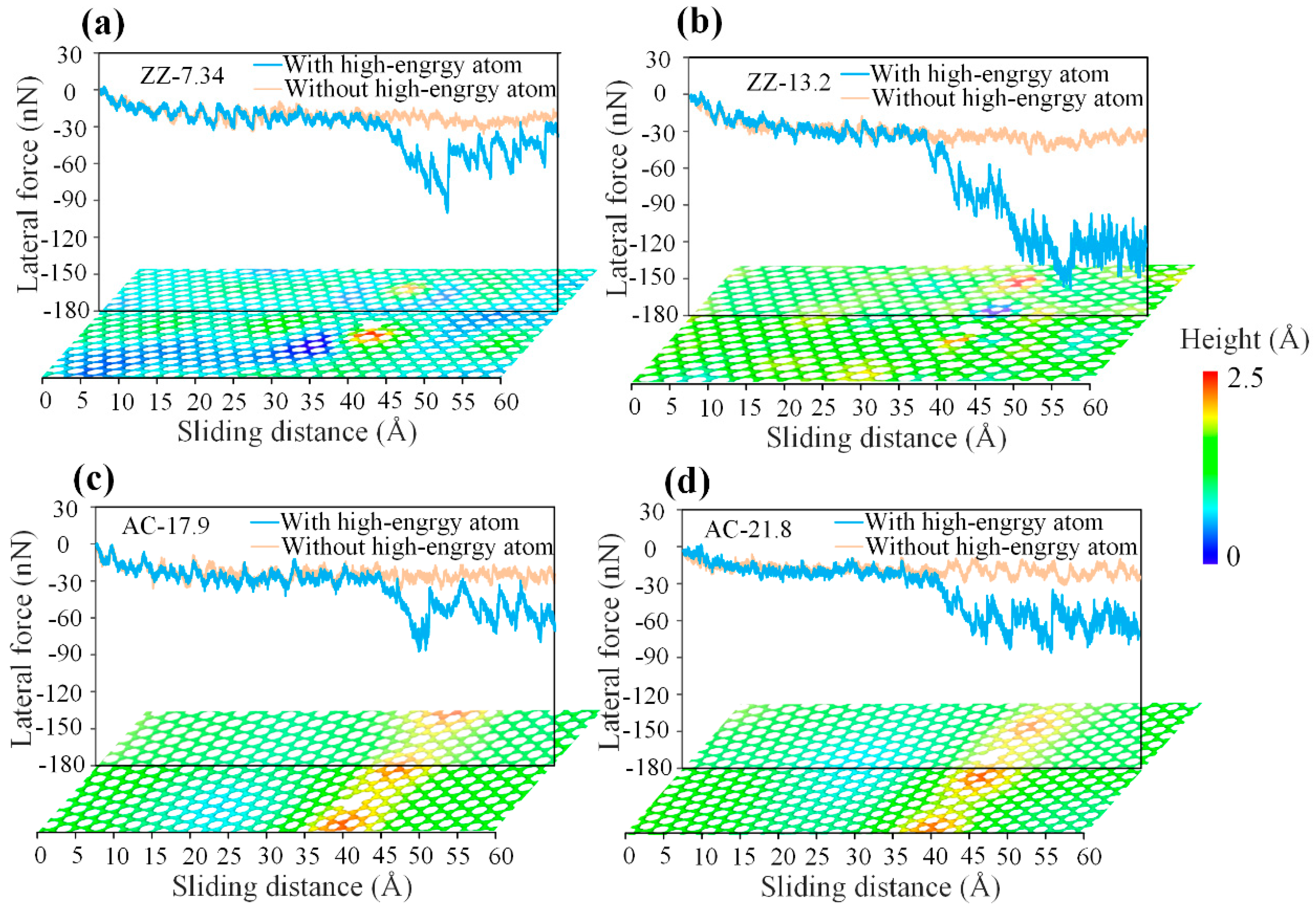

3.3. The Tribological Performance of the Heterostructure Film with Point Defect on GB Structures

4. Conclusions

- (1)

- The bicrystal structure has little influence on the friction resistance, but can reduce the mechanical strength and weaken the wear resistance performance of the heterostructure film. Furthermore, with the increase in GB misorientation angle, this weakening effect gradually decreases.

- (2)

- There exist high-energy atoms shared by heptagon and hexagon rings on the GBs, which can easily form interfacial bonds with the diamond tip. These atoms result from the misorientation angle of the GBs and can lead to stress concentration and large pre-strain of the covalent bond, thus significantly decreasing the wear resistance of the film.

- (3)

- The occurrence of point defects on the bicrystal graphene layer can reduce the strength and wear resistance of the heterostructure film. While the point defects occurring on high-energy atoms can significantly alleviate the stress concentration at GBs, this can obviously increase the mechanical strength of the heterostructure film, and thus is conducive to improving the wear resistance property of the film.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Jin, B.; Chen, G.; Zhao, J.; He, Y.; Li, Y.; Luo, J. Coupling effect of boundary tribofilm and hydrodynamic film. Cell Rep. Phys. Sci. 2022, 3, 100778. [Google Scholar] [CrossRef]

- Zhang, H.W.; Guo, Z.R.; Gao, H.; Chang, T.C. Stiffness-dependent interlayer friction of graphene. Carbon 2015, 94, 60–66. [Google Scholar] [CrossRef]

- Li, L.L.; Meng, F.W.; Zou, K.; Huang, Y.; Peng, Y.T. Friction properties of suspended graphene. Acta Phys. Sin. 2021, 70, 086801. [Google Scholar] [CrossRef]

- Yin, N.; Zhang, Z.N.; Zhang, J.Y. Frictional Contact Between the Diamond Tip and Graphene Step Edges. Tribol. Lett. 2019, 67, 75. [Google Scholar] [CrossRef]

- Guo, W.M.; Bai, Q.S.; Dou, Y.H.; Chen, S.D.; Wang, H.F. Molecular dynamics simulation of frictional strengthening behavior of graphene on stainless steel substrate. Carbon 2022, 197, 183–191. [Google Scholar] [CrossRef]

- Prasai, D.; Tuberquia, J.C.; Harl, R.R.; Jennings, G.K.; Bolotin, K.I. Graphene: Corrosioninhibiting coating. ACS Nano 2012, 6, 1102–1108. [Google Scholar] [CrossRef]

- Khan, M.H.; Jamali, S.S.; Lyalin, A.; Molino, P.J.; Jiang, L.; Liu, H.K.; Taketsugu, T.; Huang, Z. Atomically thin hexagonal boron nitride nanofilm for Cu protection: The importance of film perfection. Adv. Mater. 2017, 29, 1603937. [Google Scholar] [CrossRef]

- Zhou, F.; Li, Z.T.; Shenoy, G.J.; Li, L.; Liu, H.T. Enhanced Room-Temperature Corrosion of Copper in the Presence of Graphene. ACS Nano 2013, 7, 6939–6947. [Google Scholar] [CrossRef]

- Schriver, M.; Regan, W.; Gannett, W.J.; Zaniewski, A.M.; Crommie, M.F.; Zettl, A. Graphene as a Long-Term Metal Oxidation Barrier: Worse than Nothing. ACS Nano 2013, 7, 5763–5768. [Google Scholar] [CrossRef]

- Li, Y.F.; Zhang, W.W.; Guo, B.; Datta, D. Interlayer shear of nanomaterials: Graphene—Graphene, boron nitride—Boron nitride and graphene—Boron nitride. Acta Mech. Solida Sin. 2017, 30, 234–240. [Google Scholar] [CrossRef]

- Mandelli, D.; Leven, I.; Hod, O.; Urbakh, M. Sliding friction of graphene/hexagonal—Boron nitride heterojunctions: A route to robust superlubricity. Sci. Rep. 2017, 7, 10851. [Google Scholar] [CrossRef] [PubMed]

- Leven, I.; Krepel, D.; Shemesh, O.; Hod, O. Robust Superlubricity in Graphene/h-BN Heterojunctions. J. Phys. Chem. Lett. 2013, 4, 115–120. [Google Scholar] [CrossRef]

- Wang, J.; Khosravi, A.; Vanossi, A.; Tosatti, E. Colloquium: Sliding and pinning in structurally lubric 2D material interfaces. Rev. Mod. Phys. 2024, 96, 011002. [Google Scholar] [CrossRef]

- Hagendoorn, Y.; Pandraud, G.; Vollebregt, S.; Morana, B.; Sarro, P.M.; Steeneken, P.G. Direct Wafer-Scale CVD Graphene Growth under Platinum Thin-Films. Materials 2022, 15, 3723. [Google Scholar] [CrossRef]

- Pedrazzetti, L.; Gibertini, E.; Bizzoni, F.; Russo, V.; Lucotti, A.; Nobili, L.; Magagnin, L. Graphene Growth on Electroformed Copper Substrates by Atmospheric Pressure CVD. Materials 2022, 15, 1572. [Google Scholar] [CrossRef] [PubMed]

- Jiang, L.L.; Xiao, N.; Wang, B.R.; Grustan-Gutierrez, E.; Jing, X.; Babor, P.; Kolíbal, M.; Lu, G.; Wu, T.; Wang, H.; et al. High resolution characterization of hexagonal boron nitride coatings exposed to aqueous and air oxidative environments. Nano Res. 2017, 10, 2046–2055. [Google Scholar] [CrossRef]

- Yan, K.; Lee, H.-W.; Gao, T.; Zheng, G.; Yao, H.; Wang, H.; Lu, Z.; Zhou, Y.; Liang, Z.; Liu, Z.; et al. Ultrathin two-dimensional atomic crystals as stable interfacial layer for improvement of lithium metal anode. Nano Lett. 2014, 14, 6016–6022. [Google Scholar] [CrossRef] [PubMed]

- Cao, A.J.; Yuan, Y.T. Atomistic study on the strength of symmetric tilt grain boundaries in graphene. Appl. Phys. Lett. 2012, 100, 211912. [Google Scholar] [CrossRef]

- Liu, T.H.; Pao, C.W.; Chang, C.C. Effects of dislocation densities and distributions on graphene grain boundary failure strengths from atomistic simulations. Carbon 2012, 50, 3465–3472. [Google Scholar] [CrossRef]

- Yan, Y.; Lin, J.; Huang, K.; Zheng, X.; Qiao, L.; Liu, S.; Cao, J.; Jun, S.C.; Yamauchi, Y.; Qi, J. Tensile Strain-Mediated Spinel Ferrites Enable Superior Oxygen Evolution Activity. J. Am. Chem. Soc. 2023, 145, 24218–24229. [Google Scholar] [CrossRef]

- Qin, B.; Zhao, X.; Wang, Q.; Yao, W.; Cai, Y.; Chen, Y.; Wang, P.; Zou, Y.; Cao, J.; Zheng, X.; et al. A tandem electrocatalyst with dense heterointerfaces enabling the stepwise conversion of polysulfide in lithium-sulfur batteries. Energy Storage Mater. 2023, 55, 445–454. [Google Scholar] [CrossRef]

- Wang, Q.; Qin, B.; Jiang, Q.; Wang, B.; Chen, Y.; Yao, W.; Qi, J. Highly dispersed conductive and electrocatalytic mediators enabling rapid polysulfides conversion for lithium sulfur batteries. Chem. Eng. J. 2023, 476, 146865. [Google Scholar] [CrossRef]

- Dienwiebel, M.; Verhoeven, G.S.; Pradeep, N.; Frenken, J.W.; Heimberg, J.A.; Zandbergen, H.W. Superlubricity of graphite. Phys. Rev. Lett. 2004, 92, 126101. [Google Scholar] [CrossRef] [PubMed]

- Bai, L.C.; Srikanth, N.; Zhao, B.; Liu, B.; Liu, Z.S.; Zhou, K. Lubrication mechanisms of graphene for DLC films scratched by a diamond tip. J. Phys. D Appl. Phys. 2016, 49, 485302. [Google Scholar] [CrossRef]

- Zhao, B.; Yu, X.; Liu, Y.; Yang, L.; Zhang, Z.; Zhang, B. Frictional characteristics of heterostructure film composed of graphene and H-BN with the consideration of defects. Tribol. Int. 2021, 153, 106607. [Google Scholar] [CrossRef]

- Zhao, B.; Zhang, Y.T.; Fan, Y.Y.; Yu, X.T.; Zhang, Z.A.; Zhang, B.C. The three-body abrasive tribological characteristics of the Graphene/h-BN heterostructure film considering defects. Tribol. Int. 2022, 171, 107525. [Google Scholar] [CrossRef]

- Lee, S.M.; Kim, J.H.; Ahn, J.H. Graphene as a flexible electronic material: Mechanical limitations by defect formation and efforts to overcome. Mater. Today 2015, 18, 336–344. [Google Scholar] [CrossRef]

- Lahiri, J.; Lin, Y.; Bozkurt, P.; Oleynik, I.I.; Batzill, M. An extended defect in graphene as a metallic wire. Nat. Nanotechnol. 2010, 5, 326–329. [Google Scholar] [CrossRef]

- Huang, P.Y.; Ruiz-Vargas, C.S.; van der Zande, A.M.; Whitney, W.S.; Levendorf, M.P.; Kevek, J.W.; Garg, S.; Alden, J.S.; Hustedt, C.J.; Zhu, Y.; et al. Grains and grain boundaries in single-layer graphene atomic patchwork quilts. Nature 2011, 469, 389–392. [Google Scholar] [CrossRef]

- Yazyev, O.V.; Louie, S.G. Topological defects in graphene: Dislocations and grain boundaries. Phys. Rev. B 2010, 81, 195420. [Google Scholar] [CrossRef]

- Liu, T.H.; Gajewski, G.; Pao, C.W.; Chang, C.C. Structure, energy, and structural transformations of graphene grain boundaries from atomistic simulations. Carbon 2011, 49, 2306–2317. [Google Scholar] [CrossRef]

- Kotakoski, J.; Meyer, J.C. Mechanical properties of polycrystalline graphene based on a realistic atomistic model. Phys. Rev. B—Condens. Matter Mater. Phys. 2012, 85, 689–693. [Google Scholar] [CrossRef]

- Kavalur, A.; Kim, W.K. Molecular dynamics study on friction of polycrystalline graphene. Comput. Mater. Sci. 2017, 137, 346–361. [Google Scholar] [CrossRef]

- Liu, T.Y.; Kim, C.J. Turning a surface superrepellent even to completely wetting liquids. Science 2014, 346, 1096–1100. [Google Scholar] [CrossRef] [PubMed]

- Wei, Y.J.; Wu, J.T.; Yin, H.Q.; Shi, X.H.; Yang, R.G.; Dresselhaus, M. The nature of strength enhancement and weakening by pentagon-heptagon defects in graphene. Nat. Mater. 2012, 11, 759–763. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, X.; Xu, Q.; Ma, T.; Hu, Y.; Wang, H.; Tieu, A.K.; Luo, J. Effects of grain boundary on wear of graphene at the nanoscale: A molecular dynamics study. Carbon 2019, 143, 578–586. [Google Scholar] [CrossRef]

- Sun, X.Y.; Wu, R.N.; Xia, R.; Chu, X.H.; Xu, Y.J. Effects of Stone-Wales and Vacancy Defects in Atomic-Scale Friction on Defective Graphite. Appl. Phys. Lett. 2014, 104, 183109. [Google Scholar] [CrossRef]

- Neek-Amal, M.; Peeters, F.M. Nanoindentation of a circular sheet of bilayer graphene. Phys. Rev. B 2010, 81, 235421. [Google Scholar] [CrossRef]

- Mortazavi, B.; Ahzi, S. Thermal conductivity and tensile response of defective graphene: A molecular dynamics study. Carbon 2013, 63, 460–470. [Google Scholar] [CrossRef]

- Lin, X.; Zhang, H.W.; Guo, Z.R.; Chang, T.C. Strain engineering of friction between graphene layers. Tribol. Int. 2019, 131, 686–693. [Google Scholar] [CrossRef]

- Wang, L.; Gong, P.W.; Li, W.; Luo, T.; Cao, B.Q. Mono-dispersed Ag/Graphene nanocomposite as lubricant additive to reduce friction and wear. Tribol. Int. 2020, 146, 106228. [Google Scholar] [CrossRef]

- Hsieh, Y.P.; Hofmann, M.; Chang, K.W.; Jhu, J.G.; Li, Y.Y.; Chen, K.Y.; Yang, C.C.; Chang, W.-S.; Chen, L.-C. Complete Corrosion Inhibition through Graphene Defect Passivation. ACS Nano 2014, 8, 443–448. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.M.; Mandelli, D.; Hod, O.; Urbakh, M.; Ma, M.; Zheng, Q.S. Robust microscale superlubricity in graphite/hexagonal boron nitride layered heterojunctions. Nat. Mater. 2018, 17, 894–899. [Google Scholar] [CrossRef] [PubMed]

- Tiwari, A.; Singh Raman, R.K. Durable Corrosion Resistance of Copper Due to Multi-Layer Graphene. Materials 2017, 10, 1112. [Google Scholar] [CrossRef]

- Wang, L.F.; Duan, F.L. Nanoscale wear mechanisms of few-layer graphene sheets induced by interfacial adhesion. Tribol. Int. 2018, 123, 266–272. [Google Scholar] [CrossRef]

- Alborzi, M.S.; Rajabpour, A. Thermal transport in van der Waals graphene/boron-nitride structure: A molecular dynamics study. Eur. Phys. J. Plus 2021, 136, 959. [Google Scholar] [CrossRef]

- Barboza, A.P.M.; Souza, A.C.R.; Matos, M.J.S.; Brant, J.C.; Barbosa, T.C.; Chacham, H.; Mazzoni, M.S.; Neves, B.R. Graphene/h-BN heterostructures under pressure: From van der Waals to covalent. Carbon 2019, 155, 108–113. [Google Scholar] [CrossRef]

- Daw, M.S. Model of metallic cohesion: The embedded-atom method. Phys. Rev. B Condens. Matter 1989, 39, 7441–7452. [Google Scholar] [CrossRef]

- Liu, X.; Wang, F.; Wang, W.; Wu, H. Interfacial strengthening and self-healing effect in graphene-copper nanolayered composites under shear deformation. Carbon 2016, 107, 680–688. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, G.; Song, J.; Ding, Q. Study on the tribological properties of copper coated by graphene and h-BN from the atomic scale. Appl. Surf. Sci. 2021, 573, 151548. [Google Scholar] [CrossRef]

- Wei, B.Y.; Kong, N.; Zhang, J.; Li, H.B.; Hong, Z.J.; Zhu, H.T.; Zhuang, Y.; Wang, B. A molecular dynamics study on the tribological behavior of molybdenum disulfide with grain boundary defects during scratching processes. Friction 2021, 9, 1198–1212. [Google Scholar] [CrossRef]

- Carlsson, J.M.; Ghiringhelli, L.M.; Fasolino, A. Theory and hierarchical calculations of the structure and energetics of [0001] tilt grain boundaries in graphene. Phys. Rev. B—Condens. Matter Mater. Phys. 2011, 84, 165423. [Google Scholar] [CrossRef]

- Tison, Y.; Lagoute, J.; Repain, V.; Chacon, C.; Girard, Y.; Joucken, F.; Sporken, R.; Gargiulo, F.; Yazyev, O.V.; Rousset, S. Grain Boundaries in Graphene on SiC(000) Substrate. Nano Lett. 2014, 14, 6382–6386. [Google Scholar]

- Varchon, F.; Mallet, P.; Magaud, L.; Veuillen, J.-Y. Rotational disorder in few-layer graphene films on 6H-SiC(000-1): A scanning tunneling microscopy study. Phys. Rev. B 2008, 77, 165415. [Google Scholar] [CrossRef]

- Zhu, P.Z.; Li, R.; Gong, H.Y. Molecular Dynamics Simulation of Nanoscale Abrasive Wear of Polycrystalline Silicon. Crystals 2018, 8, 463. [Google Scholar] [CrossRef]

- Zheng, F.; Duan, F. Atomistic mechanism of the weakened wear resistance of few-layer graphene induced by point defects. Tribol. Int. 2019, 134, 87–92. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Wang, C.M.; Cheng, Y.; Xiang, Y. Mechanical properties of bilayer graphene sheets coupled by sp3 bonding. Carbon 2011, 49, 4511–4517. [Google Scholar] [CrossRef]

- Sandoz-Rosado, E.J.; Tertuliano, O.A.; Terrell, E.J. An atomistic study of the abrasive wear and failure of graphene sheets when used as a solid lubricant and a comparison to diamond-like-carbon coatings. Carbon 2012, 50, 4078–4084. [Google Scholar] [CrossRef]

- Yi, L.J.; Yin, Z.N.; Zhang, Y.Y.; Chang, T.C. A theoretical evaluation of the temperature and strain-rate dependent fracture strength of tilt grain boundaries in graphene. Carbon 2013, 51, 373–380. [Google Scholar] [CrossRef]

- Li, Y.F.; Datta, D.; Li, Z.H. Anomalous mechanical characteristics of graphene with tilt grain boundaries tuned by hydrogenation. Carbon 2015, 90, 234–241. [Google Scholar] [CrossRef]

- Kataria, A.; Verma, A.; Sanjay, M.R.; Siengchin, S. Molecular modeling of 2D graphene grain boundaries: Mechanical and fracture aspects. Mater. Today Proc. 2022, 52, 2404–2408. [Google Scholar] [CrossRef]

- Su, Y.; Yang, B.; Wei, Q.; Hu, N. Atomic-scale mechanical behaviors of polycrystalline graphene under biaxial loadings and high temperature. Ceram. Int. 2022, 48, 18918–18924. [Google Scholar] [CrossRef]

- Zhang, G.Q.; Liu, H.C.; Chen, Y.; Qin, H.S.; Liu, Y.L. Strength criterion of graphene GBs combining discrete bond strength and varied bond stretch. J. Mech. Phys. Solids 2022, 169, 105080. [Google Scholar] [CrossRef]

- Grantab, R.; Shenoy, V.B.; Ruoff, R.S. Anomalous Strength Characteristics of Tilt Grain Boundaries in Graphene. Science 2010, 330, 946–948. [Google Scholar] [CrossRef]

- Zhang, P.; Ma, L.L.; Fan, F.F.; Zeng, Z.; Peng, C.; Loya, P.E.; Liu, Z.; Gong, Y.; Zhang, J.; Zhang, X.; et al. Fracture toughness of graphene. Nat. Commun. 2014, 5, 3782. [Google Scholar] [CrossRef] [PubMed]

- Deng, Z.; Smolyanitsky, A.; Li, Q.Y.; Feng, X.Q.; Cannara, R.J. Adhesion-dependent negative friction coefficient on chemically modified graphite at the nanoscale. Nat. Mater. 2012, 11, 1032–1037. [Google Scholar] [CrossRef]

- Kwon, S.; Ko, J.H.; Jeon, K.J.; Kim, Y.H.; Park, J.Y. Enhanced Nanoscale Friction on Fluorinated Graphene. Nano Lett. 2012, 12, 6043–6048. [Google Scholar] [CrossRef]

| L-J Potential | ε (eV) | σ (Å) |

|---|---|---|

| C-Cu | 0.019996 | 3.225 |

| B-Cu | 0.0013009 | 3.3756 |

| N-Cu | 0.00080545 | 3.1872 |

| Zigzag-Oriented | Armchair-Oriented | |||||||

|---|---|---|---|---|---|---|---|---|

| ZZ-7.34 | ZZ-13.2 | ZZ-21.7 | ZZ-0 | AC-17.9 | AC-21.8 | AC-27.8 | AC-0 | |

| Fcn (nN) | 250 | 310 | 410 | 430 | 230 | 270 | 400 | 410 |

| Zigzag-Oriented | Armchair-Oriented | |||

|---|---|---|---|---|

| ZZ-7.34 | ZZ-13.2 | AC-17.9 | AC-21.8 | |

| Fcn (nN) | 300 | 370 | 300 | 310 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, B.; Huang, S.; Zhang, Y.; Ju, X.; Li, C.; Li, Z.; Xu, L. Molecular Dynamics Study on the Tribological Characteristics of Grain Boundary-Containing Graphene/h-BN Heterostructure Films. Lubricants 2024, 12, 296. https://doi.org/10.3390/lubricants12080296

Zhao B, Huang S, Zhang Y, Ju X, Li C, Li Z, Xu L. Molecular Dynamics Study on the Tribological Characteristics of Grain Boundary-Containing Graphene/h-BN Heterostructure Films. Lubricants. 2024; 12(8):296. https://doi.org/10.3390/lubricants12080296

Chicago/Turabian StyleZhao, Bo, Shifan Huang, Yutao Zhang, Xiangcheng Ju, Chengbang Li, Zhenglin Li, and Lingji Xu. 2024. "Molecular Dynamics Study on the Tribological Characteristics of Grain Boundary-Containing Graphene/h-BN Heterostructure Films" Lubricants 12, no. 8: 296. https://doi.org/10.3390/lubricants12080296

APA StyleZhao, B., Huang, S., Zhang, Y., Ju, X., Li, C., Li, Z., & Xu, L. (2024). Molecular Dynamics Study on the Tribological Characteristics of Grain Boundary-Containing Graphene/h-BN Heterostructure Films. Lubricants, 12(8), 296. https://doi.org/10.3390/lubricants12080296