Sheet Forming via Limiting Dome Height (LDH) Test: Influence of the Application of Lubricants, Location and Sheet Thickness on the Micro-Mechanical Properties of X8CrMnNi19-6-3

Abstract

1. Introduction

2. Materials and Methods

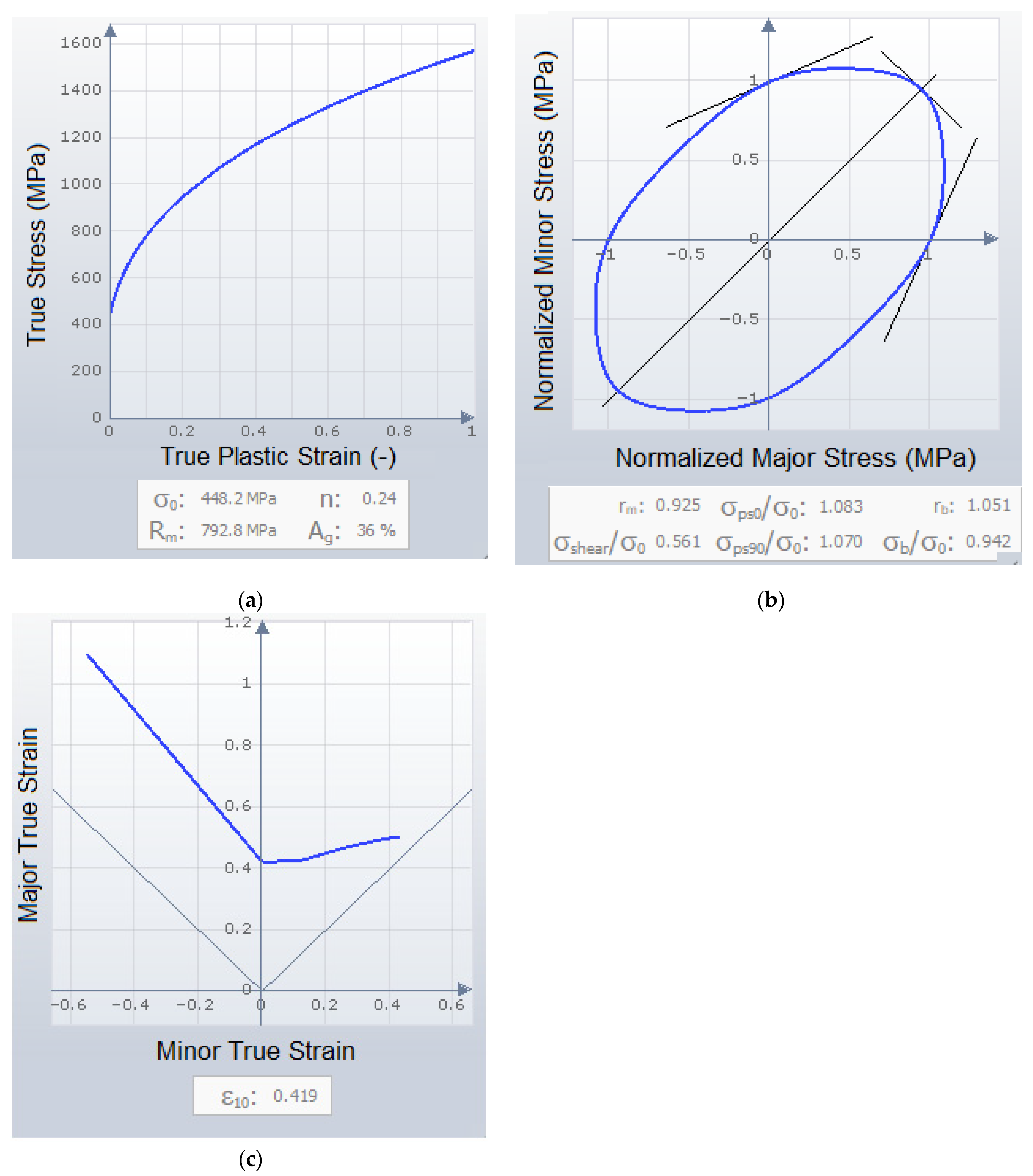

2.1. Sample Material

2.2. Deep Drawing Simulation

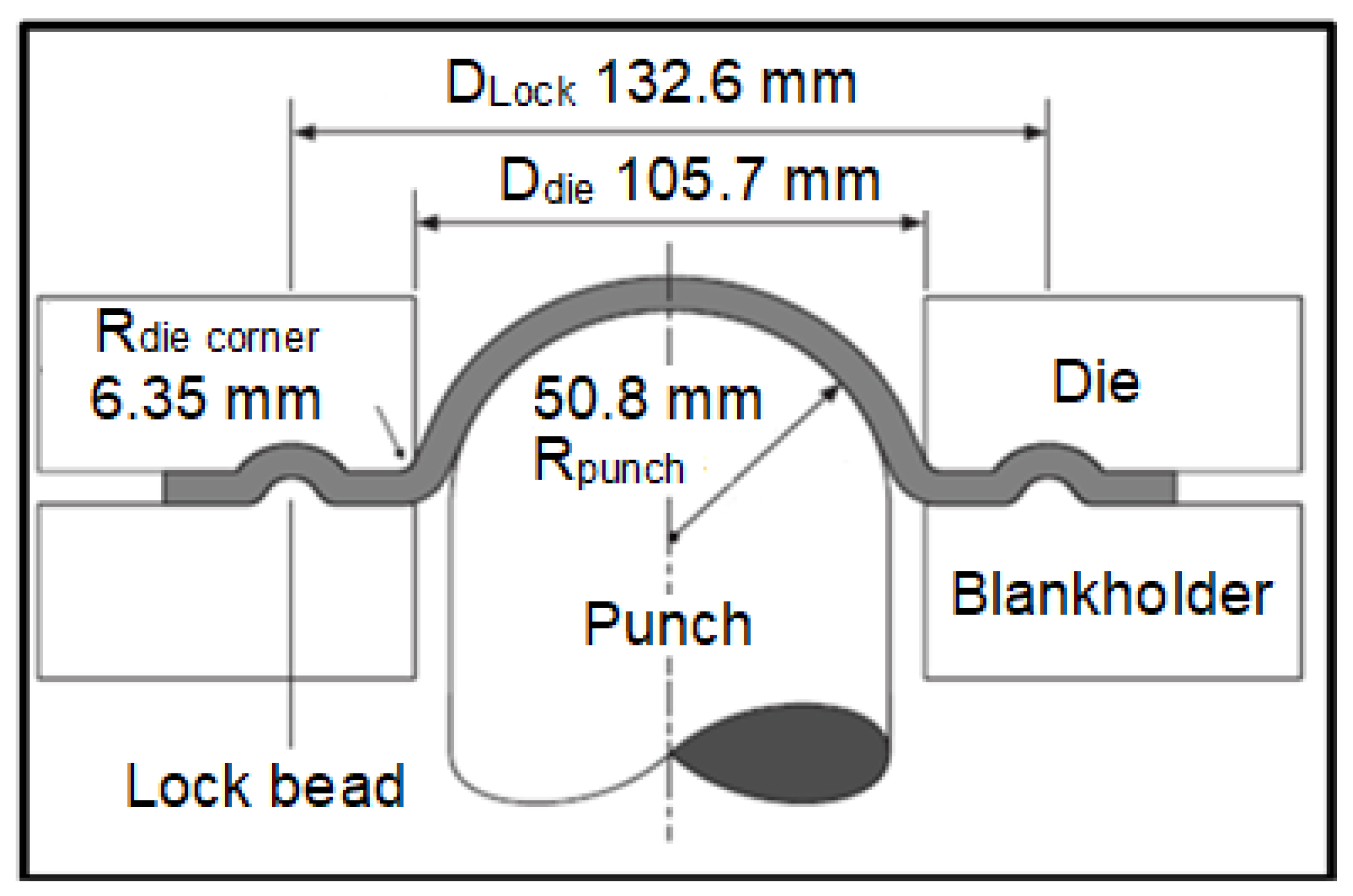

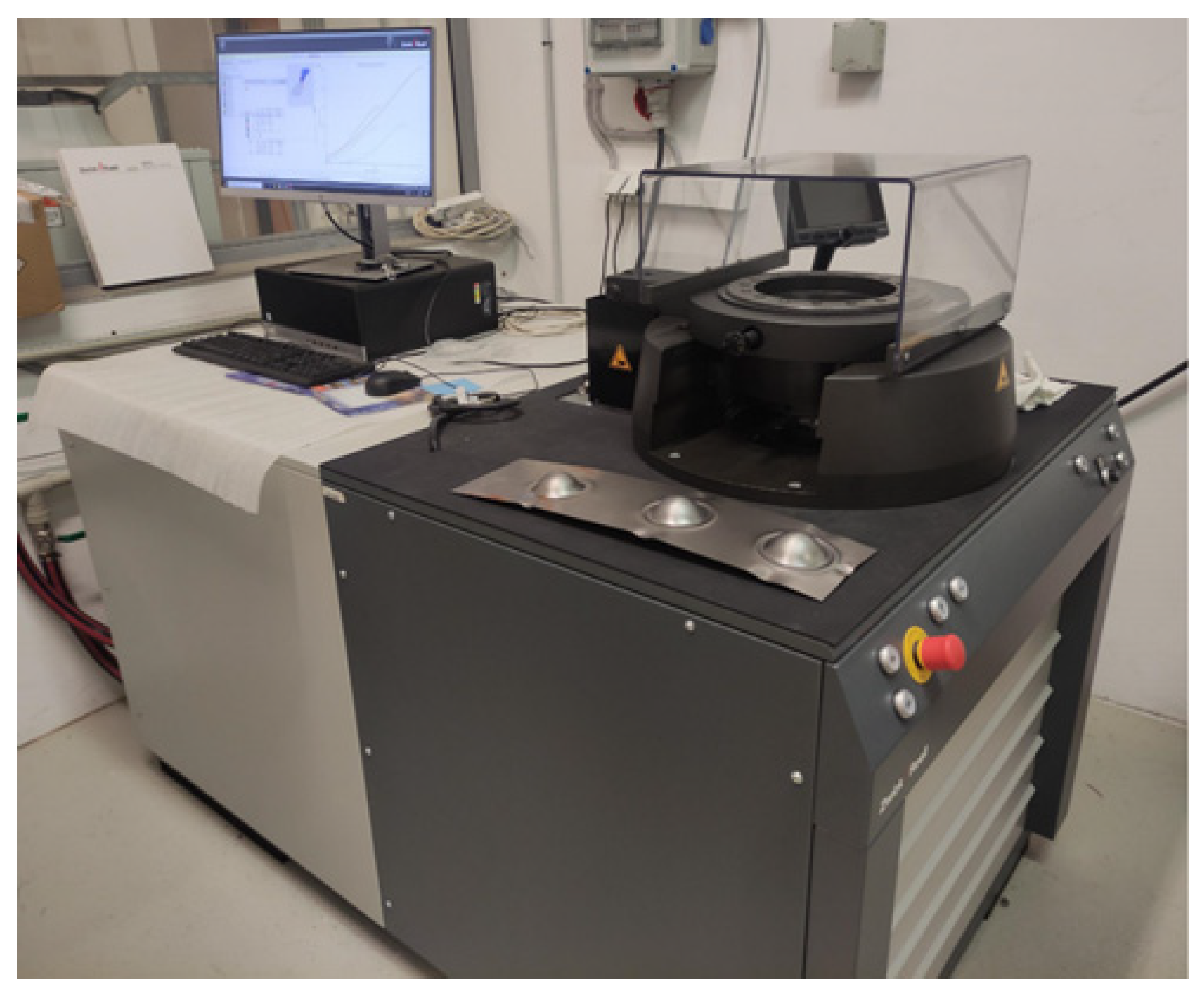

2.3. Deep Drawing of Sheet Metals

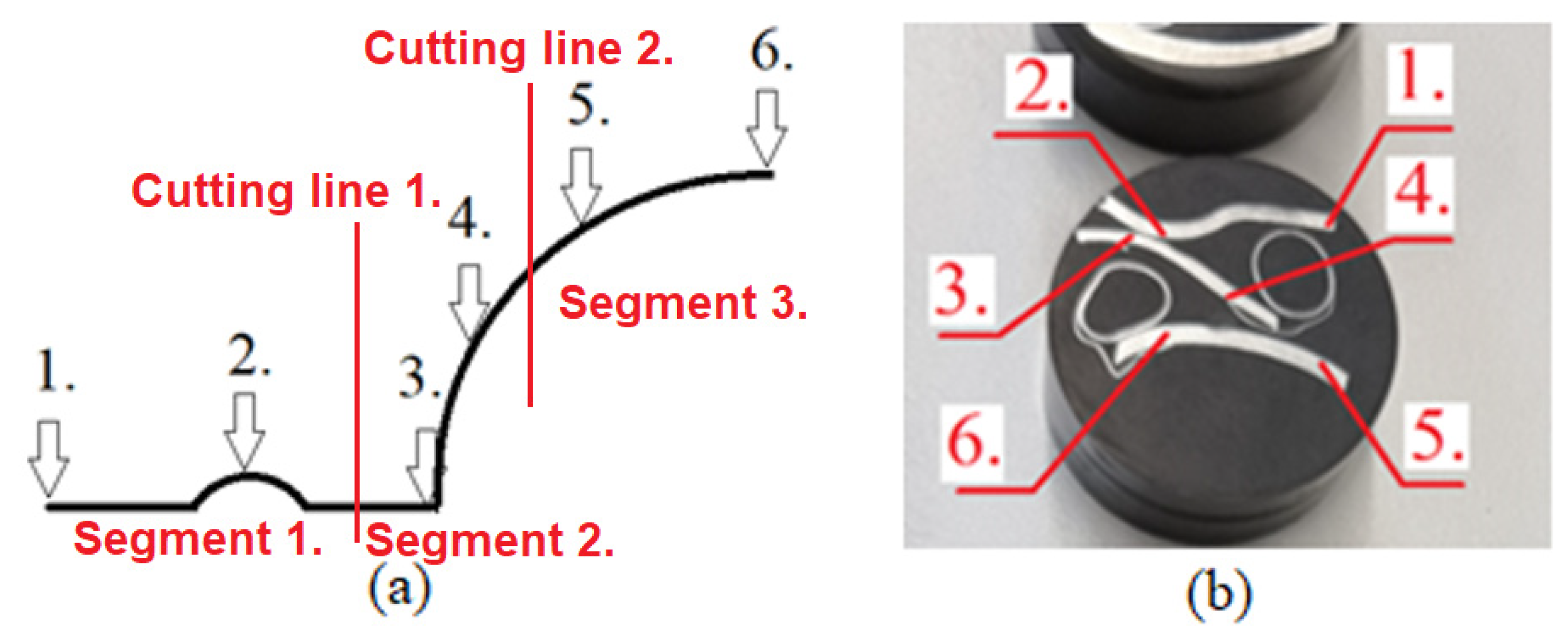

2.4. Sample Preparation

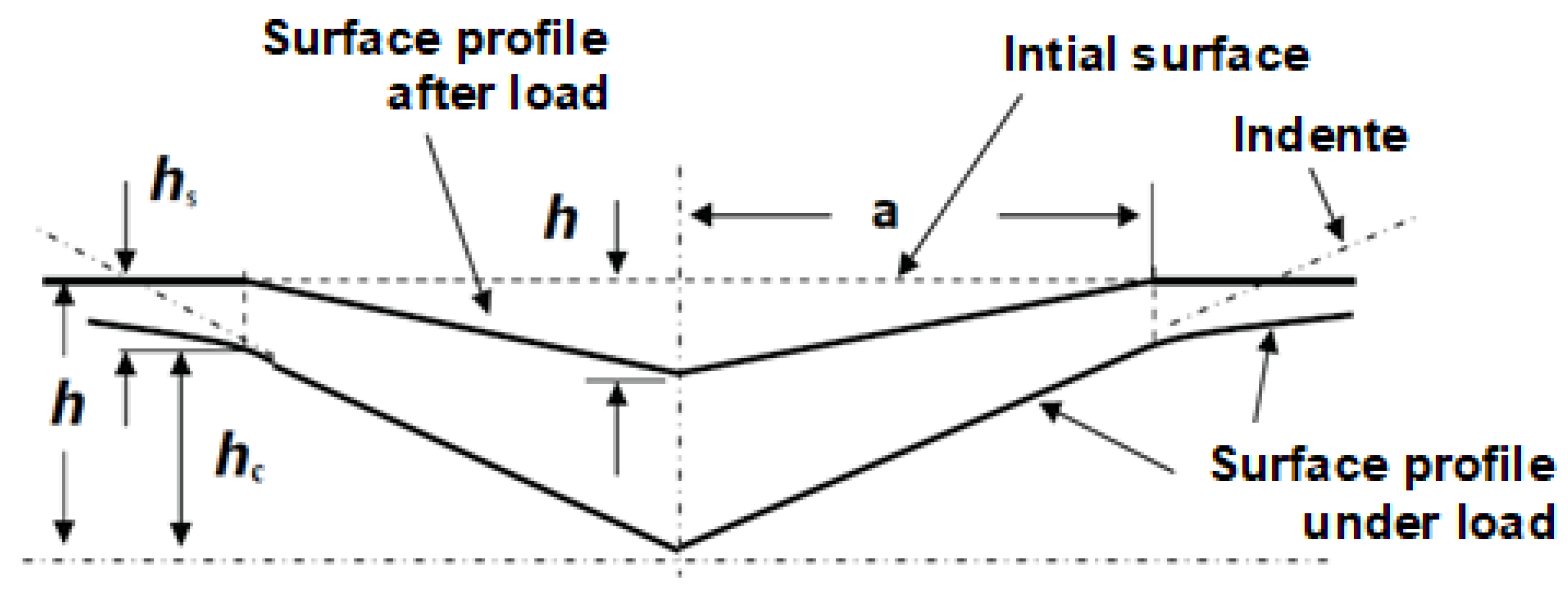

2.5. Micro-Mechanical Properties

- Area of first change to mechanical properties (1);

- Area of bead element (2);

- Area of deep drawing start (3);

- Area during deep drawing (4);

- Area during deep drawing (5);

- Area of deep drawing peak (6).

3. Results

3.1. Comparison of Lubricant Influence

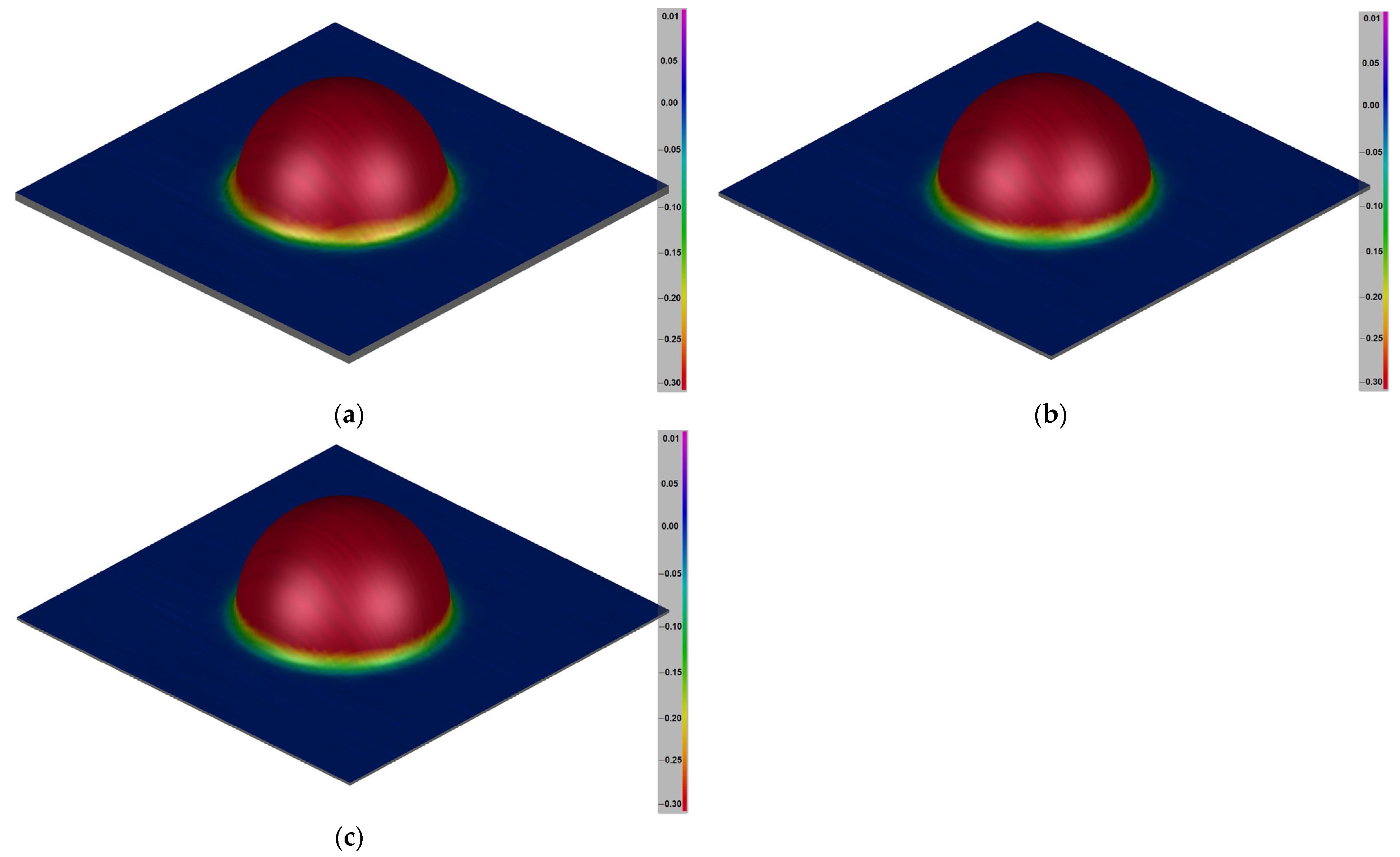

3.2. Forming Simulation

- Formability (forming limit diagram—FLD);

- Max failure;

- Thinning.

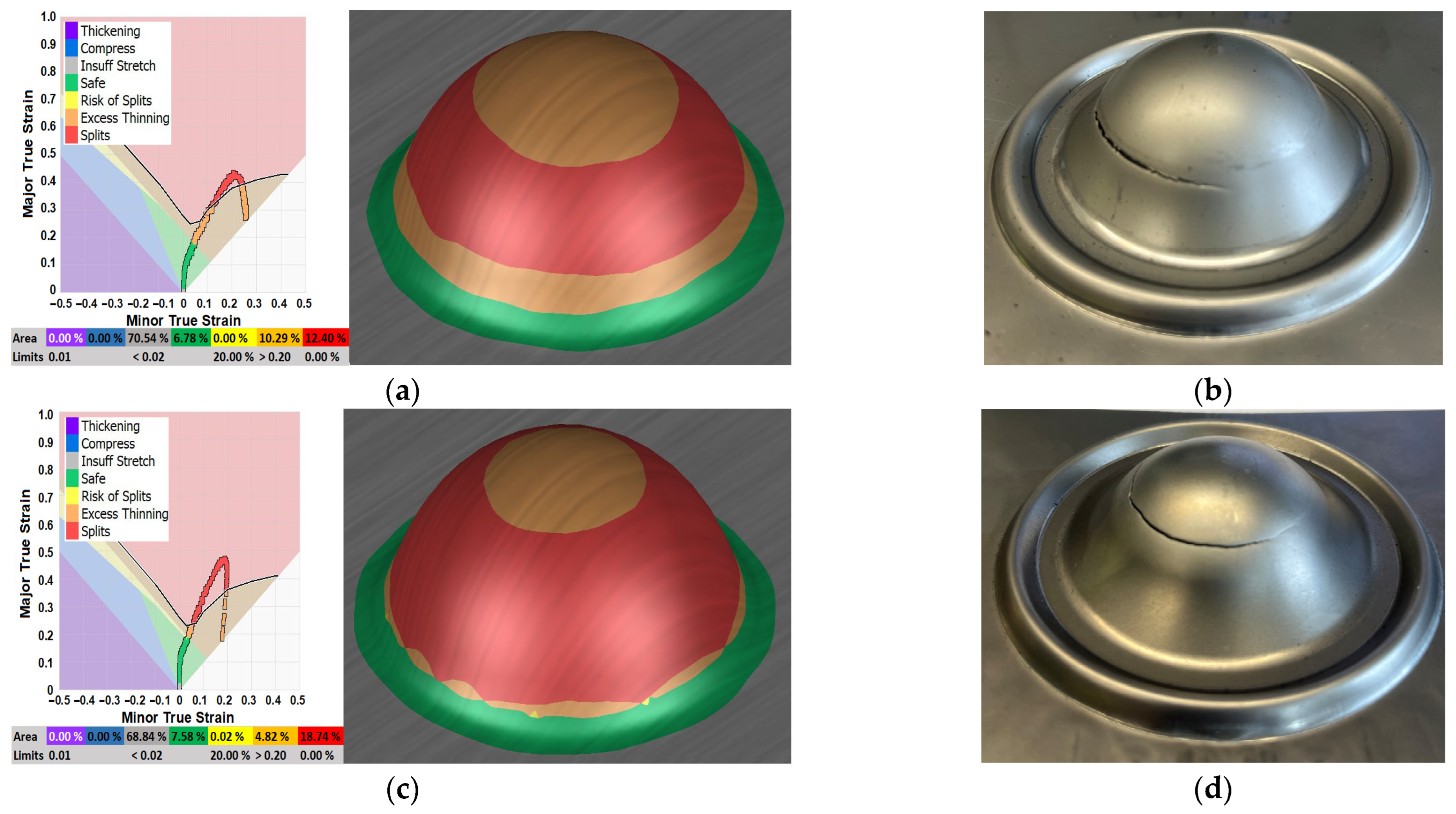

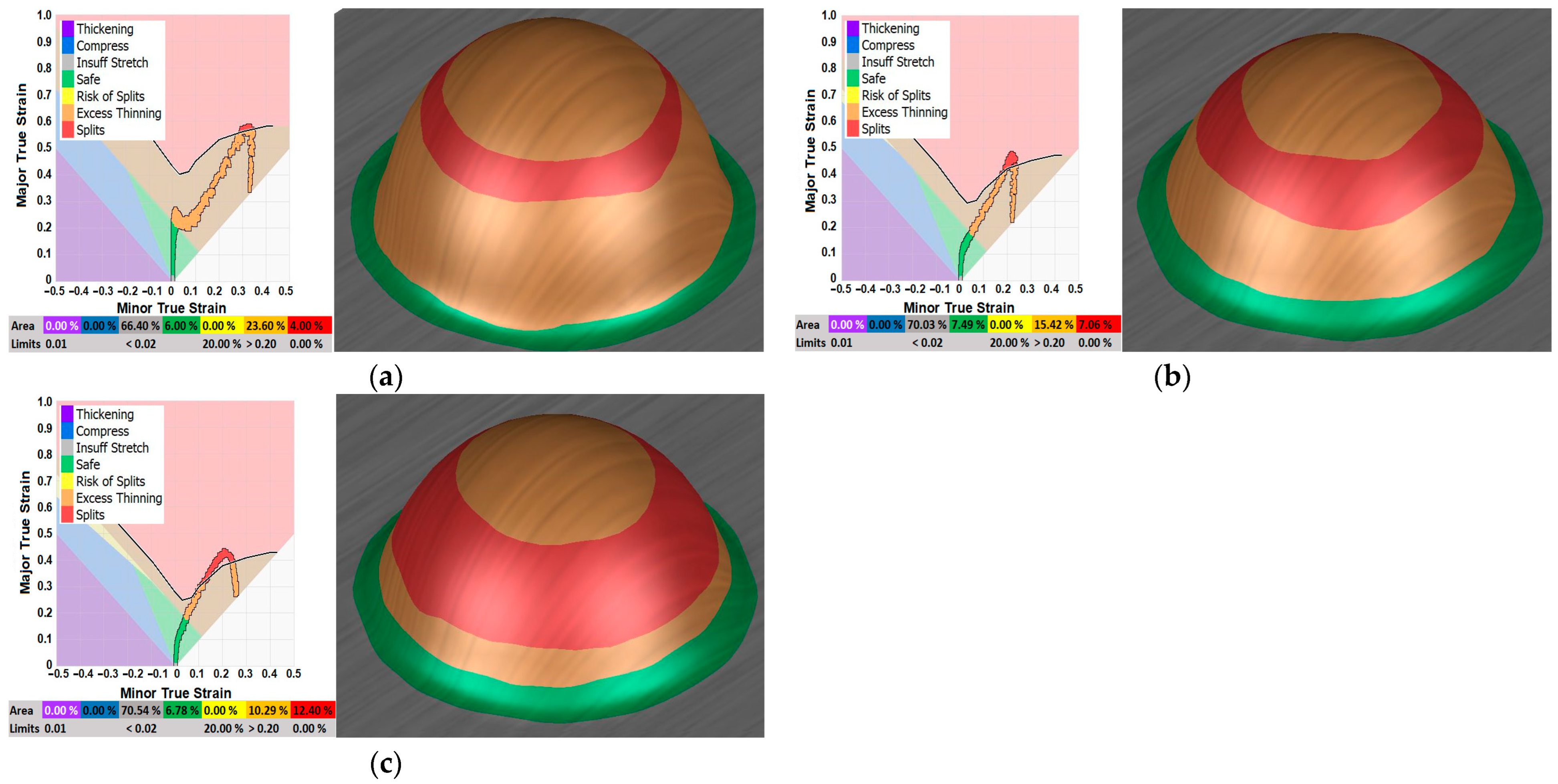

3.2.1. Formability

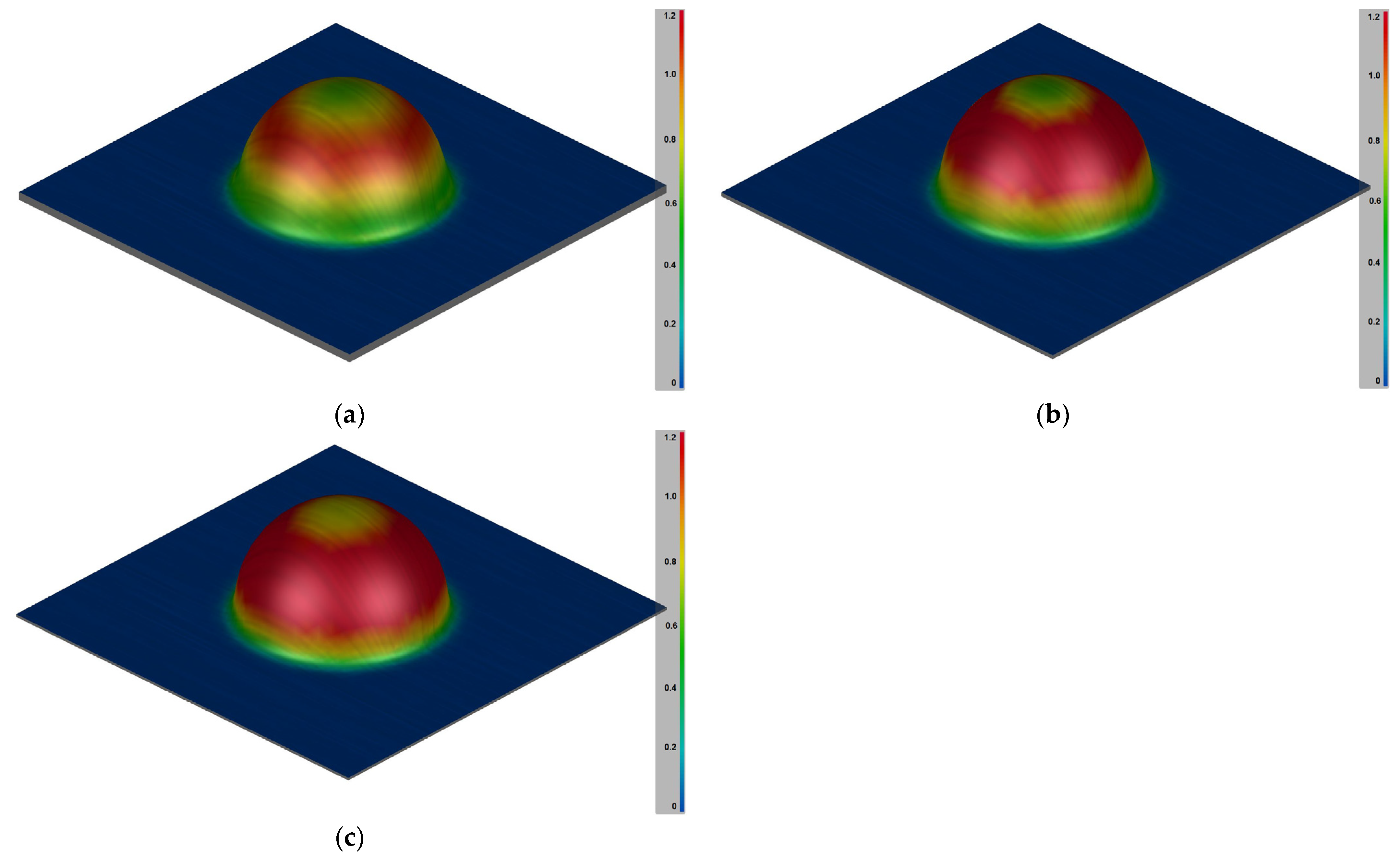

3.2.2. Max Failure

3.2.3. Thinning

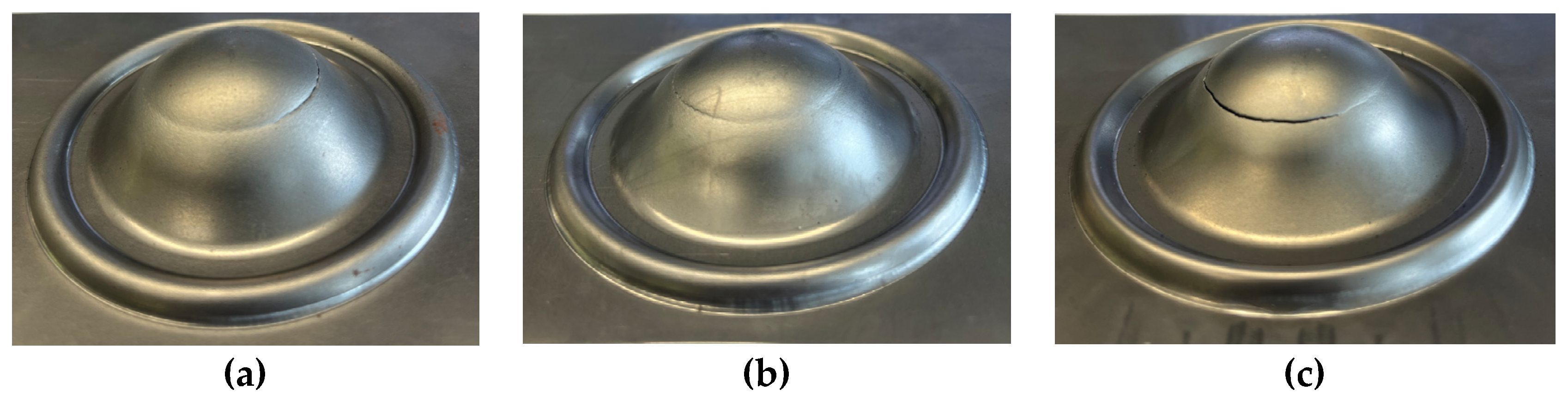

3.3. Deep Drawing of Sheet Metal by LDH Method

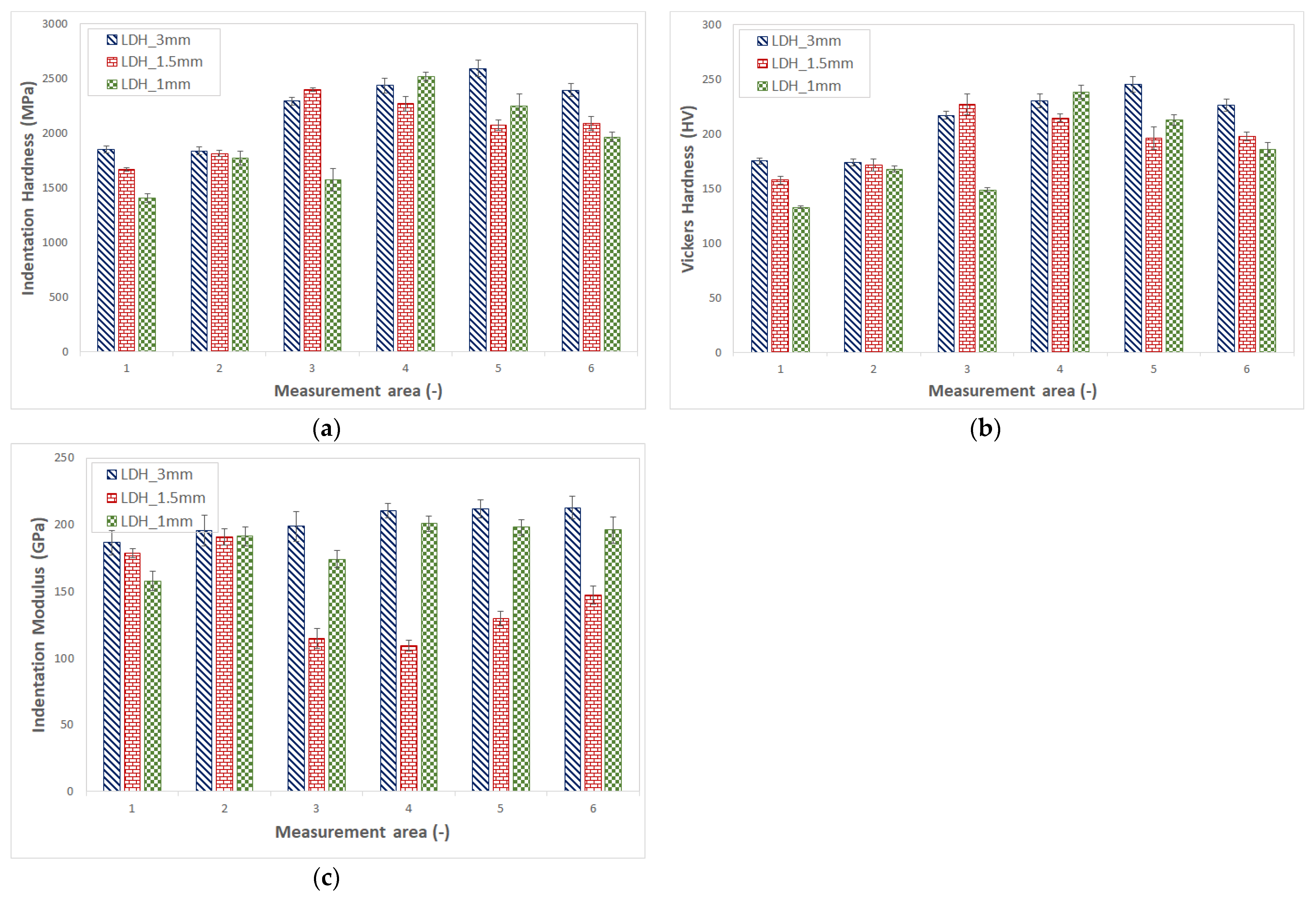

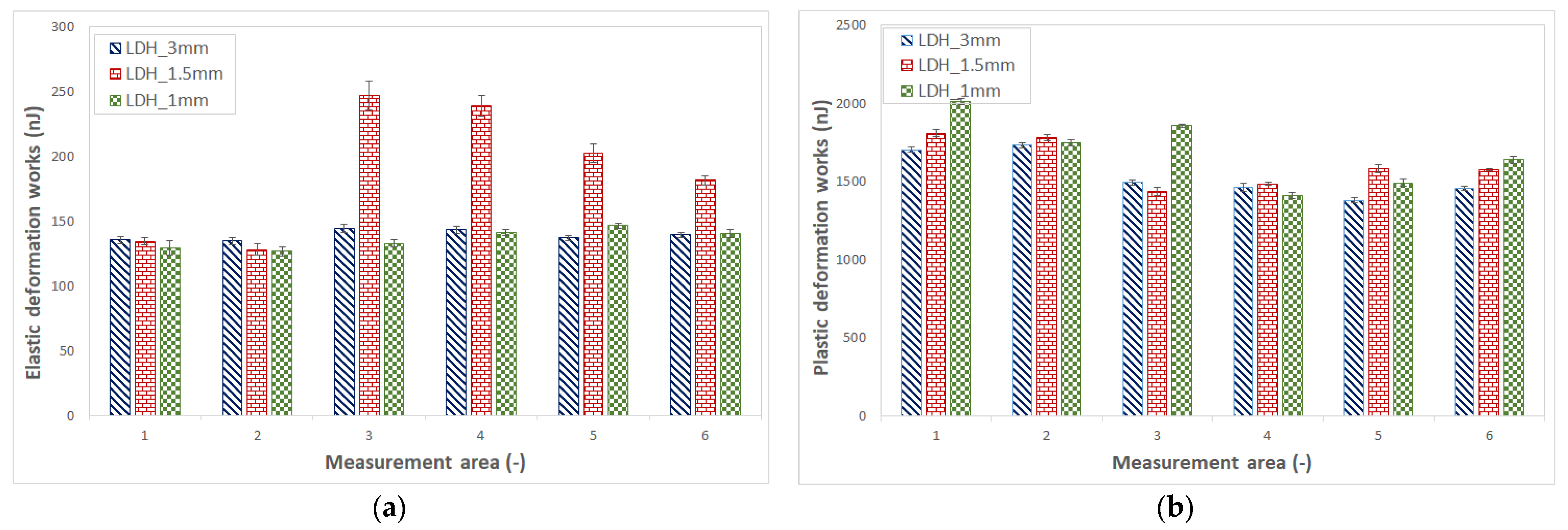

3.4. Mico-Mechanical Properties

4. Discussion

5. Conclusions

- As shown by the results of deep drawing without and with lubricant, the lubricant has a significant effect on the deep drawing of the sheet metal. The difference in depth of deep drawing with the application of lubrication was 33%. Lubrication for the deep drawing process is very important, as it leads to a reduction in the forces required, an increase in the depth of deep drawing, and a reduction in tool wear and defects on the deep drawing.

- Measurements of the micro-mechanical properties at different points in the deep drawing sheet metal showed the effect of the deep drawing point on the Vickers hardness and elastic modulus. The difference in micro-mechanical properties was up to 85%. During sheet metal deep drawing, the micro-mechanical properties of the sheet metal are increased in critical areas, which is caused by the strengthening of the sheet metal (compaction) and thus a change in the structure. These areas can be partially predicted by FEM analyses.

- Measured values were backed by simulation in AutoForm R8 software, which approximated the real process closely in most cases, where the height of the deep drawing and the characterization of the critical points corresponded to the drawing tests. Thus, it can be concluded that FEM analysis can be used to predict not only the drawing process itself but also the increase or decrease in micro-mechanical properties in particular areas of the drawn sheet, which significantly expands the possibilities of using FEM analysis in practice.

- The deep drawing process is a complex issue, and a large number of parameters need to be monitored to avoid damage to the part. An important role is played by the influence of the lubricant, which has a positive effect on the reduction in friction and the increase in the deep drawing distance, and improves the economy of the whole process.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, D. (Ed.) Handbook of Metal Forming Process; NY Research Press: New York, NY, USA, 2015. [Google Scholar]

- Dvorak, M.; Gajdos, F.; Novotny, K. Technologie Tváření: Plošné a Objemové Tváření, 5th ed.; Akademické nakladatelství CERM: Brno, Czech Republic, 2013. [Google Scholar]

- Boljanovic, V. Sheet Metal Forming Processes and Die Design; Industrial Press: New York, NY, USA, 2004. [Google Scholar]

- ČSN EN ISO 12004-2; Metallic materials—Sheet and strip—Determination of forming-limit curves—Part 2: Determination of forming-limit curves in the laboratory. 2nd ed. Czech Agency for Standardization: Prague, Czech Republic, 2021.

- Merklein, M.; Allwood, J.M.; Behrens, B.A. Bulk forming of sheet metal. CIRP Ann. 2012, 61, 725–745. [Google Scholar] [CrossRef]

- Groover, M.P. Fundamentals of Modern Manufacturing, 4th ed.; John Wiley: New York, NY, USA, 2011. [Google Scholar]

- Larsson, J.; Jansson, A.; Karlsson, P. Monitoring and evaluation of the wire drawing process using thermal imaging. Int. J. Adv. Manuf. Technol. 2019, 101, 2121–2134. [Google Scholar] [CrossRef]

- Ballikaya, H.; Savas, V.; Ozay, C. The limit drawing ratio in die angled hydromechanical deep drawing method. Int. J. Adv. Manuf. Technol. 2020, 106, 791–801. [Google Scholar] [CrossRef]

- Hoffman, H.; Schuler. Metal Forming Handbook, 2nd ed.; Springer-Verlag: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Bodhe, A.B.; Mandavgade, N.K.; Tajne, A. Selection of Blank Size for Deep Drawing of Rectangular Parts. In Smart Technologies for Energy, Environment and Sustainable Development; Springer: Singapore, 2019. [Google Scholar]

- Hirayama, S.; Iwai, H.; Tanimoto, Y. Mechanical evaluation of five flowable resin composites by the dynamic micro-indentation method. J. Dent. Biomech. 2014, 5, 1758736014533983. [Google Scholar] [CrossRef] [PubMed]

- Hufnagel, T.C.; Schuh, C.A.; Falk, M.L. Deformation of metallic glasses: Recent developments in theory, simulations, and experiments. Acta Mater. 2016, 109, 375–393. [Google Scholar] [CrossRef]

- Pouranvari, M.; Marashi, S.P.H. Critical review of automotive steels spot welding: Process, structure and properties. Sci. Technol. Weld. Join. 2013, 18, 361–403. [Google Scholar] [CrossRef]

- Idriss, M.; Bartier, O.; Mauvoisin, G.; Hernot, X. Determining the stress level of monotonic plastically pre-hardened metal sheets using the spherical instrumented indentation technique. J. Mech. Sci. Technol. 2019, 33, 183–195. [Google Scholar] [CrossRef]

- Sundararajan, G. Understanding dynamic indentation behaviour of metallic materials. Mater. Sci. Technol. 2012, 28, 1101–1107. [Google Scholar] [CrossRef]

- Huang, Z.-C.; Huang, G.-H.; Shan, F.-W.; Jiang, Y.-Q.; Zou, Y.-Q.; Nie, X.-Y. Forming quality and microstructure evolution of aa6061-t6 aluminum alloy joint during flow drill screwing process. Adv. Eng. Mater. 2023, 25, 2300054. [Google Scholar] [CrossRef]

- Tekkaya, A.; Karbasian, E.H.; Homberg, W.; Kleiner, M. Thermo-mechanical coupled simulation of hot stamping components for process design. Prod. Eng. 2007, 1, 85–89. [Google Scholar] [CrossRef]

- Lazarescu, L.; Nicodim, I.; Banabic, D. Evaluation of Drawing Force and Thickness Distribution in the Deep-Drawing Process with Variable Blank-Holding. Key Eng. Mater. 2015, 639, 33–40. [Google Scholar] [CrossRef]

- Carleer, B.; Burchitz, I.; Stippak, M. Systematic Drawbead Design; Zurich, Switzerland, 2019. [Google Scholar]

- Zaid, I.O. Effect of Different Lubricants on Deep Drawing of Galvanized Steel. Int. J. Sci. Eng. Res. 2017, 8, 1584–1589. [Google Scholar]

- Szpunar, M.; Trzepiecinski, T.; Zaba, K.; Ostrowski, R.; Zwolak, M. Effect of Lubricant Type on the Friction Behaviours and Surface Topography in Metal Forming of Ti-6Al-4V Titanium Alloy Sheets. Materials 2021, 14, 3721. [Google Scholar] [CrossRef] [PubMed]

- Dwivedi, R.; Agnihotri, G. Study of Deep Drawing Process Parameters. Mater. Today Proc. 2017, 4, 820–826. [Google Scholar] [CrossRef]

- Sahu, Y.K.; Pradhan, M.K. Modelling and Simulation of Deep Drawing Process of Circular Cup on AL1200 Using Finite Element Analysis. In Advances in Simulation, Product Design and Development; Springer: Singapore, 2020; pp. 29–42. [Google Scholar]

- Schreijag, S. Microstructure and Mechanical Behavior of Deep Drawing DC04 Steel at Different Length Scales, 18th ed.; KIT Scientific Publishing: Karlsruhe, Germany, 2013. [Google Scholar]

- Hu, P.; Ma, N.; Zhu, Y. Theories, Methods and Numerical Technology of Sheet Metal Cold and Hot Forming: Analysis, Simulation and Engineering Applications; Springer: London, UK, 2013. [Google Scholar]

- Ray, R.K.; Ghosh, P.; Bhattacharjee, D. Effects of composition and processing parameters on precipitation and texture formation in microalloyed interstitial free high strength (IFHS) steels. Mater. Sci. Technol. 2013, 25, 1154–1167. [Google Scholar] [CrossRef]

- Pereloma, E.; Timokhina, I. Bake hardening of automotive steels. Automot. Steels 2017, 259–288. [Google Scholar]

- Huang, G.; Sadagopan, S.; Schreier, H. Determination of Forming Limit and Fracture Limit Curves Using Digital Image Correlation. SAE Int. J. Mater. Manuf. 2014, 7, 574–582. [Google Scholar] [CrossRef]

- Uriya, Y.; Yanagimoto, J. Bore-expanding test for thermosetting carbon-fiber-reinforced plastic sheets. Int. J. Mater. Form. 2017, 10, 823–829. [Google Scholar] [CrossRef]

- Moore, P.; Booth, G. Mechanical testing of welds. In The Welding Engineers Guide to Fracture and Fatigue; Elsevier: Amsterdam, Netherlands, 2015; pp. 113–141. [Google Scholar]

- Muzyka, N.R. Influence if the Anisotropy of Materials on the Accuracy of Measuring of the Vickers Hardness. Strength Mater. 2007, 39, 211–218. [Google Scholar] [CrossRef]

- Chen, P.; Han, Q.; Ma, T.; Lin, D. The mechanical properties of shale based on micro-indentation test. Pet. Explor. Dev. 2015, 42, 723–732. [Google Scholar] [CrossRef]

- Li, W.; Liu, W.; Qi, F.; Chen, Y.; Xing, Z. Determination of micro-mechanical properties of additive manufactured alumina ceramics by nanoindentation and scratching. Ceram. Int. 2019, 45, 10612–10618. [Google Scholar] [CrossRef]

- ČSN EN 10080; Stainless steels—Part 1: List of stainless steels. Publisher: Praha, Czech Republic, 2024.

- ČSN EN ISO 14577; Metallic materials—Instrumented indentation test for hardness and materials parameters. Publisher: Praha, Czech Republic, 2003.

- Falsafi, J.; Demirci, E. Micro-indentation based study on steel sheet degradation through forming and flattening: Toward a predictive model to assess cold recyclability. Mater. Des. 2016, 109, 456–465. [Google Scholar] [CrossRef]

- Prates, P.A.; Adaixo, A.S.; Oliveria, M.C.; Fernandes, J.V. Numerical study on the effect of mechanical properties variability in sheet metal forming processes. Int. J. Adv. Manuf. Technol. 2018, 96, 561–580. [Google Scholar] [CrossRef]

- Li, Y.; Chen, X.; Zhai, W.; Wang, L.; Li, J.; Guoqun, Z. Effects of process parameters on thickness thinning and mechanical properties of the formed parts in incremental sheet forming. Int. J. Adv. Manuf. Technol. 2018, 98, 3071–3080. [Google Scholar] [CrossRef]

- Schmid, H.; Merklein, M. Study of the mechanical properties of sheet metals drawn through drawbeads. Manuf. Rev. 2019, 6, 14. [Google Scholar] [CrossRef]

- Xu, G.; He, J.; Lu, Z.; Li, M.; Xu, J. Prediction of mechanical properties for deep drawing steel by deep learning. Int. J. Miner. Metall. Mater. 2023, 30, 156–165. [Google Scholar] [CrossRef]

- Chrastansky, L.; Sanovec, J.; Martawirya, Y.Y.; Vales, M. Applicability Verification of Autoform Software for FEM Simulation of Mechanical Fixation of Hemmed Joints. Acta Polytech. 2019, 59, 554–559. [Google Scholar] [CrossRef]

- Ulibarri, U.; Galdos, L.; Argandona, E.S.; Mendiguren, J. Experimental and Numerical Simulation Investigation on Deep Drawing Process of Inconel 718 with and without Intermediate Annealing Thermal Treatments. Appl. Sci. 2020, 10, 581. [Google Scholar] [CrossRef]

- Bressan, J.D.; Cieto, J.C.; Vieira, F.H.; Bastos, L.S.B.; Rojas, P.A.M. A Numerical Simulation Study of Deep Drawing Testing and Experimental Results of Steel Sheets, Using a Comercial Software. Int. J. Mater. Form. 2010, 3, 231–234. [Google Scholar] [CrossRef]

- Bahanan, W.; Fatimah, S.; Go, J.H.; Oh, J.M.; Kim, M.J.; Kim, M.J.; Kang, J.H.; Kim, D.J.; Widiantara, I.P.; Ko, Y.G. A Finite Element Analysis of Cold Deep Drawing of Al Alloy Considering Friction Condition and Corner Design of Plunger. Lubricants 2023, 11, 388. [Google Scholar] [CrossRef]

- Trzepiecinski, T.; Szwajka, K.; Szewczyk, M. Pressure-Assisted Lubrication of DC01 Steel Sheets to Reduce Friction in Sheet-MetalForming Processes. Lubricants 2023, 11, 169. [Google Scholar] [CrossRef]

| Fe | C | Si | Mn | Cr | Ni | N |

|---|---|---|---|---|---|---|

| 71.4 | 0.08 | 0.4 | 7.0 | 16.5 | 4.5 | 0.10 |

| Parameter | Unit | Value |

|---|---|---|

| Force clamp | kN | 30 |

| Speed cup | mm/s | 0.5 |

| Fmax | kN | 100 |

| Force punch | kN | 70 |

| Parameter | Unit | Value |

|---|---|---|

| Appearance | - | Green/Blue |

| pH | - | 8.3–8.5 |

| Specific Gravity | - | 1.01–1.03 |

| Viscosity (ISO) | cSt | 4 |

| Sheet Metal Thickness | 3 mm | 1.5 mm | 1 mm |

|---|---|---|---|

| Fmax (kN) | 30.4 | 22.8 | 18.6 |

| Fbreak (kN) | 30.2 | 21.9 | 18.1 |

| TravelBrake (mm) | 11.7 | 11.2 | 10.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ovsik, M.; Bednarik, M.; Reznicek, M.; Stanek, M. Sheet Forming via Limiting Dome Height (LDH) Test: Influence of the Application of Lubricants, Location and Sheet Thickness on the Micro-Mechanical Properties of X8CrMnNi19-6-3. Lubricants 2024, 12, 260. https://doi.org/10.3390/lubricants12070260

Ovsik M, Bednarik M, Reznicek M, Stanek M. Sheet Forming via Limiting Dome Height (LDH) Test: Influence of the Application of Lubricants, Location and Sheet Thickness on the Micro-Mechanical Properties of X8CrMnNi19-6-3. Lubricants. 2024; 12(7):260. https://doi.org/10.3390/lubricants12070260

Chicago/Turabian StyleOvsik, Martin, Martin Bednarik, Martin Reznicek, and Michal Stanek. 2024. "Sheet Forming via Limiting Dome Height (LDH) Test: Influence of the Application of Lubricants, Location and Sheet Thickness on the Micro-Mechanical Properties of X8CrMnNi19-6-3" Lubricants 12, no. 7: 260. https://doi.org/10.3390/lubricants12070260

APA StyleOvsik, M., Bednarik, M., Reznicek, M., & Stanek, M. (2024). Sheet Forming via Limiting Dome Height (LDH) Test: Influence of the Application of Lubricants, Location and Sheet Thickness on the Micro-Mechanical Properties of X8CrMnNi19-6-3. Lubricants, 12(7), 260. https://doi.org/10.3390/lubricants12070260