Dynamic-Projection-Integrated Particle-Filtering-Based Identification of Friction Characteristic Curve for Train Wheelset on Slipping Fault Condition

Abstract

1. Introduction

- A multi-dimensional integrated particle-filtering (MDIPF)-based parameters correction method is proposed. The MDIPF constructs an error particle state transition model encompassing multi-dimensional parameters. The model effectively integrates inter-particle correlation to facilitate error fusion during the state transition process, which accelerates the correction speed of error parameters in the FFCC.

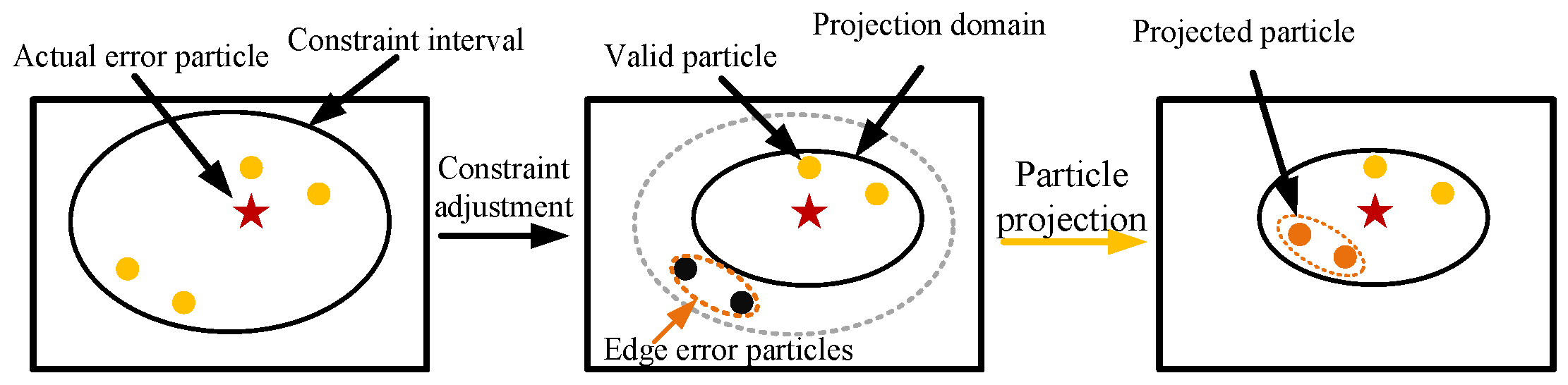

- A dynamic projection domain (DPD)-based particle refinement method is proposed. The DPD comprehensively considers the impact of multi-dimensional edge error particles on the identification speed of the FFCC. The iterative correction quantities are restructured into contraction factors to dynamically fine-tune the particle projection domain, which effectively improves the convergence speed for identifying the FFCC.

- A multi-level evaluation-based identification method for the FFCC is proposed. And the proposed identification strategy is validated, which could actualize rapid and accurate identification of the FFCC.

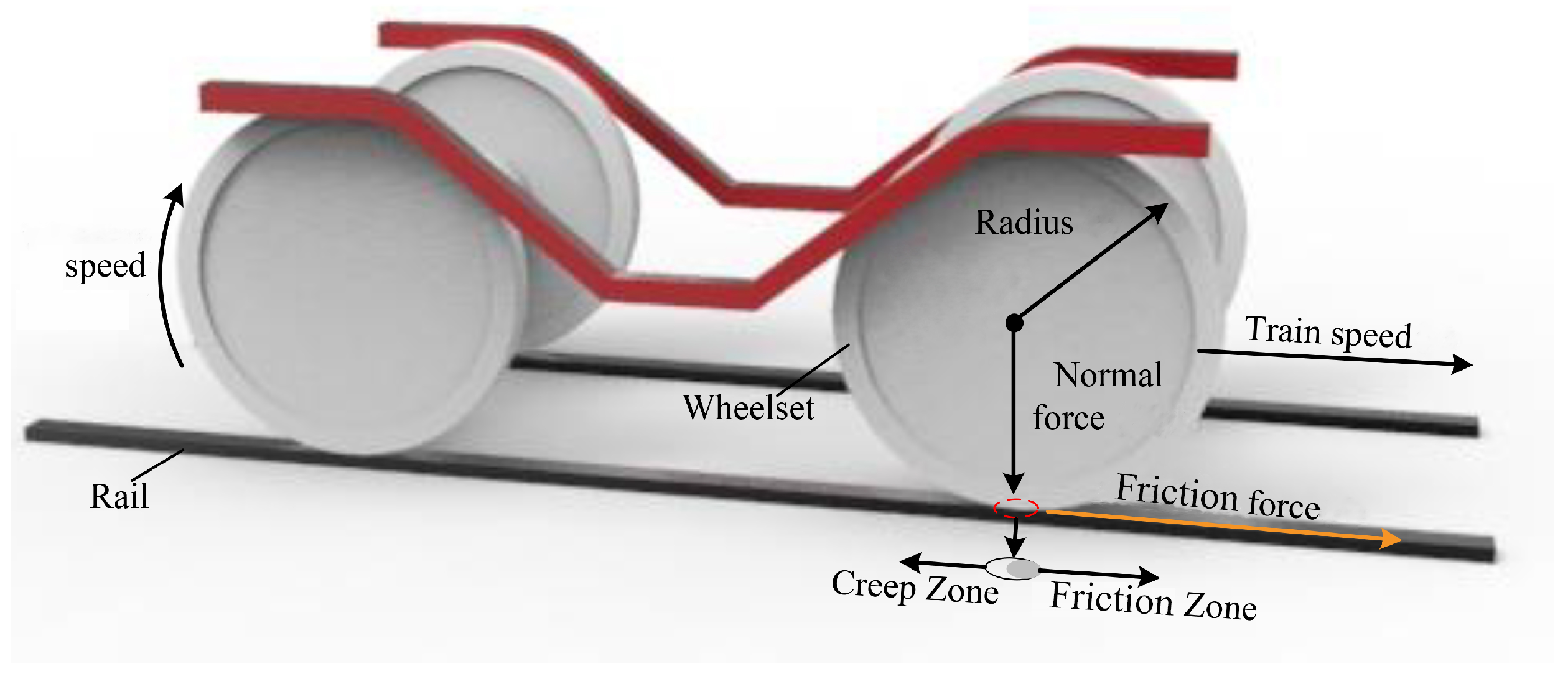

2. Wheelsets–Rail Friction Principle and Analysis of Fault Friction Characteristic Curve

2.1. Wheelsets–Rail Friction Principle

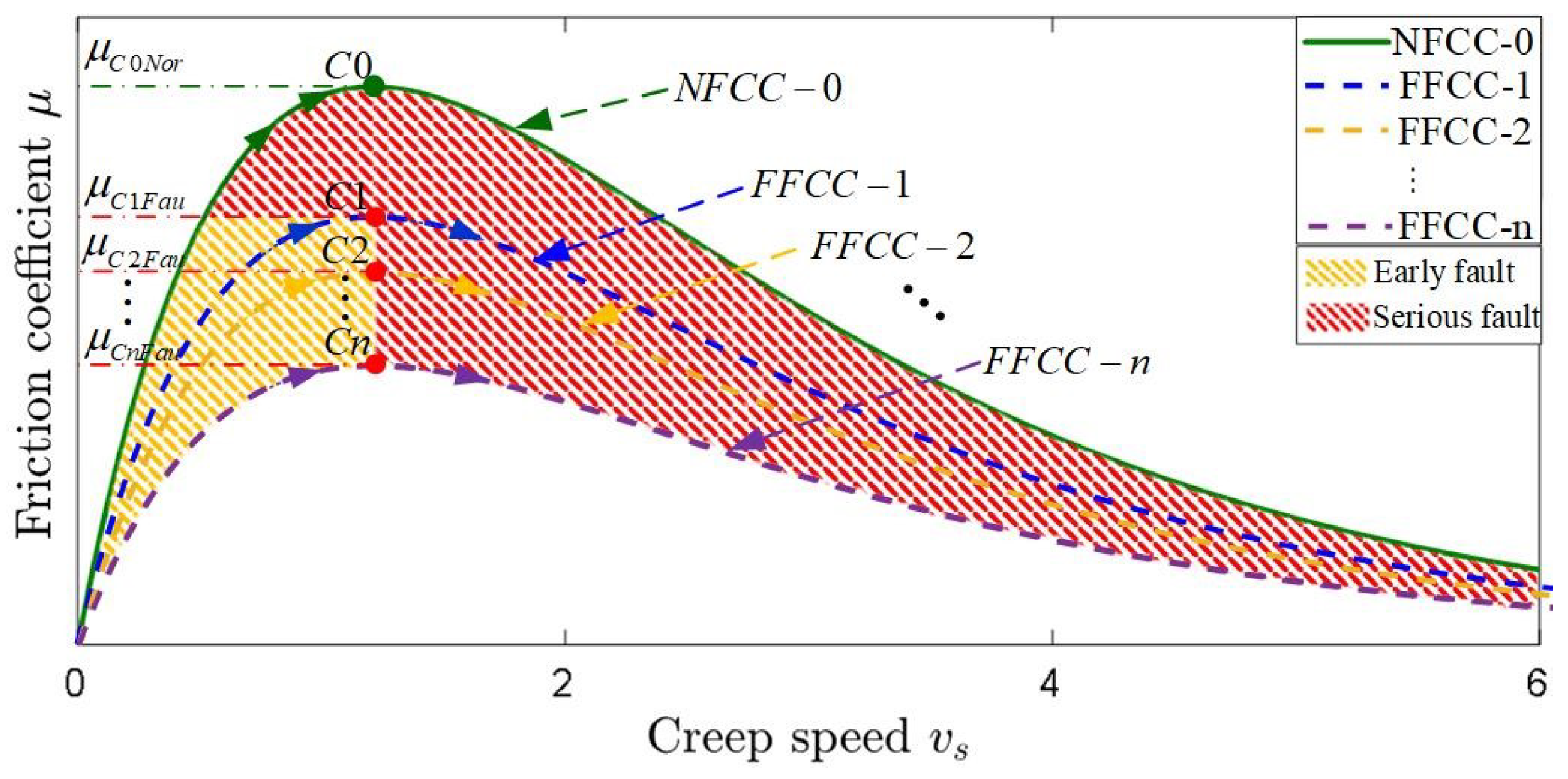

2.2. Analysis of Fault Friction Characteristic Curve

3. Dynamic-Projection-Integrated Particle-Filtering-Based Identification of the FFCC

3.1. Estimation of the Friction Coefficient of the Faulty Wheelset

3.2. Nonlinear Least Squares-Based Preliminary Identification of the FFCC

3.3. Multi-Dimensional Integrated Particle-Filtering-Based Parameters Correction

3.4. Dynamic Projection Domain-Based Particle Refinement

3.5. Multi-Level Evaluation-Based Identification for the FFCC

4. Experiment Validation

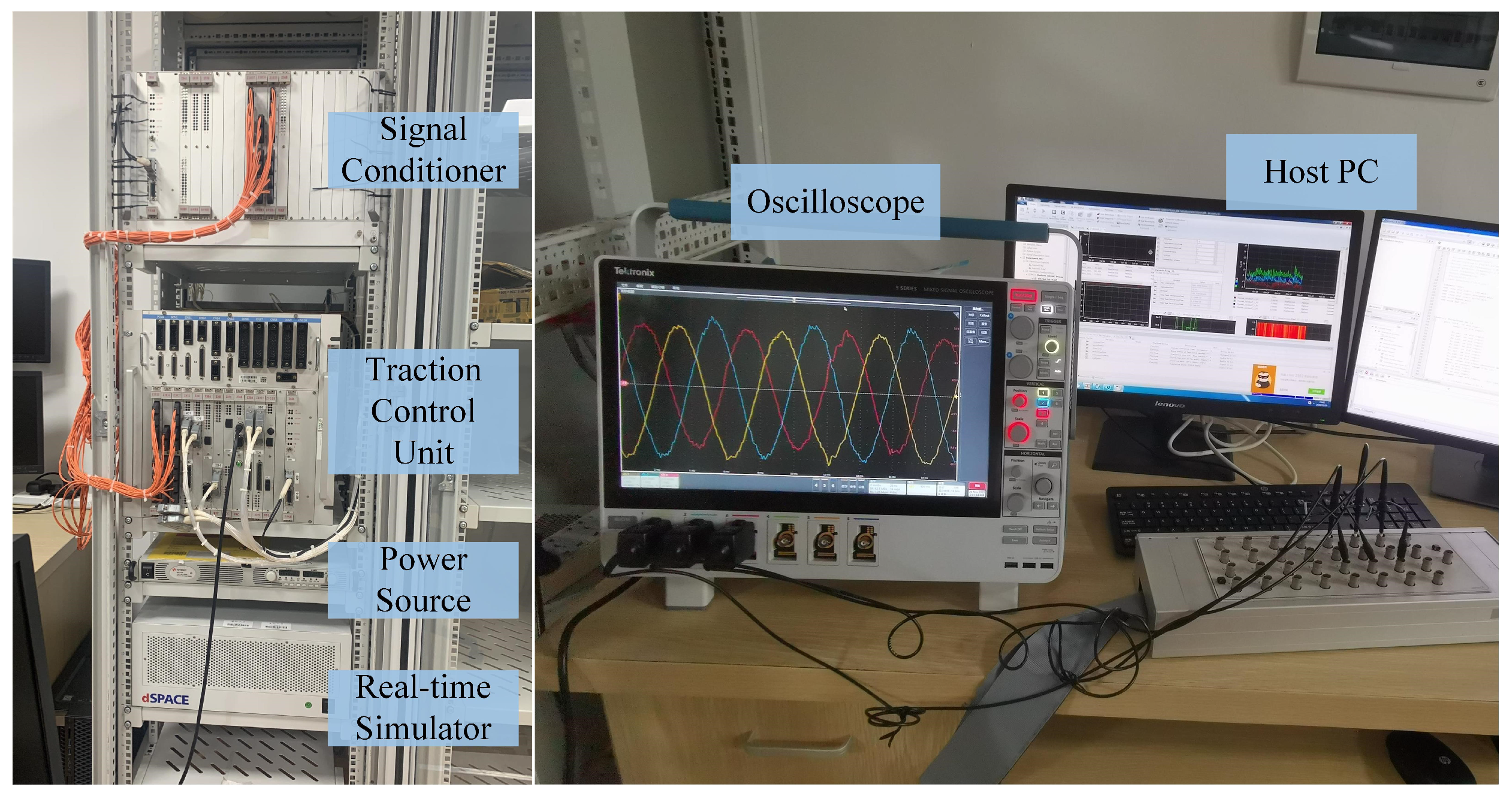

4.1. Platforms and Cases

4.2. Experimental Results

4.2.1. Case1

4.2.2. Case2

4.3. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Abbreviations | |

| DPD | dynamic projection domain |

| MDIPF | multi-dimensional integrated particle filtering |

| MLE | multi-level evaluation |

| HIL | hardware-in-the-loop |

| NFCC | normal friction characteristic curve |

| FFCC | fault friction characteristic curve |

| NLLS | Nonlinear least squares |

| EPSTM | error particle state transition model |

| TCU | traction control unit |

| SC | signal conditioner |

| Nomenclature | |

| speed of the faulty wheelset | |

| radius of the faulty wheelset | |

| train speed | |

| creep speed | |

| axle load of the faulty wheelset, | |

| g | gravitational acceleration |

| friction force | |

| s | gradient |

| H | Hessian matrix |

| state matrix | |

| input matrix | |

| output matrix | |

| feedback gain matrix | |

| parameter of the NFCC | |

| parameter of the NFCC | |

| parameter of the NFCC | |

| parameter of the FFCC | |

| parameter of the FFCC | |

| parameter of the FFCC | |

| gain parameter of the speed | |

| gain parameter of the load torque | |

| rotation inertia of the wheelset motor | |

| rotation inertia of the wheelset | |

| transmission efficiency | |

| gearbox ratio | |

Appendix A

Appendix B

References

- Peixer, M.A.; Montenegro, P.A.; Carvalho, H.; Ribeiro, D.; Bittencourt, T.N.; Calçada, R. Running safety evaluation of a train moving over a high-speed railway viaduct under different track conditions. Eng. Fail. Anal. 2021, 121, 105133. [Google Scholar] [CrossRef]

- Zhang, H.; Wei, X.; Guan, Q.; Zhang, W. Joint Maintenance Strategy Optimization for Railway Bogie Wheelset. Appl. Sci. 2022, 12, 6934. [Google Scholar] [CrossRef]

- Watanabe, A.; Kageyama, I.; Kuriyagawa, Y.; Haraguchi, T.; Kaneko, T.; Nishio, M. Study on the Influence of Environmental Conditions on Road Friction Characteristics. Lubricants 2023, 11, 277. [Google Scholar] [CrossRef]

- Do, M.T.; Cerezo, V.; Ropert, C. Questioning the approach to predict the evolution of tire/road friction with traffic from road surface texture. Surf. Topogr. Metrol. Prop. 2020, 8, 024004. [Google Scholar] [CrossRef]

- Xiao, G.; Wu, B.; Yao, L.; Shen, Q. The traction behaviour of high-speed train under low adhesion condition. Eng. Fail. Anal. 2022, 131, 105858. [Google Scholar] [CrossRef]

- Yin, S.; Peng, T.; Yang, C.; Yang, C.; Chen, Z.; Gui, W. Dynamic hybrid observer-based early slipping fault detection for high-speed train wheelsets. Control Eng. Pract. 2024, 142, 105736. [Google Scholar] [CrossRef]

- Sholevar, N.; Golroo, A.; Esfahani, S.R. Machine learning techniques for pavement condition evaluation. Autom. Constr. 2022, 136, 104190. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, Q.; He, J.; Liu, J. Review of research on key technologies for high-speed train wheel-rail condition monitoring. In Proceedings of the 8th International Symposium on Test Automation and Instrumentation, Online, 15 September 2021; pp. 257–264. [Google Scholar]

- Shrestha, S.; Wu, Q.; Spiryagin, M. Review of adhesion estimation approaches for rail vehicles. Int. J. Rail Transp. 2019, 7, 79–102. [Google Scholar] [CrossRef]

- Yuan, Z.; Wu, M.; Tian, C.; Zhou, J.; Chen, C. A review on the application of friction models in wheel-rail adhesion calculation. Urban Rail Transit. 2021, 7, 1–11. [Google Scholar] [CrossRef]

- Guo, H.; Zhao, X.; Liu, J.; Dai, Q.; Liu, H.; Chen, H. A fusion estimation of the peak tire–road friction coefficient based on road images and dynamic information. Mech. Syst. Signal Process. 2023, 189, 110029. [Google Scholar] [CrossRef]

- Ise, T.; Higuchi, M.; Suzuki, Y.; Tachiya, H. Measurement on friction coefficients of tire grounding surface in arbitrary directions under high-load. Exp. Mech. 2017, 57, 1383–1393. [Google Scholar] [CrossRef]

- Leng, B.; Jin, D.; Xiong, L.; Yang, X.; Yu, Z. Estimation of tire-road peak adhesion coefficient for intelligent electric vehicles based on camera and tire dynamics information fusion. Mech. Syst. Signal Process. 2021, 150, 107275. [Google Scholar] [CrossRef]

- Alonso, J.; López, J.M.; Pavón, I.; Recuero, M.; Asensio, C.; Arcas, G.; Bravo, A. On-board wet road surface identification using tyre/road noise and support vector machines. Appl. Acoust. 2014, 76, 407–415. [Google Scholar] [CrossRef]

- Feng, Y.; Chen, H.; Zhao, H.; Zhou, H. Road tire friction coefficient estimation for four wheel drive electric vehicle based on moving optimal estimation strategy. Mech. Syst. Signal Process. 2020, 139, 106416. [Google Scholar] [CrossRef]

- Paul, D.; Velenis, E.; Cao, D.; Dobo, T. Optimal μ-Estimation-Based regenerative braking strategy for an AWD HEV. IEEE Trans. Transp. Electrif. 2016, 3, 249–258. [Google Scholar] [CrossRef]

- Bian, M.; Chen, L.; Luo, Y.; Li, K. Research on maximum road adhesion coefficient estimation for distributed drive electric vehicle. In Proceedings of the 2013 International Conference on Mechanical and Automation Engineering, Jiujang, China, 21–23 July 2013; pp. 90–94. [Google Scholar]

- Wang, B.; Guan, H.; Lu, P.; Zhang, A. Road surface condition identification approach based on road characteristic value. J. Terramechan. 2014, 56, 103–117. [Google Scholar] [CrossRef]

- Guan, H.; Wang, B.; Lu, P.; Xu, L. Identification of maximum road friction coefficient and optimal slip ratio based on road type recognition. Chin. J. Mech. Eng. 2014, 27, 1018–1026. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, J.; Wang, F.A.; Dong, H.; Yan, Y.; Ren, Y.; Zhou, C.; Yin, G. Tire road friction coefficient estimation: Review and research perspectives. Chin. J. Mech. Eng. 2022, 35, 6. [Google Scholar] [CrossRef]

- Niu, Y.; Jiang, X.; Meng, F.; Wang, R.; Ju, G.; Zhang, S.; Meng, Z. Techniques and methods for runway friction measurement: A review of state of the art. IEEE Trans. Instrum. Meas. 2021, 70, 9510717. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, Y.; Pan, M.; Ren, F. A vehicle ABS adaptive sliding-mode control algorithm based on the vehicle velocity estimation and tyre/road friction coefficient estimations. Veh. Syst. Dyn. 2014, 52, 475–503. [Google Scholar] [CrossRef]

- Ricardo, D.; Esteves, A.; Jaime, S. A new linear parametrization for peak friction coefficient estimation in real time. In Proceedings of the 2010 IEEE Vehicle Power and Propulsion Conference, Lille, France, 1–3 September 2010; pp. 1–6. [Google Scholar]

- Bei, S.; Li, B.; Zhu, Y. Adhesion state estimation based on improved tire brush model. Adv. Mech. Eng. 2018, 10, 1687814017747706. [Google Scholar]

- Sharifzadeh, M.; Senatore, A.; Farnam, A.; Akbari, A.; Timpone, F. A real-time approach to robust identification of tyre–road friction characteristics on mixed-μ roads. Veh. Syst. Dyn. 2018, 57, 1338–1362. [Google Scholar] [CrossRef]

- Yang, C.; Peng, T.; Huang, X.; Fan, X.; Tao, H.; Yang, C.; Gui, W. Electrothermal Performance-Based FCS-MPC for Dynamic Thermal Balance Control of Traction Converters. IEEE Trans. Transp. Electrif. 2021, 8, 277–287. [Google Scholar] [CrossRef]

| Symbol | Terminology of Parameters | Value |

|---|---|---|

| axle load of the faulty wheelset | t | |

| rotation inertia of the wheelset motor | 6 kg·m2 | |

| rotation inertia of the wheelset | 80 kg·m2 | |

| radius of the faulty wheelset | m | |

| M | weight of the train | 408 t |

| g | acceleration of gravity | 9.8 m/s2 |

| gearbox ratio | ||

| transmission effciency | ||

| L | half of the center distance between two bogies | 19 m |

| half of the wheelbase | m | |

| Z | height from the coupler to the ground | m |

| z | height of bogie | m |

| Case1 (FFCC-a) | −0.005 | 0.585 | −0.580 | −0.525 | −1.100 |

| Case2 (FFCC-b) | −0.002 | 0.478 | −0.476 | −0.505 | −1.180 |

| NLLS | MDIPF | The Proposed Strategy | |

|---|---|---|---|

| MSE (FFCC-a/FFCC-b) | 6.3472 /1.4864 | 2.6921 /6.3028 | 1.0849 /6.1947 |

| RMSE (FFCC-a/FFCC-b) | 2.5000 /3.8553 | 5.2000 /2.5000 | 1.0000 /7.8706 |

| MAE (FFCC-a/FFCC-b) | 1.8000 /1.8151 | 2.8000 /1.2000 | 7.8984 /4.9837 |

| (FFCC-a/FFCC-b) | 0.9975/0.9999 | 0.9895/0.9972 | 0.9996/0.9997 |

| RT (FFAC-a/FFAC-b) | 310.6%/445.1% | 54.3%/103.9% | 31.1%/59.3% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, S.; Peng, T.; Yang, C.; Yang, C.; Gui, W.; Liu, L. Dynamic-Projection-Integrated Particle-Filtering-Based Identification of Friction Characteristic Curve for Train Wheelset on Slipping Fault Condition. Lubricants 2024, 12, 38. https://doi.org/10.3390/lubricants12020038

Yin S, Peng T, Yang C, Yang C, Gui W, Liu L. Dynamic-Projection-Integrated Particle-Filtering-Based Identification of Friction Characteristic Curve for Train Wheelset on Slipping Fault Condition. Lubricants. 2024; 12(2):38. https://doi.org/10.3390/lubricants12020038

Chicago/Turabian StyleYin, Shicai, Tao Peng, Chao Yang, Chunhua Yang, Weihua Gui, and Ling Liu. 2024. "Dynamic-Projection-Integrated Particle-Filtering-Based Identification of Friction Characteristic Curve for Train Wheelset on Slipping Fault Condition" Lubricants 12, no. 2: 38. https://doi.org/10.3390/lubricants12020038

APA StyleYin, S., Peng, T., Yang, C., Yang, C., Gui, W., & Liu, L. (2024). Dynamic-Projection-Integrated Particle-Filtering-Based Identification of Friction Characteristic Curve for Train Wheelset on Slipping Fault Condition. Lubricants, 12(2), 38. https://doi.org/10.3390/lubricants12020038