Testing the Effectiveness of Hybrid Milling and Surface Burnishing in Improving the Wear Resistance of Machine Parts Made of Structural Steel

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Specimens for Testing

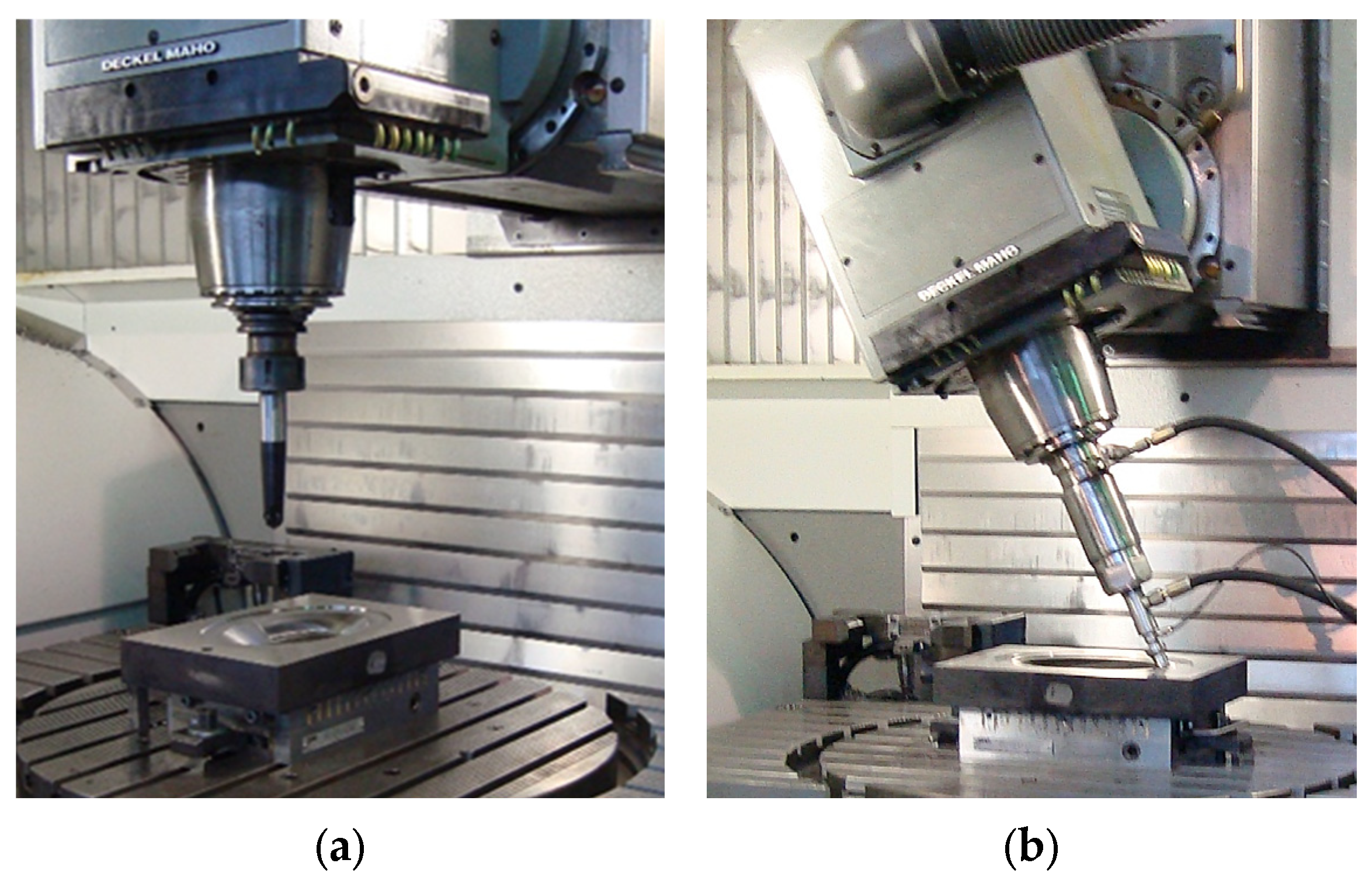

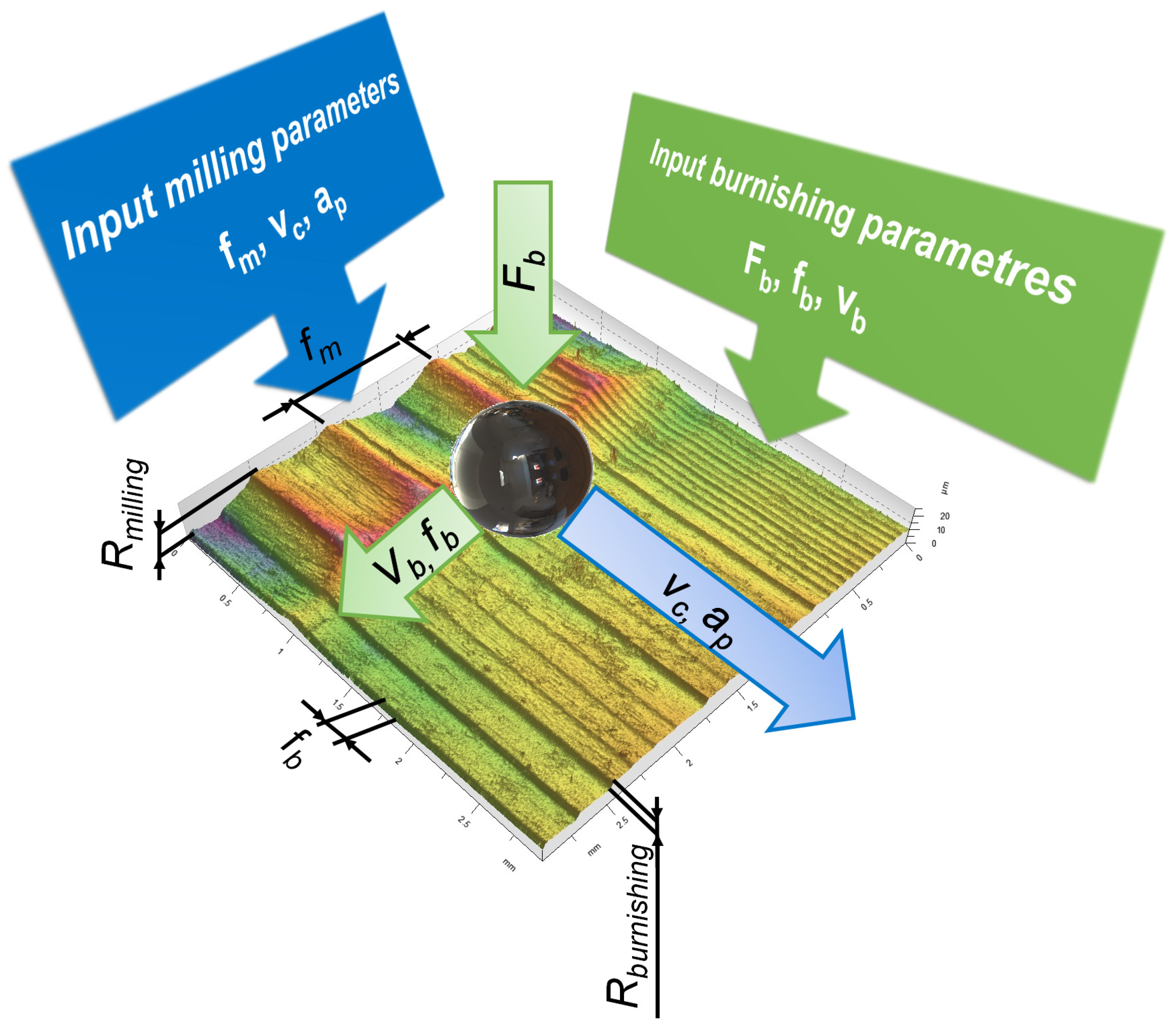

2.2. Shaping the Surface Geometrical Texture

- Surface roughness height indices such as Sa (arithmetic mean surface height), Sz (maximum surface height), Sp (maximum surface peak height) and Sv (maximum surface valley depth);

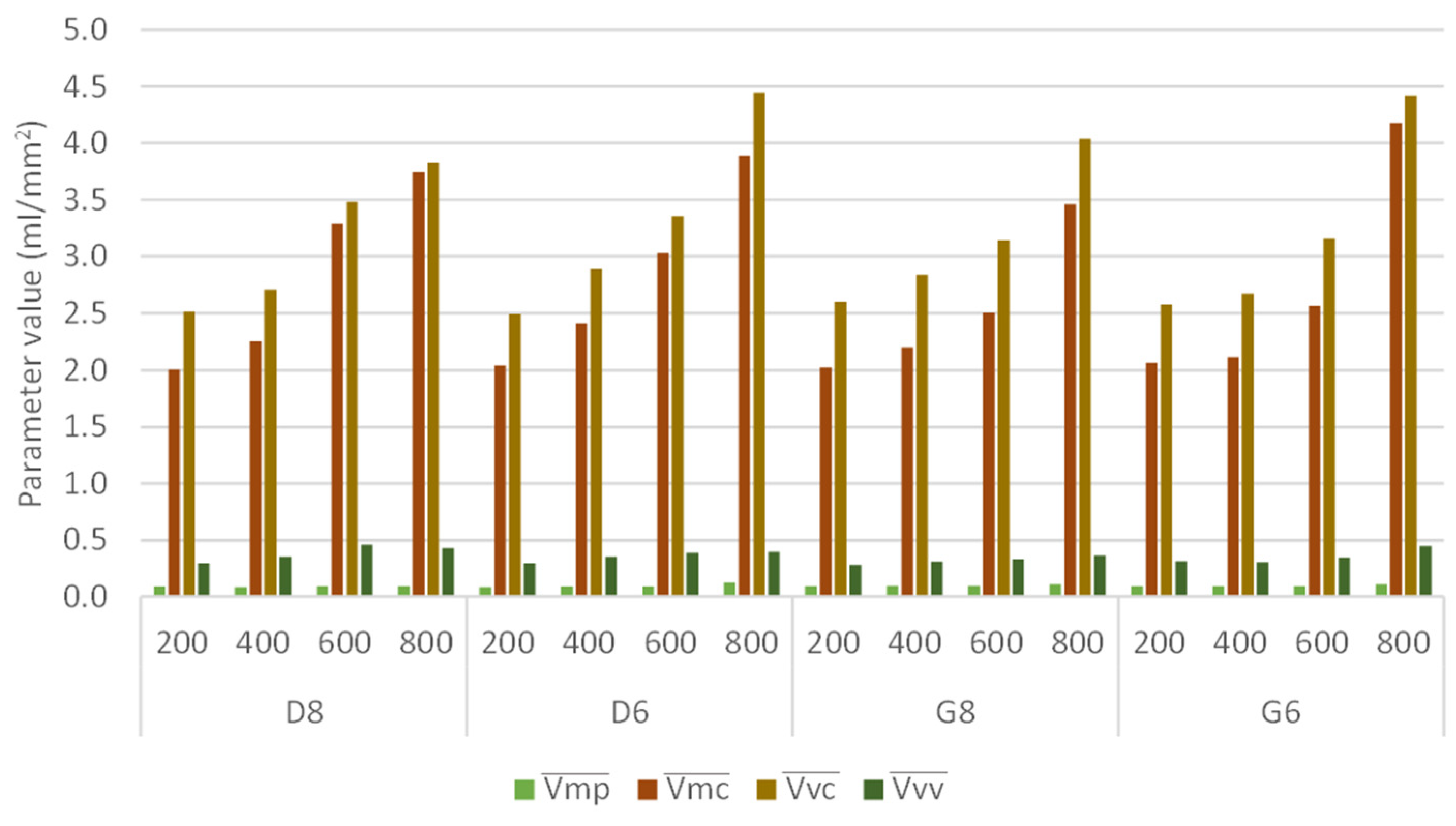

- Indices based on changes in the Abbott–Fireston curve such as Vmp (surface material peak volume), Vmc (surface material core volume), Vvc (surface void core volume) and Vvv (surface void valley volume).

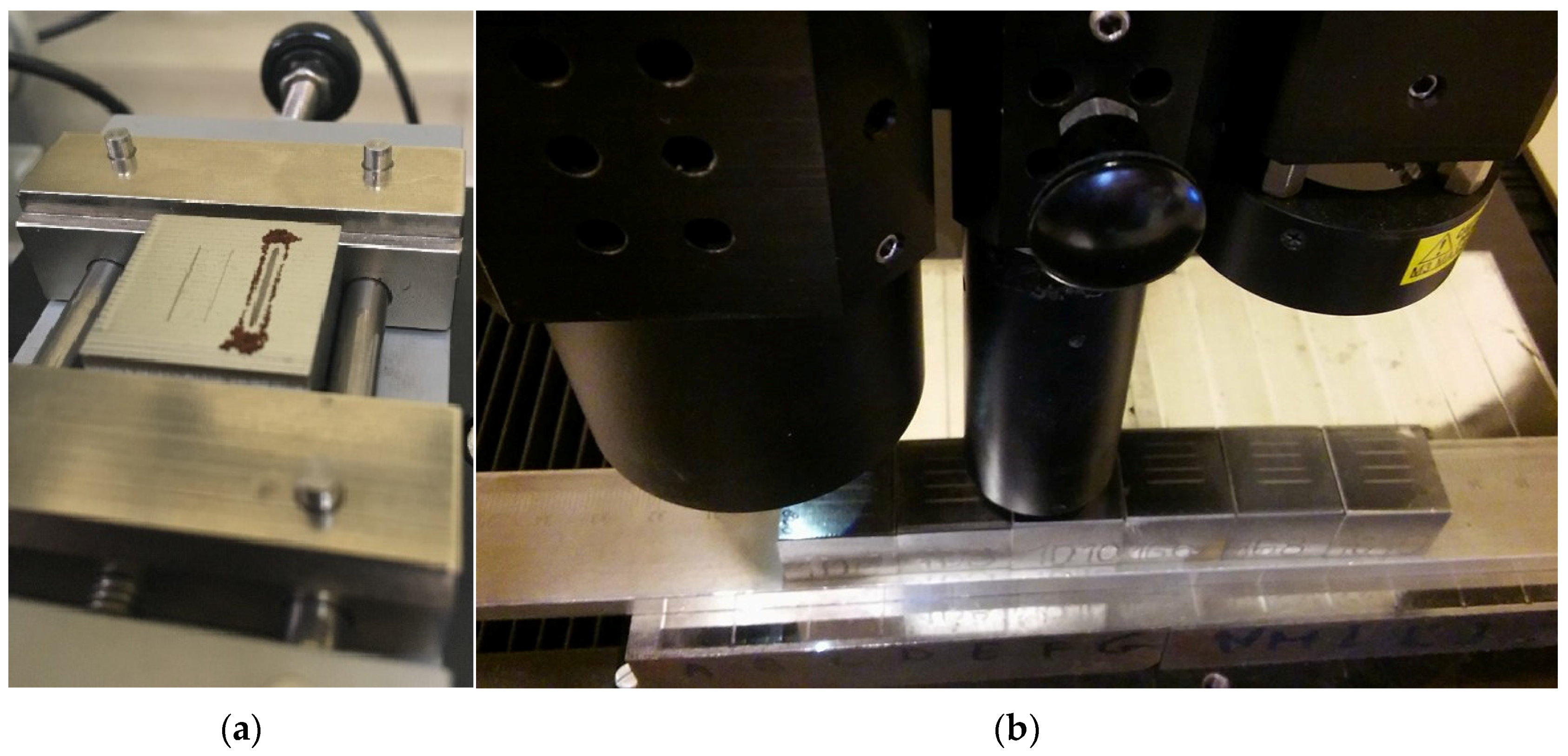

2.3. Surface Wear Tests

3. Results and Discussion

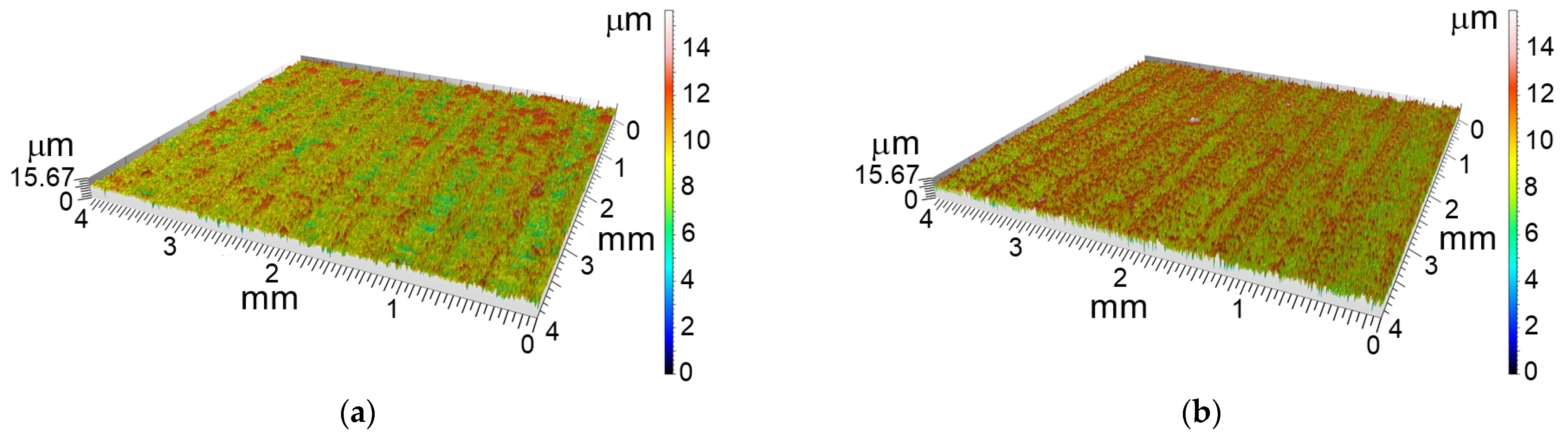

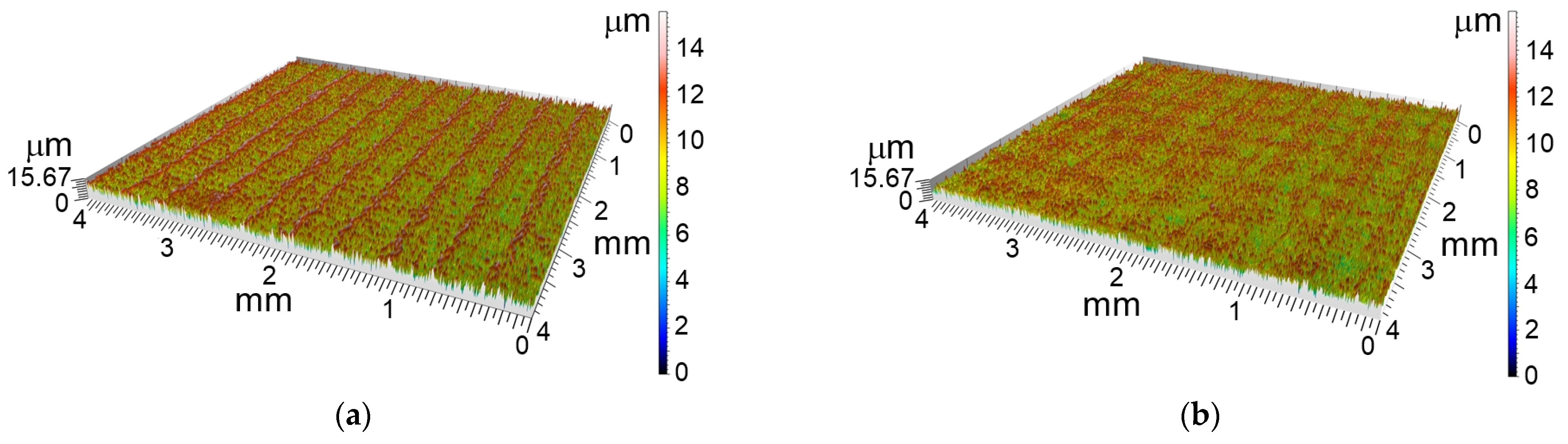

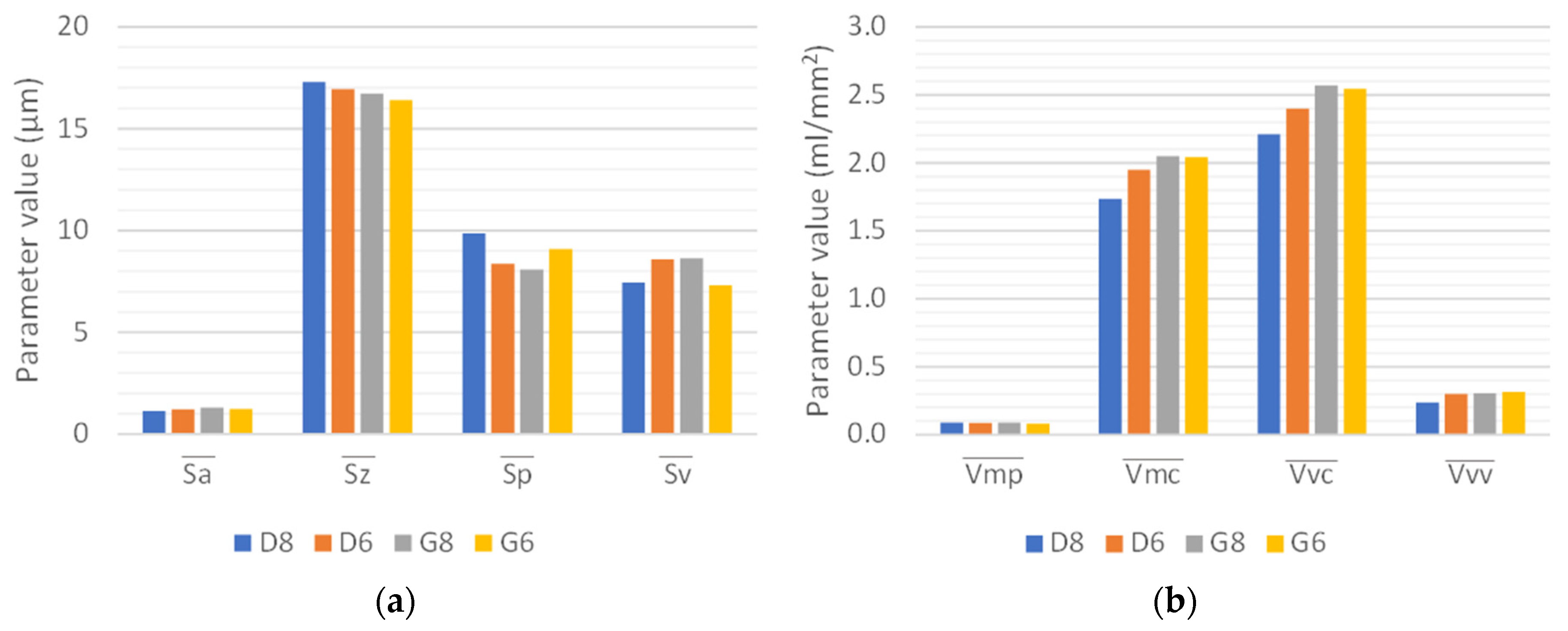

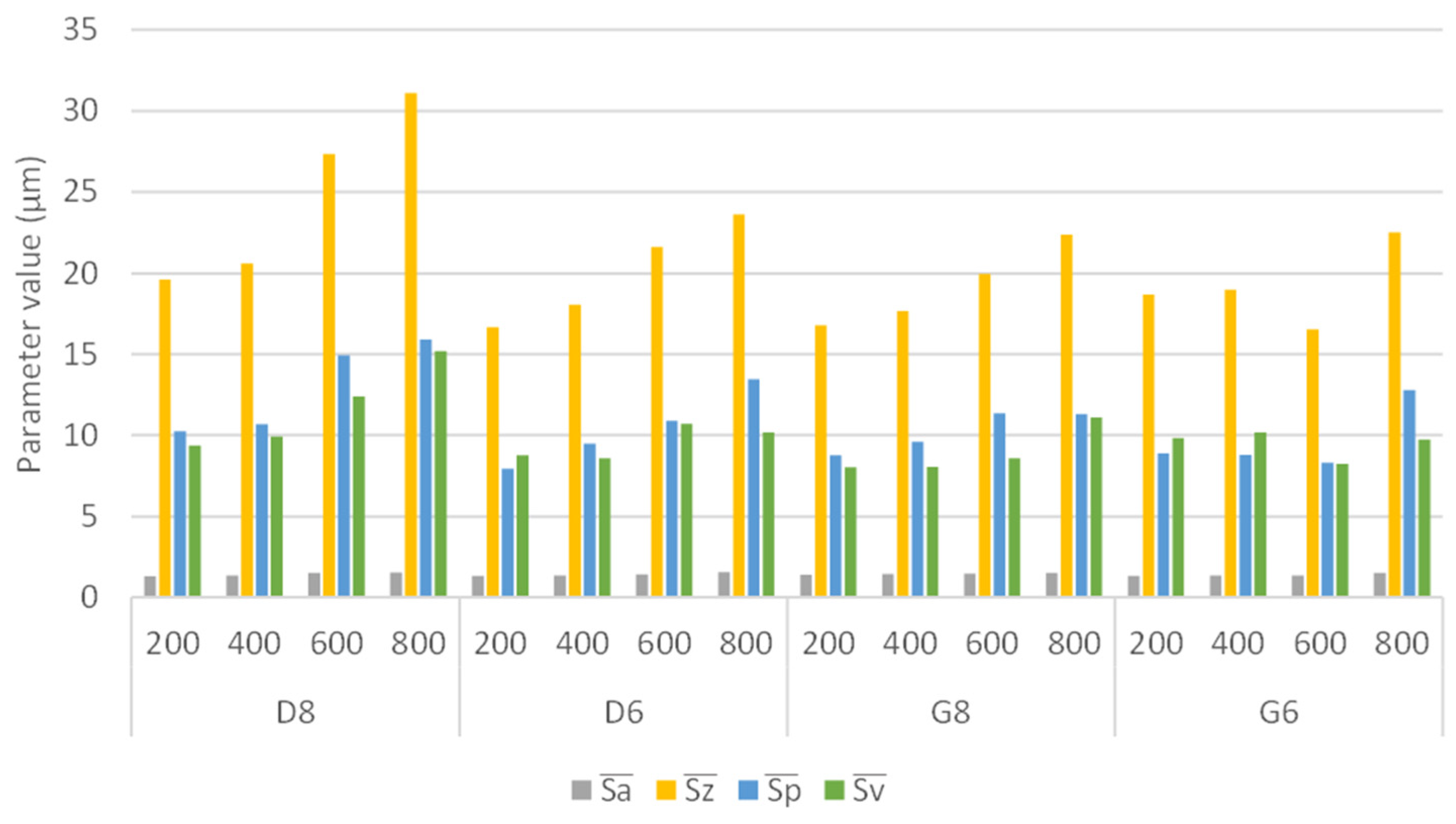

3.1. Measurements of Surface Parameters

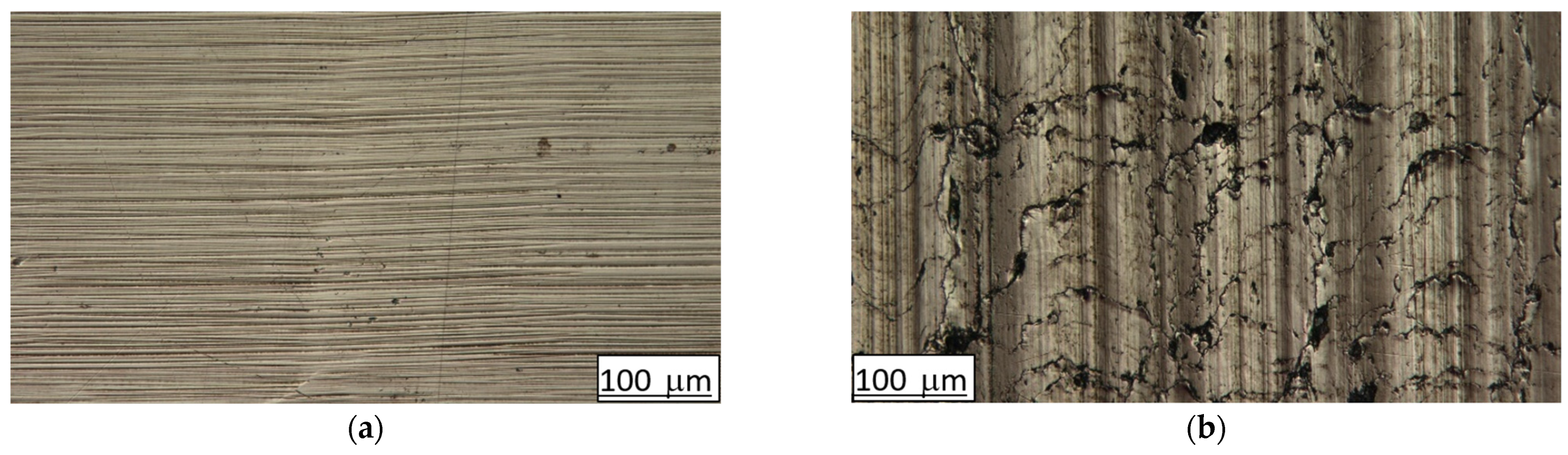

3.2. Studies of Surface Changes After Milling and Burnishing

3.3. Determination of Surface Wear

4. Conclusions

- In addition to the value of the burnishing force, the state of the surface geometrical texture after milling has a significant influence on the end result of hybrid manufacturing;

- In hybrid machining operations, it is not so much the height of the resulting irregularities and the effectiveness of their levelling by burnishing that is important, but the geometry of the irregularities. After milling, surfaces with small, regular irregularities with smooth peaks and shallow valleys were found to be the best in tribological tests. Such roughness can be plastically levelled out during burnishing. Rolled peaks that do not connect with the surface core should be avoided;

- The realisation of high-performance hybrid manufacturing (by milling and burnishing), in which irregularities of considerable heights are burnished at significant force values (often above 1 kN), can lead to good smoothness and reflectivity on the surface (i.e., low roughness). However, locally high surface consolidation at shallow depths does not necessarily lead to an increase in the resistance of the surface to abrasive wear. It is better to take care of the efficiency of the surface burnishing procedure by using a higher feed rate and a ball in the tip of the burnisher with a larger diameter;

- Experimental studies have shown that a higher burnishing force (inducing higher burnishing stresses) does not always lead to a higher wear resistance of the surface. Rather, high peaks of unevenness form in the surface, which break away and cause accelerated erosion of the surface.

- The observed effects of the favourable tribological properties at low burnishing forces require further investigation. The present study should be regarded as preliminary research, and the developed methodology for determining the actual degree of surface wear should be applied to a wider range of experimental studies. The residual stresses obtained during surface burnishing need to be better understood, and their value may be a better correlation factor between technological processing parameters and the increase in the resistance of the surface to tribological wear. Numerical simulation models can be particularly helpful for their assessment.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A. Hybrid Manufacturing

- Combination of different energy sources at the same time and in the same place (in the product shaping zone);

- Manufacturing machines combining various manufacturing techniques in a single operation;

- Combination in one process operation of steps performed at two or more stations;

- Products (parts) having a hybrid structure or function.

References

- Chybowski, L.; Nozdrzykowski, K.; Grządziel, Z.; Dorobczyński, L. Evaluation of model-based control of reaction forces at the supports of large-size crankshafts. Sensors 2020, 20, 2654. [Google Scholar] [CrossRef] [PubMed]

- Nozdrzykowski, K.; Grządziel, Z.; Dunaj, P. Determining geometrical deviations of crankshafts with limited detection possibilities due to support conditions. Measurement 2022, 189, 110430. [Google Scholar] [CrossRef]

- Nozdrzykowski, K.; Grządziel, Z.; Grzejda, R.; Warzecha, M.; Stępień, M. An analysis of reaction forces in crankshaft support systems. Lubricants 2022, 10, 151. [Google Scholar] [CrossRef]

- Sługocka, M.; Grochała, D.; Kwiatkowski, K.; Grzejda, R.; Zmarzły, P. Study of the impact of surface topography on selected mechanical properties of adhesive joints. Coatings 2024, 14, 944. [Google Scholar] [CrossRef]

- Grochała, D.; Jasiewicz, M.; Filipowicz, K.; Parus, A.; Powałka, B.; Grzejda, R.; Zmarzły, P. Assessment of the functional properties of the surfaces of ductile cast iron parts. Appl. Sci. 2024, 14, 9129. [Google Scholar] [CrossRef]

- Lawrowski, Z. Tribology: Friction, Wear and Lubrication, 1st ed.; PWN Scientific Publishing House: Warsaw, Poland, 1993. (In Polish) [Google Scholar]

- Grochała, D.; Berczyński, S.; Grządziel, Z. Stress in the surface layer of objects burnished after milling. Int. J. Adv. Manuf. Technol. 2014, 72, 1655–1663. [Google Scholar] [CrossRef]

- Ouyang, W.; Zhang, L.; Wu, H.; Wu, D.; Zhang, S.; Qin, X.; Jiang, S.; Li, S.; Zhang, W.; Sheng, L. Optimized mechanical properties of the hot forged Ti–6Al–4V alloy by regulating multiscale microstructure via laser shock peening. Int. J. Mach. Tools Manuf. 2024, 201, 104192. [Google Scholar] [CrossRef]

- Holmberg, K.; Helle, A. Tribology as basis for machinery condition diagnostics and prognostics. Int. J. Perform. Eng. 2008, 4, 255–269. [Google Scholar]

- Williams, J.A. Wear and wear particles—Some fundamentals. Tribol. Int. 2005, 38, 863–870. [Google Scholar] [CrossRef]

- Gagg, C.R.; Lewis, P.R. Wear as a product failure mechanism—Overview and case studies. Eng. Fail. Anal. 2007, 14, 1618–1640. [Google Scholar] [CrossRef]

- Varga, M. High temperature abrasive wear of metallic materials. Wear 2017, 376–377, 443–451. [Google Scholar] [CrossRef]

- López de Lacalle, L.N.; Rodríguez, A.; Lamikiz, A.; Celaya, A.; Alberdi, R. Five-axis machining and burnishing of complex parts for the improvement of surface roughness. Mater. Manuf. Process. 2011, 26, 997–1003. [Google Scholar] [CrossRef]

- Kalisz, J.; Żak, K.; Wojciechowski, S.; Gupta, M.K.; Krolczyk, G.M. Technological and tribological aspects of milling-burnishing process of complex surfaces. Tribol. Int. 2021, 155, 106770. [Google Scholar] [CrossRef]

- Teimouri, R.; Grabowski, M.; Kowalczyk, M.; Skoczypiec, S. Simulation of surface roughness alternation in milling-burnishing sequence. Measurement 2023, 218, 113160. [Google Scholar] [CrossRef]

- Mezlini, S.; Mzali, S.; Sghaier, S.; Braham, C.; Kapsa, P. Effect of a combined machining/burnishing tool on the roughness and mechanical properties. Lubr. Sci. 2014, 26, 175–187. [Google Scholar] [CrossRef]

- Boozarpoor, M.; Elyasi, M.; Hosseinzadeh, M. An investigation of the surface quality of burnished AISI 4340 steel. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2018, 232, 299–313. [Google Scholar] [CrossRef]

- Arsalani, M.; Razfar, M.R.; Abdullah, A.; Khajehzadeh, M. Fatigue behavior improvement of hardened parts using sequential hard turning, grinding, and ball burnishing operations. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2021, 235, 87–99. [Google Scholar] [CrossRef]

- Dyl, T.; Rydz, D.; Szarek, A.; Stradomski, G.; Fik, J.; Opydo, M. The influence of slide burnishing on the technological quality of X2CrNiMo17-12-2 steel. Materials 2024, 17, 3403. [Google Scholar] [CrossRef]

- Nadolny, K.; Plichta, J.; Radowski, M. Reciprocal internal cylindrical grinding integrated with dynamic centrifugal burnishing of hard-to-cut materials. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2015, 229, 265–279. [Google Scholar] [CrossRef]

- Teimouri, R.; Amini, S.; Bami, A.B. Evaluation of optimized surface properties and residual stress in ultrasonic assisted ball burnishing of AA6061-T6. Measurement 2018, 116, 129–139. [Google Scholar] [CrossRef]

- Amini, S.; Bagheri, A.; Teimouri, R. Ultrasonic assisted ball burnishing of aluminum 6061 and AISI 1045 steel. Mater. Manuf. Process. 2018, 33, 1250–1259. [Google Scholar] [CrossRef]

- Khosrojerdi, M.; Razfar, M.R.; Fesharakifard, R.; Khajehzadeh, M. Improvement of the frictional behavior of Al 7075-T6 by ultrasonic-assisted ball burnishing process. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2023, 237, 1082–1092. [Google Scholar] [CrossRef]

- Świrad, S.; Wydrzynski, D.; Nieslony, P.; Krolczyk, G.M. Influence of hydrostatic burnishing strategy on the surface topography of martensitic steel. Measurement 2019, 138, 590–601. [Google Scholar] [CrossRef]

- Qi, B.; Chai, Z.; Huang, X.; Guo, W.; Ren, X.; Chen, H.; Chen, X. Surface integrity improvement of the ground surface of Inconel 718 fabricated by forging and additive manufacturing using a robotic rotational burnishing method. J. Manuf. Process. 2024, 125, 566–579. [Google Scholar] [CrossRef]

- Zhou, Z.; Shi, H.; Zheng, Q.; Li, Y.; Jiang, Z.; Yuan, Z.; Piao, Z. Research on fabricating gradient nanostructure and enhancing wear resistance in aluminum alloy via two-dimensional ultrasonic surface burnishing. Surf. Coat. Technol. 2024, 494, 131302. [Google Scholar]

- Keymanesh, M.; Ji, H.; Zhang, X.; Wang, J.; Feng, P.; Zhang, J. Multi-roller taper burnishing of internal chamfers and its enhancement mechanism on 7050 aluminum alloy. Int. J. Fatigue 2024, 189, 108571. [Google Scholar] [CrossRef]

- Gómez-Gras, G.; Travieso-Rodríguez, J.A.; González-Rojas, H.A.; Nápoles-Alberro, A.; Carrillo, F.J.; Dessein, G. Study of a ball-burnishing vibration-assisted process. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2015, 229, 172–177. [Google Scholar] [CrossRef]

- Grochała, D.; Berczyński, S.; Grządziel, Z. Analysis of surface geometry changes after hybrid milling and burnishing by ceramic ball. Materials 2019, 12, 1179. [Google Scholar] [CrossRef]

- Mikuła, J.; Mikuła, S.; Szweda, S. Surface Strain Hardening for the Performance Improvement of Hydraulic Actuators in Powered Roof Supports. In Proceedings of the 28th International Conference on Metallurgy and Materials, Brno, Czech Republic, 22–24 May 2019; pp. 432–437. [Google Scholar]

- Szweda, S.; Mikuła, S.; Mikuła, J. Device for Burnishing of Internal Surfaces of Hydraulic Actuator Cylinders, Preferably in the Mining Powered Roof Support. PAT.233272, 11 June 2019. [Google Scholar]

- Teimouri, R.; Amini, S.; Ashrafi, H. An analytical model of burnishing forces using slab method. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2019, 233, 630–642. [Google Scholar] [CrossRef]

- Çelik, M. Effect of roller burnishing on the mechanical behavior and surface quality of Ti6Al4V alloy. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2023, 237, 2093–2101. [Google Scholar] [CrossRef]

- Jagadeesh, G.V.; Setti, S.G. Experimental investigation and estimation of compressive residual stress of ball burnished rare earth based magnesium alloy. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2024, 238, 351–362. [Google Scholar] [CrossRef]

- Rodríguez, A.; López de Lacalle, L.N.; Celaya, A.; Lamikiz, A.; Albizuri, J. Surface improvement of shafts by the deep ball-burnishing technique. Surf. Coat. Technol. 2012, 206, 2817–2824. [Google Scholar] [CrossRef]

- El-Taweel, T.A.; El-Axir, M.H. Analysis and optimization of the ball burnishing process through the Taguchi technique. Int. J. Adv. Manuf. Technol. 2009, 41, 301–310. [Google Scholar] [CrossRef]

- Gharbi, F.; Sghaier, S.; Al-Fadhalah, K.J.; Benameur, T. Effect of ball burnishing process on the surface quality and microstructure properties of AISI 1010 steel plates. J. Mater. Eng. Perform. 2011, 20, 903–910. [Google Scholar] [CrossRef]

- Korzynski, M.; Pacana, A.; Cwanek, J. Fatigue strength of chromium coated elements and possibility of its improvement with slide diamond burnishing. Surf. Coat. Technol. 2009, 203, 1670–1676. [Google Scholar] [CrossRef]

- Avilés, R.; Albizuri, J.; Rodríguez, A.; López de Lacalle, L.N. Influence of low-plasticity ball burnishing on the high-cycle fatigue strength of medium carbon AISI 1045 steel. Int. J. Fatigue 2013, 55, 230–244. [Google Scholar] [CrossRef]

- Travieso-Rodriguez, J.A.; Gómez Gras, G.; Jorba Peiró, J.; Carrillo, F.; Dessein, G.; Alexis, J.; González Rojas, H. Experimental study on the mechanical effects of the vibration-assisted ball-burnishing process. Mater. Manuf. Process. 2015, 30, 1490–1497. [Google Scholar] [CrossRef]

- Travieso-Rodriguez, J.A.; Gomez-Gras, G.; Dessein, G.; Carrillo, F.; Alexis, J.; Jorba Peiró, J.; Aubazac, N. Effects of a ball-burnishing process assisted by vibrations in G10380 steel specimens. Int. J. Adv. Manuf. Technol. 2015, 81, 1757–1765. [Google Scholar] [CrossRef]

- Revankar, G.D.; Shetty, R.; Rao, S.S.; Gaitonde, V.N. Analysis of surface roughness and hardness in ball burnishing of titanium alloy. Measurement 2014, 58, 256–268. [Google Scholar] [CrossRef]

- Revankar, G.D.; Shetty, R.; Rao, S.S.; Gaitonde, V.N. Wear resistance enhancement of titanium alloy (Ti–6Al–4V) by ball burnishing process. J. Mater. Res. Technol. 2017, 6, 13–32. [Google Scholar] [CrossRef]

- Luo, H.; Liu, J.; Wang, L.; Zhong, Q. Study of the mechanism of the burnishing process with cylindrical polycrystalline diamond tools. J. Mater. Process. Technol. 2006, 180, 9–16. [Google Scholar] [CrossRef]

- Hiegemann, L.; Weddeling, C.; Khalifa, N.B.; Tekkaya, A.E. Analytical prediction of roughness after ball burnishing of thermally coated surfaces. Procedia Eng. 2014, 81, 1921–1926. [Google Scholar] [CrossRef]

- Hiegemann, L.; Weddeling, C.; Khalifa, N.B.; Tekkaya, A.E. Prediction of roughness after ball burnishing of thermally coated surfaces. J. Mater. Process. Technol. 2015, 217, 193–201. [Google Scholar] [CrossRef]

- Korzynski, M. Modeling and experimental validation of the force–surface roughness relation for smoothing burnishing with a spherical tool. Int. J. Mach. Tools Manuf. 2007, 47, 1956–1964. [Google Scholar] [CrossRef]

- Zmarzły, P. Influence of bearing raceway surface topography on the level of generated vibration as an example of operational heredity. Indian J. Eng. Mater. Sci. 2020, 27, 356–364. [Google Scholar]

- Krajewski, S.J.; Grochała, D.; Tomków, J.; Grzejda, R. Analysis of the surface stereometry of alloyed austenitic steel after fibre laser cutting using confocal microscopy. Coatings 2023, 13, 15. [Google Scholar] [CrossRef]

- Kubiak, K.J.; Wilson, M.C.T.; Mathia, T.G.; Carval, P. Wettability versus roughness of engineering surfaces. Wear 2011, 271, 523–528. [Google Scholar] [CrossRef]

- Jothi Prakash, C.G.; Prasanth, R. Approaches to design a surface with tunable wettability: A review on surface properties. J. Mater. Sci. 2021, 56, 108–135. [Google Scholar] [CrossRef]

- Bashandeh, K.; Marchert, A.; Takayuki, U.; Polycarpou, A.A.; Meyer, J.; Lan, P. The effect of surface texturing on thin film reversible adhesive bond strength. Int. J. Adhes. Adhes. 2021, 107, 102829. [Google Scholar] [CrossRef]

- Scheers, J.; Vermeulen, M.; De Maré, C.; Meseure, K. Assessment of steel surface roughness and waviness in relation with paint appearance. Int. J. Mach. Tools Manuf. 1998, 38, 647–656. [Google Scholar] [CrossRef]

- Yaneff, P.V.; Adamsons, K.; Ryntz, R.A.; Britz, D. Structure/property relationships in flexible alkoxysilane automotive coatings. J. Coat. Technol. 2002, 74, 135–141. [Google Scholar] [CrossRef]

- Hang, J.; Yan, X.; Li, J. A review on the effect of wood surface modification on paint film adhesion properties. Coatings 2024, 14, 1313. [Google Scholar] [CrossRef]

- Zielecki, W.; Pawlus, P.; Perłowski, R.; Dzierwa, A. Surface topography effect on strength of lap adhesive joints after mechanical pre-treatment. Arch. Civ. Mech. Eng. 2013, 13, 175–185. [Google Scholar] [CrossRef]

- Malekinejad, H.; Carbas, R.J.C.; Akhavan-Safar, A.; Marques, E.A.S.; Sousa, F.C.; da Silva, L.F.M. Enhancing fatigue life and strength of adhesively bonded composite joints: A comprehensive review. Materials 2023, 16, 6468. [Google Scholar] [CrossRef]

- Dudzinska, S.; Szydlowski, M.; Grochala, D.; Bachtiak-Radka, E. Application of correlation function for analysis of surface structure shaping by hybrid manufacturing technology. In Advances in Manufacturing; Hamrol, A., Ciszak, O., Legutko, S., Jurczyk, M., Eds.; Springer: Cham, Switzerland, 2018; pp. 651–659. [Google Scholar]

- Olszak, W.; Grochała, D.; Koza, K. Tool for Surface Burnishing. PAT.220528, 5 March 2015. [Google Scholar]

- PN-EN ISO 21920-1; Geometrical Product Specifications (GPS), Surface Texture: Profile, Part 1: Indication of Surface Texture. Polish Committee for Standardization: Warsaw, Poland, 2022.

- PN-EN ISO 21920-2; Geometrical Product Specifications (GPS), Surface Texture: Profile, Part 2: Terms, Definitions and Surface Texture Partameters. Polish Committee for Standardization: Warsaw, Poland, 2022.

- PN-EN ISO 21920-3; Geometrical Product Specifications (GPS), Surface Texture: Profile, Part 3: Specification Operators. Polish Committee for Standardization: Warsaw, Poland, 2022.

- Raymond, N.; Hill, S.; Soshi, M. Characterization of surface polishing with spindle mounted abrasive disk-type filament tool for manufacturing of machine tool sliding guideways. Int. J. Adv. Manuf. Technol. 2016, 86, 2069–2082. [Google Scholar] [CrossRef]

- Pawlus, P.; Reizer, R.; Zelasko, W. Prediction of parameters of equivalent sum rough surfaces. Materials 2020, 13, 4898. [Google Scholar] [CrossRef]

- PN-EN ISO 25178-2; Geometrical Product Specifications (GPS), Surface Texture: Areal, Part 2: Terms, Definitions and Surface Texture Parameters. Polish Committee for Standardization: Warsaw, Poland, 2022.

- Grochała, D.; Grzejda, R.; Parus, A.; Berczyński, S. The wavelet transform for feature extraction and surface roughness evaluation after micromachining. Coatings 2024, 14, 210. [Google Scholar] [CrossRef]

- Kochmański, P.; Długozima, M.; Baranowska, J. Structure and properties of gas-nitrided, precipitation-hardened martensitic stainless steel. Materials 2022, 15, 907. [Google Scholar] [CrossRef]

- ASTM G99; Standard Test Method for Wear and Friction Testing with a Pin-on-Disk or Ball-on-Disk Apparatus. ASTM International: West Conshohocken, PA, USA, 2023.

- Zhu, Z.; Dhokia, V.G.; Nassehi, A.; Newman, S.T. A review of hybrid manufacturing processes—State of the art and future perspectives. Int. J. Comput. Integr. Manuf. 2013, 26, 596–615. [Google Scholar] [CrossRef]

- Chu, W.-S.; Kim, C.-S.; Lee, H.-T.; Choi, J.-O.; Park, J.-I.; Song, J.-H.; Jang, K.-H.; Ahn, S.-H. Hybrid manufacturing in micro/nano scale: A Review. Int. J. Precis. Eng. Manuf.-Green Technol. 2014, 1, 75–92. [Google Scholar] [CrossRef]

- Schuh, G.; Kreysa, J.; Orilski, S. Roadmap “Hybrid production”. Z. Wirtsch. Fabrikbetr. 2009, 104, 385–391. (In German) [Google Scholar] [CrossRef]

- Lauwers, B.; Klocke, F.; Klink, A.; Tekkaya, A.E.; Neugebauer, R.; Mcintosh, D. Hybrid processes in manufacturing. CIRP Ann. 2014, 63, 561–583. [Google Scholar] [CrossRef]

- Rajurkar, K.P.; Zhu, D.; McGeough, J.A.; Kozak, J.; De Silva, A. New developments in electro-chemical machining. CIRP Ann. 1999, 48, 567–579. [Google Scholar] [CrossRef]

- Nau, B.; Roderburg, A.; Klocke, F. Ramp-up of hybrid manufacturing technologies. CIRP J. Manuf. Sci. Technol. 2011, 4, 313–316. [Google Scholar] [CrossRef]

- Klocke, F.; Stauder, J.; Mattfeld, P.; Müller, J. Modeling of manufacturing technologies during ramp-up. Procedia CIRP 2016, 51, 122–127. [Google Scholar] [CrossRef][Green Version]

- Lauwers, B.; Klocke, F.; Klink, A. Advanced Manufacturing Through the Implementation of Hybrid and Media Assisted Processes. In Proceedings of the International Chemnitz Manufacturing Colloquium, Chemnitz, Germany, 29–30 September 2010; pp. 205–220. [Google Scholar]

- Dandekar, C.R.; Shin, Y.C.; Barnes, J. Machinability improvement of titanium alloy (Ti-6Al-4V) via LAM and hybrid machining. Int. J. Mach. Tools Manuf. 2010, 50, 174–182. [Google Scholar] [CrossRef]

- Manogharan, G.; Wysk, R.; Harrysson, O.; Aman, R. AIMS—A Metal Additive-Hybrid Manufacturing System: System architecture and attributes. Procedia Manuf. 2015, 1, 273–286. [Google Scholar] [CrossRef]

- Colledani, M.; Tolio, T.; Fischer, A.; Iung, B.; Lanza, G.; Schmitt, R.; Váncza, J. Design and management of manufacturing systems for production quality. CIRP Ann. 2014, 63, 773–796. [Google Scholar] [CrossRef]

| Specimen | fm (mm) | Fb (N) | Ra 1 (μm) | Rz 1 (μm) | Rmax 1 (μm) |

|---|---|---|---|---|---|

| D10 | Reference milling | 5.56 | 21.6 | 22.2 | |

| D8 | 0.4 | 600 | 0.94 | 4.44 | 4.87 |

| D6 | 0.4 | 200 | 0.88 | 4.00 | 4.46 |

| G10 | Reference milling | 6.29 | 25.3 | 27.2 | |

| G8 | 0.7 | 600 | 2.94 | 10.6 | 11.1 |

| G6 | 0.7 | 200 | 2.64 | 9.80 | 10.6 |

| Friction Path (m) | Specimen | (μm) | (μm) | (μm) | (μm) | (mL/mm2) | (mL/mm2) | (mL/mm2) | (mL/mm2) |

|---|---|---|---|---|---|---|---|---|---|

| 0 | D8 | 1.14 | 17.30 | 9.86 | 7.43 | 0.088 | 1.736 | 2.212 | 0.239 |

| D6 | 1.22 | 16.96 | 8.38 | 8.58 | 0.085 | 1.947 | 2.398 | 0.297 | |

| G8 | 1.29 | 16.73 | 8.09 | 8.63 | 0.087 | 2.047 | 2.571 | 0.304 | |

| G6 | 1.24 | 16.39 | 9.08 | 7.32 | 0.084 | 2.042 | 2.544 | 0.315 | |

| 200 | D8 | 1.30 | 19.60 | 10.2 | 9.37 | 0.089 | 2.008 | 2.510 | 0.297 |

| D6 | 1.34 | 16.69 | 7.93 | 8.76 | 0.085 | 2.045 | 2.490 | 0.297 | |

| G8 | 1.37 | 16.79 | 8.77 | 8.02 | 0.092 | 2.024 | 2.601 | 0.279 | |

| G6 | 1.32 | 18.69 | 8.87 | 9.82 | 0.092 | 2.069 | 2.573 | 0.315 | |

| 400 | D8 | 1.35 | 20.61 | 10.7 | 9.93 | 0.085 | 2.256 | 2.705 | 0.350 |

| D6 | 1.37 | 18.06 | 9.47 | 8.60 | 0.089 | 2.405 | 2.885 | 0.352 | |

| G8 | 1.45 | 17.65 | 9.59 | 8.06 | 0.096 | 2.204 | 2.838 | 0.308 | |

| G6 | 1.36 | 18.98 | 8.79 | 10.2 | 0.094 | 2.116 | 2.669 | 0.305 | |

| 600 | D8 | 1.50 | 27.34 | 14.9 | 12.4 | 0.094 | 3.288 | 3.481 | 0.459 |

| D6 | 1.42 | 21.61 | 10.9 | 10.7 | 0.090 | 3.030 | 3.355 | 0.389 | |

| G8 | 1.47 | 19.97 | 11.4 | 8.60 | 0.099 | 2.504 | 3.140 | 0.330 | |

| G6 | 1.37 | 16.53 | 8.30 | 8.23 | 0.095 | 2.564 | 3.158 | 0.345 | |

| 800 | D8 | 1.54 | 31.11 | 15.9 | 15.2 | 0.092 | 3.742 | 3.827 | 0.433 |

| D6 | 1.55 | 23.63 | 13.5 | 10.2 | 0.126 | 3.891 | 4.446 | 0.398 | |

| G8 | 1.50 | 22.39 | 11.3 | 11.1 | 0.110 | 3.459 | 4.037 | 0.365 | |

| G6 | 1.50 | 22.52 | 12.8 | 9.74 | 0.109 | 4.176 | 4.417 | 0.450 |

| Specimen | HV1 | S |

|---|---|---|

| D10 Reference milling | 189 | 6 |

| D8 | 295 | 15 |

| D6 | 314 | 14 |

| G10 Reference milling | 189 | 6 |

| G8 | 332 | 11 |

| G6 | 346 | 12 |

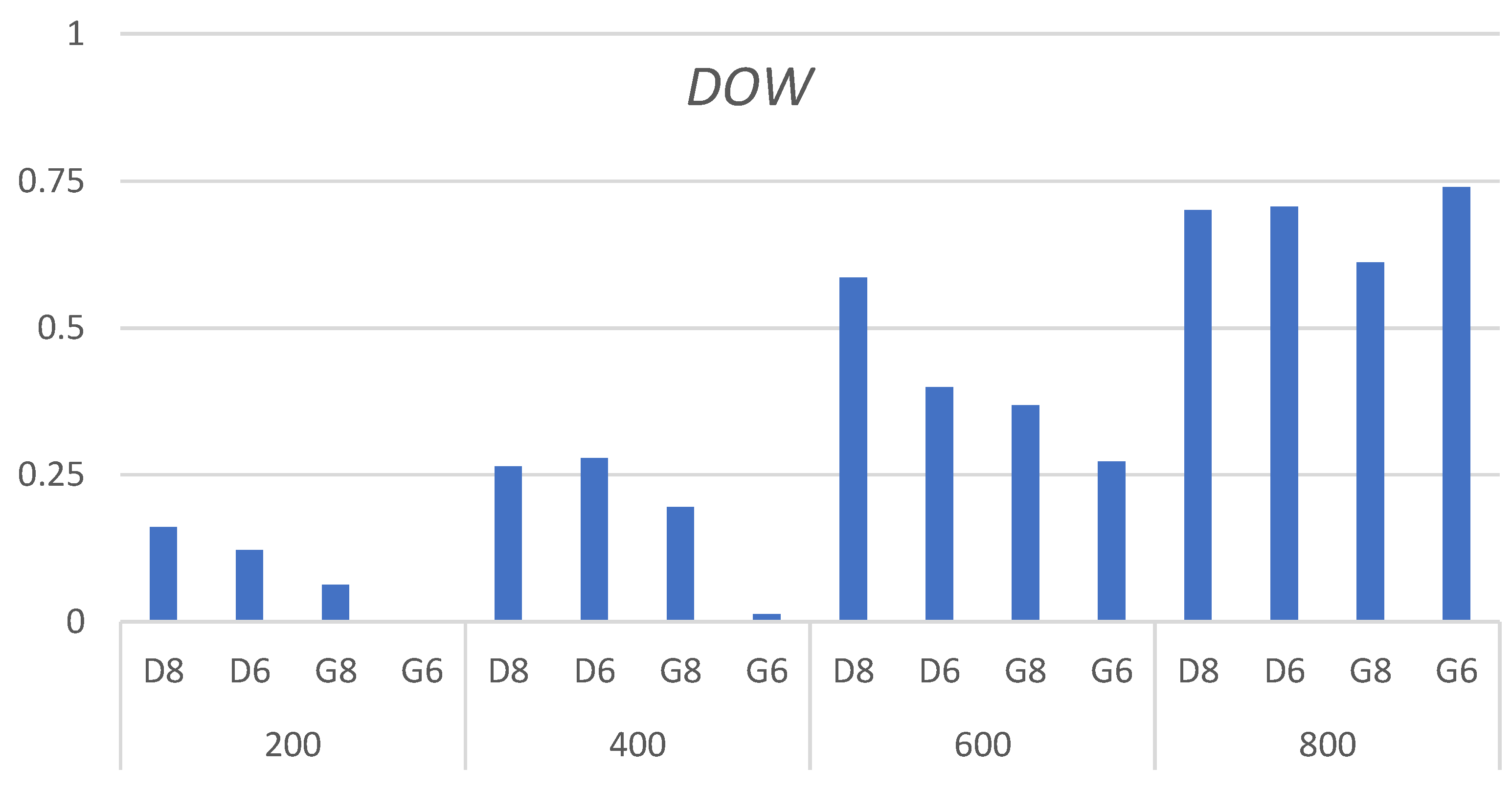

| Friction Path (m) | Specimen | W (mm) | D (μm) | A (μm2) | Norm(W) | Norm(D) | Norm(A) | Sum(WDA) | DOW |

|---|---|---|---|---|---|---|---|---|---|

| 200 | D8 | 0.295 | 2.843 | 532 | 0.234 | 0.235 | 0.093 | 0.562 | 0.161 |

| D6 | 0.326 | 1.484 | 439 | 0.328 | 0.055 | 0.063 | 0.446 | 0.123 | |

| G8 | 0.305 | 1.070 | 243 | 0.265 | 0.000 | 0.001 | 0.266 | 0.063 | |

| G6 | 0.217 | 1.660 | 241 | 0.000 | 0.078 | 0.000 | 0.078 | 0.000 | |

| 400 | D8 | 0.357 | 2.998 | 850 | 0.421 | 0.256 | 0.195 | 0.872 | 0.264 |

| D6 | 0.388 | 2.400 | 936 | 0.515 | 0.176 | 0.222 | 0.913 | 0.278 | |

| G8 | 0.322 | 2.570 | 704 | 0.317 | 0.199 | 0.148 | 0.664 | 0.195 | |

| G6 | 0.233 | 1.480 | 287 | 0.048 | 0.054 | 0.015 | 0.117 | 0.013 | |

| 600 | D8 | 0.549 | 3.793 | 1726 | 1.000 | 0.361 | 0.475 | 1.836 | 0.586 |

| D6 | 0.440 | 2.992 | 1328 | 0.673 | 0.255 | 0.347 | 1.275 | 0.399 | |

| G8 | 0.397 | 3.620 | 1185 | 0.543 | 0.338 | 0.302 | 1.183 | 0.368 | |

| G6 | 0.300 | 3.850 | 1109 | 0.250 | 0.369 | 0.277 | 0.896 | 0.273 | |

| 800 | D8 | 0.533 | 5.164 | 2384 | 0.953 | 0.543 | 0.685 | 2.181 | 0.701 |

| D6 | 0.502 | 5.435 | 2614 | 0.860 | 0.579 | 0.758 | 2.197 | 0.706 | |

| G8 | 0.431 | 5.850 | 2218 | 0.645 | 0.634 | 0.632 | 1.911 | 0.611 | |

| G6 | 0.316 | 8.610 | 3370 | 0.299 | 1.000 | 1.000 | 2.299 | 0.740 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grudzień, J.; Grochała, D.; Grzejda, R.; Kochmański, P. Testing the Effectiveness of Hybrid Milling and Surface Burnishing in Improving the Wear Resistance of Machine Parts Made of Structural Steel. Lubricants 2024, 12, 458. https://doi.org/10.3390/lubricants12120458

Grudzień J, Grochała D, Grzejda R, Kochmański P. Testing the Effectiveness of Hybrid Milling and Surface Burnishing in Improving the Wear Resistance of Machine Parts Made of Structural Steel. Lubricants. 2024; 12(12):458. https://doi.org/10.3390/lubricants12120458

Chicago/Turabian StyleGrudzień, Joanna, Daniel Grochała, Rafał Grzejda, and Paweł Kochmański. 2024. "Testing the Effectiveness of Hybrid Milling and Surface Burnishing in Improving the Wear Resistance of Machine Parts Made of Structural Steel" Lubricants 12, no. 12: 458. https://doi.org/10.3390/lubricants12120458

APA StyleGrudzień, J., Grochała, D., Grzejda, R., & Kochmański, P. (2024). Testing the Effectiveness of Hybrid Milling and Surface Burnishing in Improving the Wear Resistance of Machine Parts Made of Structural Steel. Lubricants, 12(12), 458. https://doi.org/10.3390/lubricants12120458