Modification of the Surface Layer of Grey Cast Iron by Laser Heat Treatment

Abstract

1. Introduction—Grey Cast Iron Characterization

1.1. Properties of Graphite and Grey Cast Iron

1.1.1. Graphite Characterization

1.1.2. Grey Cast Iron Characterization

1.2. Application of Grey Cast Iron

1.3. The Requirements of the Surface Layer Properties

- Journals of crankshafts (and camshafts)—the main and connecting rod operating with bearings—are exposed to frictional wear;

- Cams of camshafts cooperating with the caps of the valve tappets are exposed to wear;

- Parts of edges of the piston rings are exposed to frictional wear; the seat of valves is also exposed to wear by friction and high temperatures;

- Brake components are exposed to abrasive and corrosive wear and temperature shocks;

- Edges of the culture flap in seeders, harrow teeth, or disc harrows in agriculture machines are exposed to abrasive wear in soil, so corrosion can also appear (as an example of agriculture component).

- Wear by friction (abrasive or adhesive in most cases);

- Corrosion (in some cases);

- High temperatures (in some cases).

2. Laser Heat Treatment

- Heating:

- -

- Transformation hardening.

- -

- Annealing.

- Melting:

- -

- With chemical modification (alloying, cladding).

- -

- Without chemical modification (glazing, grain refining).

- Shocking (shock hardening).

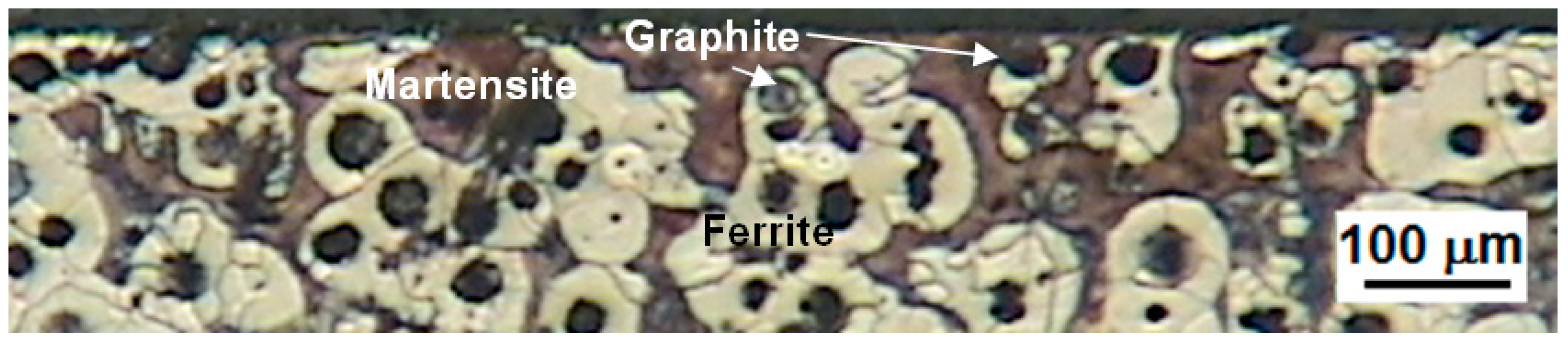

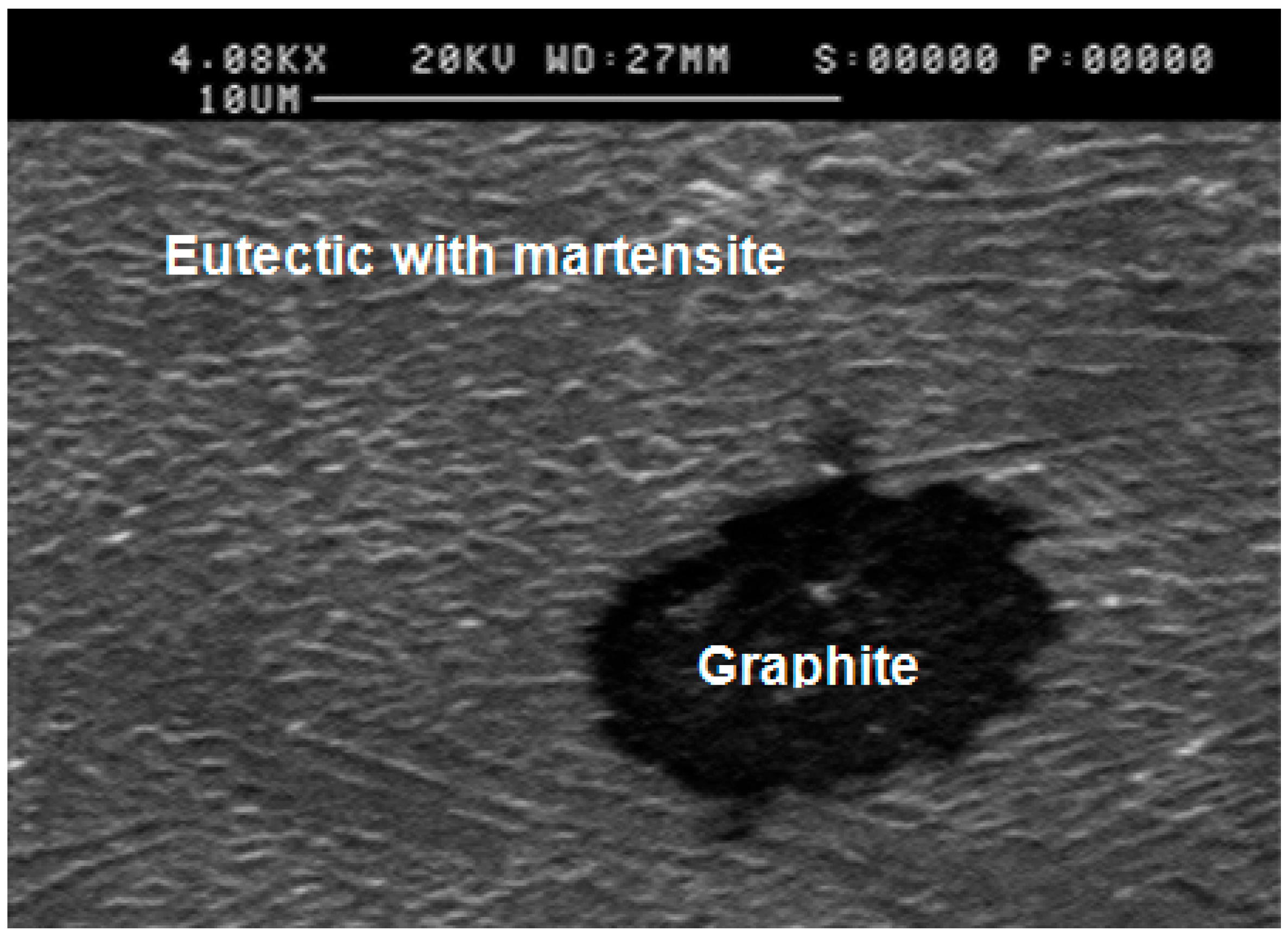

2.1. Laser Hardening from the Solid State

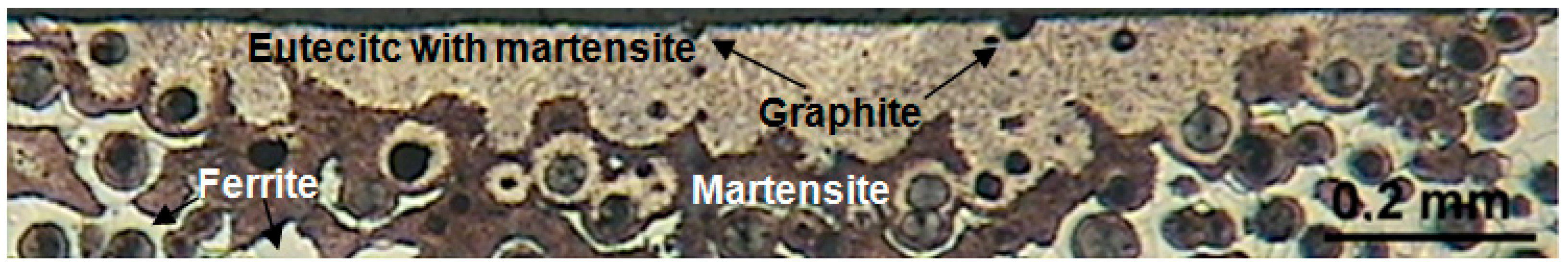

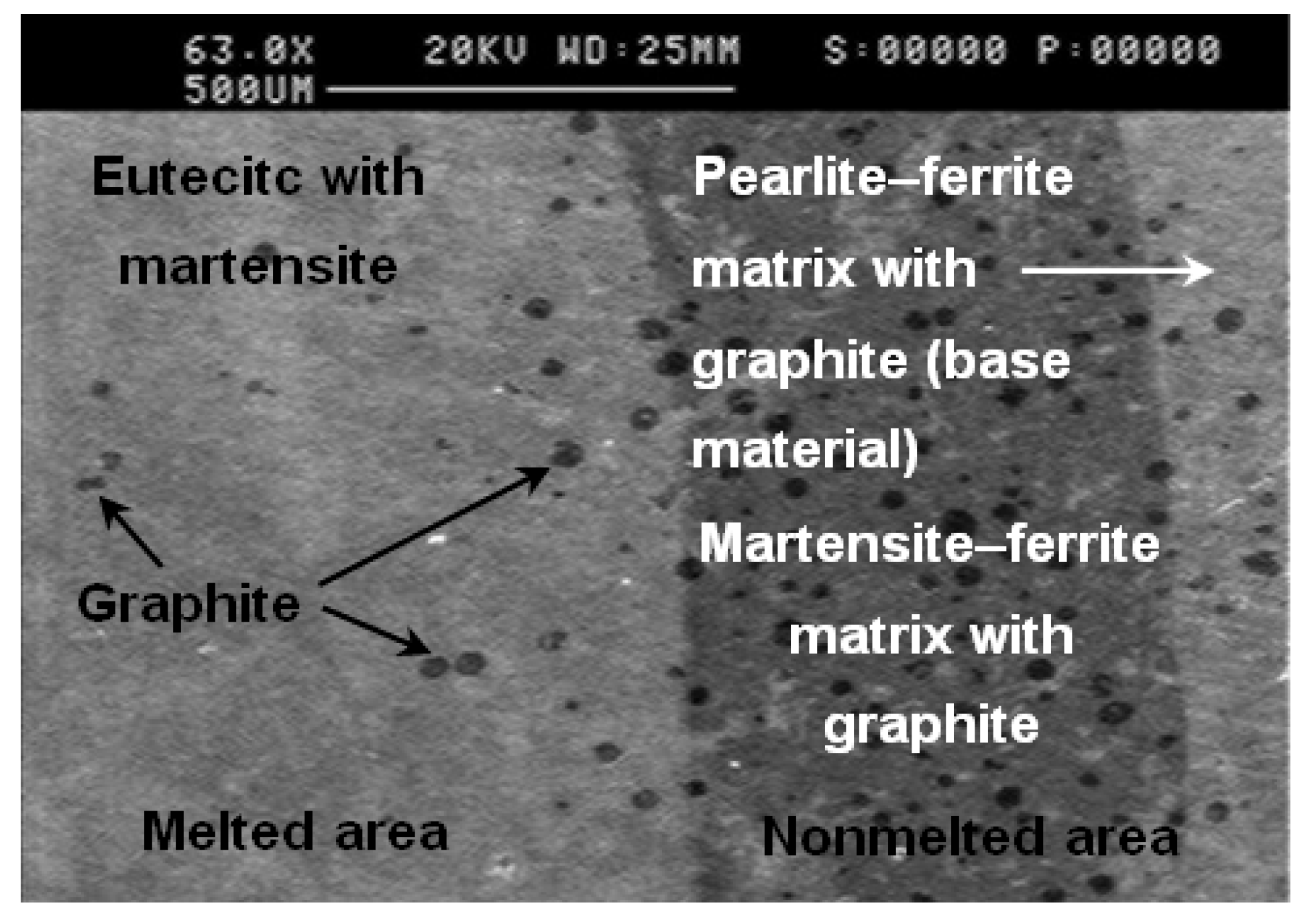

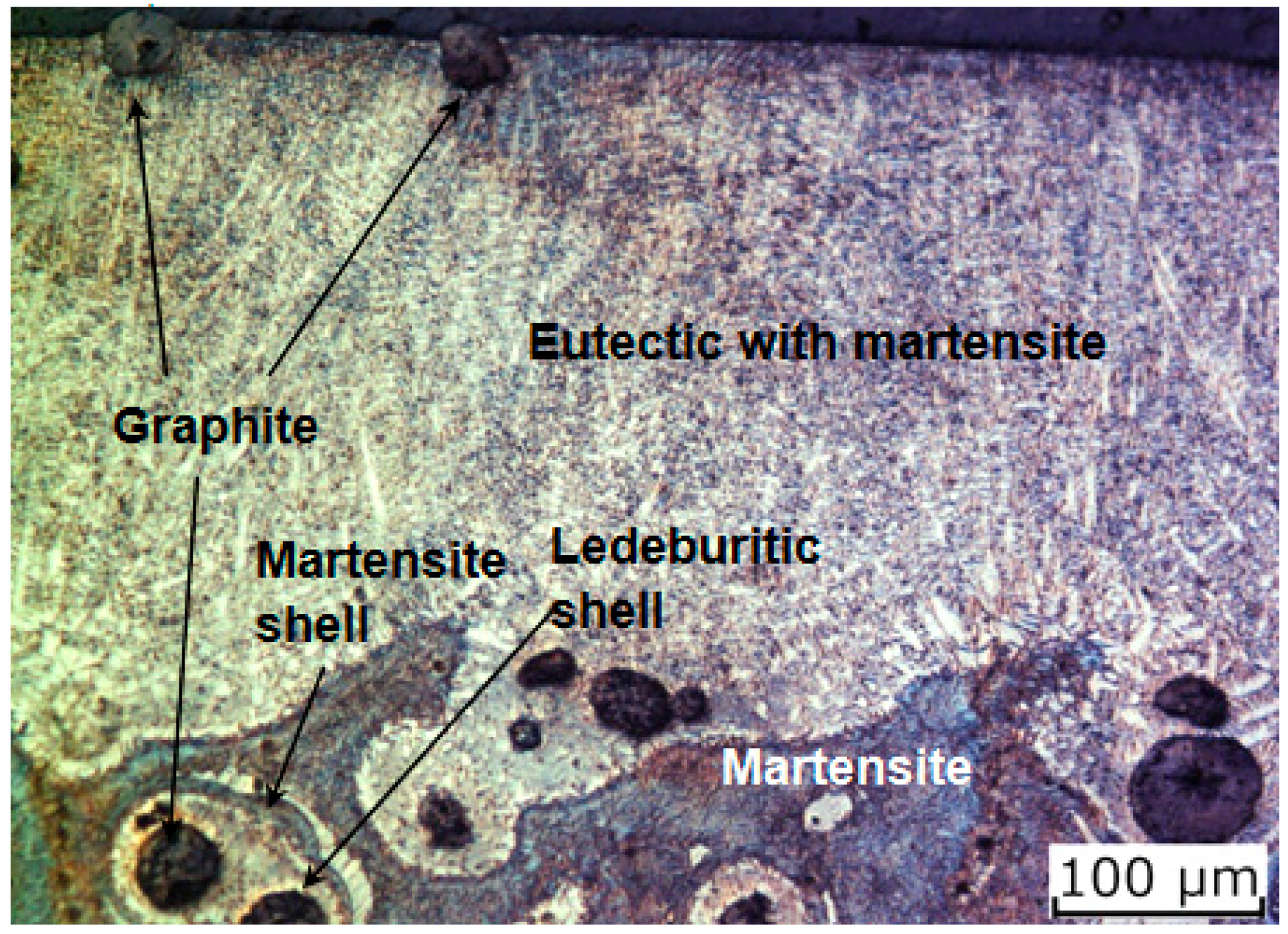

2.2. Laser Remelting

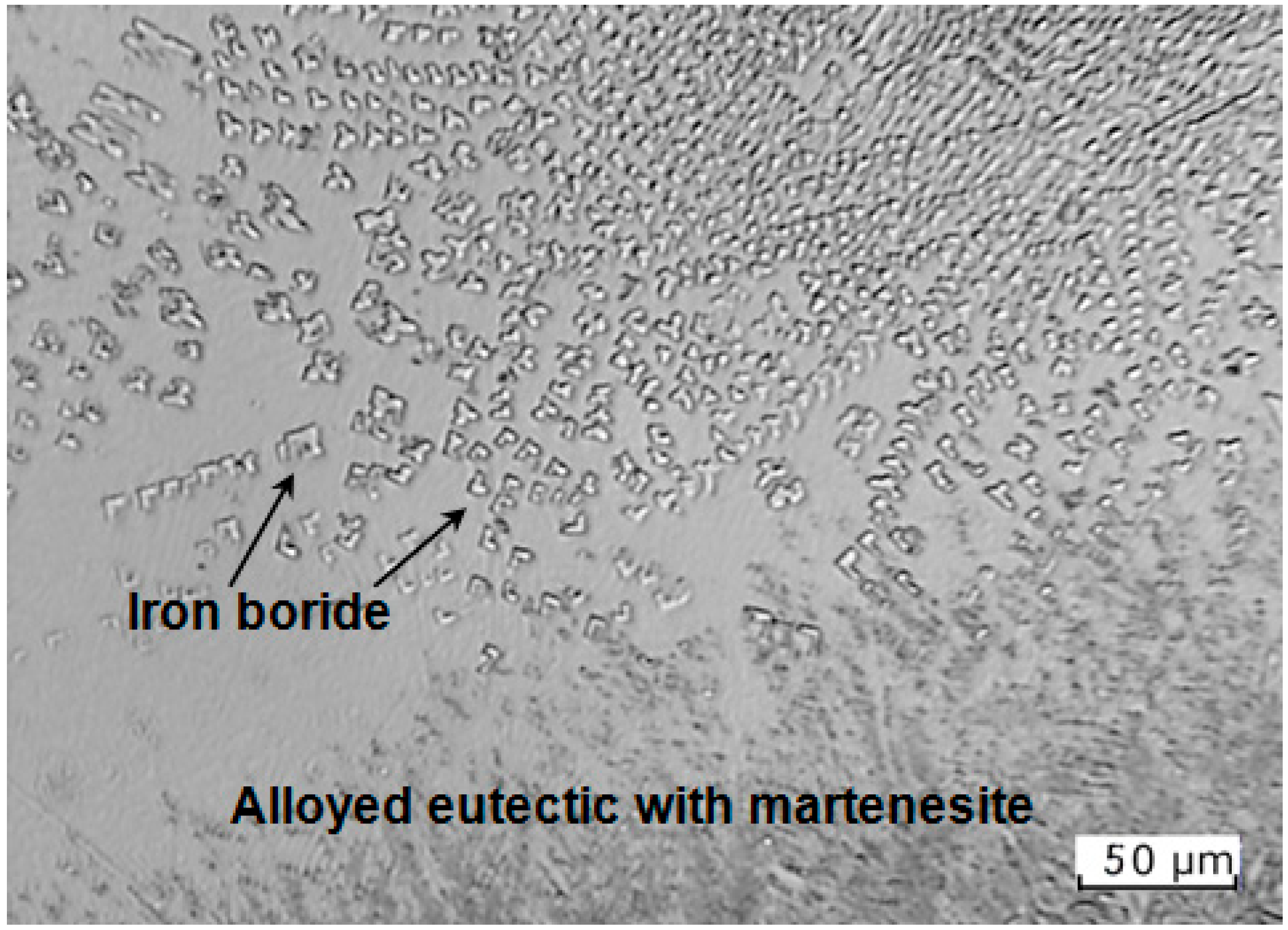

2.3. Laser Alloying

2.4. Comparison of Laser Heat Treatment Types with Austenite Transformation

- All types of treatment presented increase the hardness and microstructure homogeneity;

- All types of treatment presented enable better wear resistance to be achieved;

- Laser hardening from the solid state does not eliminate graphite;

- Laser remelting and laser alloying cause the dilution of carbon from the graphite to the melted metal matrix, but, in the case of nodular cast iron, it is possible that not all of the valuable graphite in the surface layer is lost.

3. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dobrzański, L.A. Podstawy Nauki o Materiałach i Metaloznawstwo; WNT: Gliwice, Poland, 2002. [Google Scholar]

- Rewolińska, A.; Stachowiak, A.; Kinal, G.; Paczkowska, M.; Perz, K. Zjawisko przenoszenia materiału w skojarzeniu grafit ekspandowany–stal. Tribologia 2015, 4, 167–175. [Google Scholar]

- Barbacki, A. (Ed.) Metaloznawstwo Dla Mechaników; WPP: Poznań, Poland, 1995. [Google Scholar]

- Dobrzański, L.A. Materials Science Lexicon; Verlag Dashofer: Warszawa, Pland, 2000. [Google Scholar]

- Paczkowska, M. Analiza wpływu warunków hartowania laserowego żeliwa sferoidalnego na mikrostrukturę jego warstwy powierzchniowej. In Archiwum Technologii Maszyn i Automatyzacji; PAN: Poznań, Poland, 2010; Volume 30, pp. 29–39. [Google Scholar]

- Binczyk, F.; Śmieszny, G.; Bzymek, J.; Sitko, J. Wpływ rodzaju osnowy i grafitu na własności trybologiczne żeliwa szarego. In Archiwum Odlewnictwa; PAN: Katowice, Poland, 2004; Volume 4, pp. 52–57. [Google Scholar]

- Labrecque, C.; Gagné, M. Review ductile iron: Fifty years of continuous development. Can. Met. Q. 1998, 37, 343–378. [Google Scholar] [CrossRef]

- Krawczyk, J.; Pacyna, J.; Dąbrowski, R. Rola grafitu w tribologii wysokotemperaturowej stopów na osnowie żelaza na przykładzie mechanizmów zużywania się walców hutniczych. Inżynieria Mater. 2006, 27, 174–177. [Google Scholar]

- Michalski, J.; Maszałek, J.; Kubiak, K. An experimental study of diesel engine cam and follower wear with particular referenced to the properties of the materials. Wear 2000, 240, 168–170. [Google Scholar] [CrossRef]

- Neville, A.; Morina, A.; Haque, T.; Voong, M. Compatibility between tribological surfaces and lubricant additives—How friction and wear reduction can be controlled by surface/lube synergies. Tribol. Int. 2007, 40, 1680–1695. [Google Scholar] [CrossRef]

- Guifang, S.; Rui, Z.; Peng, L.; Aixin, F.; Yongkang, Z. Laser surface alloying of C-B-W-Cr powders on nodular cast iron Rolls. Surf. Coat. Technol. 2011, 205, 2747–2754. [Google Scholar]

- Tabor, A. (Ed.) Diagnostyka Pojazdów Samochodowych—Budowa, Eksploatacja, Naprawa—Tom III—Motoryzacyjne Materiały Eksploatacyjne, Tachografy, Badania Techniczne Pojazdów, Odlewy i Wyroby z Proszków Metali w Motoryzacji, Recykling Zużytych Pojazdów, Korozja, Medycyna Pracy; Centrum Szkolenia i Organizacji Systemów Jakości Politechniki Krakowskiej im. Tadeusza Kościuszki: Ośrodek Kształcenia Kadr Kierowców “Auto-Transbud”: Kraków, Poland, 2004. [Google Scholar]

- Karamimoghadam, M.; Rezayat, M.; Moradi, M.; Mateo, A.; Casalino, G. Laser Surface Transformation Hardening for Automotive Metals: Recent Progress. Metals 2024, 14, 339. [Google Scholar] [CrossRef]

- Płaza, S.; Margielewski, L.; Celichowski, G. Wstęp do Tribologii i Tribochemia; Wydawnictwo Uniwersytetu Łódzkiego: Łódź, Poland, 2005. [Google Scholar]

- Burakowski, T.; Wierzchoń, T. Inżynieria Powierzchni Metali; WNT: Warszawa, Poland, 1995. [Google Scholar]

- Chi, Y.; Gu, G.; Yu, H.; Chen, C. Laser surface alloying on aluminum and its alloys: A review. Opt. Lasers Eng. 2018, 100, 23–37. [Google Scholar] [CrossRef]

- Jażdżewska, M.; Bartmański, M.; Zieliński, A.; Kwidzińska, D.B. Effect of Laser Treatment on Intrinsic Mechanical Stresses in Titanium and Some of Its Alloys. Appl. Sci. 2023, 13, 6276. [Google Scholar] [CrossRef]

- Domagała-Dubiel, J.; Bilewska, K.; Pawlyta, M.; Kulasa, J.; Janicki, D. Investigation of the Implementation of Laser Surface Alloying of Cu with Cr–WC. Materials 2022, 15, 5396. [Google Scholar] [CrossRef] [PubMed]

- Rajčić, B.; Petronić, S.; Čolić, K.; Stević, Z.; Petrović, A.; Mišković, Ž.; Milovanović, D. Laser Processing of Ni-Based Superalloy Surfaces Susceptible to Stress Concentration. Metals 2021, 11, 750. [Google Scholar] [CrossRef]

- Moskal, G.; Grabowski, A.; Lisiecki, A. Laser Remelting of Silicide Coatings on Mo and TZM Alloy. In Solid State Phenomena; Trans Tech Publications, Ltd.: Wollerau, Switzerland, 2015; Volume 226, pp. 121–126. [Google Scholar]

- Steen, W.M. Laser Material Processing; Springer: London, UK, 2003. [Google Scholar]

- Metzbower, E.A. Applications of Lasers in Materials Processing; American Society for Metals: Materials Park, OH, USA, 1979. [Google Scholar]

- Majumdar, J.D.; Manna, I. Laser Surface Engineering. In Handbook of Manufacturing Engineering and Technology; Springer: London, UK, 2014; pp. 2639–2676. [Google Scholar]

- Catalán, N.; Ramos-Moore, E.; Boccardo, A.; Celentano, D. Surface Laser Treatment of Cast Irons: A Review. Metals 2022, 12, 562. [Google Scholar] [CrossRef]

- Salam, Y.A.; Riyadh, A.O.; Saad, R.A.; Al-Douri, A.Y. The effect of hardening techniques on wear resistance and fatigue life of ductile cast iron. J. Teknol. 2024, 86, 115–121. [Google Scholar]

- Gu, J.; Luo, C.; Zhang, P.; Ma, P.; Ren, X. Laser cavitation peening of gray cast iron: Effect of coverage layer on the surface integrity. Appl. Surf. Sci. 2020, 521, 146295. [Google Scholar] [CrossRef]

- Wei, R.; Mao, M.; Liang, J.; Zhao, C.; Ouyang, C.; Wang, R.; Bai, Q.; Deng, R.; Li, H.; Bian, Q. Study of the effect of overlap rate on the failure form, microstructure and wear resistance of multilayer laser cladding on grey cast iron surfaces. Tribol. Int. 2024, 194, 109568. [Google Scholar] [CrossRef]

- Hamatschek, C.; Augsburg, K.; Schobel, D.; Gramstat, S.; Stich, A.; Gulden, F.; Hesse, D. Comparative Study on the Friction Behaviour and the Particle Formation Process between a Laser Cladded Brake Disc and a Conventional Grey Cast Iron Disc. Metals 2023, 13, 300. [Google Scholar] [CrossRef]

- Theron, M.; van Rooyen, C.; Malabi, K. Investigation into laser refurbishment and transformation hardening of cast iron forming dies for the automotive industry. J. Laser Appl. 2020, 32, 022071. [Google Scholar] [CrossRef]

- Paczkowska, M. The evaluation of the influence of laser treatment parameters on the type of thermal effects in the surface layer microstructure of gray irons. Opt. Laser Technol. 2016, 76, 143–148. [Google Scholar] [CrossRef]

- Syed, A.; Shaikh, F.; Karne, S.; Khorate, S.; Wagh, S. Laser hardening process simulation for cast iron. AIP Conf. Proc. 2022, 2469, 020018. [Google Scholar]

- Karthick, K.; Duraiselvam, M. Laser Surface Modification of Vermicular Cast Iron to Resist Erosion. Lasers Manuf. Mater. Process. 2023, 10, 251–265. [Google Scholar] [CrossRef]

- Záhon, L.; Kuchař, J.; Horník, J.; Krčil, J.; Kudláček, J. Laser Surface Hardening of Austempered Ductile Iron (ADI). Coatings 2024, 14, 958. [Google Scholar] [CrossRef]

- Al-Sayed, S.R.; Elgazzar, H.; Nofal, A. A comparative study of laser fluence effect on surface modification and hardness profile of austempered ductile iron. J. Mater. Res. Technol. 2024, 31, 3189–3204. [Google Scholar] [CrossRef]

- Selech, J. Analiza ekonomiczna, Działalność Statutowa, Internal documentation of Poznan University of Technology. 2012. [Google Scholar]

- Paczkowska, M. Możliwości modyfikacji struktury i własności warstwy powierzchniowej elementów maszyn przez borowanie laserowe. Inżynieria Mater. 2008, 29, 585–590. [Google Scholar]

- Roy, A.; Manna, I. Laser surface engineering to improve wear resistance of austempered ductile iron. Mater. Sci. Eng. A 2000, 297, 85–93. [Google Scholar] [CrossRef]

- Bogdanowicz, Z.; Hoffman, J.; Kalita, W. Laser strengthening of cylinder liner of an internal combustion engine. Przegląd Mech. 1995, 7–8, 26–28. [Google Scholar]

- Chen, Z.; Yu, X.; Ding, N.; Cong, J.; Sun, J.; Jia, Q.; Wang, C. Wear resistance enhancement of QT700-2 ductile iron crankshaft processed by laser hardening. Opt. Laser Technol. 2023, 164, 109519. [Google Scholar] [CrossRef]

- Ahuir-Torres, J.I.; Sharp, M.; Bakradze, N.; Batako, A.D.L. Microstructural Design of the Cast Iron via Laser Hardening with Defocused Beam of the Continuous Wave CO2 Laser. J. Phys. Conf. Ser. 2022, 2198, 012048. [Google Scholar] [CrossRef]

- Horník, J.; Krčil, J.; Mára, V.; Mores, A. Laser Surface Hardening of Graphite Cast Iron. Solid State Phenom. 2022, 334, 94–99. [Google Scholar] [CrossRef]

- Song, J.; Zheng, B.; Tang, Y.; Li, Z.; Lei, J. Surface Residual Stress and Friction Wear Behavior of Vermicular Graphite Cast Iron after Laser Remelting. J. Mater. Eng. Perform. 2024, 33, 1–13. [Google Scholar] [CrossRef]

- Grum, J.; Šturm, R. Comparison of measured and calculated thickness of martensite and ledeburite shells around graphite nodules in the hardened layer of nodular iron after laser surface remelting. Appl. Surf. Sci. 2002, 187, 116–123. [Google Scholar] [CrossRef]

- Otsubo, F.; Fukumatsu, K. Microstructure and Mechanical Properties of YAG Laser Welded Spheroidal Graphite Cast Iron. Mater. Trans. 2024, 65, 665–671. [Google Scholar] [CrossRef]

- Wróbel, T.; Studnicki, A.; Stawarz, M.; Baron, C.; Jezierski, J.; Bartocha, D.; Dojka, R.; Opiela, J.; Lisiecki, A. Improving the Abrasion Resistance of Nodular Cast Iron Castings by Remelting Their Surfaces by Laser Beam. Materials 2024, 17, 2095. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Pan, Y.; Liu, Y.; Lyu, N.; Barber, G.C.; Wang, R.; Cui, W.; Qiu, F.; Hu, M. Effects of quench-tempering and laser hardening treatment on wear resistance of gray cast iron. J. Mater. Res. Technol. 2020, 9, 8163–8171. [Google Scholar] [CrossRef]

- Chen, C.; Feng, A.; Liu, B.; Wei, Y.; Song, X. Effect of quench-tempering and laser quenching on the microstructure and properties of high-chromium cast iron. J. Mater. Res. Technol. 2022, 19, 2759–2773. [Google Scholar] [CrossRef]

- Klimpel, A.; Kobic, J.; Janicki, D.; Burdek, M.; Marczak, Z. Przetapianie laserowe warstwy wierzchniej walców z żeliwa sferoidalnego stopowego. Inżynieria Mater. 2003, 2, 88–94. [Google Scholar]

- Zhi-kai, C.; Ti, Z.; Ruo-yu, Z.; Hai-feng, Z.; Shu-chao, L.; Wan-shi, Y.; Hong, Z. Improved fatigue wear resistance of gray cast iron by localized laser carburizing. Mater. Sci. Eng. 2015, A644, 1–9. [Google Scholar]

- Yaresko, S. Tribological characteristics of the multicomponent iron-based alloys surface after laser modification. In Proceedings of the XVI International Conference on Pulsed Lasers and Laser Applications, Tomsk, Russian Federation, 10–15 September 2023; Volume 12920, pp. 1–5. [Google Scholar]

- Hong, Z.; Peng, Z.; Zhihui, Z.; Wenjun, Q.; Yan, L.; Luquan, R. Thermal Cycling Effect on the Wear Resistance of Bionic Laser Processed Gray Iron. J. Bionic Eng. 2014, 11, 288–295. [Google Scholar]

- Alabeedi, K.; Abboud, J.; Benyounis, K. Microstructure and erosion resistance enhancement of nodular cast iron by laser melting. Wear 2009, 266, 925–933. [Google Scholar] [CrossRef]

- Sai, Q.; Hao, J.; Wang, S.; Wang, Z. Improving the Properties of Gray Cast Iron by Laser Surface Modification. Materials 2023, 16, 5533. [Google Scholar] [CrossRef]

- Feldshtein, E.; Devojno, O.; Patalas-Maliszewska, J.; Kardapolava, M.; Kasiakova, I. Effect of Processing Parameters on the Formation of Alloyed Surface Layer and Its Properties on the Efficiency of Laser Alloying of Grey Cast Iron with Tungsten and Silicon Carbides. Materials 2023, 16, 6230. [Google Scholar] [CrossRef]

- Feldshtein, E.; Devojno, O.; Wojciechowski, S.; Kardapolava, M.; Kasiakova, I. On the Microstructure, Microhardness and Wear Behavior of Gray Cast Iron Surface Layer After Laser Strengthening. Materials 2022, 15, 1075. [Google Scholar] [CrossRef] [PubMed]

- Janicki, D. Effect of Chromium and Molybdenum Addition on the Microstructure of in Situ TiC-Reinforced Composite Surface Layers Fabricated on Ductile Cast Iron by Laser Alloying. Materials 2020, 13, 5750. [Google Scholar] [CrossRef] [PubMed]

- Janicki, D.; Czupryński, A.; Górka, J.; Matus, K. Effect of Cooling Rate on Microstructure of in Situ TiC-Reinforced Composite Surface Layers Synthesized on Ductile Cast Iron by Laser Alloying. Materials 2024, 17, 932. [Google Scholar] [CrossRef]

- Kotarska, A. The Laser Alloying Process of Ductile Cast Iron Surface with Titanium. Metals 2021, 11, 282. [Google Scholar] [CrossRef]

- Lont, A.; Górka, J.; Janicki, D.; Matus, K. The Laser Alloying Process of Ductile Cast Iron Surface with Titanium Powder in Nitrogen Atmosphere. Coatings 2022, 12, 227. [Google Scholar] [CrossRef]

- Xin, T.; Hong, Z.; Zhi-hui, Z.; Lu-quan, R. Thermal fatigue behavior of gray cast iron with striated biomimetic non-smooth surface. J. Mater. Process. Technol. 2008, 206, 473–480. [Google Scholar]

- Paczkowska, M. Analiza wpływu stopowania laserowego na mikrostrukturę warstwy wierzchniej żeliw szarych. Inżynieria Mater. 2015, 36, 138–142. [Google Scholar] [CrossRef]

- Riahi, M. Surface treatment of cast iron by adding different alloying elements to form a metallic glass structure layer using an industrial carbon dioxide laser. J. Mech. Work. Technol. 1996, 58, 3–12. [Google Scholar] [CrossRef][Green Version]

- Wang, S.; Hao, J.; Zhou, Y.; Gu, C.; Williams, J. Properties of Laser-Alloyed Stainless Steel Coatings on the Surface of Gray Cast Iron Discs. Lubricants 2024, 12, 232. [Google Scholar] [CrossRef]

- Zhi-kai, C.; Ti, Z.; Peng, Z.; Hai-feng, Z.; Wan-shi, Y.; Hong, Z.; Lu-quan, R. Influences of single laser tracks’ space on the rolling fatigue contact of gray cast iron. Opt. LaserTechnol. 2015, 72, 15–24. [Google Scholar]

- Minlin, Z.; Wenjin, L.; Hongjun, Z. Corrosion and wear resistance characteristics of NiCr coating by laser alloying with powder feeding on grey iron liner. Wear 2006, 260, 1349–1355. [Google Scholar]

- Zeng, D.; Xie, C.; Yung, K. Investigation of laser surface alloying of copper on high nickel austenitic ductile iron. Mater. Sci. Eng. A 2002, 333, 223–231. [Google Scholar] [CrossRef]

- Zhang, T.; Li, D. Effect of alloying yttrium on corrosion–erosion behavior of 27Cr cast white iron in different corrosive slurries. Mater. Sci. Eng. A 2002, 325, 87–97. [Google Scholar] [CrossRef]

- Ahmadkhaniha, D.; Zanella, C.; Belov, I.; Matsushita, T. Study of the process parameters influence on crack formation in laser alloying of grey cast iron. Opt. Laser Technol. 2024, 179, 111373. [Google Scholar] [CrossRef]

- Masafi, M.; Palkowski, H.; Mozaffari-Jovein, H. Microstructural properties of particle-reinforced multilayer systems of 316L and 430L alloys on Gray Cast Iron. Coatings 2023, 13, 1450. [Google Scholar] [CrossRef]

- Hao, X.; Liu, H.; Zhang, X.; Wang, Y.; Yang, C.; Liu, Y. Microstructure and Wear Resistance of a Ni–Fe–Si–B Amorphous Composite Coating by Laser Cladding. Met. Mater. Int. 2024, 30, 1–12. [Google Scholar] [CrossRef]

- Paczkowska, M. Influence of silicon and cobalt laser alloying on the microstructure and nanomechanical properties of the gray cast iron surface layer. J. Res. Appl. Agric. Eng. 2022, 67, 13–20. [Google Scholar] [CrossRef]

- Zhu, C.; Fordyce, I.; Sun, S.D.; Annasamy, M.; Fabijanic, D.; Short, K.; Paradowska, A.; Leary, M.; Brandt, M.; Easton, M. Effect of boron addition on the microstructure and wear resistance of laser beam directed energy deposited high chromium white irons. Wear 2024, 546–547, 205320. [Google Scholar] [CrossRef]

- Paczkowska, M.; Makuch, N.; Kulka, M. The influence of various cooling rates during laser alloying on nodular iron surface layer. Opt. Laser Technol. 2018, 102, 60–67. [Google Scholar] [CrossRef]

| The Surface Layer Factor | State of the Surface Layer | |||

|---|---|---|---|---|

| Untreated | Laser-Hardened | Laser-Remelted | Laser-Alloyed | |

| Grain size | Coarse-grained | Less coarse-grained | Fine, ultrafine | Fine, ultrafine, amorphous |

| Homogeneity | Poor | Poor | High | High |

| Compounds of metal matrix | Typically ferrite and pearlite | Martensite, ferrite | Martensite, austenite | Martensite, austenite, new formed phases containing alloyed element |

| Graphite presence | Present | Present (almost in the same amount) | Present but in a smaller amount in the case of nodular cast iron and visible especially in the vicinity of the surface; in the case of flake cast iron, usually all carbon from the graphite phase is diluted in the metal matrix during the treatment | |

| Hardness of the metal matrix | ~200 H0.1 | ~600 HV0.1 | >1000 H0.1 | 1200–1800 HV0.1 |

| Wear resistance | - | Increased | More increased | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paczkowska, M. Modification of the Surface Layer of Grey Cast Iron by Laser Heat Treatment. Lubricants 2024, 12, 457. https://doi.org/10.3390/lubricants12120457

Paczkowska M. Modification of the Surface Layer of Grey Cast Iron by Laser Heat Treatment. Lubricants. 2024; 12(12):457. https://doi.org/10.3390/lubricants12120457

Chicago/Turabian StylePaczkowska, Marta. 2024. "Modification of the Surface Layer of Grey Cast Iron by Laser Heat Treatment" Lubricants 12, no. 12: 457. https://doi.org/10.3390/lubricants12120457

APA StylePaczkowska, M. (2024). Modification of the Surface Layer of Grey Cast Iron by Laser Heat Treatment. Lubricants, 12(12), 457. https://doi.org/10.3390/lubricants12120457