Progress in Aluminum-Based Composites Prepared by Stir Casting: Mechanical and Tribological Properties for Automotive, Aerospace, and Military Applications

Abstract

:1. Introduction

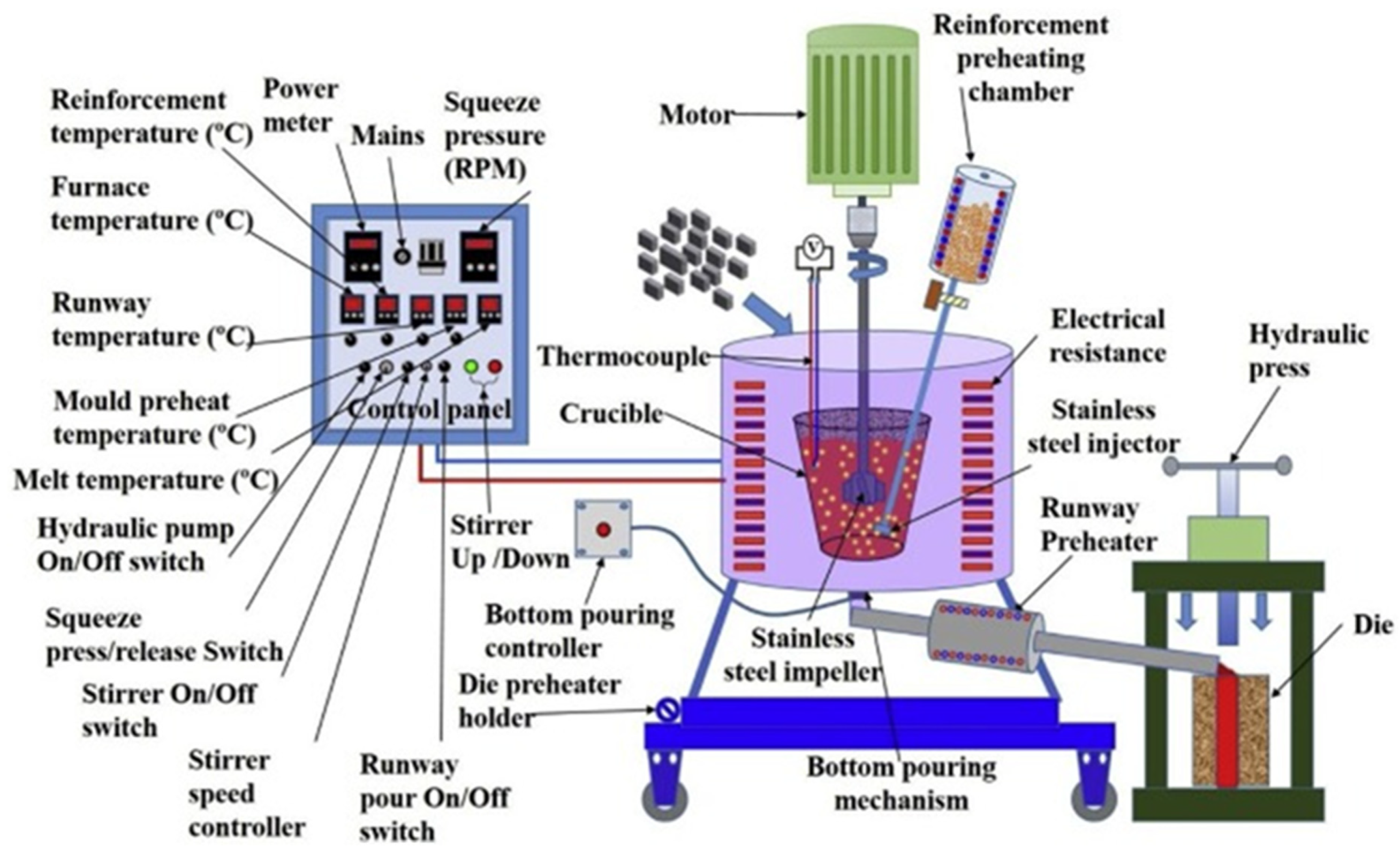

2. Processing Approach: Stir Casting

2.1. Reinforcement Size

2.2. Stirring Speed and Stirring Time

2.3. Melt Temperature

2.4. Stirrer Blade Design

3. Reinforcement Materials in AMMCs: Properties, Processing, and Performance Trends

3.1. AMMCs Reinforcement with Silicon Carbide (SiC)

3.2. AMMCs Reinforcement with Alumina Oxide (Al2O3)

3.3. AMMCs Reinforcement with B4C

3.4. AMMCs Reinforcement with Fiber

3.5. AMMCs Reinforcement with Zirconia

3.6. AMMCs Reinforcement with Fly Ash (FA)

3.7. AMMCs with Other Reinforcement

3.8. AMMCs with Hybrid Reinforcement

4. Strengthening Mechanism

4.1. Mechanism of Load Transfer

4.2. Orowan Strengthening Mechanism

4.3. Dislocation Strengthening Mechanism

4.4. Grain-Refined Strengthening

5. Challenges in Fabricating AMMCs

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sharma, A.K.; Bhandari, R.; Aherwar, A.; Rimašauskienė, R. Matrix materials used in composites: A comprehensive study. Mater. Today Proc. 2020, 21, 1559–1562. [Google Scholar] [CrossRef]

- Gül, H.; Kılıç, F.; Uysal, M.; Aslan, S.; Alp, A.; Akbulut, H. Effect of particle concentration on the structure and tribological properties of submicron particle SiC reinforced Ni metal matrix composite (MMC) coatings produced by electrodeposition. Appl. Surf. Sci. 2012, 258, 4260–4267. [Google Scholar] [CrossRef]

- Sharma, S.K.; Saxena, K.K.; Salem, K.H.; Mohammed, K.A.; Singh, R.; Prakash, C. Effects of various fabrication techniques on the mechanical characteristics of metal matrix composites: A review. Adv. Mater. Process. Technol. 2024, 10, 277–294. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Umer, R.; Khan, K.A. Review of recent trends and developments in aluminium 7075 alloys and metal matrix composites (MMCs) for aircraft applications. Results Eng. 2023, 20, 101372. [Google Scholar] [CrossRef]

- Dieringa, H.; Kainer, K.U. Particles, fibers and short fibers for the reinforcement of metal materials. In Metal Matrix Composites: Custom-Made Materials for Automotive and Aerospace Engineering; Wiley Online Library: Hoboken, NJ, USA, 2006; pp. 55–76. [Google Scholar]

- Ozkan, D.; Gok, M.S.; Karaoglanli, A.C. Carbon fiber reinforced polymer (CFRP) composite materials, their characteristic properties, industrial application areas and their machinability. In Engineering Design Applications III: Structures, Materials and Processes; Springer Nature: Berlin, Germany, 2020; pp. 235–253. [Google Scholar]

- Lloyd, D.J. Particle reinforced aluminium and magnesium matrix composites. Int. Mater. Rev. 1994, 39, 1–23. [Google Scholar] [CrossRef]

- Veličković, S.; Stojanović, B.; Babić, M.; Vencl, A.; Bobić, I.; VadaszneBognar, G.; Vučetić, F. Parametric optimization of the aluminium nanocomposites wear rate. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 19. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, P. A review on the mechanical properties, tribological behavior and the microstructural characterization of Aluminium metal matrix composites (AMMCs). Int. J. Sci. Eng. Res. 2015, 6, 1234–1245. [Google Scholar]

- Verma, A.; Chauhan, S.S.; Dwivedi, S.P. Review paper on thermal expansion and tribological behavior of composite materials. Mater. Today Proc. 2023, 79, 235–246. [Google Scholar] [CrossRef]

- Sharma, S.K.; Saxena, K.K.; Malik, V.; Mohammed, K.A.; Prakash, C.; Buddhi, D.; Dixit, S. Significance of alloying elements on the mechanical characteristics of Mg-based materials for biomedical applications. Crystals 2022, 12, 1138. [Google Scholar] [CrossRef]

- Sinclair, I.; Gregson, P.J. Structural performance of discontinuous metal matrix composites. Mater. Sci. Technol. 1997, 13, 709–726. [Google Scholar] [CrossRef]

- Veličković, S.; Stojanović, B.; Babić, M.; Bobić, I. Optimization of tribological properties of aluminum hybrid composites using Taguchi design. J. Compos. Mater. 2017, 51, 2505–2515. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-reinforced polymer composites: Manufacturing, properties, and applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef] [PubMed]

- Brabazon, D.J.B.D.; Browne, D.J.; Carr, A.J. Mechanical stir casting of aluminium alloys from the mushy state: Process, microstructure and mechanical properties. Mater. Sci. Eng. A 2002, 326, 370–381. [Google Scholar] [CrossRef]

- Sharma, S.K.; Gajević, S.; Sharma, L.K.; Pradhan, R.; Miladinović, S.; Ašonja, A.; Stojanović, B. Magnesium-Titanium Alloys: A Promising Solution for Biodegradable Biomedical Implants. Materials 2024, 17, 5157. [Google Scholar] [CrossRef] [PubMed]

- Rajan, T.P.D.; Pillai, R.M.; Pai, B.C. Reinforcement coatings and interfaces in aluminium metal matrix composites. J. Mater. Sci. 1998, 33, 3491–3503. [Google Scholar] [CrossRef]

- Singla, M.; Dwivedi, D.D.; Singh, L.; Chawla, V. Development of aluminium based silicon carbide particulate metal matrix composite. J. Miner. Mater. Charact. Eng. 2009, 8, 455. [Google Scholar] [CrossRef]

- Sharma, S.K.; Saxena, K.K.; Kumar, N. Effect of SiC on mechanical properties of Al-based metal matrix composites produced by stir casting. Met. Sci. Heat Treat. 2022, 64, 316–320. [Google Scholar] [CrossRef]

- Hillary, J.J.M.; Ramamoorthi, R.; Joseph, J.D.J.; Samuel, C.S.J. A study on microstructural effect and mechanical behaviour of Al6061–5% SiC–TiB2 particulates reinforced hybrid metal matrix composites. J. Compos. Mater. 2020, 54, 2327–2337. [Google Scholar] [CrossRef]

- Flanagan, S.; Main, J.; Lynch, P.; Vanderwiel, C.; Roth, J.T. A mechanical evaluation of an overaged aluminum metal-matrix-composite (2009 Al/SiC/15p MMC). Procedia Manuf. 2019, 34, 58–64. [Google Scholar] [CrossRef]

- Prabha, N.R.; Dhas, D.E.R.; Visakh, S. Investigation on Optimization of Wear Properties on Aluminium Hybrid Metal Matrix using Taguchi Method. Int. J. Innov. Eng. Technol. 2016, 6, 393–400. [Google Scholar]

- Pal, B.R.; Ghosh, S.; Sahoo, P. Aluminium hybrid composites reinforced with SiC and fly ash particles—Recent developments. In Recent Advances in Layered Materials and Structures; Springer Nature: Berlin, Germany, 2021; pp. 133–170. [Google Scholar]

- Keya, K.N.; Kona, N.A.; Koly, F.A.; Maraz, K.M.; Islam, M.N.; Khan, R.A. Natural fiber reinforced polymer composites: History, types, advantages and applications. Mater. Eng. Res. 2019, 1, 69–85. [Google Scholar] [CrossRef]

- Kumar, A.; Singh, V.P.; Singh, R.C.; Chaudhary, R.; Kumar, D.; Mourad, A.H.I. A review of aluminum metal matrix composites: Fabrication route, reinforcements, microstructural, mechanical, and corrosion properties. J. Mater. Sci. 2024, 59, 2644–2711. [Google Scholar] [CrossRef]

- ChinnamahammadBhasha, A.; Balamurugan, K. Studies on Al6061nanohybrid Composites Reinforced with SiO2/3x% of TiC-a Agro-Waste. Silicon 2022, 14, 13–26. [Google Scholar] [CrossRef]

- Zeinedini, A.; Shokrieh, M.M. Agglomeration phenomenon in graphene/polymer nanocomposites: Reasons, roles, and remedies. Appl. Phys. Rev. 2024, 11, 041301. [Google Scholar]

- Sharma, S.K.; Saxena, K.K. A brief overview of HA on the mechanical behavior of MMCs. AIP Conf. Proc. 2023, 2721, 070005. [Google Scholar]

- Kumar, S.S.; KarthiKeyan, G.; Selvam, K. Optimization Of Squeeze Casting process parameters on AA8011 based HmmCS under naCl envirOnment. Arch. Metall. Mater. 2024, 69, 1047–1060. [Google Scholar] [CrossRef]

- Khan, F.; Khan, O.; Parvez, M.; Ahmad, S.; Yahya, Z.; Alhodaib, A.; Yadav, A.K.; Ağbulut, Ü. K-means clustering optimization of various quantum dots and nanoparticles-added biofuels for engine performance, emission, vibration, and noise characteristics. Therm. Sci. Eng. Prog. 2024, 54, 102815. [Google Scholar] [CrossRef]

- Medya, S.; Yeo, S.H. Enhancement of acoustic cavitation streaming: A study on surface finishing of additively manufactured components. CIRP J. Manuf. Sci. Technol. 2024, 53, 1–16. [Google Scholar] [CrossRef]

- Cao, C.; Killips, A.; Li, X. Advances in the science and engineering of metal matrix nanocomposites: A review. Adv. Eng. Mater. 2024, 26, 2400217. [Google Scholar] [CrossRef]

- Bednarczyk, W.; Wątroba, M.; Cieślak, G.; Ciemiorek, M.; Hamułka, K.; Schreiner, C.; Figi, R.; Marciszko-Wiąckowska, M.; Cios, G.; Schwiedrzik, J.; et al. Enhanced mechanical properties and microstructural stability of ultrafine-grained biodegradable Zn–Li–Mn–Mg–Cu alloys produced by rapid solidification and high-pressure torsion. Mater. Sci. Eng. A 2024, 892, 146027. [Google Scholar] [CrossRef]

- Huda, M.D.; Hashmi, M.S.J.; El-Baradie, M.A. MMCs: Materials, manufacturing and mechanical properties. Key Eng. Mater. 1995, 104, 37–64. [Google Scholar] [CrossRef]

- LabusZlatanovic, D.; Pierre Bergmann, J.; Balos, S.; Hildebrand, J.; Bojanic-Sejat, M.; Goel, S. Effect of surface oxide layers in solid-state welding of aluminium alloys–review. Sci. Technol. Weld. Join. 2023, 28, 331–351. [Google Scholar] [CrossRef]

- Mussatto, A.; Ahad, I.U.; Mousavian, R.T.; Delaure, Y.; Brabazon, D. Advanced production routes for metal matrix composites. Eng. Rep. 2021, 3, e12330. [Google Scholar] [CrossRef]

- Meriga, V.S.; Boyina, A.D.; Vandana, C. Design and fabrication of low-cost electrical resistance-based metal melting furnace for casting applications. Leonado Electr. J. Pract. Technol. 2018, 32, 41–54. [Google Scholar]

- Sidhu, S.S.; Kumar, S.; Batish, A. Metal matrix composites for thermal management: A review. Crit. Rev. Solid State Mater. Sci. 2016, 41, 132–157. [Google Scholar] [CrossRef]

- Schönstedt, B.; Jacob, H.J.; Schilde, C.; Kwade, A. Scale-up of the power draw of inline-rotor–stator mixers with high throughput. Chem. Eng. Res. Des. 2015, 93, 12–20. [Google Scholar] [CrossRef]

- Mehta, V.R.; Sutaria, M.P. Investigation on the effect of stirring process parameters on the dispersion of SiC particles inside melting crucible. Met. Mater. Int. 2021, 27, 2989–3002. [Google Scholar] [CrossRef]

- Kannan, V.S.; Lenin, K.; Srinivasan, D.; Raj Kumar, D. Analysis of microstructural, mechanical and surface properties of aluminium hybrid composites obtained through stir casting. J. Inst. Eng. Ser. D 2024, 105, 733–744. [Google Scholar] [CrossRef]

- Yadav, S.; Gangwar, S.; Singh, S. Micro/nano reinforced filled metal alloy composites: A review over current development in aerospace and automobile applications. Mater. Today Proc. 2017, 4, 5571–5582. [Google Scholar] [CrossRef]

- Prasara-A, J.; Gheewala, S.H. Sustainable utilization of rice husk ash from power plants: A review. J. Clean. Prod. 2017, 167, 1020–1028. [Google Scholar] [CrossRef]

- Youssef, Y.; El-Sayed, M. Effect of reinforcement particle size and weight fraction on the mechanical properties of SiC particle reinforced Al metal matrix composites. Int. Rev. Mech. Eng. 2016, 10, 261–265. [Google Scholar] [CrossRef]

- Poddar, P.; Srivastava, V.C.; De, P.K.; Sahoo, K.L. Processing and mechanical properties of SiC reinforced cast magnesium matrix composites by stir casting process. Mater. Sci. Eng. A 2007, 460, 357–364. [Google Scholar] [CrossRef]

- Badkoobeh, F.; Mostaan, H.; Rafiei, M.; Bakhsheshi-Rad, H.R.; Berto, F. Friction stir welding/processing of Mg-based alloys: A critical review on advancements and challenges. Materials 2021, 14, 6726. [Google Scholar] [CrossRef] [PubMed]

- Shabani, M.O.; Mazahery, A. Suppression of segregation, settling and agglomeration in mechanically processed composites fabricated by a semisolid agitation processes. Trans. Indian Inst. Met. 2013, 66, 65–70. [Google Scholar] [CrossRef]

- Huang, L.J.; Geng, L.; Peng, H.X. Microstructurally inhomogeneous composites: Is a homogeneous reinforcement distribution optimal? Prog. Mater. Sci. 2015, 71, 93–168. [Google Scholar] [CrossRef]

- Moses, J.J.; Dinaharan, I.; Sekhar, S.J. Prediction of influence of process parameters on tensile strength of AA6061/TiC aluminum matrix composites produced using stir casting. Trans. Nonferrous Met. Soc. China 2016, 26, 1498–1511. [Google Scholar] [CrossRef]

- Hashim, J.; Looney, L.; Hashmi, M.S.J. Metal matrix composites: Production by the stir casting method. J. Mater. Process. Technol. 1999, 92, 1–7. [Google Scholar] [CrossRef]

- Vargas, S.; Frandsen, F.J.; Dam-Johansen, K. Rheological properties of high-temperature melts of coal ashes and other silicates. Prog. Energy Combust. Sci. 2001, 27, 237–429. [Google Scholar] [CrossRef]

- Ahmed, H.H.; Ahmed, A.R.; Darweesh, S.Y.; Khodair, Z.T.; Al-Jubbori, M.A. Processing of turbine blades using cermet composite materials. J. Fail. Anal. Prev. 2020, 20, 2111–2118. [Google Scholar] [CrossRef]

- Abdizadeh, H.; Ebrahimifard, R.; Baghchesara, M.A. Investigation of microstructure and mechanical properties of nano MgO reinforced Al composites manufactured by stir casting and powder metallurgy methods: A comparative study. Compos. Part B Eng. 2014, 56, 217–221. [Google Scholar] [CrossRef]

- Ramanathan, A.; Krishnan, P.K.; Muraliraja, R. A review on the production of metal matrix composites through stir casting–Furnace design, properties, challenges, and research opportunities. J. Manuf. Process. 2019, 42, 213–245. [Google Scholar] [CrossRef]

- He, F.; Han, Q.; Jackson, M.J. Nanoparticulate reinforced metal matrix nanocomposites—A review. Int. J. Nanopart. 2008, 1, 301–309. [Google Scholar] [CrossRef]

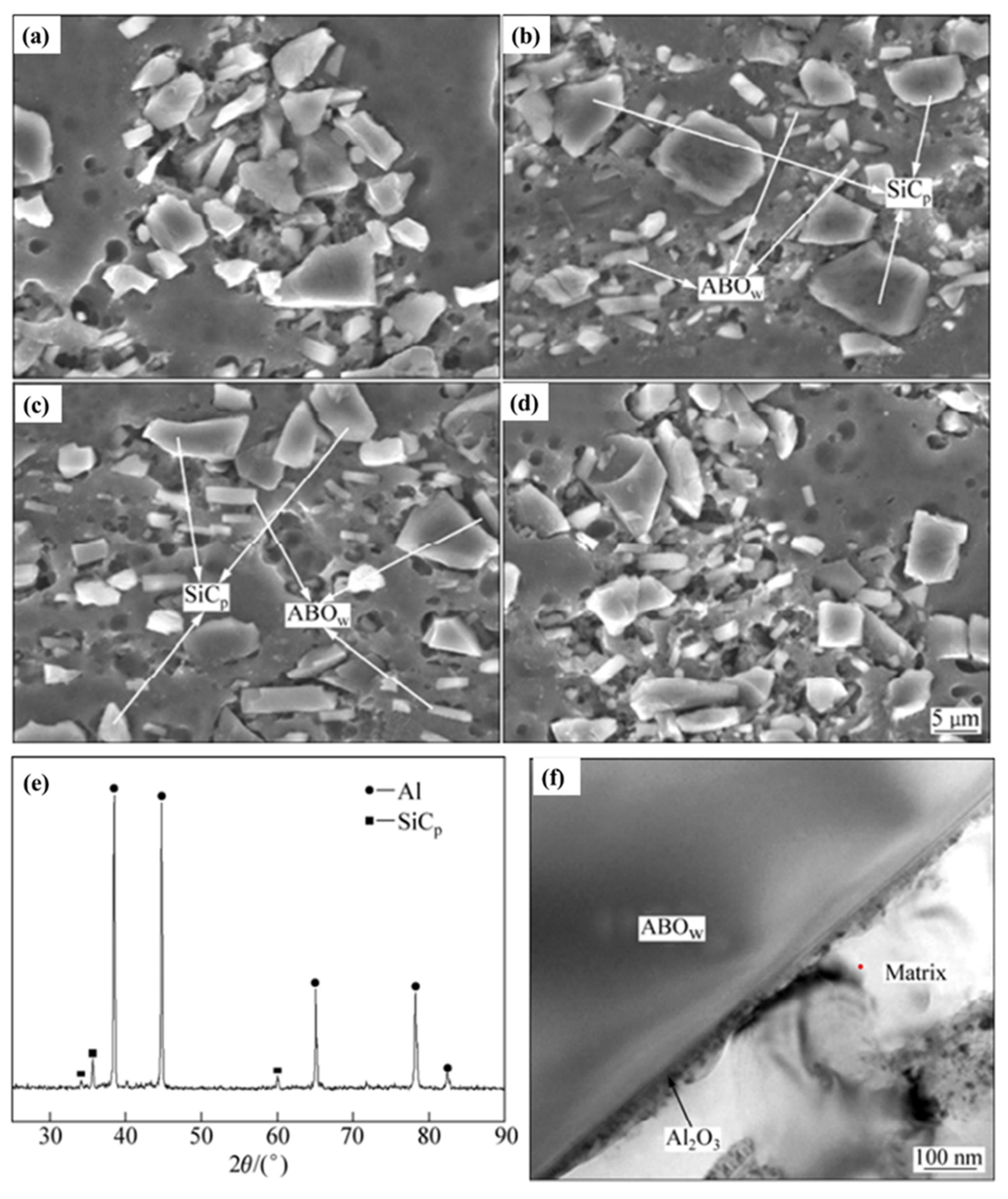

- Guan, L.N.; Lin, G.; Zhang, H.W.; Huang, L.J. Effects of stirring parameters on microstructure and tensile properties of (ABOw + SiCp)/6061Al composites fabricated by semi-solid stirring technique. Trans. Nonferrous Met. Soc. China 2011, 21, s274–s279. [Google Scholar] [CrossRef]

- McLelland, A.R.A.; Henderson, N.G.; Atkinson, H.V.; Kirkwood, D.H. Anomalous rheological behaviour of semi-solid alloy slurries at low shear rates. Mater. Sci. Eng. A 1997, 232, 110–118. [Google Scholar] [CrossRef]

- Gajević, S.; Miladinović, S.; Stojanović, B. Metallic nanocomposites: An introduction. In Nanotechnology in the Automotive Industry; Elsevier: Amsterdam, The Netherlands, 2022; pp. 155–161. [Google Scholar]

- Singh, J.; Chauhan, A. Fabrication characteristics and tensile strength of novel Al2024/SiC/red mud composites processed via stir casting route. Trans. Nonferrous Met. Soc. China 2017, 27, 2573–2586. [Google Scholar] [CrossRef]

- Kumar, G.S.P.; Koppad, P.G.; Keshavamurthy, R.; Alipour, M. Microstructure and mechanical behaviour of in situ fabricated AA6061-TiC metal matrix composites. Arch. Civ. Mech. Eng. 2017, 17, 535–544. [Google Scholar] [CrossRef]

- Bhandare, R.G.; Sonawane, P.M. Preparation of aluminium matrix composite by using stir casting method. Int. J. Eng. Adv. Technol. (IJEAT) 2013, 3, 61–65. [Google Scholar]

- Fei, N.C.; Mehat, N.M.; Kamaruddin, S. Practical applications of Taguchi method for optimization of processing parameters for plastic injection moulding: A retrospective review. Int. Sch. Res. Not. 2013, 2013, 462174. [Google Scholar] [CrossRef]

- Sahu, M.K.; Sahu, R.K. Aluminum based hybrid metal matrix composites: A review of selection philosophy and mechanical properties for advanced applications. Int. J. Mech. Prod. Eng. Res. Dev. 2020, 10, 8–28. [Google Scholar]

- Lamaka, S.V.; Shchukin, D.G.; Andreeva, D.V.; Zheludkevich, M.L.; Moehwald, H.; Ferreira, M.G. Sol-gel/polyelectrolyte active corrosion protection system. Adv. Funct. Mater. 2008, 18, 3137–3147. [Google Scholar] [CrossRef]

- Hatti, G.; Naveen, G.J.; Koti, V.; Uppin, V.S.; Lingaraju, S.V.; Janamatti, S.; Hokrani, V.V.; Pujar, S.N. Green metal matrix composites: A multi-faceted study on Al alloy composites with egg shell powder and silicon carbide as reinforcements. Metall. Res. Technol. 2024, 121, 610. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, W.; Du, H.; Ding, X.; Li, L.; Chen, H.; Gao, F.; Cui, B.; Gao, J.; Cui, H.; et al. Enhancing safety through the biodegradable pesticide microcapsules produced via melt emulsification and interfacial polymerization. Chem. Eng. J. 2024, 483, 149407. [Google Scholar] [CrossRef]

- Thirugnanasambandam, A.; Gupta, M.; Murugapandian, R. Biocompatibility and Corrosion Resistance of Si/ZrO2 Bioceramic Coating on AZ91D Using Electron Beam Physical Vapor Deposition (EB-PVD) for Advanced Biomedical Applications. Metals 2024, 14, 607. [Google Scholar] [CrossRef]

- Alnaser, I.A. Tailoring the mechanical strength and corrosion resistance of aluminum matrix composites through biochar reinforcement at varied weight percentages. Sci. Rep. 2024, 14, 19875. [Google Scholar] [CrossRef] [PubMed]

- Ravikumar, M.; Gowda, H.; Umesh, G.L.; Raghavendra, S.; Darshan, S.M.; Shivakumar, M.M.; Somashekar, S. An Experimental Investigation on Effect of B4C/CeO2 Reinforcements on Mechanical, Fracture Surface and Wear Characteristics in Al7075 Hybrid Metal Matrix Composites. Int. J. Integr. Eng. 2024, 16, 100–113. [Google Scholar]

- Sarmah, P.; Gupta, K. Recent Advancements in Fabrication of Metal Matrix Composites: A Systematic Review. Materials 2024, 17, 4635. [Google Scholar] [CrossRef]

- Wang, D.; Wu, J.; Wu, S.; Chen, X.; Li, W.; Chen, X.; Gao, C.; He, Z. Ice-Mediated Reactions and Assemblies in Diverse Domains. Adv. Funct. Mater. 2024, 34, 2315532. [Google Scholar] [CrossRef]

- Maddaiah, K.C.; Kumar, G.V.; Pramod, R. Studies on the Mechanical, Strengthening Mechanisms and Tribological Characteristics of AA7150-Al2O3 Nano-Metal Matrix Composites. J. Compos. Sci. 2024, 8, 97. [Google Scholar] [CrossRef]

- Pragathi, P.; Elansezhian, R. Mechanical and microstructure behaviour of aluminum nanocomposite fabricated by squeeze casting and ultrasonic aided squeeze casting: A comparative study. J. Alloys Compd. 2023, 956, 170203. [Google Scholar] [CrossRef]

- Kareem, A.; Qudeiri, J.A.; Abdudeen, A.; Ahammed, T.; Ziout, A. A review on AA 6061 metal matrix composites produced by stir casting. Materials 2021, 14, 175. [Google Scholar] [CrossRef]

- Mazahery, A.; Shabani, M.O. A comparative study on abrasive wear behavior of semisolid–liquid processed Al–Si matrix reinforced with coated B4C reinforcement. Trans. Indian Inst. Met. 2012, 65, 145–154. [Google Scholar] [CrossRef]

- Yan, S.J.; Dai, S.L.; Zhang, X.Y.; Yang, C.; Hong, Q.H.; Chen, J.Z.; Lin, Z.M. Investigating aluminum alloy reinforced by graphene nanoflakes. Mater. Sci. Eng. A 2014, 612, 440–444. [Google Scholar] [CrossRef]

- Yigezu, B.S.; Mahapatra, M.M.; Jha, P.K. Influence of Reinforcement Type on Microstructure, Hardness, and Tensile Properties of an Aluminum Alloy Metal Matrix Composite. J. Miner. Mater. Charact. Eng. 2013, 1, 124–130. [Google Scholar]

- Liu, J.; Chen, Z.; Zhang, F.; Ji, G.; Wang, M.; Ma, Y.; Ji, V.; Zhong, S.; Wu, Y.; Wang, H. Simultaneously increasing strength and ductility of nanoparticles reinforced Al composites via accumulative orthogonal extrusion process. Mater. Res. Lett. 2018, 6, 406–412. [Google Scholar] [CrossRef]

- Ujah, C.O.; Kallon, D.V.V. Trends in aluminium matrix composite development. Crystals 2022, 12, 1357. [Google Scholar] [CrossRef]

- Kasar, A.K.; Gupta, N.; Rohatgi, P.K.; Menezes, P.L. A brief review of fly ash as reinforcement for composites with improved mechanical and tribological properties. Jom 2020, 72, 2340–2351. [Google Scholar] [CrossRef]

- Dey, A.; Pandey, K.M. Characterization of fly ash and its reinforcement effect on metal matrix composites: A review. Rev. Adv. Mater. Sci 2016, 44, 168–181. [Google Scholar]

- Patil, N.A.; Pedapati, S.R.; Mamat, O.B.; Hidayat Syah Lubis, A.M. Effect of SiC/fly ash reinforcement on surface properties of aluminum 7075 hybrid composites. Coatings 2020, 10, 541. [Google Scholar] [CrossRef]

- Latif, R.; Wakeel, S.; Zaman Khan, N.; Noor Siddiquee, A.; Lal Verma, S.; Akhtar Khan, Z. Surface treatments of plant fibers and their effects on mechanical properties of fiber-reinforced composites: A review. J. Reinf. Plast. Compos. 2019, 38, 15–30. [Google Scholar] [CrossRef]

- Meyers, M.A.; Mishra, A.; Benson, D.J. Mechanical properties of nanocrystalline materials. Prog. Mater. Sci. 2006, 51, 427–556. [Google Scholar] [CrossRef]

- Nasreen, A.; Shaker, K.; Nawab, Y. Effect of surface treatments on metal–composite adhesive bonding for high-performance structures: An overview. Compos. Interfaces 2021, 28, 1221–1256. [Google Scholar] [CrossRef]

- Poulose, N.; Selvakumar, P.; Philip, J.T.; Ananthi, A.; Kavitha, S. Study of the Mechanical Properties of the Copper Matrix Composites (CMCs): A Review. In Materials Science Forum; Trans Tech Publications Ltd.: Wollerau, Switzerland, 2022; Volume 1075, pp. 149–171. [Google Scholar]

- Zhang, W.; Xu, J. Advanced lightweight materials for Automobiles: A review. Mater. Des. 2022, 221, 110994. [Google Scholar] [CrossRef]

- Sadeghi, B.; Cavaliere, P.D. Reviewing the integrated design approach for augmenting strength and toughness at macro-and micro-scale in high-performance advanced composites. Materials 2023, 16, 5745. [Google Scholar] [CrossRef] [PubMed]

- Kumar, K.; Dabade, B.M.; Wankhade, L.N. Influence of B4C and SiC particles on aluminium metal matrix composites: A brief overview. Mater. Today Proc. 2021, 44, 2726–2734. [Google Scholar] [CrossRef]

- Meshram, S.D.; Gupta, S.; Kulthe, M.; Kandasubramanian, B. The role of additive manufacturing in the study of carbon fiber-reinforced polymer composite. Polym. Bull. 2024, 81, 15469–15511. [Google Scholar] [CrossRef]

- Dash, K.; Sukumaran, S.; Ray, B.C. The behaviour of aluminium matrix composites under thermal stresses. Sci. Eng. Compos. Mater. 2016, 23, 1–20. [Google Scholar] [CrossRef]

- Lai, L.; Niu, B.; Bi, Y.; Li, Y.; Yang, Z. Advancements in SiC-Reinforced Metal Matrix Composites for High-Performance Electronic Packaging: A Review of Thermo-Mechanical Properties and Future Trends. Micromachines 2023, 14, 1491. [Google Scholar] [CrossRef]

- Karaoğlu, S.Y.; Karaoğlu, S.; Ünal, İ. Aerospace industry and aluminum metal matrix composites. Int. J. Aviat. Sci. Technol. 2021, 2, 73–81. [Google Scholar] [CrossRef]

- Maurya, P.; Kota, N.; Gibmeier, J.; Wanner, A.; Roy, S. Review on study of internal load transfer in metal matrix composites using diffraction techniques. Mater. Sci. Eng. A 2022, 840, 142973. [Google Scholar] [CrossRef]

- Fajoui, J.; Kchaou, M.; Sellami, A.; Branchu, S.; Elleuch, R.; Jacquemin, F. Impact of residual stresses on mechanical behaviour of hot work steels. Eng. Fail. Anal. 2018, 94, 33–40. [Google Scholar] [CrossRef]

- Sahu, M.K.; Sahu, R.K. Fabrication of aluminum matrix composites by stir casting technique and stirring process parameters optimization. In Advanced Casting Technologies; Intechopen: Rijeka, Croatia, 2018. [Google Scholar]

- Orhadahwe, T.A.; Ajide, O.O.; Adeleke, A.A.; Ikubanni, P.P. A review on primary synthesis and secondary treatment of aluminium matrix composites. Arab J. Basic Appl. Sci. 2020, 27, 389–405. [Google Scholar] [CrossRef]

- Lakshmikanthan, A.; Angadi, S.; Malik, V.; Saxena, K.K.; Prakash, C.; Dixit, S.; Mohammed, K.A. Mechanical and tribological properties of aluminum-based metal-matrix composites. Materials 2022, 15, 6111. [Google Scholar] [CrossRef]

- Gurmaita, P.K.; Pongen, R.; Gurmaita, S.K. A7075 alloy reinforced metal matrix composites fabricated through stircasting route: A review. Int. J. Cast Met. Res. 2024, 37, 208–255. [Google Scholar] [CrossRef]

- Venkateswarlu, K.; Varma, K.P.V.; Nutakki, U.K. Effect of nanoparticle reinforcement and cryogenic treatment on aluminum alloys for enhancement of mechanical and microstructural characteristics—A review. In International Journal on Interactive Design and Manufacturing (IJIDeM); Springer Nature: Berlin, Germany, 2024; pp. 1–20. [Google Scholar]

- StJohn, D.H.; Easton, M.A.; Qian, M.; Taylor, J.A. Grain refinement of magnesium alloys: A review of recent research, theoretical developments, and their application. Metall. Mater. Trans. A 2013, 44, 2935–2949. [Google Scholar] [CrossRef]

- Yigezu, B.S.; Jha, P.K.; Mahapatra, M.M. The key attributes of synthesizing ceramic particulate reinforced Al-based matrix composites through stir casting process: A review. Mater. Manuf. Process. 2013, 28, 969–979. [Google Scholar]

- Kato, K. Classification of wear mechanisms/models. In Wear–Materials, Mechanisms and Practice; Wiley Online Library: Hoboken, NJ, USA, 2005; pp. 9–20. [Google Scholar]

- Rashid, A.B.; Haque, M.; Islam, S.M.; Uddin Labib, K.R.; Chowdhury, P. Breaking Boundaries with Ceramic Matrix Composites: A Comprehensive Overview of Materials, Manufacturing Techniques, Transformative Applications, Recent Advancements, and Future Prospects. Adv. Mater. Sci. Eng. 2024, 2024, 2112358. [Google Scholar] [CrossRef]

- Zhang, G.; Tang, J.; Yang, K.; Wang, R.; Chen, Y.; Xiong, Y.; Wu, C.; Li, Z.; Wang, Y.; Lin, H. Important contributions of metal interfaces on their tribological performances: From influencing factors to wear mechanisms. Compos. Struct. 2024, 337, 118027. [Google Scholar] [CrossRef]

- Roy, M. Elevated temperature erosive wear of metallic materials. J. Phys. D Appl. Phys. 2006, 39, R101. [Google Scholar] [CrossRef]

- Ouyang, J.H.; Li, Y.F.; Zhang, Y.Z.; Wang, Y.M.; Wang, Y.J. High-temperature solid lubricants and self-lubricating composites: A critical review. Lubricants 2022, 10, 177. [Google Scholar] [CrossRef]

- Ozden, S.; Ekici, R.; Nair, F. Investigation of impact behaviour of aluminium based SiC particle reinforced metal–matrix composites. Compos. Part A Appl. Sci. Manuf. 2007, 38, 484–494. [Google Scholar] [CrossRef]

- Osman, M.A.; Atallah, A. Interparticle and particle–matrix interactions in polyethylene reinforcement and viscoelasticity. Polymer 2005, 46, 9476–9488. [Google Scholar] [CrossRef]

- Thünemann, M.; Beffort, O.; Kleiner, S.; Vogt, U. Aluminum matrix composites based on preceramic-polymer-bonded SiC preforms. Compos. Sci. Technol. 2007, 67, 2377–2383. [Google Scholar] [CrossRef]

- Peng, Z.; Fuguo, L. Effects of particle clustering on the flow behavior of SiC particle reinforced Al metal matrix composites. Rare Met. Mater. Eng. 2010, 39, 1525–1531. [Google Scholar] [CrossRef]

- Prabu, S.B.; Karunamoorthy, L.; Kathiresan, S.; Mohan, B. Influence of stirring speed and stirring time on distribution of particles in cast metal matrix composite. J. Mater. Process. Technol. 2006, 171, 268–273. [Google Scholar] [CrossRef]

- Barekar, N.S.; Tzamtzis, S.; Hari Babu, N.; Fan, Z.; Dhindaw, B.K. Processing of ultrafine-size particulate metal matrix composites by advanced shear technology. Metall. Mater. Trans. A 2009, 40, 691–701. [Google Scholar] [CrossRef]

- Kılıckap, E.; Cakır, O.; Aksoy, M.; Inan, A. Study of tool wear and surface roughness in machining of homogenisedSiC-p reinforced aluminium metal matrix composite. J. Mater. Process. Technol. 2005, 164, 862–867. [Google Scholar] [CrossRef]

- Natarajan, N.; Vijayarangan, S.; Rajendran, I. Wear behaviour of A356/25SiCp aluminium matrix composites sliding against automobile friction material. Wear 2006, 261, 812–822. [Google Scholar] [CrossRef]

- Yanming, Q.; Zehua, Z. Tool wear and its mechanism for cutting SiC particle-reinforced aluminium matrix composites. J. Mater. Process. Technol. 2000, 100, 194–199. [Google Scholar] [CrossRef]

- Sam, M.; Radhika, N. Influence of carbide ceramic reinforcements in improving tribological properties of A333 graded hybrid composites. Def. Technol. 2022, 18, 1107–1123. [Google Scholar] [CrossRef]

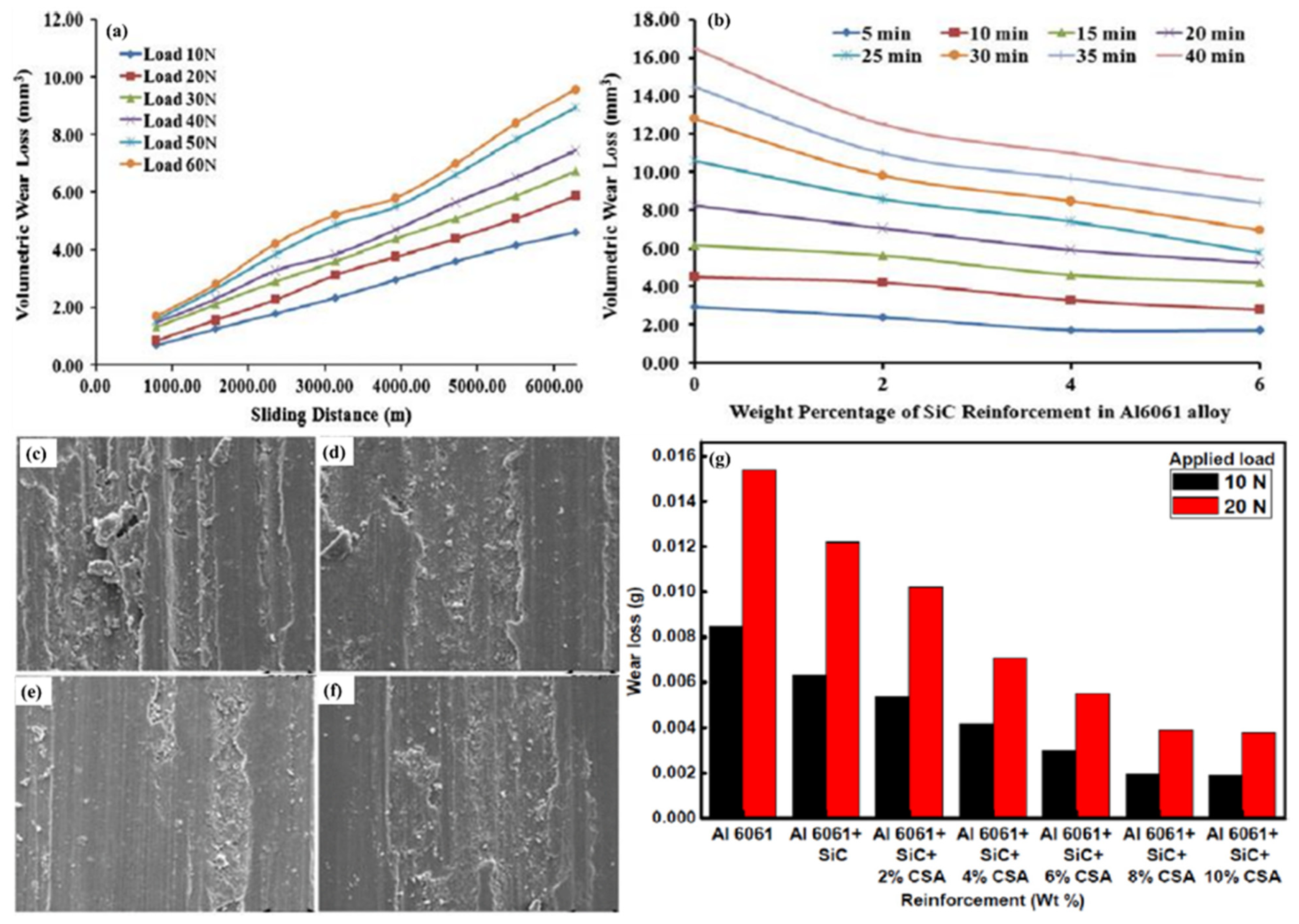

- Kumar, G.V.; Rao, C.S.P.; Selvaraj, N. Studies on mechanical and dry sliding wear of Al6061–SiC composites. Compos. Part B Eng. 2012, 43, 1185–1191. [Google Scholar] [CrossRef]

- Coyal, A.; Yuvaraj, N.; Butola, R.; Tyagi, L. An experimental analysis of tensile, hardness and wear properties of aluminium metal matrix composite through stir casting process. SN Appl. Sci. 2020, 2, 892. [Google Scholar] [CrossRef]

- Park, B.G.; Crosky, A.G.; Hellier, A.K. Fracture toughness of microsphere Al2O3–Al particulate metal matrix composites. Compos. Part B Eng. 2008, 39, 1270–1279. [Google Scholar] [CrossRef]

- Park, B.G.; Crosky, A.G.; Hellier, A.K. High cycle fatigue behaviour of microsphere Al2O3–Al particulate metal matrix composites. Compos. Part B Eng. 2008, 39, 1257–1269. [Google Scholar] [CrossRef]

- Kok, M. Production and mechanical properties of Al2O3 particle-reinforced 2024 aluminium alloy composites. J. Mater. Process. Technol. 2005, 161, 381–387. [Google Scholar] [CrossRef]

- Kumar, A.; Lal, S.; Kumar, S. Fabrication and characterization of A359/Al2O3 metal matrix composite using electromagnetic stir casting method. J. Mater. Res. Technol. 2013, 2, 250–254. [Google Scholar] [CrossRef]

- Chithra, N.V.; Karuppasamy, R.; Manickaraj, K.; Ramakrishnan, T. Effect of Reinforcement Addition on Mechanical Behavior of Al MMC-A Critical Review. J. Environ. Nanotechnol. 2024, 13, 65–79. [Google Scholar] [CrossRef]

- Mondal, D.P.; Das, S.; Jha, A.K.; Yegneswaran, A.H. Abrasive wear of Al alloy–Al2O3 particle composite: A study on the combined effect of load and size of abrasive. Wear 1998, 223, 131–138. [Google Scholar] [CrossRef]

- Vogt, R.G.; Zhang, Z.; Topping, T.D.; Lavernia, E.J.; Schoenung, J.M. Cryomilled aluminum alloy and boron carbide nano-composite plate. J. Mater. Process. Technol. 2009, 209, 5046–5053. [Google Scholar] [CrossRef]

- Babu, T.M.; Sugin, M.A.; Muthukrishnan, N. Investigation on the characteristics of surface quality on machining of hybrid metal matrix composite (Al-SiC-B4C). Procedia Eng. 2012, 38, 2617–2624. [Google Scholar] [CrossRef]

- Previtali, B.; Pocci, D.; Taccardo, C. Application of traditional investment casting process to aluminium matrix composites. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1606–1617. [Google Scholar] [CrossRef]

- Bharathiraja, P.; Xavior, A. Effect of B4C and graphene on the microstructural and mechanical properties of Al6061 matrix composites. J. Mater. Res. Technol. 2024, 31, 496–505. [Google Scholar]

- Kalaiselvan, K.; Murugan, N.; Parameswaran, S. Production and characterization of AA6061–B4C stir cast composite. Mater. Des. 2011, 32, 4004–4009. [Google Scholar] [CrossRef]

- Srivyas, P.D.; Charoo, M.S. Role of fabrication route on the mechanical and tribological behavior of aluminum metal matrix composites—A review. Mater. Today Proc. 2018, 5, 20054–20069. [Google Scholar] [CrossRef]

- Sayman, O.; Akbulut, H.; Meric, C. Elasto-plastic stress analysis of aluminum metal-matrix composite laminated plates under in-plane loading. Comput. Struct. 2000, 75, 55–63. [Google Scholar] [CrossRef]

- Atas, C.; Sayman, O. Elastic–plastic stress analysis and expansion of plastic zone in clamped and simply supported aluminum metal–matrix laminated plates. Compos. Struct. 2000, 49, 9–19. [Google Scholar] [CrossRef]

- Ding, H.Z.; Biermann, H.; Hartmann, O. A low cycle fatigue model of a short-fibre reinforced 6061 aluminium alloy metal matrix composite. Compos. Sci. Technol. 2002, 62, 2189–2199. [Google Scholar] [CrossRef]

- Lee, W.S.; Sue, W.C.; Lin, C.F. The effects of temperature and strain rate on the properties of carbon-fiber-reinforced 7075 aluminum alloy metal-matrix composite. Compos. Sci. Technol. 2000, 60, 1975–1983. [Google Scholar] [CrossRef]

- Rams, J.; Urena, A.; Escalera, M.D.; Sanchez, M. Electroless nickel coated short carbon fibres in aluminium matrix composites. Compos. Part A Appl. Sci. Manuf. 2007, 38, 566–575. [Google Scholar] [CrossRef]

- Fu, H.H.; Han, K.S.; Song, J.I. Wear properties of saffil/Al, saffil/Al2O3/Al and saffil/SiC/Al hybrid metal matrix composites. Wear 2004, 256, 705–713. [Google Scholar] [CrossRef]

- Rino, J.J.; Sivalingappa, D.; Koti, H.; Jebin, V.D. Properties of Al6063 MMC reinforced with zircon sand and alumina. IOSR J. Mech. Civ. Eng. 2013, 5, 72–77. [Google Scholar] [CrossRef]

- Das, S.; Das, S.; Das, K. RETRACTED: Abrasive wear of zircon sand and alumina reinforced Al–4.5 wt% Cu alloy matrix composites—A comparative study. Compos. Sci. Technol. 2007, 67, 746–751. [Google Scholar] [CrossRef]

- Kumar, S.; Sharma, V.; Panwar, R.S.; Pandey, O.P. Wear behavior of dual particle size (DPS) zircon sand reinforced aluminum alloy. Tribol. Lett. 2012, 47, 231–251. [Google Scholar] [CrossRef]

- Abdizadeh, H.; Ashuri, M.; Moghadam, P.T.; Nouribahadory, A.; Baharvandi, H.R. Improvement in physical and mechanical properties of aluminum/zircon composites fabricated by powder metallurgy method. Mater. Des. 2011, 32, 4417–4423. [Google Scholar] [CrossRef]

- Das, S.; Udhayabanu, V.; Das, S.; Das, K. Synthesis and characterization of zircon sand/Al-4.5 wt% Cu composite produced by stir casting route. J. Mater. Sci. 2006, 41, 4668–4677. [Google Scholar] [CrossRef]

- Panda, L.; Dash, S. Characterization and utilization of coal fly ash: A review. Emerg. Mater. Res. 2020, 9, 921–934. [Google Scholar] [CrossRef]

- Juang, S.H.; Li, C.F. Influence of Different Addition Ratios of Fly Ash on Mechanical Properties of ADC10 Aluminum Matrix Composites. Metals 2022, 12, 653. [Google Scholar] [CrossRef]

- Bahrami, A.; Soltani, N.; Pech-Canul, M.I.; Gutiérrez, C.A. Development of metal-matrix composites from industrial/agricultural waste materials and their derivatives. Crit. Rev. Environ. Sci. Technol. 2016, 46, 143–208. [Google Scholar] [CrossRef]

- Rajan, T.P.D.; Pillai, R.M.; Pai, B.C.; Satyanarayana, K.G.; Rohatgi, P.K. Fabrication and characterisation of Al–7Si–0.35 Mg/fly ash metal matrix composites processed by different stir casting routes. Compos. Sci. Technol. 2007, 67, 3369–3377. [Google Scholar] [CrossRef]

- Dou, Z.; Wu, G.; Huang, X.; Sun, D.; Jiang, L. Electromagnetic shielding effectiveness of aluminum alloy–fly ash composites. Compos. Part A Appl. Sci. Manuf. 2007, 38, 186–191. [Google Scholar] [CrossRef]

- Ramachandra, M.; Radhakrishna, K. Effect of reinforcement of flyash on sliding wear, slurry erosive wear and corrosive behavior of aluminium matrix composite. Wear 2007, 262, 1450–1462. [Google Scholar] [CrossRef]

- Girisha, L.; Raji, G. Study on properties of multi walled carbon nanotube reinforced aluminum matrix composite through casting technique. Int. J. Eng. Res. Technol. (IJERT) 2014, 3, 1372–1375. [Google Scholar]

- Golla, C.B.; Babar-Pasha, M.; Rao, R.N.; Ismail, S.; Gupta, M. Influence of TiC particles on mechanical and tribological characteristics of advanced aluminum matrix composites fabricated through ultrasonic-assisted stir casting. Crystals 2023, 13, 1360. [Google Scholar] [CrossRef]

- Gopi, K.R.; Mohandas, K.N.; Reddappa, H.N.; Ramesh, M.R. Characterization of as cast and heat treated aluminium 6061/Zircon sand/graphite particulate hybrid composites. Int. J. Eng. Adv. Technol. (IJEAT) 2013, 2, 340–344. [Google Scholar]

- Sharma, V.; Kumar, S.; Panwar, R.S.; Pandey, O.P. Microstructural and wear behavior of dual reinforced particle (DRP) aluminum alloy composite. J. Mater. Sci. 2012, 47, 6633–6646. [Google Scholar] [CrossRef]

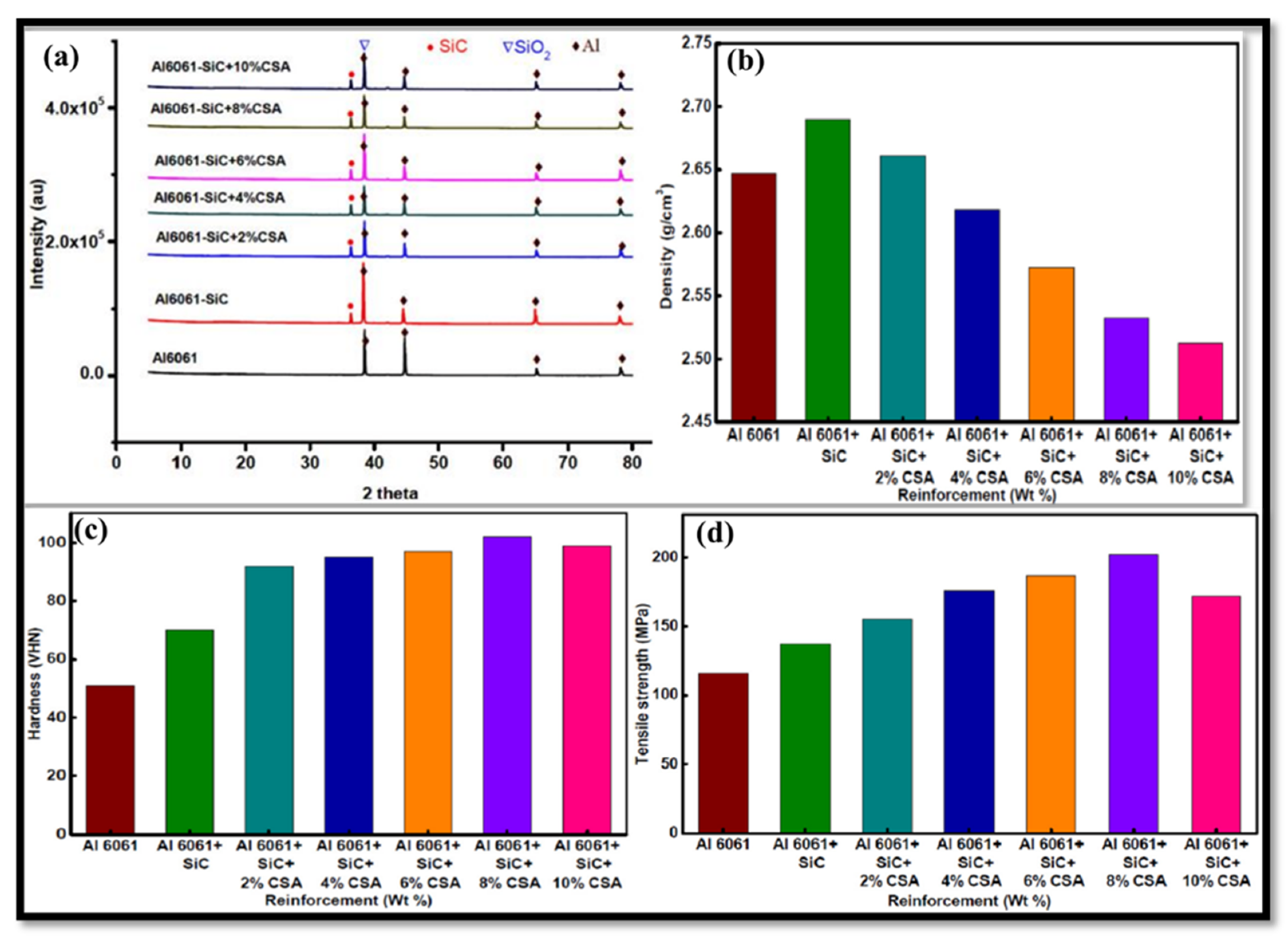

- Satheesh, M.; Pugazhvadivu, M. Investigation on physical and mechanical properties of Al6061-Silicon Carbide (SiC)/Coconut shell ash (CSA) hybrid composites. Phys. B Condens. Matter 2019, 572, 70–75. [Google Scholar] [CrossRef]

- Metan, V.; Eigenfeld, K. Controlling mechanical and physical properties of Al-Si alloys by controlling grain size through grain refinement and electromagnetic stirring. Eur. Phys. J. Spec. Top. 2013, 220, 139–150. [Google Scholar] [CrossRef]

- Ramesh, C.S.; Keshavamurthy, R.; Channabasappa, B.H.; Ahmed, A. Microstructure and mechanical properties of Ni–P coated Si3N4 reinforced Al6061 composites. Mater. Sci. Eng. A 2009, 502, 99–106. [Google Scholar] [CrossRef]

- Lakshmikanthan, P.; Prabu, B. Mechanical and tribologicalbeheaviour of aluminium Al6061-coconut shell ash composite using stir casting pellet method. J. Balk. Tribol. Assoc. 2016, 22, 4008–4018. [Google Scholar]

- Kumar, G.V.; Swamy, A.R.K.; Ramesha, A. Studies on properties of as-cast Al6061-WC-Gr hybrid MMCs. J. Compos. Mater. 2012, 46, 2111–2122. [Google Scholar] [CrossRef]

- Santosh, R.N.; Sarojini, J.; Lakshmi, V. Enhancing the Mechanical Properties of Metal Matrix Composite by Reinforcing Aluminium 6063 with Sic & Graphite. Int. J. Eng. Res. Technol 2018, 6, 1–5. [Google Scholar]

- Xian, G.; Guo, R.; Li, C. Combined effects of sustained bending loading, water immersion and fiber hybrid mode on the mechanical properties of carbon/glass fiber reinforced polymer composite. Compos. Struct. 2022, 281, 115060. [Google Scholar] [CrossRef]

- Liu, S.; Wang, Y.; Muthuramalingam, T.; Anbuchezhiyan, G. Effect of B4C and MOS2 reinforcement on micro structure and wear properties of aluminum hybrid composite for automotive applications. Compos. Part B Eng. 2019, 176, 107329. [Google Scholar] [CrossRef]

- Logesh, K.; Hariharasakthisudhan, P.; Moshi, A.A.M.; Rajan, B.S.; Sathickbasha, K. Mechanical properties and microstructure of A356 alloy reinforced AlN/MWCNT/graphite/Al composites fabricated by stir casting. Mater. Res. Express 2019, 7, 015004. [Google Scholar] [CrossRef]

- Sujan, D.; Oo, Z.; Rahman, M.; Maleque, M.; Tan, C.K. Physio-Mechanical Properties of Aluminium Metal Matrix Composites Reinforced with Al2O3 and SiC. World Academy of Science, Engineering and Technology, International Science Index 68. Int. J. Chem. Mol. Nucl. Mater. Metall. Eng. 2012, 6, 678–681. [Google Scholar]

- Radhika, N.; Subramanian, R.; Prasat, S.V. Tribological behaviour of aluminium/alumina/graphite hybrid metal matrix composite using Taguchi’s techniques. J. Miner. Mater. Charact. Eng. 2011, 10, 427. [Google Scholar] [CrossRef]

- Mahesh, V.; Joladarashi, S.; Kulkarni, S.M. Experimental study on abrasive wear behaviour of flexible green composite intended to be used as protective cladding for structures. Int. J. Mod. Manuf. Technol 2019, 11, 69–76. [Google Scholar]

- Reddy, N.S.K.; Kwang-Sup, S.; Yang, M. Experimental study of surface integrity during end milling of Al/SiC particulate metal–matrix composites. J. Mater. Process. Technol. 2008, 201, 574–579. [Google Scholar] [CrossRef]

- Alpas, A.T.; Zhang, J. Effect of microstructure (particulate size and volume fraction) and counterface material on the sliding wear resistance of particulate-reinforced aluminum matrix composites. Metall. Mater. Trans. A 1994, 25, 969–983. [Google Scholar] [CrossRef]

- Ceschini, L.; Daehn, G.S.; Garagnani, G.L.; Martini, C. Friction and wear behavior of C4Al2O3Al composites under dry sliding conditions. Wear 1998, 216, 229–238. [Google Scholar] [CrossRef]

- Uyyuru, R.K.; Surappa, M.K.; Brusethaug, S. Effect of reinforcement volume fraction and size distribution on the tribological behavior of Al-composite/brake pad tribo-couple. Wear 2006, 260, 1248–1255. [Google Scholar] [CrossRef]

- Debnath, S.; Oo, Z.; Rahman, M.; Maleque, M.; Tan, C. Physio-mechanical properties of aluminium metal matrix composites reinforced with Al2O3 and SiC. Int. J. Eng. Appl. Sci. 2012, 6, 288–291. [Google Scholar]

- Suresh, S.; Gowd, G.H.; Deva Kumar, M.L.S. Experimental investigation on mechanical properties of Al 7075/Al2O3/Mg NMMC’s by stir casting method. Sādhanā 2019, 44, 51. [Google Scholar] [CrossRef]

- Veeravalli, R.R.; Nallu, R.; Mohiuddin, S.M.M. Mechanical and tribological properties of AA7075–TiC metal matrix composites under heat treated (T6) and cast conditions. J. Mater. Res. Technol. 2016, 5, 377–383. [Google Scholar] [CrossRef]

- RamakoteswaraRao, V.; Ramanaiah, N.; Rao, M.S.; Sarcar, M.M.M.; Kartheek, G. Optimisation of process parameters for minimum volumetric wear rate on AA7075-TiC metal matrix composite. Int. J. Automot. Mech. Eng. 2016, 13, 3669–3680. [Google Scholar] [CrossRef]

- Sidharthan, S.; Raajavignesh, G.; Nandeeshwaran, R.; Radhika, N.; Jojith, R.; Jeyaprakash, N. Mechanical property analysis and tribological response optimization of SiC and MoS2 reinforced hybrid aluminum functionally graded composite through Taguchi’s DOE. J. Manuf. Process. 2023, 102, 965–984. [Google Scholar] [CrossRef]

- Saritha, P.; Raju, D.P.R.; Reddy, D.R.V.; Snehalatha, S. Mechanical Behavior of Hybrid Composites. IJMET 2018, 9, 71–76. [Google Scholar]

- More, K.A.; Pawar, S.Y. Tribological investigation of Al7075/TIC/MoS2 hybrid composite material. Int. Res. J. Eng. Technol 2018, 5, 2052–2058. [Google Scholar]

- Rao, V.R.; Ramanaiah, N.; Sarcar, M.M.M. Optimization of volumetric wear rate of aa7075-tic metal matrix composite by using taguchi technique. Jordan J. Mech. Ind. Eng. 2016, 10, 189–198. [Google Scholar]

- Devaganesh, S.; Kumar, P.D.; Venkatesh, N.; Balaji, R. Study on the mechanical and tribological performances of hybrid SiC-Al7075 metal matrix composites. J. Mater. Res. Technol. 2020, 9, 3759–3766. [Google Scholar] [CrossRef]

- Dinesh, M.; Ravindran, R. Tensile and hardness behavior of aluminum 7075 and Zinc and Chromium metal matrix composite by Stir-Casting Route. Int. Arch. Appl. Sci. Technol. 2016, 7, 39–46. [Google Scholar]

- Dhanalakshmi, S.; Mohanasundararaju, N.; Venkatakrishnan, P.G.; Karthik, V. Optimization of friction and wear behaviour of Al7075-Al2O3-B4C metal matrix composites using Taguchi method. IOP Conf. Ser. Mater. Sci. Eng. 2018, 314, 012025. [Google Scholar] [CrossRef]

- Suresh, S.; Gowd, G.H.; Kumar, M.D. Mechanical and wear behavior of Al 7075/Al2O3/SiC/mg metal matrix nanocomposite by liquid state process. Adv. Compos. Hybrid Mater. 2019, 2, 530–539. [Google Scholar] [CrossRef]

- Kumar, G.V.; Rao, C.S.P.; Selvaraj, N.; Bhagyashekar, M.S. Studies on Al6061-SiC and Al7075-Al2O3 metal matrix composites. J. Miner. Mater. Charact. Eng. 2010, 9, 43–55. [Google Scholar]

- Sreenivasan, K.S.; Kumar, S.S.; Katiravan, J. Genetic algorithm based optimization of friction welding process parameters on AA7075-SiC composite. Eng. Sci. Technol. Int. J. 2019, 22, 1136–1148. [Google Scholar] [CrossRef]

- Rahman, M.H.; Al Rashed, H.M. Characterization of silicon carbide reinforced aluminum matrix composites. Procedia Eng. 2014, 90, 103–109. [Google Scholar] [CrossRef]

- James, S.J.; Venkatesan, K.; Kuppan, P.; Ramanujam, R. Hybrid aluminium metal matrix composite reinforced with SiC and TiB2. Procedia Eng. 2014, 97, 1018–1026. [Google Scholar] [CrossRef]

- Sulaiman, S.; Marjom, Z.; Ismail, M.I.S.; Ariffin, M.K.A.; Ashrafi, N. Effect of modifier on mechanical properties of aluminium silicon carbide (Al-SiC) composites. Procedia Eng. 2017, 184, 773–777. [Google Scholar] [CrossRef]

- Pawar, P.B.; Utpat, A.A. Development of aluminium based silicon carbide particulate metal matrix composite for spur gear. Procedia Mater. Sci. 2014, 6, 1150–1156. [Google Scholar] [CrossRef]

- Padmavathi, K.R.; Ramakrishnan, R. Tribological behaviour of aluminium hybrid metal matrix composite. Procedia Eng. 2014, 97, 660–667. [Google Scholar] [CrossRef]

- Rajkumar, K.; Santosh, S.; Ibrahim, S.J.S.; Gnanavelbabu, A. Effect of Electrical discharge machining parameters on microwave heat treated Aluminium-Boron carbide-Graphite composites. Procedia Eng. 2014, 97, 1543–1550. [Google Scholar] [CrossRef]

- Kumar, N.S.; Ravindranath, V.M.; Shankar, G.S. Mechanical and wear behaviour of aluminium metal matrix hybrid composites. Procedia Mater. Sci. 2014, 5, 908–917. [Google Scholar] [CrossRef]

- Loto, R.T.; Babalola, P. Electrochemical analysis of SiC composite additions at 7.5% weight content on the corrosion resistance of monolithic aluminium alloy in sulphate–chloride solution. J. Mater. Res. Technol. 2019, 8, 2517–2527. [Google Scholar] [CrossRef]

- Rozhbiany, F.A.R.; Jalal, S.R. Reinforcement and processing on the machinability and mechanical properties of aluminum matrix composites. J. Mater. Res. Technol. 2019, 8, 4766–4777. [Google Scholar] [CrossRef]

- Pargunde, D.M.; Thokal, G.N.; Tambuskar, D.P.; Kulkarni, S.S. Development of Aluminium Based Metal Matrix Composite (AlSiC). Int. J. Adv. Eng. Res. Stud. 2013, 3, 22–25. [Google Scholar]

- Panwar, N.; Chauhan, A.; Pali, H.S.; Sharma, M.D. Fabrication of aluminum 6061 red-mud composite using stir casting and micro structure observation. Mater. Today Proc. 2020, 21, 2014–2023. [Google Scholar] [CrossRef]

- Yashpal, J.C.; Kant, S.; Panwar, N.; Sharma, M.D.; Pali, H.S. Effect of particle size variation of bagasse ash on mechanical properties of aluminium hybrid metal matrix composites. Mater. Today Proc. 2020, 21, 2024–2029. [Google Scholar] [CrossRef]

- Dhulipalla, A.; Kumar, B.U.; Akhil, V.; Zhang, J.; Lu, Z.; Park, H.Y.; Jung, Y.G.; Zhang, J. Synthesis and machining characteristics of novel TiC ceramic and MoS2 soft particulate reinforced aluminium alloy 7075 matrix composites. Manuf. Lett. 2020, 24, 82–86. [Google Scholar] [CrossRef]

- Balasubramanya, H.S.; Basavaraja, J.S.; Srinivas, S.; Kumar, V.R. Wear rate behavior of as-cast and heat treated hybrid aluminum metal matrix composites. Procedia Mater. Sci. 2014, 5, 1049–1055. [Google Scholar] [CrossRef]

- Kumar, N.S.; Suresh, R.; Shankar, G.S. High temperature wear behavior of Al2219/n-B4C/MoS2 hybrid metal matrix composites. Compos. Commun. 2020, 19, 61–73. [Google Scholar] [CrossRef]

- Siddeshkumar, N.G.; Suresh, R.; Durga Prasad, C.; Shivaram, L.; Siddalingaswamy, N.H. Evolution of the surface quality and tool wear in the high speed turning of Al2219/n-B4C/MoS2 Nano metal matrix composites. Int. J. Cast Met. Res. 2024, 37, 22–38. [Google Scholar] [CrossRef]

- Varun, K.M.; Goud, R.R. Investigation of mechanical properties of Al 7075/SiC/MoS2 hybrid composite. Mater. Today Proc. 2019, 19, 787–791. [Google Scholar] [CrossRef]

- Patil, S.; Haneef, M. A statistical analysis of optimization of wear behavior of Al7075-Beryl-Graphene hybrid composites using Taguchi technique. Mater. Today Proc. 2020, 20, 195–201. [Google Scholar] [CrossRef]

- Raju, K.; Balakrishnan, M. Experimental study and analysis of operating parameters in wire EDM process of aluminium metal matrix composites. Mater. Today Proc. 2020, 22, 869–873. [Google Scholar] [CrossRef]

- Sharma, S.K.; Saxena, K.K.; Dixit, A.K.; Singh, R.; Mohammed, K.A. Role of additive manufacturing and various reinforcements in MMCs related to biomedical applications. Adv. Mater. Process. Technol. 2024, 10, 231–248. [Google Scholar] [CrossRef]

- Zhang, Z.C.; Zhang, G.W.; Hu, Y.L.; Lv, W.Z.; Yu, H.; Ren, X.Y. Al-Ti-C (CNTs) Master Alloys Improve Room Temperature and High-Temperature Mechanical Properties of ZL205A Alloy. Mater. Today Commun. 2024, 41, 110689. [Google Scholar] [CrossRef]

- Bannaravuri, P.K.; Birru, A.K. Strengthening of mechanical and tribological properties of Al-4.5% Cu matrix alloy with the addition of bamboo leaf ash. Results Phys. 2018, 10, 360–373. [Google Scholar] [CrossRef]

- Rao, T.B. Microstructural, mechanical, and wear properties characterization and strengthening mechanisms of Al7075/SiCnp composites processed through ultrasonic cavitation assisted stir-casting. Mater. Sci. Eng. A 2021, 805, 140553. [Google Scholar] [CrossRef]

- Koch, C.C. Structural nanocrystalline materials: An overview. J. Mater. Sci. 2007, 42, 1403–1414. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, D.L. Contribution of Orowan strengthening effect in particulate-reinforced metal matrix nanocomposites. Mater. Sci. Eng. A 2008, 483, 148–152. [Google Scholar] [CrossRef]

- Singh, R.P.; Zhang, M.; Chan, D. Toughening of a brittle thermosetting polymer: Effects of reinforcement particle size and volume fraction. J. Mater. Sci. 2002, 37, 781–788. [Google Scholar] [CrossRef]

- Shabani, M.O.; Mazahery, A. Good bonding between coated B4C particles and aluminum matrix fabricated by semisolid techniques. Russ. J. Non-Ferr. Met. 2013, 54, 154–160. [Google Scholar] [CrossRef]

- Jayalakshmi, S.; Gupta, S.; Sankaranarayanan, S.; Sahu, S.; Gupta, M. Structural and mechanical properties of Ni60Nb40 amorphous alloy particle reinforced Al-based composites produced by microwave-assisted rapid sintering. Mater. Sci. Eng. A 2013, 581, 119–127. [Google Scholar] [CrossRef]

- Ramesh, M.; Selvan, M.T.; Saravanakumar, A. Evolution and recent advancements of composite materials in structural applications. In Applications of Composite Materials in Engineering; Elsevier Science Ltd.: Oxford, UK, 2025; pp. 97–117. [Google Scholar]

- Ren, J.Y.; Ji, G.C.; Guo, H.R.; Zhou, Y.M.; Tan, X.; Zheng, W.F.; Xing, Q.; Zhang, J.Y.; Sun, J.R.; Yang, H.Y.; et al. Nano-Enhanced Phase Reinforced Magnesium Matrix Composites: A Review of the Matrix, Reinforcement, Interface Design, Properties and Potential Applications. Materials 2024, 17, 2454. [Google Scholar] [CrossRef]

- Nipu, S.M.A.; Rahman, M.Z.; Alam, S.S.; Dev, B. Mechanical, Thermal and Morphological Characterization of Graphene/Al2O3-Reinforced Epoxy Hybrid Nanocomposites. Macromol. Mater. Eng. 2024, 2400180. [Google Scholar] [CrossRef]

- Monteiro, B.; Simões, S. Recent Advances in Hybrid Nanocomposites for Aerospace Applications. Metals 2024, 14, 1283. [Google Scholar] [CrossRef]

- Rong, X.; Zhao, D.; He, C.; Zhao, N. recent progress in aluminum matrix composites reinforced by in situ oxide ceramics. J. Mater. Sci. 2024, 59, 9657–9684. [Google Scholar] [CrossRef]

- Sharma, S.K.; Saxena, K.K. Effects on microstructure and mechanical properties of AZ31 reinforced with CNT by powder metallurgy: An overview. Mater. Today Proc. 2022, 56, 2038–2042. [Google Scholar] [CrossRef]

- Agrawal, A.P.; Srivastava, S.K. Investigations of fatigue crack growth rate behaviour and life prediction of Si3N4/TiB2 reinforced hybrid metal matrix composites. Int. J. Fatigue 2024, 186, 108373. [Google Scholar] [CrossRef]

- Dai, P.; Li, A.; Luo, X.; Li, H.; Yang, L.; Wen, L.; Tu, T.; Wang, C.; Liu, Y.; Zhao, W.; et al. Investigation into synergistic enhancement of strength and reduction in density for novel bimodal-sized Al2O3p reinforced CoCrFeMnNi composites. J. Mater. Res. Technol. 2024, 32, 661–673. [Google Scholar] [CrossRef]

- Kennedy, A.; Shipway, P. Materials and processing. In Introduction to Mechanical Engineering; CRC Press: Boca Raton, FL, USA, 2022; pp. 89–184. [Google Scholar]

- Pelleg, J.; Pelleg, J. The strength and strengthening of ceramics. In Mechanical Properties of Ceramics; Springer Nature: Berlin, Germany, 2014; pp. 351–415. [Google Scholar]

- Ferguson, J.B.; Schultz, B.F.; Venugopalan, D.; Lopez, H.F.; Rohatgi, P.K.; Cho, K.; Kim, C.S. On the superposition of strengthening mechanisms in dispersion strengthened alloys and metal-matrix nanocomposites: Considerations of stress and energy. Met. Mater. Int. 2014, 20, 375–388. [Google Scholar] [CrossRef]

- Roopa, A.K.; Hunashyal, A.M.; Patil, A.Y.; Kamadollishettar, A.; Patil, B.; Soudagar, M.E.M.; Shahapurkar, K.; Khan, T.Y.; Kalam, M.A. Research Article Study on Interfacial Interaction of Cement-Based Nanocomposite by Molecular Dynamic Analysis and an RVE Approach. Adv. Civ. Eng. 2023, 2023, 8404335. [Google Scholar]

- Cahill, D.G.; Ford, W.K.; Goodson, K.E.; Mahan, G.D.; Majumdar, A.; Maris, H.J.; Merlin, R.; Phillpot, S.R. Nanoscale thermal transport. J. Appl. Phys. 2003, 93, 793–818. [Google Scholar] [CrossRef]

- Hassan, S.F.; Gupta, M. Effect of different types of nano-size oxide particulates on microstructural and mechanical properties of elemental Mg. J. Mater. Sci. 2006, 41, 2229–2236. [Google Scholar] [CrossRef]

- Illgen, A.; Baaske, M.; Ballani, F.; Weidner, A.; Biermann, H. Influence of ceramic particles and fibre reinforcement in metal-matrix-composites on the VHCF behaviour. Part I: Experimental investigations of fatigue and damage behaviour. In Fatigue of Materials at Very High Numbers of Loading Cycles: Experimental Techniques, Mechanisms, Modeling and Fatigue Life Assessment; Springer: Berlin/Heidelberg, Germany, 2018; pp. 295–318. [Google Scholar]

- More, K.L.; Koester, D.A.; Davis, R.F. Microstructural characterization of a creep-deformed SiC whisker-reinforced Si3N4. Ultramicroscopy 1991, 37, 263–278. [Google Scholar] [CrossRef]

- Ujah, C.O.; Kallon, D.V.V.; Aigbodion, V.S. Tribological Properties of CNTs-Reinforced Nano Composite Materials. Lubricants 2023, 11, 95. [Google Scholar] [CrossRef]

- Taylor, A.C. Advances in nanoparticle reinforcement in structural adhesives. In Advances in Structural Adhesive Bonding; Woodhead Publishing: Sawston, UK, 2010; pp. 151–182. [Google Scholar]

- Mashabela, M.; Maringa, M.; Dzogbewu, T. Nanoparticulate reinforced composites and their application to additively manufactured TI6AL4V for use in the aerospace sector. Manuf. Rev. 2022, 9, 29. [Google Scholar] [CrossRef]

- Al-Rub, R.K.A.; Voyiadjis, G. Determination of the material intrinsic length scale of gradient plasticity theory. Int. J. Multiscale Comput. Eng. 2004, 2. [Google Scholar] [CrossRef]

- Greer, A.L. Overview: Application of heterogeneous nucleation in grain-refining of metals. J. Chem. Phys. 2016, 145, 211704. [Google Scholar] [CrossRef]

- Polmear, I. Light Alloys: From Traditional Alloys to Nanocrystals; Elsevier: Amsterdam, The Netherlands, 2005. [Google Scholar]

- Yazdani, Z.; Toroghinejad, M.R.; Edris, H.; Ngan, A.H.W. A novel method for the fabrication of Al-matrix nanocomposites reinforced by mono-dispersed TiAl3 intermetallic via a three-step process of cold-roll bonding, heat-treatment and accumulative roll bonding. J. Alloys Compd. 2018, 747, 217–226. [Google Scholar] [CrossRef]

- Dwivedi, S.P.; Sharma, S.; Li, C.; Zhang, Y.; Kumar, A.; Singh, R.; Eldin, S.M.; Abbas, M. Effect of nano-TiO2 particles addition on dissimilar AA2024 and AA2014 based composite developed by friction stir process technique. J. Mater. Res. Technol. 2023, 26, 1872–1881. [Google Scholar] [CrossRef]

- Jain, V.K.S.; Muthukumaran, S. Influence of SiC content on microstructure and tribological properties of friction stir-processed SiC/AA5083 surface composites. Metall. Mater. Trans. A 2019, 50, 2933–2944. [Google Scholar] [CrossRef]

- Kuhlmann-Wilsdorf, D. Theory of plastic deformation:-properties of low energy dislocation structures. Mater. Sci. Eng. A 1989, 113, 1–41. [Google Scholar] [CrossRef]

| Condition | SiO2 (%) | Al2O3 (%) | Fe2O3 (%) | L.O.I. (Left on Ignition) (%) | Moisture (%) | Additional |

|---|---|---|---|---|---|---|

| Fly ash (untreated) | 58.5 | 25.4 | 5.0 | 4.0 | 0.3 | Balance |

| Fly ash (treated) | 68.1 | 27.0 | 3.0 | 0.19 | 0.2 | Balance |

| S. No | Wear Regime | Overview of Wear Regime | Effects of Parameter on Wear |

|---|---|---|---|

| 1 | Mild Wear Regime | The surface remains largely intact, with minimal material loss. The primary reasons for wear are attributed to adhesion or oxidation. | 1. Load: A reduction in loads leads to the prevalence of minor wear. 2. Reinforcement Type: Hard ceramic materials such as SiC or Al₂O₃ offer resistance to abrasion, enabling the maintenance of a mild wear regime even under slightly increased loads. 3. Sliding distance and sliding velocity: Mild wear is generally associated with moderate speeds and low sliding distances. |

| 2 | Moderate wear regime | Moderate increases in wear occur as surface degradation initiates, resulting from a combination of abrasion, adhesion, and some deformation. | 1. Load: As loads rise, the material shifts from mild wear into this regime, with the reinforcement’s capacity to support the applied load playing a crucial role in this transition. 2. Particle Size and Distribution: The onset of the transition wear regime is postponed by uniformly distributed fine particles 3. Material Composition: An increased weight fraction of reinforcements such as TiC or B₄C enhances load-bearing capacity, further delaying the transition. |

| 3 | Severe Wear Regime | Significant material loss occurs as a result of plastic deformation, extreme abrasion, or even delamination. | 1. Load: When loads increase, they cause substantial wear as the reinforcement’s ability to endure stress is exceeded. 2. Velocity of Sliding and Distance: Increased speeds combined with longer sliding distances lead to heat generated by friction, which softens the matrix and speeds up wear. 3. Type and Volume of Reinforcement: While hard reinforcements mitigate significant wear, they can fail in extreme situations if their bonding is inadequate or their volume is insufficient. 4. Wear Debris: The separation of matrix material or reinforcement particles can serve as secondary abrasives, leading to an increase in wear rates. |

| References | Material Utilizes | Composition | Major Outcomes |

|---|---|---|---|

| [170] | Al7075/Al2O3/Mg | Al2O3: 1, 2, 3, 4 wt.%, Mg: 1 wt.% | Tensile, hardness, and toughness gradually increase, increasing the amount of Al2O3. Surface structure showed Al2O3 were homogeneously dispersed in Al. |

| [171] | Al7075/TiC | TiC: 2, 4, 6, 8, 10 wt.% | Up to 8 wt.% of TiC in the Al7075 alloy demonstrated good wear resistance. Wear rate and COF both decrease as the weight fraction of TiC-reinforced particles rises. |

| [172] | Al7075/TiC | TiC: 2, 4, 6, 8, 10 wt.% (Taguchi Optimization) | TiC inclusion results in an improvement in resistance to wear of Al7075 alloy. When sliding distance and sliding velocity increased, the degradation rate reduced and rose with the weight percentage of reinforcement. |

| [173] | Al7075/TiC/MoS2 | TiC: 10 wt.%, MoS2: 10 wt.% | The amount of molybdenum disulfide, applied stress, and sliding velocity all have a big impact on how quickly aluminum composites wear down. The wear rate and sliding velocity have a direct proportional connection, followed by the parameter interactions. |

| [174] | Al7075/SiC/MoS2 | SiC: 5, 10, 15 wt.%, MoS2: 3 wt.% | The tensile strength was increased only up to 5 wt.% of SiC, beyond which there is a minor reduction in the tensile strength of the composites. |

| [175] | Al7075/TiC/MoS2 | TiC: 0, 5, 10 wt.% MoS2: 3 wt.% | The proportion of reinforcement and the applied load have an impact on wear loss and COF, respectively. |

| [176] | Al7075/TiC | TiC—0, 2, 4, 6, 8 wt.% | The density, wear resistance, and hardness were enhanced by the addition of TiC particles. When sliding velocity rose, the wear rate of the composite declined and rose with the weight percentage of reinforcement. |

| [177] | Al7075/SiC/MoS2/Gr/Hexagonal boron nitride hBN | SiC: 5 wt.%, Gr: 5 wt.%, hBN: 5 wt.%, MoS2: 5 wt.% | The mechanical characteristics of the Al7075 alloy are significantly affected by the presence of graphite reinforcement. SiC particles improve the material’s ductility, whereas graphite strengthens the composite. The mechanical qualities are increased by the uniform distribution of reinforcements produced by the stir-casting procedure. Nonetheless, hBN reinforcement has better wear characteristics than SiC, Gr, and MoS2. |

| [178] | Al7075/TiC | TiC: 2, 4, 6, 8, 10 wt.% | AA7075 alloy with 8 wt.% of TiC particles had the highest micro-hardness. The wear factor, wear rate, and coefficient of friction change with sliding distance and reinforcing percentages. When the weight proportion of TiC in composites increased relative to the base alloy, the composites’ rate of wear reduced. |

| [179] | Al7075/Chromium Nanoparticle/Zinc Nanoparticle | Cr—2, 3, 4, 5, 6 wt.% Zn: 1 wt.% | When zinc nanoparticles were added, the tensile characteristics of the composites were significantly enhanced, comparable to Al alloys. Also, the manufactured composite’s hardness value increased. In contrast to other specimens, the composite containing (Al-97%Cr-4%Zn-1%) finally showed high tensile strength and hardness. |

| [180] | Al7075/Al2O3/B4C | Al2O3: 3, 6, 9, 12, 15 wt.% B4C—3 wt.% | As the weight proportion of Al2O3 in composites improves, the wear resistance is also enhanced. |

| [181] | Al7075/Al2O3/SiC/ Mg | (Al2O3 + xSiC): 1, 2, 3, 4 wt.% | The weight proportion of reinforcement increases with a rise in tensile and compressive strength, along with hardness. Al2O3 and SiC are clearly visible according to XRD examination. |

| [182] | Al6061/SiC Al7075/Al2O3 | SiC—0, 2, 4, 6 wt.% Al2O3—0, 2, 4, 6 wt.% | The composites have greater wear resistance with the addition of SiC. |

| [18] | Al7075/SiC | SiC—10 vol.% | Composites attain uniform dispersion of ceramic material. |

| [183] | Al/SiC (320 grit) | SiC: 5, 10, 15, 20, 25, 30 wt.% | An increase in impact strength and hardness is noticed with the addition of SiC. There is an increasing trend in the uniform dispersion of SiC in Al samples prepared without a stirring procedure, with manual stirring, and utilizing the two-step stir casting approach. |

| [184] | Al6061/SiC/TiB2/ Mg | SiC–10 wt.% TiB2—0, 2.5, 5 wt.% Mg—2 g | The presence of 10% SiC and 5% TiB2 in the composite results in the creation of clusters. The introduction of reinforcements has an impact on the hardness value. However, the inclusion of TiB2 up to a maximum of 5% results in the formation of pores, which in turn influences the hardness value. The addition of SiC to the base metal resulted in a 20% increase in strength for the composite. However, the inclusion of TiB2 led to a significant decrease in strength, with a measured fall of 50–60%. |

| [185] | Al12Si/(LM6)/SiC/Sr | 0.01% Sr/0.02% Sr/0.5% Sr/0.02% Sr + 10% SiC/0.5% Sr + 10% SiC | By adding Al-10Sr, the morphology of the Al has undergone a significant alteration. The vortex approach yields the greatest results when 0.5 weight percent Al-10Sr and 10 weight percent SiC are added to aluminum. SiC and Sr were added, increasing the UTS for aluminum. |

| [186] | Al/SiC | SiC—0, 2.5, 5, 7.5, 10 wt.% | Al-SiC has a far higher hardness than aluminum metal. Hardness and material toughness improve with increasing silicon carbide concentration; the greatest value is achieved at 10% SiC content. |

| [187] | Al6061/SiC/ MWCNT | SiC–15 wt.% MWCNT—0, 0.5, 1 wt.% | SiC and MWCNT-reinforced aluminum show superior resistance to dry abrasive wear. |

| [188] | Al6061/B4C/ Graphite | B4C—15 wt.% Graphite—5 wt.% | Strong bonding between the matrix and the reinforcements evidenced an even distribution of reinforcement in the matrix material and decreased porosity. |

| [189] | Al2219/B4C/MoS2 | B4C—3 wt.% MoS2—3, 4, 5 wt.% | By increasing the proportion of B4C and MoS2 reinforcing material, density rises. The hardness of composites rises as the percentage of reinforcement increases. |

| [190] | AA1060/SiC/0.3MNaCl/0.5M H2SO4 Solution | SiC—7.5 wt.% at particle size (0, 3, 9, 29, 45 µm) | Composite exhibits greater resistance to corrosion when using the smallest and largest SiC particle sizes (3 µm and 45 µm). |

| [191] | Al6063 (x)/ Mortar ash (MA)/Met coke ash (MCA)/Nano fibrillated composite (NFC)/Straw ash (SA) | x, x + 5 wt.% MA, x + 5 wt.% MCA, x + 5 wt.% NFC, x + 5 wt.% SA, x + 5 wt.% of MCA, NFC, SA, and MA | Because of the strong atomic bonds between the atoms, the MMCs have a higher hardness than the Al 6063 alloy. The MA composite increases the hardness of MMCs. The impact strength rose with the addition of MA and SA reinforcements. Additionally, the addition of NFC and MCA reduces surface roughness during turning. |

| [192] | Al/Groundnut shell ash (GSA)/ SiC | GSA and SiC (10:0, 7.5:2.5, 5.0:5.0, 2.5:7.5, 0:10) | Tensile strength and hardness rose as the weight percentage of the reinforcing phase grew, but they somewhat decreased as the GSA content increased. The percentage elongation slightly increased as the GSA content rose. There was no continuous pattern of improvement with increasing SiC–GSA amount. GSA content increased along with improvements in fracture toughness. GSA complimentary reinforcement can be used to produce high-performance, low-cost aluminum matrix composites. |

| [193] | Al/SiC (360 grit)– | SiC: 5, 10, 15, 20, 25, and 30 wt.% | As reinforcement is added, density (g/cc) and hardness (BHN) both rise. Impact Strength rises with an increase in SiC particle weight fraction and falls with an increase in reinforced. SiCp was distributed uniformly. |

| [194] | Al6061/Red-mud | Red-mud: 4, 4, 12, 16, 20 wt.% | The surface characteristics of the castings that have undergone heat treatment have improved. Red muck is distributed throughout the alloy very uniformly. |

| [195] | Al6061/Al2O3/Bagasse ash | Al2O3–5 wt.% Bagasse ash–8 wt.% (37 μm, 53 μm, 75 μm) | Because the reinforcements in hybrid composites are smaller than those in base metal, they have greater mechanical characteristics. The microstructural pictures showed that the aluminum reinforcements were distributed uniformly. |

| [196] | Al7075/TiC/MoS2 | TiC—0, 2, 4 wt.% MoS2—0, 2 wt.% | TiC is a hard ceramic substance; thus, as the amount of TiC grew, the hardness increased as well. The soft phase MoS2 is what caused the hardness values to decrease when MoS2 was added to the aforementioned AMCs. The microstructures of the synthesized AMCs, created using the stir casting procedure, demonstrate that the TiC and MoS2 microparticles are dispersed randomly throughout the AA7075 matrix. |

| [197] | Al365/SiC/ Graphite (Gr) | SiC: 3, 6, and 9 wt.% Gr: 3 wt.% | Reduced normal load and increased sliding speed result in a reduction in wear rate. Car disc brakes benefit from the improved tribological qualities of composite materials due to the increase of SiC in the material and the solid lubrication provided by graphite particles. |

| [198] | Al2219/n-B4C/MoS2 | Al2219 Al2219 + 2% n-B4C Al2219 + 2% n-B4C + 2% MoS2 | In comparison to the Al2219 matrix, the specific wear rate of Al2219 is greater and that of nanocomposites is lower. The wear rates of Al2219 + 2% n-B4C and Al2219 + 2% n-B4C + 2% MoS2 nanocomposites steadily decrease when temperature is raised (500 to 1000 °C). Al2219 + 2% n-B4C + 2% MoS2 has a greater wear resistance than Al2219 + 2% n-B4C and Al2219 matrix. |

| [199] | Al7075/B4C/MoS2 | B4C–4, 8, and 12 wt.% MoS2–3 wt.% | Hybrid composites’ hardness, ultimate strength, and yield tensile strength rise with an increased proportion of multi-reinforcement. Friction coefficient rises in B4C. |

| [200] | Al7075/SiC/MoS2 | SiC—3, 6, and 9 wt.% MoS2: 1 wt.% | Out of all the specimens, the one with the highest strength in the tensile test is Al7075 + 9% SiC + 1% MoS2. As the weight percentage of silicon carbide (SiC) grows, the hardness value also increases. |

| [201] | Al7075/Graphene/Beryl | Graphene—0, 0.5, 1 wt.%, Beryl: 6 wt.% | The wear of the composite decreases with increasing reinforcing weight proportion. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sharma, S.K.; Gajević, S.; Sharma, L.K.; Pradhan, R.; Sharma, Y.; Miletić, I.; Stojanović, B. Progress in Aluminum-Based Composites Prepared by Stir Casting: Mechanical and Tribological Properties for Automotive, Aerospace, and Military Applications. Lubricants 2024, 12, 421. https://doi.org/10.3390/lubricants12120421

Sharma SK, Gajević S, Sharma LK, Pradhan R, Sharma Y, Miletić I, Stojanović B. Progress in Aluminum-Based Composites Prepared by Stir Casting: Mechanical and Tribological Properties for Automotive, Aerospace, and Military Applications. Lubricants. 2024; 12(12):421. https://doi.org/10.3390/lubricants12120421

Chicago/Turabian StyleSharma, Sachin Kumar, Sandra Gajević, Lokesh Kumar Sharma, Reshab Pradhan, Yogesh Sharma, Ivan Miletić, and Blaža Stojanović. 2024. "Progress in Aluminum-Based Composites Prepared by Stir Casting: Mechanical and Tribological Properties for Automotive, Aerospace, and Military Applications" Lubricants 12, no. 12: 421. https://doi.org/10.3390/lubricants12120421

APA StyleSharma, S. K., Gajević, S., Sharma, L. K., Pradhan, R., Sharma, Y., Miletić, I., & Stojanović, B. (2024). Progress in Aluminum-Based Composites Prepared by Stir Casting: Mechanical and Tribological Properties for Automotive, Aerospace, and Military Applications. Lubricants, 12(12), 421. https://doi.org/10.3390/lubricants12120421