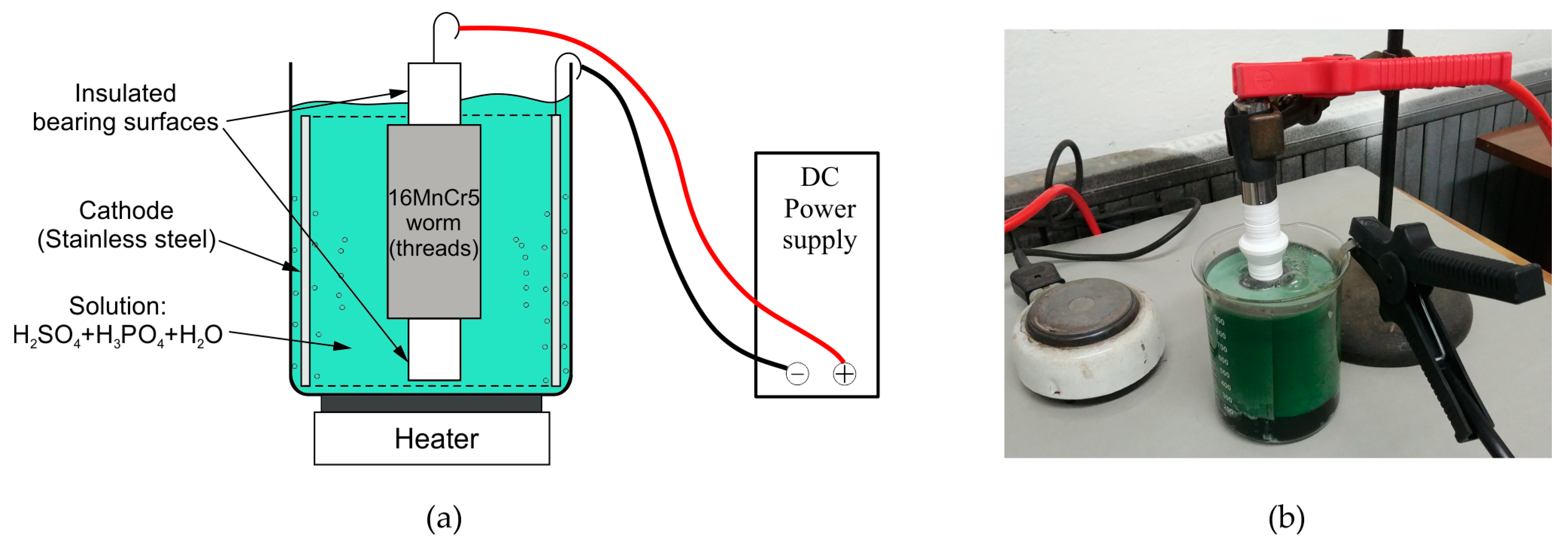

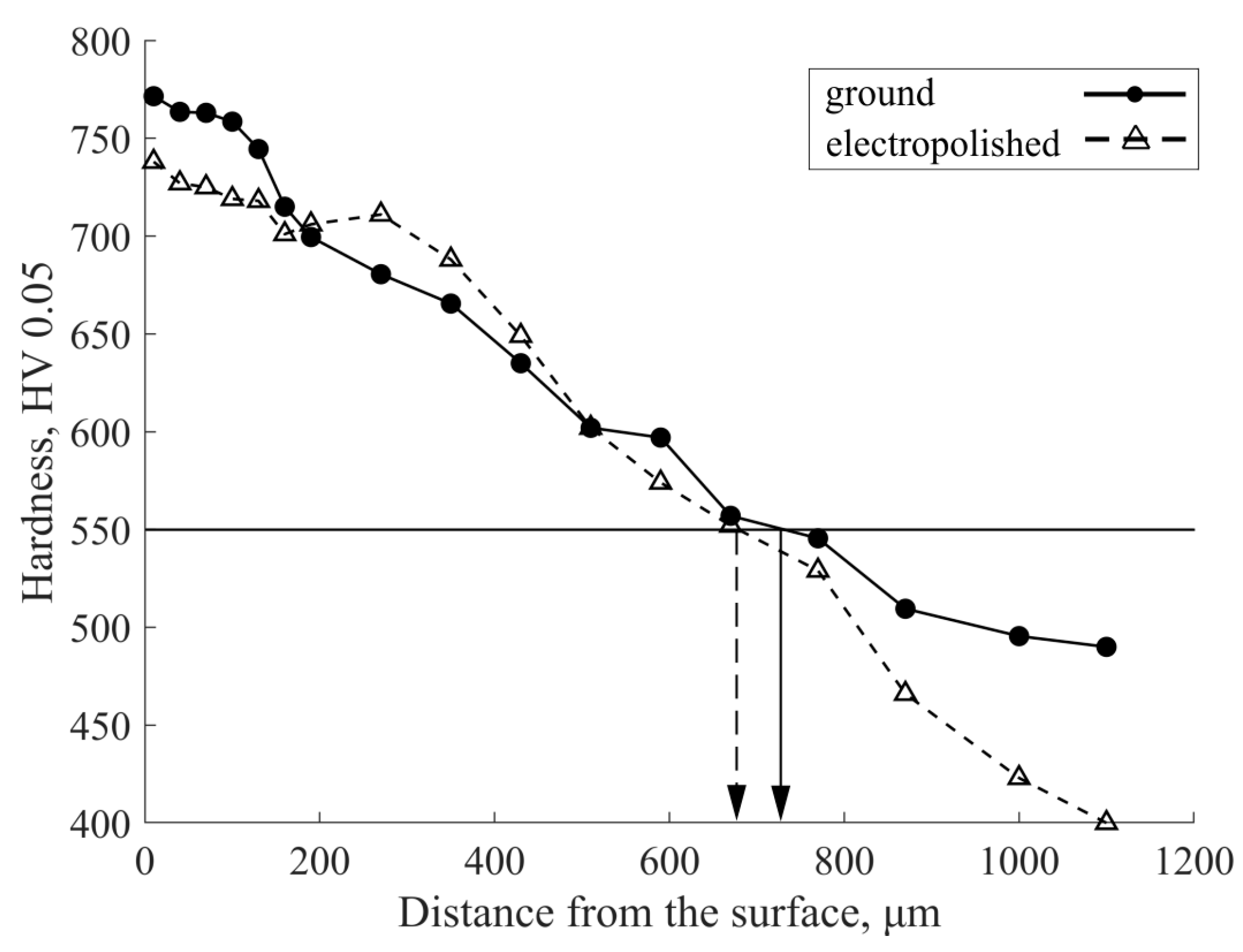

In this section, the effects of electropolishing on material microstructure, hardness profile, surface topography, and chemical composition of 16MnCr5 steel worms are presented and discussed, followed up with the results of worm pair experimental testing and comparison with conventional worm pairs.

3.3. Surface Topography

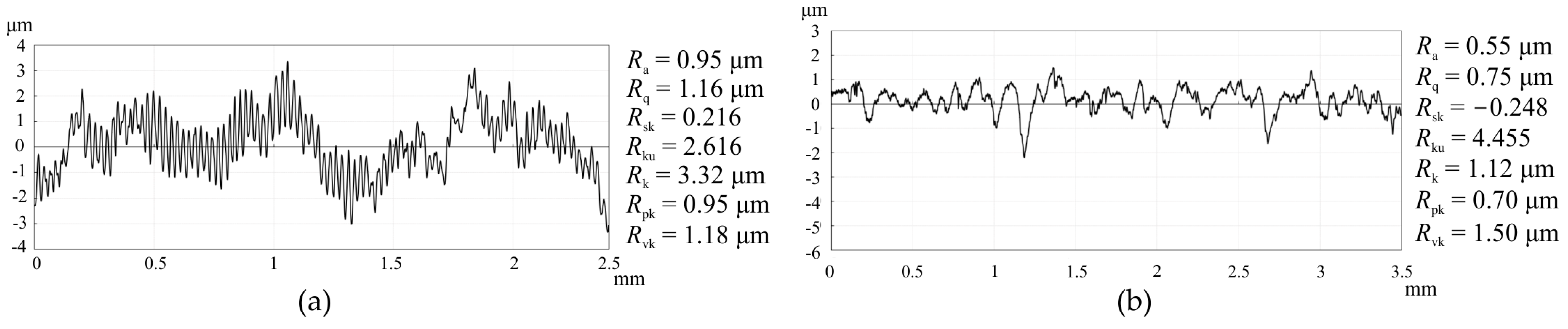

Surface profile measurements were performed using a Mitutoyo SJ-500 measuring instrument according to the ISO 4287 standard [

39]. Examples of surface profiles with corresponding surface parameters of worm wheel and ground and electropolished worms are presented in

Figure 7. Electropolished worms were characterized by many pits. Worm EP-1 had deeper pits (≈2–5 μm) compared to shallower pits on worm EP-2 (≈1–2 μm). This observation can be attributed to different current densities as worm EP-1 was electropolished with a current density of 20 A/dm

2 compared to 15 A/dm

2 employed on worm EP-2. An additional noticeable difference was found in pit diameters. Lower current density employed on worm EP-2 enlarged existing pits/valleys of ground surface that were approximately 1 μm deep, resulting in 50–100 μm pit diameters. On the other hand, pit diameters on worm EP-1 surface were in the range of 20–50 μm.

Regarding surface texture properties, the goal was to produce a surface characterized by pits and negative

Rsk and higher

Rku surface parameters. Pitted or dimpled surfaces are often characterized by negative

Rsk and higher

Rku values; such surface textures have already shown friction-reduction characteristics [

11,

40,

41,

42]. Pits (or dimples) act as oil reservoirs, providing secondary lubrication and reducing friction. Furthermore, the significant increase in

Ra was aimed to be avoided because it usually results in higher friction and wear. In the presented case, the average surface roughness increased from

Ra = 0.25 for ground worms to

Ra ≈ 0.50 for electropolished worms. This observation results in two types of surface textures that were applied and tested on worm pairs. The first one is the electropolished worm surface (worm EP-1), which has characteristics similar to surfaces mentioned in the literature, with surface parameters

Rsk = −0.996 and

Rku = 7.228 and deeper but smaller pits. The second one is the electropolished worm surface (worm EP-2) with slightly different characteristics, namely

Rsk = −0.008 and

Rku = 3.554, but shallower and larger pits. Surface parameter values are presented in detail in

Table 8.

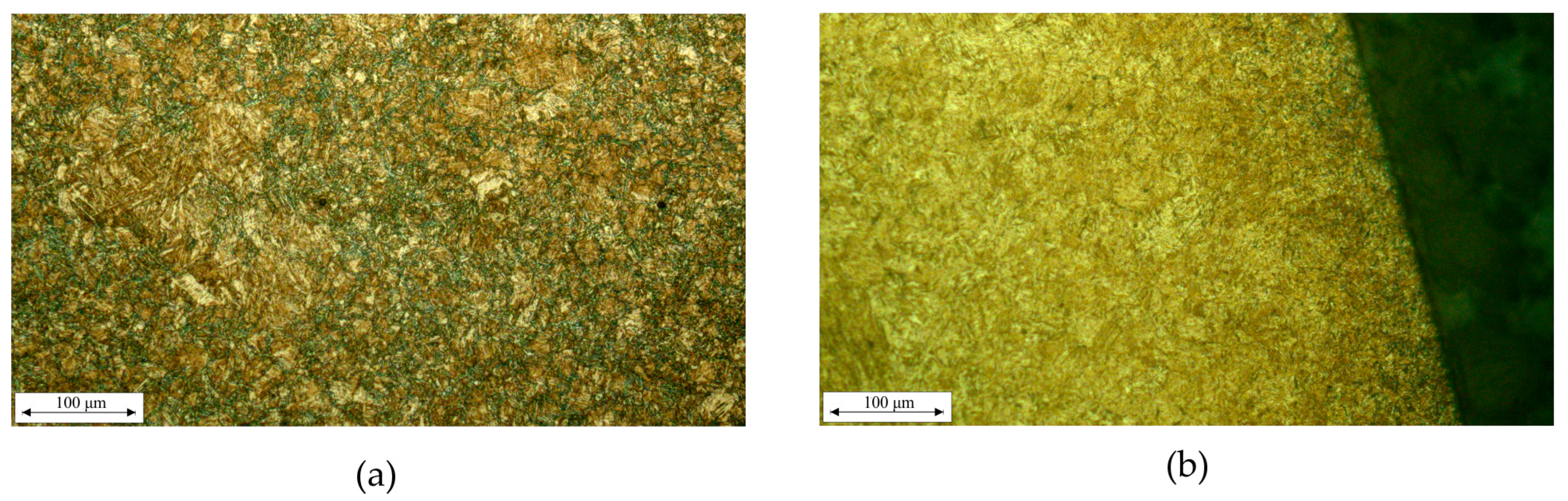

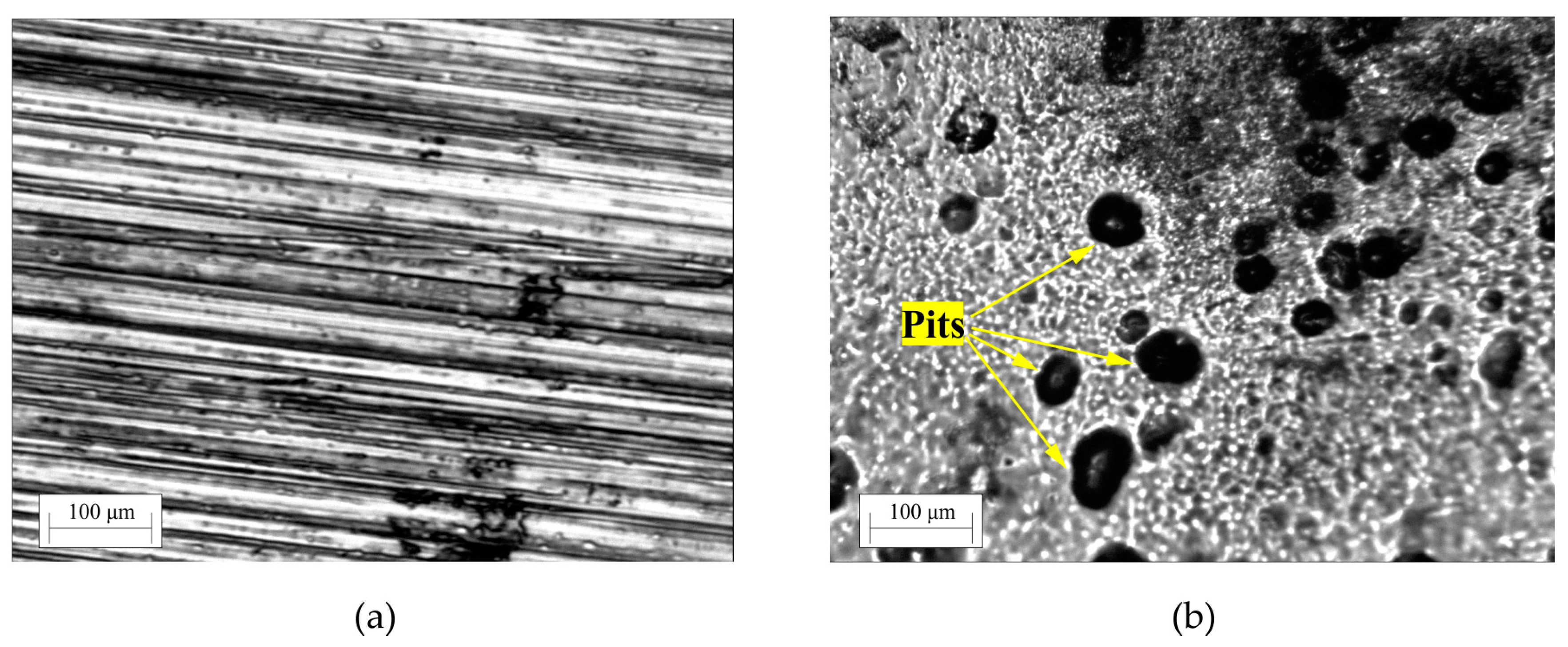

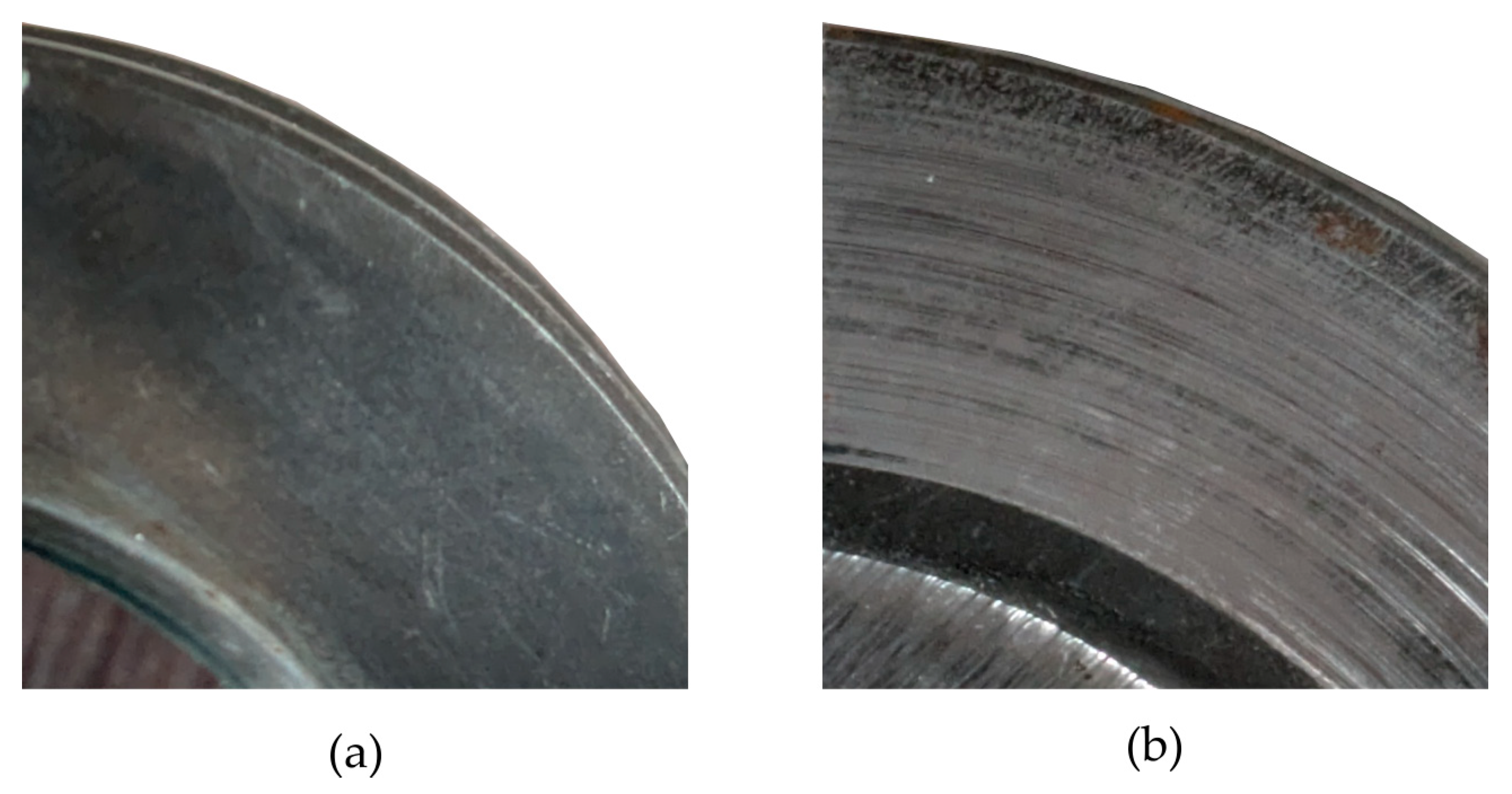

Ground and electropolished worm surfaces are shown in

Figure 8. Ground worm’s surface is characterized by grinding marks, while the electropolished surface has many irregular pits/dimples distributed stochastically. The pit area density was 11% in the regions with more pits. In contrast, the pit area density in sparser regions reduced to 9% of the total surface area. In previous research [

11], electropolishing 16MnCr5 steel discs with a current density of 30 A/dm

2 yielded a similar albeit slightly higher pit area density of 12%. Generally, 5% to 20% pit area density was reported as beneficial regarding friction reduction [

43,

44,

45,

46,

47].

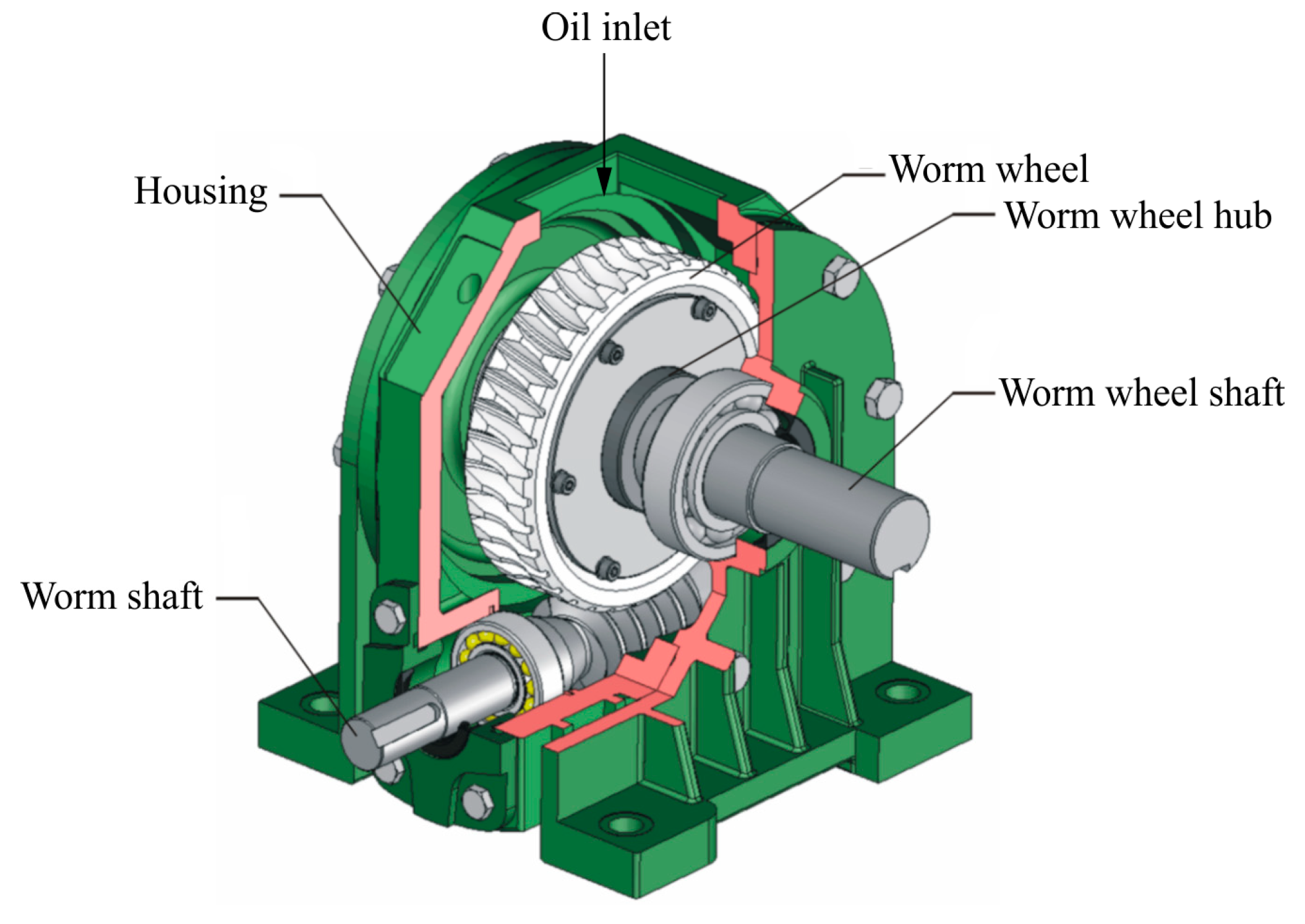

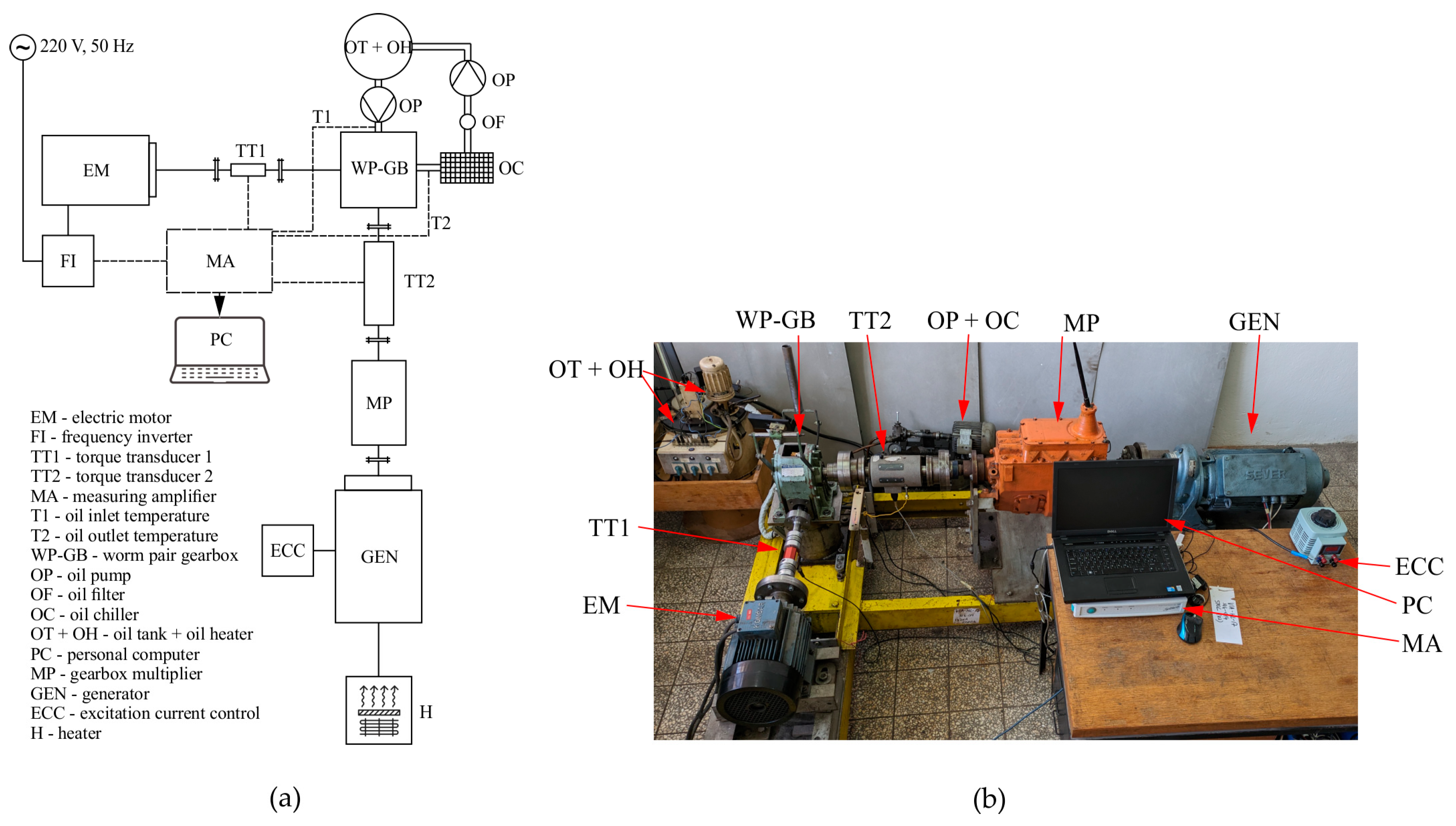

3.4. Worm Gear Pair Experimental Tests

Experimental testing conditions, such as nominal rotational worm speed, nominal working load, and oil temperature, were selected to replicate realistic working conditions for employed worm gear pair geometry and materials. Also, working conditions were selected to satisfy surface durability (i.e., pitting resistance) and wear load capacity calculation procedures according to ISO/TS 14521 [

26]. Tests were carried out for

NL = 2∙× 10

6 worm wheel load cycles. Tested worm pair combinations, testing conditions, and values calculated according to ISO/TS 14521 are presented in

Table 9. Worm pair designations that will be used for the remainder of this paper can be found in the rightmost column of

Table 9.

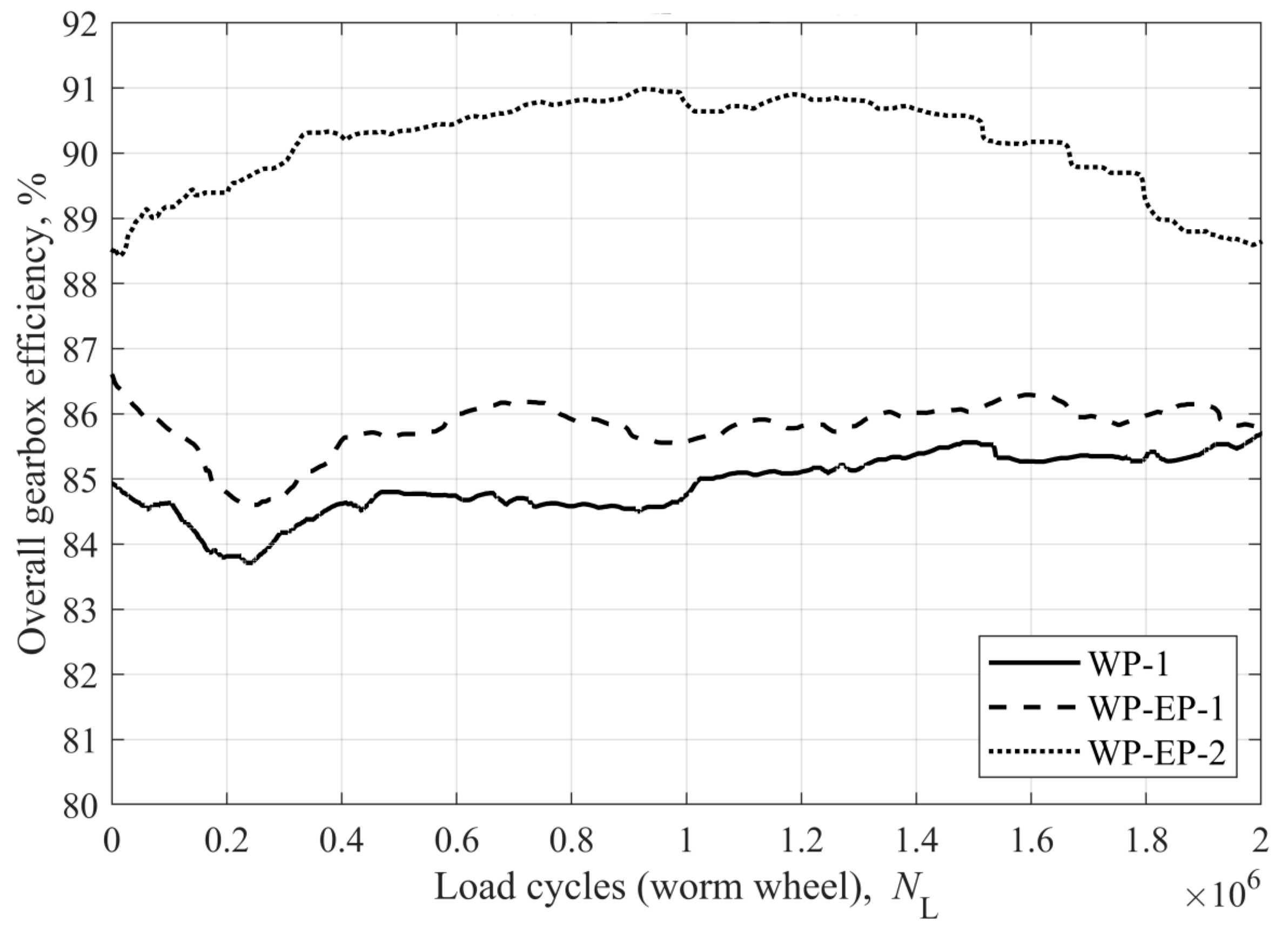

The comparison of the overall gearbox efficiency is presented in

Figure 9. The average efficiencies of WP-1, WP-EP-1, and WP-EP-2 were 84.9%, 85.8%, and 90.1%, respectively. The worm gear pair WP-2 will be discussed separately due to the occurrence of scuffing. Both worm gear pairs with electropolished worms showed improved efficiencies compared to WP-1. As mentioned, the electropolished surface had many pits that had multiple functions. Pits act as oil reservoirs, providing secondary lubrication, increasing oil film thickness, and enhancing heat dissipation which is attributed to an increase in overall efficiency. Also, pits can improve the tribological behaviour of contacting surfaces by entrapping abrasive particles [

48]. In the case of worm gear pairs, the latter function can be particularly useful as worm wheel wear is usually one or two orders of magnitude larger than wear in steel gears in general. This phenomenon is especially pronounced during the running-in phase and early stages of the operation.

A more noticeable increase in efficiency rating was found for WP-EP-2, where the worm surface was characterized by shallower but larger pits. The explanation for such a phenomenon lies in the geometry of the pits. In the locations of deeper pits in the contact zone, the lubricant experiences a severe decrease in pressure, leading to a lower viscosity that prevents the lubricant from completely separating the contacting surfaces [

49]. Also, a countereffect of textured surfaces in non-conformal contacts (as in gears and worm pairs) can occur. An occurrence of cavitation inside deeper cavities in highly loaded non-conformal contacts can result in an increase in the coefficient of friction compared to an untextured surface [

50]. On the other hand, the benefit of shallower pits can be explained by their smaller volume, which is more easily filled with oil to build additional hydrodynamic pressure and thus provide the separation of contacting surfaces [

40].

An example of surface profiles after the test is shown in

Figure 10. By comparing the surface profiles of the electropolished worm before and after the test, it can be concluded that minimal to no wear occurred on the electropolished surface of the worm as its surface topography remained unchanged. The values of

Ra,

Rsk, and

Rku were similar to those before the test (

Figure 7). In addition, the surface pits produced by electropolishing did not deteriorate. The softer oxide surface layer was damaged and removed during worm gear pair operation, presumably already in the running-in phase [

11,

51]. The appearance of worm threads after electropolishing and after the test can be seen in

Figure 11.

In contrast to conventional steel–steel gear material pairs, the steel–bronze pair favours the surface texture on a harder steel worm as most of the wear takes place on a softer bronze worm wheel. A similar finding was reported by Kasem et al. [

48]. The authors suggested that surfaces textured with small and shallow dimples could reduce friction in lubricated contact with one contacting body having high wear resistance. Regardless of surface parameters used in the design of surface textures, the presented results imply that in the case of worm gear pairs, the focus should be placed primarily on the pit/dimple geometry and then complemented by surface parameters as a promising guide towards successful surface texturing application.

The additional phenomenon of electropolished steel surfaces in contact with bronze is higher bronze wear and therefore faster running-in [

11]. By observing efficiency plots in

Figure 9, faster running-in can be observed for WP-EP-2. At the same time, up to

NL = 2.5 × 10

5, both WP-1 and WP-EP-1 had a period of decreasing efficiency, indicating a prolonged running-in process until the steady-state running was reached at approximately

NL = 4 × 10

5. Higher wear was evident in both WP-EP-1 and WP-EP-2 compared to WP-1.

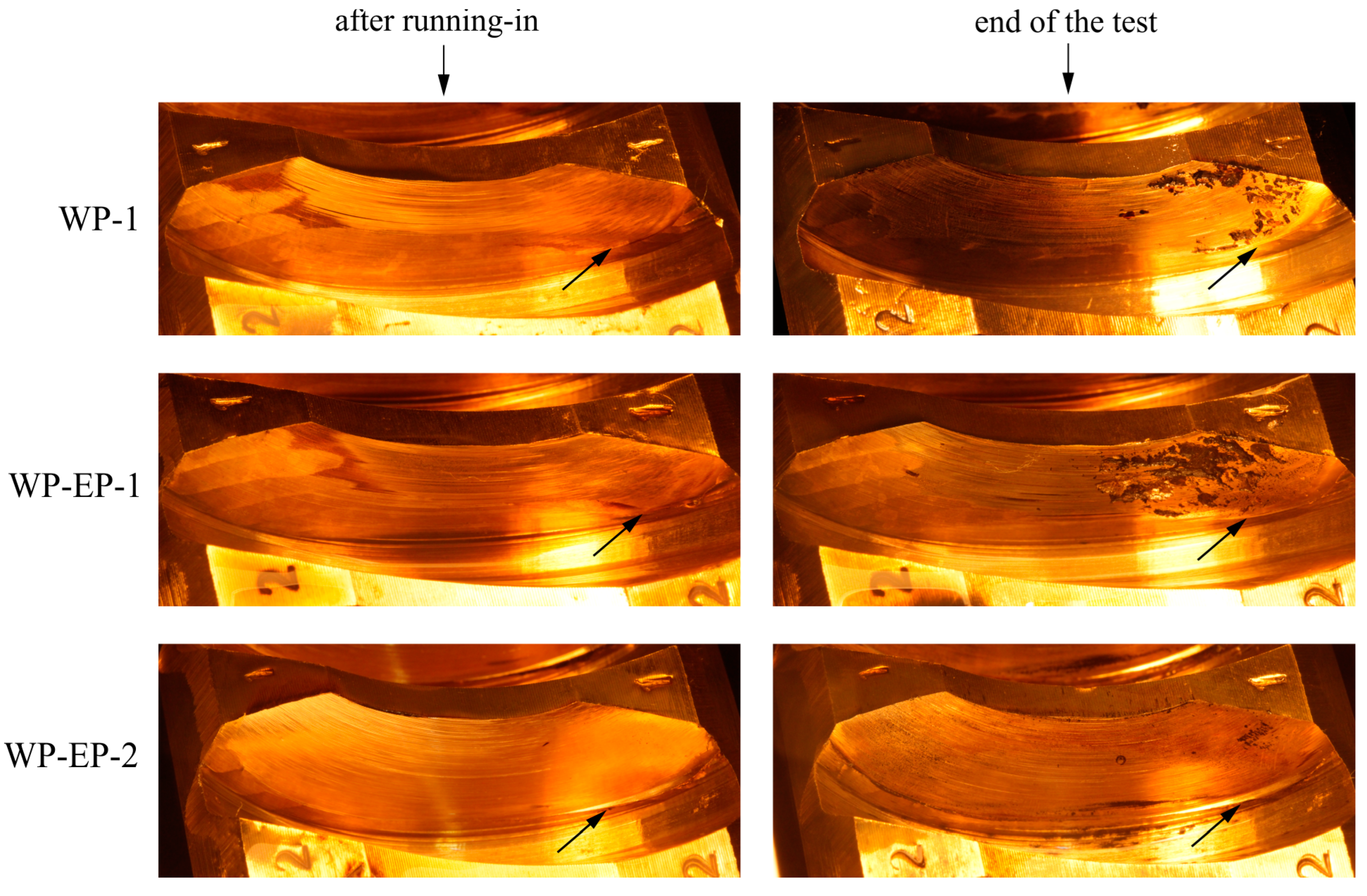

A visual representation of worm wheel wear after running-in and at the end of the test is given in

Figure 12. By inspecting the lower right section of the worm wheel tooth flank, the ridge on the WP-EP-2 worm wheel is considerably larger compared to the other two worm wheels. Generally, the difference in wear between “after running-in” and “end-of-test” figures is negligible. This observation suggests that, as anticipated, most wear occurred during the running-in phase due to the nature of wear in sliding contacts [

52]. The average tooth thicknesses of a worm wheel based on 36 measurements per worm wheel (

z2 = 36) are shown in

Table 10. Tooth thickness was measured at the middle of the flank on the worm wheel pitch diameter.

Based on the tooth thickness measurement, the worm wheel in WP-EP-2 experienced the most wear, which can be observed in

Figure 12. Larger wear during the running-in phase resulted in a larger initial contact pattern than worm wheels in WP-1 and WP-EP-1. Contact patterns can be recognized by abrasive grooves in the direction of sliding and matted surface appearance.

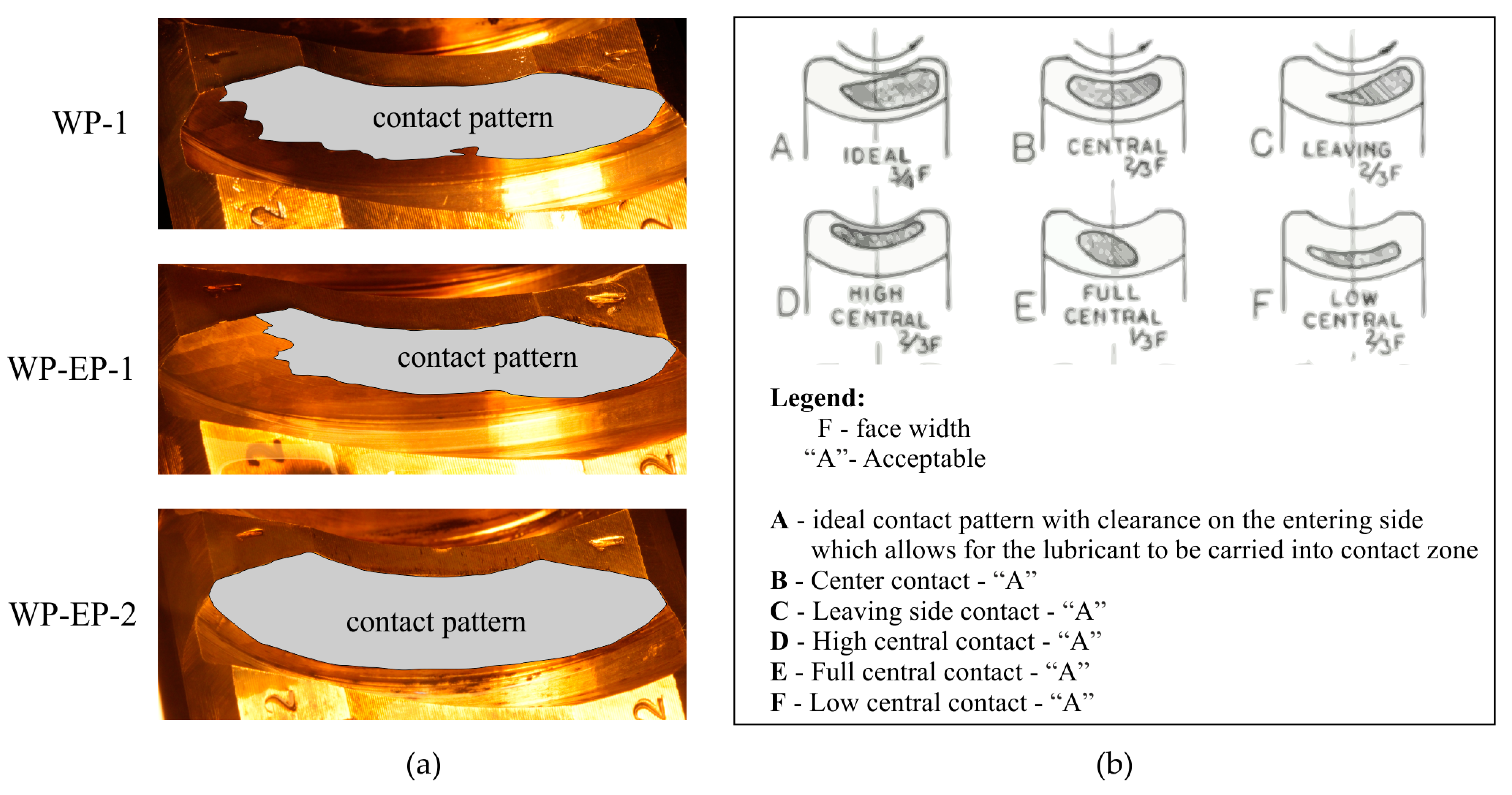

More clear representation of contact patterns can be found in

Figure 13. Contact pattern adjustment in worm gear pairs is usually carried out by axial alignment of the worm wheel shaft. Larger contact patterns contribute to more uniform contact stress distribution, which can affect the uniformity and thickness of oil film. This observation also explains the difference in pitting, as the worm wheel in WP-EP-1 experienced the most pitting while having the smallest contact pattern among tested worm pairs. The relationship between contact patterns, pitting, and worm pair efficiency is relatively complex. In the case of 16MnCr5-CuSn12 worm pairs, Huber [

53] concluded that neither larger contact patterns nor variation in load or pitting have an explicit or clear effect on the overall efficiency of worm gear pairs. In addition, pitting can provide additional lubrication in the contact zone as pits can act as oil reservoirs, resulting in pitted worm wheels having a similar efficiency rating to non-pitted ones [

13,

54].

As per

Figure 13, the contact pattern established in WP-EP-2 can be considered a full contact pattern. In general, a full contact pattern in worm pairs is avoided as it limits the oil from entering the contact zone, promoting the onset of scuffing and, consequently, worm gear pair failure [

55]. Instead, incomplete but acceptable contact patterns primarily positioned on the leaving side of the worm wheel tooth flank are frequently present (

Figure 13). Although the full contact pattern was established in WP-EP-2, no problems with scuffing occurred. Moreover, the highest overall efficiency and lowest pitting were recorded for WP-EP-2. This finding suggests that electropolishing modifies the worm surface to provide improved or additional lubrication that can consistently and reliably support full contact patterns in worm gear pairs.

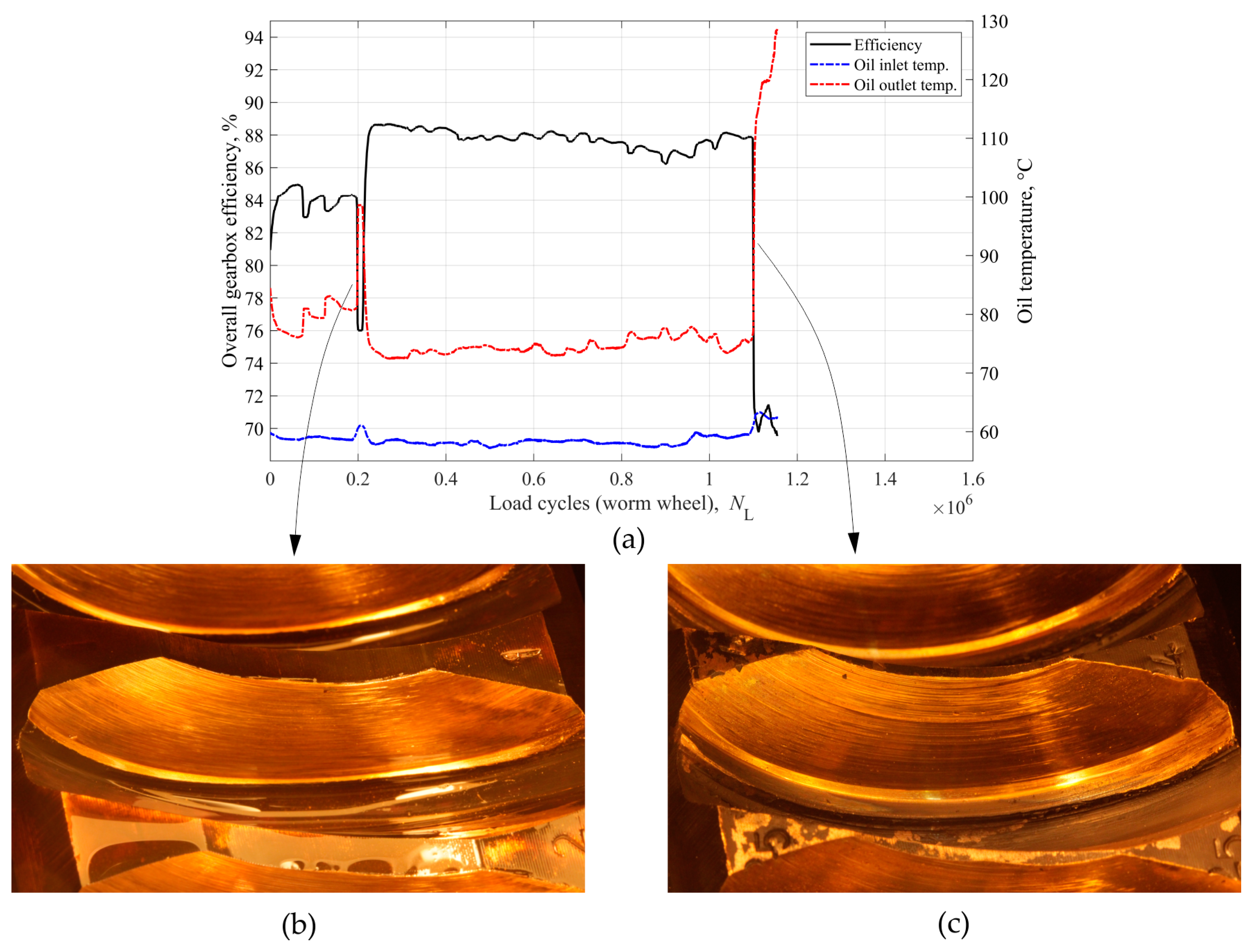

An additional test run was carried out to study the behaviour of conventional worm gear pair WP-2 under a full contact pattern. The results are presented in

Figure 14. The test run ended prematurely due to two periods of intense scuffing. In worm gear pairs, scuffing occurs primarily as a consequence of improper lubricating conditions. Due to the dominant sliding motion in the mesh, the oil is constantly scrapped off from contacting surfaces. Therefore, an adequate amount of constant oil supply is necessary for worm gear pairs to function properly. When a full contact pattern is established, the contact spans across the whole worm wheel tooth flank surface, starting from entering and spreading towards the leaving side of the flank. If a contact is established on the entering side of the worm wheel tooth flank, the oil cannot properly supply the contact zone and the temperature in the contact zone will rise significantly. The rise in contact temperatures in turn reduces the oil viscosity, oil film thickness, and desorption of the lubricant from the surface. The sudden increase in heat in the contact zone leads to the micro-welding of asperities in contact. Finally, as surfaces leave the contact, the welded material is torn apart, promoting the adhesive wear of contacting surfaces.

In the example of WP-2, the first scuffing period was noticed at

NL = 2 × 10

5, while the second was observed at

NL = 1.1 × 10

6, causing worm pair failure. The overall efficiency was relatively high between the two scuffing periods, accompanied by high sliding wear. The high wear rate prevented pitting formation as the material was constantly removed from the worm wheel tooth flank. The high wear rate also sharply decreased worm wheel tooth thickness (

Figure 14b). By the end of the test, worm wheel teeth were completely worn out and pointed (

Figure 14c). Scuffing periods were characterized by low efficiency and a high rise in oil outlet temperature. The oil outlet temperature was approximately 74 °C in other tested worm pairs. In contrast, during two periods of severe scuffing observed in WP-2, the oil temperature was 81 °C during the first period and almost 130 °C before the test was aborted. These findings indicate that the operation of conventional worm gear pairs with an established full contact pattern is not sustainable as improper lubrication conditions can lead to the breakdown of lubrication and scuffing.

While this research focused primarily on the feasibility of surface texturing in worm gear pairs, the question of how different surface texture parameters influence the tribological behaviour of worm gear pairs remains open. Various surface textures can be produced and investigated by varying electropolishing conditions regarding overall efficiency rating and wear behaviour. The main difference and disadvantage of surface texture produced by electropolishing is its stochastic nature and inability to control the pit/dimple geometry and structure. On the other hand, electropolishing is a relatively simple, fast, and affordable process compared to other common surface texturing methods (e.g., laser surface texturing, chemical etching), especially when application on complex geometry is considered. Therefore, comparing different textures produced by electropolishing to optimize surface texture parameters for highly loaded non-conformal contacts as found in gears will be of future interest.

Furthermore, as steel worms experience little wear, there is a possibility to apply two-step electropolishing to “recycle” steel worms. Firstly, conventional electropolishing can be used to remove wear marks and then, in the second step, electropolishing with altered parameters can be employed to produce surface texture. In this way, the need for producing new worms is reduced. A potential disadvantage of this approach is the degraded dimensional accuracy of such worms as electropolishing removes surface material, leading to increased clearance and backlash in worm gear pairs. Nonetheless, this proposed approach remains open for future investigations.