Study on the Effects of CeO2 on the Micro-Structure and Wear Resistance of CuCrZr Plasma Cladding Coatings

Abstract

:1. Introduction

2. Materials and Methods

2.1. Coating Preparation

2.2. Characterization and Testing Methods

3. Results and Discussion

3.1. XRD Phase Analysis

3.2. Microstructure and Element Distribution of Coatings

3.3. Mechanical Properties of Coating

3.4. Coating Friction and Wear

4. Conclusions

- (1)

- The microstructure of CuCrZr-CeO2 coating transitions from columnar to equiaxial with increasing CeO2 content, leading to gradual homogenization. This transformation occurs due to the ability of CeO2 particles to nucleate at grain boundaries in CuCrZr, reinforcing their strength and inhibiting grain growth.

- (2)

- With increasing CeO2 content, the hardness of CuCrZr-CeO2 coating initially increased and then decreased. The optimal hardness of CuCrZr-CeO2 coating reached 75.3 when the CeO2 content was 0.15%, representing a 5.31% increase. CeO2 is a ceramic material known for its high hardness and excellent wear resistance, attributed to its stable lattice structure. The addition of CeO2 effectively enhances the overall hardness of the CuCrZr matrix by forming a strong bond with the metal matrix. Furthermore, the appropriate CeO2 content can impede dislocation movement, thereby enhancing material strengthening. This optimization of fine structure contributes to improving the hardness and strength of the coating.

- (3)

- The addition of CeO2 resulted in a reduction of approximately 18.7% in the friction coefficient of the coating containing 0.15% CeO2 under a 10 N load, as compared to the coating without CeO2. Experimental evidence supports the notion that the inclusion of CeO2 is beneficial in decreasing the friction coefficient. The wear mechanism observed is a combination of adhesive and abrasive wear.

- (4)

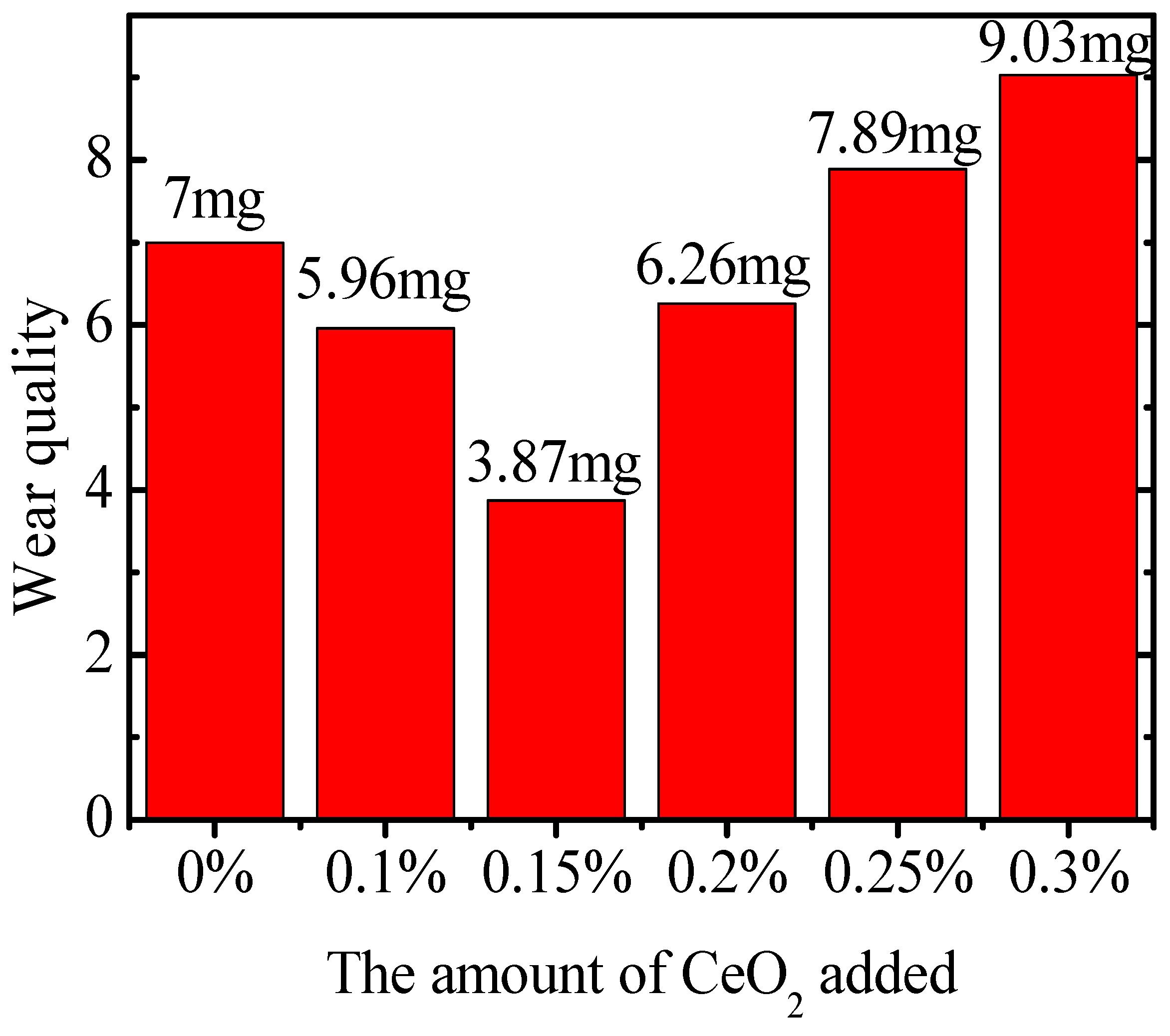

- With the rise in CeO2 supplementation, the coating wear initially decreased before increasing, leading to enhancements in coating hardness and wear resistance. At a CeO2 supplementation level of 0.15%, wear decreased from 7.00 mg to 3.87 mg, marking a reduction of 3.13 mg, which is a 44.7% decrease compared to CuCrZr coating without CeO2 supplementation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xiang, H.J.; Qiao, Z.M.; Lv, Q.A. Principle and Technology of Electromagnetic Railgun; Beijing Institute of Technology Press: Beijing, China, 2022. [Google Scholar]

- Lu, J.Y.; MA, W.M. Electromagnetic Orbital Launch Theory and Technology; Science Press: Beijing, China, 2020. [Google Scholar]

- Du, X.Y.; Liu, S.W.; Guan, J. Design and Performance Analysis of an Electromagnetic Railgun. J. Phys. Conf. Ser. 2022, 2378, 012008. [Google Scholar] [CrossRef]

- Liu, Z.Y. Preparation of Conductive Antifriction Coating for Electromagnetic Gun Armature and Study on Current-Carrying Friction Properties; Xiangtan University: Xiangtan, China, 2022. [Google Scholar]

- Lv, Q.A.; Xiang, H.J.; Lei, B.; Zhang, Q.; Zhao, K.Y.; Li, Z.Y. Physical Principle and Relevant Restraining Methods About Velocity Skin Effect. IEEE Trans. Plasma Sci. 2015, 43, 1523–1530. [Google Scholar]

- Lian, G.F.; Que, L.Z.; Cao, Q. Effect of CeO2 content on microstructure and properties of laser cladding Ni45A+TiC composite coating. Surf. Technol. 2019, 52, 448–456. [Google Scholar]

- Li, S.; Liu, D.F.; Liu, G.; Xin, S.W.; Deng, Z.; Li, C.; Chen, T. Study on the preparation of CeO2-doped AlCoCrFeNiTi high entropy alloy bioinert coatings by laser cladding: The effect of CeO2 particle size on the tribological properties of the coatings. Surf. Coat. Technol. 2023, 475, 130155. [Google Scholar] [CrossRef]

- Wang, X.; Yao, P.; Zhou, H.; Fan, K.; Deng, M.; Kang, L.; Yuan, Z.; Lin, Y. Research Progress on Surface Damage and Protection Strategies of Armature–Rail Friction Pair Materials for Electromagnetic Rail Launch. Materials 2024, 17, 277. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Shi, W.; Lin, Y.; Jiang, L.; Wang, L.; He, K. Effect of CeO2 Content on Microstructure and Wear Resistance of Laser-Cladded Ni-Based Composite Coating. Lubricants 2024, 12, 227. [Google Scholar] [CrossRef]

- Le, T.T.; Venugopal, I.P.; Truong, T.H.; Cao, D.N.; Le, H.C.; Nguyen, X.P. Effects of CeO2 nanoparticles on engine features, tribology behaviors, and environment. Energy Sources Part A Recovery Util. Environ. Eff. 2023, 45, 8791–8822. [Google Scholar]

- Prakash, S.D.; Shubham, S. Effect of CeO2–Ni addition on the behavior of AZ91-A356 based composite fabricated by friction solid state technique. Mater. Chem. Phys. 2024, 311, 128551. [Google Scholar]

- Ma, G.F.; Li, Z.P.; Zhao, X.R.; Wang, Z. Microstructure and corrosion-resisting properties of CeO2-SiO2-Al2O3 composite coatings prepared by plasma electrolytic oxidation on aluminum matrix composites. J. Alloys Compd. 2024, 1008, 176673. [Google Scholar] [CrossRef]

- Safari, A.; Mozammel, M.; Emarati, S.M.; Khalil-Allafi, J. Fabrication of a durable corrosion-resistant superamphiphobic CeO2–TiO2 ceramic nanocomposite coating on AZ31B Mg alloy by plasma electrolyte oxidation. Ceram. Int. 2024, 50, 34657–34669. [Google Scholar] [CrossRef]

- Hu, R.; Wang, R.D.; Zhang, J.; Zhang, C.; Zhang, Y.; Li, G.; Lu, X.; Yang, Y.; Liu, Q. An in-situ synthesised TiC/Ni60A composite coating on copper by plasma cladding. Mater. Sci. Technol. 2023, 39, 729–735. [Google Scholar] [CrossRef]

- Peng, Y.; Zhang, W.; Li, T.; Zhang, M.; Liu, B.; Liu, Y.; Wang, L.; Hu, S. Effect of WC content on microstructures and mechanical properties of FeCoCrNi high-entropy alloy/WC composite coatings by plasma cladding. Surf. Coat. Technol. 2020, 38, 125326. [Google Scholar] [CrossRef]

- Cao, L.; Xia, Y.; Cui, H.; Li, Q.; Zhu, B.; Wang, Q. Microstructural characteristics of TiB2–TiC–NiAl composite coatings via Plasma Cladding Process. Surf. Eng. 2019, 35, 997–1002. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, R.; Hu, R.; Zhang, Y.; Wu, W.; Lu, X. Layer-by-layer analysis: Tribological behaviour of Ni60A coating on copper substrate prepared by plasma cladding. Mater. Sci. Technol. 2022, 17, 1467–1473. [Google Scholar] [CrossRef]

- Wei, S.Y.; Wang, C.M.; Peng, W.Y.; Luo, R.K.; Chen, Y.; Wan, Z.Z.; Jin, Y. Effects of process parameters and annealing on microstructure and properties of CoCrFeMnNi high-entropy alloy coating prepared by plasma cladding. China Foundry 2023, 6, 491–502. [Google Scholar] [CrossRef]

- Huang, Y.; Dong, S.; Lü, K.; Li, G.; Jiang, J.; Deng, L.; Chen, W.; Cao, X. Effects of CeO2 doping on the mechanical, infrared radiative, and thermophysical properties of Pr2Zr2O7 ceramics for potential thermal protective coatings. Ceram. Int. 2024, 50, 48862–48868. [Google Scholar] [CrossRef]

- Yang, C.; Jing, C.N.; Fu, T.L.; Lin, T.; Guo, W.; Liu, N. Effect of CeO2 on the microstructure and properties of AlCoCrFeNi2.1 laser cladding coatings. J. Alloys Compd. 2024, 976, 2948. [Google Scholar] [CrossRef]

- Meng, J.B.; Wang, S.K.; Guan, Q.Y.; Dong, X.; Li, L.; Yu, H.; Li, H. Fabrication and performance of composite coating doped with CeO2 nanoparticles by plasma electrolytic oxidation on Cu–Zn alloy surface. J. Appl. Electrochem. 2023, 53, 2347–2357. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, S.L.; Zhao, L.; Yang, C.D.; Wu, L.P.; Guo, Y.; Ang, A.S.M. Corrosion Behavior of Plasma-Sprayed Al2O3-3%TiO2 Coatings Doped with CeO2. J. Therm. Spray Technol. 2022, 32, 290–305. [Google Scholar] [CrossRef]

- Zhang, H.; Zhuang, J.; Li, J. The Effect of Laser-Cladded Co6, T400, and Ni-Based 30WC Coatings on the Wear Resistance of H13 Steel. Coatings 2024, 14, 114. [Google Scholar] [CrossRef]

| Zr | Cr | Cu |

|---|---|---|

| 0.12% | 0.79% | Bal. |

| Zr | Cr | Cu |

|---|---|---|

| 0.1–0.25% | 0.7–0.8% | Bal. |

| Parameter | Value |

|---|---|

| Cladding mode | Hand cladding |

| Powder feeding method | Pneumatic powder feed |

| Protective gas type | High purity argon |

| Cladding current | Main arc current 143 |

| Ionic gas (L/min) | 2.5 |

| Shielding gas velocity (L/min) | 5 |

| Speed of powder gas delivery (L/min) | 2.8 |

| The quantity of powder dispensed (g/min) | 280 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Xiang, H.; Cao, G.; Qiao, Z.; Lv, Q.; Yuan, X.; Liang, C.; Wang, Q. Study on the Effects of CeO2 on the Micro-Structure and Wear Resistance of CuCrZr Plasma Cladding Coatings. Lubricants 2024, 12, 409. https://doi.org/10.3390/lubricants12120409

Wang Y, Xiang H, Cao G, Qiao Z, Lv Q, Yuan X, Liang C, Wang Q. Study on the Effects of CeO2 on the Micro-Structure and Wear Resistance of CuCrZr Plasma Cladding Coatings. Lubricants. 2024; 12(12):409. https://doi.org/10.3390/lubricants12120409

Chicago/Turabian StyleWang, Yang, Hongjun Xiang, Genrong Cao, Zhiming Qiao, Qing’ao Lv, Xichao Yuan, Chunyan Liang, and Qirui Wang. 2024. "Study on the Effects of CeO2 on the Micro-Structure and Wear Resistance of CuCrZr Plasma Cladding Coatings" Lubricants 12, no. 12: 409. https://doi.org/10.3390/lubricants12120409

APA StyleWang, Y., Xiang, H., Cao, G., Qiao, Z., Lv, Q., Yuan, X., Liang, C., & Wang, Q. (2024). Study on the Effects of CeO2 on the Micro-Structure and Wear Resistance of CuCrZr Plasma Cladding Coatings. Lubricants, 12(12), 409. https://doi.org/10.3390/lubricants12120409