Research on the Sealing Performance of Segmented Annular Seals Based on Fluid–Solid–Thermal Coupling Model

Abstract

1. Introduction

2. Numerical Model

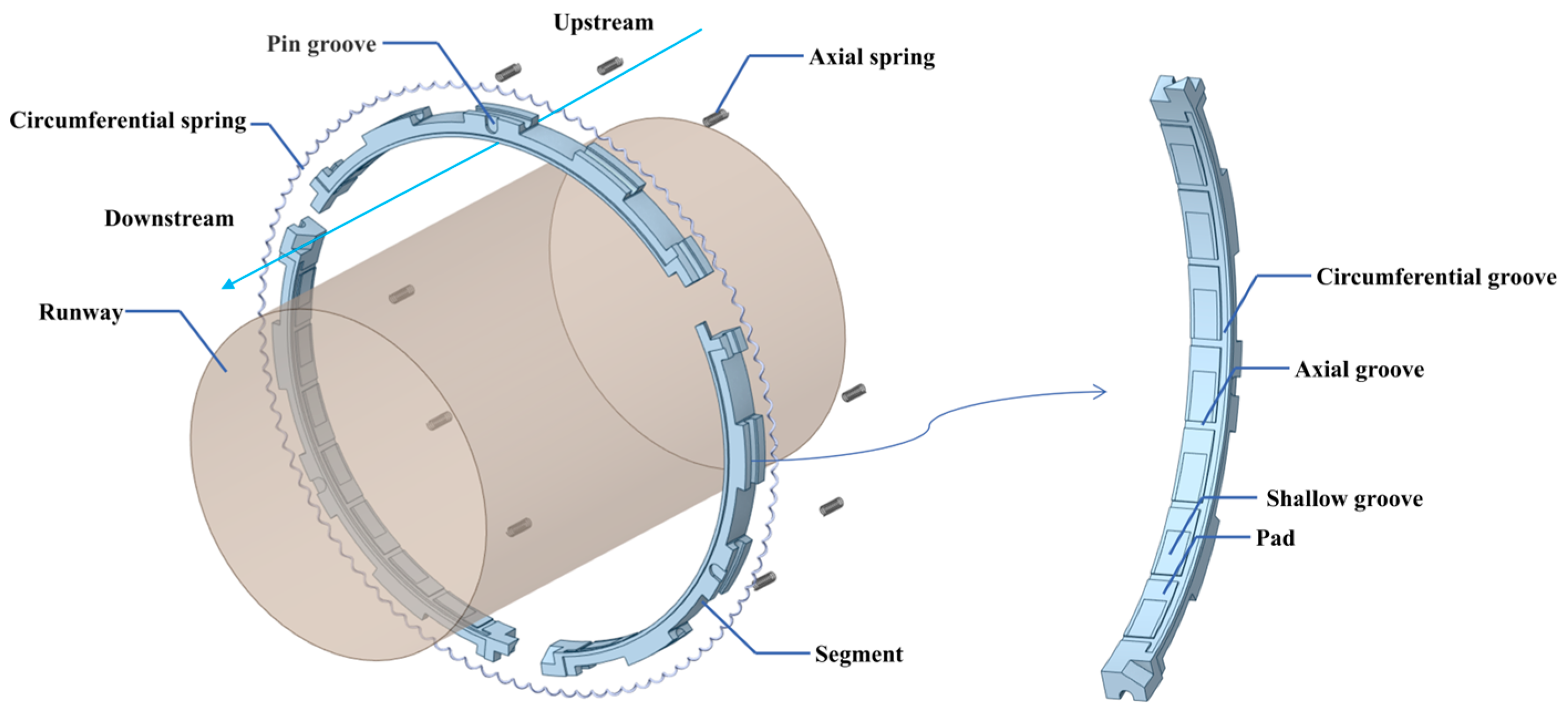

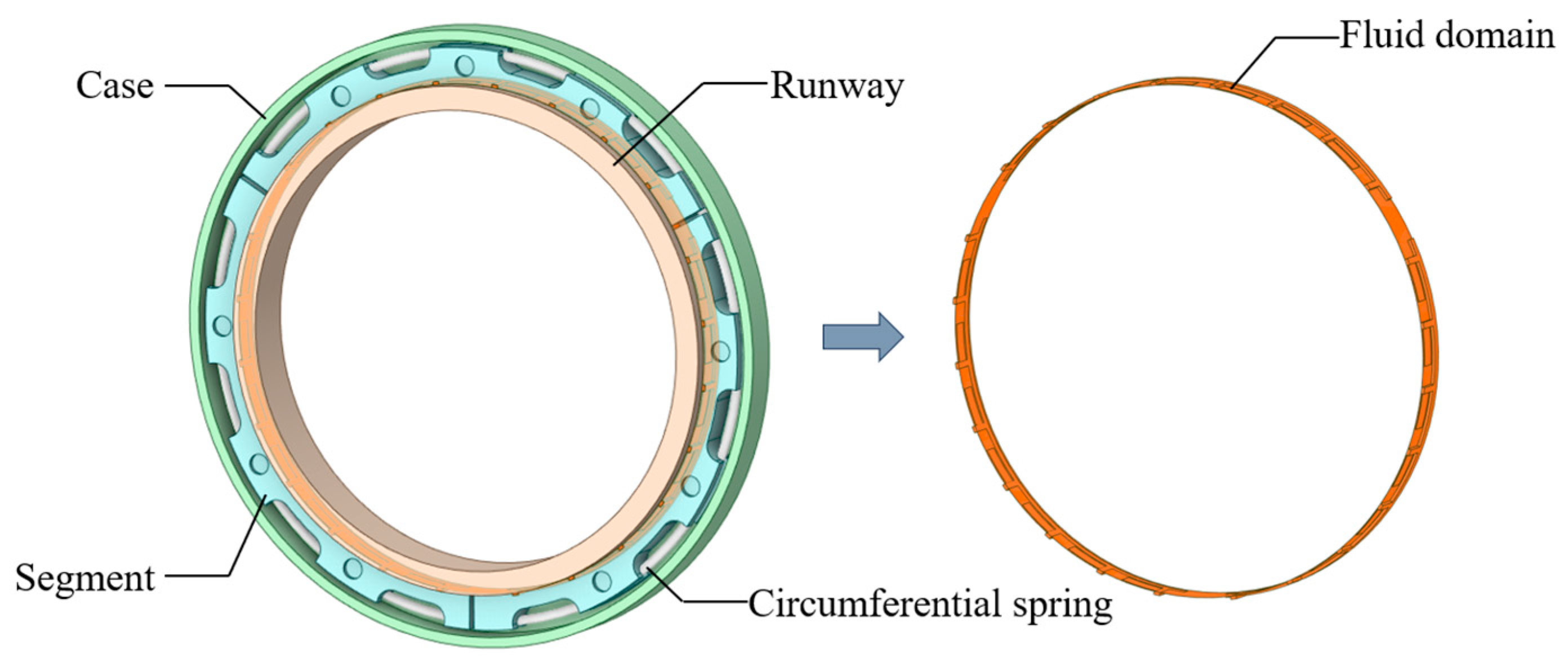

2.1. Working Principle

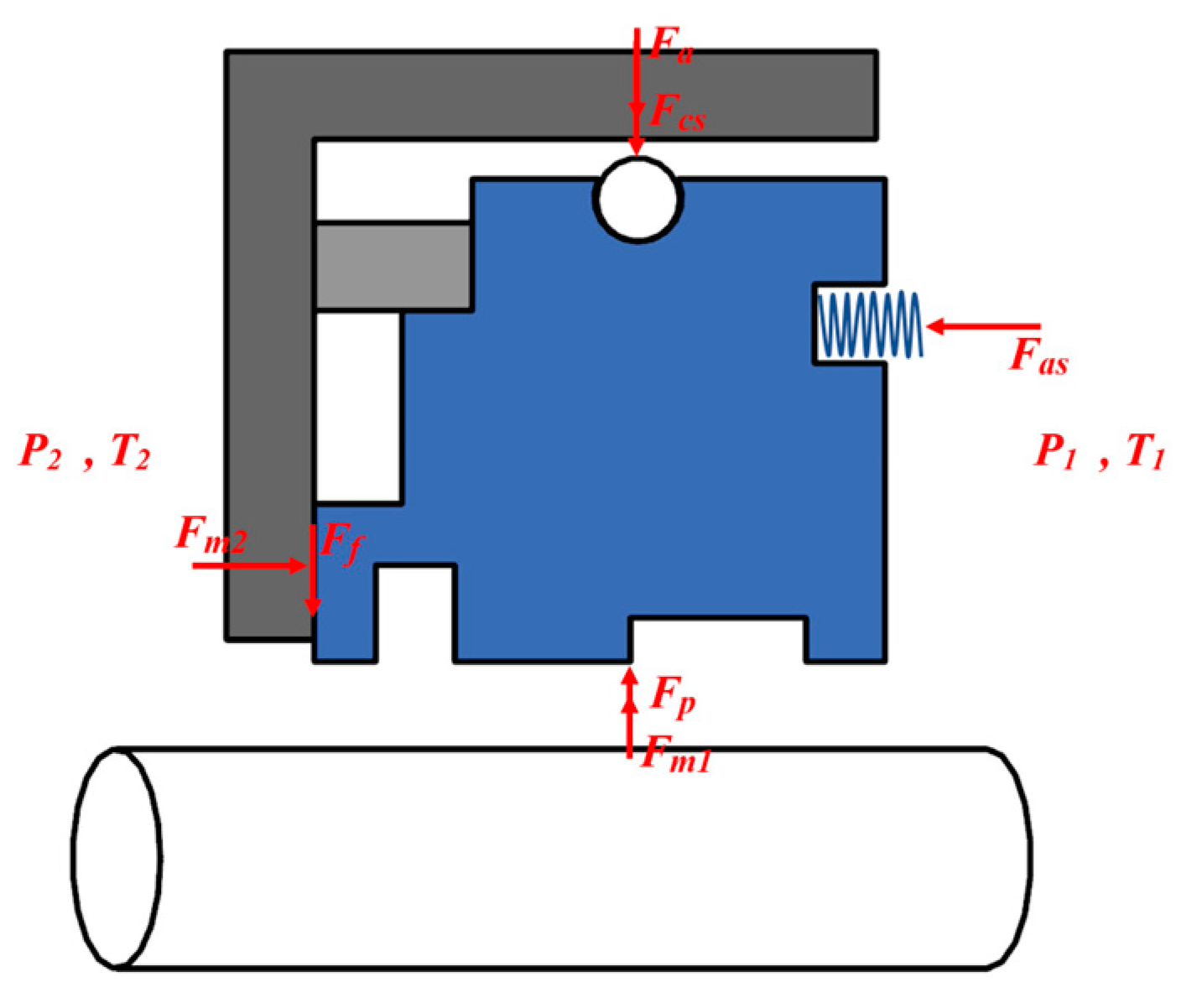

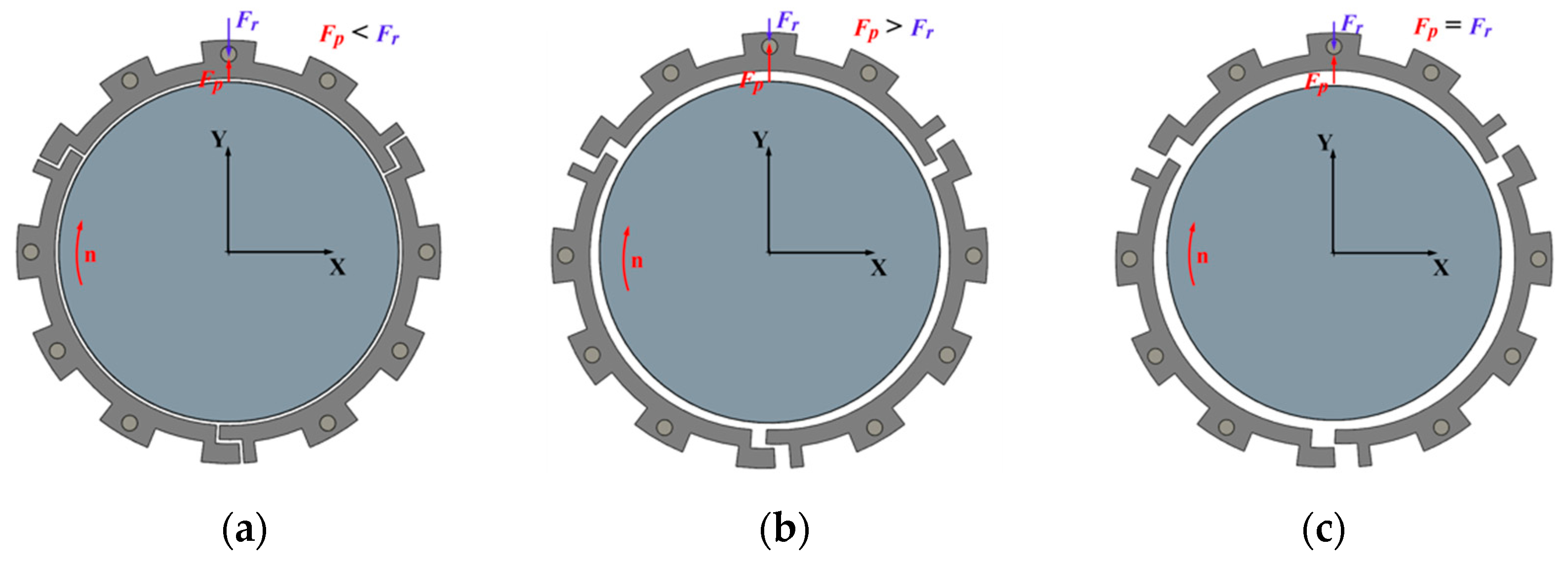

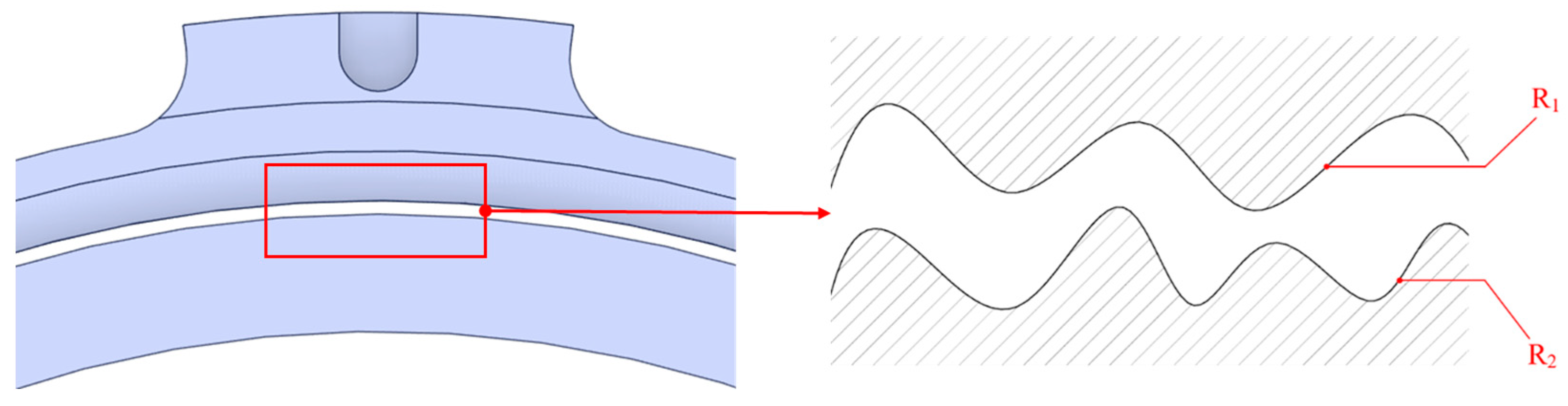

2.1.1. Theoretical Model

2.1.2. Force Analysis

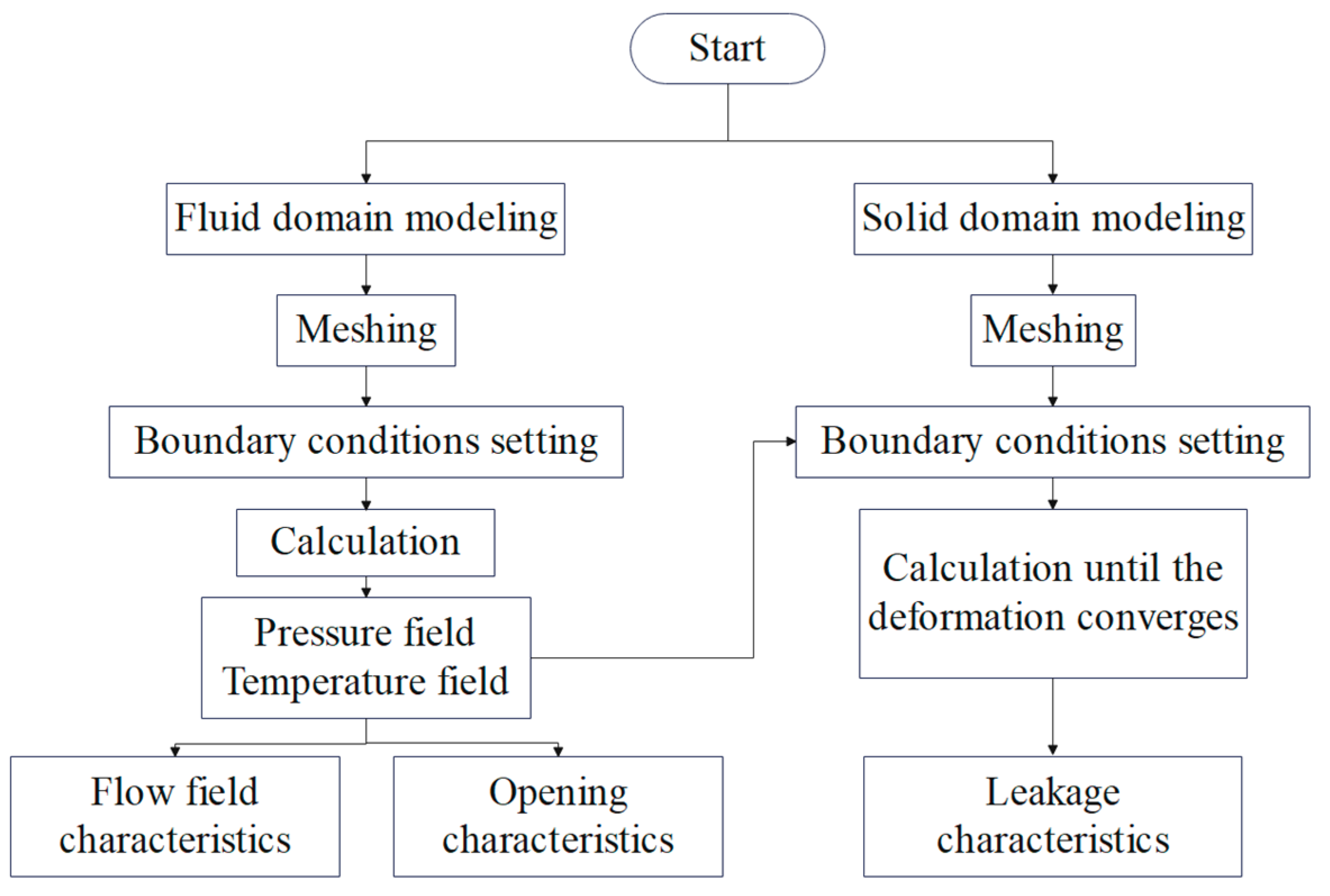

2.2. Method of Analysis

2.2.1. Method of Flow Field Characteristics Analysis

2.2.2. Method of Opening Characteristics Analysis

- Establish the fluid domain model according to contact gas film thickness;

- Calculate the opening resistance according to structural parameters, Equations (1) and (2);

- Set the opening rotation speed until the opening force is slightly larger than the opening resistance.

2.2.3. Method of Leakage Characteristics Analysis

2.2.4. Fluid–Solid–Thermal Coupling Calculation Flowchart for a Segmented Annular Seal

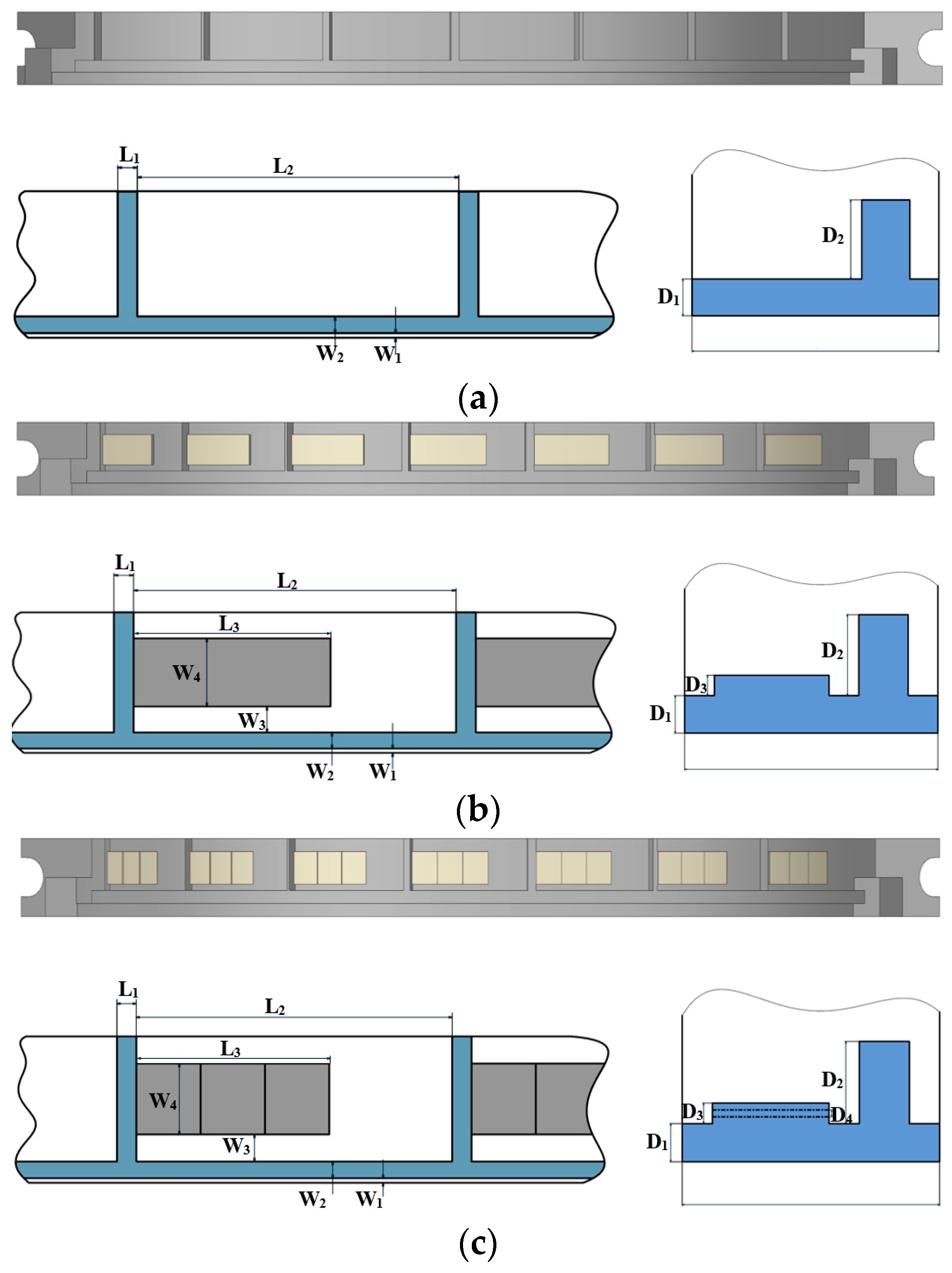

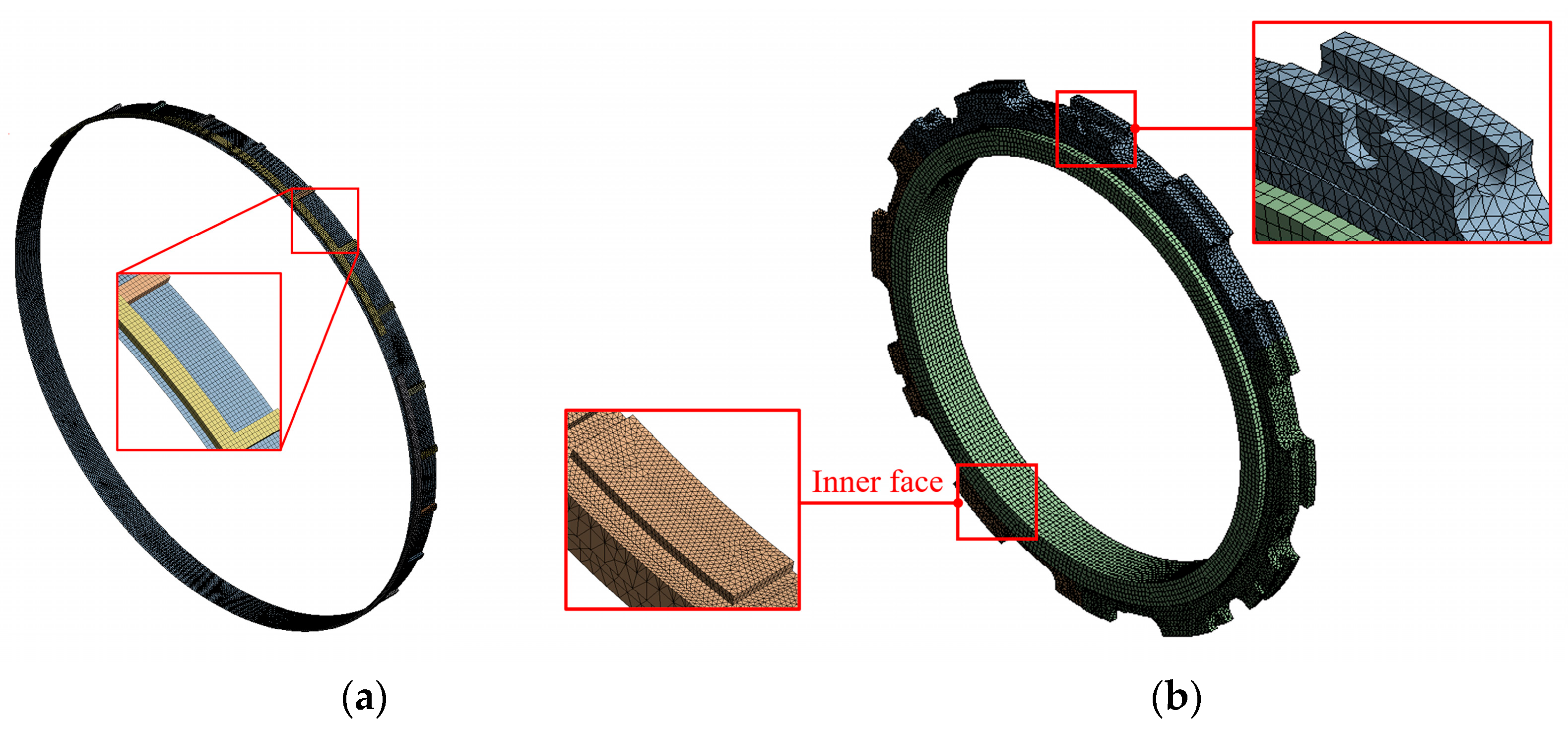

2.3. Calculation Model

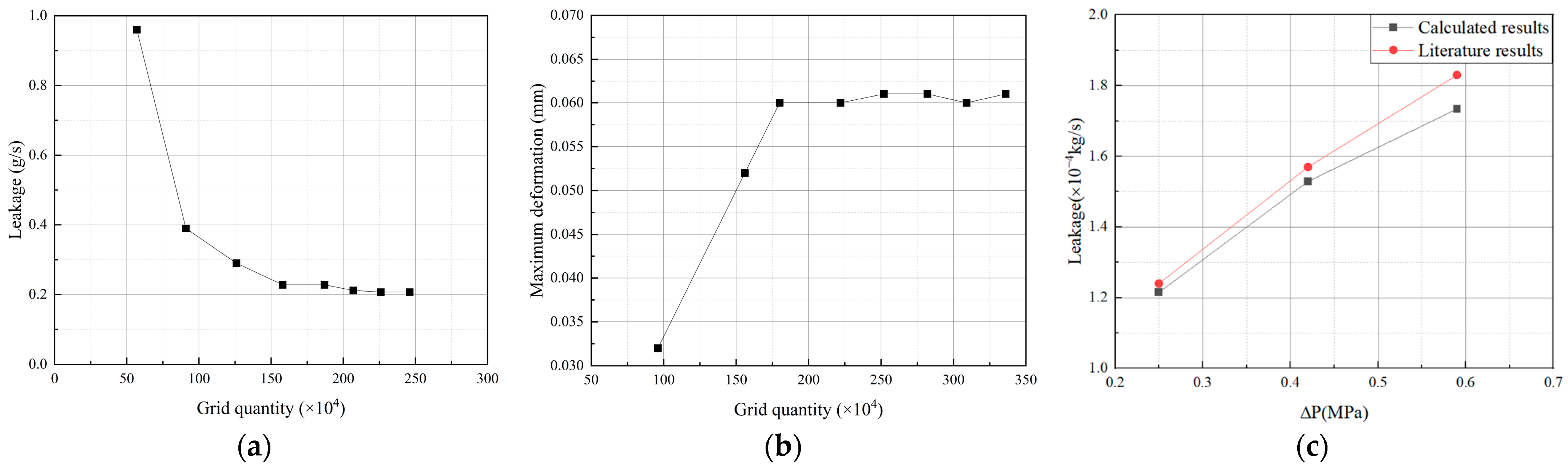

3. Grid Independence Verification and Model Verification

4. Results

4.1. Fluid Field Characteristics Analysis

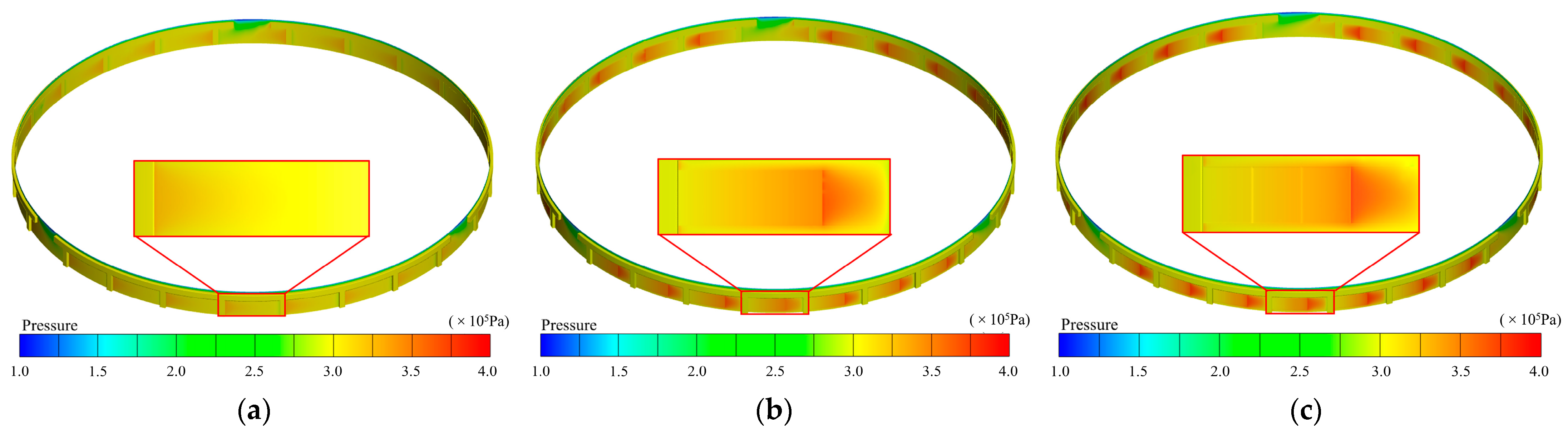

4.1.1. Pressure Distribution Cloud Analysis

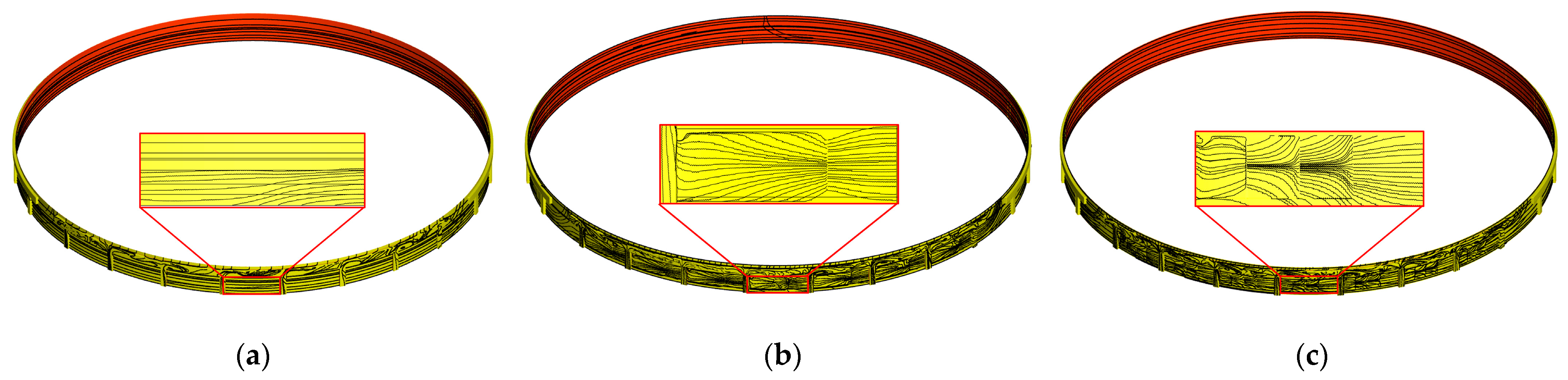

4.1.2. Velocity Distribution Cloud Analysis

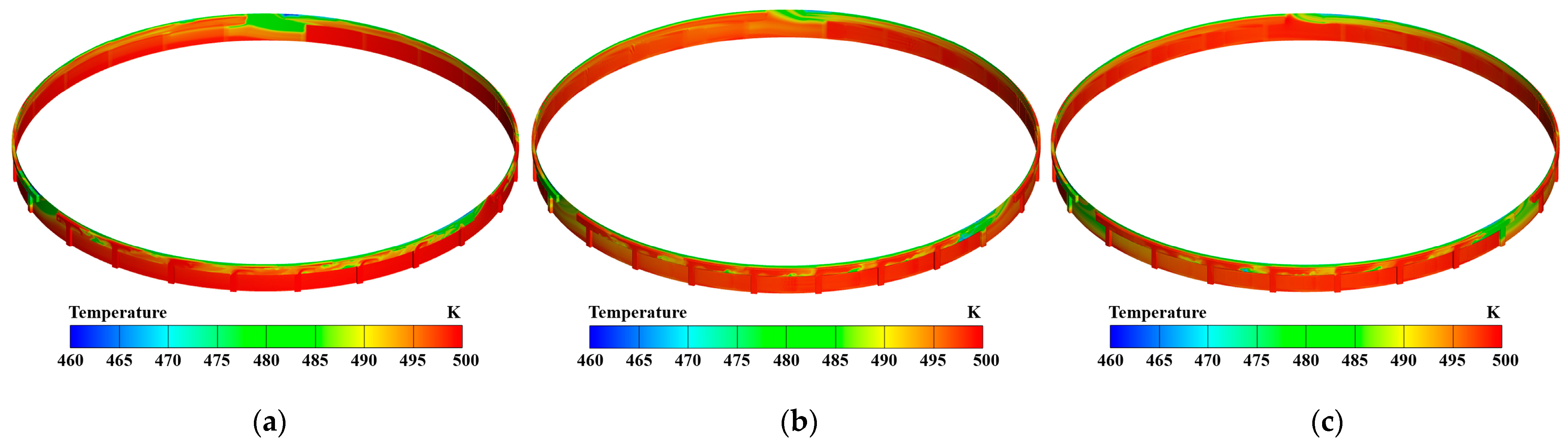

4.1.3. Temperature Distribution Cloud Analysis

4.2. Opening Characteristics Analysis

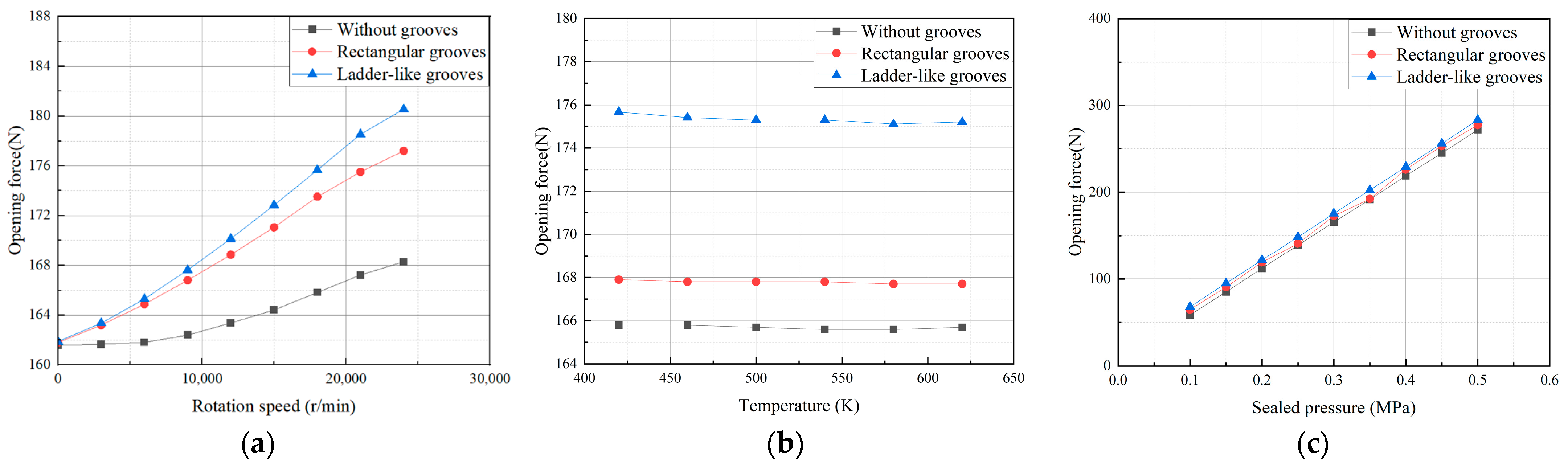

4.2.1. Effect of Operating Parameters on Opening Force

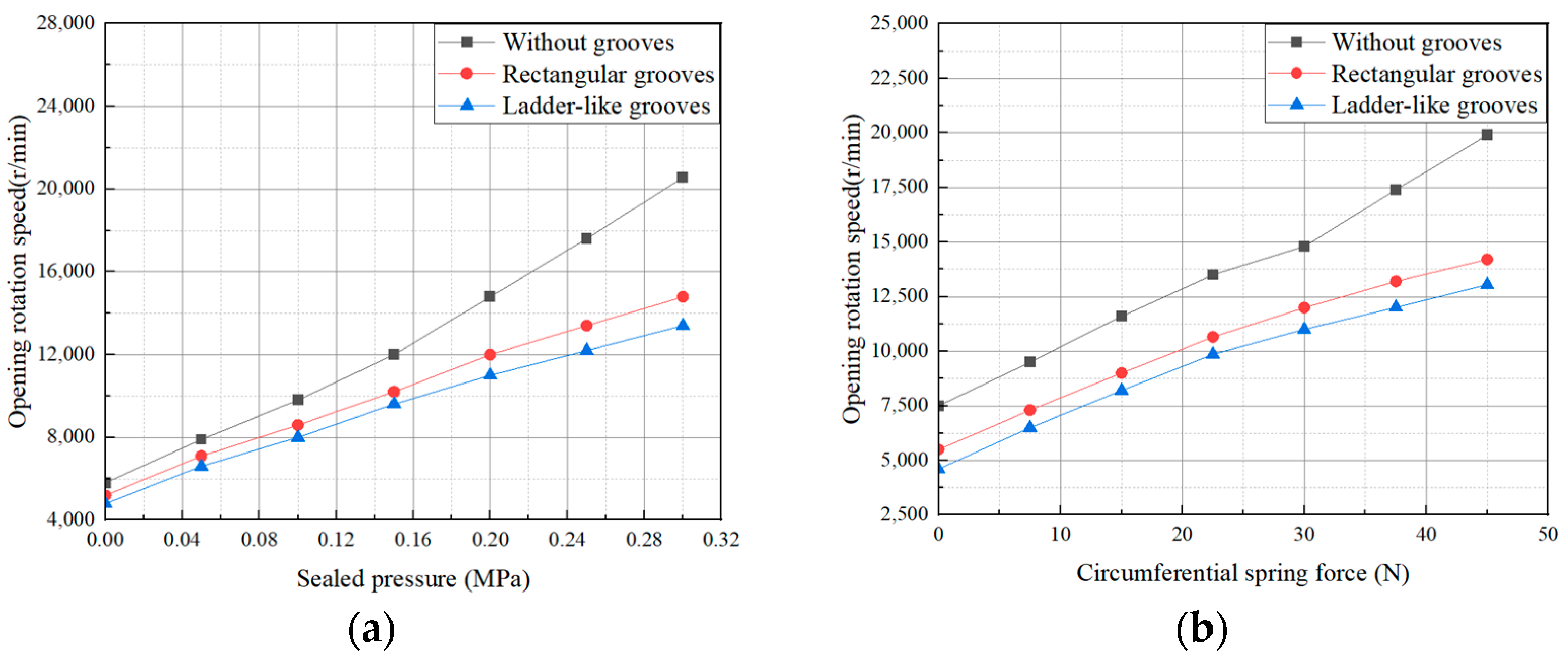

4.2.2. Effect of Sealed Pressure and Spring Force on Opening Rotation Speed

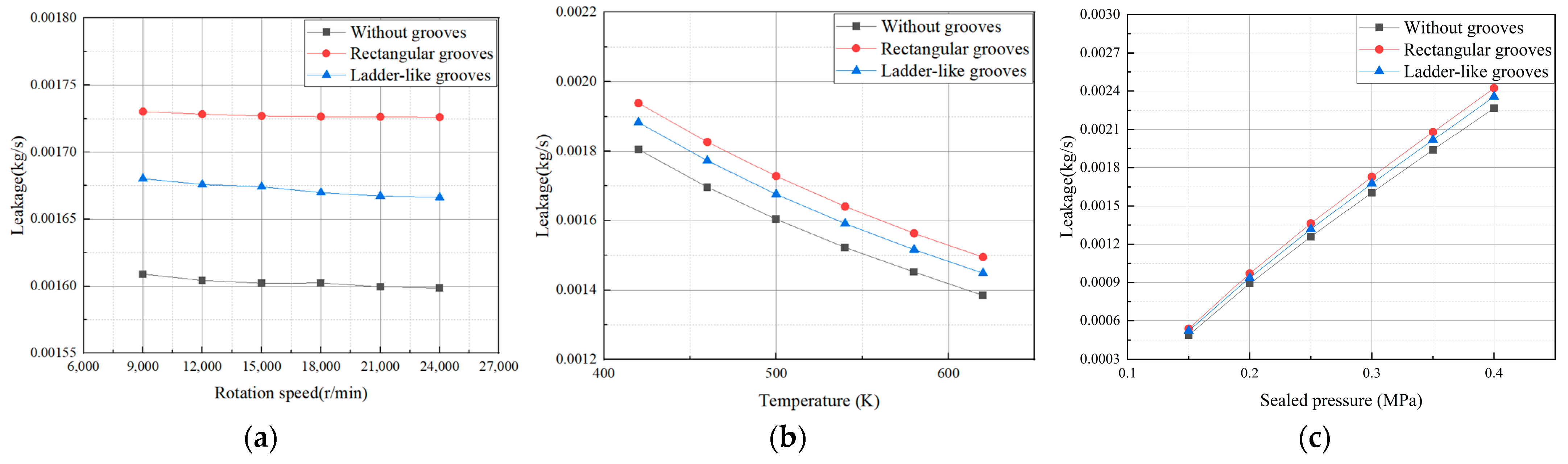

4.3. Leakage Characteristics Analysis

5. Conclusions

- (1)

- The setting of shallow grooves can effectively enhance the hydrodynamic effect by squeezing the fluid, and the enhancement effect of the ladder-like grooves is more significant than that of the rectangular grooves. However, the change in the groove type has little effect on the fluid temperature field.

- (2)

- For the seals with arbitrarily shaped shallow grooves in this paper, the sealed pressure has the most significant influence on the opening force of the seal; the greater the sealed pressure, the greater the opening force. The increase in rotational speed will also promote the opening force. However, the temperature has no obvious effect on the opening force.

- (3)

- Both the increase in the leakage pressure and the increase in the circumferential spring force will lead to an increase in the opening speed. Under the conditions of a high speed and a large spring force, the opening rotation speed of the seal without shallow grooves reaches around 20,000 r/min, which makes it difficult to open.

- (4)

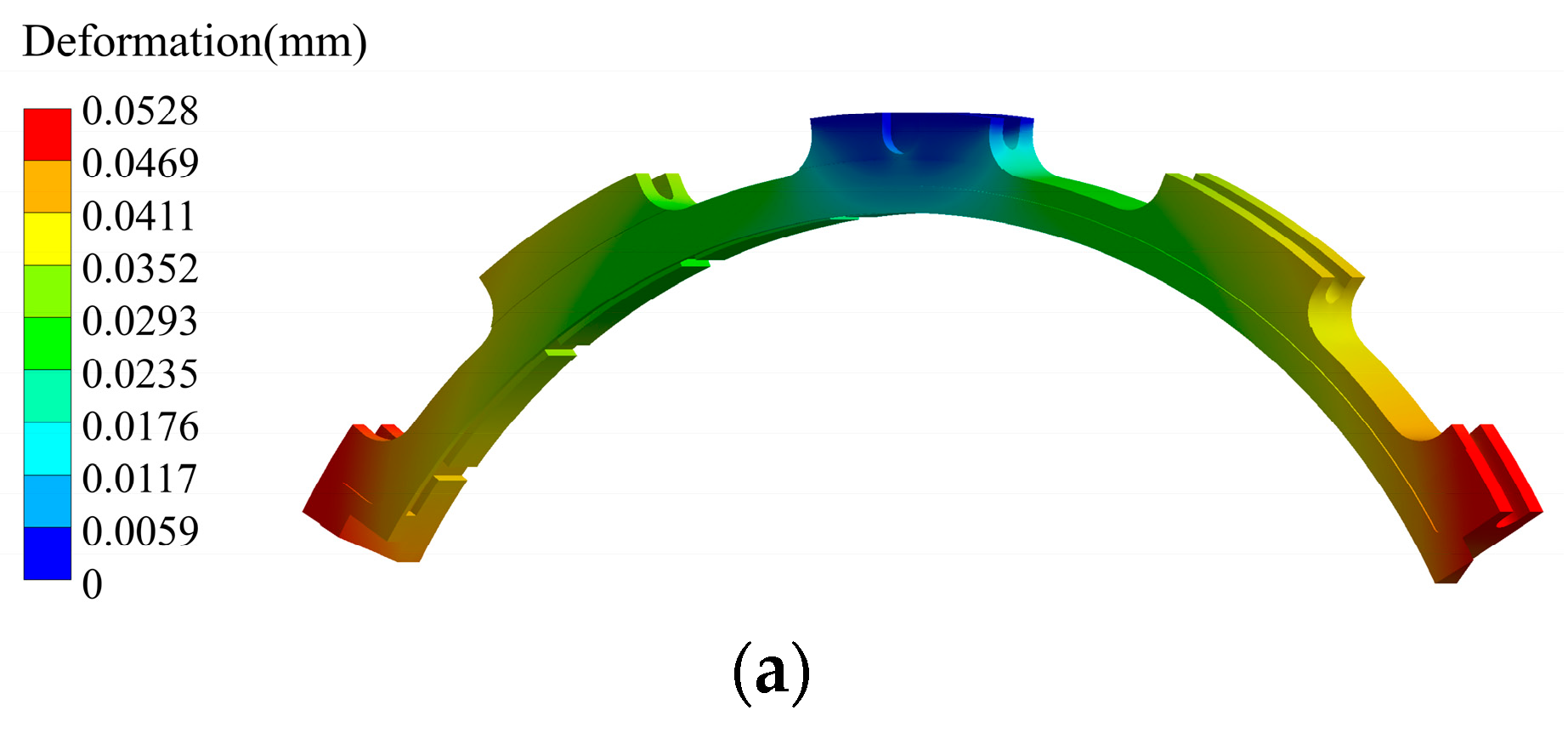

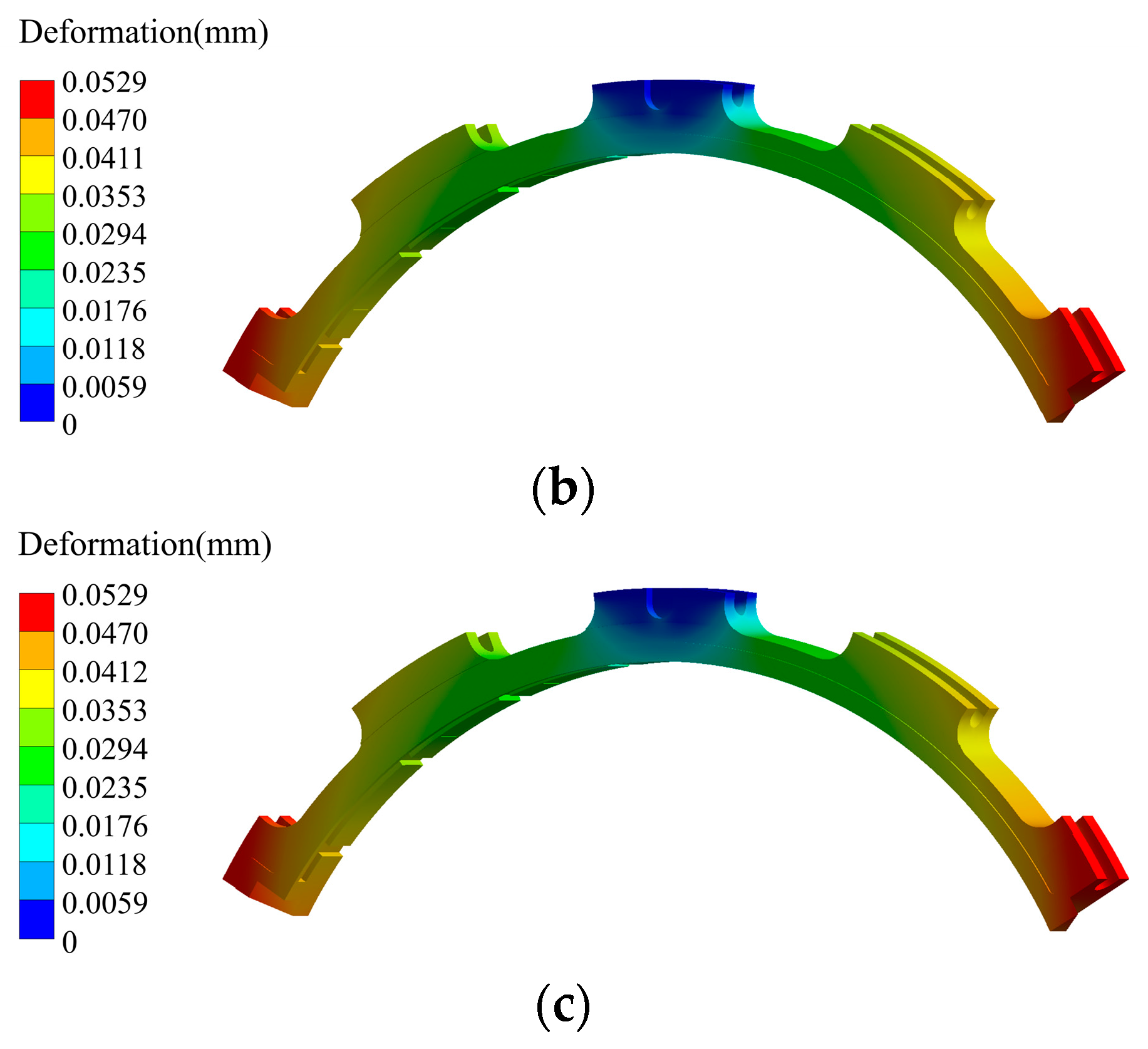

- The total deformation of the segment increases gradually from the middle to the lap joint, while the shallow groove design has little effect on the total deformation.

- (5)

- An increase in the sealed pressure will lead to an increase in the leakage. When the sealed pressure increases from 0.15 MPa to 0.4 MPa, the maximum increase in the leakage of the seal with specific groove design is 4.657 times that of the original. Nevertheless, the leakage decreases with the increase in temperature and rotation speed.

- (6)

- Among the seals with three groove structures, the seal with ladder-like grooves has the best opening performance and is easy to open and maintain a frictionless seal under high parameter conditions. Compared to the seal without shallow grooves, the leakage of the seal with ladder-like grooves has only a small increase.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mayhew, E.; Bill, R.; Voorhees, W. Military Engine Seal Development-Potential for Dual Use. In Proceedings of the 30th Joint Propulsion Conference and Exhibit, Indianapolis, IN, USA, 27–29 June 1994. [Google Scholar]

- Ellen, R.; Mayhew, E. Air Force Seal Activity USA: Aero Propulsion & Power Directorate Wright Laboratory; NASA: Washington, DC, USA, 1980. [Google Scholar]

- Sorokina, N.E.; Redchitz, A.V.; Ionov, S.G.; Avdeev, V.V. Different exfoliated graphite as a base of sealing materials. J. Phys. Chem. Solids 2006, 67, 1202–1204. [Google Scholar] [CrossRef]

- Song, Y.Z.; Zhai, G.T.; Song, J.R.; Li, G.S.; Shi, J.L. Seal and Wear Properties of Graphite from MCMBs/Pitch-Based Carbon/Phenolic-Based Carbon Composites. Carbon Int. J. Spons. Am. Carbon Soc. 2006, 44, 2793–2796. [Google Scholar] [CrossRef]

- Baklanova, N.I.; Zima, T.M.; Boronin, A.I.; Kosheev, S.V.; Titov, A.T.; Isaeva, N.V.; Graschenkov, D.V.; Solntsev, S.S. Protective ceramic multilayer coatings for carbon fibers. Surf. Coat. Technol. 2006, 201, 2313–2319. [Google Scholar] [CrossRef]

- Burcham, R.E. High-Speed Cryogenic Self-Acting ShaftSeals for Liquid Rocket Turbopumps; NASA-CR-168194; NASA: Washington, DC, USA, 1983. [Google Scholar]

- Oike, M.; Nagao, R. Characteristics of a Shaft Seal System for the LE-7 Liquid Oxygen Turbopump. In Proceedings of the 31st Joint Propulsion Conference and Exhibit, San Diego, CA, USA, 10–12 July 1995. [Google Scholar]

- Arghir, M.; Mariot, A. Theoretical Analysis of the Static Characteristics of the Carbon Segmented Seal. J. Tribol. Trans. Asme 2017, 139, 062202. [Google Scholar] [CrossRef]

- Yang, H.W.; Bai, S.X. Gas Hydrodynamic Lubrication Performance of Split Floating Ring Seals with Rayleigh Step Grooves. J. Propuls. Technol. 2022, 43, 87–94. [Google Scholar]

- Bai, S.X.; Chu, D.D.; Ma, C.H.; Yang, J.; Bao, S.Y. Thermo-Hydrodynamic Effect of Gas Split Floating Ring Seal with Rayleigh step Grooves. Materials 2023, 16, 2283. [Google Scholar] [CrossRef]

- Li, Q.Z.; Li, S.X.; Zheng, Y.; Ma, W.J.; Zhuang, S.G. Sensitive parameters affecting performance of three-petal high-speed floating-ring seal. J. Beijing Univ. Aeronaut. Astronaut. 2020, 46, 571–578. [Google Scholar]

- Wang, S.; Sun, D.; Yang, Z.; Xu, W.F.; Zhao, H.; Wen, S.F. Investigation of static and rotordynamic characteristics of the segmented annular seals based on the differential quadrature method. Tribol. Int. 2024, 196, 109657. [Google Scholar] [CrossRef]

- Dahite, S.; Arghir, M. Thermogasodynamic Analysis of the Segmented Annular Seal. J. Tribol. 2021, 143, 072301. [Google Scholar] [CrossRef]

- Yun, R.D.; Chen, Z.Y.; Liu, Y.; Zhang, J.Y. Effects of Circumferential Spring Force Distribution on Sealing Performance of Circumferential Seal. J. Propuls. Technol. 2021, 42, 1361–1371. [Google Scholar]

- Chen, Z.X.; Peng, X.D.; Zhao, W.J.; Jiang, J.B. Deformation Characteristics and Control Strategies of a Dynamic Segmented Circumferential Seal. J. Tribol. 2023, 43, 143–156. [Google Scholar]

- Ma, R.M.; Zhao, X.; Li, S.X.; Chen, X.Z.; Zhao, H.C. Seal characteristics and friction and wear of dynamic pressure split floating ring seal. J. Propuls. Technol. 2022, 43, 210099. [Google Scholar]

- Yan, Y.T.; Wei, R.; Hu, G.Y.; Wang, F.C.; Zhang, L.J. Circumferential Seal Characteristics with Thermal-Fluid-Structure Multi-physics Field Coupling. J. Aeroengine Power 2020, 35, 305–317. [Google Scholar]

- Arghir, M.; Dahite, S. Numerical Analysis of Lift Generation in a Radial Segmented Gas Seal. In Proceedings of the ASME Turbo Expo 2019: Turbomachinery Technical Conference and Exposition, Phoenix, AZ, USA, 17–21 June 2019. [Google Scholar]

- Dahite, S.; Arghir, M. Numerical modelling of a segmented annular seal with enhanced lift effects. Mech. Syst. Signal Process. 2021, 152, 107455. [Google Scholar] [CrossRef]

- Fourt, E.; Arghir, M. Experimental Analysis of the Leakage Characteristics of Three Types of Annular Segmented Seals. J. Eng. Gas Turbines Power 2023, 145, 91–105. [Google Scholar] [CrossRef]

- Fan, R.F.; Zhao, H.; Ren, G.Z.; He, Y.; Sun, D.; Wang, X.Y. Influence of rotor micro-texture on oil leakage flow characteristics of circular graphite seal. J. Aerosp. Power 2024, 40, 20240102. [Google Scholar]

- Ren, G.Z.; Li, Y.P.; Sun, D.; Zhao, H.; Wen, S.F.; Wang, X.Y. Numerical Study on Leakage Characteristics of Dynamic Pressure Split Floating Ring Seal with Fluid-solid-thermal Coupling. J. Aeroengine Power 2022, 37, 114–123. [Google Scholar]

- Zhang, Z.S.; Cui, G.X. Fluid Mechanics, 2nd ed.; Tsinghua University Press: Beijing, China, 2015; pp. 108–146. [Google Scholar]

- Hu, T.X.; Zhou, K.; Wang, X.Y.; Ning, L.; Zou, H.Y. Numerical calculation and experiment on leakage characteristics of floating ring seal. J. Aerosp. Power 2020, 35, 888–896. [Google Scholar]

- Yakhot, V.; Orszag, S.A. Renormalization group analysis of turbulence: I basic theory. J. Sci. Comput. 1986, 1, 3–51. [Google Scholar] [CrossRef]

- Cai, Y. Research on Multi-Field Coupling and Sealing Performance of a Single Carbon-Graphite Circumferential Seal. Master’s Thesis, Sichuan University, Chengdu, China, 2021. [Google Scholar]

- Gulich, J.F. Centrifugal Pumps; Springer: New York, NY, USA, 2007. [Google Scholar]

- Peng, X.D.; Li, J.Y.; Sheng, S.E.; Yin, X.N.; Bai, S.X. Effect of surface roughness on performance prediction and geometric optimization of a spiral-groove face seal. Tribology 2007, 6, 567–572. [Google Scholar]

- Ren, H.; Li, F.C.; Du, L. Numerical calculation for the effect of FSI on marine propeller strength. J. Wuhan Univ. Technol. 2015, 39, 144–147. [Google Scholar]

- Zhou, H.N.; Li, G.Q.; Wang, C.F. Multi physical field coupling characteristics of high speed graphite seals. Lubr. Eng. 2024, 49, 49–59. [Google Scholar]

- Allen, G.P. Self-Acting Lift-Pad Geometry for Circumferential Seals-a Non-Contacting Concept; NASA-TP-1583C.1; NASA: Washington, DC, USA, 1980. [Google Scholar]

| Parameter | Value |

|---|---|

| Rotor diameter D/(mm) | 100 |

| Segmented number | 3 |

| Step number | 3 |

| Circumferential width of axial groove L1/(mm) | 1.265 |

| Circumferential width of pad L2/(mm) | 11.5 |

| Circumferential width of shallow groove L3/(mm) | 7.8 |

| Width of shallow groove W1/(mm) | 1.5 |

| Width of circumferential groove W2/(mm) | 1.5 |

| Width between circumferential groove and shallow groove, W3/(mm) | 0.55 |

| Width of shallow groove, W4/(mm) | 3 |

| Initial seal clearance D1/(μm) | 1.06, 3 |

| Depth of axial and circumferential groove, D2/(mm) | 0.6 |

| Depth of shallow groove, D3/(mm) | 0.03 |

| Material Properties | Carbon Graphite | Structural Steel |

|---|---|---|

| Density /(kg/m3) | 2100 | 7800 |

| Modulus of elasticity /(GPa) | 14 | 210 |

| Poisson’s ratio | 0.25 | 0.3 |

| Thermal conductivity /(W·m−1·K) | 434 | 900 |

| Coefficient of thermal expansion /(10−6 °C) | 6 | 11 |

| Parameter | Value |

|---|---|

| Rotating speed n/(r/min) | 0–2.4 × 105 |

| Inlet temperature T/(K) | 420–620 |

| Sealed pressure P0/(MPa) | 0.1–0.5 |

| Outlet pressure P1/(MPa) | 0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Z.; Jia, L.; Si, J.; Li, N.; Wang, H.; Li, B.; Guo, Y.; Zhao, S.; Luo, W. Research on the Sealing Performance of Segmented Annular Seals Based on Fluid–Solid–Thermal Coupling Model. Lubricants 2024, 12, 407. https://doi.org/10.3390/lubricants12120407

He Z, Jia L, Si J, Li N, Wang H, Li B, Guo Y, Zhao S, Luo W. Research on the Sealing Performance of Segmented Annular Seals Based on Fluid–Solid–Thermal Coupling Model. Lubricants. 2024; 12(12):407. https://doi.org/10.3390/lubricants12120407

Chicago/Turabian StyleHe, Zhenpeng, Lanhao Jia, Jiaxin Si, Ning Li, Hongyu Wang, Baichun Li, Yuhang Guo, Shijun Zhao, and Wendong Luo. 2024. "Research on the Sealing Performance of Segmented Annular Seals Based on Fluid–Solid–Thermal Coupling Model" Lubricants 12, no. 12: 407. https://doi.org/10.3390/lubricants12120407

APA StyleHe, Z., Jia, L., Si, J., Li, N., Wang, H., Li, B., Guo, Y., Zhao, S., & Luo, W. (2024). Research on the Sealing Performance of Segmented Annular Seals Based on Fluid–Solid–Thermal Coupling Model. Lubricants, 12(12), 407. https://doi.org/10.3390/lubricants12120407