Combining Artificial Neural Networks and Mathematical Models for Unbalance Estimation in a Rotating System under the Nonlinear Journal Bearing Approach

Abstract

1. Introduction

- Vibration Response Prediction: Utilization of coupled mathematical models to predict the vibration response of a rotor supported by nonlinear journal bearings.

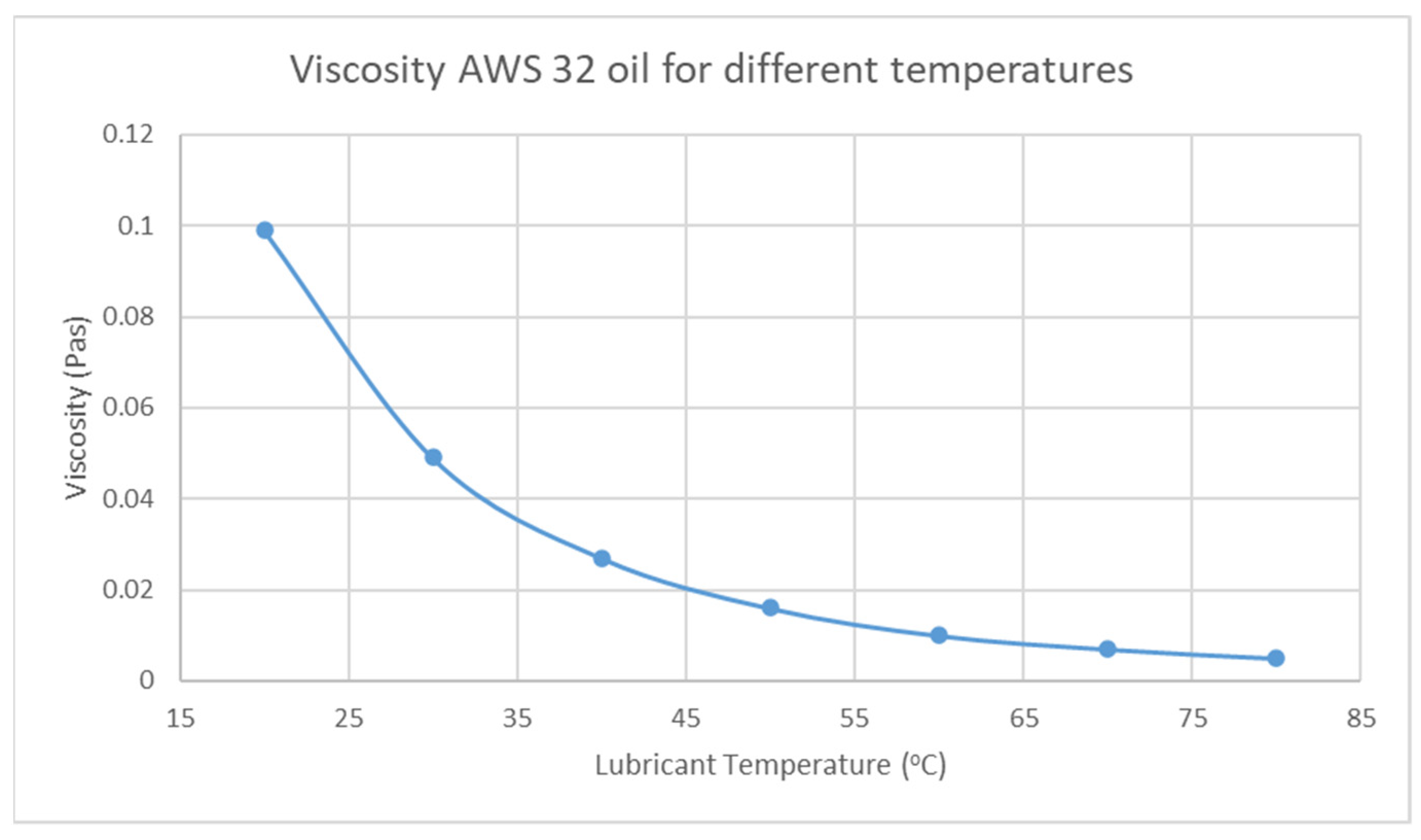

- Investigation of Critical Parameters: Investigation of the effect of essential factors, such as lubricant temperature and rotation speed, on the rotor’s vibration response.

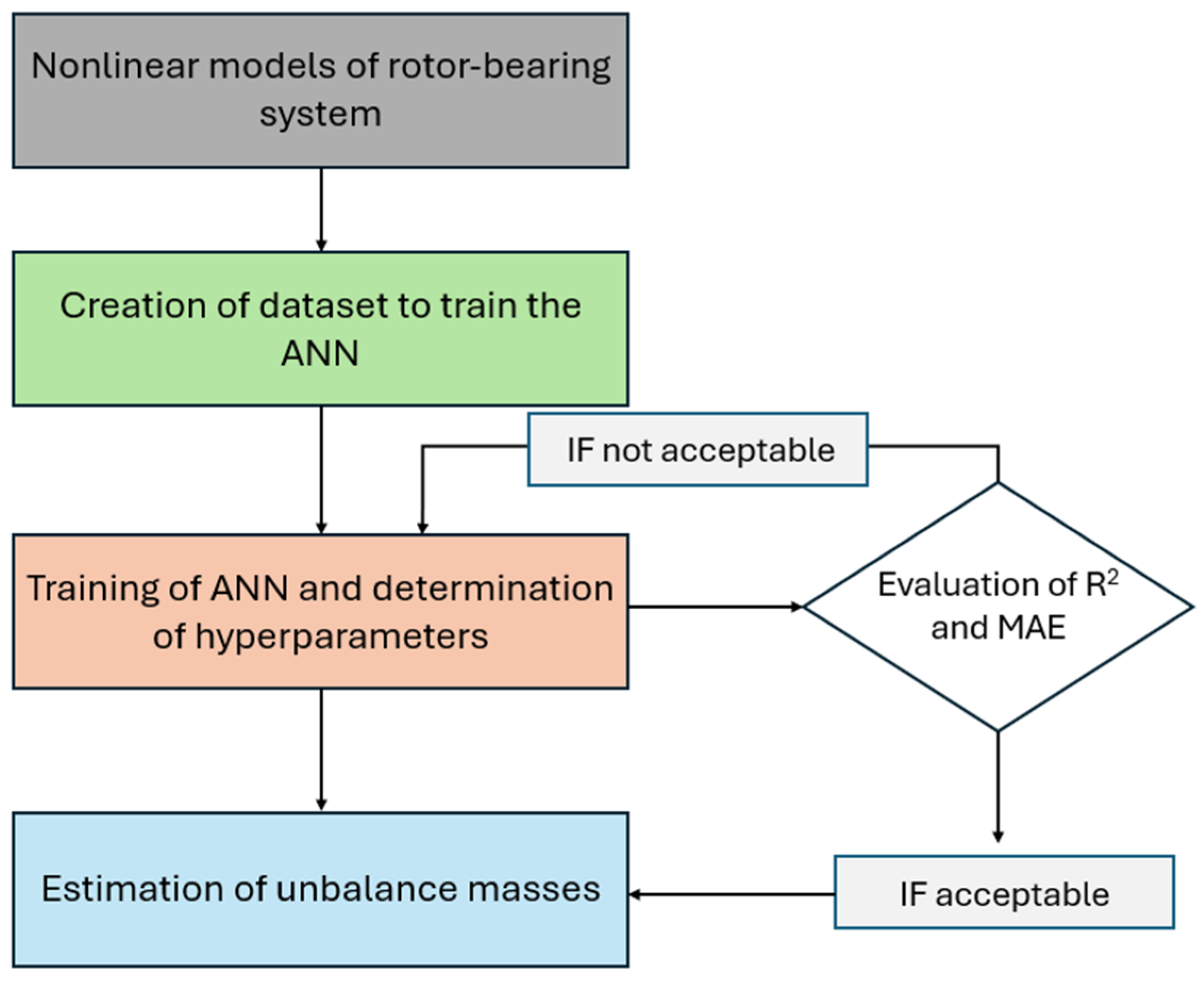

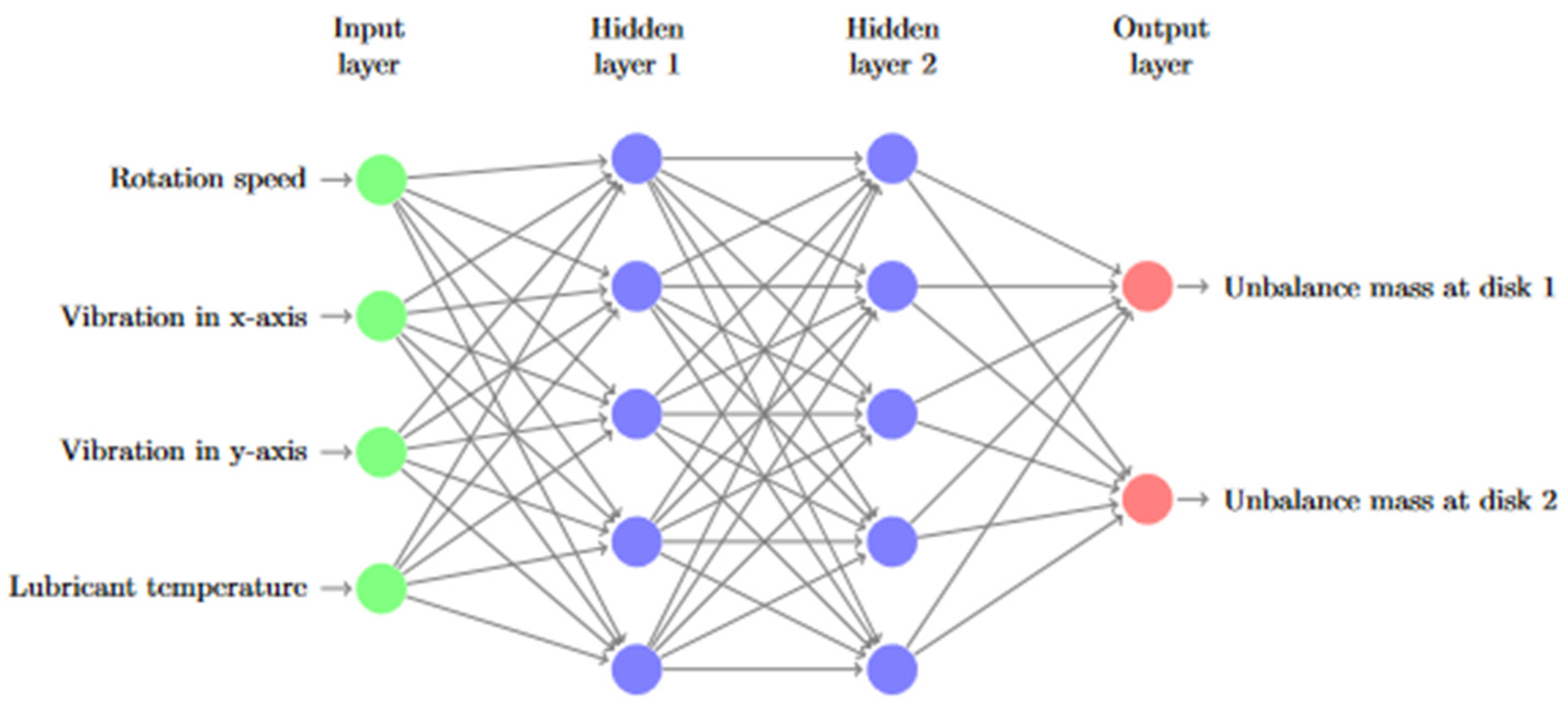

- ANN Development: Development of an artificial neural network (ANN) to estimate the unbalance masses, considering the effect of oil temperature on the bearing.

2. Mathematical Analysis of Nonlinear Rotor–Bearing System

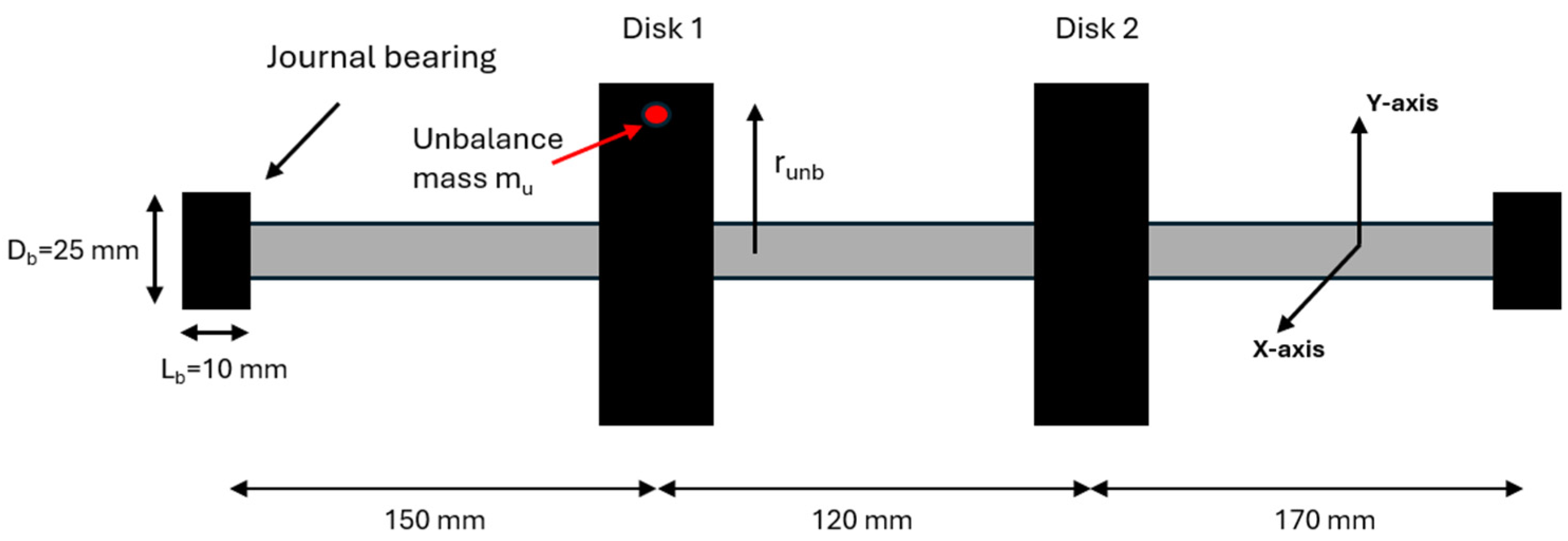

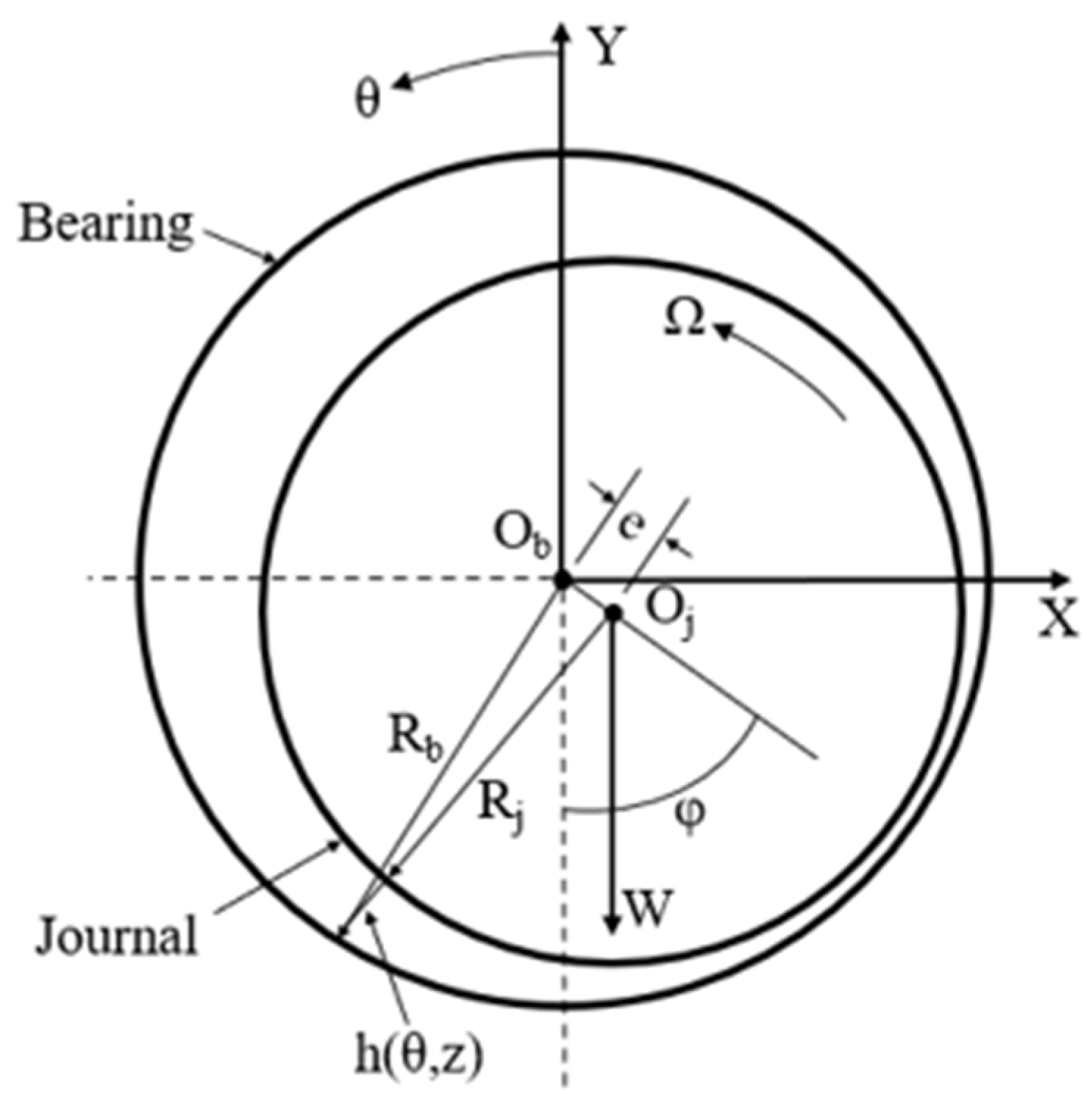

2.1. Presentation of Rotor–Bearing System

- ;

- ;

- ;

- ;

- ;

- ;

- ;

- ;

- ;

- .

2.2. Mathematical Analysis of Nonlinear Rotating System

2.2.1. Newmark Method

2.2.2. State Space Representation

3. Simulation Results of Nonlinear Rotor–Bearing System

3.1. Nonlinear Analysis of Rotor Vibrations

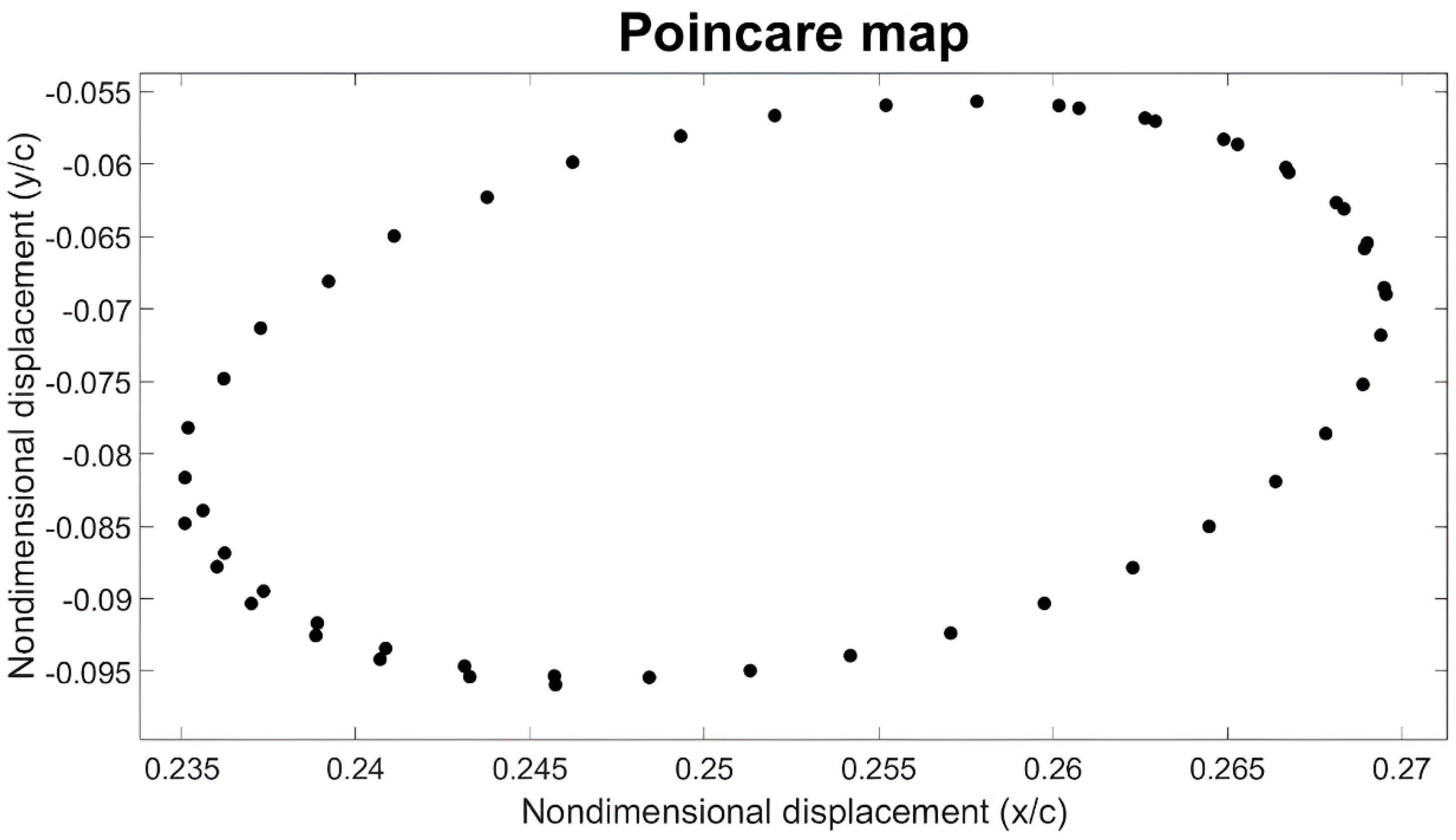

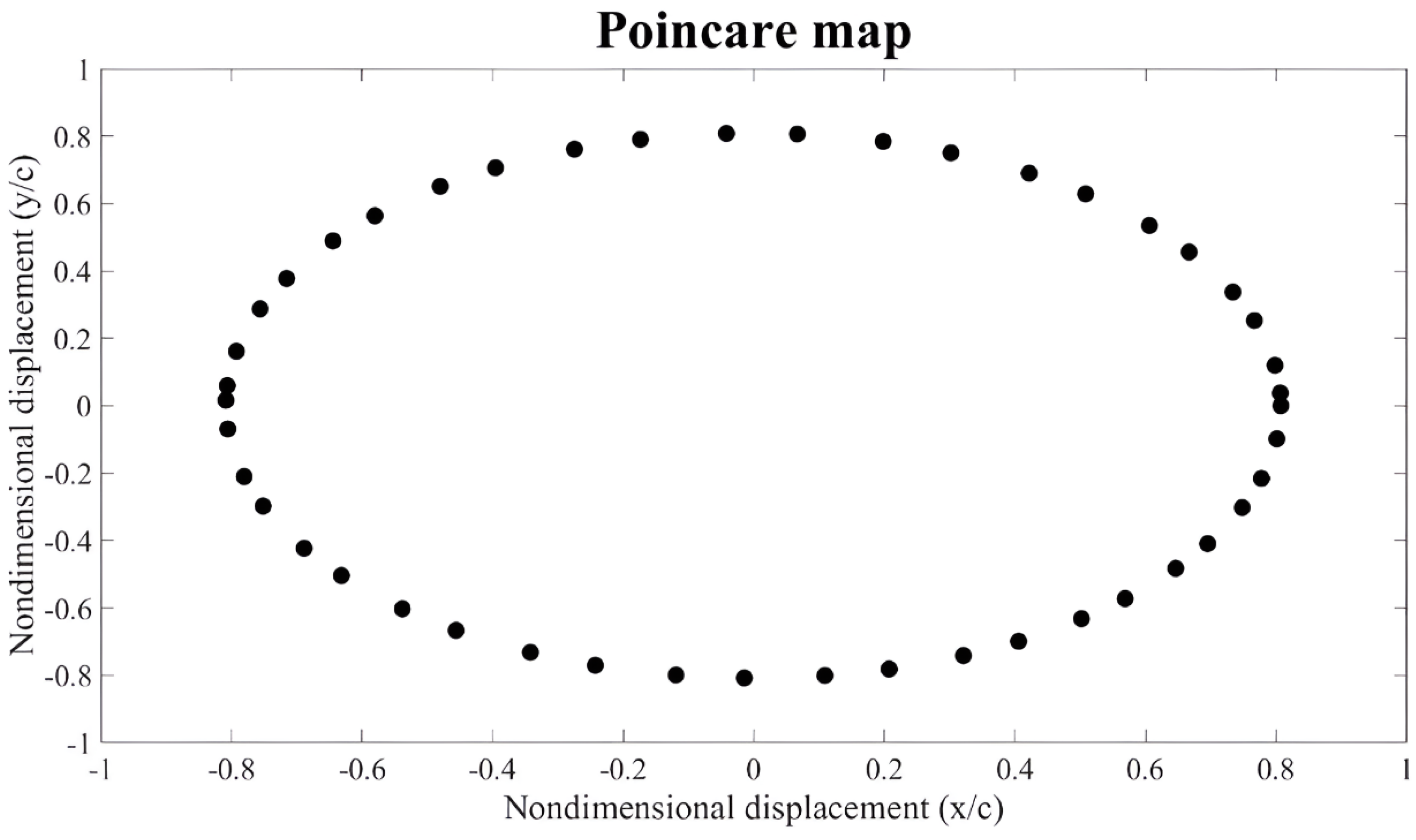

3.1.1. Poincare Map

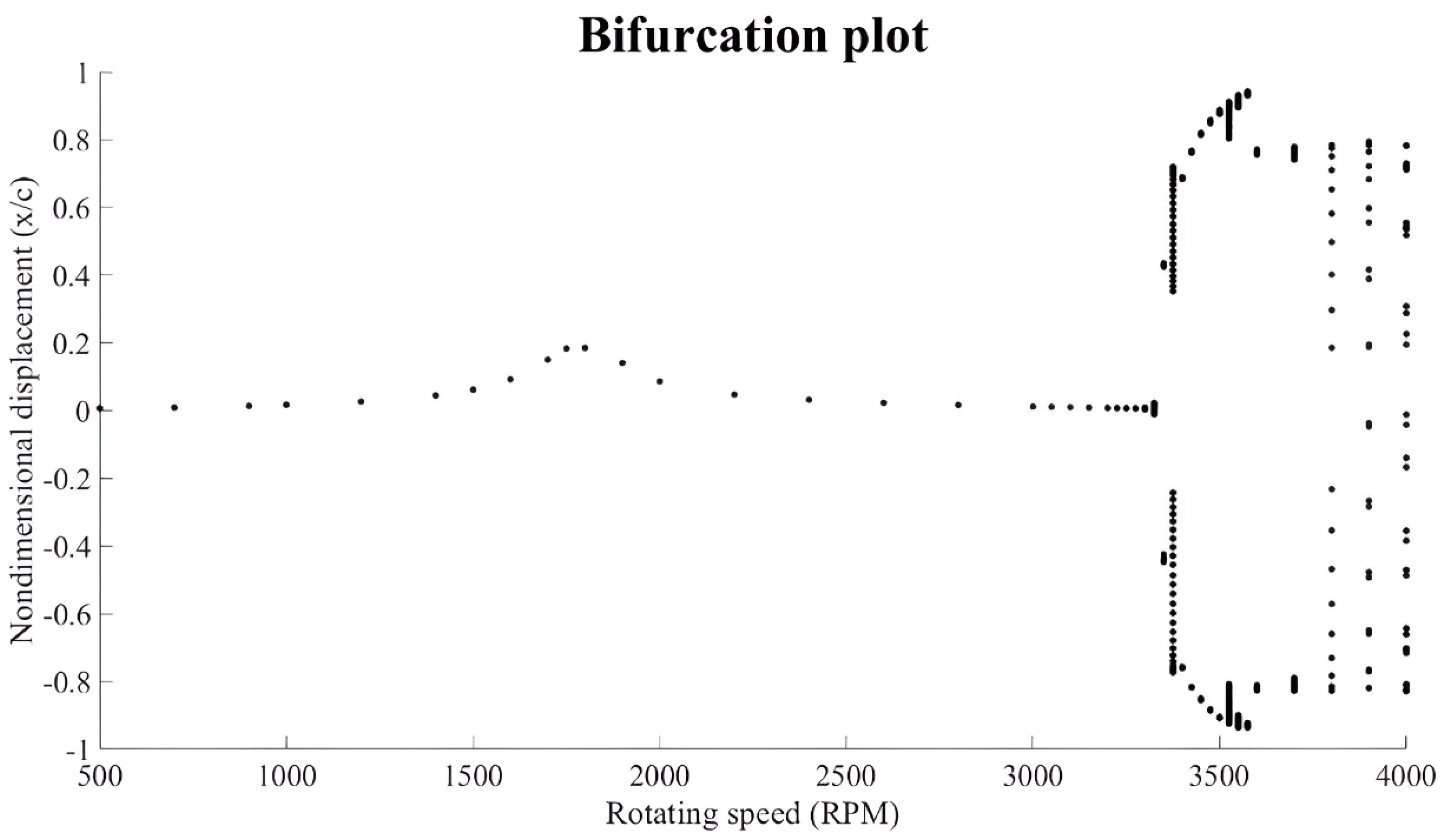

3.1.2. Bifurcation Analysis

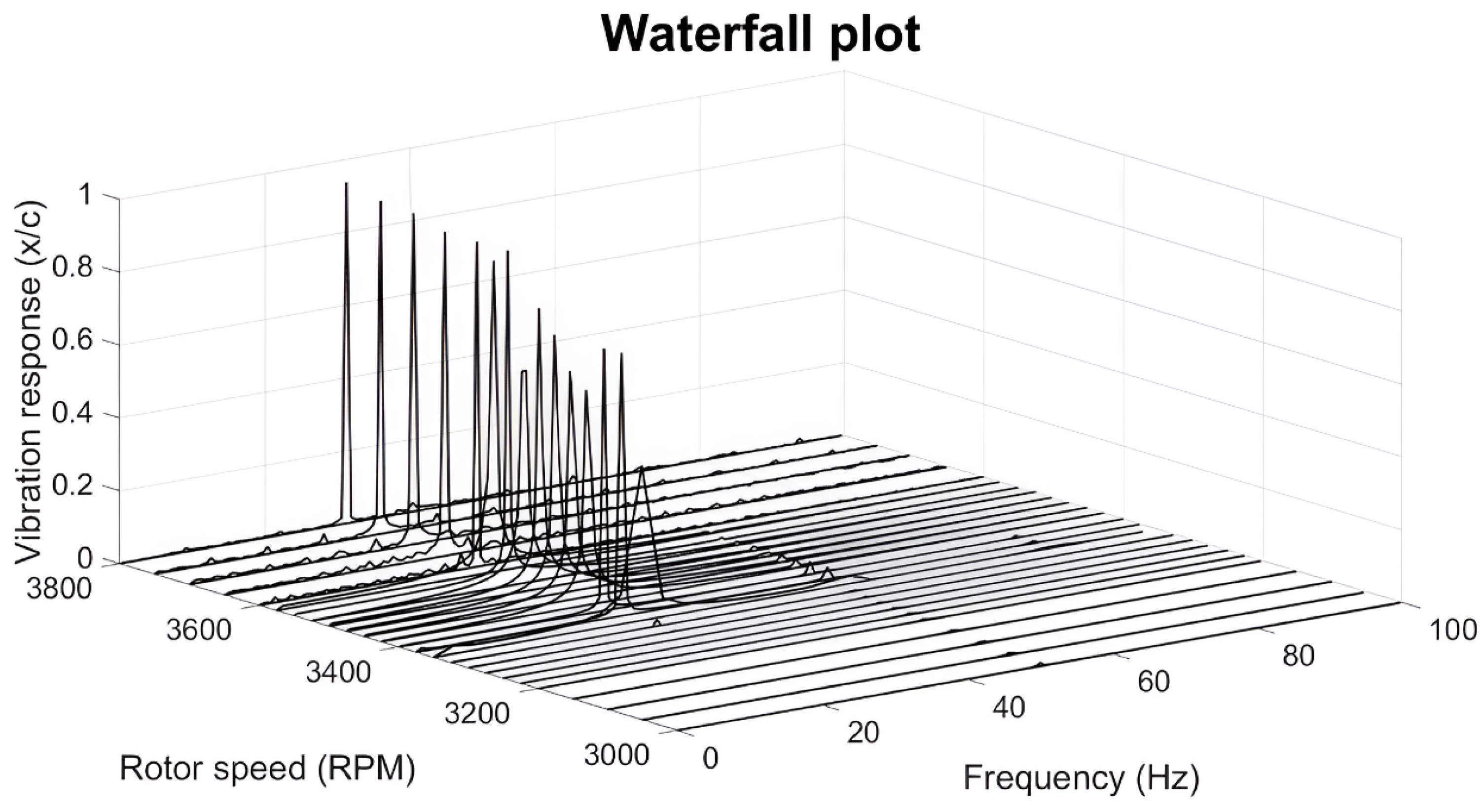

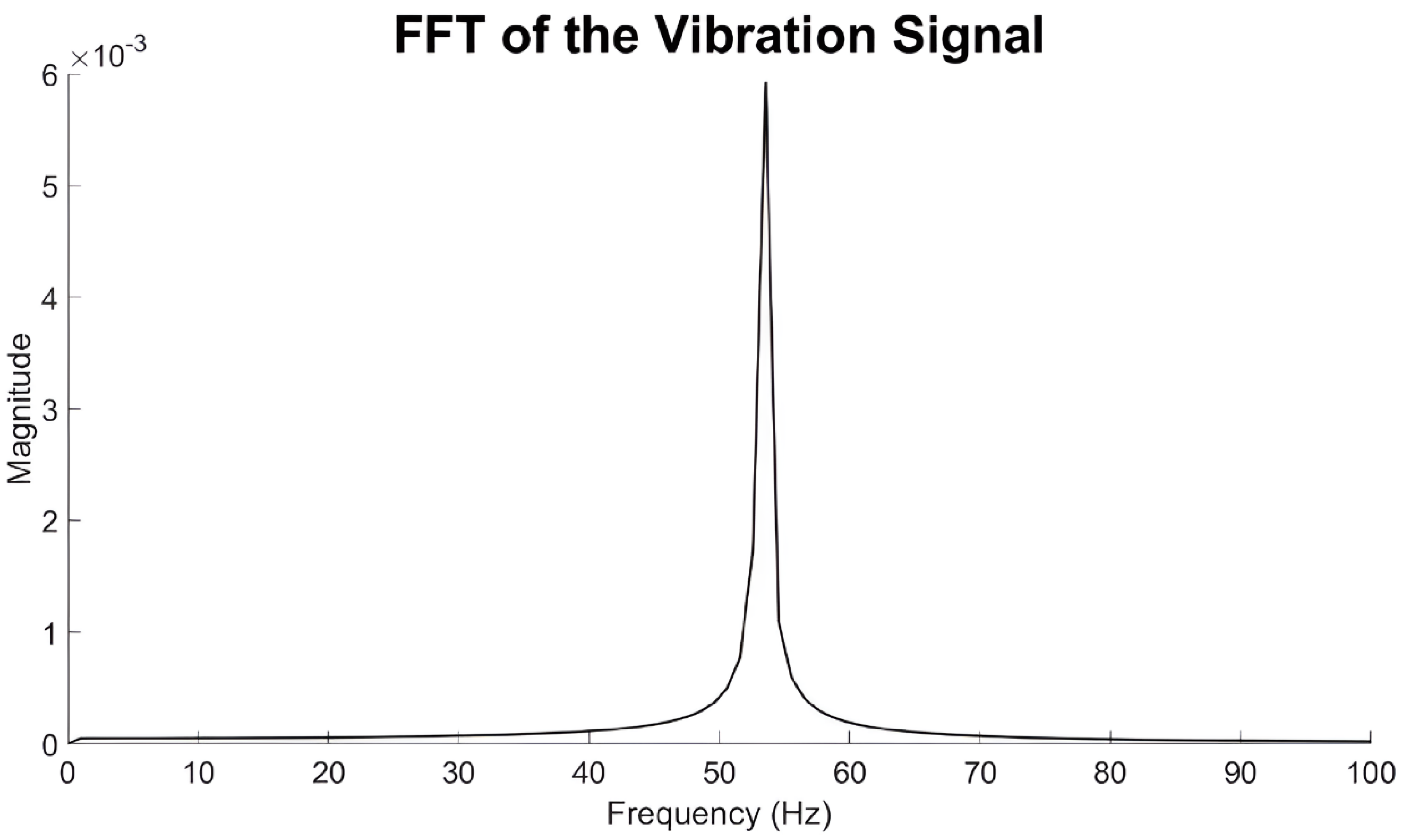

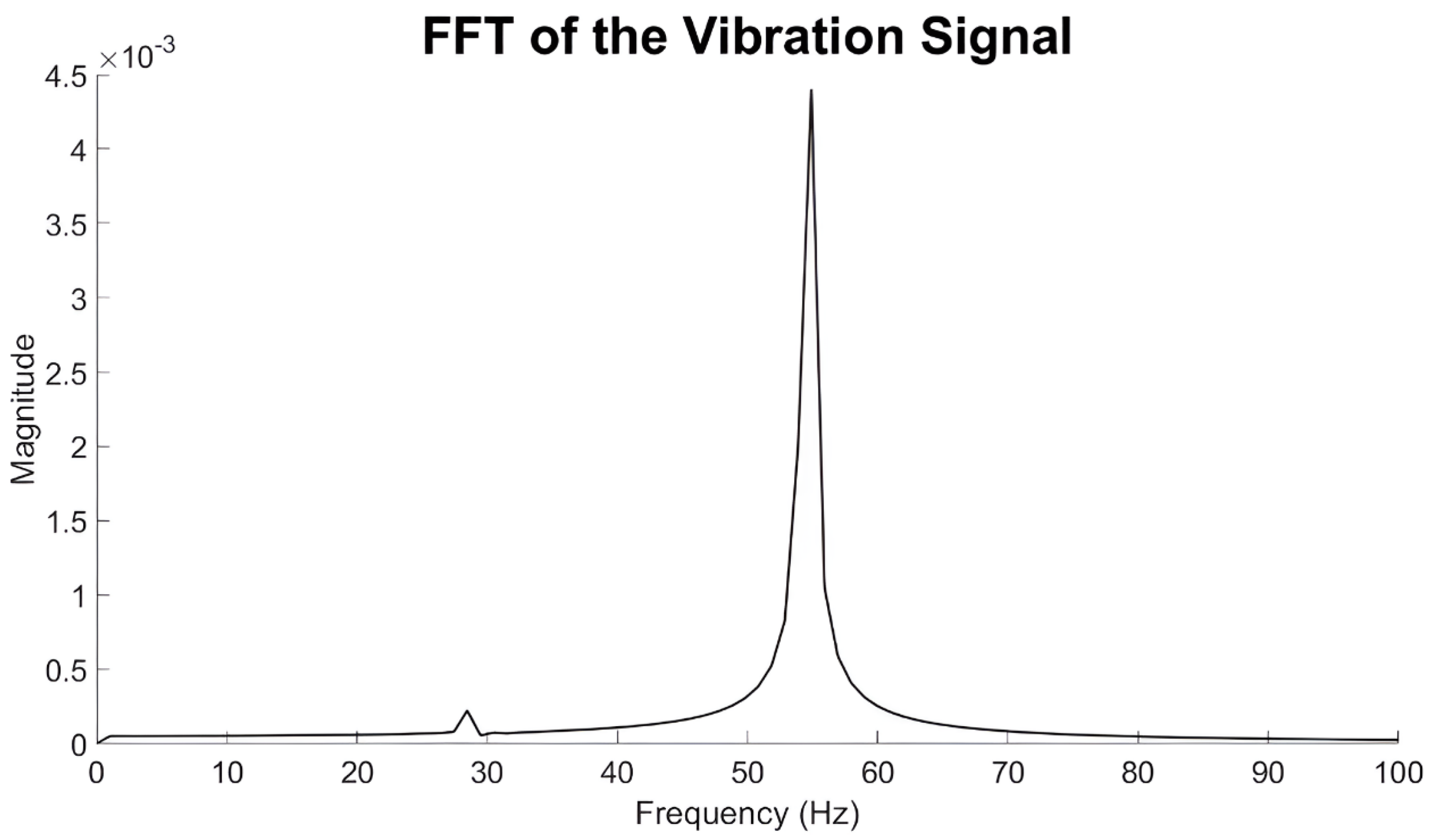

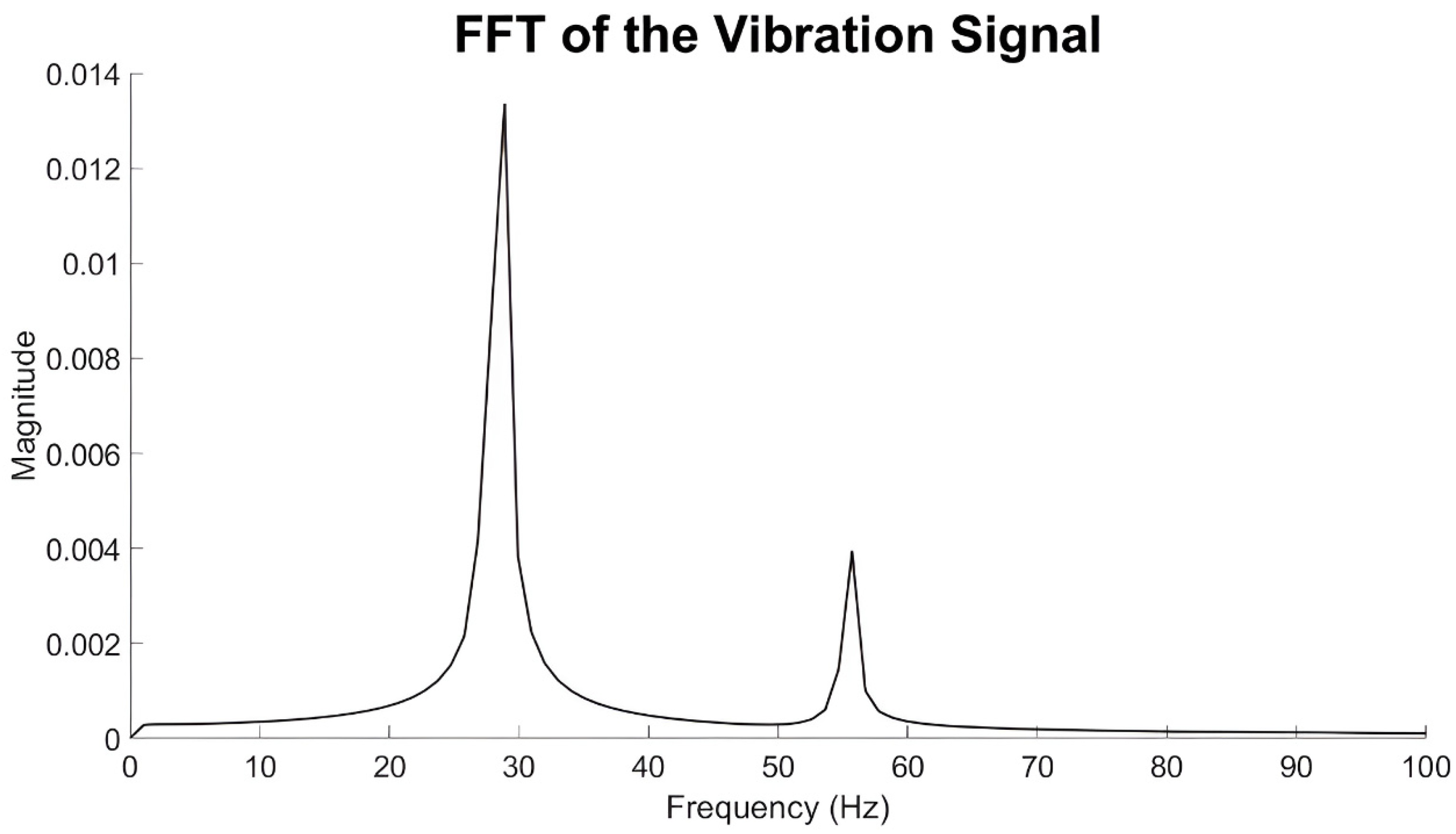

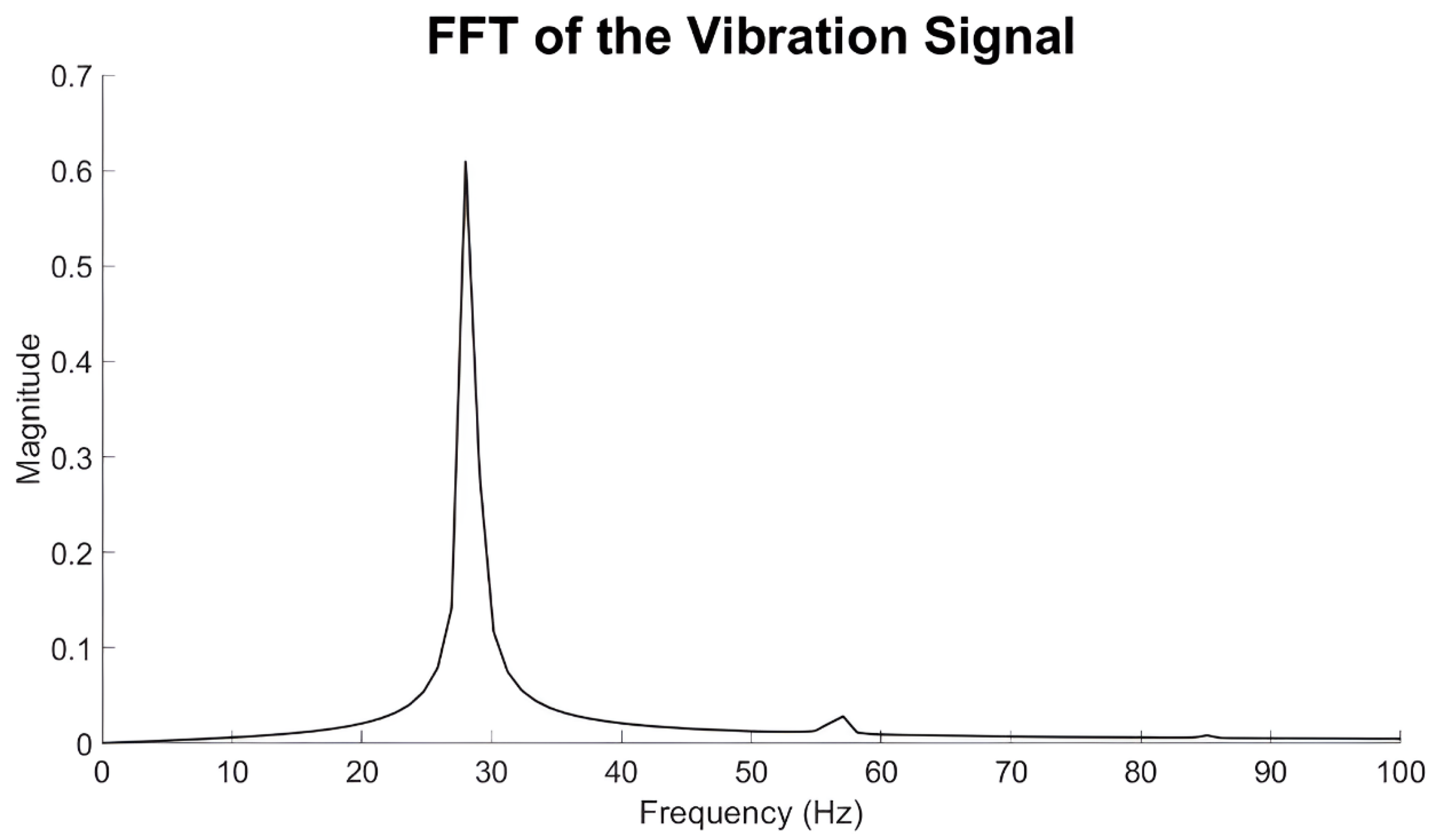

3.1.3. Frequency Domain Analysis

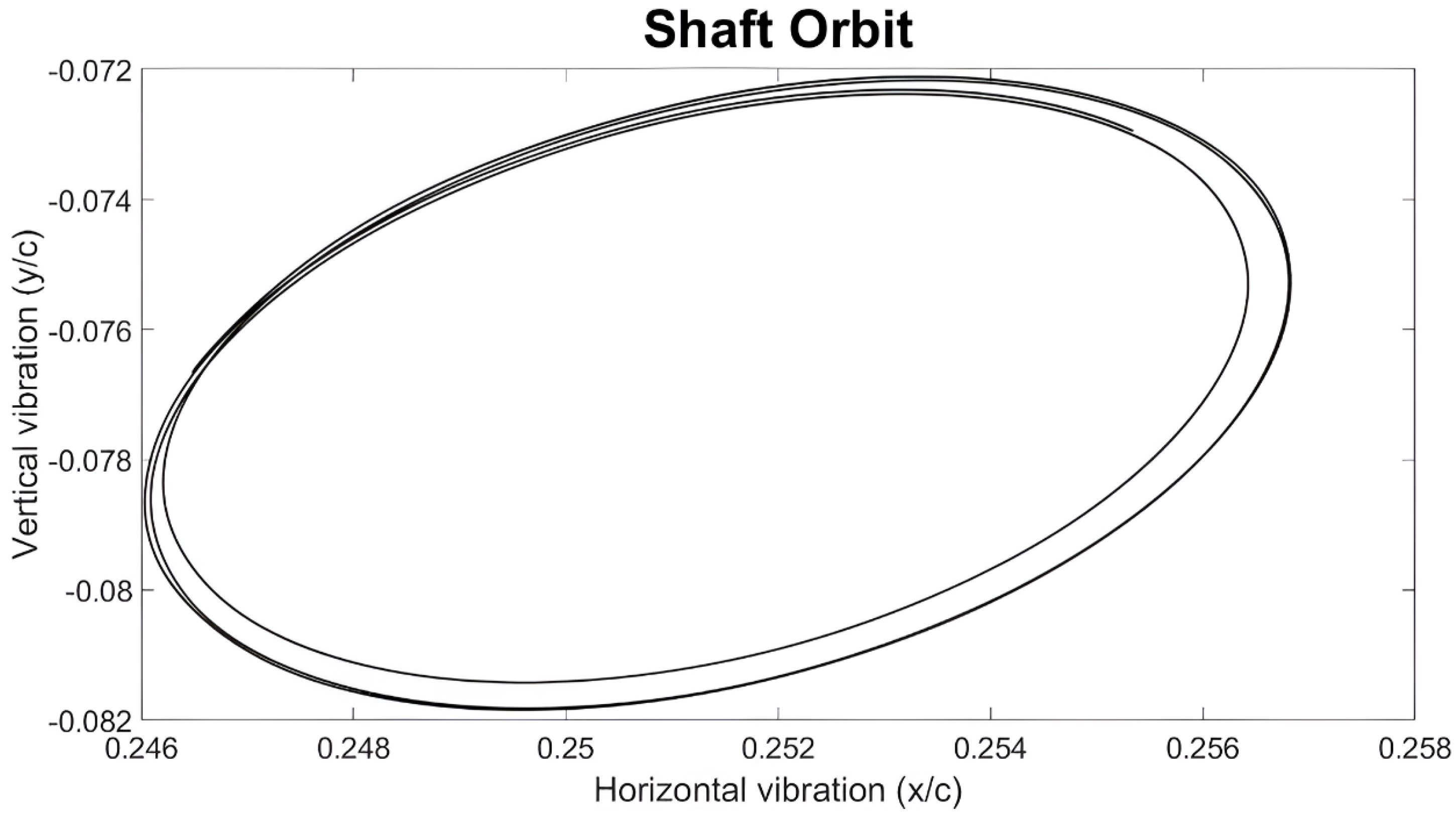

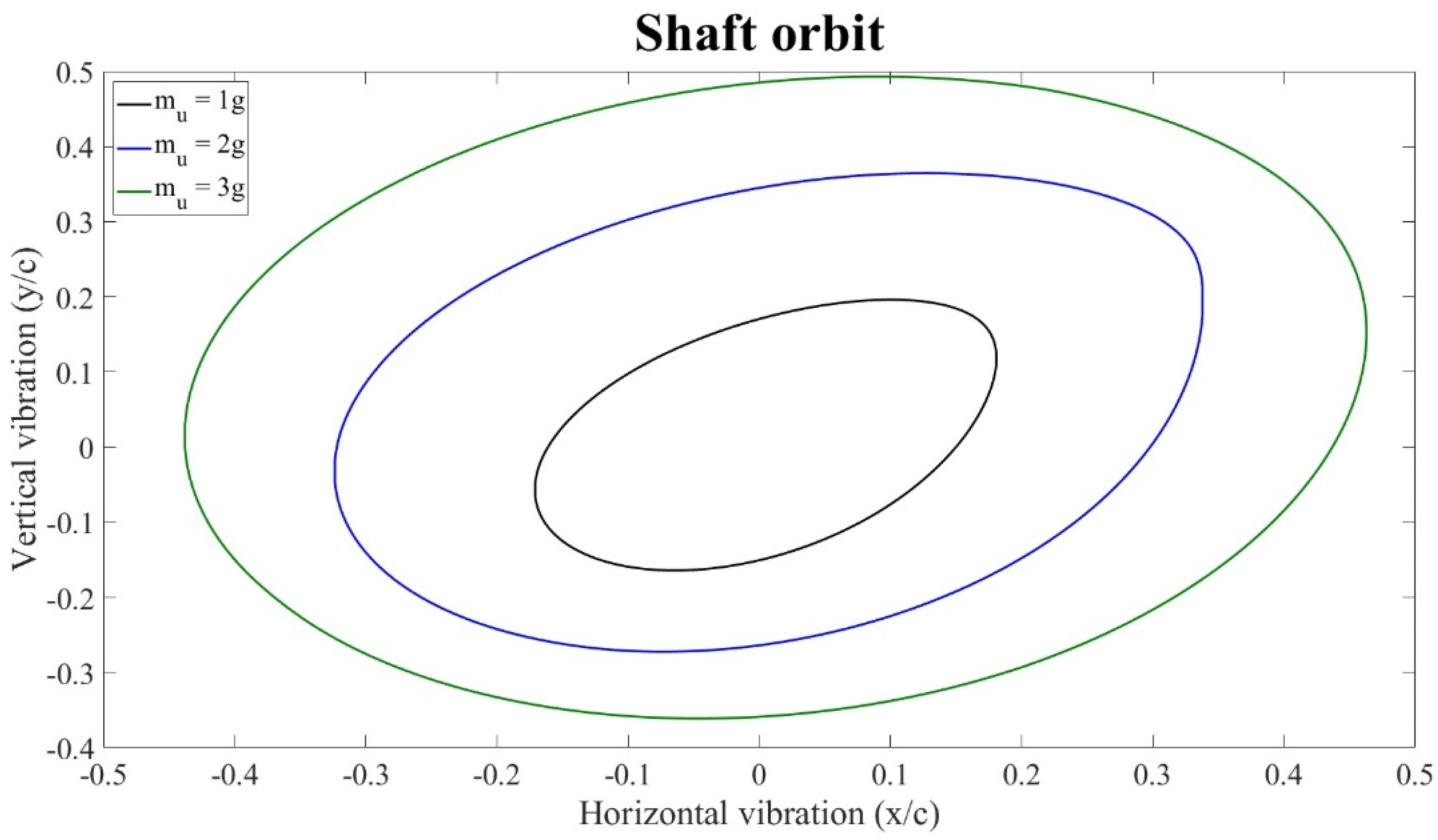

3.1.4. Orbit Plots

3.1.5. Validation of Mathematical Model

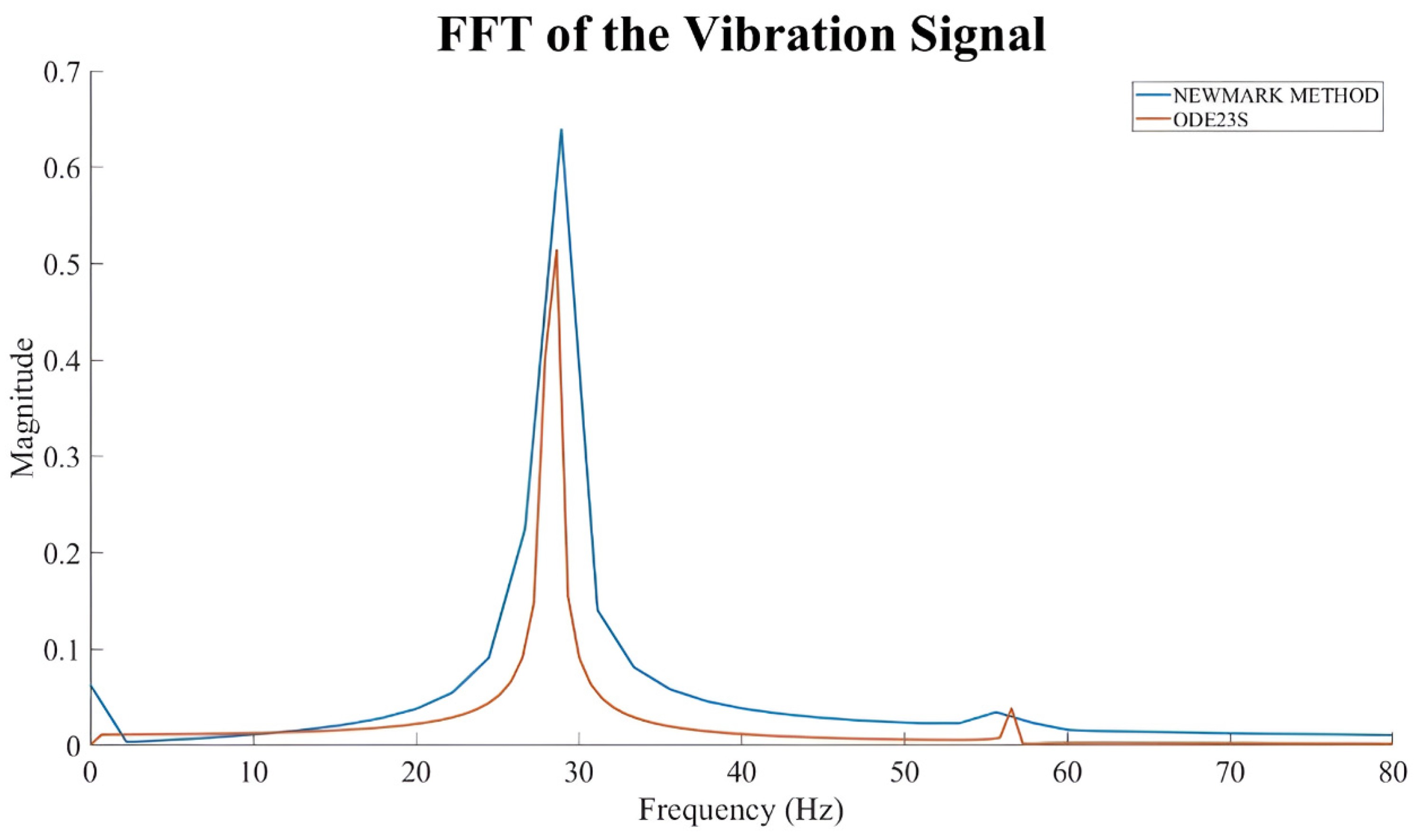

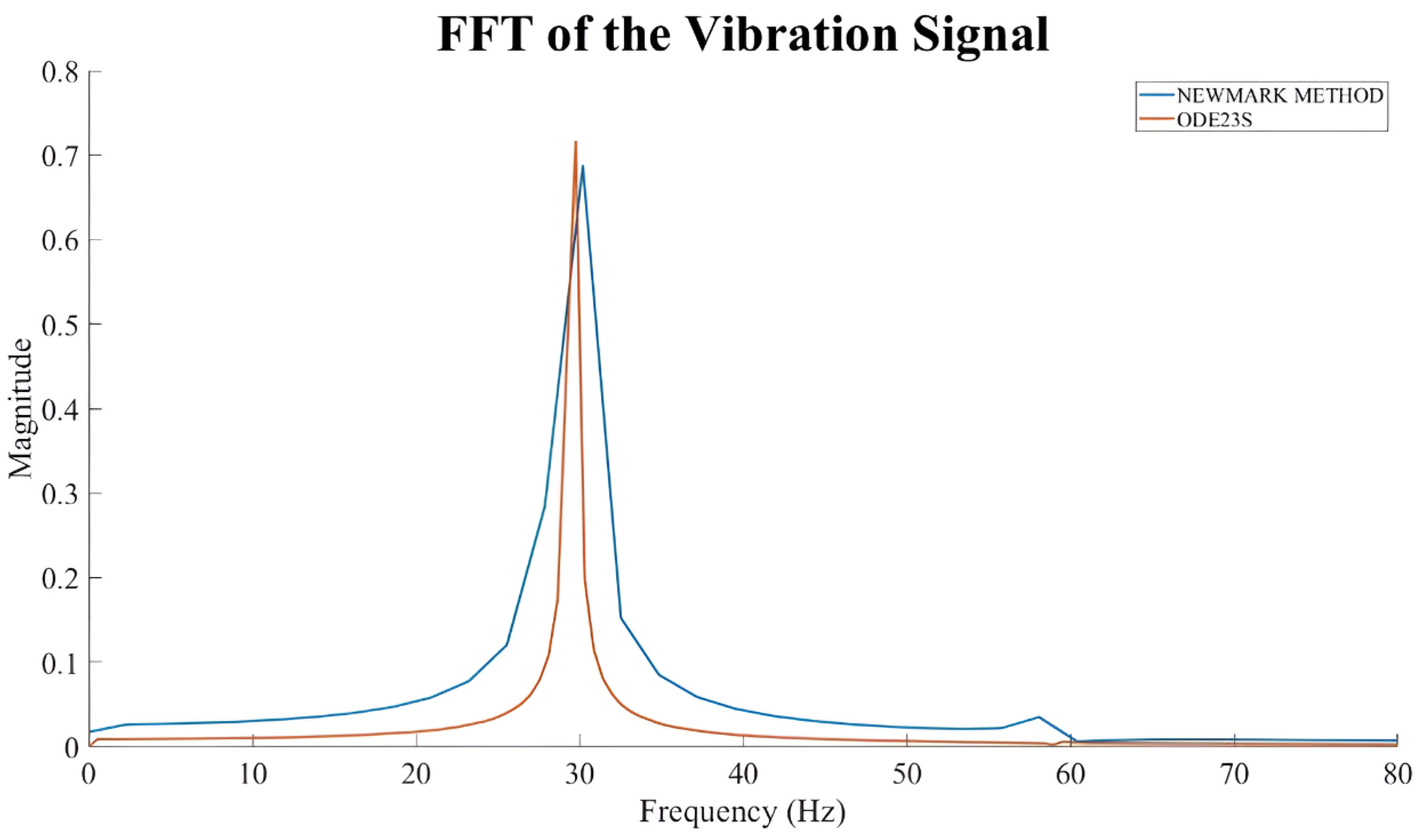

3.2. Comparison of Numerical Integration Methods

3.3. Effect of Lubricant Temperature on Vibration Response and Necessity of Nonlinear Model

4. Development of Artificial Neural Networks for Unbalance Estimation

5. Discussion

6. Conclusions

- Nonlinear metrics like Poincare maps, bifurcation diagrams, and waterfall plots are very useful for understanding the behavior of the rotating system under various operating conditions.

- The two different solvers, ODE23S and the Newmark method, provide similar and robust results.

- The vibration response is affected by the lubricant temperature and rotation speed and, therefore, all these phenomena should be studied and taken into account in the simulations.

- The utilization of artificial neural networks provides a very effective tool for online monitoring of unbalance due to fast and accurate calculation. The neural network achieves great performance (R2 is greater than 0.928 for all the outputs.)

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Vázquez, J.A.; Barrett, L.E.; Flack, R.D. A Flexible Rotor on Flexible Bearing Supports: Stability and Unbalance Response. J. Vib. Acoust. 2000, 123, 137–144. [Google Scholar] [CrossRef]

- Chen, J.; Lin, C.; Peng, D.; Ge, H. Fault Diagnosis of Rotating Machinery: A Review and Bibliometric Analysis. IEEE Access 2020, 8, 224985–225003. [Google Scholar] [CrossRef]

- Shao, H.; Xia, M.; Han, G.; Zhang, Y.; Wan, J. Intelligent Fault Diagnosis of Rotor-Bearing System under Varying Working Conditions with Modified Transfer Convolutional Neural Network and Thermal Images. IEEE Trans. Ind. Inform. 2021, 17, 3488–3496. [Google Scholar] [CrossRef]

- Chen, X.; Wang, S.; Qiao, B.; Chen, Q. Basic Research on Machinery Fault Diagnostics: Past, Present, and Future Trends. Front. Mech. Eng. 2017, 13, 264–291. [Google Scholar] [CrossRef]

- Qiao, Z.; Chen, K.; Zhou, C.; Ma, H. An improved fault model of wind turbine gear drive under multi-stage cracks. Simul. Model. Pract. Theory 2023, 122, 102679. [Google Scholar] [CrossRef]

- Polyakov, R.; Majorov, S.; Kudryavcev, I.; Krupenin, N. Predictive Analysis of Rotor Machines Fluid-Film Bearings Operability. Vibroeng. Procedia 2020, 30, 61–67. [Google Scholar] [CrossRef]

- Wang, T.; Han, Q.; Chu, F.; Feng, Z. Vibration Based Condition Monitoring and Fault Diagnosis of Wind Turbine Planetary Gearbox: A Review. Mech. Syst. Signal Process. 2019, 126, 662–685. [Google Scholar] [CrossRef]

- Alsaleh, A.; Sedighi, H.M.; Ouakad, H.M. Experimental and Theoretical Investigations of the Lateral Vibrations of an Unbalanced Jeffcott Rotor. Front. Struct. Civ. Eng. 2020, 14, 1024–1032. [Google Scholar] [CrossRef]

- Wang, J.; Ye, L.; Gao, R.X.; Li, C.; Zhang, L. Digital Twin for Rotating Machinery Fault Diagnosis in Smart Manufacturing. Int. J. Prod. Res. 2018, 57, 3920–3934. [Google Scholar] [CrossRef]

- Mereles, A.; Alves, D.S.; Cavalca, K.L. Bifurcations and limit cycle prediction of rotor systems with fluid-film bearings using center manifold reduction. Nonlinear Dyn. 2023, 111, 17749–17767. [Google Scholar] [CrossRef]

- Visnadi, L.B.; De Castro, H.F. Influence of bearing clearance and oil temperature uncertainties on the stability threshold of cylindrical journal bearings. Mech. Mach. Theory 2019, 134, 57–73. [Google Scholar] [CrossRef]

- Ahmed, O.; El-Sayed, T.; Sayed, H. Finite element analyses of rotor/bearing system using second-order journal bearings stiffness and damping coefficients. J. Vib. Control 2023, 30, 3961–3984. [Google Scholar] [CrossRef]

- Eling, R.; Wierik, M.T.; Van Ostayen, R.; Rixen, D. Towards Accurate Prediction of Unbalance Response, Oil Whirl and Oil Whip of Flexible Rotors Supported by Hydrodynamic Bearings. Lubricants 2016, 4, 33. [Google Scholar] [CrossRef]

- Alves, D.S.; Cavalca, K.L. Investigation into the influence of bearings nonlinear forces in unbalance identification. J. Sound Vib. 2021, 492, 115807. [Google Scholar] [CrossRef]

- De Castro, H.F.; Cavalca, K.L.; Nordmann, R. Whirl and Whip Instabilities in Rotor-Bearing System Considering a Nonlinear Force Model. J. Sound Vib. 2008, 317, 273–293. [Google Scholar] [CrossRef]

- Jing, J.; Meng, G.; Yi, S.; Xia, S.-Y. On the Non-Linear Dynamic Behavior of a Rotor–Bearing System. J. Sound Vib. 2004, 274, 1031–1044. [Google Scholar] [CrossRef]

- Ma, H.; Wang, X.; Niu, H.; Li, H. Effects of Different Disc Locations on Oil-Film Instability in a Rotor System. J. Vibroeng. 2014, 16, 3248–3259. Available online: https://www.extrica.com/article/15094 (accessed on 15 November 2023).

- Alves, D.S.; Cavalca, K.L. Numerical Identification of Nonlinear Hydrodynamic Forces. In Proceedings of the 10th International Conference on Rotor Dynamics—IFToMM. IFToMM 2018; Cavalca, K., Weber, H., Eds.; Mechanisms and Machine Science; Springer: Cham, Switzerland, 2019; Volume 60. [Google Scholar] [CrossRef]

- Ma, H.; Li, H.; Zhao, X.; Niu, H.; Wen, B. Effects of Eccentric Phase Difference between Two Discs on Oil-Film Instability in a Rotor–Bearing System. Mech. Syst. Signal Process. 2013, 41, 526–545. [Google Scholar] [CrossRef]

- Kartheek, A.; Vijayan, K.; Sun, X.; Marburg, S. Stochastic Analysis of Flexible Rotor Supported on Hydrodynamic Bearings. Mech. Syst. Signal Process. 2023, 203, 110699. [Google Scholar] [CrossRef]

- Luo, H.; Bo, L.; Peng, C.; Hou, D. Detection and quantification of oil whirl instability in a rotor-journal bearing system using a novel dynamic recurrence index. Nonlinear Dyn. 2022, 111, 2229–2261. [Google Scholar] [CrossRef]

- Sayed, H.; El-Sayed, T. Nonlinear dynamics and bifurcation analysis of journal bearings based on second order stiffness and damping coefficients. Int. J. Non-Linear Mech. 2022, 142, 103972. [Google Scholar] [CrossRef]

- Reddy, M.C.S.; Sekhar, A.S. Identification of Unbalance and Looseness in Rotor Bearing Systems Using Neural Networks. Available online: http://www.nacomm2011.ammindia.org/files/papers/nacomm2011_attachment_183_1.pdf (accessed on 10 December 2023).

- Gohari, M.; Kord, A. Unbalance Rotor Parameters Detection Based on Artificial Neural Network. Int. J. Acoust. Vib. 2019, 24, 113–118. [Google Scholar] [CrossRef]

- Katsaros, K.P.; Nikolakopoulos, P.G. Performance Prediction Model for Hydrodynamically Lubricated Tilting Pad Thrust Bearings Operating under Incomplete Oil Film with the Combination of Numerical and Machine-Learning Techniques. Lubricants 2023, 11, 113. [Google Scholar] [CrossRef]

- Miraskari, M.; Hemmati, F.; Gadala, M.S. Nonlinear Dynamics of Flexible Rotors Supported on Journal Bearings—Part I: Analytical Bearing Model. J. Tribol. 2017, 140, 021704. [Google Scholar] [CrossRef]

- Garoli, G.Y.; De Castro, H.F. Analysis of a rotor-bearing nonlinear system model considering fluid-induced instability and uncertainties in bearings. J. Sound Vib. 2019, 448, 108–129. [Google Scholar] [CrossRef]

- Capone, G. Orbital motions of rigid symmetric rotor supported on journal bearings. La Mecc. Ital. 1986, 199, 37–46. [Google Scholar]

- Capone, G. Analytical description of fluid-dynamic force field in cylindrical journal bearing. Energ. Elettr. 1991, 3, 105–110. [Google Scholar]

- DuBois, G.B.; Ocvirk, F.W. The Short Bearing Approximation for Plain Journal Bearings. Trans. Am. Soc. Mech. Eng. 1955, 77, 1173–1178. [Google Scholar] [CrossRef]

- Friswell, M.I.; Penny, J.E.T.; Garvey, S.D.; Lees, A.W. Dynamics of Rotating Machines; Cambridge University Press: Cambridge, UK, 2010. [Google Scholar] [CrossRef]

- Zorzi, E.S.; Nelson, H.D. Finite element simulation of Rotor-Bearing systems with internal damping. J. Eng. Power 1977, 99, 71–76. [Google Scholar] [CrossRef]

- Kaps, P.; Poon, S.W.H.; Bui, T.D. Rosenbrock methods for Stiff ODEs: A comparison of Richardson extrapolation and embedding technique. Computing 1985, 34, 17–40. [Google Scholar] [CrossRef]

- Bathe, K. Finite Element Procedures. 1995. Available online: http://archives.umc.edu.dz/handle/123456789/116606 (accessed on 1 October 2024).

- Newmark, N.M. A method of computation for structural dynamics. J. Eng. Mech. Div. 1959, 85, 67–94. [Google Scholar] [CrossRef]

- Qian, D.; Liu, Z.; Yan, J.; Sun, L.; Wang, Y. Numerical and Experimental Research on Periodic Solution Stability of Inclined Rotor Journal Bearing System. In Proceedings of the ASME 2011 Turbo Expo: Turbine Technical Conference and Exposition. Volume 6: Structures and Dynamics, Parts A and B, Vancouver, BC, Canada, 6–10 June 2011; ASME: New York, NY, USA, 2011; pp. 321–330. [Google Scholar] [CrossRef]

- Golmohammadi, A.; Safizadeh, M.S. A machine learning-based approach for detection of whirl instability and overheating faults in journal bearings using multi-sensor fusion method. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 162. [Google Scholar] [CrossRef]

- Chang-Jian, C. Bifurcation analysis of a rotor-bearing system with temperature-dependent viscosity. J. Low Freq. Noise Vib. Act. Control 2023, 43, 75–88. [Google Scholar] [CrossRef]

- Alves, D.S.; Fieux, G.; Machado, T.H.; Keogh, P.S.; Cavalca, K.L. A parametric model to identify hydrodynamic bearing wear at a single rotating speed. Tribol. Int. 2021, 153, 106640. [Google Scholar] [CrossRef]

- Larsson, R.; Larsson, P.O.; Eriksson, E.; Sjöberg, M.; Höglund, E. Lubricant properties for input to hydrodynamic and elastohydrodynamic lubrication analyses. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2000, 214, 17–27. [Google Scholar] [CrossRef]

- Ikumi, T.; Galeote, E.; Pujadas, P.; de la Fuente, A.; López-Carreño, R. Neural Network-Aided Prediction of Post-Cracking Tensile Strength of Fibre-Reinforced Concrete. Comput. Struct. 2021, 256, 106640. [Google Scholar] [CrossRef]

- Dietterich, T. Overfitting and Undercomputing in Machine Learning. ACM Comput. Surv. 1995, 27, 326–327. [Google Scholar] [CrossRef]

- Pang, B.; Nijkamp, E.; Wu, Y.N. Deep Learning with TensorFlow: A Review. J. Educ. Behav. Stat. 2019, 45, 227–248. [Google Scholar] [CrossRef]

| Properties of the Rotating System | |

|---|---|

| Young’s Modulus | E = 210 GPa |

| Density | ρ = 7810 kg/m3 |

| Diameter of shaft | ds = 10 mm |

| Diameter of disk | dd = 75 mm |

| Thickness of disk | th = 25 mm |

| Length of shaft | Ls = 440 mm |

| Regression Neural Network | ||

|---|---|---|

| Metrics | Output 1 (m1) | Output 2 (m2) |

| MAE | 0.0078 g | 0.0091 g |

| R2 | 0.957 | 0.964 |

| Regression Neural Network | ||

|---|---|---|

| Metrics | Output 1 (m1) | Output 2 (m2) |

| MAE | 0.0086 g | 0.0084 g |

| R2 | 0.955 | 0.959 |

| Regression Neural Network | ||

|---|---|---|

| Metrics | Output 1 (m1) | Output 2 (m2) |

| MAE | 0.0092 g | 0.0075 g |

| R2 | 0.928 | 0.932 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tselios, I.; Nikolakopoulos, P. Combining Artificial Neural Networks and Mathematical Models for Unbalance Estimation in a Rotating System under the Nonlinear Journal Bearing Approach. Lubricants 2024, 12, 344. https://doi.org/10.3390/lubricants12100344

Tselios I, Nikolakopoulos P. Combining Artificial Neural Networks and Mathematical Models for Unbalance Estimation in a Rotating System under the Nonlinear Journal Bearing Approach. Lubricants. 2024; 12(10):344. https://doi.org/10.3390/lubricants12100344

Chicago/Turabian StyleTselios, Ioannis, and Pantelis Nikolakopoulos. 2024. "Combining Artificial Neural Networks and Mathematical Models for Unbalance Estimation in a Rotating System under the Nonlinear Journal Bearing Approach" Lubricants 12, no. 10: 344. https://doi.org/10.3390/lubricants12100344

APA StyleTselios, I., & Nikolakopoulos, P. (2024). Combining Artificial Neural Networks and Mathematical Models for Unbalance Estimation in a Rotating System under the Nonlinear Journal Bearing Approach. Lubricants, 12(10), 344. https://doi.org/10.3390/lubricants12100344