Abstract

Electric vehicles (EVs) continue to evolve, and sales continue to increase as the world pushes toward improved sustainability. This drives the need for research to understand the unique environments in which fluids operate within the Electric Drive Units (EDUs) of EVs in order to improve durability and reduce frictional losses. However, for this to happen, test rigs are required to operate with an electric current passing across the test parts and through the lubricant. Very few electrified test rigs currently exist, with most being adaptations of rigs undertaken by academia and independent and national research labs. In this work, the PCS Mini Traction Machine (MTM) was modified to supply a voltage across a tribological contact. New parts for the MTM were designed in collaboration with the instrument manufacturer. Work was undertaken in both the author’s labs and the manufacturer’s labs with the aim of bringing a commercially available unit to market as quickly as possible. A test matrix was completed on the MTM utilizing a range of temperatures, loads, and voltage inputs for three different lubricants commonly used in EDUs. The test matrix consisted of 36 test conditions, with some runs performed in triplicate, resulting in 81 tests for each oil and a total matrix of 243 tests. The test matrix was run to obtain the results and to test the robustness of the rig design. After testing was completed, the MTM disc wear scars were measured. The results from these measurements indicate that the application of alternating current (AC) and direct current (DC) causes a significant increase in the wear scar compared to non-electrified test conditions. This, in turn, results in increased traction values under non-electrified conditions. It was also noted that the repeatability of the traction curves and end-of-test wear was reduced under both AC and DC electrified conditions.

1. Introduction

Electric vehicles typically use brushless AC induction or permanent magnet motors as their main method of propulsion. The energy for these motors is supplied by DC battery packs that are integrated into the vehicle. An inverter is used to convert the DC voltage from the battery into the three-phase AC power required to operate the motor. Using high carrier frequencies to switch the DC power on and off, the inverter simulates the AC power by utilizing a pulse-width modulated (PWM) signal to approximate the curve of a sine wave [1]. Figure 1 shows a simple overview of the architecture of most electric vehicles.

Figure 1.

Basic architecture of a typical electric vehicle.

Inside the electric drive unit (EDU), there are numerous tribological contacts that need to be considered, including roller element contacts, gear meshing, and high-speed sliding. Many such contacts experience traction, which is a combination of sliding and rolling. A common tribology bench test for measuring the traction coefficients of fluids is the PCS Mini Traction Machine (MTM). The MTM utilizes two motors to rotate a ball and a disc independently at different speeds while in contact and under load to measure the traction response of a lubricant. The sliding and rolling behavior, as well as the load and temperature, can be controlled to produce a Stribeck curve, which is a plot of the traction coefficient versus speed. The Stribeck curve is a valuable tribological metric for understanding the lubrication regimes of fluids [2]. Mapping the lubrication regimes of fluids is critical for understanding lubricant behavior and for the development of new base oils, additives, materials, coatings, and surface finishes.

At the Society of Tribology and Lubrication Engineers (STLE) E-Mobility conferences held in the fall of 2021, 2022, and 2023, numerous presentations discussed the importance of evaluating traction, friction, and wear in environments representative of electric vehicles but emphasized the lack of available test methods to do this [3,4,5]. It was noted that most electrified rigs are adaptations of standard equipment undertaken by academia and independent and national research labs [6,7,8,9,10,11,12,13,14].

One method of performing these evaluations in a novel way is to induce an electrical potential across the contact pair, which is the subject of this work. In a previous work, the authors electrified a Block-on-Ring (BoR) test rig to investigate the effect of electrification on friction and wear [6]. In that work, the BoR was chosen due to the ease with which the addition of electrical current across the test samples (block and ring) could be achieved. Having found a significant effect, the authors selected a more widely utilized test rig that could easily and repeatedly produce a Stribeck curve for this work. The aim of this work was two-fold: (1) to investigate the effects of electrification in a rig that offers a more representative EDU tribopair, and (2) to work with a test rig manufacturer to develop an electrified version that could be made available to the industry in a timely manner.

2. Background

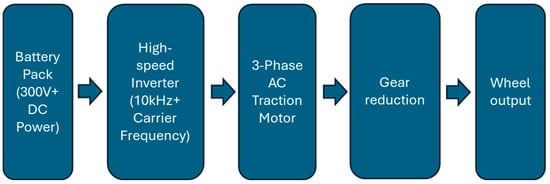

Due to the presence of the large AC motor, rotating components are exposed to shaft voltages and the large electric field inherent with such a high voltage. Shaft voltage generation is not a new concept; frictional-based electrostatics and manufacturing-based magnetic field asymmetry are both historical phenomena that cause motor shaft voltage generation [15,16,17]. A relatively new effect is caused by the high switching frequencies of the inverter. Faster switching inverters provide advantages to system efficiency by mimicking a more exact sine wave. However, the speed at which the voltage changes causes local voltage spikes on the shaft [18,19]. Figure 2 shows the details of this process.

Figure 2.

Representation of voltage build-up on the shaft due to rapid transition of the common-mode voltage (CMV) [6].

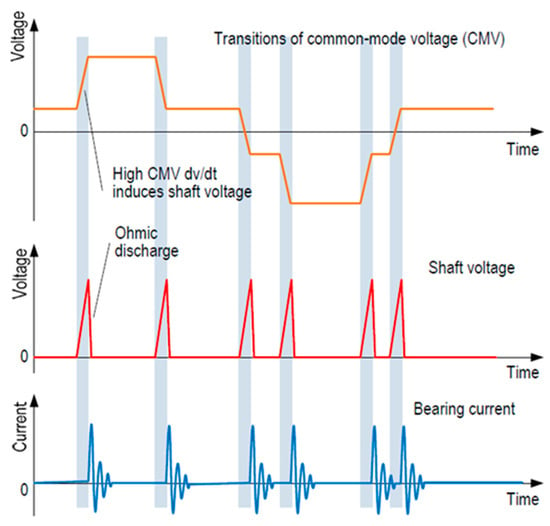

After these stray voltages are generated, numerous grounding paths are available. The precise grounding path is highly operational and system-dependent [20]. Figure 3 displays the common grounding paths inside a motor.

Figure 3.

Grounding paths for generated currents inside electric motor systems [6].

While grounding through the load side is theoretically possible, a more common grounding path involves flow through the electric motor’s deep-groove ball bearings, which support the rotor within the motor housing. Due to their proximity to the origin point of the stray currents, the motor bearings are widely considered the rotating component most at risk from current flow through them. The potential across the bearing builds until the voltage becomes strong enough to break down the dielectric strength of the thin film of the lubricant separating the ball from the bearing race. Once this breakdown occurs, the rapid transfer of current across the bearing can result in surface damage, as shown in Figure 4. This damage is called fluting [21,22,23].

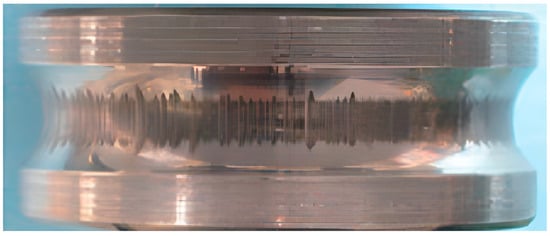

Figure 4.

Example of electrically induced wear on the inner race of a bearing.

3. Materials and Methods

3.1. Overview

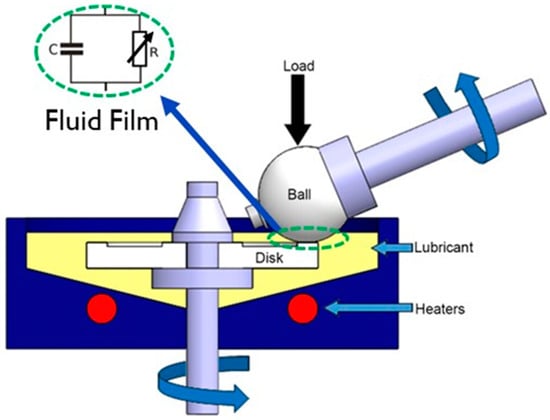

The goal of this study was to evaluate the friction and wear behavior of lubricants in an electrified environment by modifying the MTM to apply a current across the ball and disc test samples. The MTM schematic shown in Figure 5 enables motion studies applicable to different types of contacts, particularly gear meshing, due to its ability to change the slide-roll ratio (SRR).

Figure 5.

Schematic diagram of the mini traction machine (MTM).

The SRR represents the degree to which the ball rolls and/or slides against the disc. This is achieved by independently controlling the speed of the ball and disc. A 100% SRR represents the ball and disc traveling at the same speed, while an SRR of 0% represents pure rolling (disc stationary), and an SRR of 200% represents pure sliding (ball stationary) with the SRR defined as in Equation (1), where u1 is the disc speed and u2 is the ball speed at the contact between the disc and the ball. Controlling the SRR will allow for the simulation of rolling and sliding contacts, such as gears or roller elements. As shown in Figure 5, the lubricant forms a film between the ball and disc. Electrically, the film will have some impedance, which is dictated by the film thickness and electrical resistivity of the fluid.

3.2. Test Parameters

The current types (AC, DC, or non-electrified) were chosen as the electrical variables of interest, and an external power supply was used to apply these variables to the MTM. The power supplies used were Associated Power Technologies 8500 Series, Lake Forest Illinois USA for AC and EVENTEK KPS305D, Buchanan Michigan USA for DC. The electric conditions to which the MTM test components were subjected were selected to represent the voltage and amplitude found, but considered extreme, in an EV motor-gearbox system.

The temperature of the lubricant also varied in the matrix. The temperature ranged from 20 °C to 120 °C. This range was chosen based on data collected during the fluid aging study in a battery electric vehicle (BEV) undertaken at the Southwest Research Institute (SwRI) [24,25]. As the temperature changes, the lubricant viscosity and film thickness change, altering the performance of the fluid, which impacts friction, wear mechanisms, and wear rates.

The third test parameter was the load. Three loads, 5 N, 40 N, and 75 N, were selected. The highest load capability of the MTM test rig to maximize the contact pressure is 75 N. An increased load reduces the film thickness and hence causes more boundary contact of the test components.

3.3. Test Rig

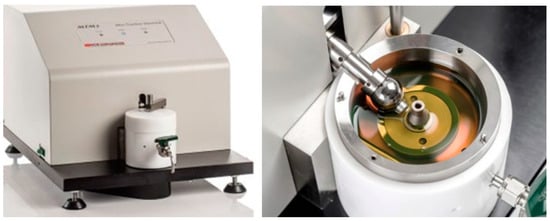

In a previous work, when a BoR module was electrified, care was taken to heat the lubricant in an external bath [6]. This measure was taken to remove any concern that the heating elements were creating further effects on the lubricant due to the magnetic fields. However, the MTM bath is enclosed and heated in situ, as shown in Figure 6.

Figure 6.

Images of the MTM test rig (left) and disc and ball test specimens in a lubricant bath with the cover removed (right) (courtesy PCS Instruments).

After investigating the effect of internal vs. external heating on the BoR, it was concluded that internal heating had no effect on the test results. It was, therefore, decided that the lubricant heating method on the MTM should not be changed.

Another challenge was ensuring that the MTM rig itself was isolated from the power being supplied to the test components. Ideally, the current would only pass through the ball and disc. Any stray voltage can result in damaged circuit boards and permanent damage to the rig. In addition, the power being supplied to the test components needed to be passed through the rotating parts only.

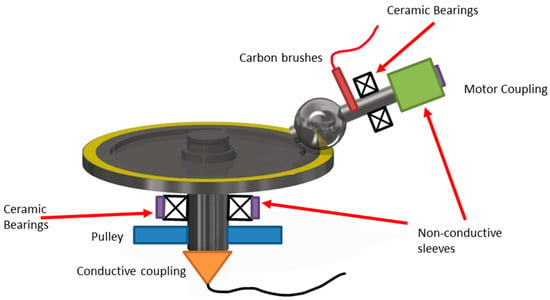

The electrified MTM design was configured using different types of electrically insulating materials to allow for electrical potential across the ball, disc, and lubricant while maintaining electrical isolation from the test rig itself. This work was performed in collaboration with PCS Instruments, the manufacturer of the MTM. Figure 7 shows the final solution with more details in a US Patent [26].

Figure 7.

Schematic diagram of the MTM showing the different components used to electrically isolate the ball and disc (courtesy PCS Instruments).

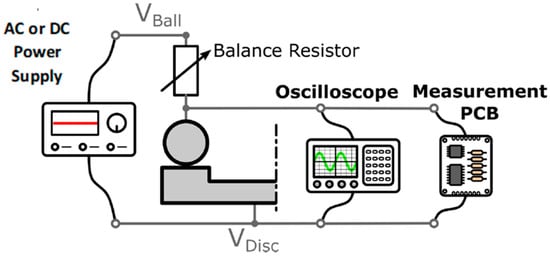

The MTM was isolated from the test components by replacing the standard steel bearings with ceramic bearings. Non-conductive sleeves were also added between the drive shafts and the motor couplings. To apply a potential across the ball, the shaft was fitted with a carbon brush and slip ring. The disc is driven by a pulley system—the motor drive is connected to the disc drive via a rubber belt. The lower portion of the disc drive shaft was fitted with conductive coupling to allow an electrical connection. The resulting electrical circuit used in the PCS Instruments MTM-EC is shown in Figure 8 and is internal to the MTM-EC test rig.

Figure 8.

MTM test parts and the circuit used to electrify the test parts (courtesy PCS Instruments).

Numerous tests were conducted using the modified components, resulting in several observations and improvements. The carbon brushes maintained a long lifespan; they only needed to be replaced once during the course of this study. The slip ring wire tended to break after several tests. The slip ring was replaced with a more robust stainless steel sleeve that was connected directly to the carbon brush and drive shaft.

3.4. Test Fluids and Parts

Three different fluids were used in this study: MERCON® ULV (ULV), DEXRON®-VI (DEX), and automatic gear oil (AGO). All three fluids are commonly used in EDUs and EV gearboxes, and are readily available for purchase. The viscosity, density, and dielectric breakdown of lubricants are presented in Section 4.

Separate AC and DC power supplies were used to control the different voltage and current configurations. During this development stage, the power supplies were controlled independently of the instrument software. When in use, current was supplied after the initial run-in step of the test profile. In the final PCS Instruments MTM-EC, the power supply is integral to the system and is controlled within the software.

To maintain consistency during the test program, MTM balls and discs were purchased from the rig manufacturer in the same manufacturing batch. During the manufacturing process, strict quality control is maintained in the material and surface finish. Table 1 shows the material specification. Before testing, the samples were sonicated in hexane for 20 min at an elevated temperature to remove any debris or residue. The samples were then weighed on a scale. After testing, the samples followed the same cleaning and weighing process as that performed during the initial preparation to determine mass loss/gain after testing.

Table 1.

MTM specimen specifications.

3.5. Test Procedure

Due to the matrix size, only tests at 40 °C and 100 °C were run in triplicate, and the test procedure was a half-hour run-in with no electrification, followed by Stribeck curve measurements at the required test specifications (i.e., load, temperature, and electrification). The test matrix is shown in Table 2. In total, 81 tests were performed for each fluid. A total of 243 tests were performed for the full matrix. It should be noted that not all test data and results are presented herein. Only the initial findings will be discussed. Work to understand these results is ongoing, and additional results will be published in future papers.

Table 2.

Test Matrix for one oil—repeats shown in cells.

During the preliminary test phase, one of the initial observations was the importance of when electrification was engaged and disengaged. Arcing will tend to occur when the ball and disc are partially separated. Meaning, at the start of the test, electrification must be applied after the ball and disc come into contact. Similarly, electrification must be turned off before the ball and disc are separated at the end of the test. If electrification is applied prior to the parts coming into contact or turned off after they separate at the end of a test, then arcing occurs. This caused damage in the form of large pits on the surface of the disc and ball, as shown on the disc in Figure 9.

Figure 9.

Disc showing wear track and pits in the track caused by arcing.

3.6. Wear Measurements

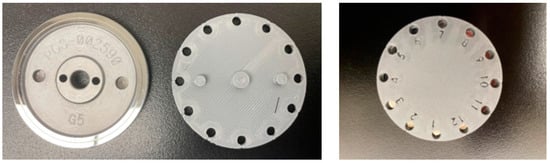

At the end of the testing, the wear track on the disc was examined using a white light interferometer, with a roughness repeatability of 2 nm, at 12 equally spaced locations, as defined by a cover disc with holes to allow measurements to be taken. See Figure 10. These measurements are given as 3D volumetric wear, and the resulting individual wear measurements are an average of these 12 measurements.

Figure 10.

End of the test, the MTM disc (left), 3D printed cover plate upside down (center), and 3D cover plate placed on top of the MTM disc (right).

3.7. Lubricant Properties

The breakdown voltage of the lubricant can affect how the lubricant behaves in the test rig when AC and DC potentials are applied, as well as the viscosity changes caused by electrification. The breakdown voltage was measured per ASTM D1816, and the lubricant viscosity under non-electrification and AC and DC currents were measured in a Rheometer instrumented for electrorheology. The lubricant density was also measured at 40 °C and 100 °C per ASTM D7042.

4. Results and Discussion

With a total matrix of 243 tests, not all data are presented and discussed in this manuscript. The main purpose of this paper is to introduce the test rig, test matrix conditions, and some immediate test findings. Analysis and further work are being undertaken to understand the patterns found in the full data set. This paper will present the results for the three oils at 40 N load and 40 °C and 100 °C only, with those temperatures having been run in triplicate. Table 3 shows the notation used for the test conditions throughout this section and in future papers.

Table 3.

Notations used for the test conditions.

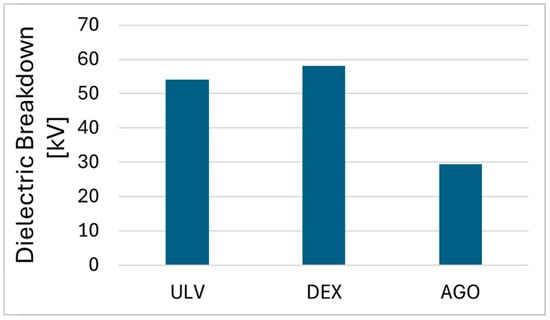

4.1. Lubricant Breakdown Voltage

Figure 11 shows the breakdown voltage for each lubricant. Measurements were taken using a GlobalCorr TOR-80 to ASTM D1816. The two automatic fluids, ULV and DEX, have very similar breakdown voltages, and the gear oil, AGO, has a noticeably lower breakdown voltage. With a lower breakdown voltage, it is easier for the current supplied to travel between the test components and through the lubricant. As such, smaller, more frequent arcing of lower energy intensity is expected in the AGO testing, with higher energy and less frequent arcing events with the ULV and DEX fluids.

Figure 11.

Dielectric breakdown comparison for all lubricants.

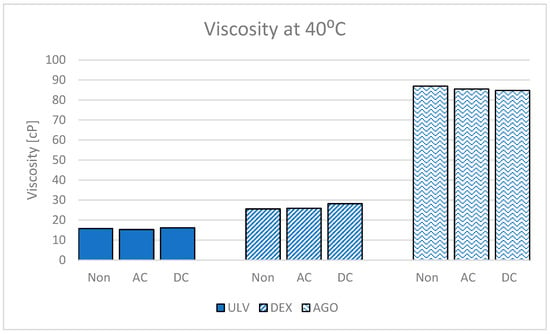

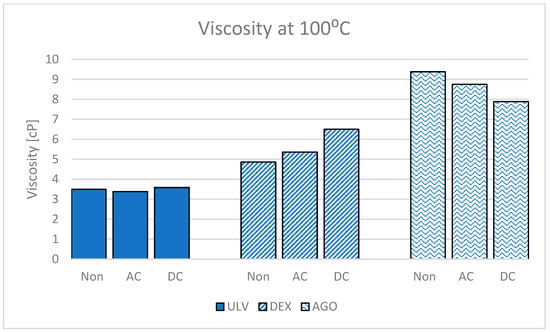

4.2. Lubricant Viscosity

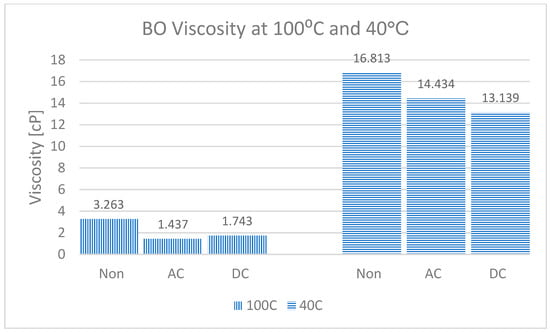

The dynamic viscosity of the lubricants was measured on an Anton Paar MCR series Rheometer with a cup and bob test geometry retrofitted for electrorheology with torque repeatability within ±0.015 µNm. The fluid cup is grounded, while the bob is electrified with a brush-type connection to the spindle shaft. An AC or DC power supply is connected and controlled independently from the Rheometer software. All the tests involved rotational shear at 300 s−1. Tests were conducted at 40 °C and 100 °C, as well as under non-electrified, AC, and DC electrified conditions. The viscosity of each fluid changed when electrified, with some increasing and others decreasing. The plots in Figure 12 and Figure 13 show the viscosity under all conditions. Table 4 provides the same data with percentage changes. The response to electrification and the current type is attributed to the chemical composition of the fluids. The base oil, additive package, and polymer types will all have an effect.

Figure 12.

Viscosity of all lubricants at 40 °C, comparing non-electrified to electrified conditions.

Figure 13.

Viscosity of all lubricants at 100⁰C, comparing non-electrified to electrified conditions.

Table 4.

Viscosity changes under AC and DC as a percentage of non-electrified at 40 °C and 100 °C for all three oils. Red denotes a viscosity decrease and green denotes a viscosity increase.

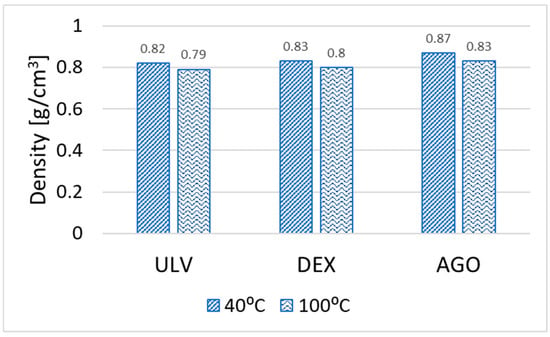

4.3. Lubricant Density

Figure 14 shows the density of each lubricant. Measurements were taken using an Anton Paar SVM 3001 per ASTM D7042. There is currently no means of measuring density under electrified conditions; therefore, all the results are for non-electrified conditions. The difference in density between the ULV and DEX lubricants both at 40 °C and 100 °C is negligible, being 1.2–1.3%. The AGO lubricant density increases just under 5% than that of the ULV and DEX lubricants at both 40 °C and 100 °C.

Figure 14.

Density of all lubricants under non-electrified conditions.

4.4. Stribeck Curves

Stribeck curves, showing the traction coefficient versus speed, are plotted for all three fluids discussed previously, as well as for a base oil for comparison. Plots are presented for non-electrified conditions, AC, and DC, with three tests each at 40 °C and 100 °C. All results shown were run at a 40 N load.

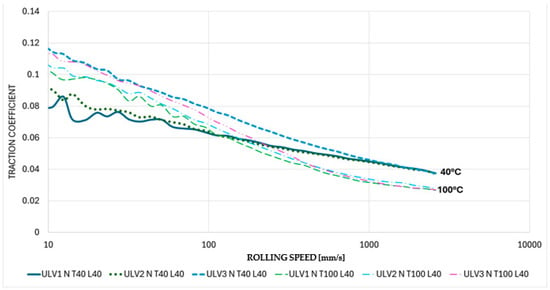

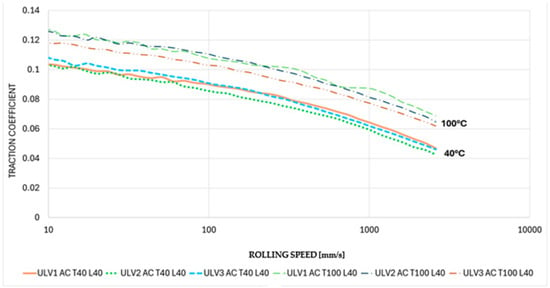

4.4.1. MERCON ULV Fluid (ULV)

For the non-electrified condition, Figure 15, the ULV fluid yields a higher traction coefficient at 40 °C (0.037) than at 100 °C (0.027) at the highest rolling speed. Although the higher speed values converge, they start at different values between 0.08 and 0.12, with no order between the 40 °C and 100 °C values. At 40 °C, the lubricant has a higher viscosity, leading to less entrainment at lower speeds. As the speed increases, the lubricant regime shifts to hydrodynamic, allowing a thicker film at the 40 °C condition. However, when AC power is applied, as shown in Figure 16, the trend is the opposite, giving higher traction coefficients at 100 °C (Avg. 0.065) than at 40 °C (Avg. 0.045). It is also of note that the starting values with AC power have more of an order than non-electrified, with 100 °C starting around 0.12, and 40 °C starting around 0.11. When DC power is applied, as shown in Figure 17, the trend is similar to that of AC power, but not as distinct or separated between the 40 °C and 100 °C runs. Under both AC and DC, the starting and finishing values are higher than those under non-electrified conditions. Elelctrification causes more wear on the surface, thereby increasing the surface roughness and contact area of the test parts. There is also an effect on the viscosity of the fluid that will affect its performance. The lubricant entrainment becomes more complex and does not have the typical trend of a non-electrified result under both temperature conditions.

Figure 15.

Non-electrified Stribeck curves for Mercon® ULV at 40 °C and 100 °C for a 40 N applied load.

Figure 16.

AC electrified Stribeck curves for Mercon® ULV at 40 °C and 100 °C for a 40 N applied load.

Figure 17.

DC electrified Stribeck curves for Mercon® ULV at 40 °C and 100 °C for a 40 N applied load.

Additionally, for all non-electrified repeat tests, Figure 15, the traction converges to the same value at higher speeds, showing high repeatability. When AC or DC power is applied, the repeats no longer converge to the same value, noticeably reducing the repeatability of the test runs.

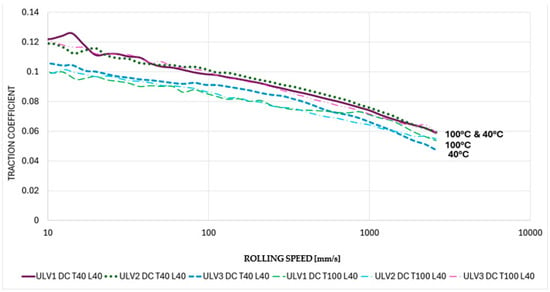

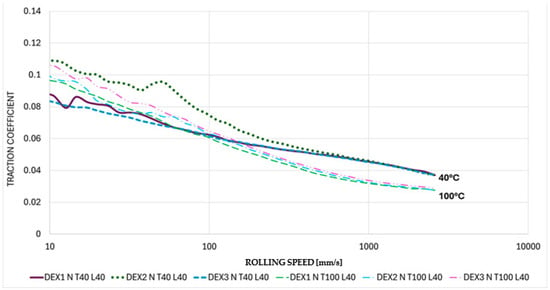

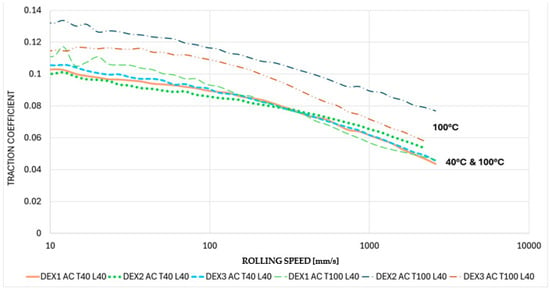

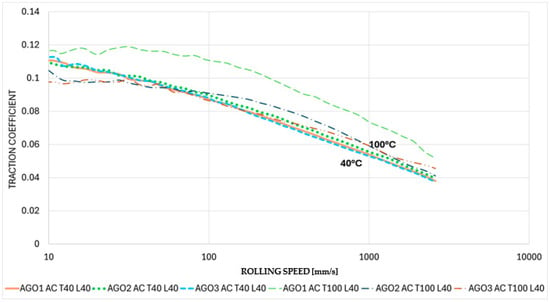

4.4.2. DEXRON VI Fluid (DEX)

For the non-electrified condition, Figure 18, the DEX fluid yields a higher traction coefficient at 40 °C (0.037) than at 100 °C (0.029) at the highest rolling speed, the same as the non-electrified ULV fluid, Figure 15. However, for the DEX fluid, it is when the DC power is applied, Figure 20, that the trend is opposite, giving higher traction coefficients at 100 °C (Avg. 0.072) than at 40 °C (Avg. 0.044). When AC power is applied, Figure 19 shows that the trend is similar to that of DC power, but not as distinct. As was seen with the ULV fluid, the DEX fluid also starts and finishes at a higher traction coefficient under AC and DC conditions. Again, the repeatability under non-electrified conditions is high, with convergence at higher speeds to the same values for the three runs at 40 °C and the three runs at 100 °C. This repeatability is lost once AC power is applied and is reduced under DC power conditions. Electrification causes a complex response due to its effect on lubricant viscosity and wear induced on the test parts.

Figure 18.

Non-electrified Stribeck curves for DEXRON® VI at 40 °C and 100 °C for a 40 N applied load.

Figure 19.

AC electrified Stribeck curves for DEXRON® VI at 40 °C and 100 °C for a 40 N applied load.

Figure 20.

DC electrified Stribeck curves for DEXRON® VI at 40 °C and 100 °C for a 40 N applied load.

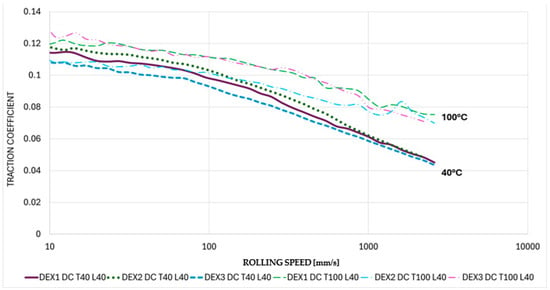

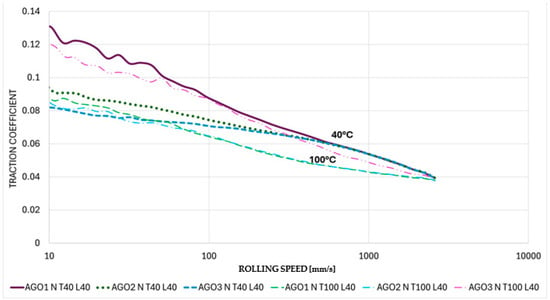

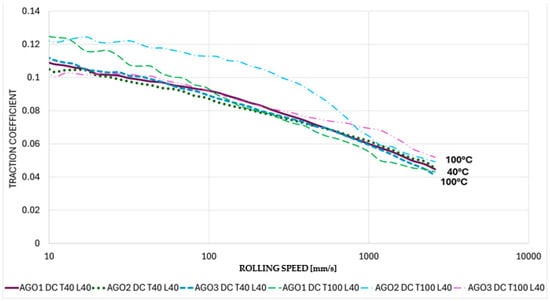

4.4.3. Automatic Gear Oil (AGO)

The Stribeck response of the AGO lubricant differed from those of the other two fluids. In all cases, the traction coefficient converged to the same (non-electrified) or similar values (AC and DC) under the highest speed condition. 0.039 for non-electrified, Avg. 0.042 for AC, and Avg. 0.046 for DC. The viscosity of the AGO is much higher than that of other fluids. The viscosity is such that the film thickness is similar at high speeds in the hydrodynamic region, resulting in a similar traction coefficient at both temperatures. However, the low-speed and mid-speed traction responses had the opposite trend when an electric potential was applied. Non-electrified, Figure 21, the mid-speed traction coefficient is higher at 40 °C and lower at 100 °C. For AC electrification, Figure 22, the mid-speed traction response at 100 °C was nearly the same or slightly higher than that at 40 °C. For DC electrification, as shown in Figure 23, the magnitude of traction for the two runs was much higher at 100 °C at lower speeds than at 40 °C. The third run at DC conditions and 100 °C was similar to the 40 °C run, exhibiting a lack of repeatability once the current was applied across the test components. As with the other two fluids, it was observed that electrification resulted in a complex traction response.

Figure 21.

Non-electrified Stribeck curves for AGO at 40 °C and 100 °C for a 40 N applied load.

Figure 22.

AC electrified Stribeck curves for AGO at 40 °C and 100 °C for a 40 N applied load.

Figure 23.

DC electrified Stribeck curves for AGO at 40 °C and 100 °C for a 40 N applied load.

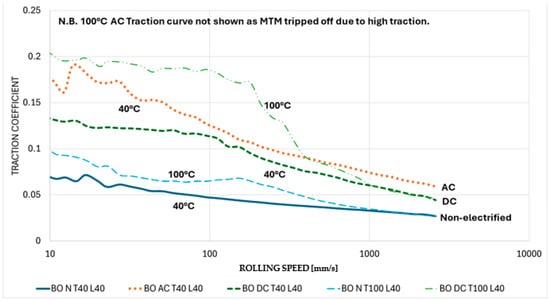

4.4.4. YUBASE 4+ Base Oil (BO)

A base oil was also tested to compare the traction and repeatability of the fully formulated lubricants. Figure 24 shows the Stribeck curves for a BO with no additives at 40 °C and 100 °C under non-electrified, AC, and DC conditions. One run for each condition is shown. These results show the expected outcome, with 100 °C non-electrified having a higher traction coefficient than non-electrified 40 °C. The 100 °C result exhibits a higher traction coefficient than the 40 °C result because of the reduction in viscosity due to temperature, and hence, the reduction in film thickness. Both the 100 °C and 40 °C non-electrified Stribeck curves converge at a higher speed. When DC current is applied, both the 100 °C and 40 °C traction coefficient values are significantly higher than those when non-electrified, but again converge at higher speeds. The AC results at 40 °C have a higher traction coefficient than the DC results at 40 °C. The 100 °C AC test would not run, tripping the rig off due to the excessively high traction coefficient values. In part, this is due to a reduction in viscosity of the BO under AC and DC conditions, as shown in Figure 25, with 100 °C AC condition giving 1.4 cP. However, there has to be more occurring in the base oil than just a viscosity change; otherwise, all the 100 °C traction curves would be considerably higher than the 40 °C traction curves.

Figure 24.

Non-electrified and AC and DC electrification at 40 °C and 100 °C for BO.

Figure 25.

BO viscosity at 100 °C and 40 °C under non-electrified AC and DC conditions.

4.5. Stribeck Discussion

As shown in Figure 15, Figure 16, Figure 17, Figure 18, Figure 19, Figure 20, Figure 21, Figure 22 and Figure 23, the triplicate runs undertaken with non-electrification are repeatable for all three oils. However, once AC or DC current is applied, although they may start with very similar traction coefficients, they become very different shortly after the test. The tribological explanation for this is that wear begins to occur immediately and that this wear, due to the presence of electrification, changes the roughness of the running surfaces. This roughness results in the same lubricant film thickness, offering less protection against separation of the parts and, hence, a higher traction coefficient, as observed in all electrified tests.

In all three test oils (ULV, DEX, and AGO) under non-electrified conditions, it is observed that, unlike the YUBASE 4+, the 100 °C traction values are lower than the 40 °C traction values. This is due to the additive package becomes operational at 100 °C but not at 40 °C, and therefore reducing the traction coefficients.

When the oils are electrified, the traction coefficient responds as expected when running a lubricant with no additive, as seen with YUBASE 4+. This suggests that electrification of the test parts disrupts the ability of the additives to work and prevents them from reducing the traction coefficient values.

The AGO lubricant is a more viscous fluid than the ULV and DEX lubricants. This results in a greater film thickness between the ball and disc throughout the entire speed range of the MTM than that experienced by the ULV and DEX lubricants. Hence, the convergence of the traction coefficient at the highest speeds. This convergence repeatability disappears under AC and DC conditions, particularly at 100 °C, and can be explained by the decrease in viscosity, which is particularly noticeable at 100 °C when the AGO lubricant is subjected to AC and DC power, as shown in Figure 12 and Figure 13.

The YUBASE 4+ results in Figure 24 show that supplying an AC or DC current across the test components through the oil increases the traction coefficient values significantly. This shows that the choice of base oil and additive package is important when blending a fluid for EVs.

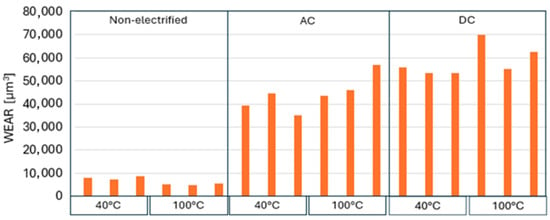

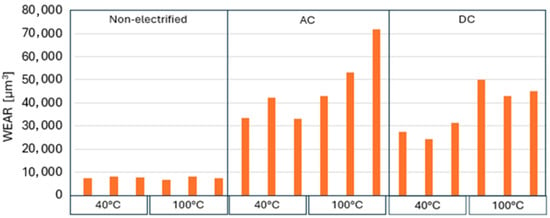

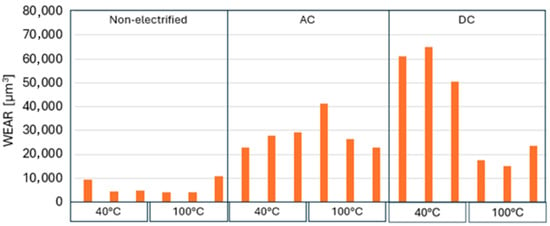

4.6. Wear Results and Discussion

To further understand the test results, the wear on each disc was measured. The results are plotted in Figure 26, Figure 27 and Figure 28.

Figure 26.

Wear volume at non-electrified, AC, and DC electrification for MERCON® ULV at 40 °C and 100 °C for a 40 N applied load.

Figure 27.

Wear volume at non-electrified, AC, and DC electrification for DEXRON® VI at 40 °C and 100 °C for a 40 N applied load.

Figure 28.

Wear volume at non-electrified, AC, and DC electrification for AGO at 40 °C and 100 °C for a 40 N applied load.

As shown in Figure 26, Figure 27 and Figure 28, the wear volume significantly increases when electrification is applied compared to the non-electrified condition. Once wear starts to occur, it is dependent on many different factors very specific to that contact pair; hence, the repeatability of high wear events is always low. In this test, the lack of repeatability is aggravated by the presence of AC and DC currents as the lubricant breaks down and the current arcs between the MTM ball and disc.

In the authors’ previous work electrifying a Block-on-Ring [6], it was observed that the DC wear values were generally higher than the AC values. Interestingly, in this work, this is only correct for the ULV lubricant and 40 °C AGO lubricant. For the other conditions and DEX, it is the other way round. This is most likely due to the difference in contact, with Block-on-Ring being total sliding, and these tests being 100% rolling (as per Equation (1)). It is also possible that changing the polarity of the contacts could change the wear behavior, as has been observed in previous work [27,28]. This was not investigated in this work.

A further area of interest is the difference in wear scars between the fluids and electrification type. Table 5 shows one of the white light interferometer measurements for each of the fluids under each method of electrification. Images are all 0.9 mm high and 1.3 mm wide.

Table 5.

Whitelight interferometer images for each fluid under each electrification condition.

Under non-electrification, all three fluids resulted in only a slight observable wear on the disc surface. Once AC and DC power are applied across the ball and disc, wear tracks can be easily observed in the images. Pits (dark spots in the images) are also visible. However, pits do not occur within the wear track but outside, where there is no contact between the test parts. This is likely a result of arcing. Also of interest is the difference in the type of wear occurring. This is most clearly observed when comparing AGO AC with AGO DC electrification. The DC image shows lines of wear in the direction of travel, whereas this is not seen in the AC image, where general surface wear is observed instead. This was an unexpected finding that shows that there is much more to understand before lubricants can be formulated to specifically work in these electrified environments.

5. Conclusions

This work resulted in the electrification of an MTM test rig and the development, in partnership with a manufacturer, of a commercially available electrified MTM (PCS MTM-EC). A large test matrix was applied to the electrified MTM under non-electrified AC and DC conditions. A subset of these test results has been presented.

These results show that the traction coefficients of a lubricant, both additized and base oil, can be significantly changed under AC and DC electrification. All lubricants increased their overall traction coefficient values from the start to the end of the test when AC and DC were applied across the test components. This is caused by viscosity modification due to the AC and DC, as well as effects on the additive package. In some cases, the viscosity increased, and in others, it decreased when AC and DC were applied.

In all cases, the wear observed on the disc increased significantly when AC and DC were applied across the test components. The type of wear was also observed to be inconsistent across all conditions, and in all tests, pits were observed outside the wear track, which was attributed to arcing.

When testing the BO at 100 °C, the traction coefficient was higher than when testing at 40 °C under non-electrified, AC, and DC conditions. This is due to the lower viscosity at the higher temperature. When testing the three formulated lubricants under non-electrified conditions, the 100 °C traction coefficients were lower than those at 40 °C traction coefficients. This is the result of the additive package being chemically active and lowering the traction coefficient. However, when the AC and DC were applied to the formulated lubricant tests, this no longer occurred, and they behaved like the BO, with a higher traction coefficient at higher temperatures. This shows that the additives ceased to work as designed during AC and DC tests.

This work has shown that the interaction between dielectric breakdown and viscosity modification of base oils and additives under electrified conditions needs to be understood in more depth. This is required before lubricants for EVs can be developed that will satisfy the operating environment to which they are subjected. This work has also resulted in a commercially available test rig to enable this work to be undertaken in commercial labs, not just research labs.

6. Patents

U.S. Patent Application 18/665.830. Apparatus and Method to Evaluate the Effect of Electrical Potential Between Moving Surfaces. Filed 16 May 2024.

Author Contributions

P.L. and C.S. wrote the paper and managed the research project. P.L., C.S., M.M., and A.V. all contributed to the data processing, analysis, and conclusions. M.M. supervised the work undertaken in the labs. All authors have read and agreed to the published version of the manuscript.

Funding

Funding for the testing at Southwest Research Institute was provided by Southwest Research Institute’s Internal Research and development program.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors upon request.

Acknowledgments

The authors would like to thank Robert Gray for running the MTM tests, Jereme Arellano for the viscosity testing, and Isaias Reyes for the whitelight imaging and dielectric breakdown testing. All work was undertaken in the Tribology Research and Evaluation labs at the Southwest Research Institute and funded by an Internal Research award.

Conflicts of Interest

The authors declare that this research was conducted in the absence of any commercial or financial relationships that could be construed as potential conflicts of interest.

References

- He, F.; Xie, G.; Luo, J. Electrical bearing failures in electric vehicles. Friction 2020, 8, 4–28. [Google Scholar] [CrossRef]

- Jacobson, B. The Stribeck memorial lecture. Tribol. Int. 2003, 36, 781–789. [Google Scholar] [CrossRef]

- Canter, N. Tribology and Lubrication for E-Mobility: Findings from the Inaugural STLE Conference on Electric Vehicles; Society of Tribologists and Lubrication Engineers: Park Ridge, IL, USA, 2022. [Google Scholar]

- Canter, N. Tribology and Lubrication for E-Mobility: Findings from the 2nd STLE Conference on Electric Vehicles; Society of Tribologists and Lubrication Engineers: Park Ridge, IL, USA, 2023. [Google Scholar]

- Canter, N. Tribology and Lubrication for E-Mobility: Findings from the 3rd STLE Conference on Electric Vehicles; Society of Tribologists and Lubrication Engineers: Park Ridge, IL, USA, 2024. [Google Scholar]

- Lee, P.M.; Sanchez, C.; Frazier, C.; Velasquez, A.; Kostan, T. Tribological evaluation of electric vehicle driveline lubricants in an electrified environment. Front. Mech. Eng. 2023, 9, 1215352. [Google Scholar] [CrossRef]

- Arole, K.; Chen, Y.; Delgado, A.; Hubbard, J.; Liang, H. Urea-ZrP Nanoparticle-enabled Electro-responsivity. J. Mol. Liq. 2022, 363, 119803. [Google Scholar] [CrossRef]

- Chen, Y.; Renner, P.; Liang, H. Using Electrochemical Impendence to Characterize Thermal Performance of Working Lubricants. Surf. Topogr. Metrol. Prop. 2021, 9, 035035. [Google Scholar] [CrossRef]

- Chen, Y.; Liang, H. Tribological Evaluation of Electrical Resistance of Lubricated Contacts. ASME J. Trib. 2020, 142, 114502. [Google Scholar] [CrossRef]

- Deshpande, P.; Yelkarasi, C.; Lee, S.; Farfan-Cabrera, L.I.; Erdemir, A. Electrotribochemical formation of abrasive nano-carbon particles under electrified conditions on lubricated sliding contacts. Carbon 2024, 228, 119425. [Google Scholar] [CrossRef]

- Cao-Romero-Gallegos, J.A.; Farfan-Cabrera, L.I.; Erdemir, A.; Pascual-Francisco, J.B. Lubricated sliding wear of gear material under electrification—A new approach to understanding of the influence of shift currents in the wear of EV transmissions. Wear 2023, 523, 204782. [Google Scholar] [CrossRef]

- Cao-Romero-Gallegos, J.A.; Taghizadeh, S.; Aguilar-Rosas, O.A.; Dwyer-Joyce, R.S.; Farfan-Cabrera, L.I. The effect of electrical current on lubricant film thickness in boundary and mixed lubrication contacts measured with ultrasound. Friction 2024, 12, 1882–1896. [Google Scholar] [CrossRef]

- Demas, N.G.; Lorenzo-Martin, C.; Luna, R.; Erck, R.A.; Greco, A.C. The Effect of Current and Lambda on White-Etch-Crack Failures. Tribol. Int. 2023, 189, 108951. [Google Scholar] [CrossRef]

- Gould, B.; Demas, N.; Erck, R.; Lorenzo-Martin, M.C.; Ajayi, O.; Greco, A.C. The Effect of Electrical Current on Premature Failures and Microstructural Degradation in Bearing Steel. Int. J. Fatigue 2021, 145, 106078. [Google Scholar] [CrossRef]

- Hadden, T.; Jiang, J.W.; Bilgin, B.; Yang, Y.; Sathyan, A.; Dadkhah, H. A review of shaft voltages and bearing currents in EV and HEV motors. In Proceedings of the IECON 2016-42nd Annual Conference of the IEEE Industrial Electronics Society, Florence, Italy, 23–26 October 2016; pp. 1578–1583. [Google Scholar]

- Ma, J.; Xue, Y.; Han, Q.; Li, X.; Yu, C. Motor bearing damage induced by bearing current: A Review. Machines 2022, 10, 1167. [Google Scholar] [CrossRef]

- Tawfiq, K.B.; Gulec, M.; Sergeant, P. Bearing current and shaft voltage in electric machines: A comprehensive research review. Machines 2023, 11, 550. [Google Scholar] [CrossRef]

- Somani, A.; Gupta, R.K.; Mohapatra, K.K.; Mohan, N. On the causes of circulating currents in PWM drives with open-end winding AC machines. IEEE Trans. Ind. Electron. 2012, 60, 3670–3678. [Google Scholar] [CrossRef]

- Tischmacher, H.; Gattermann, S.; Kriese, M.; Wittek, E. Bearing wear caused by converter-induced bearing currents. In Proceedings of the IECON 36th Annual Conference on IEEE Industrial Electronics Society, Glendale, AZ, USA, 7–10 November 2010; pp. 784–791. [Google Scholar]

- Evo, M.T.; Alzamora, A.M.; Zaparoli, I.O.; de Paula, H. Inverter-Induced bearing currents: A thorough study of the cause-and-effect chains. Proc. IEEE Ind. Appl. Mag. 2022, 29, 57–66. [Google Scholar] [CrossRef]

- Huan, J.; Li, S.; Xia, Z.; Wang, Y.; Wang, W.; Shi, G. Experimental study on electric corrosion damage of bearing and solution. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 10349–10358. [Google Scholar] [CrossRef]

- Harder, A.; Zaiat, A.; Becker-Dombrowsky, F.M.; Puchtler, S.; Kirchner, E. Investigation of the voltage-induced damage progression on the raceway surfaces of thrust ball bearings. Machines 2022, 10, 832. [Google Scholar] [CrossRef]

- Suzumura, J. Prevention of electrical pitting on rolling bearings by electrically conductive grease. Q. Rep. RTRI 2016, 57, 42–47. [Google Scholar] [CrossRef] [PubMed]

- Hudson, C.; Smith, I.; Wileman, C. EV Fluid Performance Investigation (IONIQ5), Southwest Research Institute Internal Research and Development Report; 2025. [Google Scholar]

- Hudson, C.; Smith, I.; Wileman, C. Development of Hybrid Drivetrain Fluids and Hardware Testing (RAV4), Southwest Research Institute Internal Research and Development Report; 2024. [Google Scholar]

- Sanchez, C.; Lee, P.M.; Hamer, J.C.; Welham, T.W.G.; Wainwright, B.P.; Smeeth, M. Apparatus and Method to Evaluate the Effect of Electrical Potential Between Moving Surfaces. U.S. Patent Application 18/665.830, 2024. [Google Scholar]

- Gangopadhyay, A.; Paputa Peck, M.C.; Simko, S.J. Wear control in a lubricated contact through externally applied electric current. Tribol. Trans. 2010, 45, 302–309. [Google Scholar] [CrossRef]

- Mahmoud, M.M.; Mohamed, M.K.; Ali, W.Y. Tribological behaviour of lubricated surfaces under application of electric current. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2009, 224, 73–79. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).