Exploring the Boundaries of Electrically Induced Bearing Damage in Grease-Lubricated Rolling Contacts

Abstract

1. Introduction

1.1. Electrification of the Transportation Industry

1.2. Greases in Elastohydrodynamic Lubrication (EHL)

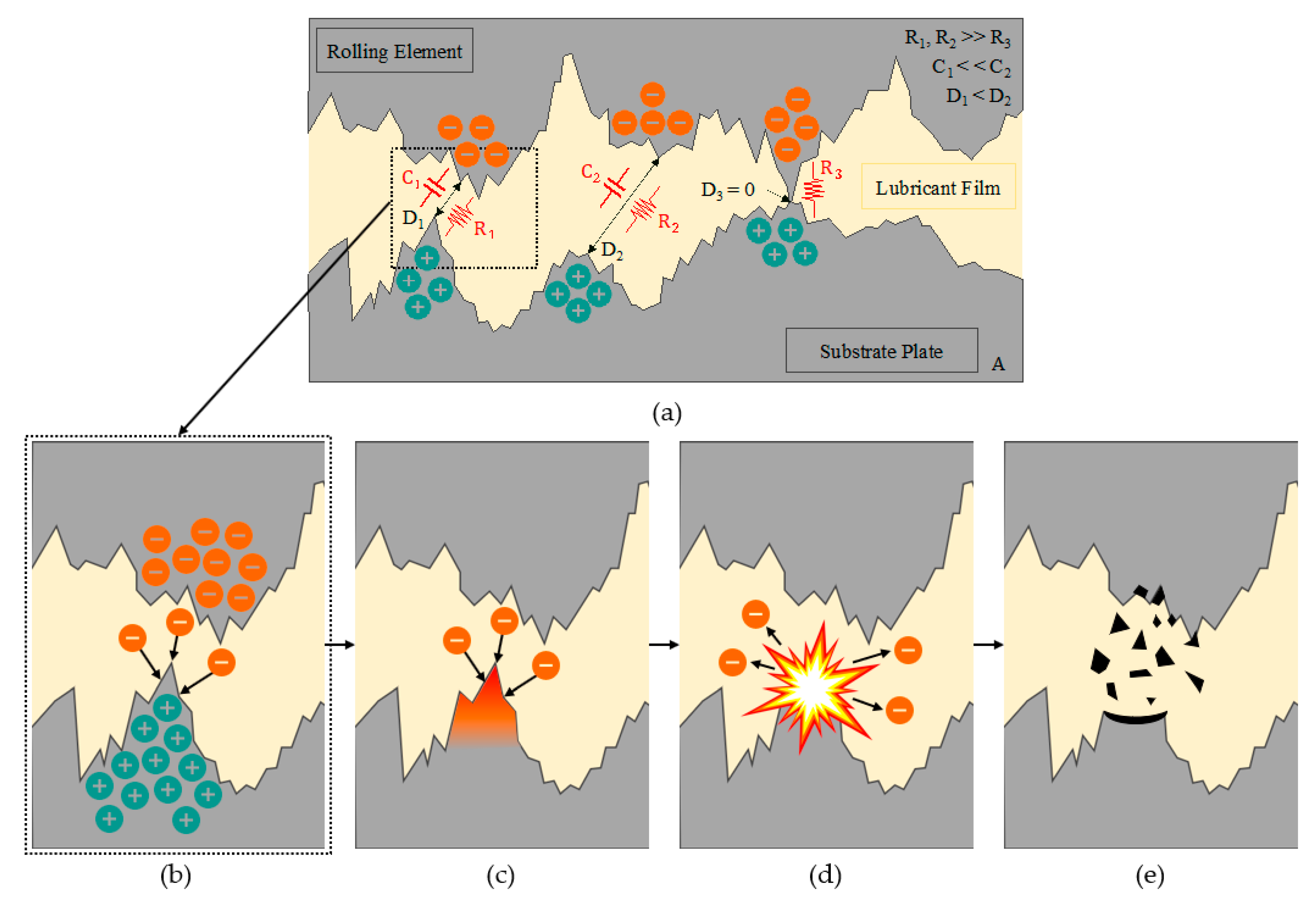

1.3. Causes of Electrical Damage in Electric Motors

1.4. Arc Formation and Propogation

1.5. Electrical Damage to Mechanical Systems

2. Materials and Methods

2.1. General Test Apparatus Overview

2.2. Electrical Circuit, Test Samples, & Mechanical Loading

2.3. Grease Selection

3. Results

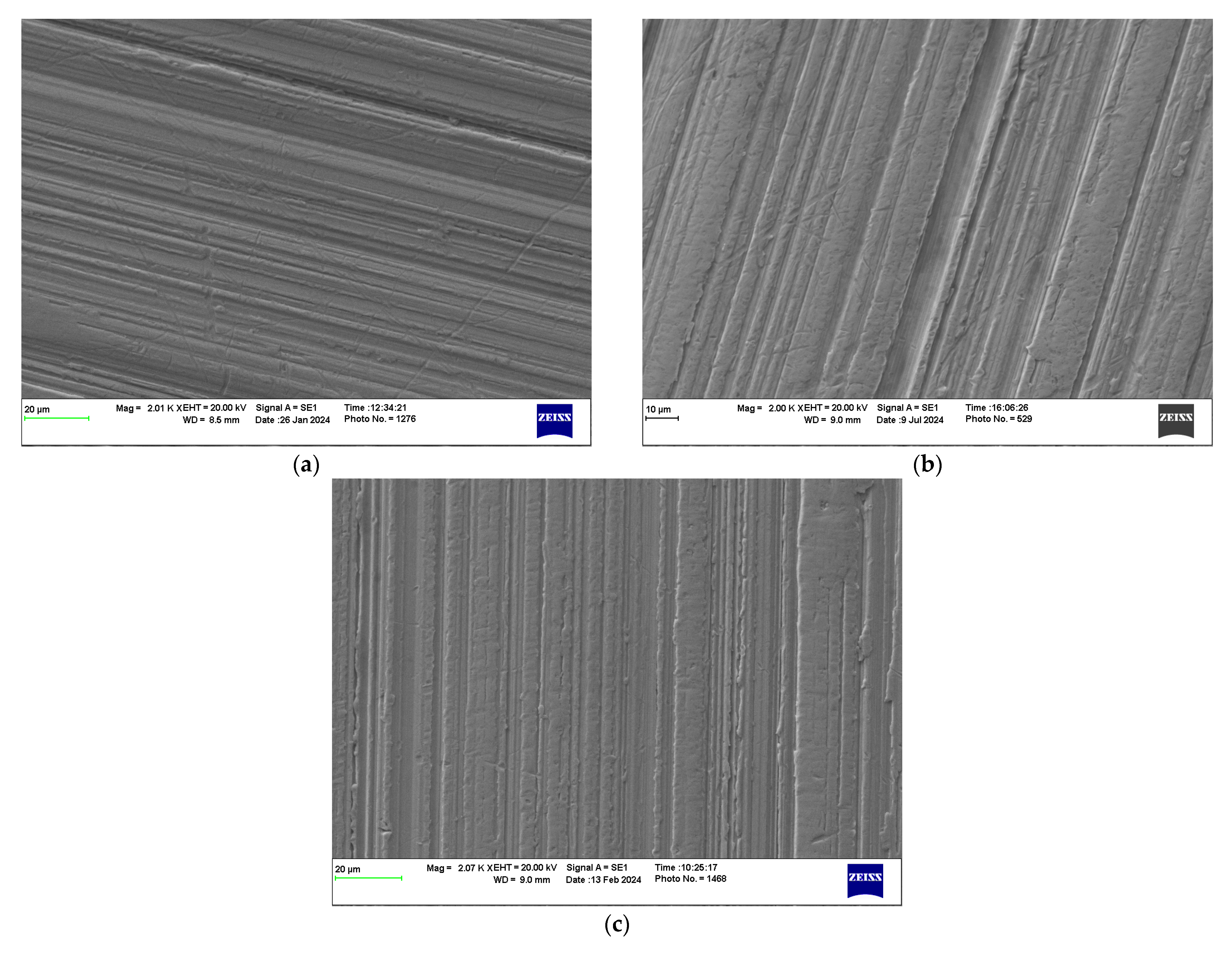

3.1. Full Rotational Testing

3.2. Complete Revolutions/Cycle Testing

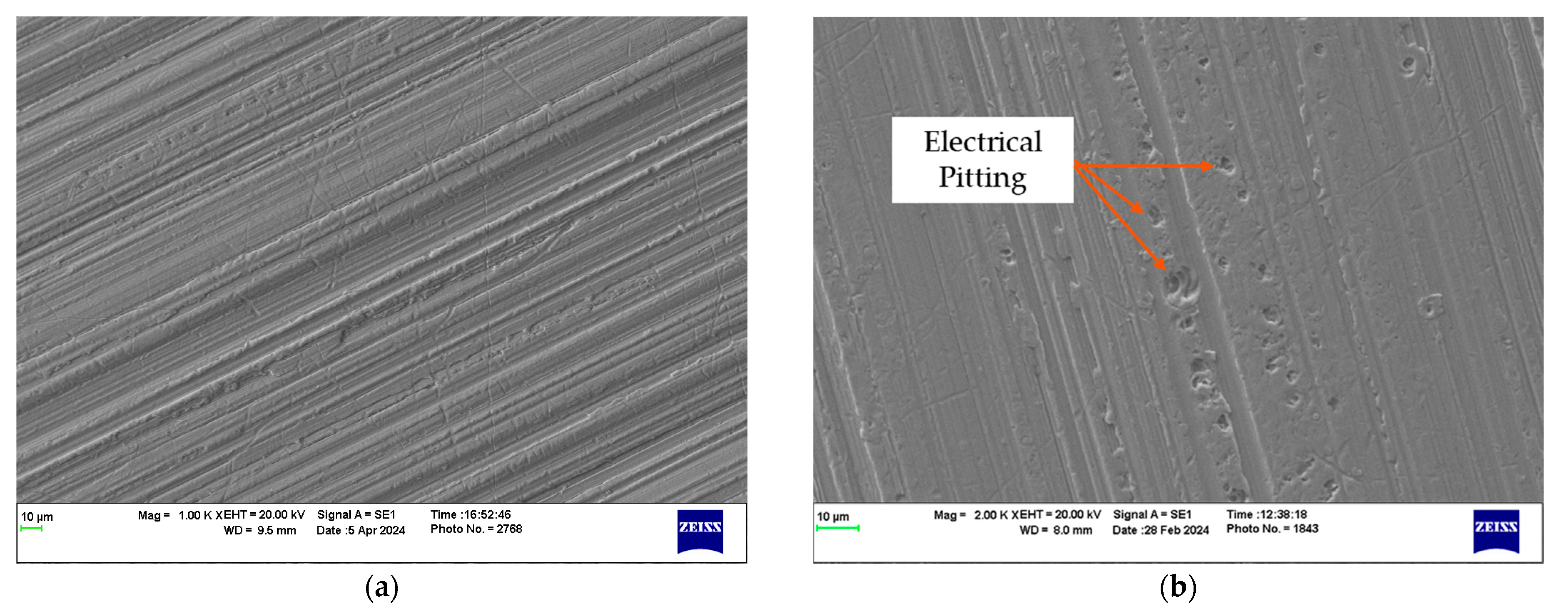

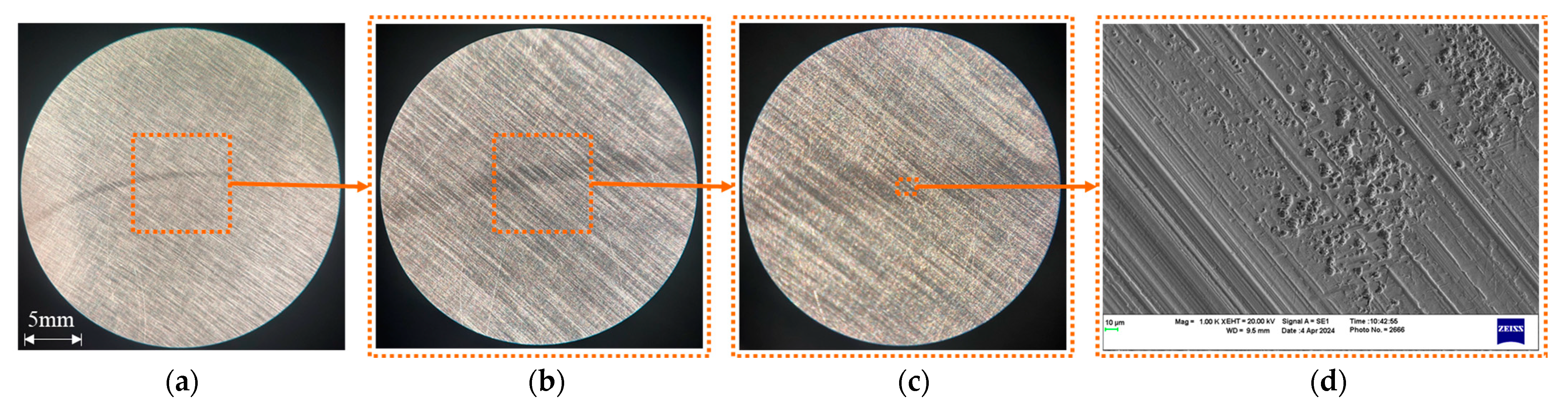

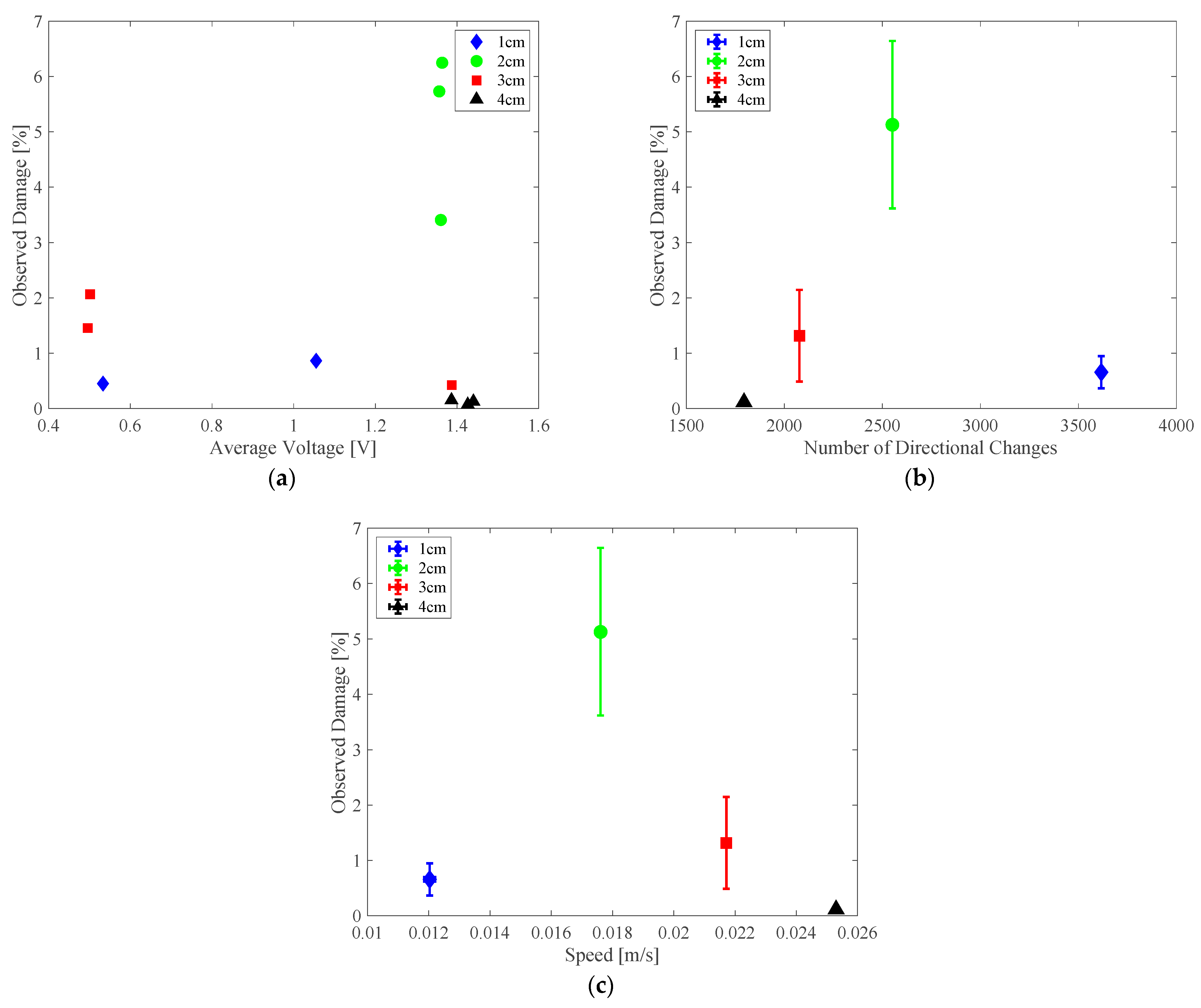

3.3. Extended Track Reciprocating Testing

4. Discussion

5. Conclusions

- Little to no definitive electrical damage was present after the complete rotational or full revolution/cycle tests were conducted.

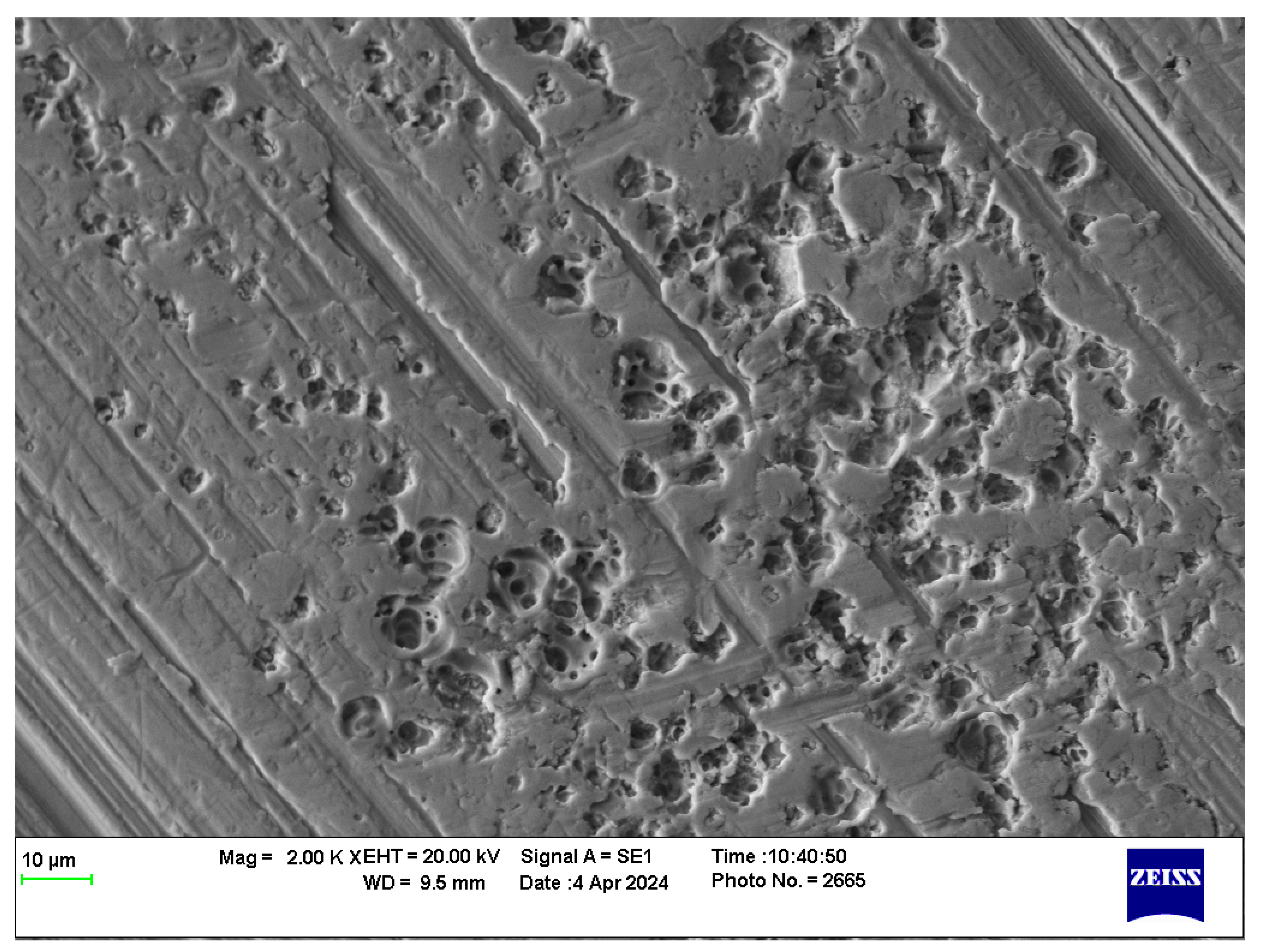

- Significant pitting damage occurred during reciprocating tests with track lengths between 1 cm and 4 cm. Among these, the 2 cm track length showed the most severe damage.

- The speed of the rolling element may affect the film thickness generated due to the EHL mechanism. Likewise, the thickness of the film affects the insulative and capacitive properties of the dielectric lubricant. Thin films are expected to pass charge easier than thicker films, which act as total dielectrics. Intermediate films are expected to be key for charge accumulation and discharge.

- The varying track lengths for reciprocating tests have significant implications for the charge dissipation patterns. Charge may not be discharged over long distances and sustained motion in a single concentrated area. During start/stop conditions, the extended time at a single location allows for a more intense and destructive ablation. This suggests that more damage would be concentrated near the track ends of reciprocating tracks. This is supported by the pitting location that was captured in the SEM images. Vehicles that make frequent stops, such as delivery vehicles or commuter transportation, may be more susceptible to this damage given this effect.

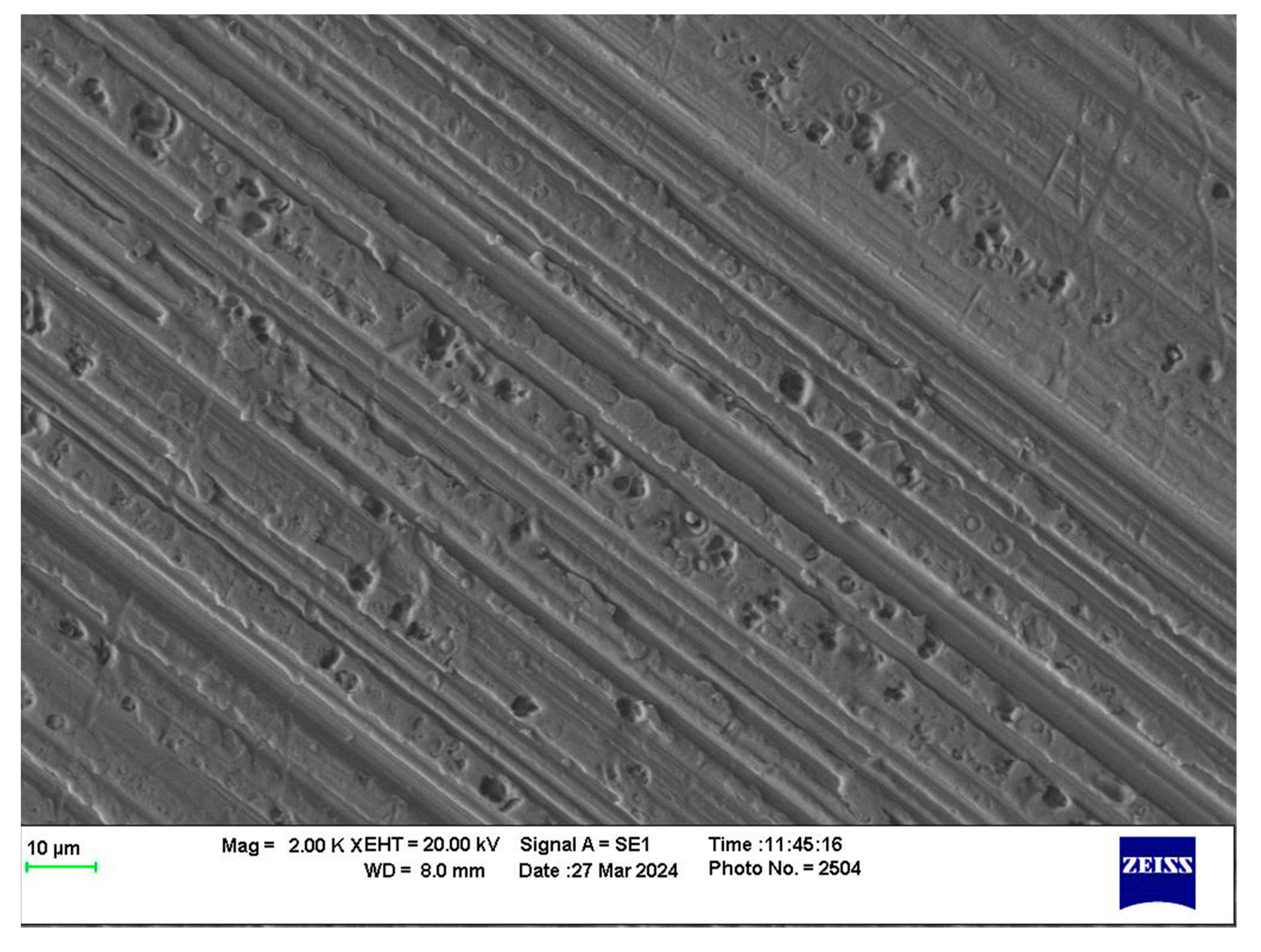

- The primary location of pitting along the asperity or roughness ridges reiterates the mechanism/model, suggesting that the pits are the remains of exploded asperities.

- Evidence of thermal fatigue from cracking reiterates the high energy (heat) generated during the pit formation process. While the cracks are not attributed to surface fatigue, thermal expansion may result in surface fatigue or premature mechanical failure.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- IEA. Electric Car Sales, 2016–2023—Charts—Data & Statistics. Available online: https://www.iea.org/data-and-statistics/charts/electric-car-sales-2016-2023 (accessed on 2 October 2023).

- IEA. Global EV Outlook 2023—Analysis. Available online: https://www.iea.org/reports/global-ev-outlook-2023 (accessed on 3 October 2023).

- Hamidizadeh, S.; Alatawneh, N.; Chromik, R.R.; Lowther, D.A. Comparison of Different Demagnetization Models of Permanent Magnet in Machines for Electric Vehicle Application. IEEE Trans. Magn. 2016, 52, 1–4. [Google Scholar] [CrossRef]

- Sebastian, T. Temperature effects on torque production and efficiency of PM motors using NdFeB magnets. In Proceedings of the Conference Record of the 1993 IEEE Industry Applications Conference Twenty-Eighth IAS Annual Meeting, Toronto, ON, Canada, 2–8 October 1993; Volume 1, pp. 78–83. [Google Scholar] [CrossRef]

- Chen, Y.; Jha, S.; Raut, A.; Zhang, W.; Liang, H. Performance Characteristics of Lubricants in Electric and Hybrid Vehicles: A Review of Current and Future Needs. Front. Mech. Eng. 2020, 6, 571464. [Google Scholar] [CrossRef]

- Farfan-Cabrera, L.I. Tribology of electric vehicles: A review of critical components, current state and future improvement trends. Tribol. Int. 2019, 138, 473–486. [Google Scholar] [CrossRef]

- Lugt, P.M. Modern advancements in lubricating grease technology. Tribol. Int. 2016, 97, 467–477. [Google Scholar] [CrossRef]

- Hemanth, G.; Suresha, B. Hybrid and electric vehicle tribology: A review. Surf. Topogr. Metrol. Prop. 2021, 9, 043001. [Google Scholar] [CrossRef]

- Rezasoltani, A.; Khonsari, M.M. On Monitoring Physical and Chemical Degradation and Life Estimation Models for Lubricating Greases. Lubricants 2016, 4, 34. [Google Scholar] [CrossRef]

- Gurt, A.; Khonsari, M.M. Testing Grease Consistency. Lubricants 2021, 9, 14. [Google Scholar] [CrossRef]

- Gonda, A.; Capan, R.; Bechev, D.; Sauer, B. The Influence of Lubricant Conductivity on Bearing Currents in the Case of Rolling Bearing Greases. Lubricants 2019, 7, 108. [Google Scholar] [CrossRef]

- Huber, F.; Berwanger, J.; Polesya, S.; Mankovsky, S.; Ebert, H.; Giessibl, F.J. Chemical bond formation showing a transition from physisorption to chemisorption. Science 2019, 366, 235–238. [Google Scholar] [CrossRef]

- Xie, G.; Guo, D.; Luo, J. Lubrication under charged conditions. Tribol. Int. 2015, 84, 22–35. [Google Scholar] [CrossRef]

- Jackson, R.L.; Coker, A.B.; Tucker, Z.; Hossain, M.S.; Mills, G. An Investigation of Silver-Nanoparticle-Laden Lubricants for Electrical Contacts. IEEE Trans. Compon. Packag. Manuf. Technol. 2019, 9, 193–200. [Google Scholar] [CrossRef]

- Minami, I. Molecular Science of Lubricant Additives. Appl. Sci. 2017, 7, 445. [Google Scholar] [CrossRef]

- Jablonka, K.; Glovnea, R.; Bongaerts, J.; Morales-Espejel, G. The effect of the polarity of the lubricant upon capacitance measurements of EHD contacts. Tribol. Int. 2013, 61, 95–101. [Google Scholar] [CrossRef]

- Ahmed Abdalglil Mustafa, W.; Dassenoy, F.; Sarno, M.; Senatore, A. A review on potentials and challenges of nanolubricants as promising lubricants for electric vehicles. Lubr. Sci. 2022, 34, 1–29. [Google Scholar] [CrossRef]

- Scarlett, N.A. Paper 21: Use of Grease in Rolling Bearings. Proc. Inst. Mech. Eng. Conf. Proc. 1967, 182, 585–624. [Google Scholar] [CrossRef]

- Åström, H. Irregular film thickness fluctuations in elastohydrodynamic lubrication of a point contact lubricated with lubricating grease. Tribologia 1992, 11, 179–184. [Google Scholar]

- Cann, P.M.; Webster, M.N.; Doner, J.P.; Wikstrom, V.; Lugt, P. Grease Degradation in R0F Bearing Tests. Tribol. Trans. 2007, 50, 187–197. [Google Scholar] [CrossRef]

- Wang, J.; Guo, Z.; Hu, W.; Lu, H.; Li, J. Investigating the effects of base oil type on microstructure and tribological properties of polyurea grease. Tribol. Int. 2024, 194, 109573. [Google Scholar] [CrossRef]

- Zhang, X.; Glovnea, R. Grease film thickness measurement in rolling bearing contacts. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2021, 235, 1430–1439. [Google Scholar] [CrossRef]

- Cann, P.M.; Williamson, B.P.; Coy, R.C.; Spikes, H.A. The behaviour of greases in elastohydrodynamic contacts. J. Phys. Appl. Phys. 1992, 25, A124. [Google Scholar] [CrossRef]

- Farcas, F.; Gafitanu, M.D. Some influence parameters on greases lubricated rolling contacts service life. Wear 1999, 225–229, 1004–1010. [Google Scholar] [CrossRef]

- Åström, H.; Östensen, J.O.; Höglund, E. Lubricating Grease Replenishment in an Elastohydrodynamic Point Contact. J. Tribol. 1993, 115, 501–506. [Google Scholar] [CrossRef]

- Zhang, S.; Klinghart, B.; Jacobs, G.; von Goeldel, S.; König, F. Prediction of bleeding behavior and film thickness evolution in grease lubricated rolling contacts. Tribol. Int. 2024, 193, 109369. [Google Scholar] [CrossRef]

- Taycan, Taycan 4S, Turbo and Turbo S—The Battery—Porsche Taycan. Available online: https://media.porsche.com/mediakit/taycan/en/porsche-taycan/die-batterie (accessed on 16 October 2023).

- Model 3 Owner’s Manual. Available online: https://www.tesla.com/ownersmanual/model3/en_us/ (accessed on 16 October 2023).

- Hadden, T.; Jiang, J.W.; Bilgin, B.; Yang, Y.; Sathyan, A.; Dadkhah, H.; Emadi, A. A Review of Shaft Voltages and Bearing Currents in EV and HEV Motors. In Proceedings of the IECON 2016—42nd Annual Conference of the IEEE Industrial Electronics Society, Florence, Italy, 23–26 October 2016; pp. 1578–1583. [Google Scholar] [CrossRef]

- He, F.; Xie, G.; Luo, J. Electrical bearing failures in electric vehicles. Friction 2020, 8, 4–28. [Google Scholar] [CrossRef]

- Abu-Rub, H.; Bayhan, S.; Moinoddin, S.; Malinowski, M.; Guzinski, J. Medium-Voltage Drives: Challenges and existing technology. IEEE Power Electron. Mag. 2016, 3, 29–41. [Google Scholar] [CrossRef]

- Habibullah, M.; Lu, D.D.-C.; Xiao, D.; Rahman, M.F. Finite-State Predictive Torque Control of Induction Motor Supplied From a Three-Level NPC Voltage Source Inverter. IEEE Trans. Power Electron. 2017, 32, 479–489. [Google Scholar] [CrossRef]

- Cao Romero, J.A.; Reyes-Avendaño, J.; Soriano, J.; Farfan-Cabrera, L.; Erdemir, A. A Pin-on-Disc Study on the Electrified Sliding Wear of EVs Powertrain Gears; SAE International: Warrendale, PA, USA, 2022. [Google Scholar] [CrossRef]

- Amjad, S.; Neelakrishnan, S.; Rudramoorthy, R. Review of design considerations and technological challenges for successful development and deployment of plug-in hybrid electric vehicles. Renew. Sustain. Energy Rev. 2010, 14, 1104–1110. [Google Scholar] [CrossRef]

- Rind, S.; Ren, Y.; Jiang, L. Traction motors and speed estimation techniques for sensorless control of electric vehicles: A review. In Proceedings of the 2014 49th International Universities Power Engineering Conference (UPEC), Cluj-Napoca, Romania, 2–5 September 2014; pp. 1–6. [Google Scholar] [CrossRef]

- Shami, U.T.; Akagi, H. Identification and Discussion of the Origin of a Shaft End-to-End Voltage in an Inverter-Driven Motor. IEEE Trans. Power Electron. 2010, 25, 1615–1625. [Google Scholar] [CrossRef]

- Fišer, R.; Ferkolj, S. Magnetic field analysis of induction motor with rotor faults. COMPEL—Int. J. Comput. Math. Electr. Electron. Eng. 1998, 17, 206–211. [Google Scholar] [CrossRef]

- Asakura, Y.; Akagi, H. Mechanism of Shaft End-to-End Voltage Generation by Asymmetry in an Inverter-Driven Motor. Electr. Eng. Jpn. 2013, 185, 48–56. [Google Scholar] [CrossRef]

- Prashad, H. Investigation of damaged rolling-element bearings and deterioration of lubricants under the influence of electric fields. Wear 1994, 176, 151–161. [Google Scholar] [CrossRef]

- Zika, T.; Gebeshuber, I.C.; Buschbeck, F.; Preisinger, G.; Gröschl, M. Surface analysis on rolling bearings after exposure to defined electric stress. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2009, 223, 787–797. [Google Scholar] [CrossRef]

- Muetze, A.; Binder, A. Don’t lose your bearings. IEEE Ind. Appl. Mag. 2006, 12, 22–31. [Google Scholar] [CrossRef]

- Kudelina, K.; Asad, B.; Vaimann, T.; Belahcen, A.; Rassõlkin, A.; Kallaste, A.; Lukichev, D.V. Bearing Fault Analysis of BLDC Motor for Electric Scooter Application. Designs 2020, 4, 42. [Google Scholar] [CrossRef]

- Magdun, O.; Gemeinder, Y.; Binder, A. Investigation of influence of bearing load and bearing temperature on EDM bearing currents. In Proceedings of the 2010 IEEE Energy Conversion Congress and Exposition (ECCE), Atlanta, GA, USA, 12–16 September 2010; pp. 2733–2738. [Google Scholar] [CrossRef]

- Slade, P.G.; Taylor, E.D. Electrical breakdown in atmospheric air between closely spaced (0.2/spl mu/m-40/spl mu/m) electrical contacts. IEEE Trans. Compon. Packag. Technol. 2002, 25, 390–396. [Google Scholar] [CrossRef]

- Chen, Z.-K.; Sawa, K. Characteristics of Ag contact morphology in breaking arcs. Wear 1996, 199, 237–244. [Google Scholar] [CrossRef]

- Torres, J.-M.; Dhariwal, R.S. Electric field breakdown at micrometre separations. Nanotechnology 1999, 10, 102. [Google Scholar] [CrossRef]

- Van Rensselar, J. The Tribology of Electric Vehicles. Tribol. Lubr. Technol. 2019, 75, 34–44. [Google Scholar]

- Liu, Z.; Zhang, L. A review of failure modes, condition monitoring and fault diagnosis methods for large-scale wind turbine bearings. Measurement 2020, 149, 107002. [Google Scholar] [CrossRef]

- Walther, H.C.; Holub, R.A. Lubrication of electric motors as defined by IEEE standard 841-2009, shortcomings and potential improvement opportunities. In Proceedings of the 2014 IEEE Petroleum and Chemical Industry Technical Conference (PCIC), San Francisco, CA, USA, 8–10 September 2014; pp. 91–98. [Google Scholar] [CrossRef]

- Boškoski, P.; Petrovčič, J.; Musizza, B.; Juričić, Đ. Detection of lubrication starved bearings in electrical motors by means of vibration analysis. Tribol. Int. 2010, 43, 1683–1692. [Google Scholar] [CrossRef]

- Bond, S.; Jackson, R.L.; Mills, G. The influence of various grease compositions and silver nanoparticle additives on electrically induced rolling-element bearing damage. Friction 2024, 12, 796–811. [Google Scholar] [CrossRef]

- Bor-Jenq, W.; Nannaji, S.; Ernest, R. Static-gap, single-spark erosion of Ag-CdO and pure metal electrodes. Wear 1992, 157, 31–49. [Google Scholar] [CrossRef]

- Chatterton, S.; Pennacchi, P.; Vania, A. Electrical pitting of tilting-pad thrust bearings: Modelling and experimental evidence. Tribol. Int. 2016, 103, 475–486. [Google Scholar] [CrossRef]

- Graf, S.; Koch, O.; Sauer, B. Influence of Parasitic Electric Currents on an Exemplary Mineral-Oil-Based Lubricant and the Raceway Surfaces of Thrust Bearings. Lubricants 2023, 11, 313. [Google Scholar] [CrossRef]

- Farfan-Cabrera, L.I.; Cao-Romero-Gallegos, J.A.; Lee, S.; Komurlu, M.U.; Erdemir, A. Tribological behavior of H-DLC and H-free DLC coatings on bearing materials under the influence of DC electric current discharges. Wear 2023, 522, 204709. [Google Scholar] [CrossRef]

- Liu, W. The prevalent motor bearing premature failures due to the high frequency electric current passage. Eng. Fail. Anal. 2014, 45, 118–127. [Google Scholar] [CrossRef]

- Raadnui, S.; Kleesuwan, S. Electrical pitting wear debris analysis of grease-lubricated rolling element bearings. Wear 2011, 271, 1707–1718. [Google Scholar] [CrossRef]

- Robles, E.; Matallana, A.; Aretxabaleta, I.; Andreu, J.; Fernández, M.; Martín, J.L. The role of power device technology in the electric vehicle powertrain. Int. J. Energy Res. 2022, 46, 22222–22265. [Google Scholar] [CrossRef]

- Suzumura, J. Prevention of Electrical Pitting on Rolling Bearings by Electrically Conductive Grease. Q. Rep. RTRI 2016, 57, 42–47. [Google Scholar] [CrossRef]

- Sanchez Garrido, D.; Leventini, S.; Martini, A. Effect of Temperature and Surface Roughness on the Tribological Behavior of Electric Motor Greases for Hybrid Bearing Materials. Lubricants 2021, 9, 59. [Google Scholar] [CrossRef]

- Graf, S.; Werner, M.; Koch, O.; Götz, S.; Sauer, B. Breakdown voltages in thrust bearings: Behavior and Measurement. Tribol. Trans. 2023, 66, 488–496. [Google Scholar] [CrossRef]

- García Tuero, A.; Rivera, N.; Rodríguez, E.; Fernández-González, A.; Viesca, J.L.; Hernández Battez, A. Influence of Additives Concentration on the Electrical Properties and the Tribological Behaviour of Three Automatic Transmission Fluids. Lubricants 2022, 10, 276. [Google Scholar] [CrossRef]

- Flores-Torres, S.; Holt, D.G.L.; Carey, J.T. Method for Preventing or Minimizing Electrostatic Discharge and Dielectric Breakdown in Electric Vehicle Powertrains. US20180100120A1, 12 April 2018. Available online: https://patents.google.com/patent/US20180100120A1/en (accessed on 8 November 2023).

- Crilly, L.; Jackson, R.L.; Mills, G.; Bond, S.; Bhargava, S. An Exploration of the Friction, Wear, and Electrical Effects of Nanoparticle Enhanced and Conventional Lubricants. IEEE Trans. Compon. Packag. Manuf. Technol. 2022, 12, 1757–1770. [Google Scholar] [CrossRef]

- Noguchi, S.; Kakinuma, S.; Kanada, T. Measurement of Direct Current Voltage Causing Electrical Pitting. J. Adv. Mech. Des. Syst. Manuf. 2010, 4, 1084–1094. [Google Scholar] [CrossRef]

- Slade, P.G. The Arc and Interruption. In Electrical Contacts; CRC Press: Boca Raton, FL, USA, 1999; pp. 433–486. [Google Scholar]

- Schwirzke, F.; Hallal, M.P.; Maruyama, X.K. Onset of breakdown and formation of cathode spots. IEEE Trans. Plasma Sci. 1993, 21, 410–415. [Google Scholar] [CrossRef]

- Morris, S.A.; Leighton, M.; Morris, N.J. Electrical Field Strength in Rough Infinite Line Contact Elastohydrodynamic Conjunctions. Lubricants 2022, 10, 87. [Google Scholar] [CrossRef]

| Track Length [cm] | Observed Damage [%] | No. of Directional Changes [#] | Max. Linear Speed [m/s] | Avg. Voltage [V] |

|---|---|---|---|---|

| 1 | 0.6563 | 3617 | 1.203 × 10−2 | 0.7941 |

| 2 | 5.129 | 2551 | 1.761 × 10−2 | 1.360 |

| 3 | 1.315 | 2076 | 2.172 × 10−2 | 0.7950 |

| 4 | 0.1167 | 1794 | 2.530 × 10−2 | 1.417 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Janik, J.R.; Saha, S.; Jackson, R.L.; Mills, G. Exploring the Boundaries of Electrically Induced Bearing Damage in Grease-Lubricated Rolling Contacts. Lubricants 2024, 12, 268. https://doi.org/10.3390/lubricants12080268

Janik JR, Saha S, Jackson RL, Mills G. Exploring the Boundaries of Electrically Induced Bearing Damage in Grease-Lubricated Rolling Contacts. Lubricants. 2024; 12(8):268. https://doi.org/10.3390/lubricants12080268

Chicago/Turabian StyleJanik, Jack R., Sudip Saha, Robert L. Jackson, and German Mills. 2024. "Exploring the Boundaries of Electrically Induced Bearing Damage in Grease-Lubricated Rolling Contacts" Lubricants 12, no. 8: 268. https://doi.org/10.3390/lubricants12080268

APA StyleJanik, J. R., Saha, S., Jackson, R. L., & Mills, G. (2024). Exploring the Boundaries of Electrically Induced Bearing Damage in Grease-Lubricated Rolling Contacts. Lubricants, 12(8), 268. https://doi.org/10.3390/lubricants12080268