Graphite Fluoride as a Novel Solider Lubricant Additive for Ultra-High-Molecular-Weight Polyethylene Composites with Excellent Tribological Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of GrF-UHMW-PE Composites

2.3. X-ray Diffraction (XRD) and Fourier-Transform Infrared Spectroscopy (FT-IR)

2.4. Ball Indentation Hardness

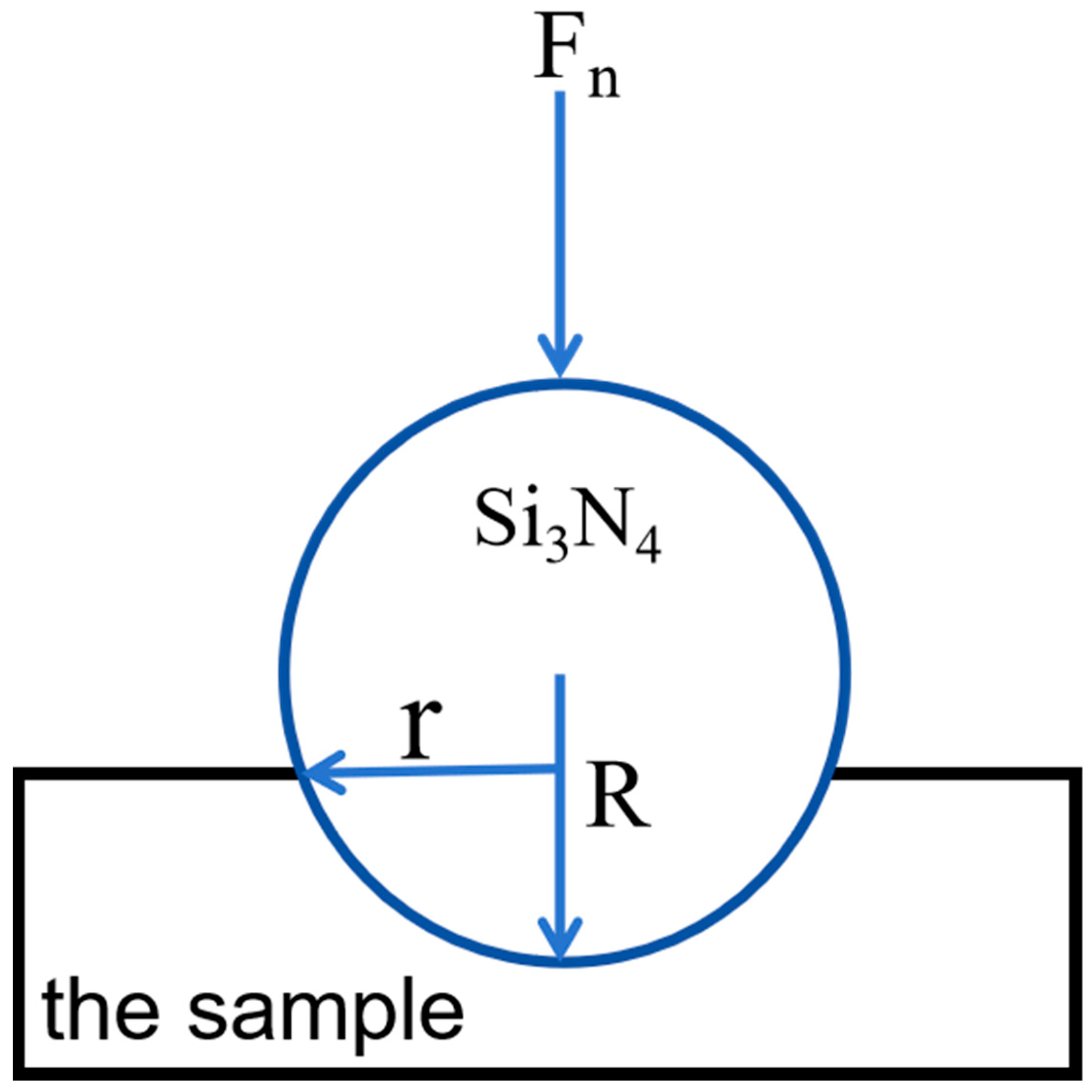

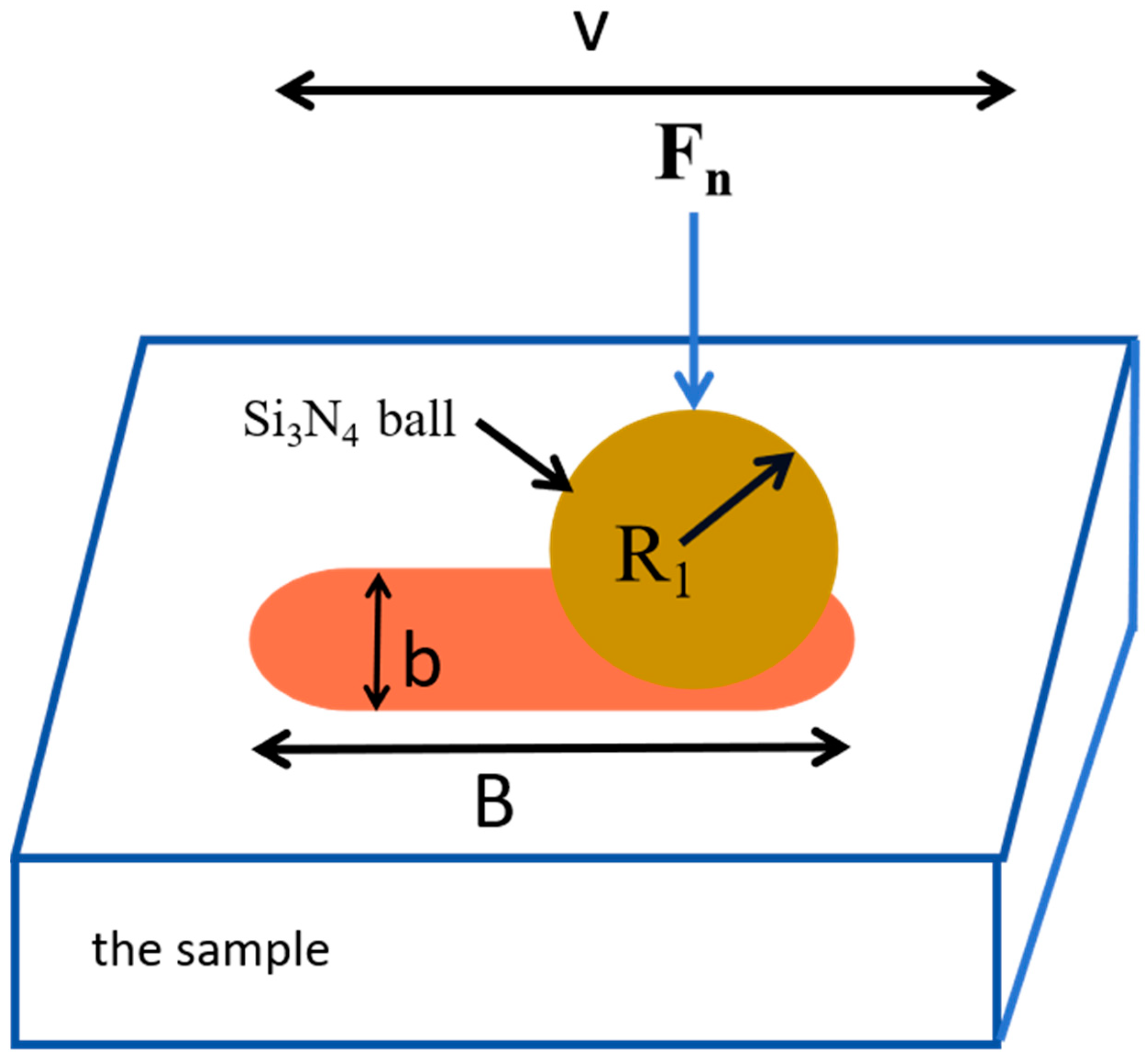

2.5. Tribological Testing

2.6. Scanning Electron Microscope (SEM)

3. Results and Discussion

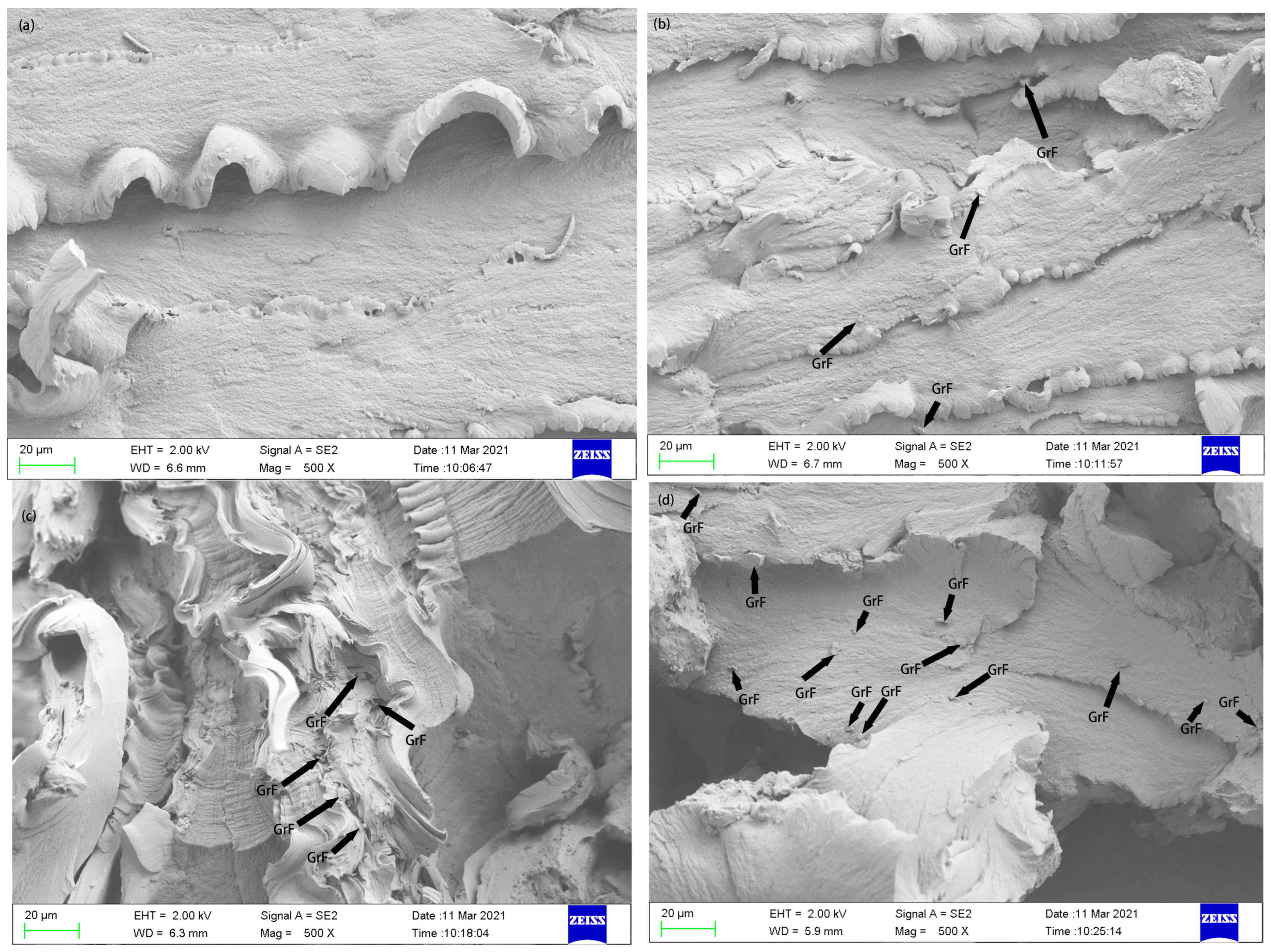

3.1. SEM of Tensile Sections

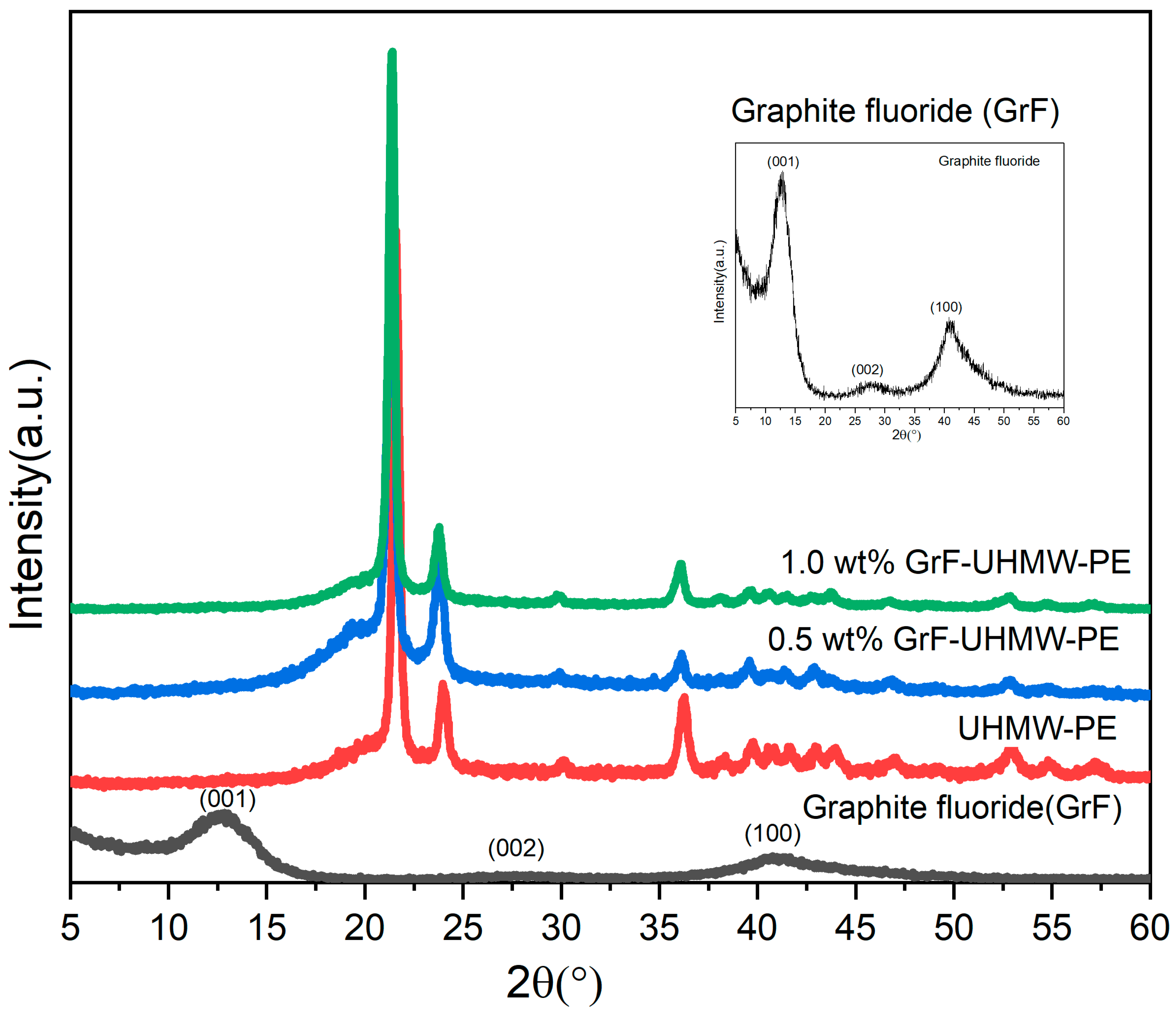

3.2. XRD Patterns of the Composites

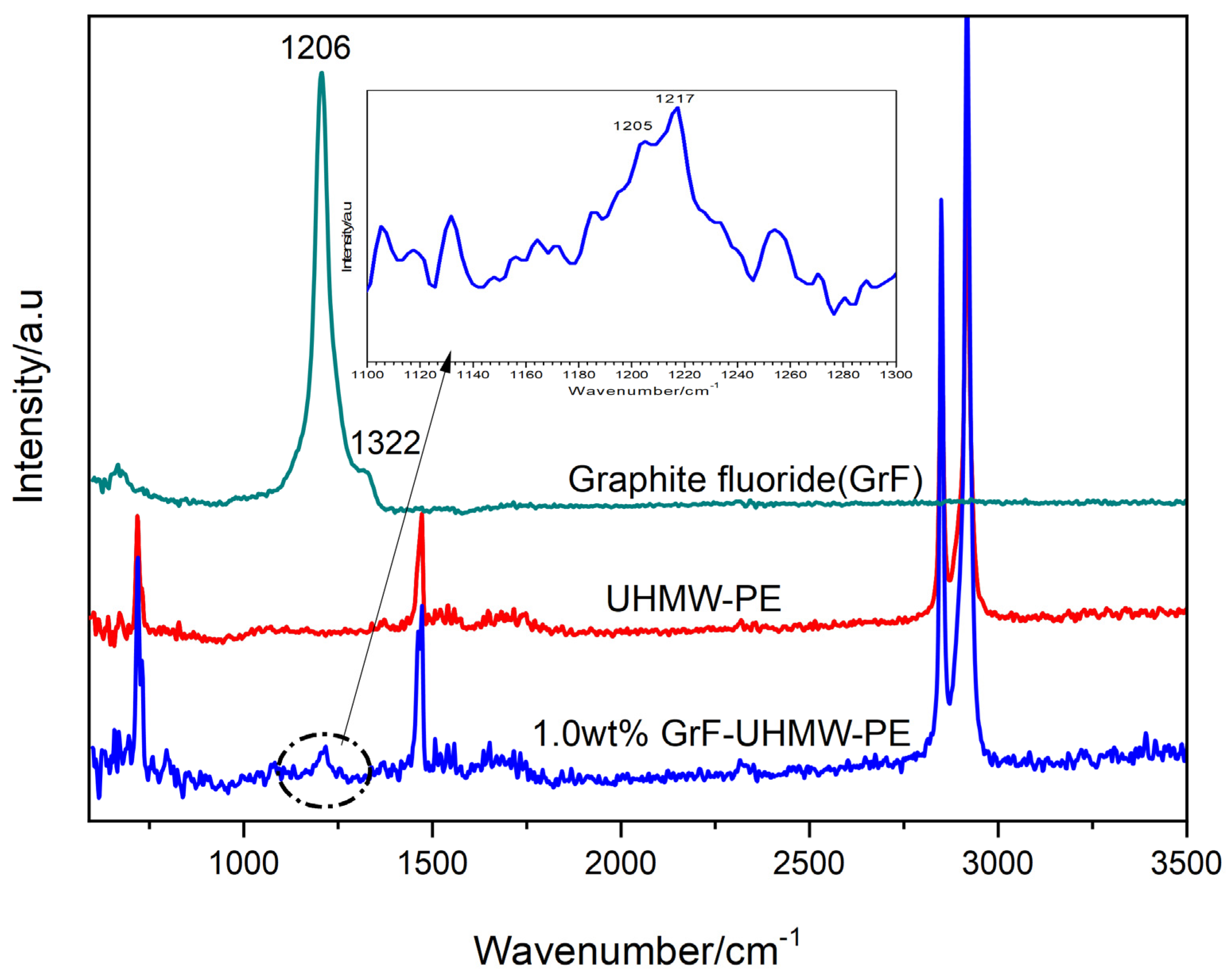

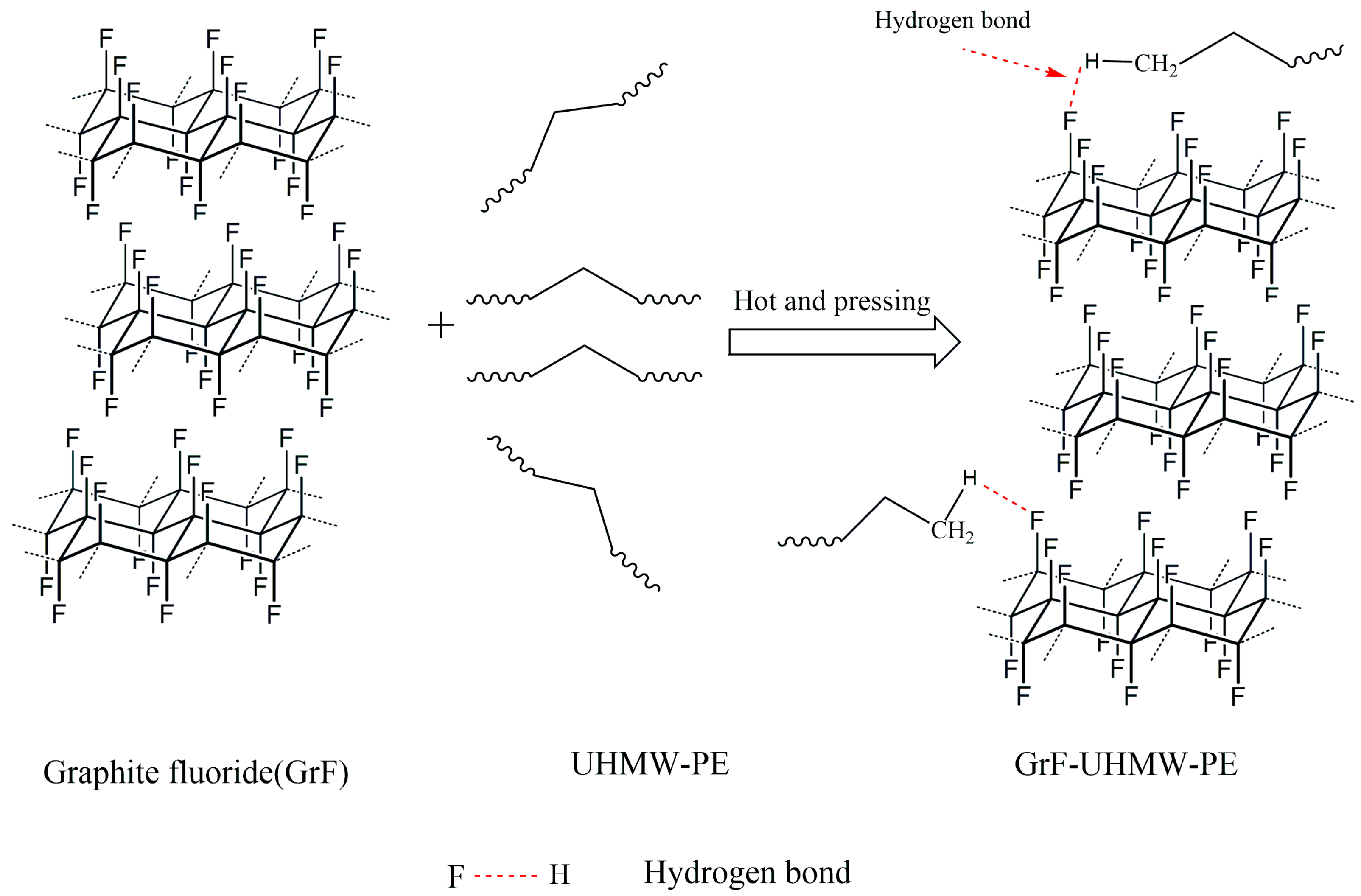

3.3. FT-IR Spectrometry of the Composites

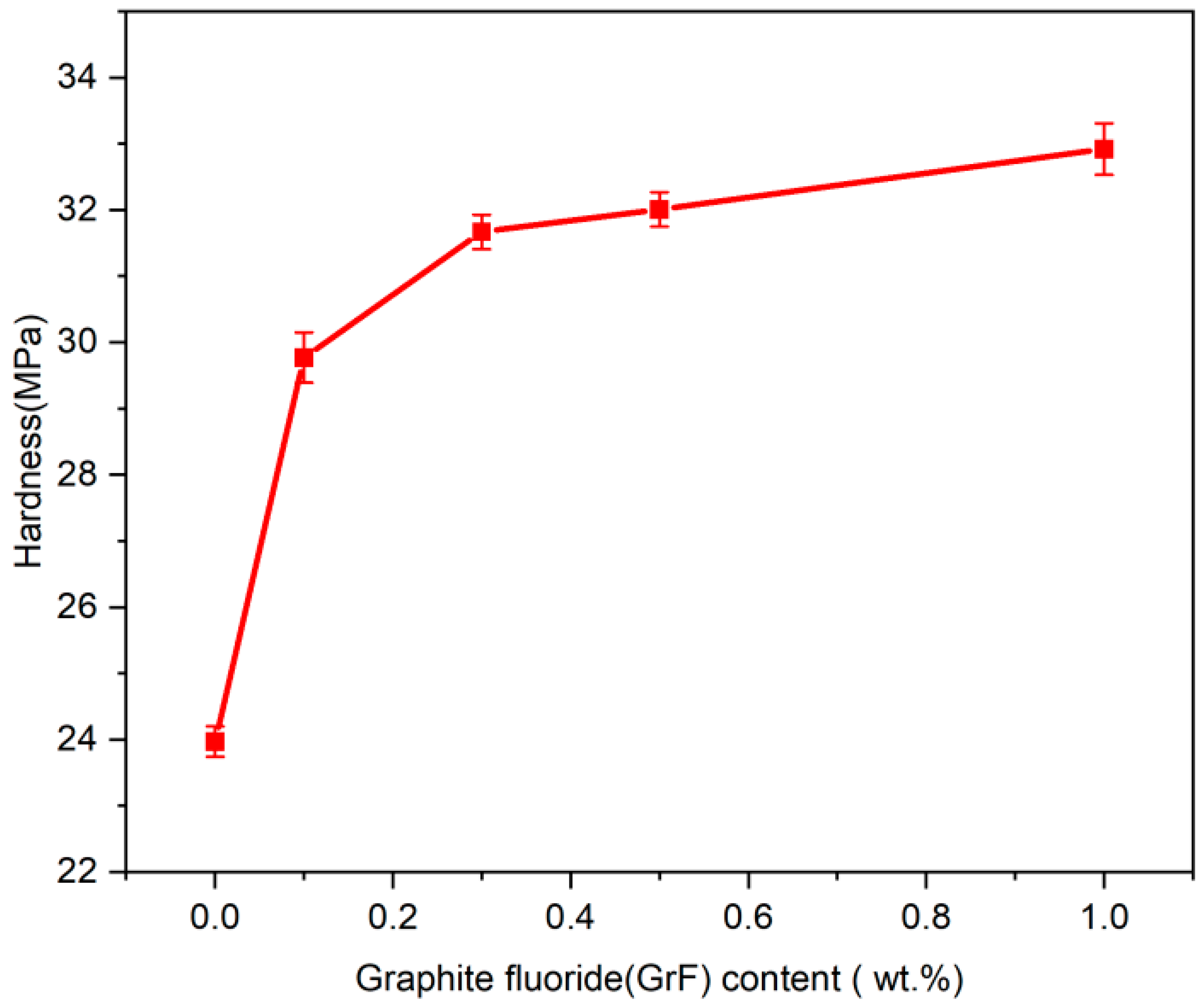

3.4. The Hardness of the Composites

3.5. Tribological Properties of the Composites

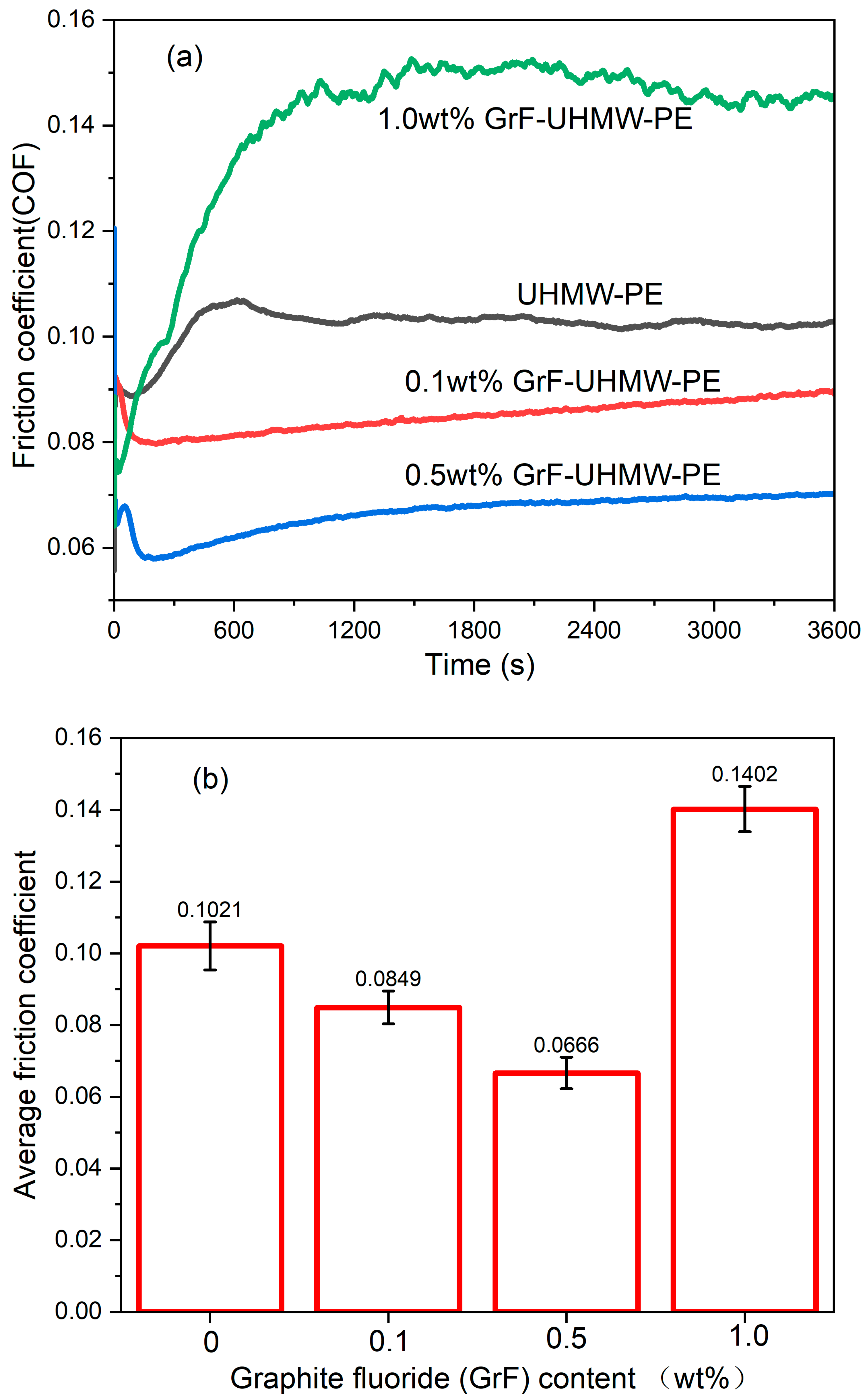

3.5.1. The Coefficient of Friction (COF)

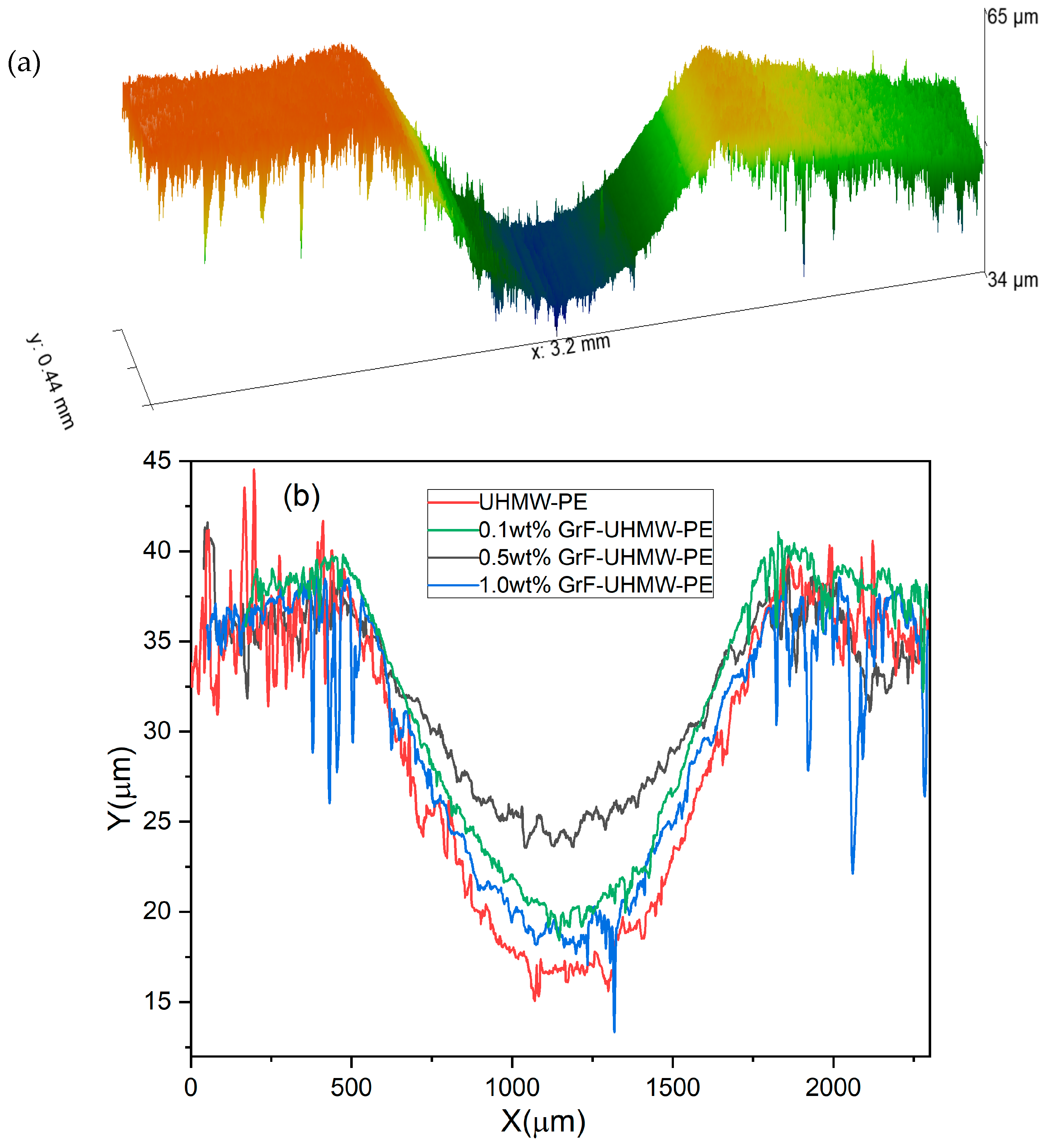

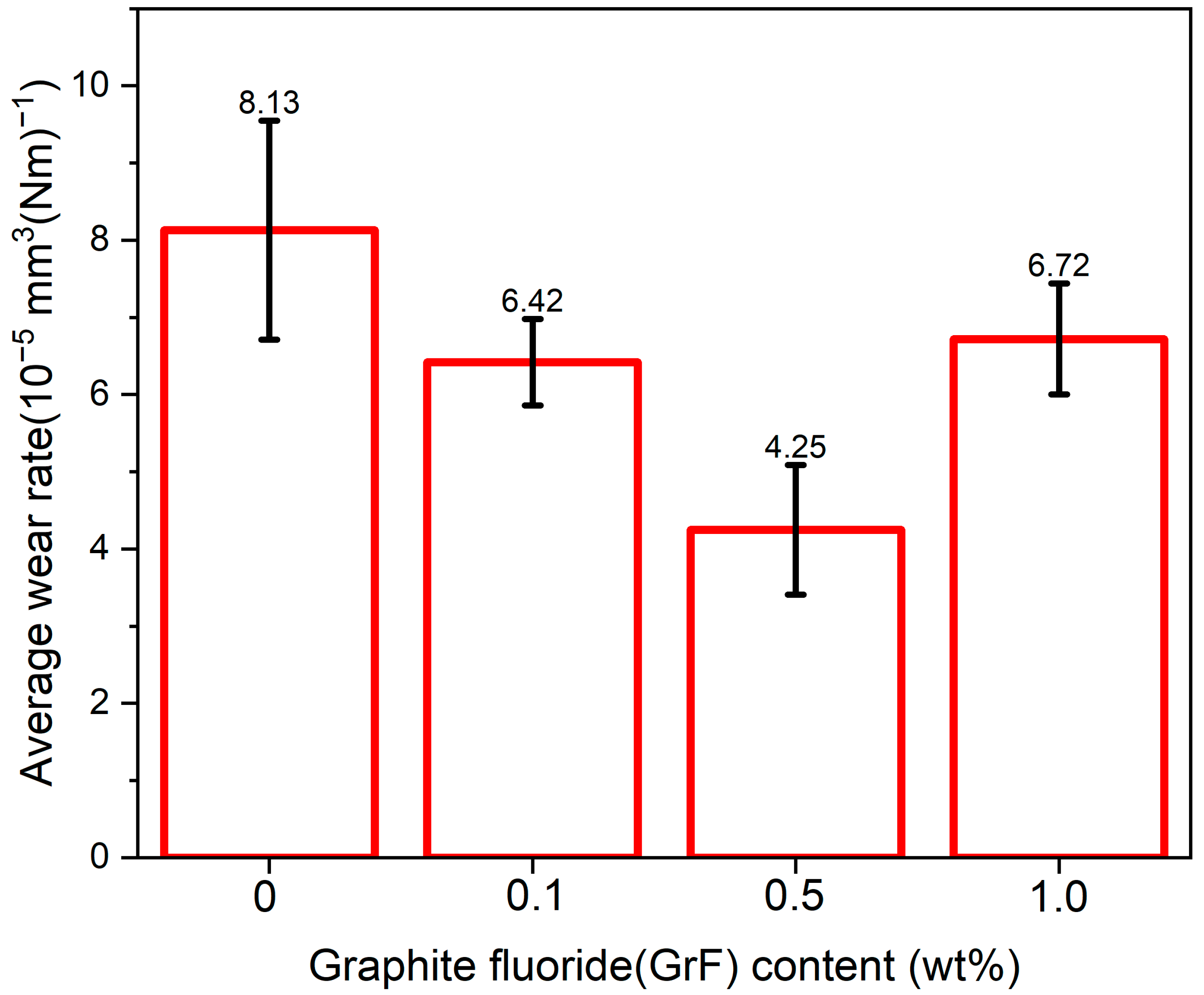

3.5.2. The Wear of the Composites

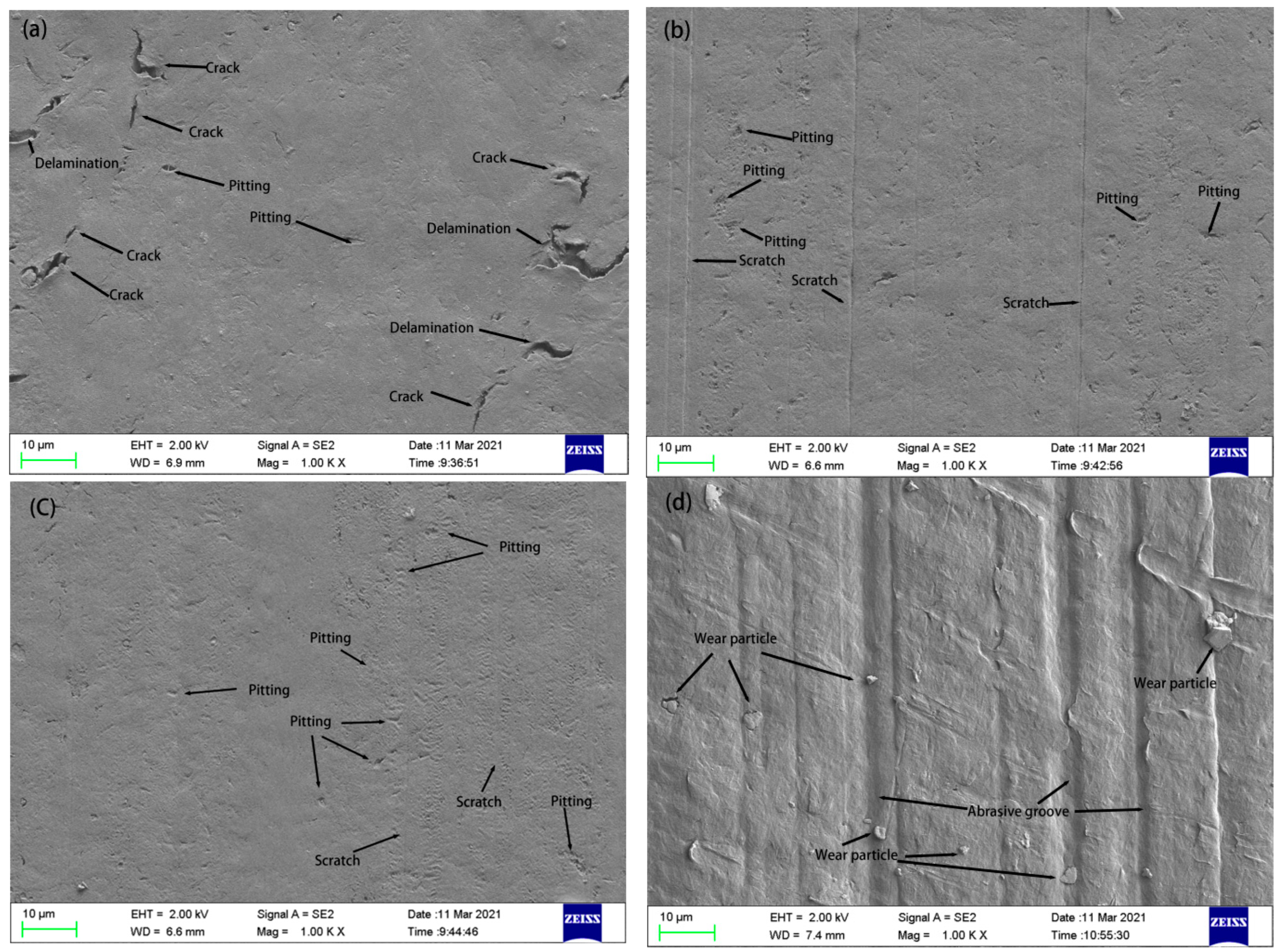

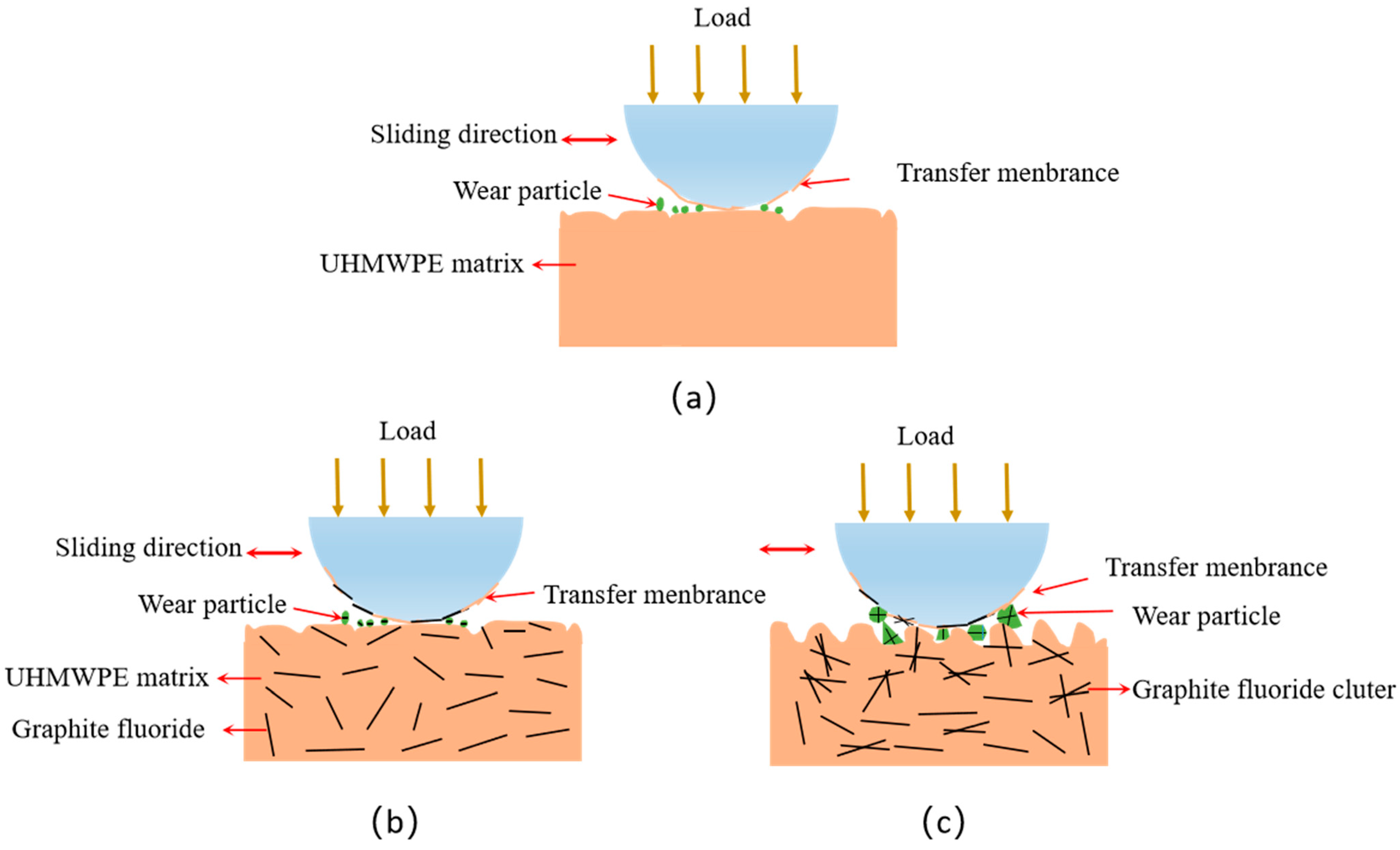

3.5.3. SEM of Worn Surfaces and Wear Mechanism of the Composites

4. Conclusions

- The hydrogen bonds (C-F···H-C) were formed and enhanced interfacial interaction between GrF and UHMW-PE, according to the results of FT-IR spectrometry.

- Adding GrF can significantly enhance the hardness of the composites. At 1.0 wt% GrF, the hardness increased by 37%, compared to pure UHMW-PE.

- At a lower GrF concentration, GrF exhibited remarkable lubricant properties and anti-wear properties. At 0.5 wt% GrF concentration, the COF and wear rate were reduced by 34.76% and 47.72%, respectively, compared to the UHMW-PE. At a high GrF concentration, the COF significantly increased while the anti-wear properties decreased.

- As the concentration of GrF increased, the wear modes of the composites transitioned from fatigue wear to abrasive wear.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kurtz, S.M. UHMWPE Biomaterials Handbook: Ultra High Molecular Weight Polyethylene in Total Joint Replacement and Medical Devices; Academic Press: Cambridge, MA, USA, 2009. [Google Scholar]

- Anaya-Garza, K.; Domínguez-Crespo, M.; Torres-Huerta, A.; Brachetti-Sibaja, S.; Moreno-Palmerin, J. UHMWPE/OPA Composite Coatings on Ti6Al4V Alloy as Protective Barriers in a Biological-Like Medium. In Environmental Concerns and Remediation: Proceedings of F-EIR Conference 2021; Springer: Cham, Switzerland, 2022; pp. 1–12. [Google Scholar]

- Liu, Z.; Du, Y.; Ma, H.; Li, J.; Zhang, X.; Zhu, E.; Shi, C.; Zhu, Z.; Zhao, S. Mechanism of boron carbide particles improving the wear resistance of UHMWPE: Structure-property relationship. Polymer 2022, 245, 124733. [Google Scholar] [CrossRef]

- Rahman, M.M.; Biswas, M.A.S.; Hoque, K.N. Recent development on micro-texturing of UHMWPE surfaces for orthopedic bearings: A review. Biotribology 2022, 31, 100216. [Google Scholar] [CrossRef]

- Patil, N.A.; Njuguna, J.; Kandasubramanian, B. UHMWPE for biomedical applications: Performance and functionalization. Eur. Polym. J. 2020, 125, 109529. [Google Scholar] [CrossRef]

- Bistolfi, A.; Giustra, F.; Bosco, F.; Sabatini, L.; Aprato, A.; Bracco, P.; Bellare, A. Ultra-high molecular weight polyethylene (UHMWPE) for hip and knee arthroplasty: The present and the future. J. Orthop. 2021, 25, 98–106. [Google Scholar] [CrossRef]

- Baena, J.C.; Wu, J.; Peng, Z. Wear performance of UHMWPE and reinforced UHMWPE composites in arthroplasty applications: A review. Lubricants 2015, 3, 413–436. [Google Scholar] [CrossRef]

- Kandahari, A.M.; Yang, X.; Laroche, K.A.; Dighe, A.S.; Pan, D.; Cui, Q. A review of UHMWPE wear-induced osteolysis: The role for early detection of the immune response. Bone Res. 2016, 4, 16014. [Google Scholar] [CrossRef]

- Dwivedi, Y.; Laurent, M.P.; Sarvepalli, S.; Schmid, T.M.; Wimmer, M.A. Albumin protein cleavage affects the wear and friction of ultra-high molecular weight polyethylene. Lubricants 2017, 5, 33. [Google Scholar] [CrossRef]

- Dangsheng, X. Friction and wear properties of UHMWPE composites reinforced with carbon fiber. Mater. Lett. 2005, 59, 175–179. [Google Scholar] [CrossRef]

- Wang, L.L.; Zhang, L.Q.; Tian, M. Mechanical and tribological properties of acrylonitrile–butadiene rubber filled with graphite and carbon black. Mater. Des. 2012, 39, 450–457. [Google Scholar] [CrossRef]

- Moghadam, A.D.; Omrani, E.; Menezes, P.L.; Rohatgi, P.K. Mechanical and tribological properties of self-lubricating metal matrix nanocomposites reinforced by carbon nanotubes (CNTs) and graphene—A review. Compos. Part B Eng. 2015, 77, 402–420. [Google Scholar] [CrossRef]

- Khun, N.W.; Zhang, H.; Lim, L.H.; Yang, J. Mechanical and tribological properties of graphene modified epoxy composites. Appl. Sci. Eng. Prog. 2015, 8, 101–109. [Google Scholar]

- Miao, X.; Li, Z.; Liu, S.; Hou, K.; Wang, J.; Yang, S. Ionic bridging strengthened MXene/GO nanocomposite films with extraordinary mechanical and tribological properties. Appl. Surf. Sci. 2023, 625, 157181. [Google Scholar] [CrossRef]

- Huang, Z.; Zheng, Z.; Zhao, S.; Dong, S.; Luo, P.; Chen, L. Copper matrix composites reinforced by aligned carbon nanotubes: Mechanical and tribological properties. Mater. Des. 2017, 133, 570–578. [Google Scholar] [CrossRef]

- Zhou, S.; Zhang, Q.; Wu, C.; Huang, J. Effect of carbon fiber reinforcement on the mechanical and tribological properties of polyamide6/polyphenylene sulfide composites. Mater. Des. 2013, 44, 493–499. [Google Scholar] [CrossRef]

- Pang, W.; Wu, J.; Zhang, Q.; Li, G. Graphene oxide enhanced, radiation cross-linked, vitamin E stabilized oxidation resistant UHMWPE with high hardness and tensile properties. RSC Adv. 2017, 7, 55536–55546. [Google Scholar] [CrossRef]

- Ni, Z.; Pang, W.; Chen, G.; Lu, P.; Qian, S. The influence of irradiation on thermal and mechanical properties of UHMWPE/GO nanocomposites. Russ. J. Appl. Chem. 2017, 90, 1876–1882. [Google Scholar] [CrossRef]

- Tai, Z.; Chen, Y.; An, Y.; Yan, X.; Xue, Q. Tribological behavior of UHMWPE reinforced with graphene oxide nanosheets. Tribol. Lett. 2012, 46, 55–63. [Google Scholar] [CrossRef]

- Bhattacharyya, A.; Chen, S.; Zhu, M. Graphene reinforced ultra high molecular weight polyethylene with improved tensile strength and creep resistance properties. Express Polym. Lett. 2014, 8, 74–84. [Google Scholar] [CrossRef]

- Chih, A.; Ansón-Casaos, A.; Puértolas, J. Frictional and mechanical behaviour of graphene/UHMWPE composite coatings. Tribol. Int. 2017, 116, 295–302. [Google Scholar] [CrossRef]

- Reddy, K.S.N.; Unnikrishnan, D.; Balachandran, M. Investigation and optimization of mechanical, thermal and tribological properties of UHMWPE–graphite nanocomposites. Mater. Today Proc. 2018, 5, 25139–25148. [Google Scholar] [CrossRef]

- Di Vittorio, S.; Dresselhaus, M.; Dresselhaus, G. A model for disorder in fluorine-intercalated graphite. J. Mater. Res. 1993, 8, 1578–1585. [Google Scholar] [CrossRef]

- Yang, L.; Li, Y.; Wang, L.; Pei, Y.; Wang, Z.; Zhang, Y.; Lin, H.; Li, X. Exfoliated fluorographene quantum dots as outstanding passivants for improved flexible perovskite solar cells. ACS Appl. Mater. Interfaces 2020, 12, 22992–23001. [Google Scholar] [CrossRef] [PubMed]

- Giraudet, J.; Claves, D.; Guérin, K.; Dubois, M.; Houdayer, A.; Masin, F.; Hamwi, A. Magnesium batteries: Towards a first use of graphite fluorides. J. Power Sources 2007, 173, 592–598. [Google Scholar] [CrossRef]

- Kumaran, A.A.; Chithrambattu, A.; Vedhanarayanan, B.; Rajukrishnan, S.B.A.; Praveen, V.K.; Kizhakayil, R.N. Fluoride-philic reduced graphene oxide–fluorophore anion sensors. Mater. Adv. 2022, 3, 6809–6817. [Google Scholar] [CrossRef]

- Zhao, F.-G.; Kong, Y.-T.; Pan, B.; Hu, C.-M.; Zuo, B.; Dong, X.; Li, B.; Li, W.-S. In situ tunable pillaring of compact and high-density graphite fluoride with pseudocapacitive diamines for supercapacitors with combined predominance in gravimetric and volumetric performances. J. Mater. Chem. A 2019, 7, 3353–3365. [Google Scholar] [CrossRef]

- Lei, F.; Wu, B.; Sun, H.; Jiang, F.; Yang, J.; Sun, D. Simultaneously improving the anticorrosion and antiscratch performance of epoxy coatings with graphite fluoride via large-scale preparation. Ind. Eng. Chem. Res. 2018, 57, 16709–16717. [Google Scholar] [CrossRef]

- Mittal, D.; Singh, D.; Sharma, S.K. Thermal characteristics and tribological performances of solid lubricants: A mini review. Adv. Rheol. Mater. 2023. [Google Scholar] [CrossRef]

- Fusaro, R.L.; Sliney, H.E. Graphite fluoride (CFx) n—A new solid lubricant. Asle Trans. 1970, 13, 56–65. [Google Scholar] [CrossRef]

- Thomas, P.; Bilas, P.; Molza, A.; Legras, L.; Mansot, J.L.; Guérin, K.; Dubois, M. 14—Fluorinated Nanocarbons for Lubrication. In New Fluorinated Carbons: Fundamentals and Applications; Boltalina, O.V., Nakajima, T., Eds.; Elsevier: Boston, MA, USA, 2017; pp. 325–360. [Google Scholar]

- Fusaro, R.L.; Sliney, H.E. Preliminary Investigation of Graphite Fluoride (CF X) N as a Solid Lubricant; National Aeronautics and Space Administration: Washington, DC, USA, 1969. [Google Scholar]

- Fusaro, R.L.; Sliney, H.E. Lubricating characteristics of polyimide bonded graphite fluoride and polyimide thin films. ASLE Trans. 1973, 16, 189–196. [Google Scholar] [CrossRef]

- Yan, Y.T.; Wang, R.; Song, W.L. The preparation and Tribological Properties of graphite fluoride. Adv. Mater. Res. 2014, 941, 1544–1547. [Google Scholar] [CrossRef]

- Sun, H.; Jiang, F.; Lei, F.; Chen, L.; Zhang, H.; Leng, J.; Sun, D. Graphite fluoride reinforced PA6 composites: Crystallization and mechanical properties. Mater. Today Commun. 2018, 16, 217–225. [Google Scholar] [CrossRef]

- Sun, H.; Li, T.; Lei, F.; Yang, M.; Li, D.; Huang, X.; Sun, D. Graphite fluoride and fluorographene as a new class of solid lubricant additives for high-performance polyamide 66 composites with excellent mechanical and tribological properties. Polym. Int. 2020, 69, 457–466. [Google Scholar] [CrossRef]

- Lu, P.; Wu, M.; Ni, Z.; Huang, G. Oxidative degradation behavior of irradiated GO/UHMWPE nanocomposites immersed in simulated body fluid. Polym. Bull. 2021, 78, 5153–5164. [Google Scholar] [CrossRef]

- Hertz, H. The contact of elastic solids. J. Reine. Angew. Math. 1881, 92, 156–171. [Google Scholar]

- Zdero, R.; Bagheri, Z.S.; Rezaey, M.; Schemitsch, E.H.; Bougherara, H. The biomechanical effect of loading speed on Metal-on-UHMWPE contact mechanics. Open Biomed. Eng. J. 2014, 8, 28. [Google Scholar] [CrossRef][Green Version]

- Kapps, V.; Maru, M.M.; Kuznetsov, O.; Achete, C.A. Identifying differences in the tribological performance of GUR 1020 and GUR 1050 UHMWPE resins associated to pressure× velocity conditions in linear reciprocating sliding tests. J. Mech. Behav. Biomed. Mater. 2023, 145, 106038. [Google Scholar] [CrossRef] [PubMed]

- Pang, W.; Ni, Z.; Chen, G.; Huang, G.; Huang, H.; Zhao, Y. Mechanical and thermal properties of graphene oxide/ultrahigh molecular weight polyethylene nanocomposites. Rsc Adv. 2015, 5, 63063–63072. [Google Scholar] [CrossRef]

- Shafiee, M.; Aamazani SA, A. Optimization of UHMWPE/graphene nanocomposite processing using ziegler-natta catalytic system via response surface methodology. Polym.-Plast. Technol. Eng. 2014, 53, 969–974. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, M.; Tang, Z.; Wu, G. Radiation effects of UHMW-PE fibre on gel fraction and mechanical properties. Radiat. Phys. Chem. 2011, 80, 274–277. [Google Scholar] [CrossRef]

- Thalladi, V.R.; Weiss, H.-C.; Bläser, D.; Boese, R.; Nangia, A.; Desiraju, G.R. C−H···F Interactions in the Crystal Structures of Some Fluorobenzenes. J. Am. Chem. Soc. 1998, 120, 8702–8710. [Google Scholar] [CrossRef]

- Chen, Y.; Qi, Y.; Tai, Z.; Yan, X.; Zhu, F.; Xue, Q. Preparation, mechanical properties and biocompatibility of graphene oxide/ultrahigh molecular weight polyethylene composites. Eur. Polym. J. 2012, 48, 1026–1033. [Google Scholar] [CrossRef]

- Lorenzo-Bonet, E.; Hernandez-Rodriguez, M.A.L.; Perez-Acosta, O.; De la Garza-Ramos, M.A.; Contreras-Hernandez, G.; Juarez-Hernandez, A. Characterization and tribological analysis of graphite/ultra high molecular weight polyethylene nanocomposite films. Wear 2019, 426–427, 195–203. [Google Scholar] [CrossRef]

- Aliyu, I.K.; Mohammed, A.S.; Al-Qutub, A. Tribological Performance of UHMWPE/GNPs Nanocomposite Coatings for Solid Lubrication in Bearing Applications. Tribol. Lett. 2018, 66, 144. [Google Scholar] [CrossRef]

- Tsai, J.-L.; Tu, J.-F. Characterizing mechanical properties of graphite using molecular dynamics simulation. Mater. Des. 2010, 31, 194–199. [Google Scholar] [CrossRef]

- Momber, A.W.; Irmer, M.; Marquardt, T. Effects of polymer hardness on the abrasive wear resistance of thick organic offshore coatings. Prog. Org. Coat. 2020, 146, 105720. [Google Scholar] [CrossRef]

- Unal, H.; Sen, U.; Mimaroglu, A. Abrasive wear behaviour of polymeric materials. Mater. Des. 2005, 26, 705–710. [Google Scholar] [CrossRef]

- Zhao, G.; Wang, T.; Wang, Q. Friction and wear behavior of the polyurethane composites reinforced with potassium titanate whiskers under dry sliding and water lubrication. J. Mater. Sci. 2011, 46, 6673–6681. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, G.; Zhang, T.; Chen, Y.; Yang, F.; Huang, H.; Zhao, Y. Graphite Fluoride as a Novel Solider Lubricant Additive for Ultra-High-Molecular-Weight Polyethylene Composites with Excellent Tribological Properties. Lubricants 2023, 11, 403. https://doi.org/10.3390/lubricants11090403

Huang G, Zhang T, Chen Y, Yang F, Huang H, Zhao Y. Graphite Fluoride as a Novel Solider Lubricant Additive for Ultra-High-Molecular-Weight Polyethylene Composites with Excellent Tribological Properties. Lubricants. 2023; 11(9):403. https://doi.org/10.3390/lubricants11090403

Chicago/Turabian StyleHuang, Guodong, Tao Zhang, Yi Chen, Fei Yang, Huadong Huang, and Yongwu Zhao. 2023. "Graphite Fluoride as a Novel Solider Lubricant Additive for Ultra-High-Molecular-Weight Polyethylene Composites with Excellent Tribological Properties" Lubricants 11, no. 9: 403. https://doi.org/10.3390/lubricants11090403

APA StyleHuang, G., Zhang, T., Chen, Y., Yang, F., Huang, H., & Zhao, Y. (2023). Graphite Fluoride as a Novel Solider Lubricant Additive for Ultra-High-Molecular-Weight Polyethylene Composites with Excellent Tribological Properties. Lubricants, 11(9), 403. https://doi.org/10.3390/lubricants11090403