Significant Improvement in Wear Resistance of CoCrFeNi High-Entropy Alloy via Boron Doping

Abstract

:1. Introduction

2. Experimental Procedures

3. Results and Discussion

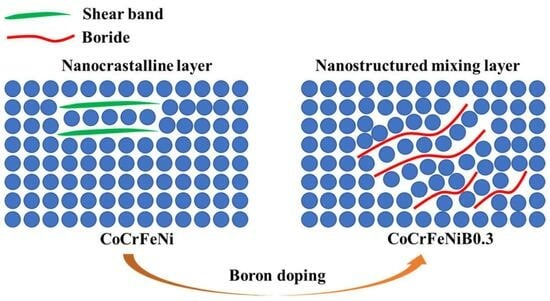

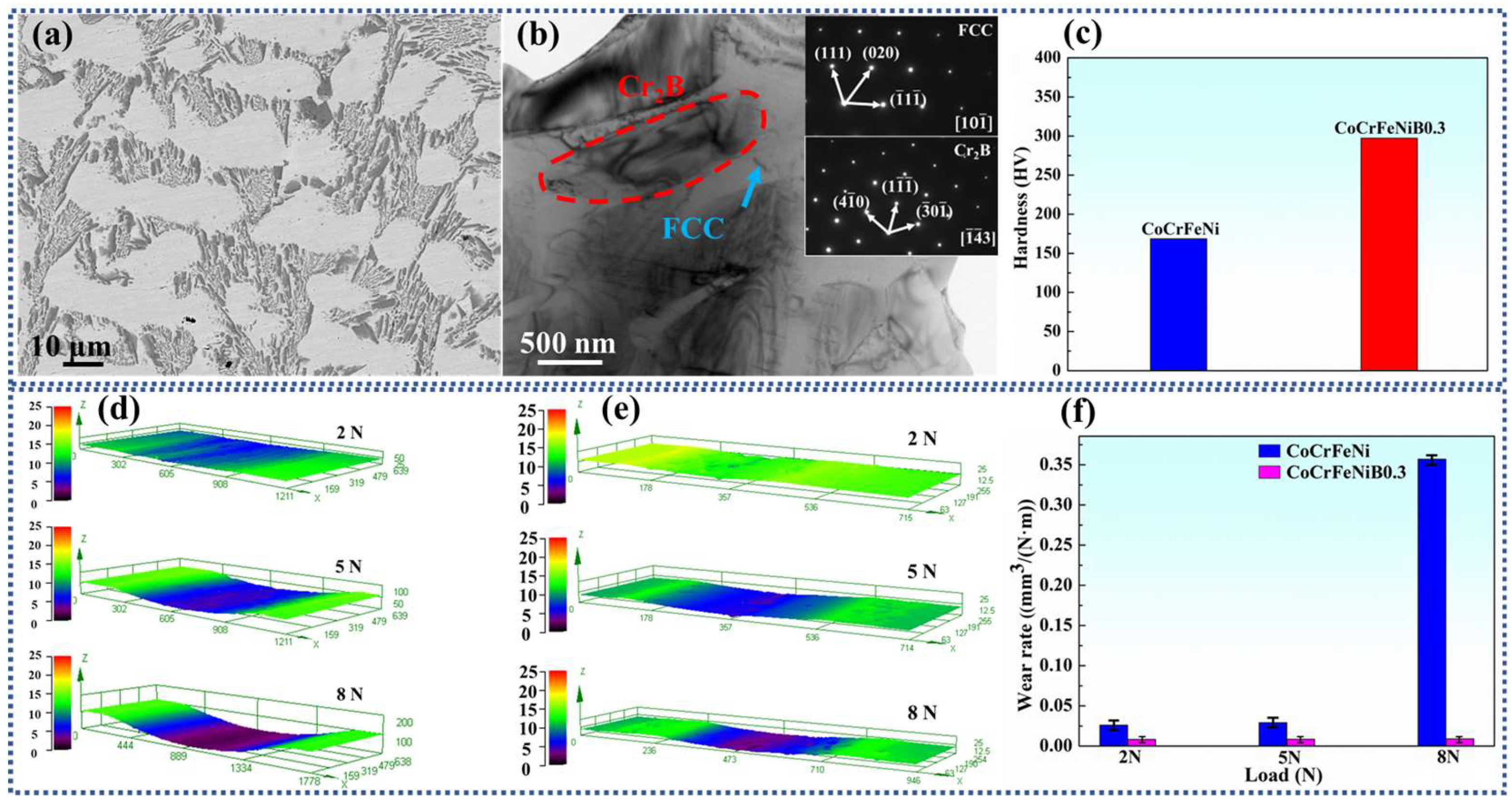

3.1. Microstructure and Wear Properties

3.2. Worn Morphology

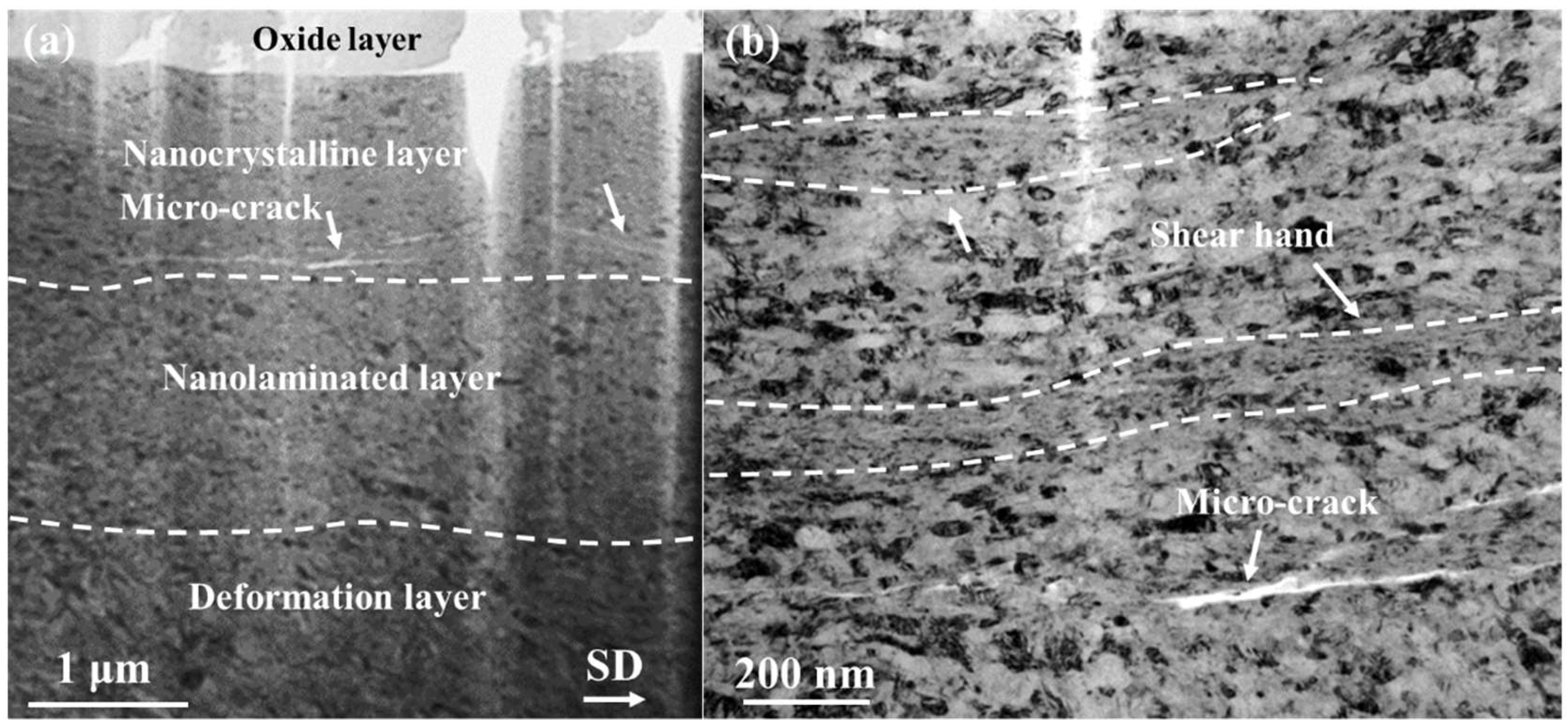

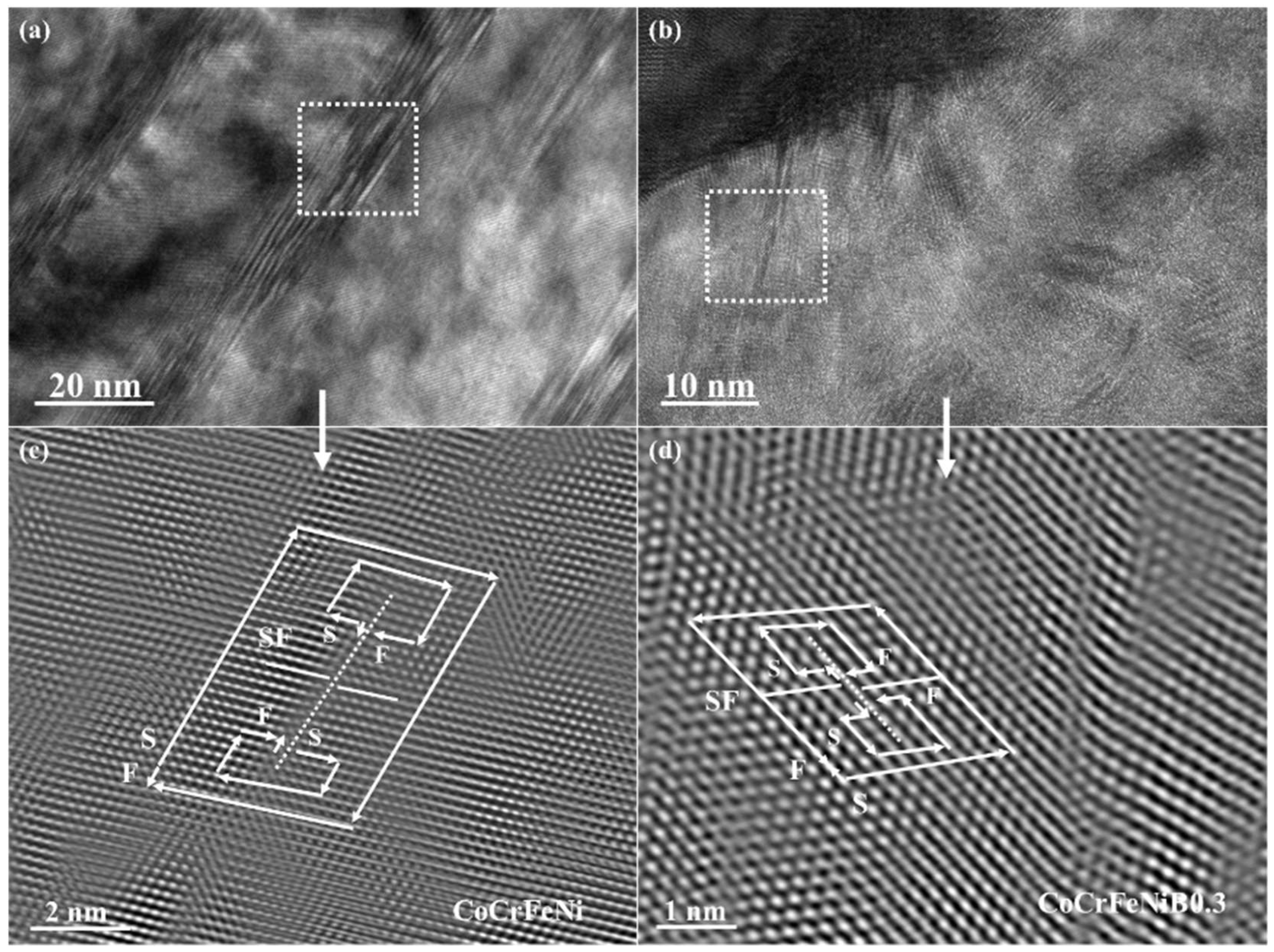

3.3. Worn Subsurface Structure

4. Conclusions

- The wear formation of CoCrFeNi HEA mixed with boron changed from abrasive wear to delamination wear.

- The shear instability caused by the fragmentation of precipitation and the joint action of hard particles led to the formation of a nanostructured mixing layer.

- The formation of a hard phase made only a small contribution to the improvement in wear resistance, whereas the formation of a nanostructured mixing layer and the reduction in the shear band were key to the substantial improvement in the wear resistance of materials.

- By adding interstitial elements to change the deformation mechanism and improve wear resistance, this study may provide a new strategy for the design of wear-resistant HEAs.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Gludovatz, B.; Hohenwarter, A.; Catoor, D.; Chang, E.H.; George, E.P.; Ritchie, R.O. A fracture-resistant high-entropy alloy for cryogenic applications. Science 2014, 345, 1153–1158. [Google Scholar] [CrossRef]

- Jiang, H.; Jiang, L.; Qiao, D.; Lu, Y.; Wang, T.; Cao, Z.; Li, T. Effect of Niobium on Microstructure and Properties of the CoCrFeNbxNi High Entropy Alloys. J. Mater. Sci. Technol. 2017, 33, 712–717. [Google Scholar] [CrossRef]

- Liu, Y.; Xie, Y.; Cui, S.; Yi, Y.; Xing, X.; Wang, X.; Li, W. Effect of Mo Element on the Mechanical Properties and Tribological Responses of CoCrFeNiMox High-Entropy Alloys. Metals 2021, 11, 486. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, B.; Zhu, S.; Tao, X.; Tian, H.; Wang, Z. Achieving enhanced wear resistance in CoCrNi medium-entropy alloy co-alloyed with multi-elements. Materials Letters. Mater. Lett. 2022, 313, 131650. [Google Scholar] [CrossRef]

- Hao, X.; Zhen, J.; Zhao, X.; Ma, J.; Chen, H.; Guo, S.; Wang, C.; Wang, C. Effect of Sn addition on the tribological behaviors of CoCrFeNi high entropy alloys. J. Alloys Compd. 2022, 909, 164657. [Google Scholar] [CrossRef]

- He, M.; Eizadjou, M.; Chen, H.; Liu, H.; Chang, L.; Ringer, S.P. Microstructure and properties of CoCrFeNi-based multi-principal element alloys containing C and Sc. J. Mater. Sci. 2022, 57, 9442–9453. [Google Scholar] [CrossRef]

- Du, Y.; Pei, X.; Tang, Z.; Zhang, F.; Zhou, Q.; Wang, H.; Liu, W. Mechanical and tribological performance of CoCrNiHfx eutectic medium-entropy alloys. J. Mater. Sci. Technol. 2021, 90, 194–204. [Google Scholar] [CrossRef]

- Lan, L.W.; Wang, X.J.; Guo, R.P.; Yang, H.J.; Qiao, J.W. Effect of environments and normal loads on tribological properties of nitrided Ni45(FeCoCr)40(AlTi)15 high-entropy alloys. J. Mater. Sci. Technol. 2020, 42, 85–96. [Google Scholar] [CrossRef]

- Wu, J.; Lin, S.; Yeh, J.; Chen, S.; Huang, Y.; Chen, H. Adhesive wear behavior of AlxCoCrCuFeNi high-entropy alloys as a function of aluminum content. Wear 2006, 261, 513–519. [Google Scholar] [CrossRef]

- Joseph, J.; Haghdadi, N.; Shamlaye, K.; Hodgson, P.; Barnett, M.; Fabijanic, D. The sliding wear behaviour of CoCrFeMnNi and AlxCoCrFeNi high entropy alloys at elevated temperatures. Wear 2019, 428, 32–44. [Google Scholar] [CrossRef]

- Zhang, A.; Han, J.; Su, B.; Li, P.; Meng, J. Microstructure, mechanical properties and tribological performance of CoCrFeNi high entropy alloy matrix self-lubricating composite. Mater. Des. 2017, 114, 253–263. [Google Scholar] [CrossRef]

- Yang, L.; Cheng, Z.; Zhu, W.; Zhao, C.; Ren, F. Significant reduction in friction and wear of a high-entropy alloy via the formation of self-organized nanolayered structure. J. Mater. Sci. Technol. 2021, 73, 1–8. [Google Scholar] [CrossRef]

- Verma, A.; Tarate, P.; Abhyankar, A.C.; Mohape, M.R.; Gowtam, D.S.; Deshmukh, V.P.; Shanmugasundaram, T. High temper- ature wear in CoCrFeNiCux high entropy alloys: The role of Cu. Scr. Mater. 2018, 161, 28–31. [Google Scholar] [CrossRef]

- Dong, J.; Wu, H.; Chen, Y.; Zhang, Y.; Wu, Y.; Yin, S.; Du, Y.; Hua, K.; Wang, H. Study on self-lubricating properties of AlCo CrFeNi2.1 eutectic high entropy alloy with electrochemical boronizing. Surf. Coat. Technol. 2022, 433, 128082. [Google Scholar] [CrossRef]

- Nakajo, H.; Nishimoto, A. Boronizing of CoCrFeMnNi high-entropy alloys using spark plasma sintering. J. Manuf. Mater. Process. 2022, 6, 29. [Google Scholar] [CrossRef]

- Hou, J.; Zhang, M.; Yang, H.; Qiao, J.; Wu, Y. Surface strengthening in Al0.25CoCrFeNi high-entropy alloy by boronizing. Mater. Lett. 2019, 238, 258–260. [Google Scholar]

- Wu, Y.H.; Yang, H.J.; Guo, R.P.; Wang, X.J.; Shi, X.H.; Liaw, P.K.; Qiao, J.W. Tribological behavior of boronized Al0.1CoCrFeNi high-entropy alloys under dry and lubricated conditions. Wear 2020, 460–461, 203452. [Google Scholar] [CrossRef]

- Meng, A.; Liang, F.; Gu, L.; Mao, Q.; Zhang, Y.; Chen, X.; Zhao, Y. An exceptionally wear-resistant CoFeNi2 medium entropy alloy via tribo-induced nanocrystallites with amorphous boundaries. Appl. Surf. Sci. 2023, 614, 156102. [Google Scholar] [CrossRef]

- Miao, J.; Liang, H.; Zhang, A.; He, J.; Meng, J.; Lu, Y. Tribological behavior of an AlCoCrFeNi2.1 eutectic high-entropy alloy sliding against different counterfaces. Tribol. Int. 2021, 153, 106599. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, C.; Shi, S.; Li, T.; Zou, L.; Lu, Y.; Liaw, P.K. Tuning deformation mechanisms of face-centered-cubic high-entropy alloys via boron doping. J. Alloys Compd. 2022, 911, 165103. [Google Scholar] [CrossRef]

- Aguilar-Hurtado, J.Y.; Vargas-Uscategui, A.; Zambrano-Mera, D.; Palma-Hillerns, R. The effect of boron content on the micro structure and mechanical properties of Fe50-XMn30Co10Cr10BX (x = 0, 0.3, 0.6 and 1.7 wt%) multi-component alloys prepared by arc-melting. Mater. Sci. Eng. A 2019, 748, 244–252. [Google Scholar] [CrossRef]

- Aguilar-Hurtado, J.Y.; Vargas-Uscategui, A.; Paredes-Gil, K.; Palma-Hillerns, R.; Tobar, M.J.; Amado, J.M. Boron addition in a non-equiatomic Fe50Mn30Co10Cr10 alloy manufactured by laser cladding: Microstructure and wear abrasive resistance. Appl. Surf. Sci. 2020, 515, 146084. [Google Scholar] [CrossRef]

- Nagarjuna, C.; You, H.; Ahn, S.; Song, J.; Jeong, K.; Madavali, B.; Song, G.; Na, Y.; Won, J.W.; Kim, H.; et al. Worn surface and subsurface layer structure formation behavior on wear mechanism of CoCrFeMnNi high entropy alloy in different sliding conditions. Appl. Surf. Sci. 2021, 549, 149202. [Google Scholar] [CrossRef]

- Cheng, Z.; Yang, L.; Huang, Z.; Wan, T.; Zhu, M.; Ren, F. Achieving low wear in a μ-phase reinforced high-entropy alloy and associated subsurface microstructure evolution. Wear 2021, 474, 203755. [Google Scholar] [CrossRef]

- Zhang, X.; Tong, Y.; Hu, Y.; Liang, X.; Chen, Y.; Wang, K.; Zhang, M.; Xu, J. Microstructure and Performance of Fe50Mn30Cr10Ni10 High-Entropy Alloy Produced by High-Efficiency and Low-Cost Wire Arc Additive Manufacturing. Lubricants 2022, 10, 344. [Google Scholar] [CrossRef]

- Singh, J.B.; Wen, J.; Bellon, P. Nanoscale characterization of the transfer layer formed during dry sliding of Cu-15 wt.% Ni-8 wt.% Sn bronze alloy. Acta Mater. 2008, 56, 3053–3064. [Google Scholar] [CrossRef]

- Hughes, D.A.; Dawson, D.B.; Korellis, J.S.; Weingarten, L.I. Near surface microstructures developing under large sliding loads. J. Mater. Eng. Perform. 1994, 3, 459–475. [Google Scholar] [CrossRef]

- Zhang, L.J.; Yu, P.F.; Fan, J.T.; Zhang, M.D.; Zhang, C.Z.; Cui, H.Z.; Li, G. Investigating the micro and nanomechanical properties of CoCrFeNi-Cx high-entropy alloys containing eutectic carbides. Mater. Sci. Eng. A 2020, 796, 140065. [Google Scholar] [CrossRef]

- Tu, J.; Xu, K.; Liu, Y.; Luo, J.; Zhou, Z.; Ding, L. Characterization of deformation substructure evolution in metastable Fe49Mn30Co10Cr10B1 interstitial high entropy alloy. Intermetallics 2022, 144, 107508. [Google Scholar] [CrossRef]

- Günen, A.; Soylu, B.; Karakaş, Ö. Titanium carbide coating to improve surface characteristic, wear and corrosion resistance of spheroidal graphite cast irons. Surf. Coat. Technol. 2022, 437, 128280. [Google Scholar] [CrossRef]

- Mohseni, H.; Nandwana, P.; Tsoi, A.; Banerjee, R.; Scharf, T.W. In situ nitrided titanium alloys: Microstructural evolution during solidification and wear. Acta Mater. 2015, 83, 61–74. [Google Scholar] [CrossRef]

- Chen, X.; Han, Z.; Lu, K. Wear mechanism transition dominated by subsurface recrystallization structure in Cu-Al alloys. Wear 2014, 320, 41–50. [Google Scholar] [CrossRef]

- Wang, J.; Guo, X.; Qin, J.; Zhang, D.; Lu, W. Microstructure and mechanical properties of investment casted titanium matrix composites with B4C additions. Mater. Sci. Eng. A 2015, 628, 366–373. [Google Scholar] [CrossRef]

- Luan, J.H.; Jiao, Z.B.; Chen, G.; Liu, C.T. Effects of boron additions and solutionizing treatments on microstructures and ductility of forged Ti-6Al-4V alloys. J. Alloys Compd. 2015, 624, 170–178. [Google Scholar] [CrossRef]

- Christian, J.W.; Mahajan, S. Deformation twinning. Progress. Mater. Sci. 1995, 39, 1–157. [Google Scholar]

- Meyers, M.A.; Vöhringer, O.; Lubarda, V.A. The onset of twinning in metals: A constitutive description. Acta Mater. 2001, 49, 4025–4039. [Google Scholar] [CrossRef]

- Han, W.Z.; Zhang, Z.F.; Wu, S.D.; Li, S.X. Combined effects of crystallographic orientation, stacking fault energy and grain size on deformation twinning in fcc crystals. Philos. Mag. 2008, 88, 3011–3029. [Google Scholar] [CrossRef]

- Rosenfield, A.R. A shear instability model of sliding wear. Wear 1987, 116, 319–328. [Google Scholar] [CrossRef]

- Venkataraman, B.; Sundararajan, G. The sliding wear behaviour of Al-SiC particulate composites-II. The characterization of subsurface deformation and correlation with wear behaviour. Acta Mater. 1996, 44, 461–473. [Google Scholar] [CrossRef]

- An, X.H.; Wu, S.D.; Wang, Z.G.; Zhang, Z.F. Significance of stacking fault energy in bulk nanostructured materials: Insights from Cu and its binary alloys as model systems. Prog. Mater. Sci. 2019, 101, 1–45. [Google Scholar] [CrossRef]

- An, X.; Lin, Q.; Qu, S.; Yang, G.; Wu, S.; Zhang, Z. Influence of stacking-fault energy on the accommodation of severe shear strain in Cu-Al alloys during equal-channel angular pressing. J. Mater. Res. 2009, 24, 3636–3646. [Google Scholar] [CrossRef]

- Mohammed, A.A.S.; El-Danaf, E.A.; Radwan, A.A. A criterion for shear banding localization in polycrystalline FCC metals and alloys and critical working conditions for different microstructural variables. Mater. Process. Technol. 2007, 186, 14–21. [Google Scholar] [CrossRef]

- Cottrell, A.H. Theory of dislocations. J. Mech. Phys. Solids 1957, 5, 223. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Miao, J.; Wang, C.; Li, T.; Zou, L.; Lu, Y. Significant Improvement in Wear Resistance of CoCrFeNi High-Entropy Alloy via Boron Doping. Lubricants 2023, 11, 386. https://doi.org/10.3390/lubricants11090386

Zhang H, Miao J, Wang C, Li T, Zou L, Lu Y. Significant Improvement in Wear Resistance of CoCrFeNi High-Entropy Alloy via Boron Doping. Lubricants. 2023; 11(9):386. https://doi.org/10.3390/lubricants11090386

Chicago/Turabian StyleZhang, Haitao, Junwei Miao, Chenglin Wang, Tingju Li, Longjiang Zou, and Yiping Lu. 2023. "Significant Improvement in Wear Resistance of CoCrFeNi High-Entropy Alloy via Boron Doping" Lubricants 11, no. 9: 386. https://doi.org/10.3390/lubricants11090386

APA StyleZhang, H., Miao, J., Wang, C., Li, T., Zou, L., & Lu, Y. (2023). Significant Improvement in Wear Resistance of CoCrFeNi High-Entropy Alloy via Boron Doping. Lubricants, 11(9), 386. https://doi.org/10.3390/lubricants11090386