Tribological Investigation of the Effect of Nanosized Transition Metal Oxides on a Base Oil Containing Overbased Calcium Sulfonate

Abstract

1. Introduction

2. Materials and Methods

3. Results

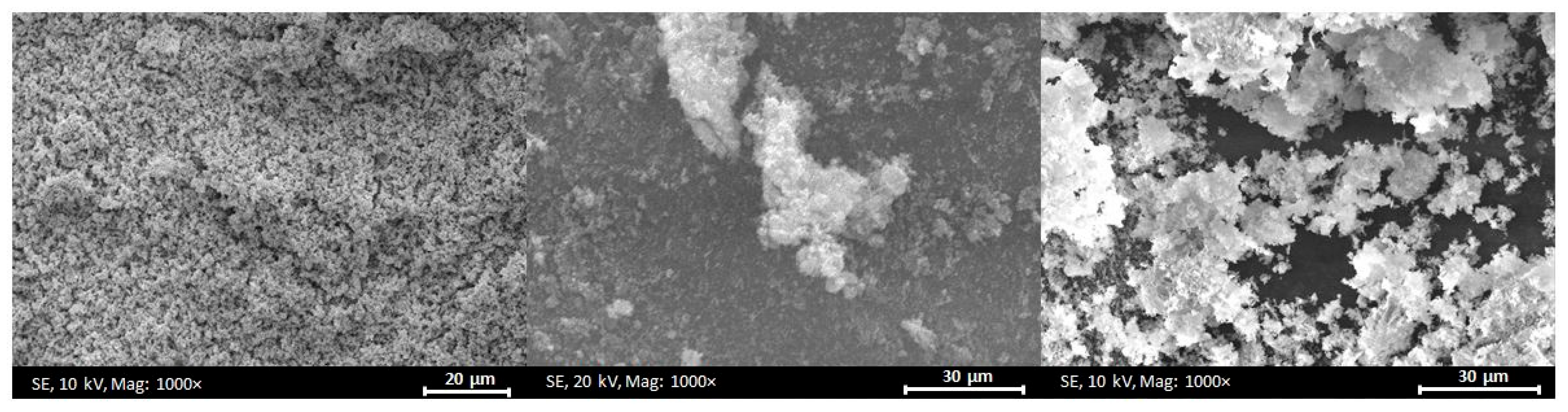

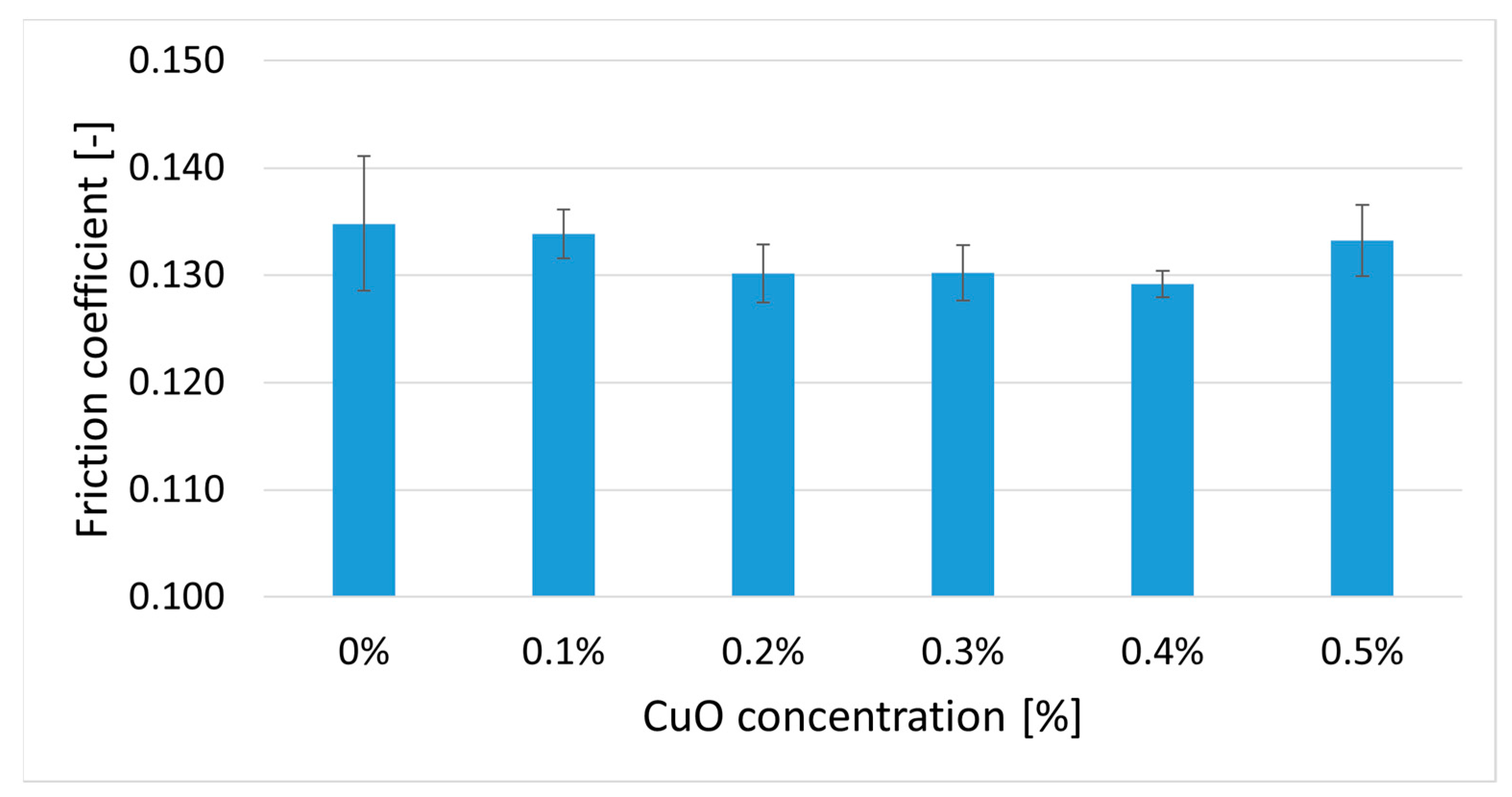

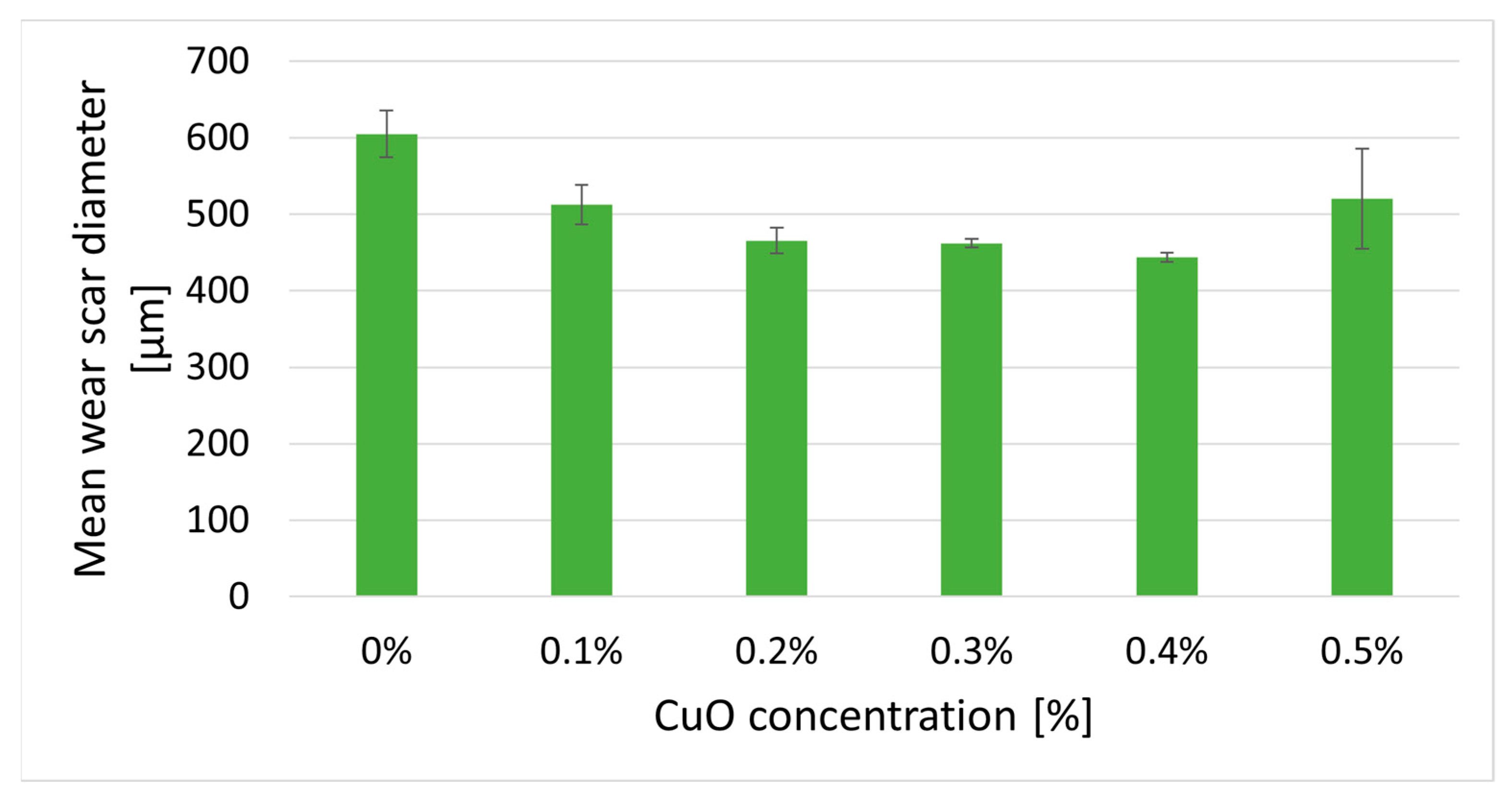

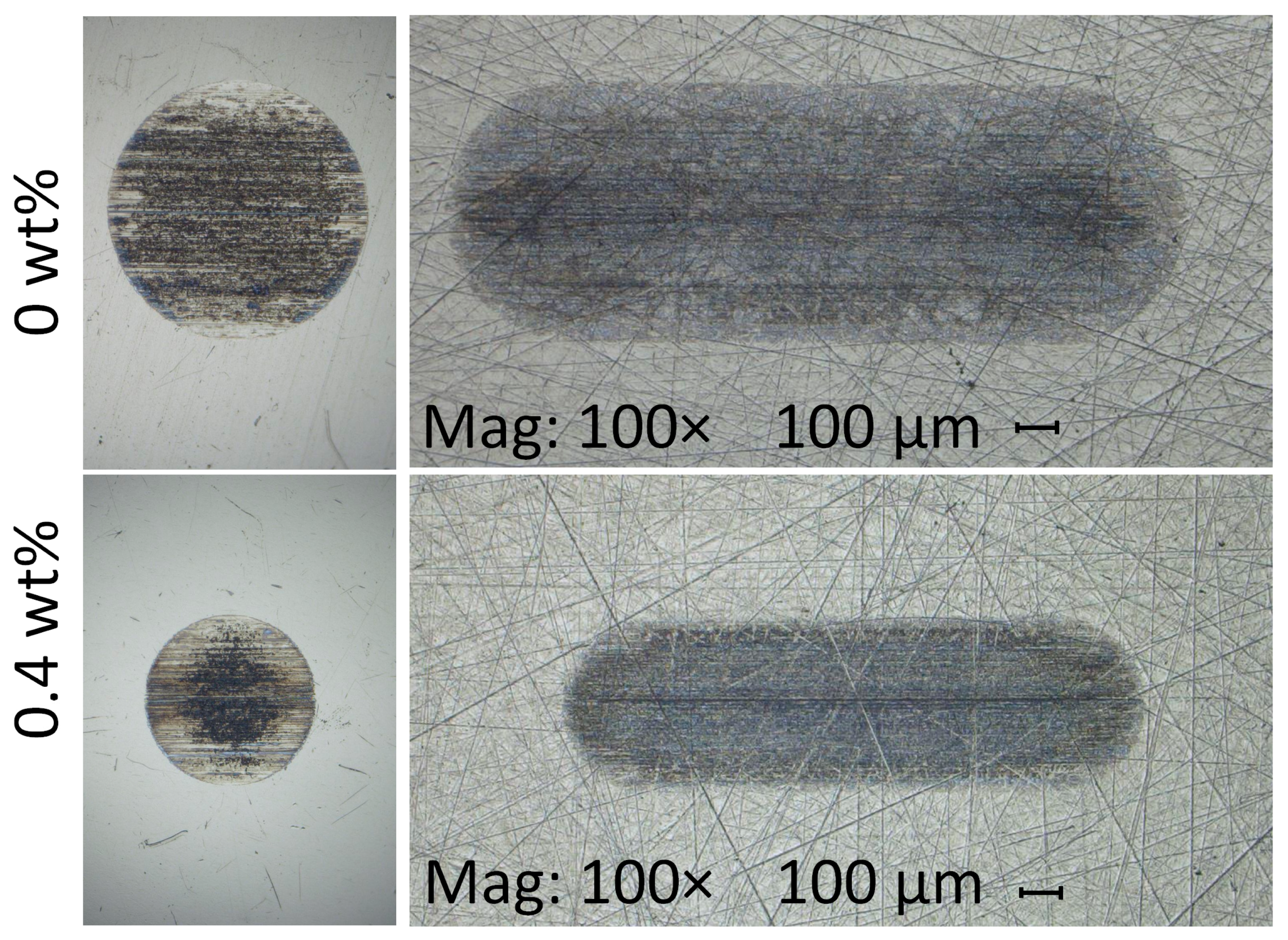

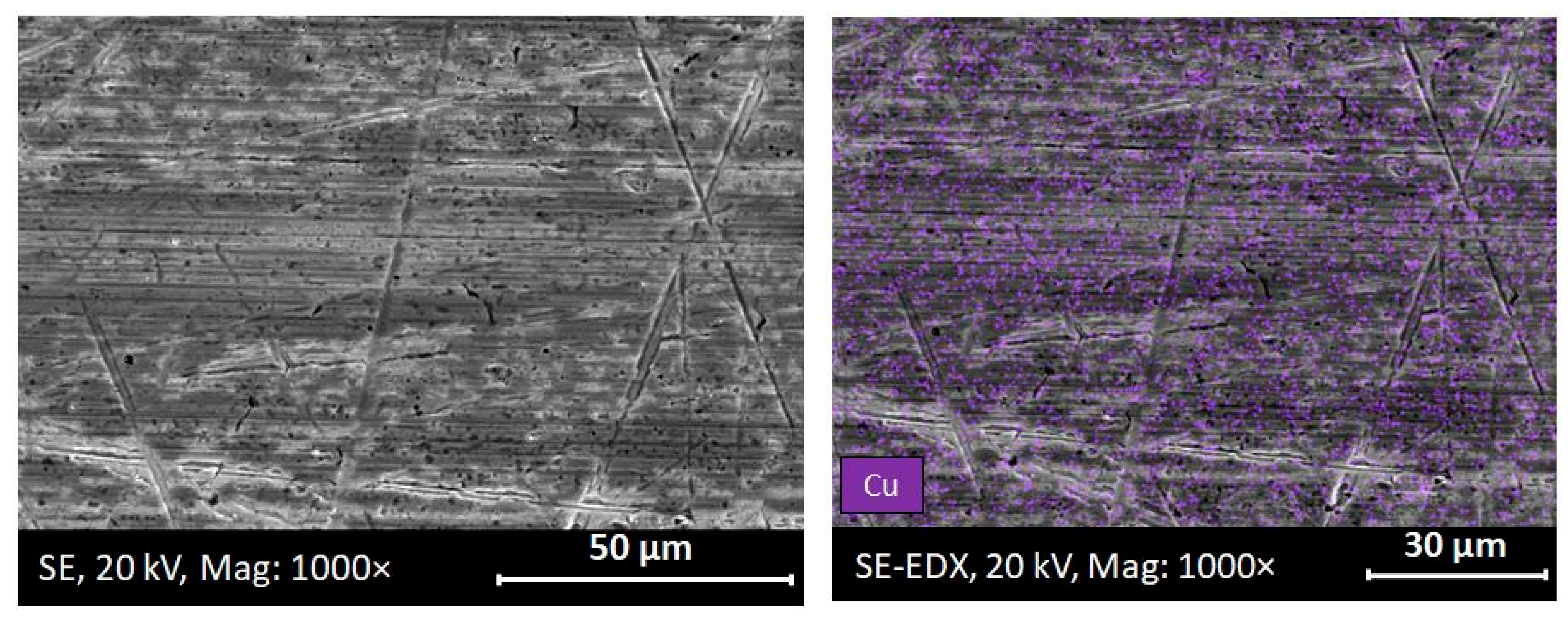

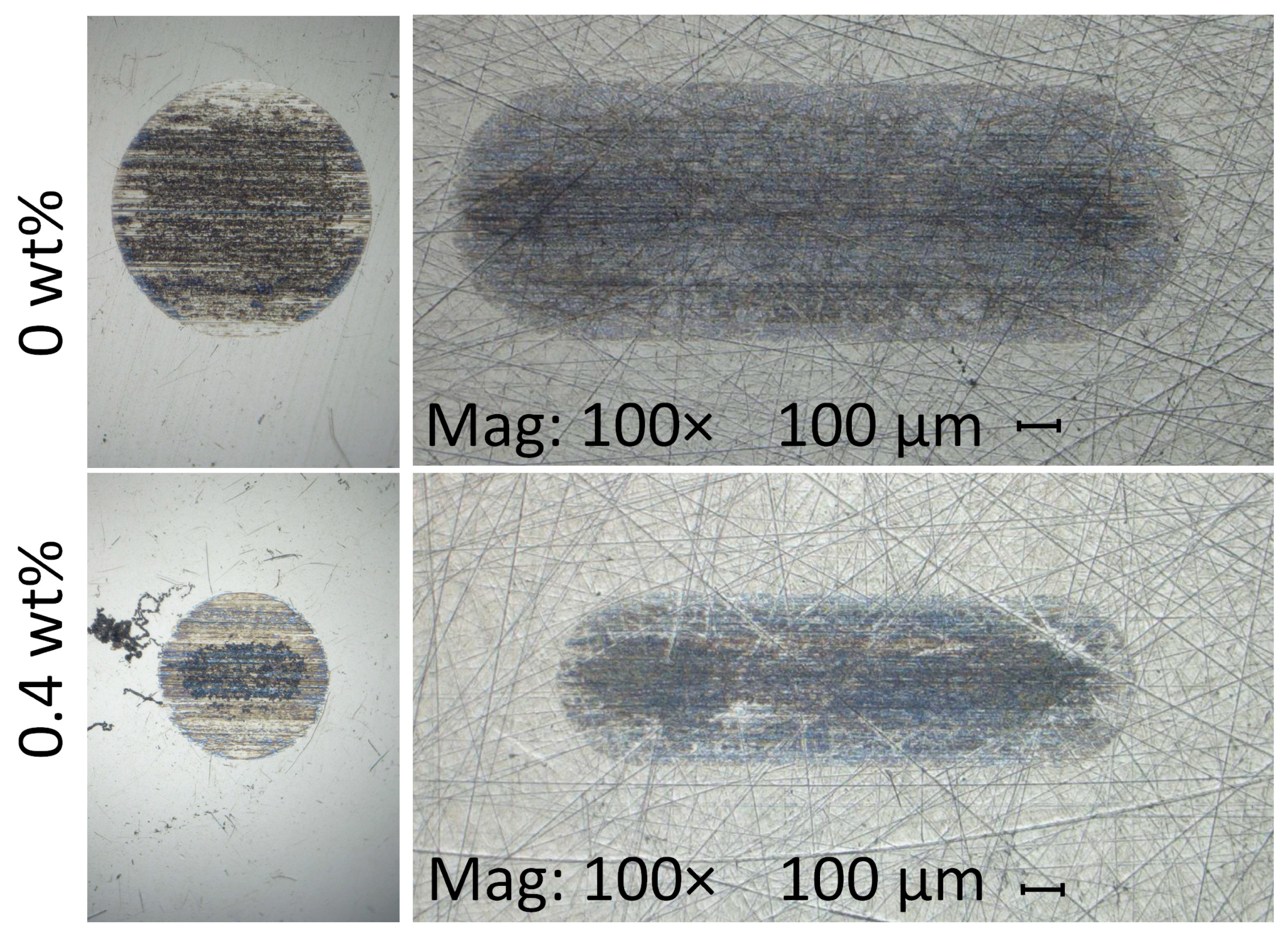

3.1. Cupric Oxide

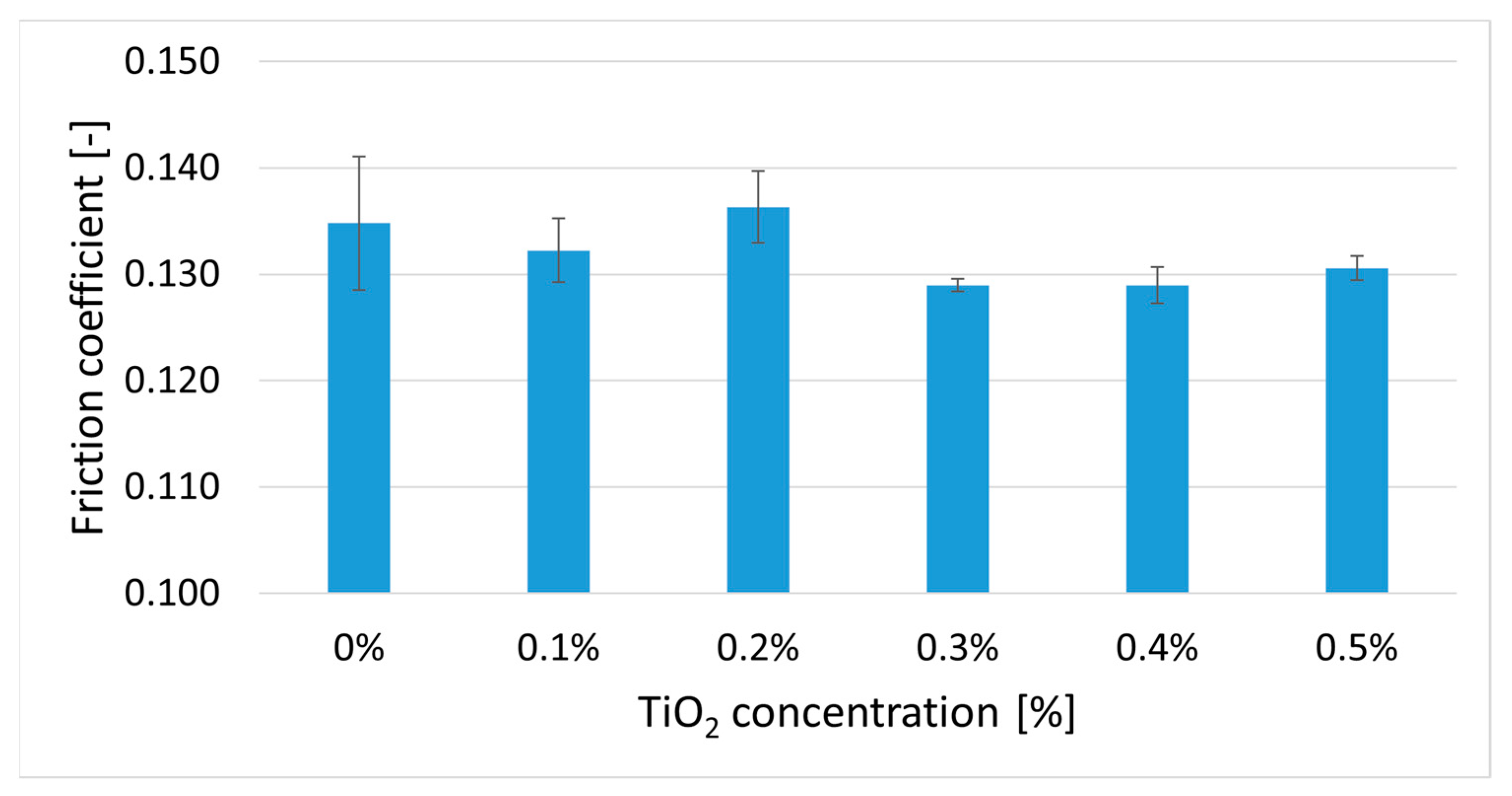

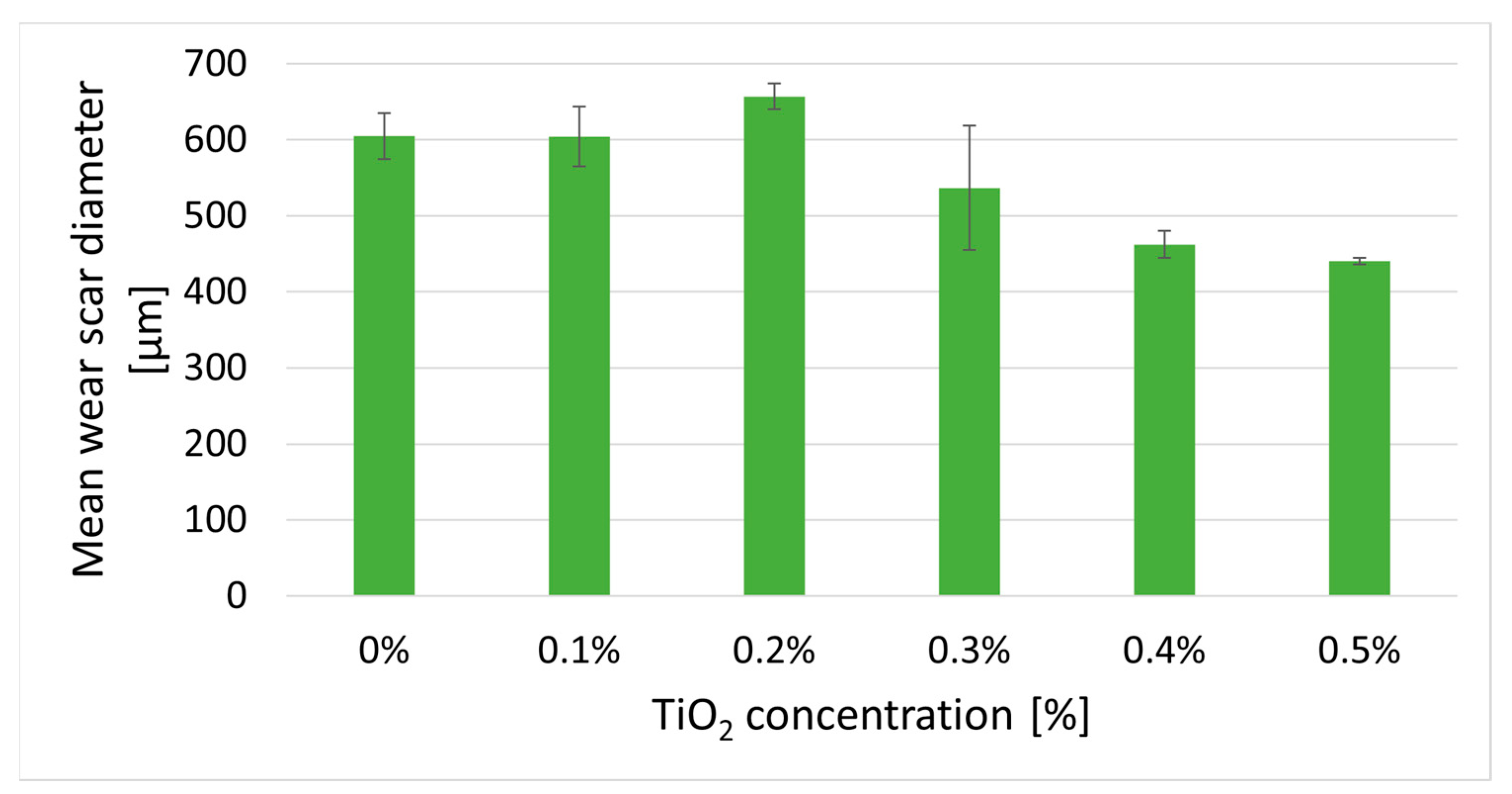

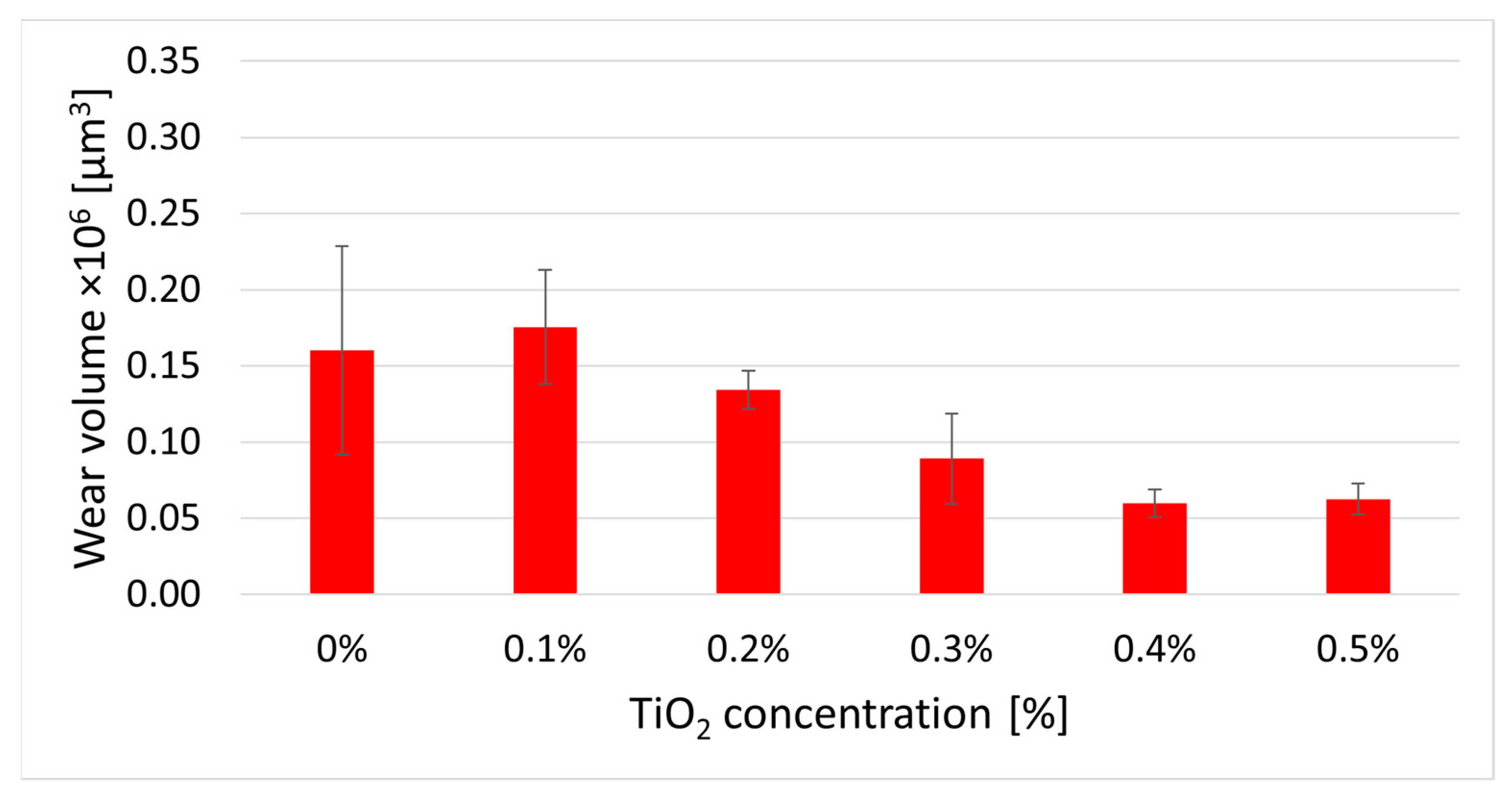

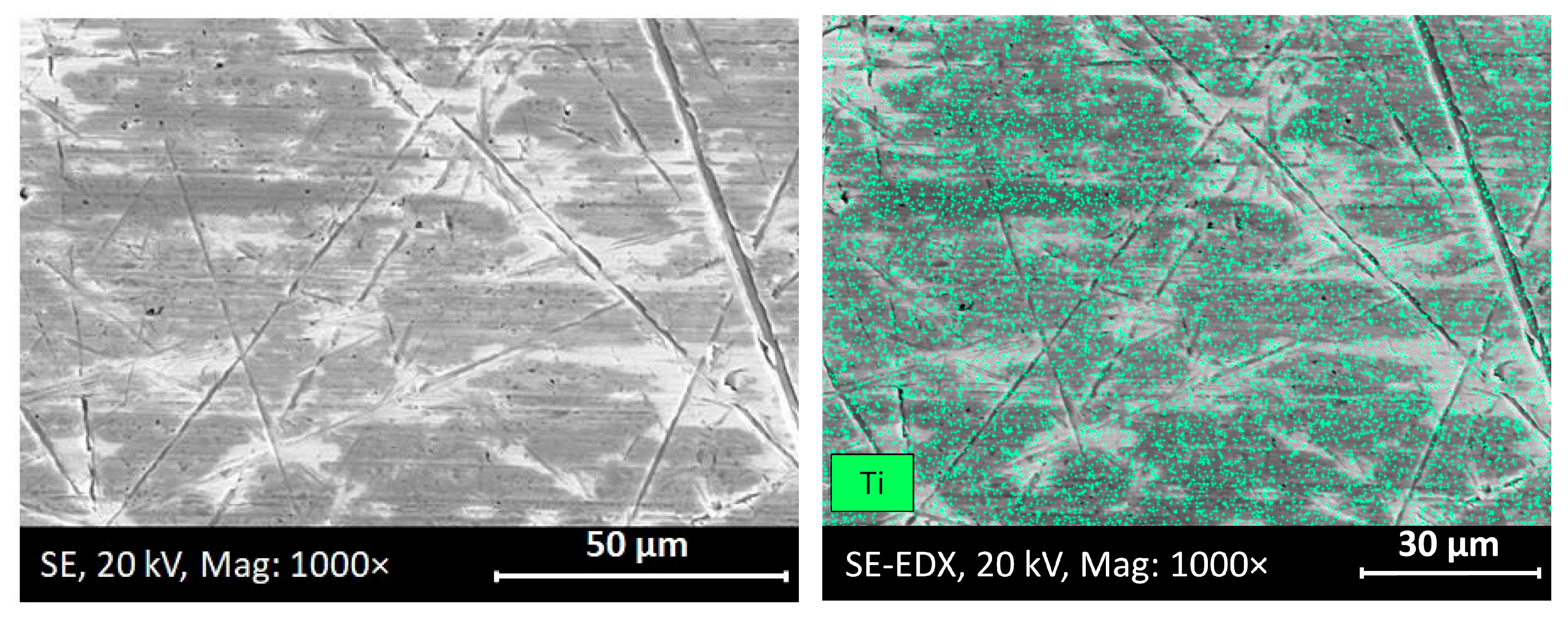

3.2. Titanium Dioxide

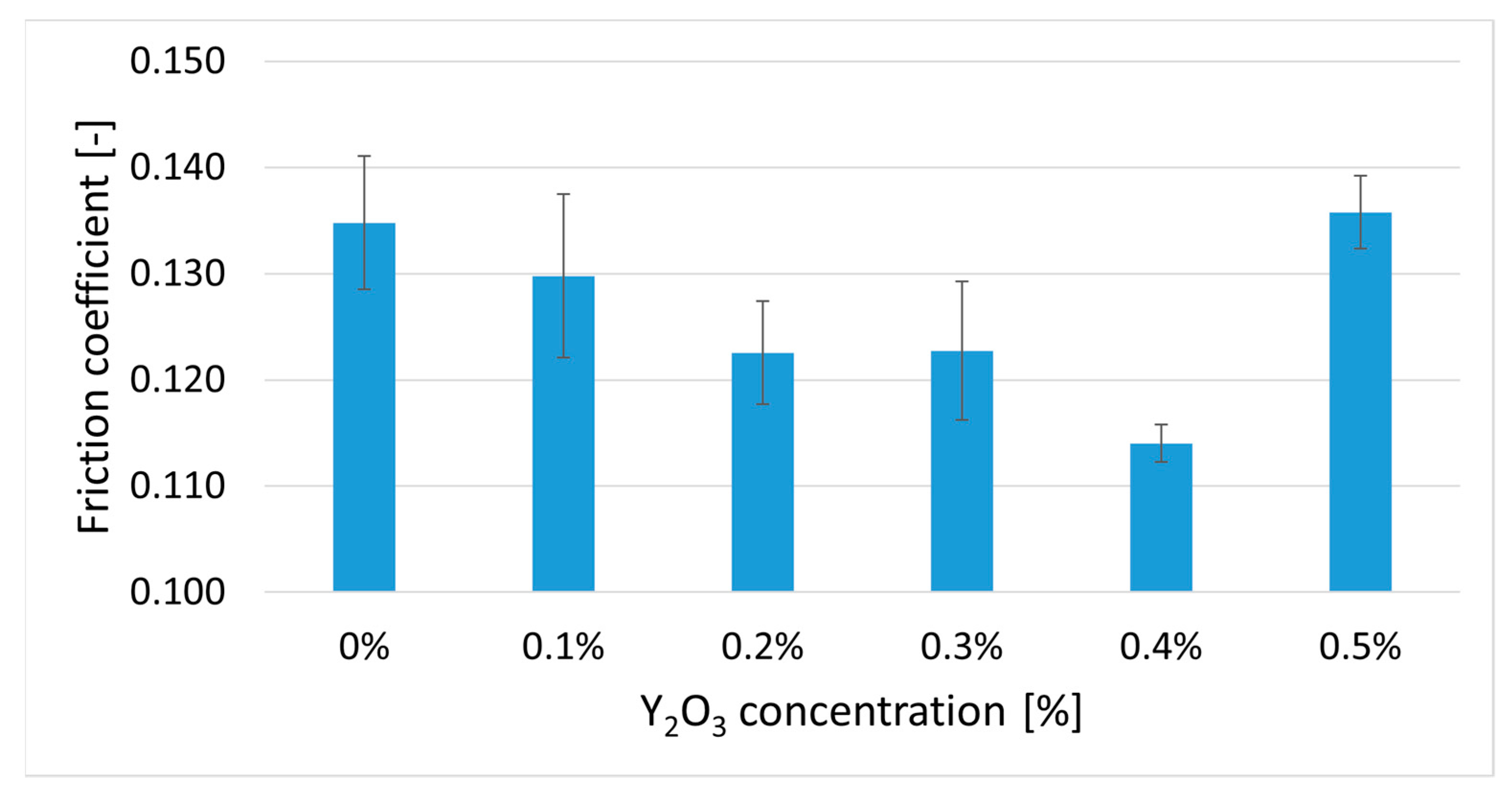

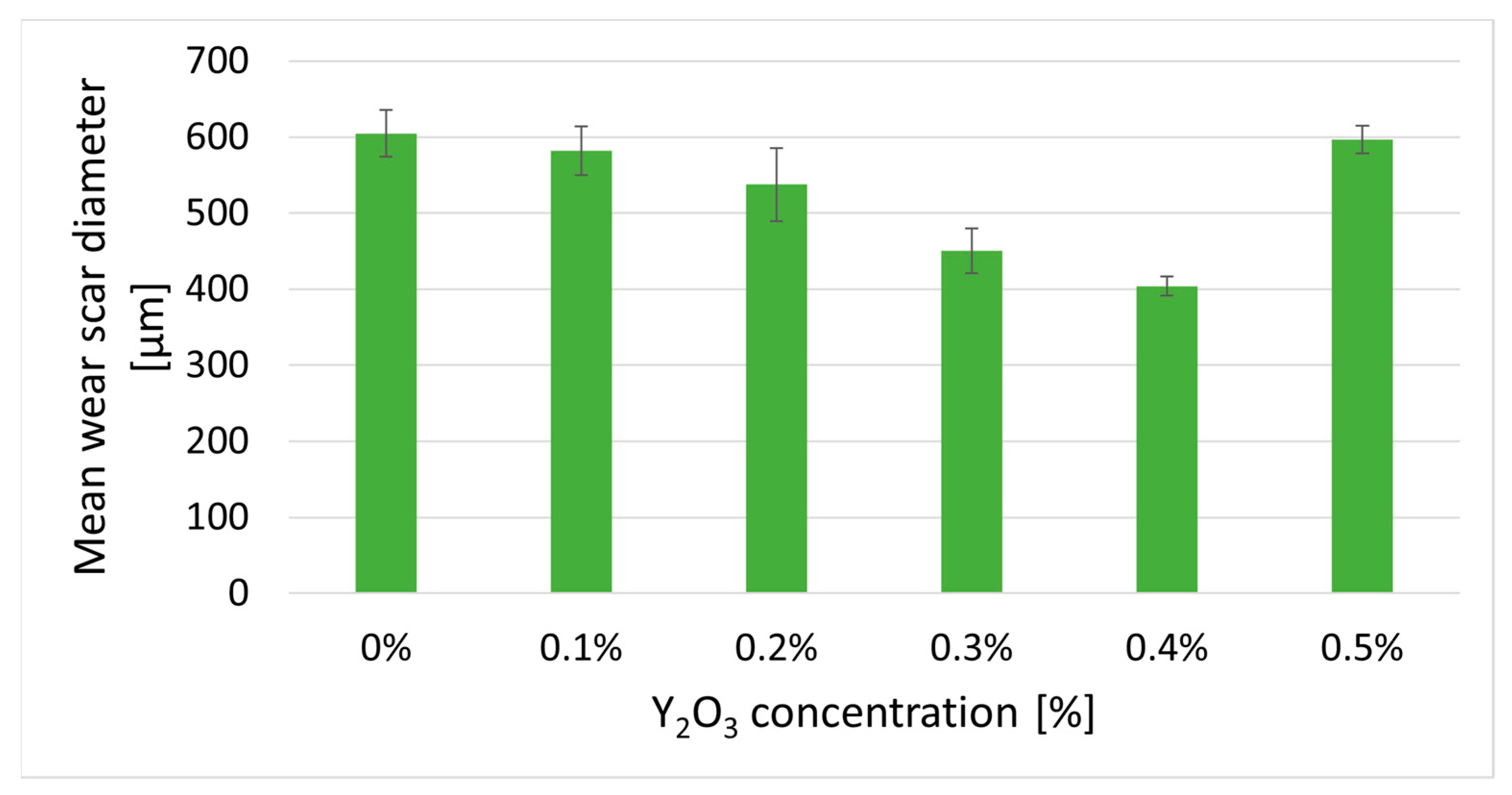

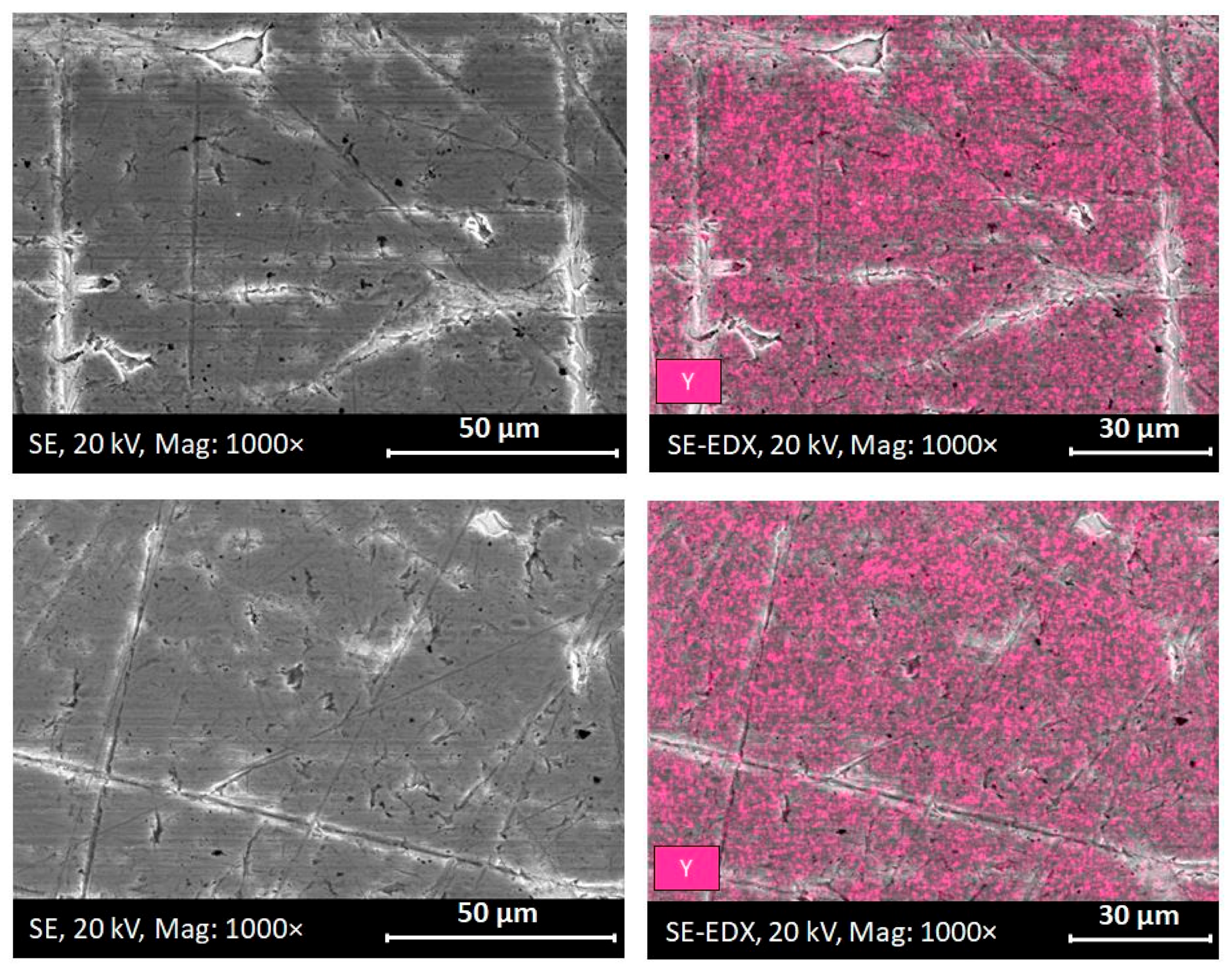

3.3. Yttrium Oxide

4. Discussion and Conclusions

- It was found that the tested oxide nanoparticles surface-modified with ethyl oleate can be effectively used in the presence of overbased calcium sulfonate.

- In the given tribology system, the optimal concentration of copper(II) oxide is 0.4 wt%, which resulted in a 4% reduction in friction, a 27% reduction in wear diameter and a 48% reduction in wear volume. The SEM+EDX analysis showed that copper(II) oxide and the overbased calcium sulfonate together created a boundary layer with favorable tribological properties on the surface, with a copper content of 0.37 norm.wt%.

- In the tested tribology system, the optimal concentration of titanium dioxide is 0.4 wt%, which resulted in a 4% reduction in friction, a 24% reduction in wear diameter and a 63% reduction in wear volume. The SEM+EDX analysis showed that titanium dioxide and the overbased calcium sulfonate together created a boundary layer with favorable tribological properties on the surface, with a copper content of around 0.42 norm.wt%.

- In the given tribology system, the optimal concentration of yttrium(III) oxide is 0.4 wt%, which resulted in a 15% reduction in friction, a 33% reduction in wear diameter and a 77% reduction in wear volume. The SEM+EDX analysis showed that yttrium(III) oxide and the overbased calcium sulfonate have a synergic effect on each other. The two additives formed a strong boundary layer with favorable tribological properties on the surface, with a high calcium (1.8–1.88 norm.wt%) and yttrium content (5.66–6.17 norm.wt%).

- During the EDX analysis, it was established that the protective layer created with overbased calcium sulfonate has a higher calcium content in the dead ends of the wear track and a lower calcium content in the center of the wear track.

| Result | 0.4% CuO | 0.4% TiO2 | 0.4% Y2O3 |

|---|---|---|---|

| Coefficient of friction | −4% | −4% | −15% |

| Mean wear scar diameter | −27% | −24% | −33% |

| Wear volume | −48% | −63% | −77% |

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shahnazar, S.; Bagheri, S.; Hamid, S.B.A. Enhancing lubricant properties by nanoparticle additives. Int. J. Hydrogen Energy 2016, 41, 3153–3170. [Google Scholar] [CrossRef]

- Duan, L.; Li, J.; Duan, H. Nanomaterials for lubricating oil application: A review. Friction 2023, 11, 647–684. [Google Scholar] [CrossRef]

- Akl, S.; Elsoudy, S.; Abdel-Rehim, A.A.; Salem, S.; Ellis, M. Recent Advances in Preparation and Testing Methods of Engine-Based Nanolubricants: A State-of-the-Art Review. Lubricants 2021, 9, 85. [Google Scholar] [CrossRef]

- Waqas, M.; Zahid, R.; Bhutta, M.U.; Khan, Z.A.; Saeed, A. A Review of Friction Performance of Lubricants with Nano Additives. Materials 2021, 14, 6310. [Google Scholar] [CrossRef]

- Youngji, Y.; Jong, W.H.; Hyunsoo, L.; Sang, W.H.; Jeong, Y.P. Shape-dependent adhesion and friction of Au nanoparticles probed with atomic force microscopy. Nanotechnology 2015, 26, 135707. [Google Scholar]

- Hudson, L.K.; Eastoe, J.; Dowding, P.J. Nanotechnology in action: Overbased nanodetergents as lubricant oil additives. Adv. Colloid Interface Sci. 2006, 123–126, 425–431. [Google Scholar] [CrossRef]

- Chinas-Castillo, F.; Spikes, H.A. Film Formation by Colloidal Overbased Detergents in Lubricated Contacts. Tribol. Trans. 2000, 43, 357–366. [Google Scholar] [CrossRef]

- Richardson, A.D.; Evans, M.-H.; Wang, L.; Ingram, M.; Rowland, Z.; Llanos, G.; Wood, R.J.K. The effect of over-based calcium sulfonate detergent additives on white etching crack (WEC) formation in rolling contact fatigue tested 100Cr6 steel. Tribol. Int. 2019, 133, 246–262. [Google Scholar] [CrossRef]

- Zhongyi, H.; Liping, X.; Sheng, H.; Aixi, C.; Jianwei, Q.; Xisheng, F. Tribological and Antioxidation Synergistic Effect Study of Sulfonate-Modified Nano Calcium Carbonate. PLoS ONE 2013, 8, e62050. [Google Scholar] [CrossRef][Green Version]

- Topolovec-Miklozic, K.; Forbus, T.R.; Spikes, H. Film Forming and Friction Properties of Overbased Calcium Sulphonate Detergents. Tribol. Lett. 2008, 29, 33–44. [Google Scholar] [CrossRef]

- Giasson, S.; Palermo, T.; Buffeteau, T.; Desbat, B.; Turlet, J.M. Study of boundary film formation with overbased calcium sulfonate by PM-IRRAS spectroscopy. Thin Solid Film. 1994, 252, 111–119. [Google Scholar] [CrossRef]

- Palermo, T.; Giasson, S.; Buffeteau, T.; Desbat, B.; Turlet, J.M. Study of deposit and friction films of overbased calcium sulphonate by PM-IRRAS spectroscopy. Lubr. Sci. 1996, 8, 119–127. [Google Scholar] [CrossRef]

- Cizaire, L.; Martin, J.M.; Gresser, E.; Truong Dinh, N.; Heau, C. Tribochemistry of Overbased Calcium Detergents Studied by ToF-SIMS and Other Surface Analyses. Tribol. Lett. 2004, 17, 715–721. [Google Scholar] [CrossRef]

- Kubo, T.; Fujiwara, S.; Nanao, H.; Minami, I.; Mori, S. TOF-SIMS analysis of boundary films derived from calcium sulfonates. Tribol. Lett. 2006, 23, 171–176. [Google Scholar] [CrossRef]

- Burkinshaw, M.; Neville, A.; Morina, A.; Sutton, M. Calcium sulphonate and its interactions with ZDDP on both aluminium–silicon and model silicon surfaces. Tribol. Int. 2012, 46, 41–51. [Google Scholar] [CrossRef]

- Greenall, A.; Neville, A.; Morina, A.; Sutton, M. Investigation of the interactions between a novel, organic anti-wear additive, ZDDP and overbased calcium sulphonate. Tribol. Int. 2012, 46, 52–61. [Google Scholar] [CrossRef]

- Fatima, N.; Minami, I.; Holmgren, A.; Marklund, P.; Berglund, K.; Larsson, R. Influence of water on the tribological properties of zinc dialkyl-dithiophosphate and over-based calcium sulphonate additives in wet clutch contacts. Tribol. Int. 2015, 87, 113–120. [Google Scholar] [CrossRef]

- Zhang, H.; Mo, Y.; Lv, J.; Wang, J. Tribological Behavior of WS2 Nanoparticles as Additives in Calcium Sulfonate Complex–Polyurea Grease. Lubricants 2023, 11, 259. [Google Scholar] [CrossRef]

- Wu, C.; Liu, Z.; Ni, J.; Yang, K.; Yang, H.; Li, X. Improved tribological and bearing vibration performance of calcium sulfonate complex grease dispersed with MoS2 and oxide nanoparticles. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2023, 237, 1941–1955. [Google Scholar] [CrossRef]

- Alves, S.M.; Mello, V.S.; Faria, E.A.; Camargo, A.P.P. Nanolubricants developed from tiny CuO nanoparticles. Tribol. Int. 2016, 100, 263–271. [Google Scholar] [CrossRef]

- Tóth, Á.D.; Szabó, Á.I.; Kuti, R.; Rohde-Brandenburger, J. Tribological Investigation of Applicability of Nano-Sized Cupric Oxide (CuO) Ceramic Material in Automotive Vehicles. FME Trans. 2020, 49, 335–343. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, Y.; Zhang, S.; Chen, Y.; Zhang, P.; Zhang, Z. Preparation and evaluation of tribological properties of oil-soluble rice-like CuO nanoparticles. Ind. Lubr. Tribol. 2015, 67, 276–283. [Google Scholar] [CrossRef]

- Jatti, V.S.; Singh, T.P. Copper oxide nano-particles as friction-reduction and anti-wear additives in lubricating oil. J. Mech. Sci. Technol. 2015, 29, 793–798. [Google Scholar] [CrossRef]

- Gupta, H.; Rai, S.K.; Krishna, N.S.; Anand, G. The effect of copper oxide nanoparticle additives on the rheological and tribological properties of engine oil. J. Dispers. Sci. Technol. 2021, 42, 622–632. [Google Scholar] [CrossRef]

- Asnida, M.; Hisham, S.; Awang, N.W.; Amirruddin, A.K.; Noor, M.M.; Kadirgama, K.; Ramasamy, D.; Najafi, G.; Tarlochan, F. Copper (II) oxide nanoparticles as additive in engine oil to increase the durability of piston-liner contact. Fuel 2018, 212, 656–667. [Google Scholar] [CrossRef]

- Gulzar, M.; Masjuki, H.H.; Varman, M.; Kalam, M.A.; Mufti, R.A.; Zulkifli, N.W.M.; Yunus, R.; Zahid, R. Improving the AW/EP ability of chemically modified palm oil by adding CuO and MoS2 nanoparticles. Tribol. Int. 2015, 88, 271–279. [Google Scholar] [CrossRef]

- Rajaganapathy, C.; Vasudevan, D.; Murugapoopathi, S. Tribological and rheological properties of palm and brassica oil with inclusion of CuO and TiO2 additives. Mater. Today Proc. 2021, 37, 207–213. [Google Scholar] [CrossRef]

- Chaurasia, S.K.; Singh, N.K.; Singh, L.K. Friction and wear behavior of chemically modified Sal (Shorea Robusta) oil for bio based lubricant application with effect of CuO nanoparticles. Fuel 2020, 282, 118762. [Google Scholar] [CrossRef]

- Zhao, J.; Yang, G.; Zhang, Y.; Zhang, S.; Zhang, C.; Gao, C.; Zhang, P. Controllable synthesis of different morphologies of CuO nanostructures for tribological evaluation as water-based lubricant additives. Friction 2021, 9, 963–977. [Google Scholar] [CrossRef]

- Wu, C.; Xiong, R.; Ni, J.; Yao, L.; Chen, L.; Li, X. Effects of CuO nanoparticles on friction and vibration behaviors of grease on rolling bearing. Tribol. Int. 2020, 152, 106552. [Google Scholar] [CrossRef]

- Ta, T.-N.; Chern, S.-Y.; Horng, J.-H. Tribological Behavior of Ionic Liquid with Nanoparticles. Materials 2021, 14, 6318. [Google Scholar] [CrossRef]

- Ilie, F.; Covaliu, C. Tribological Properties of the Lubricant Containing Titanium Dioxide Nanoparticles as an Additive. Lubricants 2016, 4, 12. [Google Scholar] [CrossRef]

- Suryawanshi, S.R.; Pattiwar, J.T. Effect of TiO2 Nanoparticles Blended with Lubricating Oil on the Tribological Performance of the Journal Bearing. Tribol. Ind. 2018, 40, 370–391. [Google Scholar] [CrossRef]

- Birleanu, C.; Pustan, M.; Cioaza, M.; Molea, A.; Popa, F.; Contiu, G. Effect of TiO2 nanoparticles on the tribological properties of lubricating oil: An experimental investigation. Sci. Rep. 2022, 12, 5201. [Google Scholar] [CrossRef]

- Shaik, S.V.; Dev Sing, D.; Patil, A. Experimental investigation of tribological properties of TiO2 nanoparticles in engine oil. Mater. Today Proc. 2021, 46, 883–889. [Google Scholar]

- Ali, M.K.A.; Xianjun, H.; Mai, L.; Qingping, C.; Turkson, R.F.; Bicheng, C. Improving the tribological characteristics of piston ring assembly in automotive engines using Al2O3 and TiO2 nanomaterials as nano-lubricant additives. Tribol. Int. 2016, 103, 540–554. [Google Scholar] [CrossRef]

- Zhang, R.; Qiao, D.; Liu, X.; Guo, Z.; Hu, L.; Shi, L. Well Dispersive TiO2 Nanoparticles as Additives for Improving the Tribological Performance of Polyalphaolefin Gel Lubricant. Ind. Eng. Chem. Res. 2018, 57, 10379–10390. [Google Scholar] [CrossRef]

- Zhang, H.; Han, S.; Hu, W.; Li, J. Tribological study of TiO2 nanoparticles modified with stearic acid as additives in lithium grease. Ind. Lubr. Tribol. 2021, 73, 904–910. [Google Scholar] [CrossRef]

- Ye, W.; Cheng, T.; Ye, Q.; Guo, X.; Zhang, Z.; Dang, H. Preparation and tribological properties of tetrafluorobenzoic acidmodified TiO2 nanoparticles as lubricant additives. Mater. Sci. Eng. A 2003, 359, 82–85. [Google Scholar] [CrossRef]

- Kao, M.-J.; Lin, C.-R. Evaluating the role of spherical titanium oxide nanoparticles in reducing friction between two pieces of cast iron. J. Alloys Compd. 2009, 483, 456–459. [Google Scholar] [CrossRef]

- Wu, Y.Y.; Tsui, W.C.; Liu, T.C. Experimental analysis of tribological properties of lubricating oils with nanoparticle additives. Wear 2007, 262, 819–825. [Google Scholar] [CrossRef]

- Tóth, Á.D.; Szabó, Á.I.; Leskó, M.Z.; Rohde-Brandenburger, J.; Kuti, R. Tribological Properties of the Nanoscale Spherical Y2O3 Particles as Lubricant Additives in Automotive Application. Lubricants 2022, 10, 28. [Google Scholar] [CrossRef]

- Szabó, Á.I.; Tóth, Á.D.; Leskó, M.Z.; Hargitai, H. Investigation of the Applicability of Y2O3–ZrO2 Spherical Nanoparticles as Tribological Lubricant Additives. Lubricants 2022, 10, 152. [Google Scholar] [CrossRef]

- Chen, C.-Y.; Papadopoulos, K.D. Ethanol’s effects on acid neutralization by motor oils. Tribol. Int. 2019, 132, 24–29. [Google Scholar] [CrossRef]

- Tóth, Á.D.; Mike-Kaszás, N.; Bartus, G.; Hargitai, H.; Szabó, Á.I. Surface Modification of Silica Nanoparticles with Ethyl Oleate for the Purpose of Stabilizing Nanolubricants Used for Tribological Tests. Ceramics 2023, 6, 980–993. [Google Scholar] [CrossRef]

- ISO 19291:2016(E); Lubricants—Determination of Tribological Quantities for Oils and Greases—Tribological Test in the Translator Oscillation Apparatus. International Organization for Standardization: Geneva, Switzerland, 2016.

- Tóth, Á.D.; Paulovics, L.; Hanula, B.; Kopp, A.; Knaup, J. Development of Testing Methodology for Tribological Characterization of Different Engine Lubricants. In Proceedings of the Reibung, Schmierung und Verschleiß—Forschung und praktische Anwendung, Göttingen, Germany, 25–27 September 2017; Gesellshchaft für Tribologie e.V.: Aachen, Germany, 2017. [Google Scholar]

| Element | Stroke-Middle Section | Dead Center |

|---|---|---|

| Fe | 91.51 | 90.07 |

| Cr | 1.68 | 1.69 |

| Si | 0.34 | 0.36 |

| O | 2.70 | 3.80 |

| C | 2.32 | 2.48 |

| Ca | 0.95 | 1.11 |

| S | 0.13 | 0.12 |

| Cu | 0.37 | 0.37 |

| Element | Stroke-Middle Section | Dead Center |

|---|---|---|

| Fe | 91.72 | 88.12 |

| Cr | 1.73 | 1.68 |

| Si | 0.28 | 0.31 |

| O | 2.72 | 5.41 |

| C | 2.44 | 2.94 |

| Ca | 0.63 | 1.05 |

| S | 0.07 | 0.09 |

| Ti | 0.42 | 0.41 |

| Element | Stroke-Middle Section | Dead Center |

|---|---|---|

| Fe | 79.60 | 79.78 |

| Cr | 1.61 | 1.59 |

| Si | 0.41 | 0.35 |

| O | 7.84 | 8.18 |

| C | 2.50 | 2.49 |

| Ca | 1.80 | 1.88 |

| S | 0.07 | 0.07 |

| Y | 6.17 | 5.66 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tóth, Á.D.; Hargitai, H.; Szabó, Á.I. Tribological Investigation of the Effect of Nanosized Transition Metal Oxides on a Base Oil Containing Overbased Calcium Sulfonate. Lubricants 2023, 11, 337. https://doi.org/10.3390/lubricants11080337

Tóth ÁD, Hargitai H, Szabó ÁI. Tribological Investigation of the Effect of Nanosized Transition Metal Oxides on a Base Oil Containing Overbased Calcium Sulfonate. Lubricants. 2023; 11(8):337. https://doi.org/10.3390/lubricants11080337

Chicago/Turabian StyleTóth, Álmos Dávid, Hajnalka Hargitai, and Ádám István Szabó. 2023. "Tribological Investigation of the Effect of Nanosized Transition Metal Oxides on a Base Oil Containing Overbased Calcium Sulfonate" Lubricants 11, no. 8: 337. https://doi.org/10.3390/lubricants11080337

APA StyleTóth, Á. D., Hargitai, H., & Szabó, Á. I. (2023). Tribological Investigation of the Effect of Nanosized Transition Metal Oxides on a Base Oil Containing Overbased Calcium Sulfonate. Lubricants, 11(8), 337. https://doi.org/10.3390/lubricants11080337