High Temperature Friction and Wear Behavior of PTFE/MoS2 Composites

Abstract

:1. Introduction

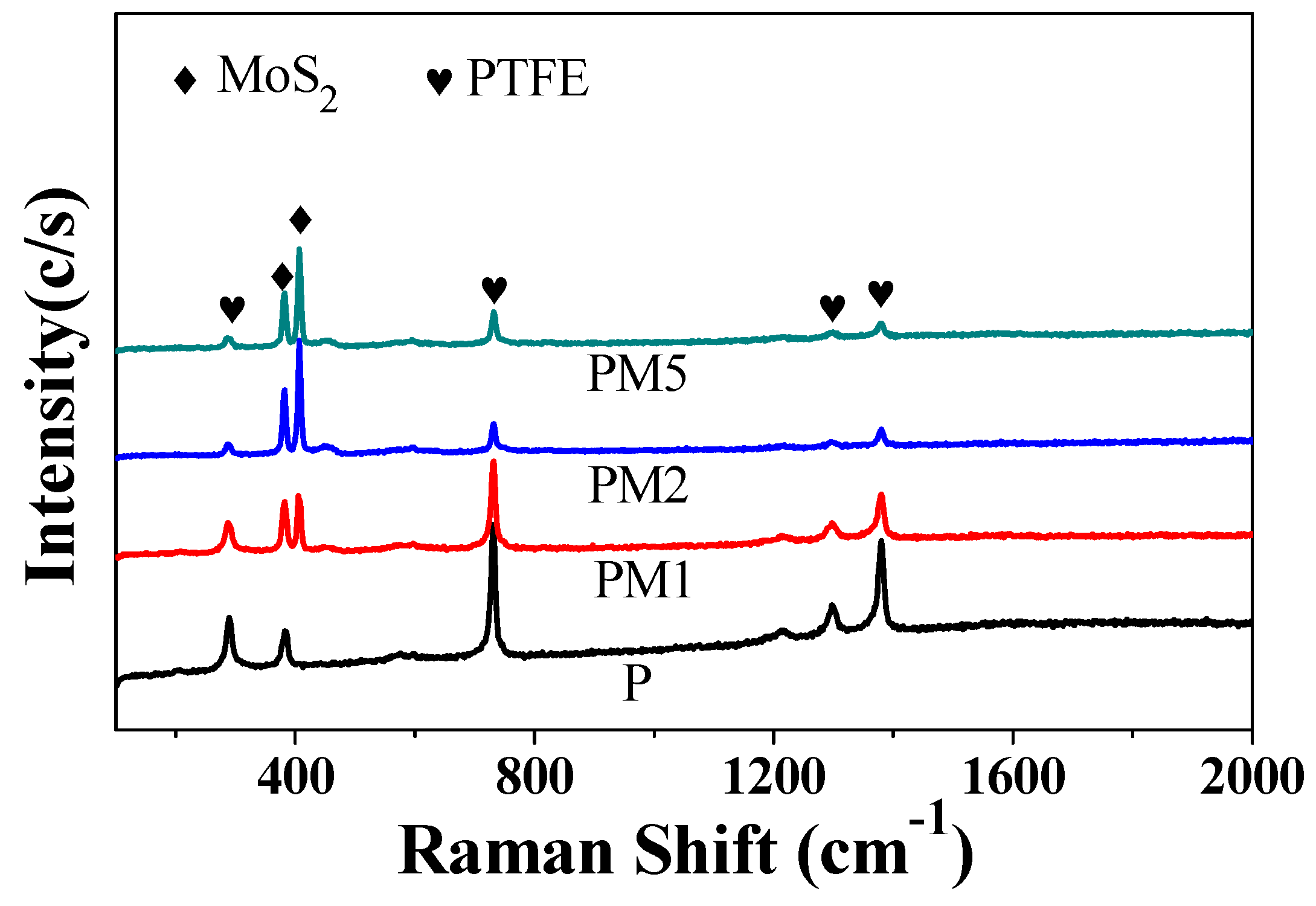

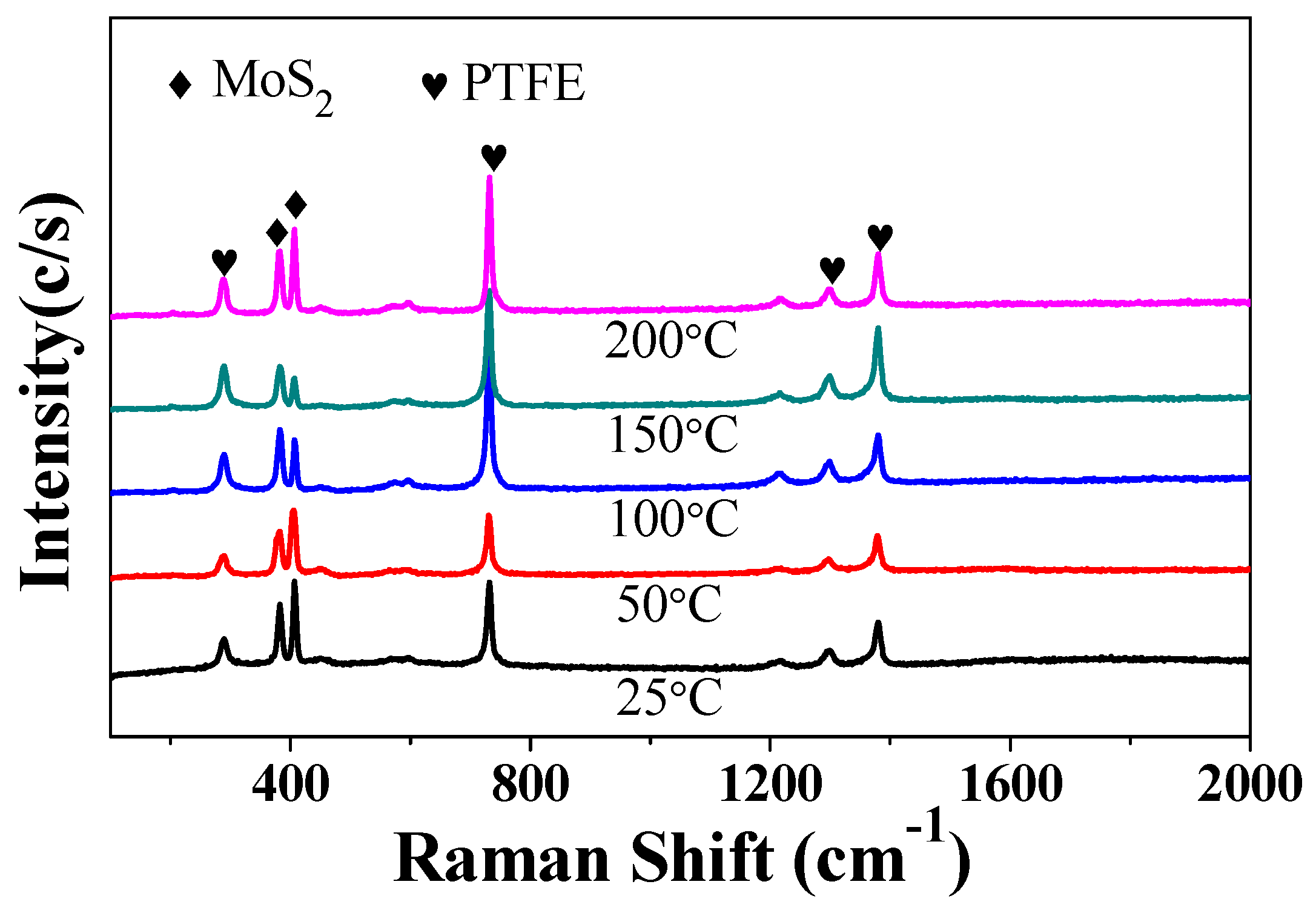

2. Experimental Part

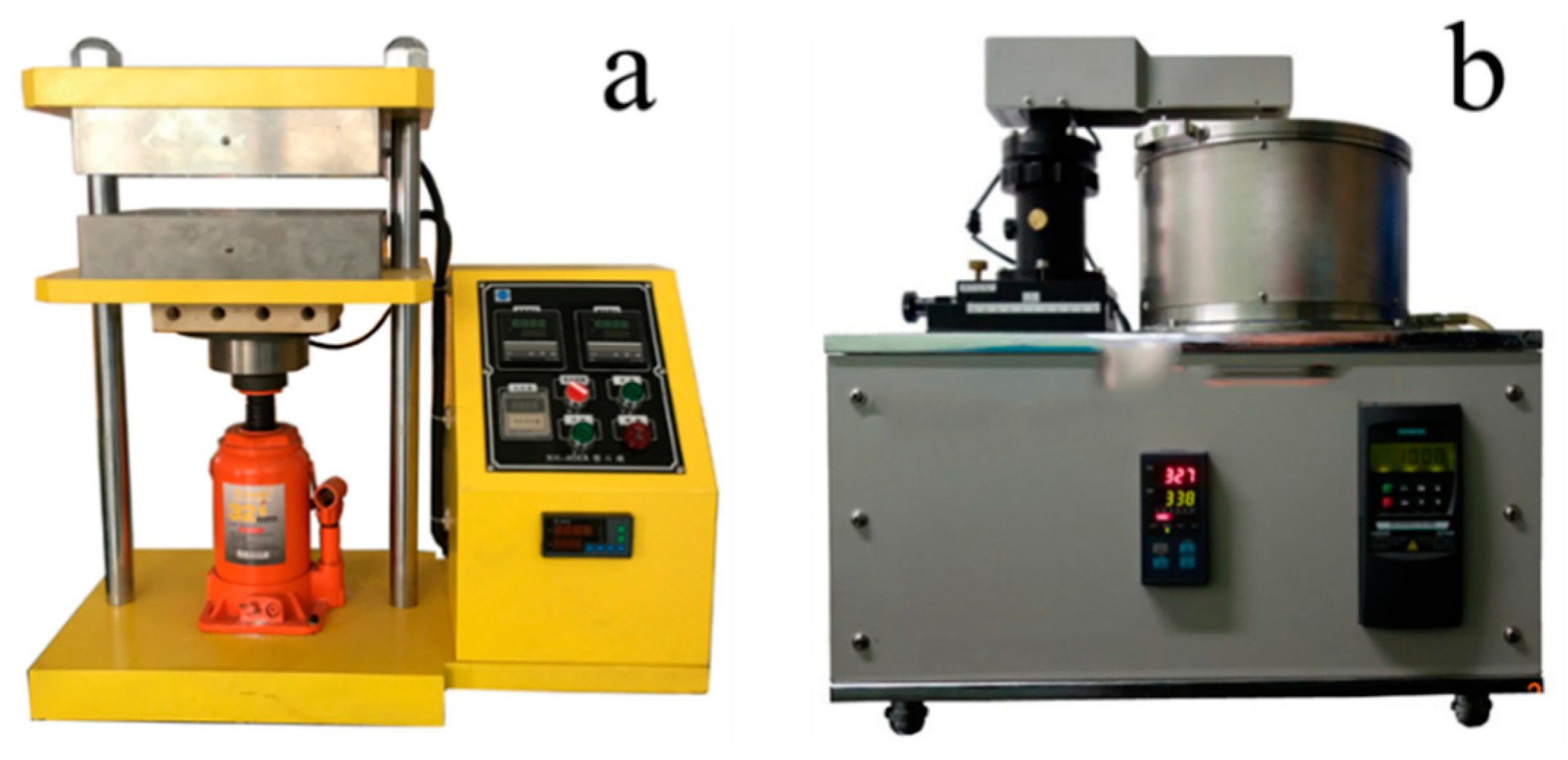

2.1. Materials Preparation

2.2. Tribological Performance Tests

2.3. Characterization

3. Results and Discussion

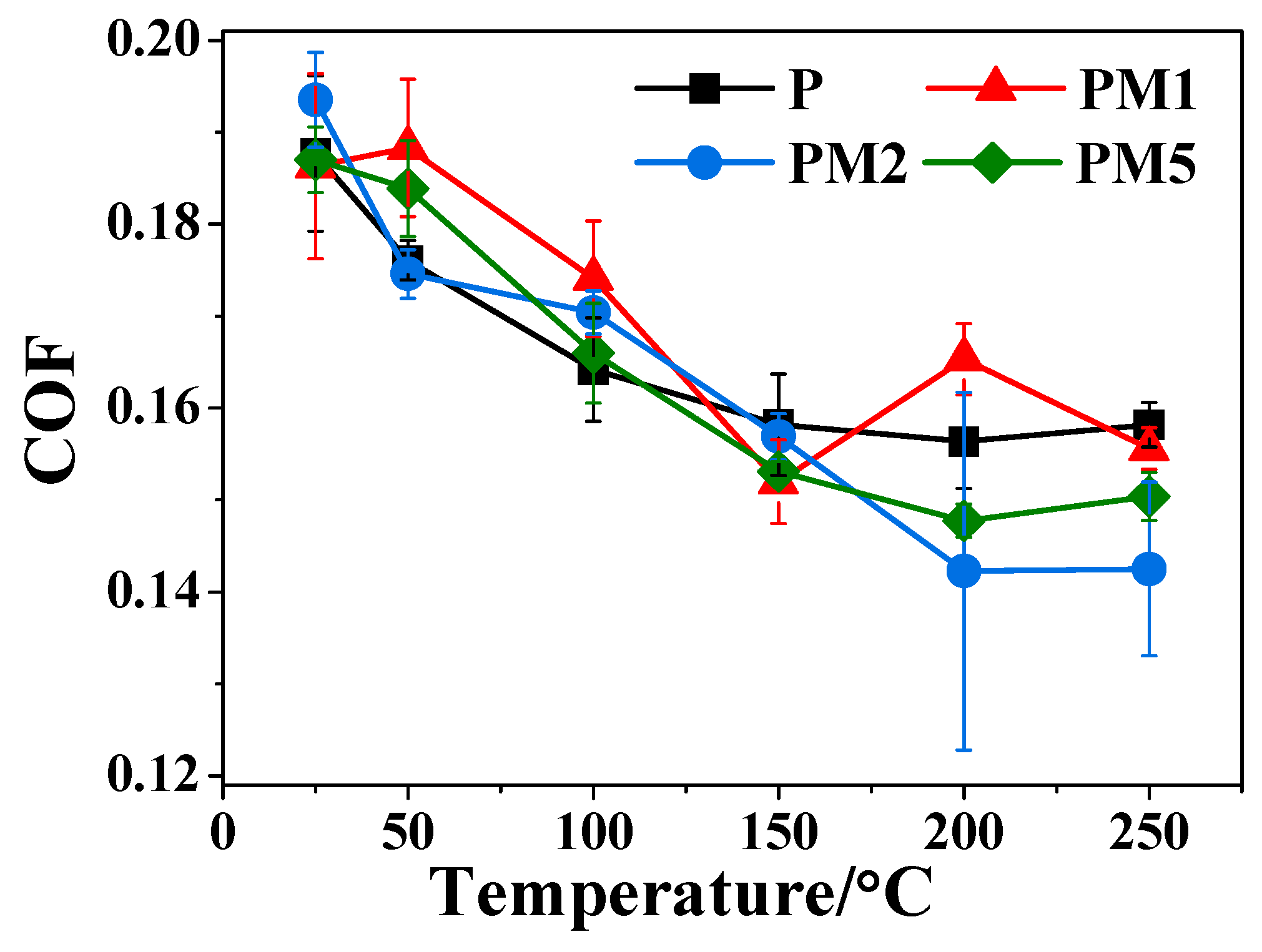

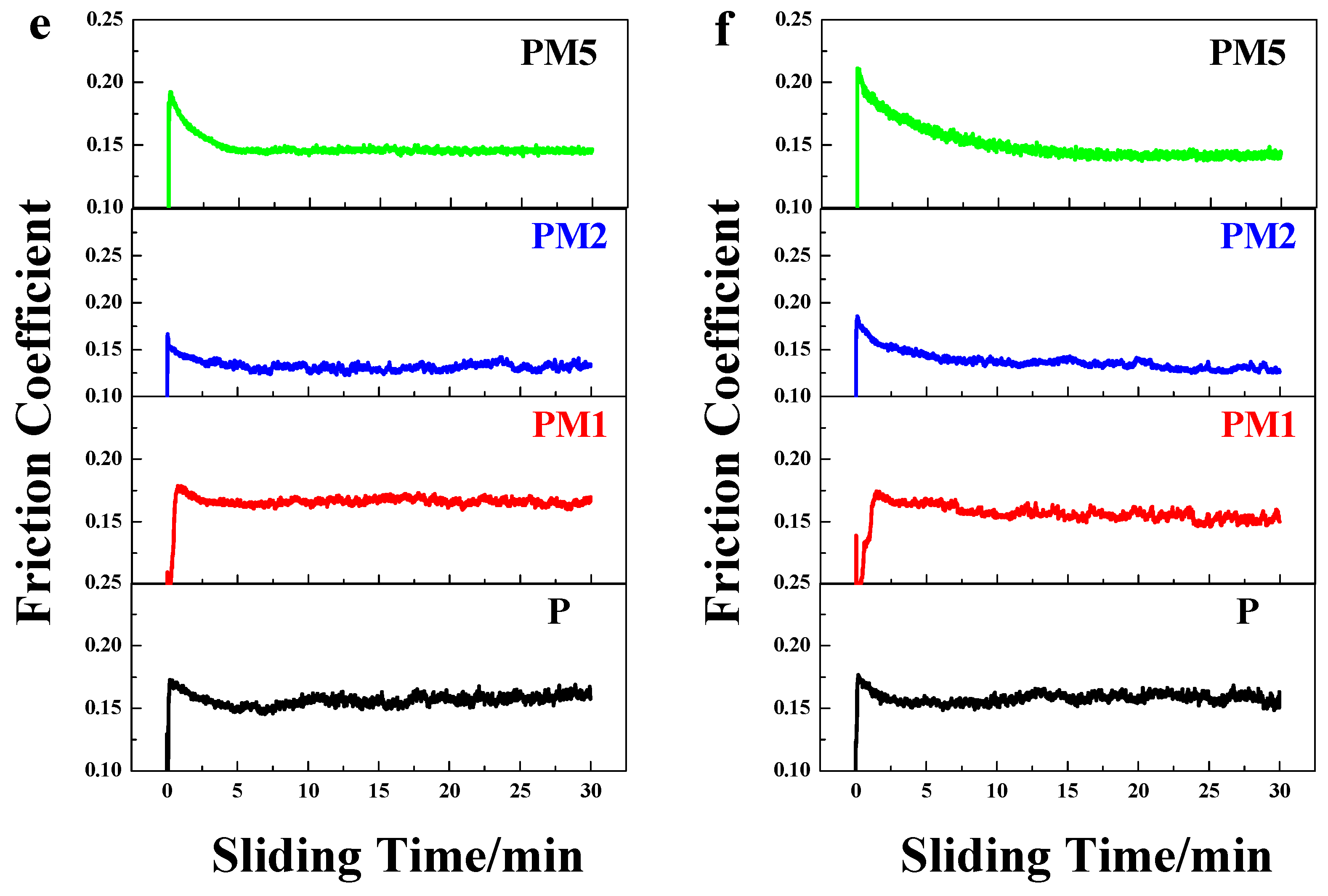

3.1. Friction and Wear Performance Test

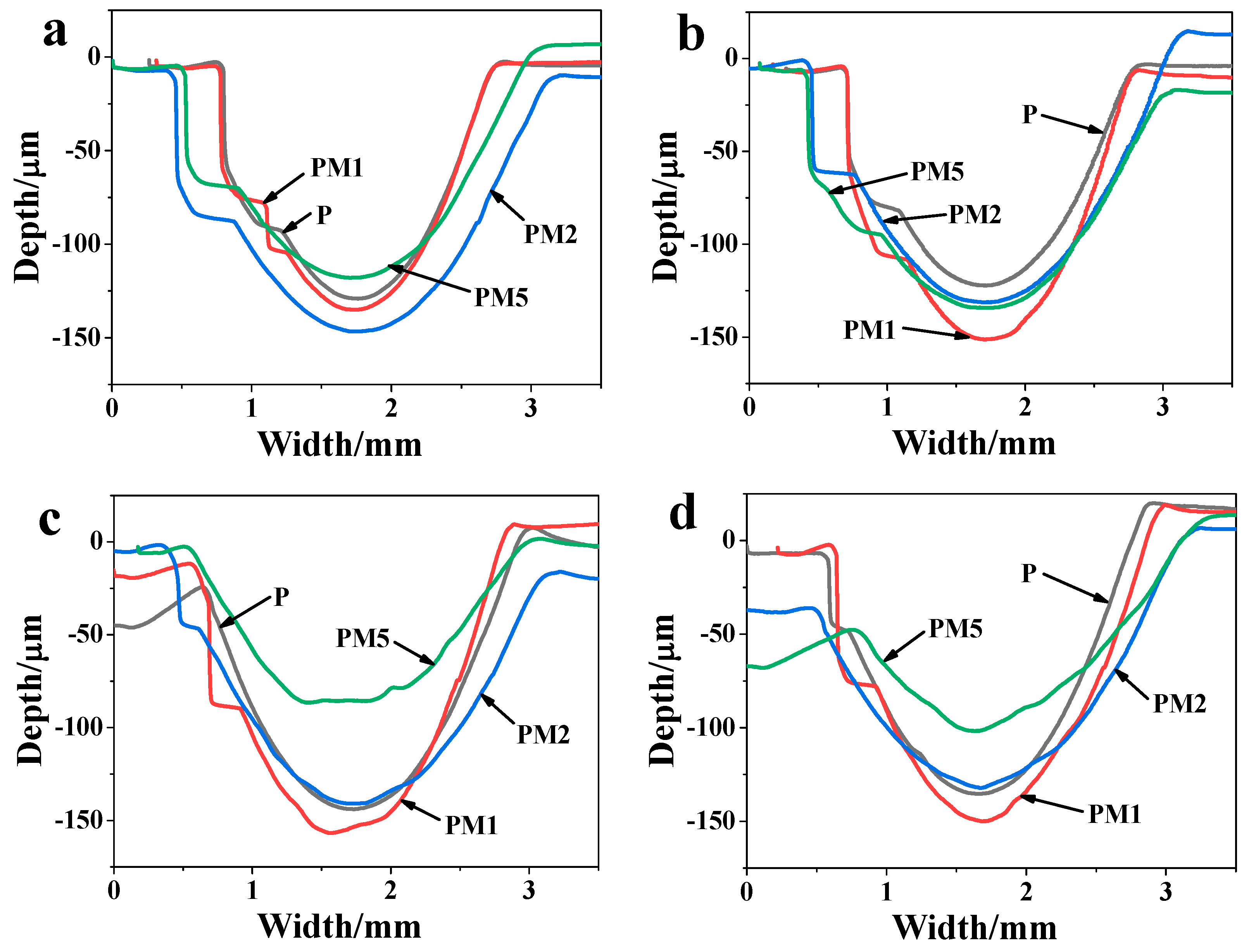

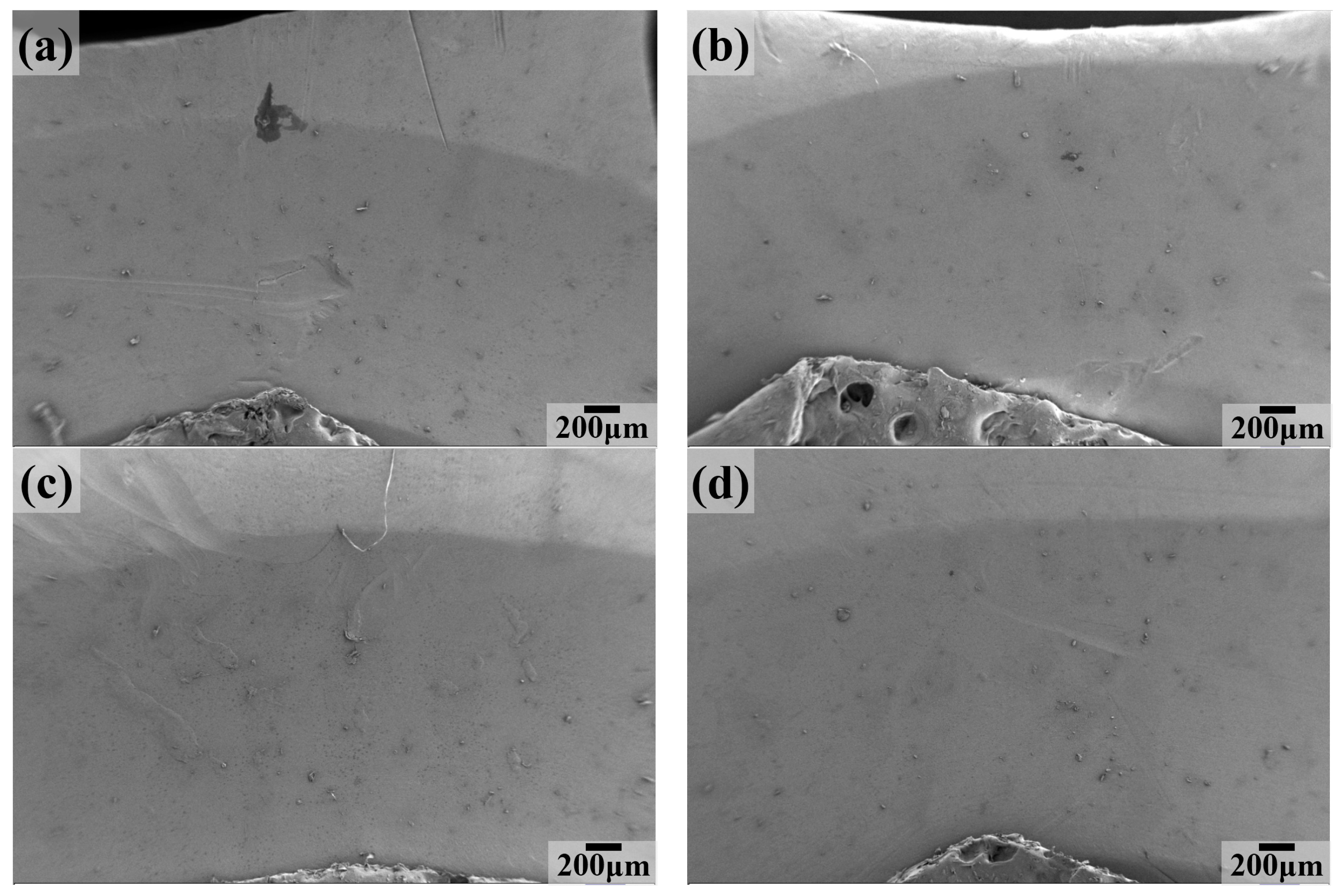

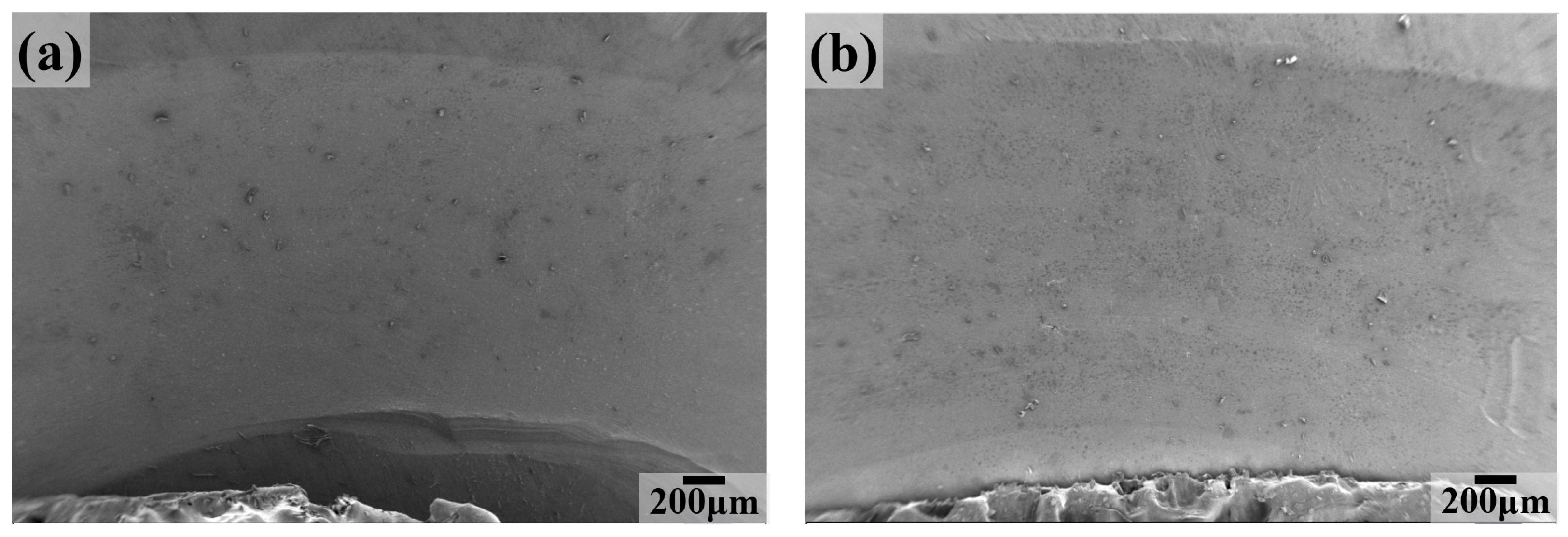

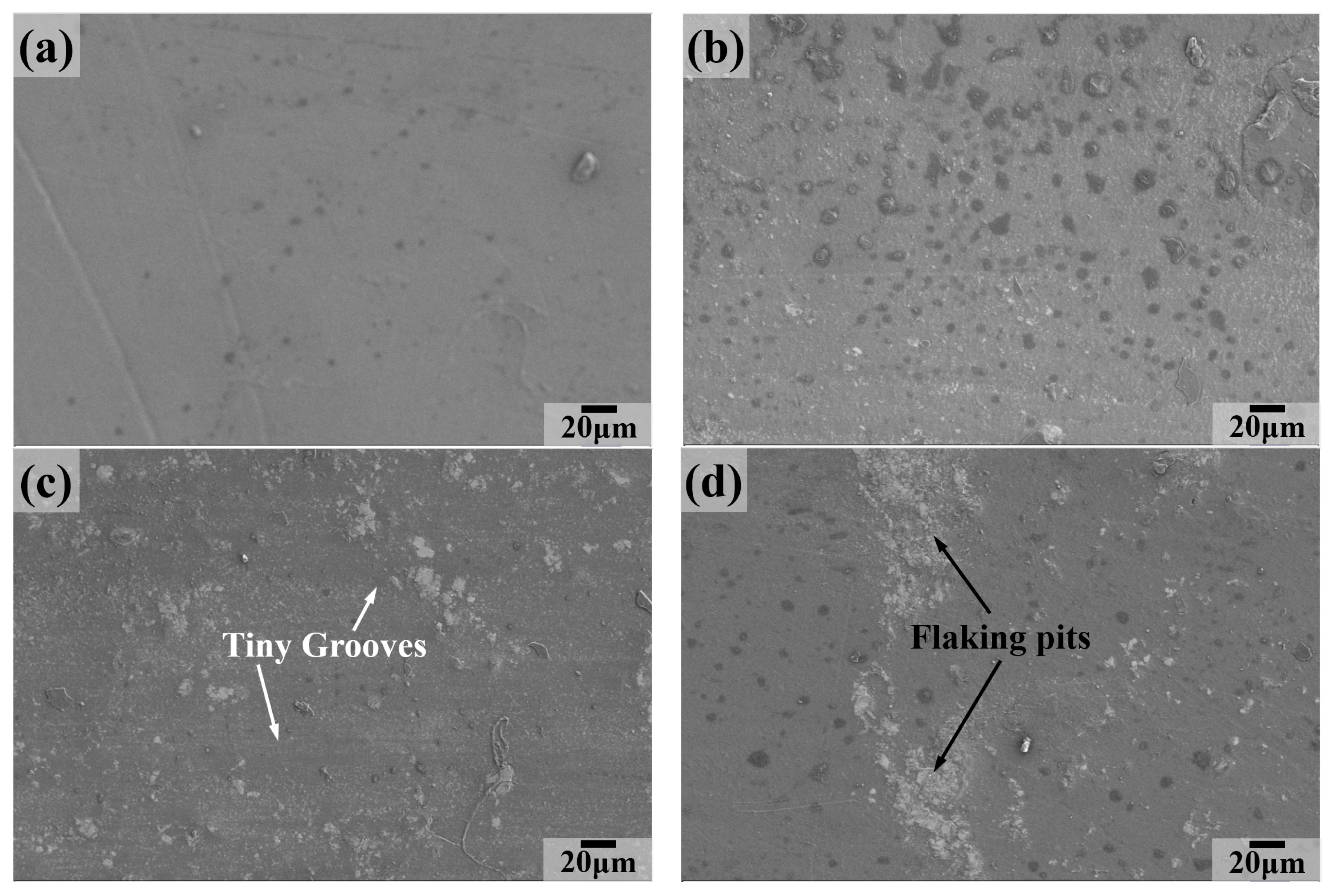

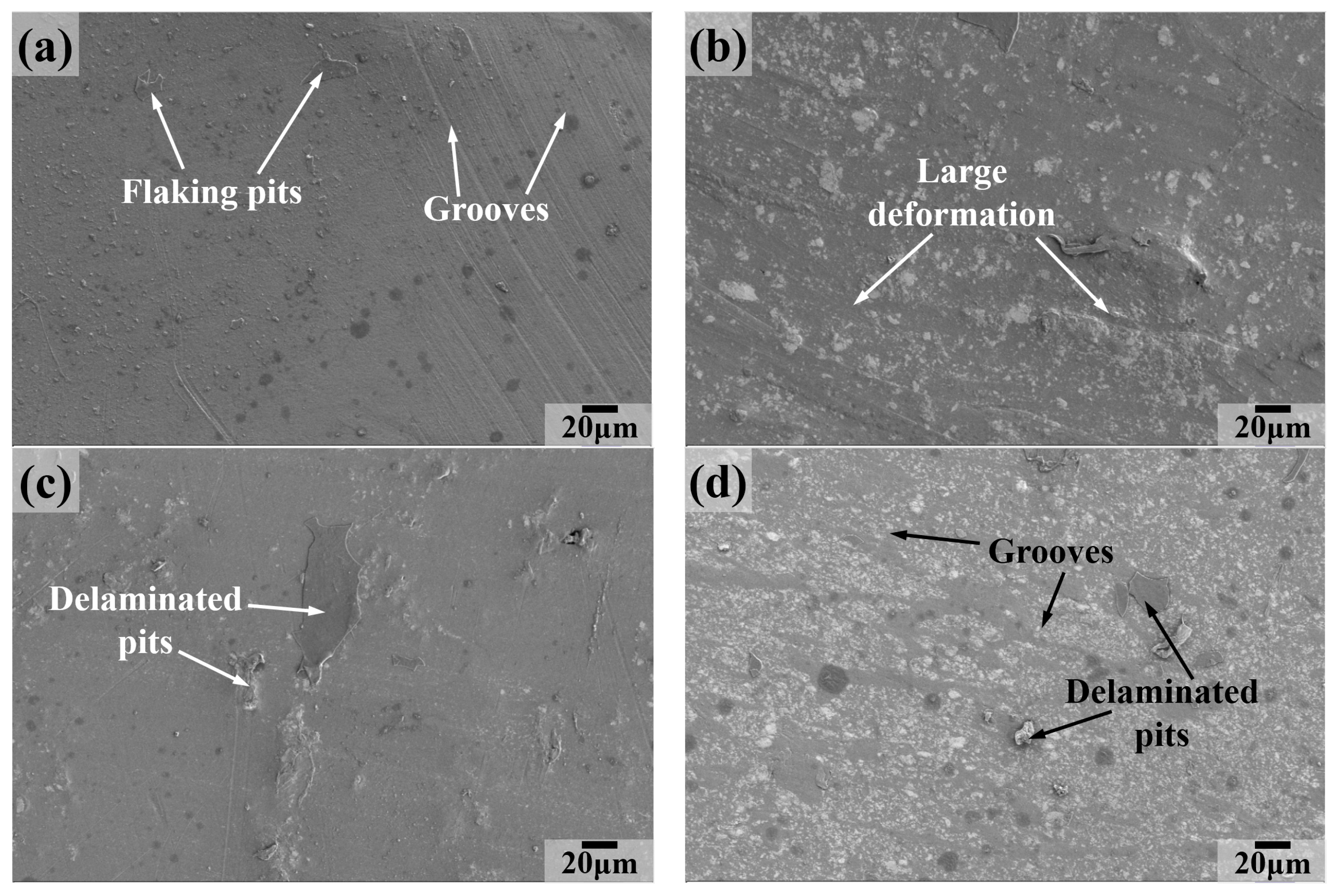

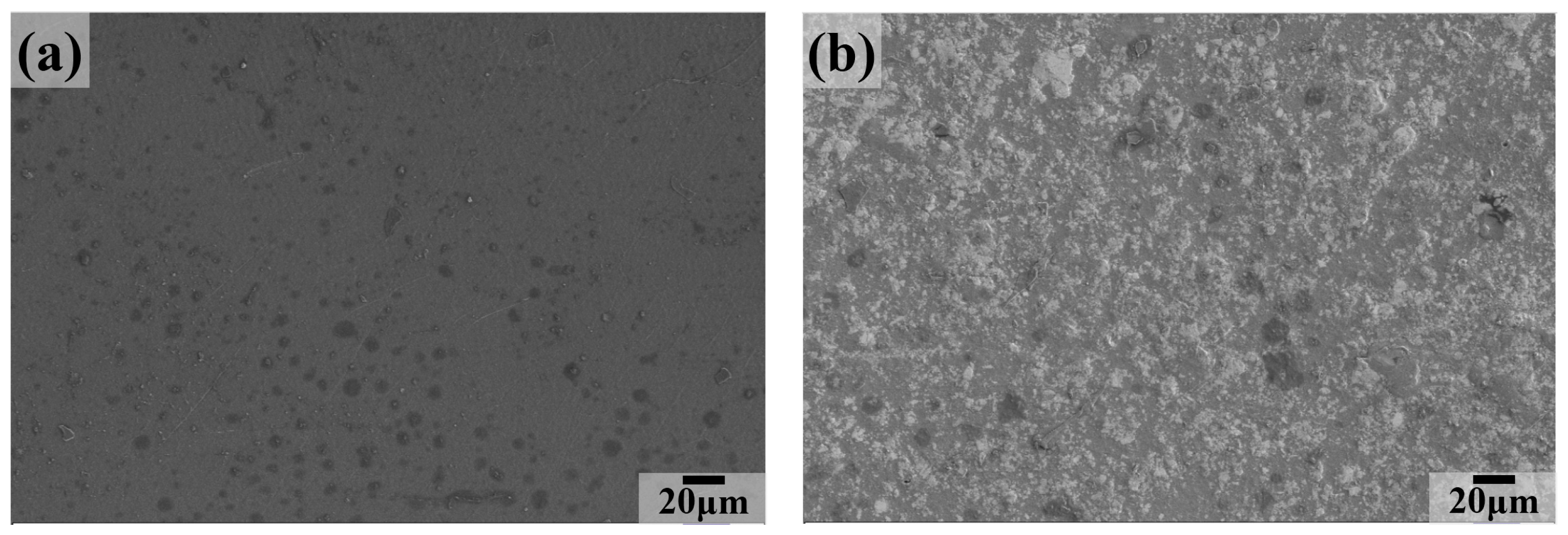

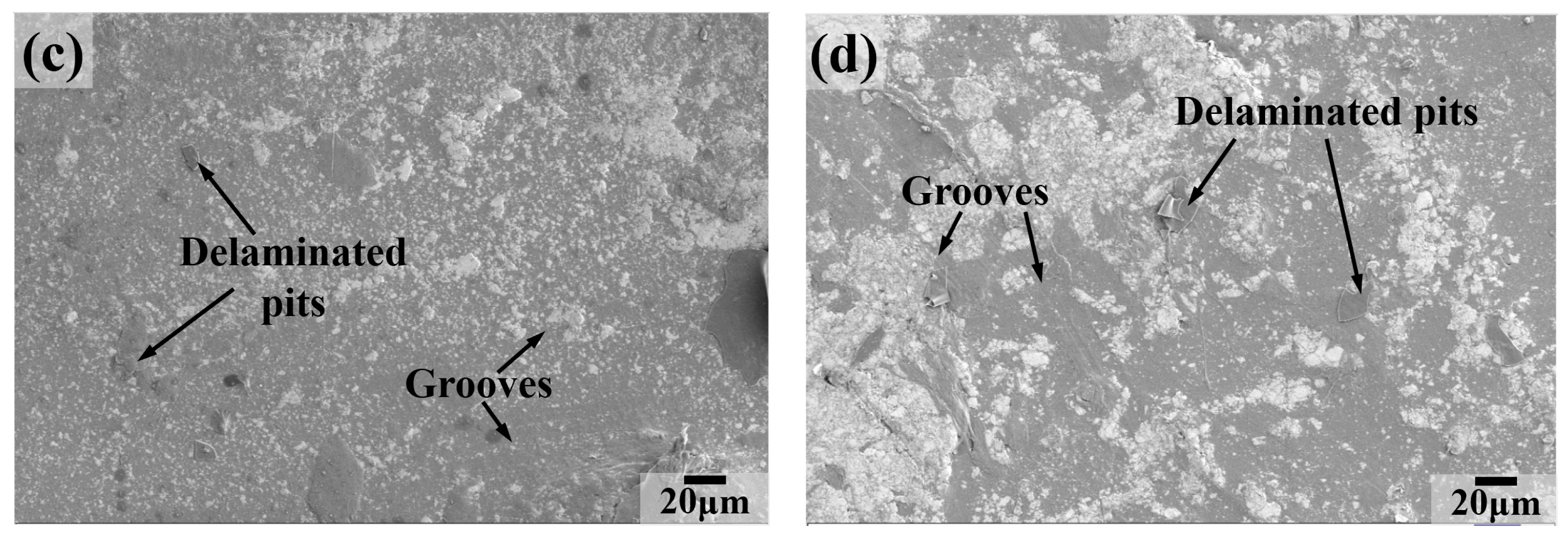

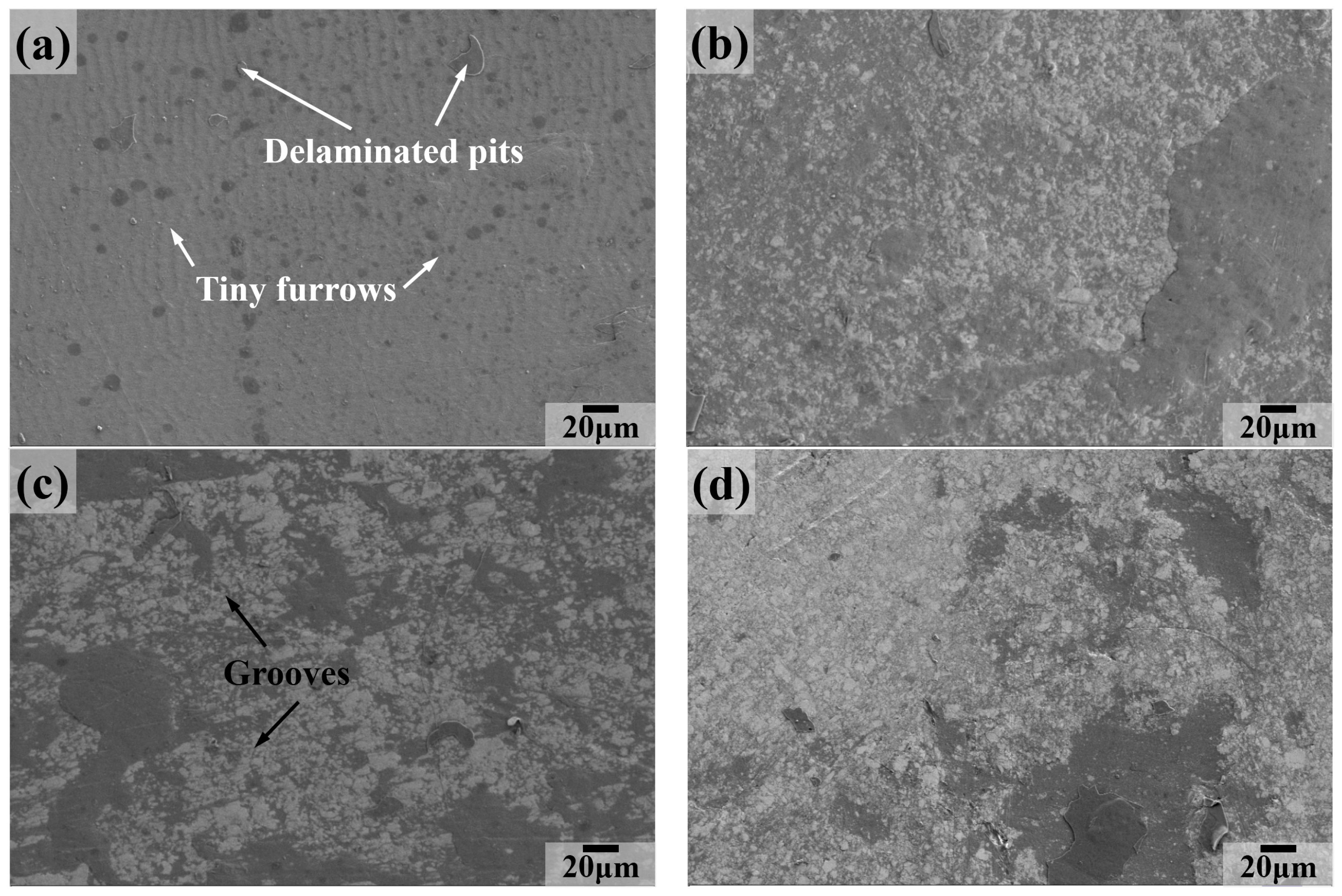

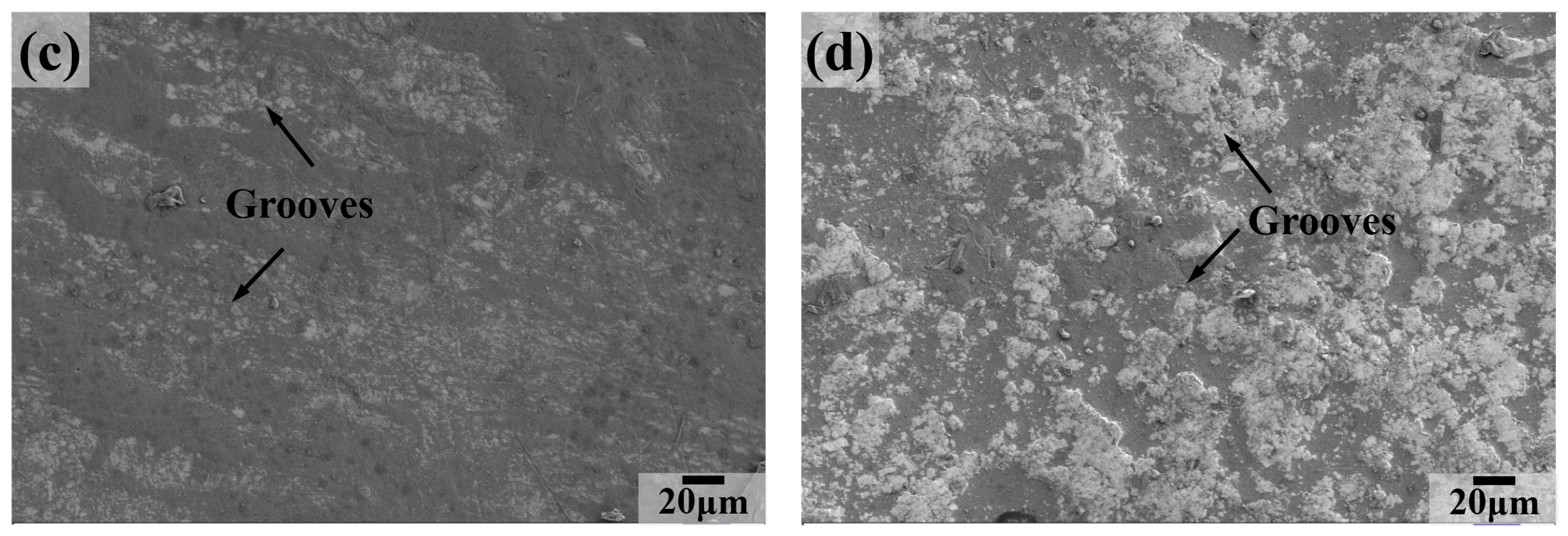

3.2. Worn Surface Analysis

4. Conclusions

- (1)

- Generally, all four composites show excellent tribological performance under the testing temperatures from 25 to 250 °C. The COF and wear rate are approximately (0.14–0.19) and (4.18–13.38 × 10−4 mm3/Nm);

- (2)

- Adding MoS2 solid lubricating into the PTFE matrix could increase the lubricating and the wear resistance properties of PTFE composites, especially at high temperatures (200 and 250 °C). Generally, the COF in the mass decreases with the increase in testing temperatures, while the wear rate remains at a stable value. As for the effect of the MoS2 content, from 25 °C to 150 °C, all four composites show a similar COF and wear rate, while at 200 and 250 °C, P and PM1 present the highest value, and composites of PM2 and PM5 show the best wear resistance and lubricating properties. By comparison, the optimal content is 2 wt.%.

- (3)

- Both solid lubricating and testing temperature play essential roles in the variations of wear mechanism. At low testing temperatures (25–100 °C), the worn surfaces are relatively smooth and the main wear mechanism is slight abrasive wear. From 150 °C to 250 °C, large delamination and grooves appeared on the worn surface and the main wear mechanism transformed to fatigue and severe abrasive wear.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Biswas, S.; Vijayan, K. Friction and wear of PTFE-a review. Wear 1992, 158, 193–211. [Google Scholar] [CrossRef]

- Van Meter, K.; Junk, C.; Campbell, K.; Babuska, T.; Krick, B. Ultralow wear self-mated PTFE composites. Macromolecules 2022, 55, 3924–3935. [Google Scholar] [CrossRef]

- Conte, M.; Igartua, A. Study of PTFE composites tribological behavior. Wear 2012, 296, 568–574. [Google Scholar] [CrossRef]

- Pan, D.; Fan, B.; Qi, X.; Yang, Y.; Hao, X. Investigation of PTFE tribological properties using molecular dynamics simulation. Tribol. Lett. 2019, 67, 28. [Google Scholar] [CrossRef]

- Blanchet, T.; Kennedy, F. Sliding wear mechanism of polytetrafluoroethylene (PTFE) and PTFE composites. Wear 1992, 153, 229–243. [Google Scholar] [CrossRef]

- Şahin, Y. Dry Wear and metallographic study of PTFE polymer composites. Mech. Compos. Mater. 2018, 54, 403–414. [Google Scholar] [CrossRef]

- Wang, H.; Qi, X.; Zhang, W.; Dong, Y.; Fan, B.; Zhang, Y. Tribological properties of PTFE/Kevlar fabric composites under heavy loading. Tribol. Int. 2020, 151, 106507. [Google Scholar] [CrossRef]

- Lv, Y.; Wang, W.; Xie, G.; Luo, J. Self-lubricating PTFE-based composites with black phosphorus nanosheets. Tribol. Lett. 2018, 66, 61. [Google Scholar] [CrossRef]

- Wang, N.; Wang, H.; Ren, J.; Gao, G.; Zhao, G.; Yang, Y.; Wang, J.; Yang, S. A case study of PTFE@SiO2 core-shell solid lubricant. Tribol. Int. 2021, 160, 107016. [Google Scholar] [CrossRef]

- Zhen, J.; Han, Y.; Zhu, L.; Hou, W.; Liu, Y.; Huang, W.; Yang, L.; Yuan, L.; Jia, Z.; Zhang, R. MoS2/CF synergistic enhancement to improve the friction and wear properties of UHMWPE composites. Tribol. Int. 2023, 179, 108097. [Google Scholar] [CrossRef]

- Qi, Y.; Sun, B.; Zhang, Y.; Gao, G.; Zhang, P.; Zheng, X. Tribological properties of nano-ZrO2 and PEEK reinforced PTFE composites based on molecular dynamics. Lubricants 2023, 11, 194. [Google Scholar] [CrossRef]

- Van Meter, K.; Babuska, T.; Junk, C.; Campbell, K.; Sidebottom, M.; Grejtak, T.; Kustas, A.; Krick, B. Ultralow wear behavior of Iron-Cobalt-filled PTFE composites. Tribol. Lett. 2022, 71, 4. [Google Scholar] [CrossRef]

- Zhang, L.; Xie, T.; Li, W. Effect of different kinds of fillers on the terrace-like structure of the transfer film and the wear behavior of the PTFE-based composites. Tribol. Lett. 2023, 71, 31. [Google Scholar] [CrossRef]

- Meng, Z.; Wang, Y.; Liu, H.; Yan, Y.; Yan, F. Reinforced UHMWPE composites by grafting TiO2 on ATP nanofibers for improving thermal and tribological properties. Tribol. Int. 2022, 172, 107585. [Google Scholar] [CrossRef]

- Xie, T.; Shi, Y. Effects of LaF3/CeF3 on the friction transfer of PTFE-based composites. Tribol. Int. 2021, 161, 107069. [Google Scholar] [CrossRef]

- Sawae, Y.; Morita, T.; Takeda, K.; Onitsuka, S.; Kaneuti, J.; Yamaguchi, T.; Sugimura, J. Friction and wear of PTFE composites with different filler in high purity hydrogen gas. Tribol. Int. 2021, 157, 106884. [Google Scholar] [CrossRef]

- Zuo, Z.; Yang, Y.; Song, L.; Zhang, Z.; Jin, X. Characterization and tribological performance of polyethersulfone/PTFE compound filled with Na-montmorillonite. Tribol. Lett. 2021, 69, 138. [Google Scholar] [CrossRef]

- Cai, T.; Zhan, S.; Yang, T.; Jia, D.; Tu, J.; Li, Y.; Li, J.; Duan, H. Influence mechanism of organic-modified α-zirconium phosphate on tribological properties of UHMWPE. Wear 2023, 512–513, 204548. [Google Scholar] [CrossRef]

- Hirst, W.; Lancaster, J. The influence of speed on metallic wear. Proc. R. Soc. Lond. Ser. A 1960, 259, 228–241. [Google Scholar]

- Zhen, J.; Zhu, S.; Cheng, J.; Qiao, Z.; Liu, W.; Yang, J. Effects of sliding speed and testing temperature on the tribological behavior of a nickel-alloy based solid-lubricating composite. Wear 2016, 368–369, 45–52. [Google Scholar] [CrossRef]

- Amenta, F.; Bolelli, G.; De Lorenzis, S.; Bertarini, A.; Lusvarghi, L. Tribological behavior of reinforced PTFE composites and unreinforced polyketone-based materials against coated steel. Lubricants 2022, 10, 5. [Google Scholar] [CrossRef]

- Saisnith, V.; Fridrici, V. A study of the wear damage of a PTFE coating: The effects of temperature and environment on its mechanical and tribological properties. Wear 2021, 480–481, 203946. [Google Scholar] [CrossRef]

- Xiong, D.; Ge, S. Friction and wear properties of UHMWPE/Al2O3 ceramic under different lubricating conditions. Wear 2001, 250, 242–245. [Google Scholar] [CrossRef]

- Hu, Y.; Tan, D.; Xu, C.; He, Q.; Yang, X.; Gao, H.; Lewis, R. Influence of high temperature on the tribological properties of hybrid PTFE/Kevlar fabric composite. Tribol. Int. 2022, 174, 107781. [Google Scholar] [CrossRef]

- Bandaru, A.; Weaver, P.; Higgins, R. Abrasive wear performance of hygrothermally aged glass/PTFE composites. Polym. Test. 2021, 103, 107369. [Google Scholar] [CrossRef]

- Gürgen, S.; Sert, A.; Kuşhan, M. An investigation on wear behavior of UHMWPE/carbide composites at elevated temperatures. J. Appl. Polym. Sci. 2021, 138, 50245. [Google Scholar] [CrossRef]

- Gürgen, S. Wear behavior of UHMWPE composites under oxidative effect. Polym. Degrad. Stab. 2022, 199, 109912. [Google Scholar] [CrossRef]

- Song, F.; Yang, Z.; Zhao, G.; Wang, Q.; Zhang, X.; Wang, T. Tribological performance of filled PTFE-based friction material for ultrasonic motor under different temperature and vacuum degrees. J. Appl. Polym. Sci. 2017, 134, 45358. [Google Scholar] [CrossRef]

- Gomes, J.; Silva, O.; Silva, C.; Pardini, L.; Silva, R. The effect of sliding speed and temperature on the tribological behaviour of carbon-carbon composites. Wear 2001, 249, 240–245. [Google Scholar] [CrossRef]

- Zhen, J.; Cheng, J.; Tan, H.; Sun, Q.; Zhu, S.; Yang, J.; Liu, W. Investigation of tribological characteristics of nickel alloy-based solid-lubricating composites at elevated temperatures under vacuum. Friction 2021, 9, 990–1001. [Google Scholar] [CrossRef]

- Chen, X.; Kong, Y.; Wang, M.; Huang, X.; Huang, Y.; Lv, Y.; Li, G. Wear and aging behavior of vulcanized natural rubber nanocomposites under high-speed and high-load sliding wear conditions. Wear 2022, 498–499, 204341. [Google Scholar] [CrossRef]

- Zhou, X.; Gao, Y.; Wang, Y.; Xiao, P.; Huang, X. Effects of ZrC particles, load and sliding speed on the wear behavior of the ZrC/2024Al composites. Wear 2022, 506–507, 204465. [Google Scholar] [CrossRef]

- Chan, H.; Rong, L.; Cheng, S.; Kwek, J.; Isoni, V.; Reginald, T. Understanding the adsorption and desorption of sitagliptin phosphate, onohydrate on SS2343, glass, and PTFE using QCM-D and raman spectroscopy. Langmuir 2022, 38, 10575–10584. [Google Scholar] [CrossRef]

- Ma, W.; Lu, J. Effect of sliding speed on surface modification and tribological behavior of copper-graphite composite. Tribol. Lett. 2011, 41, 363–370. [Google Scholar] [CrossRef]

| Composites | PTFE (wt.%) | MoS2 (wt.%) |

|---|---|---|

| P | 100 | 0 |

| PM1 | 99 | 1 |

| PM2 | 98 | 2 |

| PM5 | 95 | 5 |

| Material | P, PM1, PM2, PM5 |

|---|---|

| Testing temperatures | 25 °C, 50 °C, 100 °C, 150 °C, 200 °C, 250 °C |

| Sliding speed | 0.33 m/s |

| Load | 10 N |

| Test time | 30 min |

| Counterpart materials | GCr15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhen, J.; Han, Y.; Wang, H.; Jiang, Z.; Wang, L.; Huang, Y.; Jia, Z.; Zhang, R. High Temperature Friction and Wear Behavior of PTFE/MoS2 Composites. Lubricants 2023, 11, 312. https://doi.org/10.3390/lubricants11080312

Zhen J, Han Y, Wang H, Jiang Z, Wang L, Huang Y, Jia Z, Zhang R. High Temperature Friction and Wear Behavior of PTFE/MoS2 Composites. Lubricants. 2023; 11(8):312. https://doi.org/10.3390/lubricants11080312

Chicago/Turabian StyleZhen, Jinming, Yunxiang Han, Huabao Wang, Zhenguo Jiang, Li Wang, Yuqiang Huang, Zhengfeng Jia, and Ran Zhang. 2023. "High Temperature Friction and Wear Behavior of PTFE/MoS2 Composites" Lubricants 11, no. 8: 312. https://doi.org/10.3390/lubricants11080312

APA StyleZhen, J., Han, Y., Wang, H., Jiang, Z., Wang, L., Huang, Y., Jia, Z., & Zhang, R. (2023). High Temperature Friction and Wear Behavior of PTFE/MoS2 Composites. Lubricants, 11(8), 312. https://doi.org/10.3390/lubricants11080312