Abstract

Water-based lubrication, due to the poor film-forming ability of water, faces challenges in achieving effective lubrication for titanium alloys. This study systematically investigates the frictional performance of phosphorus-based extreme pressure (EP) additives and self-emulsifying esters (SEE) on the surface of titanium alloy (TB6) under different pressures and temperatures. The core lubricant consists of SEE with nonylphenol polyoxyethylene ether phosphate ester (NPEP), polyoxyethylene oleyl ether phosphate ester (POEP), and alcohol ether phosphate ester (AEP). Results show that SEE significantly improves the film-forming ability of the aqueous solution, while phosphate ester forms a strong chemical adsorption film on the alloy surface via P-O-Ti covalent bonds, enhancing the strength of the lubricating film. The combination of SEE and phosphate esters in the water-based solution enables effective lubrication for titanium alloys. Particularly, the mixture of POEP and SEE demonstrates excellent synergistic effects, making it an ideal blend for water-based cutting fluids for titanium alloys. This study elucidates the lubrication mechanisms and action ranges between different additives, providing important guidance for the development and promotion of water-based cutting fluids.

1. Introduction

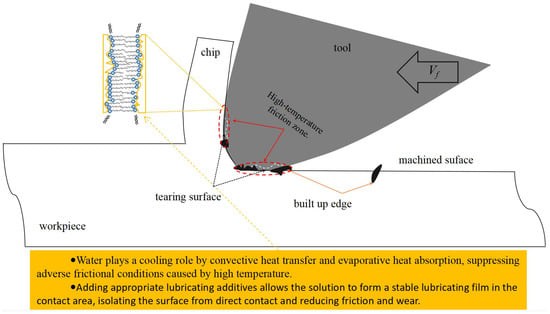

Titanium is commonly considered the “metal of the 21st century” due to its outstanding properties such as high strength, low density, exceptional corrosion resistance, and excellent temperature resistance making it an ideal material for aircraft manufacturing [1]. However, working with titanium alloys is often challenging due to various issues encountered during the cutting process, as depicted in Figure 1. For instance [2,3,4,5,6,7,8,9], titanium alloys possess characteristics of exothermic deformation and low thermal conductivity, resulting in the generation of substantial heat within the cutting deformation zone. The dissipation of this heat becomes challenging, leading to elevated cutting temperatures. Furthermore, due to titanium’s high chemical reactivity, it readily adheres to the cutting tool in the high-temperature machining zone, forming chip lumps that adversely affect the surface quality of the workpiece. Additionally, titanium alloys exhibit a limited range of plastic deformation and can chemically react with oxygen and nitrogen in the high-temperature cutting region, leading to material hardening and the formation of hardened layers. Consequently, this causes an increase in cutting forces, intensifies friction and wear between the tool and workpiece, and ultimately damages the tool’s lifespan. In the series of titanium alloys, TB6 (Ti-10V-2Fe-3Al), as a near-β titanium alloy, not only is lightweight, but has outstanding corrosion resistance, low thermal conductivity, and a high load tolerance, thus widely being used in manufacturing critical components, especially in some high-end manufacturing like the aerospace industry [10,11]. However, titanium alloy represented by TB6 is more difficult to machine and manufacture than other titanium alloys [12].

Figure 1.

Common problems on the friction surface during titanium alloy processing and the role of water-based cutting fluid.

To achieve efficient processing of titanium alloys, many researchers have studied the cooling and lubrication methods. Various new cooling and lubrication methods have been proposed, such as cryogenic lubrication (liquid nitrogen LN2) [13], minimal quantity lubrication (MQL) [14], and the minimum quantity of cooling lubrication technique (MQCL) [15]. However, the application of these research results in the actual processing of aircraft components was limited by factors such as component characteristics, machine tool structure, and supporting processes. The use of metalworking fluid as a cooling and lubricating medium remains the most effective and practical conventional method for processing titanium alloy components. However, traditional metalworking fluids have generally been deficient in lubrication when processing titanium alloys, which results in problems such as frequent tool wear, tool changes, and low processing efficiency. Therefore, it is urgent to develop new high-lubricity metalworking fluids for the special working conditions of titanium alloys.

In the design of processing technology for titanium alloys, it is important to consider reducing cutting temperature and adhesion. To achieve this, a water-based cutting fluid is preferred because it provides excellent cooling [16]. However, the film-forming ability of a water-based cutting fluid is poor. Some studies show that adding water-soluble polymers with surface activity to water can not only increase the viscosity of water, but also prevent the metal-to-metal contacts by the adsorpted polymers on the surfaces [17,18,19,20,21,22,23]. Benedicto et al. [24] investigated the influence of synthetic esters’ molecular structure in oil-in-water emulsions and their interaction with the surface. The results showed that the protective effect on the tool highly depends on the film-forming ability of synthetic esters. By increasing the content of esters, a stronger adsorption on the metal surface can be achieved, resulting in better anti-wear performance. Moreover, the lubrication performance of a self-emulsifying ester (SEE) of polymerized fatty acid on the surface of titanium alloy Ti-6Al-4V was investigated [25]. The SEE aqueous droplets spread easily on the titanium alloy surface, leading to physical adsorption and achieving superior boundary lubrication, while reducing adhesive and abrasive wear significantly.

However, so far, the reported water-soluble additives for the lubrication on the metalworking of titanium alloys are mostly single component. The interaction between different functional additives, which is important to the lubricity of metalworking fluid, has received less attention. Additionally, past experimental studies [26,27,28,29,30] have mainly focused on the TC4 titanium alloy, with little research attention given to lubrication of the TB6 titanium alloy. It is not yet clear whether the additives, especially SEE that exhibit good lubrication performance for the TC4 titanium alloy could effectively be applied to the metalworking of the TB6 titanium alloy.

In this work, the interaction between the SEE and the EP additives was analyzed, and the lubricating mechanism of the compounded lubricating additives was explained. First, we examined the tribological properties of samples treated with SEE, phosphate esters, and their mixed solutions under a constant load (100 N, 30 °C). Next, to further investigate the influence of the load, a step-up-loading test was conducted ranging from 100 N to 1000 N, evaluating the anti-wear and anti-friction performance of the solutions under different loads. By recording the variation in wear rates at different initial pressures (100 N, 200 N, 300 N, 400 N, 500 N), the load-carrying capacity of the solution’s lubricating film was compared. Subsequently, under constant pressure conditions (100 N, 200 N, 300 N), the high-temperature stability of the lubricating film was analyzed by varying the temperature (30 °C, 90 °C). Additionally, XPS was employed to explore the chemical composition of the friction surfaces. Finally, the actual processing performance of the solution was evaluated using a tapping torque measurement.

2. Materials and Methods

2.1. Materials

The self-emulsifying ester (SEE) used in this study was purchased from Croda Company and is a high-polymer fatty acid polyester. SEEs are built on a polymerized fatty acid backbone, where some of the fatty acid groups react with ethylene oxide to yield polyethylene glycol ester functionalities. Other carboxylic acid groups are esterified using a mono-alcohol. As a result, SEE molecules are compounds with various functional groups and exhibit good self-emulsification in water [25]. Except for SEE, three commercial phosphate esters were used as extreme pressure additives. These include polyoxyethylene oleyl ether phosphate (POEP, purchased from Blaser company, Ruegsau, Switzerland), nonylphenol polyoxyethylene ether phosphate (NPEP, purchased from Raleigh Trading Co., Ltd., Shanghai, China) and alcohol ether phosphate (AEP, purchased from Runlaibo Chemical Company, Shanghai, China). The physical and chemical properties of these additives are shown in Table 1.

Table 1.

Properties of phosphate esters.

2.2. Tribological Performance Measurement

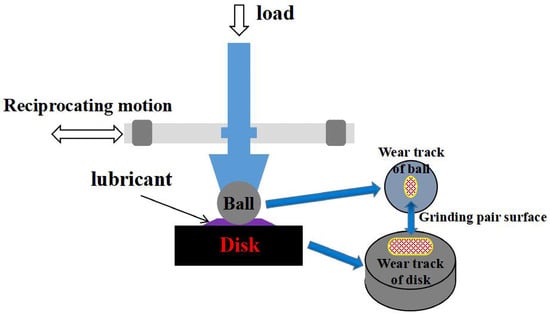

The tribological performance of the lubricants was measured using a high-frequency reciprocating linear vibration machine (SRV-5, Optimal) using a ball-on-disc as the frictional pair (Figure 2). The bottom disks were TB6 titanium alloy with a diameter of 24 mm. A YG8 (WC-Co) hard alloy ball with a diameter of 10 mm was used to slide against the TB6 disks. The tests were conducted at a normal load of 100, 200, 300, 400, and 500 N, and a step-up-loading test increased from 100 N to 1000 N and the initial load of 100 N was maintained for 180 s and the elevated loads were held for 100 s each. The reciprocating frequency was 20 Hz, and the reciprocating stroke was 2 mm. All friction tests were lubricated with 2 mL lubricants (listed in Table 2) conducted at air atmosphere and the tests with fixed normal load lasted 5 min. Each measurement was repeated three times. The COF values were calculated by averaging the instantaneous COF values, and their error bars were calculated and used to depict the standard deviation between repetitions conducted for the same composite. At the end of each test, ultrasonic cleaning for 5 min was performed on the disc and ball separately using alcohol and deionized water. The wear volume of the composites was obtained by a white-light interferometer (MICROXAM-3D), which was equipped with relevant software that can analyze the 3D data and directly show the value.

Figure 2.

Schematic diagram of SRV friction and wear experiment. The diameter of YG8 ball was 10 mm, with a surface roughness (Ra) of 25 nm. The diameter of the TB6 disk was 24 mm, with a height of 7.88 mm and a Ra of 0.1 um.

Table 2.

Solution configuration for friction and wear test.

2.3. Material Characterization

Quanta200 scanning electron microscopy (SEM) combined with energy dispersion spectrometry (EDS) was used for surface analysis of the worn-out YG8 ball and TB6 disk. The chemical compositions of the worn surface on TB6 disk were characterized using the Thermo Scientific Nexsa G2 X-ray photoelectron spectroscopy (XPS).

2.4. Machining Performance Measurement

Machining performances of the compounded lubricating components were measured by a tapping torque test system (Microtap TTT, Taufkirchen, Germany) on TB6 alloy workpiece with standard holes of φ3.7 (±0.01) mm at a machining speed of 500 rpm with a tapping depth of 10 mm. The maximum torque was set to 500 N·cm, and if the torque value exceeded this maximum value during tapping, the tapping would stop immediately and the tap would be withdrawn. The lower the recorded torque value during the tapping process, the better the machining performance.

3. Results

3.1. Tribological Properties of Samples under Constant Loading

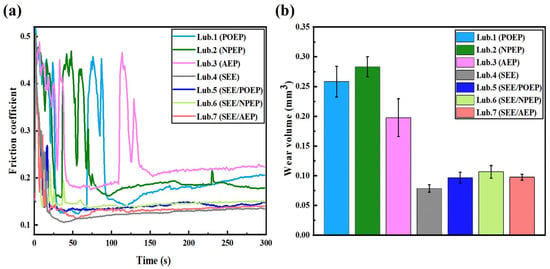

Figure 3a displays the curve of the friction coefficient (CoF) achieved under a constant load of 100 N and a temperature of 30 °C. When lubricated with Lub 1, Lub 2, and Lub 3, the CoF curves show considerable fluctuation, and all the curves stabilize at a coefficient of about 0.2. On the other hand, for the samples compounded with SEE (Lub 4, Lub 5, Lub 6 and Lub 7), the running-in time is shortened, and the stable CoF value is about 0.15. Lub 4 exhibits the lowest CoF and the best anti-friction performance. This may be because SEE has a higher molecular weight than phosphate esters, allowing it to more easily spread on the metal surface and form a stable lubricating film of a certain thickness, thereby improving the lubrication performance. This also indicates that the SEE aqueous solution has good film-forming ability on the surface of TB6.

Figure 3.

(a) The friction coefficients and (b) volume of wear under a constant loading of 100 N.

Figure 3b illustrates the wear volume of the TB6 titanium alloy disk. The results indicate that the addition of SEE to NPPE, AEP, and POEP would reduce the wear volume significantly. Specifically, when mixed with SEE, the wear volume of the POEP solution decreases by 64.9%, from 0.265 mm3 to 0.093 mm3. The wear volume of NPPE decreases by 60.6%, and the wear volume of AEP decreases by 53.9%. It is noteworthy that Lub 4 exhibits the lowest wear volume of 0.076 mm3. The results indicate that SEE has the best anti-wear performance among the four additives, which is consistent with the results of the CoF analysis. However, when SEE is mixed with phosphate esters, they compete for adsorption [31]. Some phosphate ester molecules will preferentially adsorb on the surface, hindering the adsorption of SEE molecules and resulting in a decrease in the compactness of the SEE oil film. Therefore, the tribological performance is reduced.

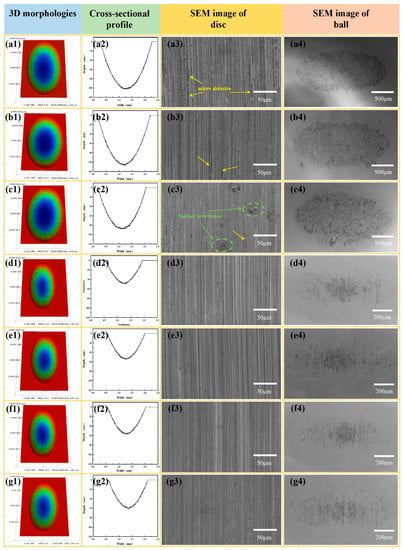

Figure 4 shows the wear conditions of the TB6 discs and the adhesion of the ball under different solutions after the SRV test.

Figure 4.

Under the test condition of constant load 100 N, three-dimensional (3D) morphologies, cross-sectional profile, and SEM image of wear marks on disc and ball: (a1–a4) Lub 1; (b1–b4) Lub 2; (c1–c4) Lub 3; (d1–d4) Lub 4; (e1–e4) Lub 5; (f1–f4) Lub 6; (g1–g4) Lub 7.

The wear volume (Figure 4(a1–c1)) and the wear scar depth (Figure 4(a2–c2)) were relatively large when the Lub 1, Lub 2, and Lub 3 were used for lubrication individually. However, lubricating with the Lub 4, Lub 5, Lub 6, and Lub 7 resulted in lower wear volume (Figure 4(d1–g1)) and smaller scratch depth (Figure 4(d2–g2)). Figure 4(a3–c3) shows that when lubricated with Lub 1, Lub 2, and Lub 3, the scratched surfaces had deep furrows and were accompanied by noticeable small abrasive particles. Although the scratched surface of the Lub 3 experiment had relatively shallower furrows compared to the ones of Lub 1 and Lub 2, it had large surface area tumors (Figure 4(c3)), indicating that APE experienced severe adhesive wear during the lubrication process. When lubricated with the Lub 4, Lub 5, Lub 6, and Lub 7, the furrows became shallower, the number of small abrasive particles between the furrows decreased, and the large surface lumps disappeared (Figure 4(d3–g3)). This indicates that SEE can effectively reduce the adhesive wear and the abrasive wear of the scratched surface, resulting in a smoother surface. The wear marks on the ball were examined in order to compare the differences in the adhesion phenomena of titanium alloys under various lubrication processes. Figure 4(a4–g4) revealed that a layer of material adhered to the surface of the ball. By conducting a careful comparison of the adhesion phenomena on the ball, we observed that the adhesion areas on the ball surface lubricated with Lub 1, Lub 2, and Lub 3 were relatively large (Figure 4(a4–c4)). However, the adhesions on the ball surface of the ones that added SEE to the lubricant (Figure 4(d4–g4)) decreased significantly. Although adhesion was still observed on the ball surface lubricated with a SEE-containing solution (Lub 4, Lub 5, Lub 6, and Lub 7), it mainly occurred at the center of the ball, and the adhesion around the periphery decreased significantly or even disappeared.

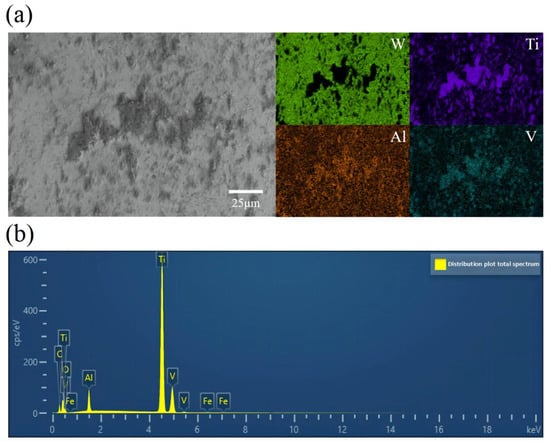

Figure 5 displays the EDS analysis results of the wear scar on the disc and the adhered material on the ball when lubricated with Lub 1. Lubricating with other solutions exhibited similar results, which was not listed here. The dominant elements in the adhered layer are titanium, aluminum, and vanadium, which match the primary composition elements of TB6. As a result, it can be inferred that the titanium alloy is detached from the disc and adheres to the ball during the friction process. These observations suggest that the polar molecules of SEE adsorbed on the surface of the titanium alloy formed a boundary lubricating oil film that had a certain thickness and bearing capacity. This lubricant separated the surfaces of the friction pair effectively, reducing the contact area between the ball and the alloy disk. Consequently, this lubricant played a crucial role in lowering the CoF and the wear rate that were observed by the above experiments. Figure 5b did not show an obvious P element peak, possibly due to the low content that was not detected, but it was enough to indicate that no chemical reaction film was generated on the titanium alloy surface by the phosphate ester at 100 N and 30 °C, and its lubrication effect was mainly due to the adsorption of the lubricant.

Figure 5.

EDS analysis of (a) the adhered material on the ball and (b) the wear scar on the disc.

3.2. The Effect of Loading on the Lubrication Performance

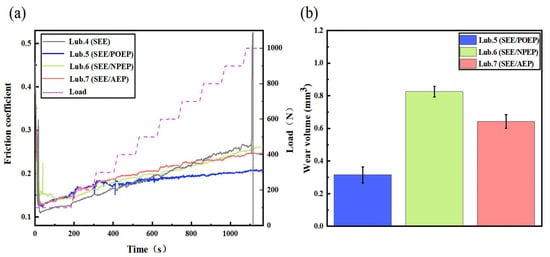

To investigate the lubrication performance of the phosphate ester/SEE mixtures under different loadings, a step-up-loading test was conducted. The test was carried out using the following parameters: a stroke of 2 mm, a frequency of 20 Hz, and a loading gradient set to increase by 100 N every 20 s. Figure 6a presents the recorded CoFs from the tests. It was observed that the CoF of Lub 4 remained the lowest when the loadings were lower than 500 N. However, when the loadings increased to above 500 N, the CoF of Lub 5 became lower than that of Lub 4. Additionally, as the loadings were increased to above 800 N, the CoFs of Lub 6 and Lub 7 became lower than that of Lub 4. At 1000 N, the CoF of Lub 4 sharply increased, and the experiment was immediately terminated. Based on these preliminary observations, it can be speculated that the added phosphates underwent a frictional chemical reaction under high loadings, resulting in a decrease in the CoF, which shows a good contrast to the results shown in Figure 3. Under higher loadings, the physically adsorbed film was squeezed out and the increasing loadings were borne by the direct contact between rough peaks, resulting in an increase in the CoF [32]. On the other hand, the mechanical actions may lead to the gradual precipitation of the active phosphorus element contained in the solution between the rough peaks, causing a frictional chemical reaction to occur and forming a chemical reaction membrane with low shear strength to reduce the CoF.

Figure 6.

(a) The friction coefficients and (b) wear volume of step-up-loading test.

Figure 6b shows the final recorded wear volumes of Lub 5, Lub 6, and Lub 7 in the step-up-loading test. Since the oil film of Lub 4 was prone to breaking under high loadings, it was inconvenient to calculate the wear volume and, therefore, was not listed here. The wear track of the TB6 disk lubricated by Lub 6 had the highest wear volume of 0.817 mm3, followed by the one lubricated by Lub 7 with a wear volume of 0.624 mm3. Among them, the one lubricated by Lub 5 had the lowest wear volume at only 0.301 mm3. These results demonstrate that the POEP and SEE compounded system (Lub 5) shows the best anti-wear performance in this work, particularly under high loadings and long-time lubrication conditions. Generally, copolymers with a high hydrophobic content exhibit strong adsorption strength on metal surfaces [33,34]. The wear size is negatively related to the carbon chain length of the phosphate ester providing a load-bearing capacity. Therefore, the addition of POEP, which has a longer carbon chain, to the SEE solution enhances the strength of the oil film, preventing it from being squeezed out, easily and effectively protecting the metal surface.

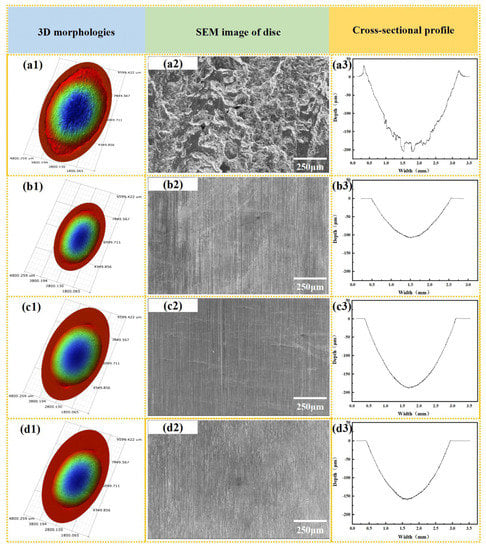

Figure 7 shows the 3D morphologies, cross-sectional profile, and SEM image of the wear scar on the disk in the step-up-loading test. Upon analysis of the 3D morphologies, it was found that the wear scars lubricated by the Lub 4 displayed some evident cracks on the surface (as shown in Figure 7(a1). The SEM images of the worn surfaces were consistent with the results of the 3D morphology analysis. The surfaces of Lub 5, Lub 6, and Lub 7 were relatively flat even though there were some micro-scratches (as shown in Figure 7(b2–d2)), which may be due to the plastic deformation of the metal surface under high loads. In contrast, the abrasive surface of Lub 4 (as seen in Figure 7(a2)) has been destroyed completely, indicating the lubricating oil film on the metal surface had been broken during the friction process resulting in direct ball and disk contacts on the friction surfaces, which corresponds to the results shown in Figure 6 a and consistent to the wear depths (205 μm illustrated in Figure 7(a3)).

Figure 7.

Three-dimensional (3D) morphologies, cross-sectional profile, and SEM images of wear scars on titanium alloy discs in step-up-loading test: (a1–a3) lub 4; (b1–b3) lub 5; (c1–c3) lub 6; (d1–d3) lub 7.

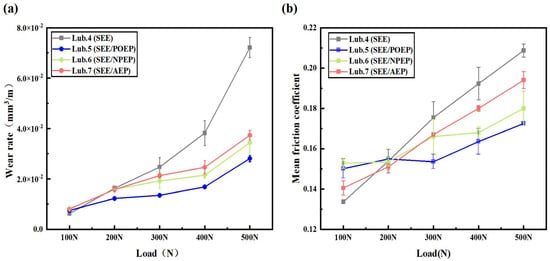

Figure 8a displays the wear rate of the disc under constant loadings of 100, 200, 300, 400, and 500 N at 30 °C for a duration of 5 min, with the maximum Hertz contact stress in the initial state being 1.362 GPa, 1.716 GPa, 1.964 GPa, 2.162 GPa, and 2.329 GPa, respectively. Figure 8b shows the corresponding average CoFs. The wear rate gradually increases with the load, while a critical load value can be observed in the wear rate curves [35]. Below this critical value, the increase in wear rate is relatively slow as the load increases. Once the load exceeds the critical value, the wear rate sharply increases, indicating that the load surpasses the carrying capacity of the lubricating oil film. The data in Figure 8a reveals that the wear rate of Lub 4 sharply increases when the loadings reach 500 N, suggesting that its carrying capacity lies between 400 N and 500 N. Conversely, the wear rate of Lub 5, Lub 6, and Lub 7 increases relatively slowly with increasing load, indicating that the phosphoric ester effectively enhances the carrying capacity of the oil film. The mean CoFs also increase with the increase in loadings. It can be concluded that the SEE solution exhibits the best anti-wear and friction-reducing performance at a loading of only 100 N, while the mixed POEP and SEE solution demonstrates the best anti-wear and friction-reducing performance at higher loadings (300 N, 400 N, or 500 N).

Figure 8.

At 100–500 N, the friction performance of the Lub 4, Lub 5, Lub 6, and Lub 7: (a) wear rate; (b) average friction coefficient.

3.3. Effect of Temperature

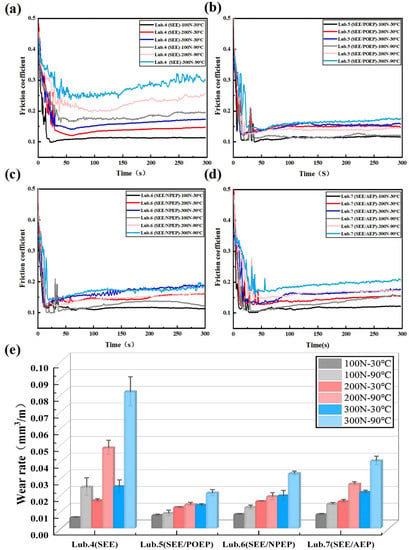

This section compares the anti-wear and friction-reducing performance of Lub 4, Lub 5, Lub 6, and Lub 7 on the Ti10V2Fe3Al/WC-Co friction pair system under loads of 100~300 N at both room temperature and high temperature. Since water evaporates at 100 °C, the upper temperature limit was set to 90 °C. Figure 9a shows that the CoFs of the Lub 4 increased sharply at high temperatures. In contrast, Lub 5, Lub 6, Lub 7 were less affected by the temperature. Lub 5 (Figure 9b) or Lub 6 (Figure 9c) exhibited similar CoFs at both room and high temperatures. Though Lub 7 (Figure 9d) shows a significant increase in CoFs at high temperatures compared to room temperature, the CoFs were lower and more stable than the Lub 4.

Figure 9.

At 100 N~300 N (30 °C or 90 °C), (a–d) the friction coefficients and (e) the wear rate of the Lub 4, Lub 5, Lub 6, and Lub 7.

Figure 9e compares the wear rates of different systems as a function of loads under 30 °C and 90 °C, respectively. It is observed that the wear rate increased with increasing loads for all the solutions at 30 and 90 °C. The wear rate of Lub 4 was higher at 90 °C. At a loading of 300 N, the wear rate of Lub 4 increased by 230%, from 0.0247 mm3/m to 0.0815 mm3/m. Although the solutions mixed with phosphate esters showed higher wear rates at 90 °C, the increase was significantly reduced. Especially, Lub 5 showed the minimal increase, which was 53.7% at 300 N, indicating that it was least affected by temperature. The corresponding results of Lub 6 and Lub 7 were 73.1% and 88.5%, respectively.

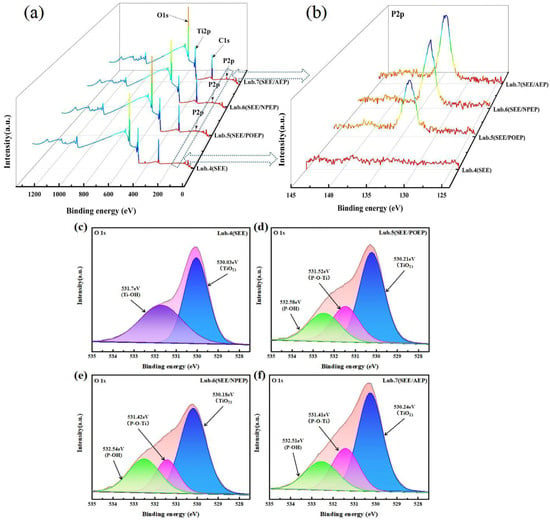

3.4. Wear Mark Characterization

To investigate the effect of phosphate esters on the worn surface of titanium alloy during the friction process, the wear marks lubricated by Lub 4, Lub 5, Lub 6, and Lub 7 were characterized. Figure 10a,b, respectively, shows the full spectrum and phosphorus narrow spectrum of the four samples by XPS. The phosphorus element peaks detected near 133 eV were present in the wear marks lubricated by Lub 5, Lub 6, and Lub 7 [36], other than Lub 4. Analyzing this experimental phenomenon in combination with previous tests, it can be inferred that some tribochemical reactions occurred on the friction surface, and organic phosphates were generated on the metal surface.

Figure 10.

XPS analysis results of the wear scar surface lubricated by the Lub 4, Lub 5, Lub 6, and Lub 7 (a) full spectrum; (b) narrow spectrum of phosphorus element; (c–f) narrow spectrum of oxygen element.

To further analyze the bonding forms between the phosphorus-containing compounds and the titanium alloy surface, the oxygen narrow spectra inside the wear marks were fitted with peaks. The results are shown in Figure 10c–f. The three peaks centered at 530.21 eV, 531.52 eV, and 532.58 eV appearing on the wear scar surface lubricated by Lub 5 (Figure 10d) were assigned to TiO2, P-O-Ti, and P-OH, respectively [37,38,39,40,41], which are similar to the surfaces lubricated by Lub 6 and Lub 7. However, the results of Lub 4 (Figure 10c) shows only two peaks centered at 530.03 eV and 531.7 eV, which are assigned to TiO2 and Ti-OH, respectively. The titanium element has a high chemical activity and can easily absorb oxygen and water molecules from the air, resulting in TiO2 and Ti-OH co-existing on the surface of Lub 4. Combined with the previous experimental phenomena, it can be inferred that the phosphate molecules can be connected to the surface of the TB6 through the P-O-Ti covalent bonds. This connection can make the lubricant molecules difficult to extrude and remove from the metal surface, thereby improving the lubricity of the solution under high temperatures and loadings.

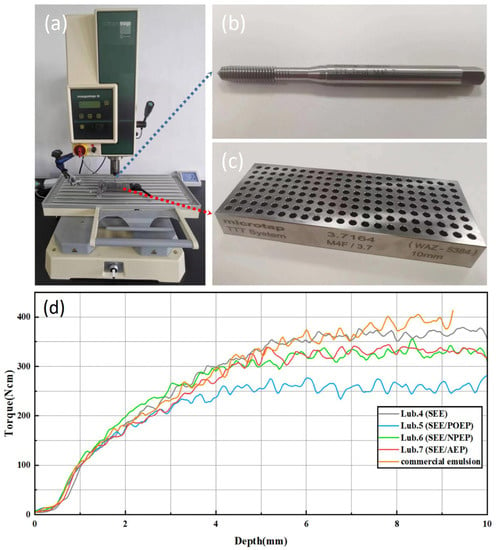

3.5. Tapping Performance of SEE-Phosphate Ester Mixed Solution

To evaluate the machining performance of the Lub 4, Lub 5, Lub 6, and Lub 7 solutions on TB6 titanium alloy, they were compared with a widely used commercial cutting fluid in the aerospace industry for machining titanium alloys in a tapping torque test. The threading mode adopted in this experiment is extrusion threading, where the extrusion tap (TTT_M4F-T coated tool, as shown in Figure 11b) is used to process the threads through cold extrusion, which involves metal plastic deformation. This processing mode eliminates chip evacuation issues in blind hole machining, and due to the absence of chip flutes in the extrusion tap, it has higher strength compared to cutting taps, making it less prone to issues, such as cutting-edge dulling and tap breakage. First, the thread-forming tap is coated with the lubricating fluid. It is then inserted into the hole. Titanium alloy is extremely difficult to machine, and inadequate lubrication can result in a high tapping torque and severe adhesion between the tool and workpiece. Due to the smaller diameter of the hole, the fluid must also possess good permeability to work effectively, forming a lubricating film between the tap and the titanium alloy surface. Figure 11d illustrates the relationship between the recorded torque and tapping depth during the tapping process. When using commercial emulsion as the lubricant, the tapping process stopped, and the tap was retracted at a depth of 9.24 mm. This was accompanied by noticeable jamming and noise, indicating insufficient lubrication, as the torque required for the operation exceeded the predefined maximum torque value. The tapping depths of Lub 4, Lub 5, Lub 6, and Lub 7 reached 10 mm, which indicates the entire tapping process successfully completed. The stabilized torque of Lub 4 was around 360 N·cm, while Lub 6 and Lub 7 were around 330 N·cm, and Lub 5 had the smallest torque, around 260 N·cm. The tapping torque shows that the SEE solution exhibits better lubricity and excellent wetting properties compared to a commercial cutting fluid, and compounding SEE with phosphate ester can improve lubrication performance and reduce processing torque values, with the best effect being achieved by mixing POEP with SEE.

Figure 11.

Tapping torque test of TB6 Titanium Alloy (a) Microtap TTT equipment; (b) TTT_M4F-T coated tool, size M4 (0.7 mm pitch, 4 mm tapping diameter); (c) TB6 alloy workpiece (Standard hole φ3.7 (±0.01) mm, roundness 0.005 mm, effective hole depth 10 mm, hole wall smoothness 0.05 mm); (d) the torque recorded during the tapping process as a function of tapping depth.

4. Conclusions

The friction and wear properties of several aqueous solutions for the friction pair of titanium alloy TB6 disc and cemented carbide ball were studied. The main conclusions are summarized as follows:

- The tribological test results showed that under room temperature and a loading of 100 N, the maximum Hertz contact loading in the initial state was 1.362 GPa, and the self-emulsifying ester (SEE) aqueous solution had excellent anti-wear and anti-friction properties, which can reduce the adhesion of titanium alloys effectively and improve the smoothness of the worn surface. However, the addition of phosphate ester has a certain antagonistic effect on the lubrication of the system;

- Under higher temperatures and loadings, the SEE molecules were squeezed out of the friction surface, which caused a sharp drop in the lubricating performance of the solution. However, adding organic phosphate to the solution can improve the anti-wear and anti-friction performance effectively;

- The XPS results indicated that organic phosphates can form strong chemical bonds (P-O-Ti covalent bonds) with the surface of the titanium alloy during the friction process, which generated a protective layer that can prevent the lubricant molecules from being squeezed out, thereby enhancing the stability of the solution under high temperatures and loadings and improving the anti-wear and anti-friction properties;

- It is found that the POEP with a longer carbon chain showed a better synergistic effect with SEE, and the compounding can make the aqueous solution exhibit a satisfactory frictional behavior even under high temperatures and high loadings. This investigation may be helpful to achieve an excellent boundary lubrication effect on titanium alloys and develop water-based cutting fluids that are suitable for machining titanium alloys.

Author Contributions

Conceptualization, L.L., Y.S. and X.L.; methodology, L.L.; investigation, L.L., L.H. and G.T.; writing—original draft preparation, L.L.; writing—review and editing, all; supervision, L.L.; project administration, L.L. and X.L.; funding acquisition, X.L. All authors have read and agreed to the published version of the manuscript.

Funding

The authors gratefully acknowledge the financial support of The National Key R&D Program of China (Grant No. 2020YFB2010600), the Tribology Science Fund of State Key Laboratory of Tribology (Grants No. X220281VN220), the National Natural Science Foundation of China (52105176), the Natural Science Foundation of Guangdong Province (Grants No. 2023A1515030204), Regional Joint Fund of Guangdong Province (Grants No. 2022A1515140150, 2022A1515110068), and the Science Fund of Jihua Laboratory (X210281TN210).

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Pramanik, A.; Littlefair, G. Machining of titanium alloy (Ti-6Al-4V)—Theory to application. Mach. Sci. Technol. 2015, 19, 1–49. [Google Scholar] [CrossRef]

- Daniyan, I.A.; Adeodu, A.; Mpofu, K.; Ramatsetse, B.; Muvunzi, R. Enhancing the Machinability of Titanium Alloy (TI6AL4V): A Comprehensive Review of Literature. In Advances in Manufacturing Technologies and Production Engineering; Bentham Science Publishers: Sharjah, United Arab Emirates, 2022; pp. 4–21. [Google Scholar]

- Liu, W.; Li, G.; Shao, Z.; Wu, X.; Ma, G.; Wang, F. Advance in experimental research on cutting temperature of titanium alloys. Int. J. Adv. Manuf. Technol. 2023, 126, 1827–1844. [Google Scholar] [CrossRef]

- Rahman Rashid, R.; Sun, S.; Wang, G.; Dargusch, M. Machinability of a near beta titanium alloy. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2011, 225, 2151–2162. [Google Scholar] [CrossRef]

- Revuru, R.S.; Posinasetti, N.R.; Vsn, V.R. Application of cutting fluids in machining of titanium alloys—A review. Int. J. Adv. Manuf. Technol. 2017, 91, 2477–2498. [Google Scholar] [CrossRef]

- Williams, J.C.; Boyer, R.R. Opportunities and issues in the application of titanium alloys for aerospace components. Metals 2020, 10, 705. [Google Scholar] [CrossRef]

- You, S.H.; Lee, J.H.; Oh, S.H. A study on cutting characteristics in turning operations of titanium alloy used in automobile. Int. J. Precis. Eng. Manuf. 2019, 20, 209–216. [Google Scholar] [CrossRef]

- Philip, J.T.; Mathew, J.; Kuriachen, B. Tribology of Ti6Al4V: A review. Friction 2019, 7, 497–536. [Google Scholar] [CrossRef]

- Hourmand, M.; Sarhan, A.A.; Sayuti, M.; Hamdi, M. A comprehensive review on machining of titanium alloys. Arab. J. Sci. Eng. 2021, 46, 7087–7123. [Google Scholar] [CrossRef]

- Liu, W.; Ao, S.; Li, Y.; Liu, Z.; Wang, Z.; Luo, Z.; Wang, Z.; Song, R. Jet electrochemical machining of TB6 titanium alloy. Int. J. Adv. Manuf. Technol. 2017, 90, 2397–2409. [Google Scholar] [CrossRef]

- Liu, Y.; Qu, N. Obtaining high surface quality in electrolyte jet machining TB6 titanium alloy via enhanced product transport. J. Mater. Process. Technol. 2020, 276, 116381. [Google Scholar] [CrossRef]

- Bai, D.; Sun, J.; Chen, W.; Wang, T. Wear mechanisms of WC/Co tools when machining high-strength titanium alloy TB6 (Ti-10V-2Fe-3Al). Int. J. Adv. Manuf. Technol. 2017, 90, 2863–2874. [Google Scholar] [CrossRef]

- García-Martínez, E.; Miguel, V.; Martínez-Martínez, A.; Manjabacas, M.C.; Coello, J. Sustainable lubrication methods for the machining of titanium alloys: An overview. Materials 2019, 12, 3852. [Google Scholar] [CrossRef]

- Xu, J.; Ji, M.; Chen, M.; El Mansori, M. Experimental investigation on drilling machinability and hole quality of CFRP/Ti6Al4V stacks under different cooling conditions. Int. J. Adv. Manuf. Technol. 2020, 109, 1527–1539. [Google Scholar] [CrossRef]

- Pervaiz, S.; Ahmad, N.; Ishfaq, K.; Khan, S.; Deiab, I.; Kannan, S. Implementation of Sustainable Vegetable-Oil-Based Minimum Quantity Cooling Lubrication (MQCL) Machining of Titanium Alloy with Coated Tools. Lubricants 2022, 10, 235. [Google Scholar] [CrossRef]

- Bagherzadeh, A.; Kuram, E.; Budak, E. Experimental evaluation of eco-friendly hybrid cooling methods in slot milling of titanium alloy. J. Clean. Prod. 2021, 289, 125817. [Google Scholar] [CrossRef]

- Fang, J.; Bai, P.; Ouyang, C.; Liu, C.; Wen, X.; Li, Y.; Meng, Y.; Ma, L.; Tian, Y. Influence of Adsorption Characteristics of Surfactants Sodium Dodecyl Sulfate and Aerosol-OT on Dynamic Process of Water-Based Lubrication. Lubricants 2022, 10, 147. [Google Scholar] [CrossRef]

- Lee, S.-J.; Sohn, Y.-C.; Kim, C.-L. Friction and wear characteristics of polydimethylsiloxane under water-based lubrication conditions. Materials 2022, 15, 3262. [Google Scholar] [CrossRef]

- Tang, Z.; Li, S. A review of recent developments of friction modifiers for liquid lubricants (2007-present). Curr. Opin. Solid State Mater. Sci. 2014, 18, 119–139. [Google Scholar] [CrossRef]

- Tu, T.; Wang, W.; Wan, Y.; Pu, J. Tribology properties of the aqueous solution of polyvinylpyrrolidone. Mater. Sci. 2014, 4, 103–110. [Google Scholar]

- Wang, C.; Bai, X.; Guo, Z.; Dong, C.; Yuan, C. Friction and wear behaviours of polyacrylamide hydrogel microsphere/UHMWPE composite under water lubrication. Wear 2021, 477, 203841. [Google Scholar] [CrossRef]

- Zhang, C.; Zheng, M.; Dai, Y. Lubricating properties of polyalkylene glycol and organic phosphate ester mixed aqueous solutions. Sci. China Technol. Sci. 2013, 56, 2988–2993. [Google Scholar] [CrossRef]

- Zhang, C.H.; Zhao, Y.C.; Björling, M.; Wang, Y.; Luo, J.B.; Prakash, B. EHL properties of polyalkylene glycols and their aqueous solutions. Tribol. Lett. 2012, 45, 379–385. [Google Scholar] [CrossRef]

- Benedicto, E.; Rubio, E.M.; Aubouy, L.; Sáenz-Nuño, M.A. Formulation of sustainable water-based cutting fluids with polyol esters for machining titanium alloys. Metals 2021, 11, 773. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, C.; Dai, Y.; Luo, J. Tribological properties of titanium alloys under lubrication of SEE oil and aqueous solutions. Tribol. Int. 2017, 109, 40–47. [Google Scholar] [CrossRef]

- Dong, S.; Wang, W.; Gao, Y.; Deng, G. Tribological Properties of Different-Sized Black Phosphorus Nanosheets as Water-Based Lubrication Additives for Steel/Titanium Alloy Wear Contact. Metals 2022, 12, 288. [Google Scholar] [CrossRef]

- Kuo, C.; Hsu, Y.; Chung, C.; Chen, C.-C.A. Multiple criteria optimisation in coated abrasive grinding of titanium alloy using minimum quantity lubrication. Int. J. Mach. Tools Manuf. 2017, 115, 47–59. [Google Scholar] [CrossRef]

- Rahim, E.; Sasahara, H. High speed MQL drilling of titanium alloy using synthetic ester and palm oil. In Proceedings of the 36th International MATADOR Conference, Manchester, UK, 14–16 July 2010; Springer: London, UK; pp. 193–196.

- Wood, P.; Boud, F.; Carter, W.; Varasteh, H.; Gunputh, U.; Pawlik, M.; Clementson, J.; Lu, Y.; Hossain, S.; Broderick, M. On the Lubricity and Comparative Life Cycle of Biobased Synthetic and Mineral Oil Emulsions in Machining Titanium Ti-6Al-4V at Low Cutting Speed. J. Manuf. Mater. Process. 2022, 6, 154. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, C.; Dai, Y.; Luo, J. Lubricity and adsorption of castor oil sulfated sodium salt emulsion solution on titanium alloy. Tribol. Lett. 2019, 67, 61. [Google Scholar] [CrossRef]

- Papay, A. Antiwear and extreme-pressure additives in lubricants. Lubr. Sci. 1998, 10, 209–224. [Google Scholar] [CrossRef]

- Bowden, F.; Gregory, J.; Tabor, D. Lubrication of metal surfaces by fatty acids. Nature 1945, 156, 97–101. [Google Scholar] [CrossRef]

- Lee, S.; Iten, R.; Müller, M.; Spencer, N.D. Influence of Molecular Architecture on the Adsorption of Poly(ethylene oxide)-Poly(propylene oxide)-Poly (ethylene oxide) on PDMS Surfaces and Implications for Aqueous Lubrication. Macromolecules 2004, 37, 8349–8356. [Google Scholar] [CrossRef]

- Lin, B.; Tieu, A.K.; Zhu, H.; Kosasih, B.; Novareza, O. Micro-scratch behaviour of adsorbed film formed by aqueous copolymer lubricants with phosphate ester additive on Ti-coated surface. Ind. Lubr. Tribol. 2017, 69, 881–890. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, C.; Wang, Y.; Dai, Y.; Luo, J. Friction and wear performance of titanium alloy against tungsten carbide lubricated with phosphate ester. Tribol. Int. 2016, 95, 27–34. [Google Scholar] [CrossRef]

- Li, Z.; Ren, T. Synergistic effects between alkylphosphate-ammonium ionic liquid and alkylphenylborate as lubricant additives in rapeseed oil. Tribol. Int. 2017, 109, 373–381. [Google Scholar] [CrossRef]

- Adolphi, B.; Jähne, E.; Busch, G.; Cai, X. Characterization of the adsorption of ω-(thiophene-3-yl alkyl) phosphonic acid on metal oxides with AR-XPS. Anal. Bioanal. Chem. 2004, 379, 646–652. [Google Scholar] [CrossRef]

- Brodard-Severac, F.; Guerrero, G.; Maquet, J.; Florian, P.; Gervais, C.; Mutin, P.H. High-field 17O MAS NMR investigation of phosphonic acid monolayers on titania. Chem. Mater. 2008, 20, 5191–5196. [Google Scholar] [CrossRef]

- Köbl, J.; Wechsler, D.; Kataev, E.Y.; Williams, F.J.; Tsud, N.; Franchi, S.; Steinrück, H.-P.; Lytken, O. Adsorption of phenylphosphonic acid on rutile TiO2 (110). Surf. Sci. 2020, 698, 121612. [Google Scholar] [CrossRef]

- Mani, G.; Johnson, D.M.; Marton, D.; Dougherty, V.L.; Feldman, M.D.; Patel, D.; Ayon, A.A.; Agrawal, C.M. Stability of self-assembled monolayers on titanium and gold. Langmuir 2008, 24, 6774–6784. [Google Scholar] [CrossRef] [PubMed]

- Viornery, C.; Chevolot, Y.; Léonard, D.; Aronsson, B.-O.; Péchy, P.; Mathieu, H.J.; Descouts, P.; Grätzel, M. Surface modification of titanium with phosphonic acid to improve bone bonding: Characterization by XPS and ToF-SIMS. Langmuir 2002, 18, 2582–2589. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).