Determination of Safety-Oriented Pavement-Friction Performance Ratings at Network Level Using a Hybrid Clustering Algorithm

Abstract

1. Introduction

2. Literature Review

2.1. Threshold-Based Rating Methods

2.2. Multilevel-Based Rating Methods

3. Data and Integration

3.1. Datasets

3.2. Integration

- Data reorganization: Using the year and road type (i.e., interstate highways, US highways, and state roads) obtained from both datasets, the crash and friction data were grouped in pairs, resulting in the formation of nine groups of sub-datasets.

- Spatial integration: Using geographic information systems (GIS) coordinates or reference posts, the distances between each crash event location and all friction-test locations were calculated. Each crash event was then linked to the friction measurement with the shortest distance, which is commonly 1 mile or less, considering the interval of friction testing by INDOT.

- Data merging: All data points generated in the spatial-integration step were merged based on the road name.

- Safety-oriented filtering: A meticulous filtering approach was implemented to eliminate crash events caused by factors unrelated to friction. These factors included vehicle malfunctions, driver usage of cellphones or telematics, and driver illness.

4. Methodology

4.1. Density-Based Spatial Clustering of Applications with Noise

4.2. Gaussian Mixture Model

4.3. DBSCAN-GMM Algorithm

4.4. Chi-Square Test

5. Results and Analysis

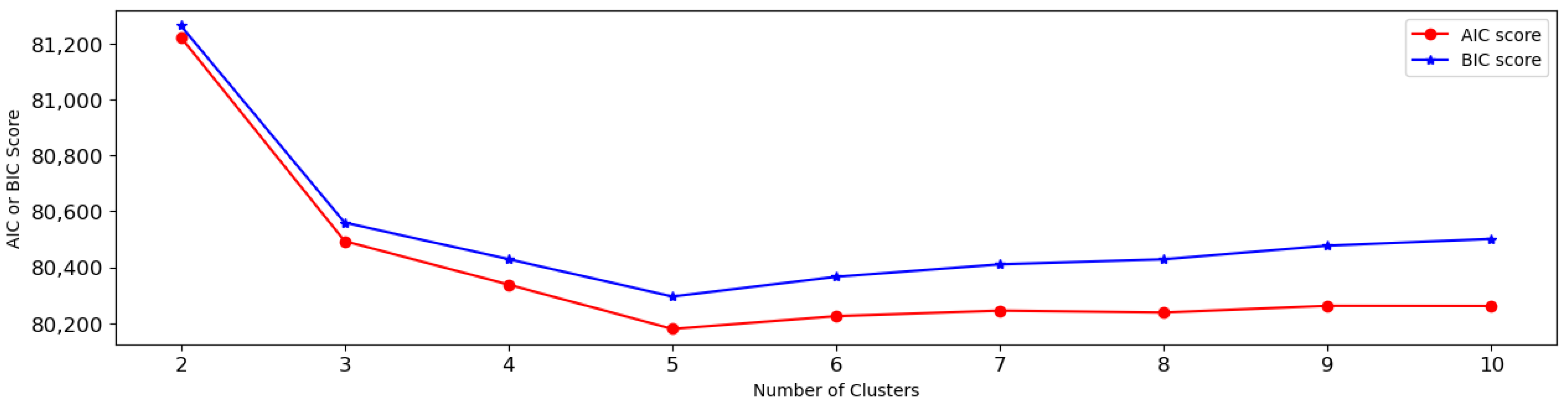

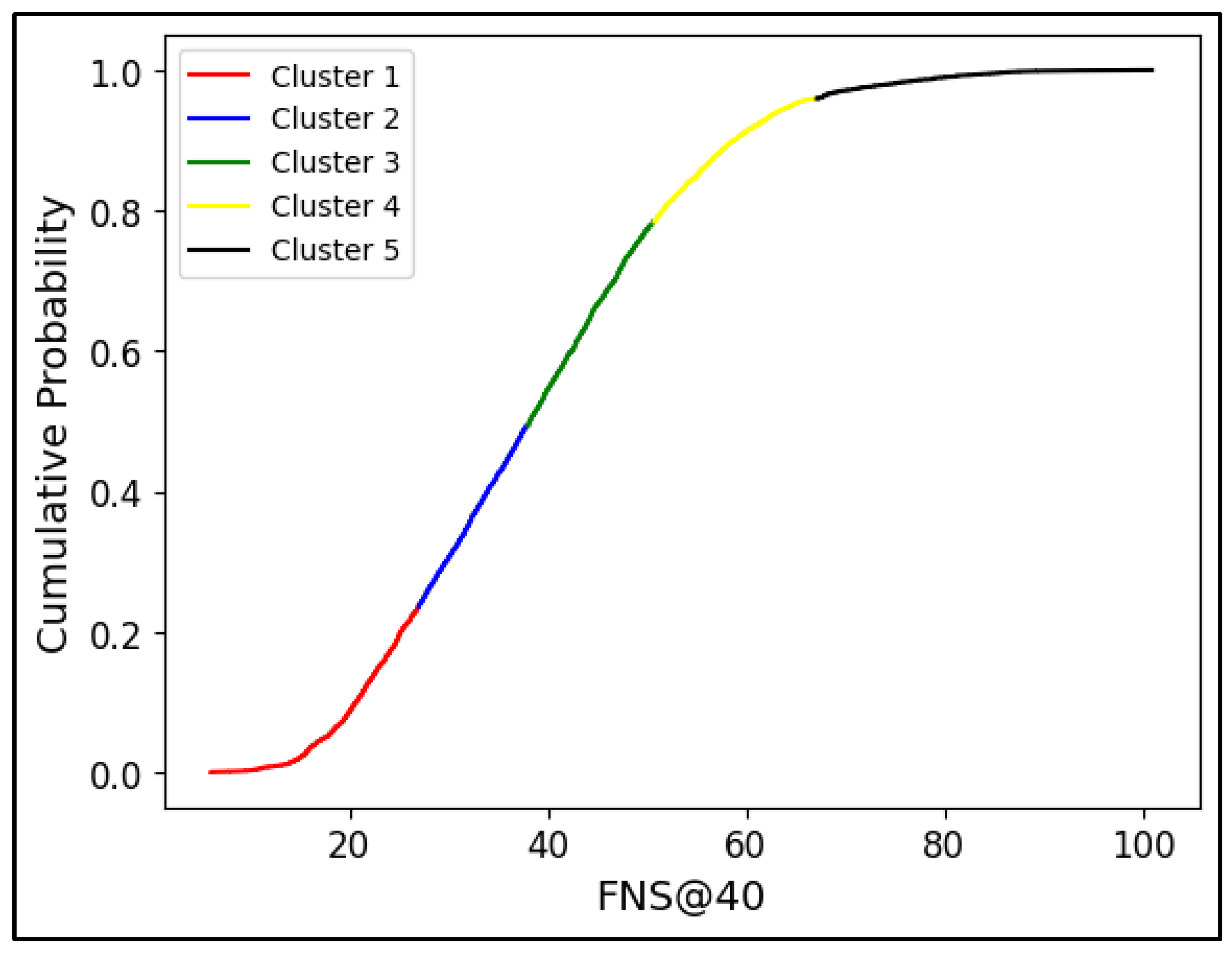

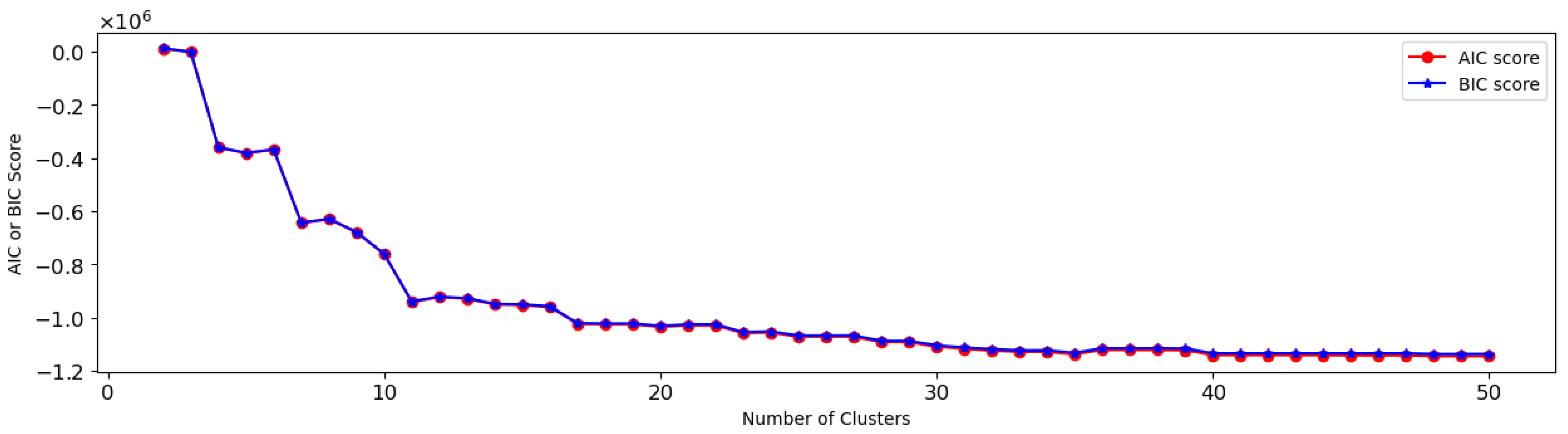

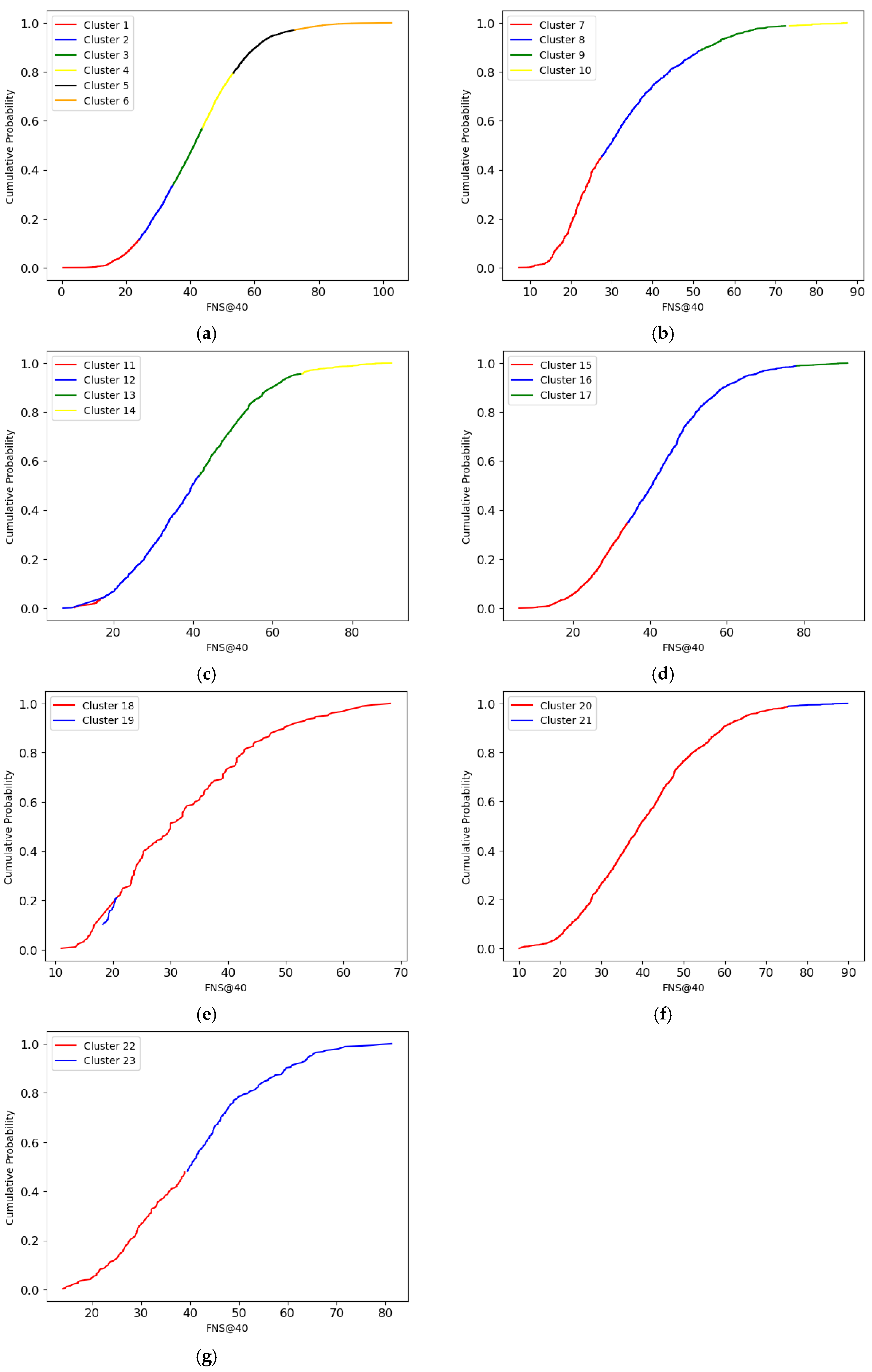

5.1. One-Dimensional Clustering Analysis

5.2. Two-Dimensional Clustering Analysis

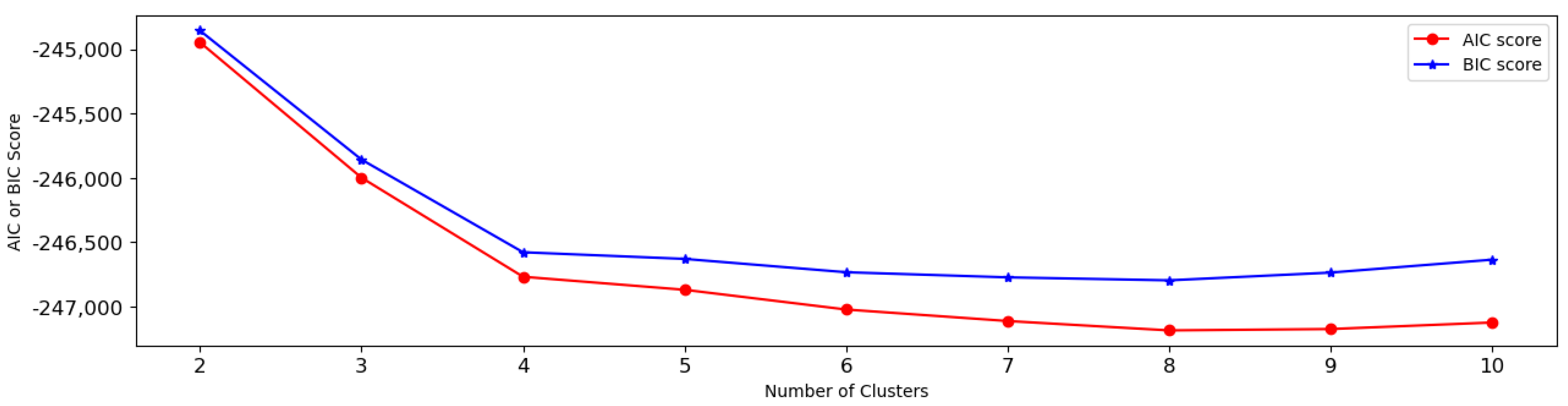

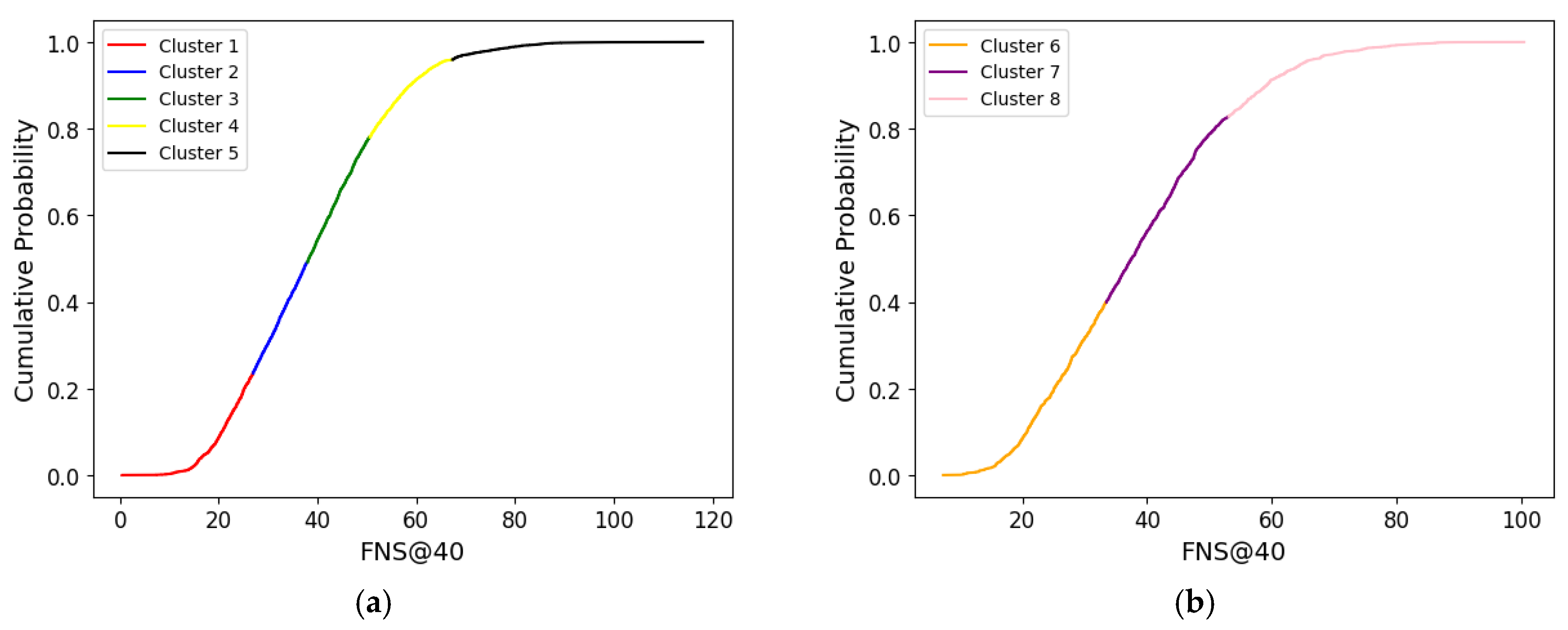

5.3. Multi-Dimensional Clustering Analysis

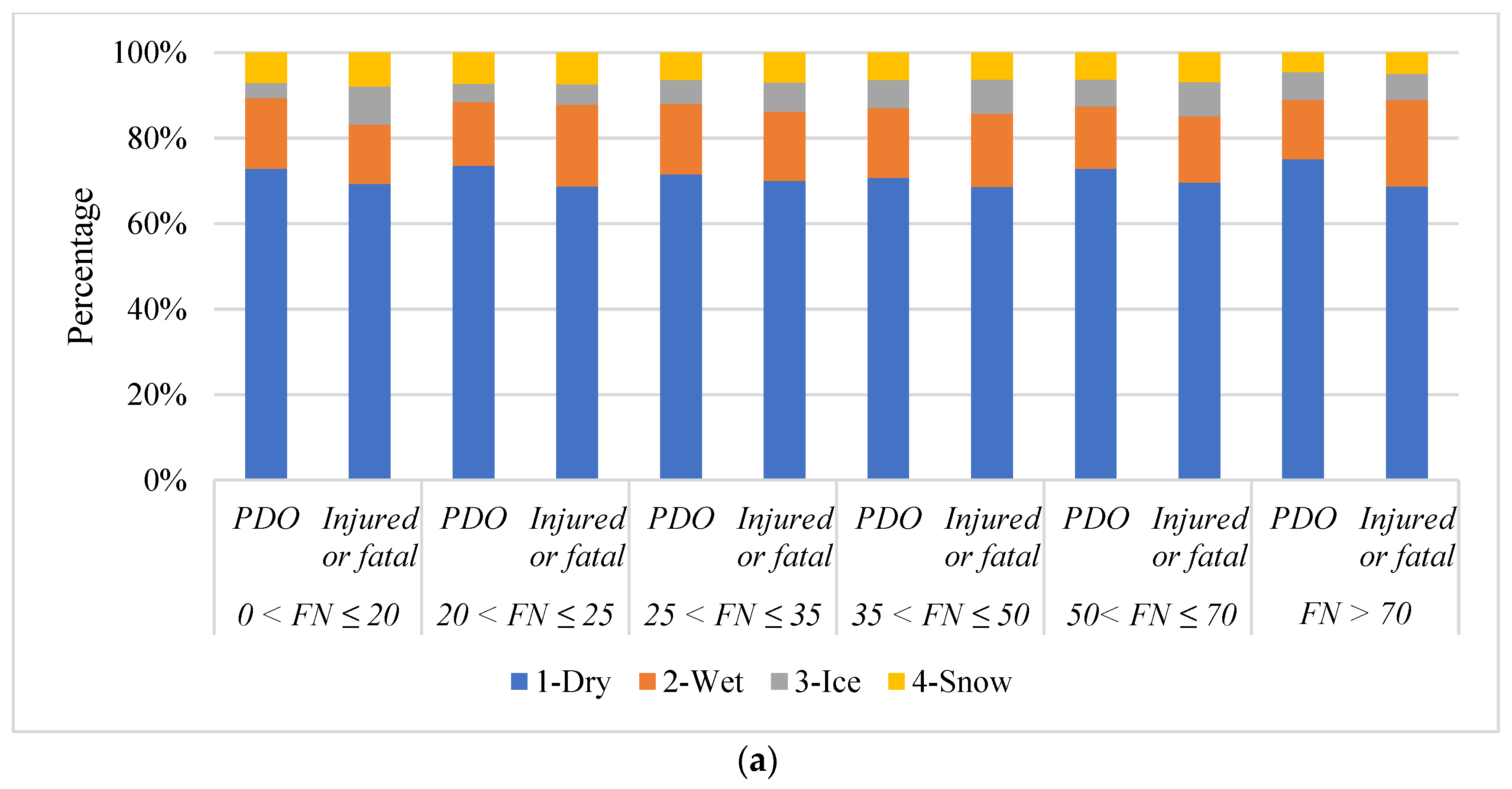

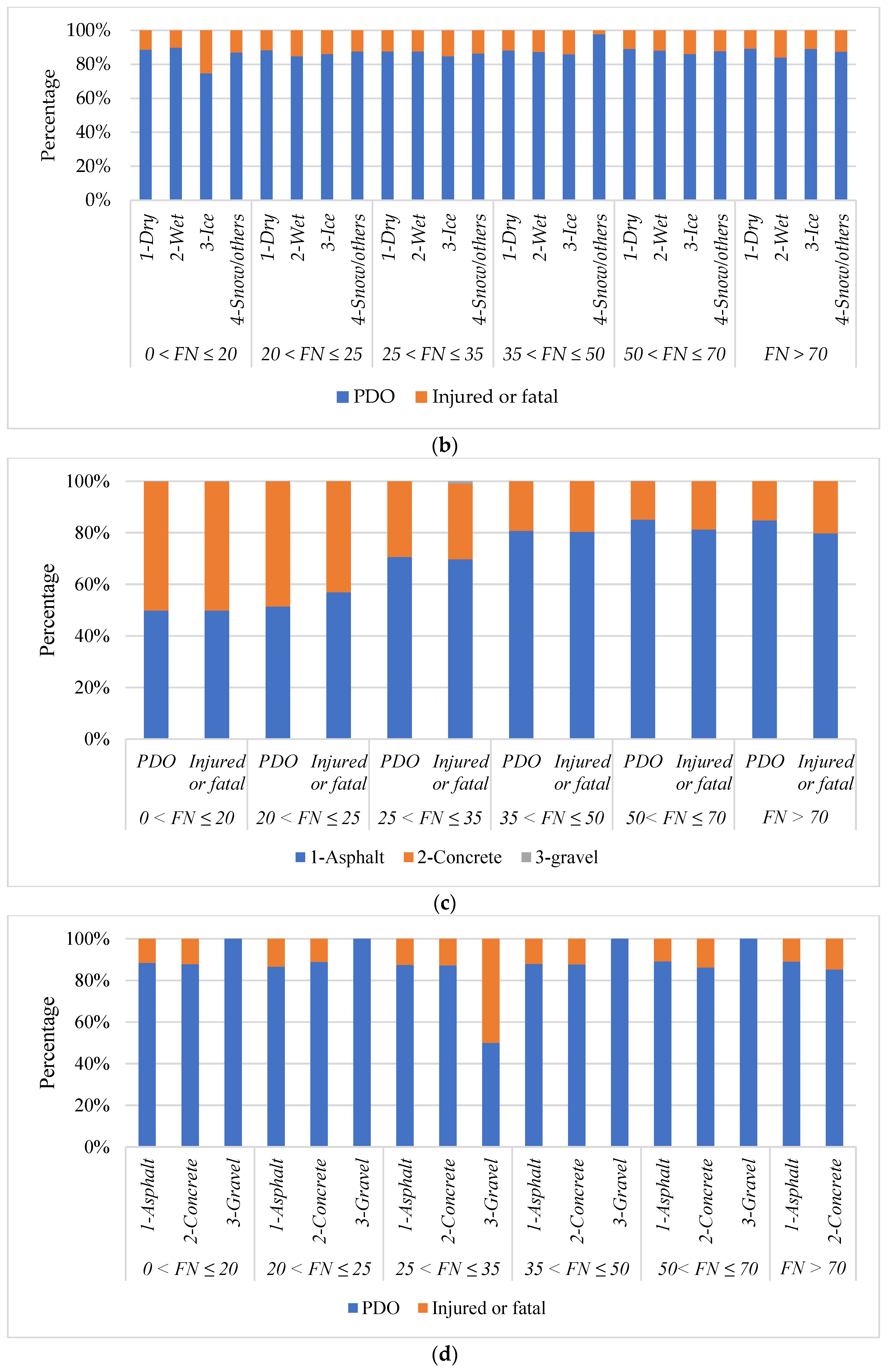

5.4. Chi-Square Test Analysis

- .

- .

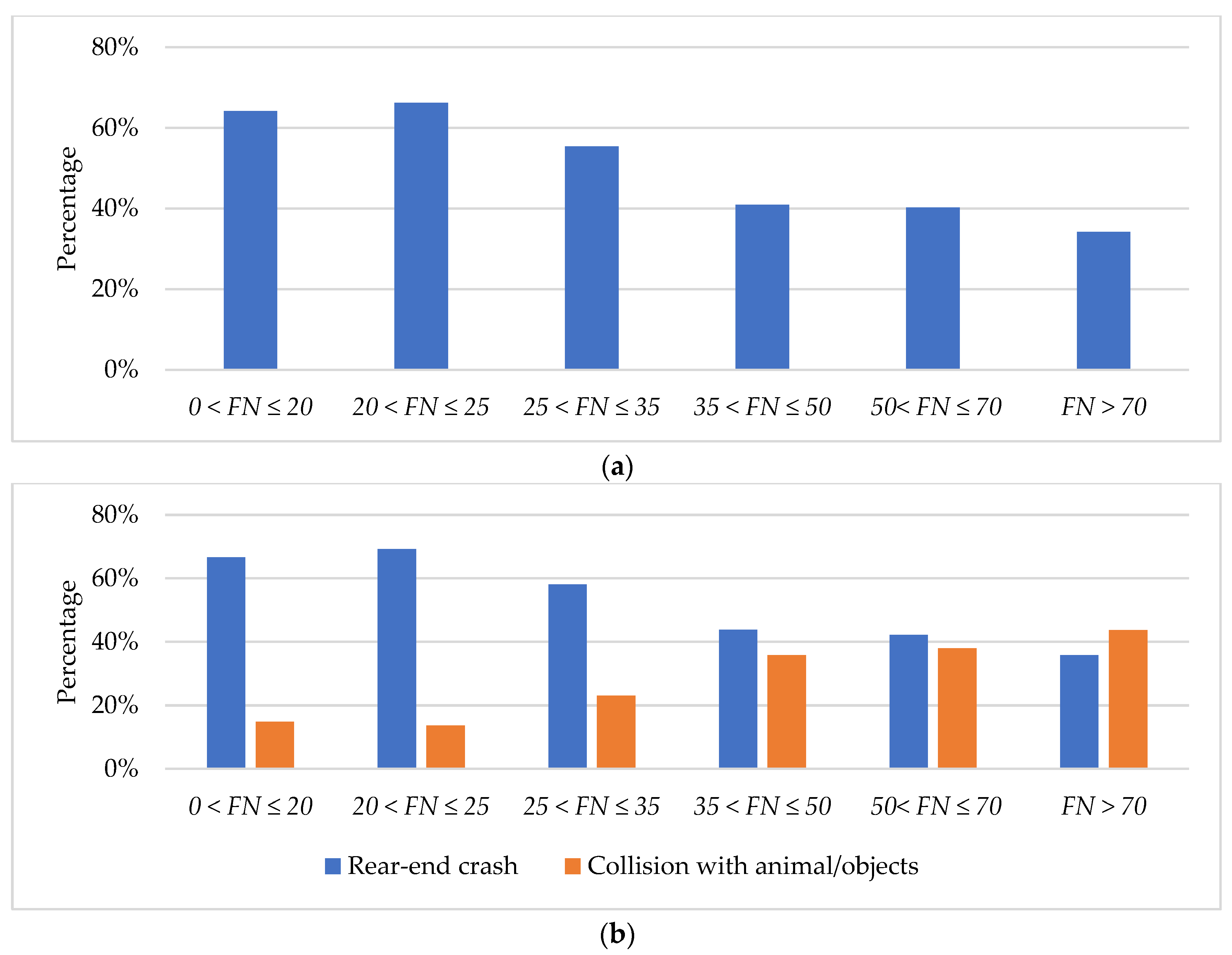

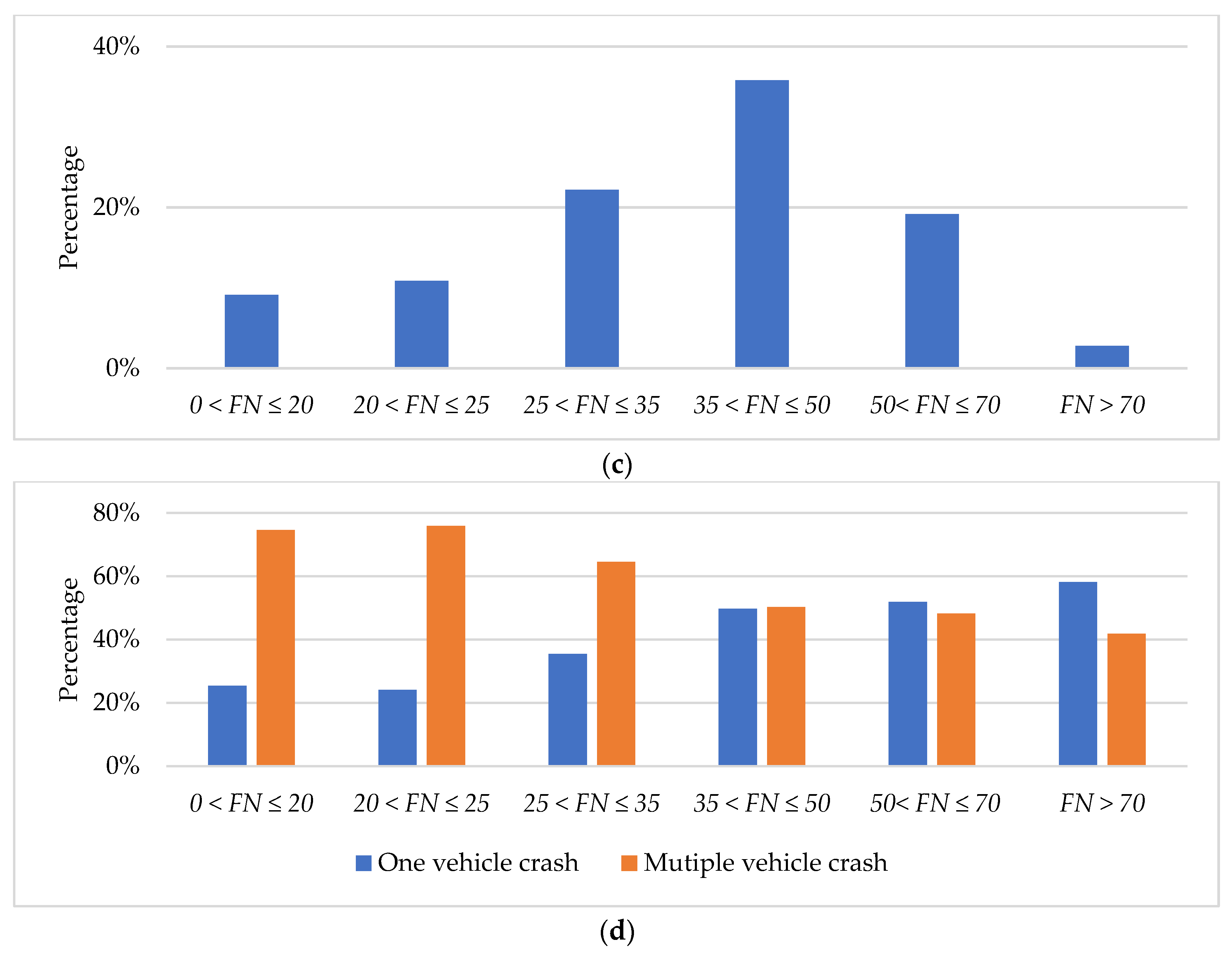

- FNS ∈ (0, 20]: Due to the extremely low FNS, the collision consequences in this range are much more serious than other FNS intervals, and extra attention should be paid to this type of road.

- FNS ∈ (20, 25]: Similarly, the low FNS caused more serious crashes especially when the pavement surface is wet or covered with ice, snow, or other loose coverings. However, it is evident that shorter following distances are more likely to cause crashes. The underlying reason is attributed to inadequate friction, which hinders drivers from braking effectively and subsequently leads to rear-end collisions [15].

- FNS ∈ (25, 35]: The 25th percentile of FNS falls within this range. There is a higher prevalence of gravel surfaces compared to other intervals. This increased presence of gravel surfaces contributes to a higher incidence of injuries and fatal accidents. Furthermore, an observable trend within this rating range is a shift from multiple-vehicle crashes to an increasing number of single-vehicle crashes. This shift suggests that the characteristics of the road surface within this FNS range may influence the nature and type of accidents that occur, emphasizing the importance of addressing road conditions, and promoting safe driving practices to mitigate the risk of accidents in this range.

- FNS ∈ (35, 50]: The means and median of FNS were distributed within this range. Over 97% of crashes occurring on snow surfaces were classified as PDO crashes, with only 2.19% resulting in injury or fatal accidents. The proportion of PDO crashes and injured or fatal crashes on other surface conditions is almost the same as in other ratings. Even though the majority of speed-related crashes occur within this range, it is believed that road surfaces with FNS In this range can ensure the safety of drivers traveling at required speed limitations.

- FNS ∈ (50, 70]: The 75th percentile of FNS, which is around 50, is in close proximity to this range. Within this range, concrete roads exhibit a slightly higher susceptibility to injury and fatal crashes, while asphalt roads display a slightly higher likelihood of the occurrence of PDO crashes.

- FNS ∈ (70, ∞): Similar to the case of FNS falling between 50 and 70, concrete roads with FNS values greater than 70 demonstrate an elevated vulnerability to injury and fatal crashes. Furthermore, collisions with animals/objects are more likely to happen in this range.

- A friction number of 20 is the flag value of friction that indicates necessary actions are warranted to restore pavement friction.

- A friction number ranging between 20 and 25 indicates the pavement friction may be lower than the flag value in the coming year(s), which can facilitate district pavement engineers to better plan pavement preservation, overlay, and resurfacing activities.

- A friction number of 35 is the minimum friction requirement for pavement warranty projects [43].

- A friction number greater than 70 is commonly required for new high friction surface treatment (HFST) that is commonly utilized at crash-prone areas with exceptionally high friction demand, such as sharp curves, ramps, bus stops, intersections, tunnel entrances, and steep grades [44].

6. Conclusions

- In scenarios where the pavement exhibits an exceptionally low FNS (FNS < 25), the magnitude of collision consequences is markedly elevated in comparison to pavement characterized by higher FNS values, specifically when the road surface is subjected to the influence of water, ice, snow, or other unconsolidated substances. Additionally, in this range, there is an increasing likelihood of crashes attributable to small vehicles following distances. This phenomenon can be attributed to the diminished frictional characteristics of the road surface, which hinder optimal braking capabilities and consequently contribute to an augmented incidence of rear-end collisions.

- The 25th percentile FNS falls within the range of 25 and 35. Within this range, there is a notable transition from multi-vehicle crashes to an elevated occurrence of single-vehicle crashes. Additionally, the presence of a higher number of gravel surfaces within this range leads to more severe crashes.

- The median and average FNS values fall within the range of 35 and 50. This range represents the first acceptable FNS range, characterized by a significantly low rate of injury or fatal crashes.

- For pavements with relatively high FNS (FNS > 50), concrete roads exhibit a slightly higher susceptibility to injury and fatal crashes compared to asphalt roads. Moreover, the increased likelihood of single-vehicle crashes within this range contributes to a higher probability of collisions with animals or objects.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- American Association of State Highway and Transportation Officials (AASHTO). Guide for Pavement Friction, 2nd ed.; American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2022. [Google Scholar]

- Henry, J.J. Evaluation of Pavement Friction Characteristics. NCHRP Synthesis of Highway Practice 291; Transportation Research Board: Washington, DC, USA, 2000. [Google Scholar]

- Li, S.; Noureldin, S.; Zhu, K. Upgrading the INDOT Pavement Friction Testing Program; Publication FHWA/IN/JTRP-2003/23; Joint Transportation Research Program, Indiana Department of Transportation and Purdue University: West Lafayette, IN, USA, 2004. [Google Scholar] [CrossRef]

- Federal Highway Administration (FHWA). Pavement Friction Management; Technical Advisory, T 5040.38; Federal Highway Administration (FHWA): Washington, DC, USA, 2010. [Google Scholar]

- Li, S.; Noureldin, S.; Jiang, Y.; Sun, Y. Evaluation of Pavement Surface Friction Treatments; Publication FHWA/IN/JTRP-2012/04; Joint Transportation Research Program, Indiana Department of Transportation and Purdue University: West Lafayette, Indiana, 2012. [Google Scholar] [CrossRef]

- Elkhazindar, A.; Hafez, M.; Ksaibati, K. Incorporating pavement friction management into pavement asset management systems: State department of transportation experience. CivilEng 2022, 3, 541–561. [Google Scholar] [CrossRef]

- McGovern, C.; Rusch, P.; Noyce, D.A. State Practices to Reduce Wet Weather Skidding Crashes; FHWA-SA-11-21; Office of Safety, Federal Highway Administration: Washington, DC, USA, 2011. [Google Scholar]

- Neaylon, K. Guidance for the Development of Policy to Manage Skid Resistance; Publication no: AP-R374-11; Austroads: Sydney, Australia, 2011. [Google Scholar]

- Cook, D.; Donbavand, J.; Whitehead, D. Improving a Great Skid Resistance Policy: New Zealand’s state highways. In Proceedings of the 4th International Safer Roads Conference, Cheltenham, UK, 18–21 May 2014. [Google Scholar]

- Highways England. Design Manual for Roads and Bridges (DMRB)—Pavement Inspection and Assessment: CS 228 Skidding Resistance, Revision 2; Highways England: Birmingham, UK, 2021. [Google Scholar]

- Murad, M.M.; Abaza, K.A. Pavement friction in a program to reduce wet weather traffic accidents at the network level. Transp. Res. Rec. 2006, 1949, 126–136. [Google Scholar] [CrossRef]

- Mayora, J.; Piña, R. An assessment of the skid resistance effect on traffic safety under wet-pavement conditions. Accid. Anal. Prev. 2009, 41, 881–886. [Google Scholar] [CrossRef] [PubMed]

- Xiao, J.; Kulakowski, B.T.; EI-Gindy, M. Prediction of Risk of Wet-Pavement Accidents: Fuzzy Logic Model. Transp. Res. Rec. 2000, 1717, 28–36. [Google Scholar] [CrossRef]

- Li, S.; Xiong, R.; Yu, D.; Zhao, G.; Cong, P.; Jiang, Y. Friction Surface Treatment Selection: Aggregate Properties, Surface Characteristics, Alternative Treatments, and Safety Effects (Joint Transportation Research Program Publication No. FHWA/IN/JTRP-2017/09); Purdue University: West Lafayette, IN, USA, 2017. [Google Scholar]

- Zhao, G.; Liu, L.; Li, S.; Tighe, S. Assessing pavement friction need for safe integration of autonomous vehicles into current road system. J. Infrastruct. Syst. 2021, 27. [Google Scholar] [CrossRef]

- McCarthy, R.; Flintsch, G.; de León Izeppi, E. Impact of skid resistance on dry and wet weather crashes. J. Transp. Eng. Part B Pavements 2021, 147, 04021029. [Google Scholar] [CrossRef]

- American Association of State Highway and Transportation Officials (AASHTO). Highway Safety Manual, 1st ed.; American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2010. [Google Scholar]

- Gramling, W.L. Current Practices in Determining Pavement Condition; NCHRP Synthesis of Highway Practice 203; Transportation Research Board: Washington, DC, USA, 1994. [Google Scholar]

- Baladi, G.Y.; Dawson, T.; Musunuru, G.; Prohaska, M.; Thomas, K. Pavement Performance Measures and Forecasting and the Effects of Maintenance and Rehabilitation Strategy on Treatment Effectiveness (Revised). FHWA-HRT-17-095; Turner-Fairbank Highway Research Center, Federal Highway Administration: McLean, VA, USA, 2017. [Google Scholar]

- ASTM E274/E274M-15; Standard Test Method for Skid Resistance of Paved Surfaces Using a Full-Scale Tire. ASTM: West Conshohocken, PA, USA, 2020.

- ASTM E303-22; Standard Test Method for Measuring Surface Frictional Properties Using the British Pendulum Tester. ASTM: West Conshohocken, PA, USA, 2022.

- ASTM E1911-19; Standard Test Method for Measuring Surface Frictional Properties Using the Dynamic Friction Tester. ASTM: West Conshohocken, PA, USA, 2019.

- ASTM E1845-15; Standard Practice for Calculating Pavement Macrotexture Mean Profile Depth. ASTM: West Conshohocken, PA, USA, 2015.

- ASTM E965-15; Standard Test Method for Measuring Pavement Macrotexture Depth Using a Volumetric Technique. ASTM: West Conshohocken, PA, USA, 2019.

- ASTM E2157-15; Standard Test Method for Measuring Pavement Macrotexture Properties Using the Circular Track Meter. ASTM: West Conshohocken, PA, USA, 2019.

- ASTM E1960-07; Standard Practice for Calculating International Friction Index of a Pavement Surface. ASTM: West Conshohocken, PA, USA, 2015.

- Shaffer, S.J.; Christiaen, A.C.; Rogers, M.J. Assessment of Friction-Based Pavement Methods and Regulations; TASK 2003E1; Turner-Fairbank Highway Research Center, Federal Highway Administration: McLean, VA, USA, 2006. [Google Scholar]

- ASTM E501-08; Standard Specification for Standard Rib Tire for Pavement Skid-Resistance tests. ASTM: West Conshohocken, PA, USA, 2020.

- ASTM E524-08; Standard Specification for Standard Smooth Tire for Pavement Skid-Resistance Tests. ASTM: West Conshohocken, PA, USA, 2020.

- Kummer, H.W.; Meyer, W.E. Tentative Skid-resistance Requirements for Main Rural Highways; NCHRP Report 37; Transportation Research Board: Washington DC, USA, 1967. [Google Scholar]

- Noyce, D.A.; Bahia, H.U.; Yambo, J.; Chapman, J.; Bill, A. Incorporating Road Safety into Pavement Management: Maximizing Surface Friction for Road Safety Improvements; Report No. MRUTC 04-04; Traffic Operations and Safety Laboratory, University of Wisconsin-Madison: Madison, WI, USA, 2007. [Google Scholar]

- Kuttesch, J.S. Quantifying the Relationship between Skid Resistance and Wet Weather Accidents for Virginia Data. Master’s Thesis, Faculty of Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 2004. [Google Scholar]

- Li, S.; Zhu, Z.; Noureldin, S. Considerations in developing a network pavement inventory friction test program for a state highway agency. J. Test. Eval. 2005, 33, 287–294. [Google Scholar]

- Zhan, Y.; Li, J.Q.; Yang, G.; Wang, K.C.P.; Yu, W. Friction-ResNets: Deep residual network architecture for pavement skid resistance evaluation. J. Transp. Eng. Part B Pavements 2020, 146, 04020027. [Google Scholar] [CrossRef]

- Zhao, G.; Jiang, Y.; Li, S.; Tighe, S. Exploring implicit relationships between pavement surface friction and vehicle crash severity using interpretable extreme gradient boosting method. Can. J. Civ. Eng. 2021, 49, 1206–1219. [Google Scholar] [CrossRef]

- Indiana State Police (ISP). Automated Reporting Information Exchange System (ARIES) 6 User Manual; Indiana State Police (ISP): Indianapolis, IN, USA, 2023. [Google Scholar]

- Ester, M.; Kriegel, H.P.; Sander, J.; Xu, X. A density-based algorithm for discovering clusters in large spatial databases with noise. In Proceedings of the 2nd International Conference on Knowledge Discovery and Data Mining, Portland, OR, USA, 2–4 August 1996; Volume 96, pp. 226–231. [Google Scholar]

- Pedregosa, F.; Varoquaux, G.; Gramfort, A.; Michel, V.; Thirion, B.; Grisel, O.; Blondel, M.; Prettenhofer, P.; Weiss, R.; Dubourg, V.; et al. Scikit-learn: Machine learning on Python. J. Mach. Learn. Res. 2011, 12, 2825–2830. [Google Scholar]

- Akaike, H. A new look at the statistical model identification. IEEE Trans. Autom. Control 1974, 19, 716–723. [Google Scholar] [CrossRef]

- Schwarz, G. Estimating the dimension of a model. Ann. Stat. 1978, 6, 461–464. Available online: http://www.jstor.org/stable/2958889 (accessed on 28 May 2023). [CrossRef]

- Agresti, A. Categorical Data Analysis, 3rd ed.; Wiley: Hoboken, NJ, USA, 2013; pp. 69–86. Available online: https://mybiostats.files.wordpress.com/2015/03/3rd-ed-alan_agresti_categorical_data_analysis.pdf (accessed on 26 May 2023).

- Kassu, A.; Anderson, M. Analysis of severe and non-sever traffic crash on wet and dry highways. Transp. Res. Interdiscip. Perspect. 2019, 2, 100043. [Google Scholar] [CrossRef]

- Standard Specification; Indiana Department of Transportation: Indianapolis, IN, USA, 2022.

- High Friction Surface Treatment. Recurring Special Provision (RSP) 617-T-213; Indiana Department of Transportation: Indianapolis, IN, USA, 2017. [Google Scholar]

| Source | Test Condition | Threshold Value |

|---|---|---|

| Kummer and Meyer [30] | Rib tire, 40 mph | 37 |

| Henry [2] | Rib or smooth tire, 40 mph | 30~45 |

| Noyce et al. [31] | Rib tire, 40 mph | 35 |

| Kuttesch [32] | Smooth tire, 40 mph | 25~30 |

| Li et al. [33] | Smooth tire, 40 mph | 20 |

| Zhao et al. [15] | Smooth tire, 40 mph | 20 |

| Variables | Description | Categories | |||

|---|---|---|---|---|---|

| FNS | Friction numbers | NA | |||

| Crash-Severity Level | Property damage only (PDO), and injury or fatality. | 0 = PDO (87.94%) | 1 = Injury or Fatality (12.06%) | ||

| Surface Condition | Affected by weather when crashes happened. | 1 = Dry (71.57%) | 2 = Wet/Water (15.91%) | 3 = Ice (5.99%) | 4 = Snow/Others (6.52%) |

| Road Geometrics | Grade, level, and hillcrest. | 1 = Grade (17.18%) | 2 = Level (78.44%) | 3 = Hillcrest (4.38%) | |

| Surface Material | Asphalt, concrete, and gravel | 1 = Asphalt (73.42%) | 2 = Concrete (26.53%) | 3 = Gravel (0.5%) | |

| No. | Friction Number (FN) |

|---|---|

| 1 | 0 < FN ≤ 25 |

| 2 | 25 < FN ≤ 35 |

| 3 | 35 < FN ≤ 50 |

| 4 | 50 < FN ≤ 70 |

| 5 | FN > 70 |

| No. | Friction Number (FN) |

|---|---|

| 1 | 0 < FN ≤ 20 |

| 2 | 20 < FN ≤ 25 |

| 3 | 25 < FN ≤ 35 |

| 4 | 35 < FN ≤ 45 |

| 5 | 45 < FN ≤ 50 |

| 6 | 50< FN ≤ 70 |

| 7 | FN > 70 |

| FNS | Variable 1 | Variable 2 | χ2 | df | p-Value | Accept or Not |

|---|---|---|---|---|---|---|

| 0 < FN ≤ 20 | Severity Level | Surface Condition | 20.0990 | 3 | 0.0002 | Reject |

| Road Geometric | 4.7952 | 2 | 0.0909 | Accept | ||

| Surface Material | 0.6405 | 2 | 0.7260 | Accept | ||

| 20 < FN ≤ 25 | Severity Level | Surface Condition | 5.4039 | 3 | 0.1445 | Accept |

| Road Geometric | 0.7559 | 2 | 0.6853 | Accept | ||

| Surface Material | 4.3729 | 2 | 0.1123 | Accept | ||

| 25 < FN ≤ 35 | Severity Level | Surface Condition | 2.8680 | 3 | 0.4124 | Accept |

| Road Geometric | 1.6748 | 2 | 0.4328 | Accept | ||

| Surface Material | 7.7221 | 2 | 0.0210 | Reject | ||

| 35 < FN ≤ 45 | Severity Level | Surface Condition | 5.6471 | 3 | 0.1301 | Accept |

| Road Geometric | 0.2079 | 2 | 0.9013 | Accept | ||

| Surface Material | 0.5696 | 2 | 0.7522 | Accept | ||

| 45 < FN ≤ 50 | Severity Level | Surface Condition | 1.9873 | 3 | 0.5751 | Accept |

| Road Geometric | 3.1309 | 2 | 0.2090 | Accept | ||

| Surface Material | 0.1312 | 2 | 0.9365 | Accept | ||

| 50< FN ≤ 70 | Severity Level | Surface Condition | 3.9647 | 3 | 0.2653 | Accept |

| Road Geometric | 0.0896 | 2 | 0.9562 | Accept | ||

| Surface Material | 6.7126 | 2 | 0.0349 | Reject | ||

| FN > 70 | Severity Level | Surface Condition | 3.0918 | 3 | 0.3777 | Accept |

| Road Geometric | 1.0527 | 2 | 0.5908 | Accept | ||

| Surface Material | 1.3914 | 1 | 0.2382 | Accept |

| No. | Friction Number (FN) |

|---|---|

| 1 | 0 < FN ≤ 20 |

| 2 | 20 < FN ≤ 25 |

| 3 | 25 < FN ≤ 35 |

| 4 | 35 < FN ≤ 50 |

| 5 | 50< FN ≤ 70 |

| 6 | FN > 70 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bao, J.; Jiang, Y.; Li, S. Determination of Safety-Oriented Pavement-Friction Performance Ratings at Network Level Using a Hybrid Clustering Algorithm. Lubricants 2023, 11, 275. https://doi.org/10.3390/lubricants11070275

Bao J, Jiang Y, Li S. Determination of Safety-Oriented Pavement-Friction Performance Ratings at Network Level Using a Hybrid Clustering Algorithm. Lubricants. 2023; 11(7):275. https://doi.org/10.3390/lubricants11070275

Chicago/Turabian StyleBao, Jieyi, Yi Jiang, and Shuo Li. 2023. "Determination of Safety-Oriented Pavement-Friction Performance Ratings at Network Level Using a Hybrid Clustering Algorithm" Lubricants 11, no. 7: 275. https://doi.org/10.3390/lubricants11070275

APA StyleBao, J., Jiang, Y., & Li, S. (2023). Determination of Safety-Oriented Pavement-Friction Performance Ratings at Network Level Using a Hybrid Clustering Algorithm. Lubricants, 11(7), 275. https://doi.org/10.3390/lubricants11070275