Mechanism and Experimental Study on Electrostatic Atomization Using Needle-Shaped Electrodes

Abstract

1. Introduction

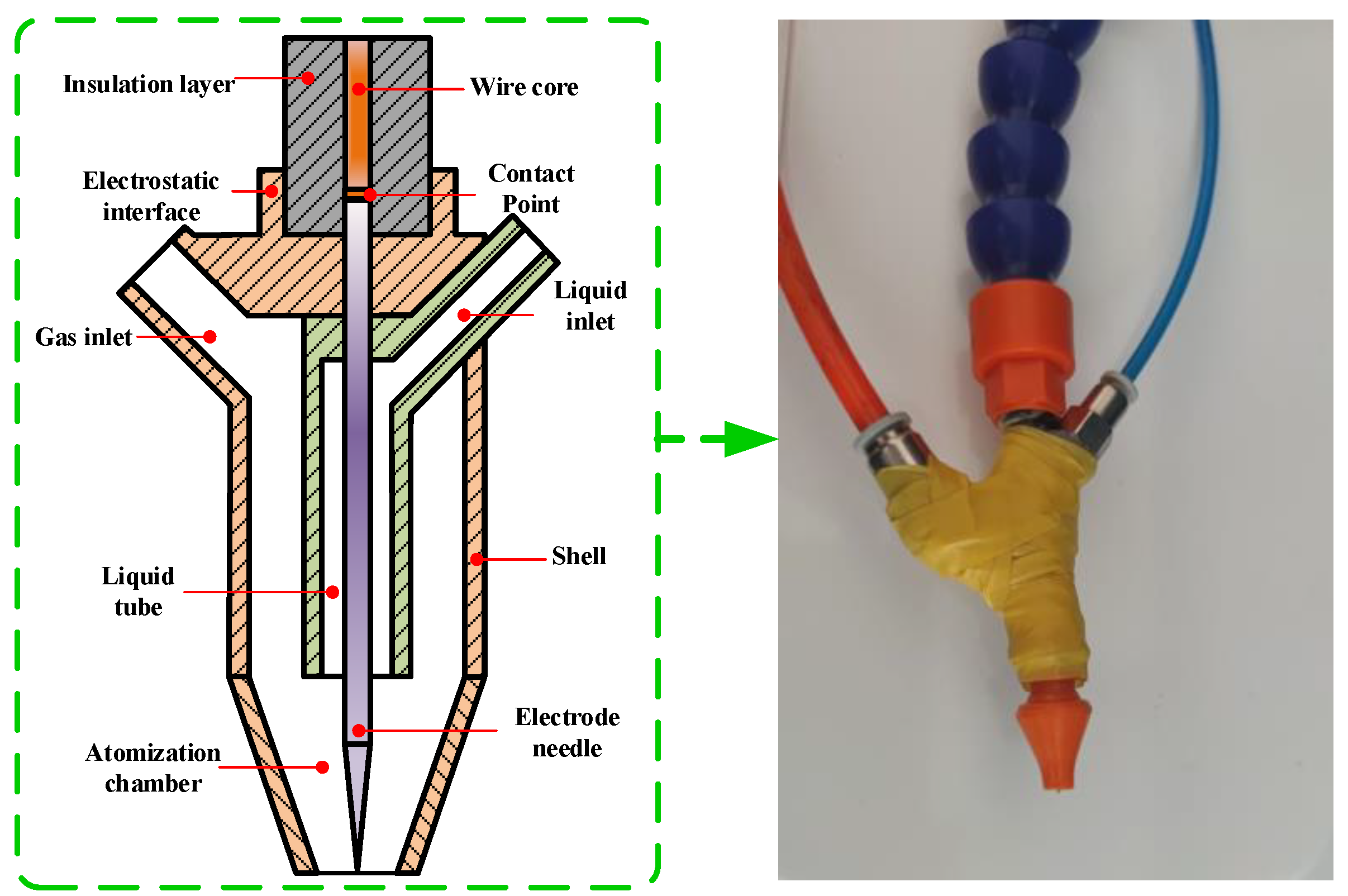

2. Nozzle Structure

3. Atomization Mechanism

3.1. Lubricant Charging Characteristics

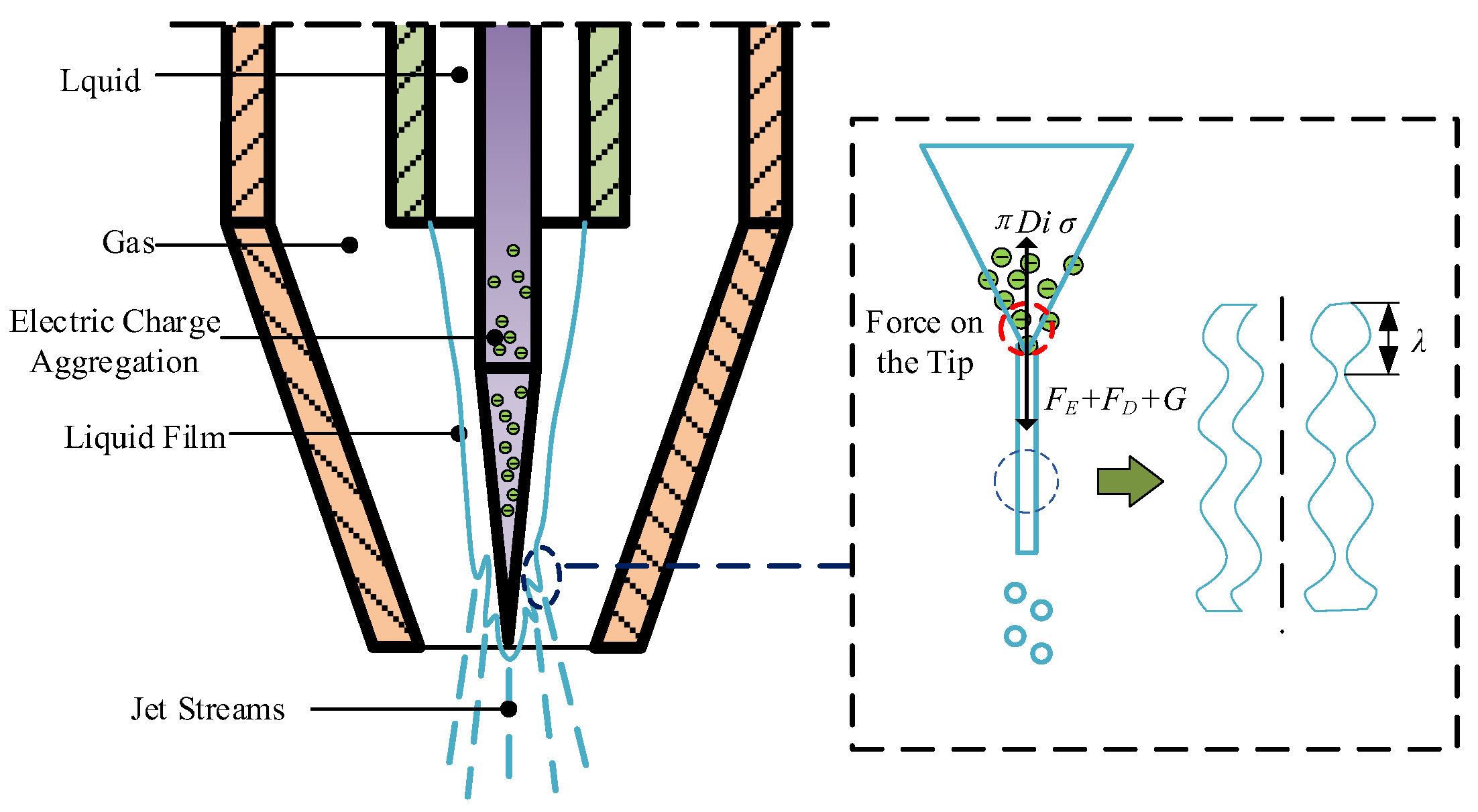

3.2. Cone-Jet Model

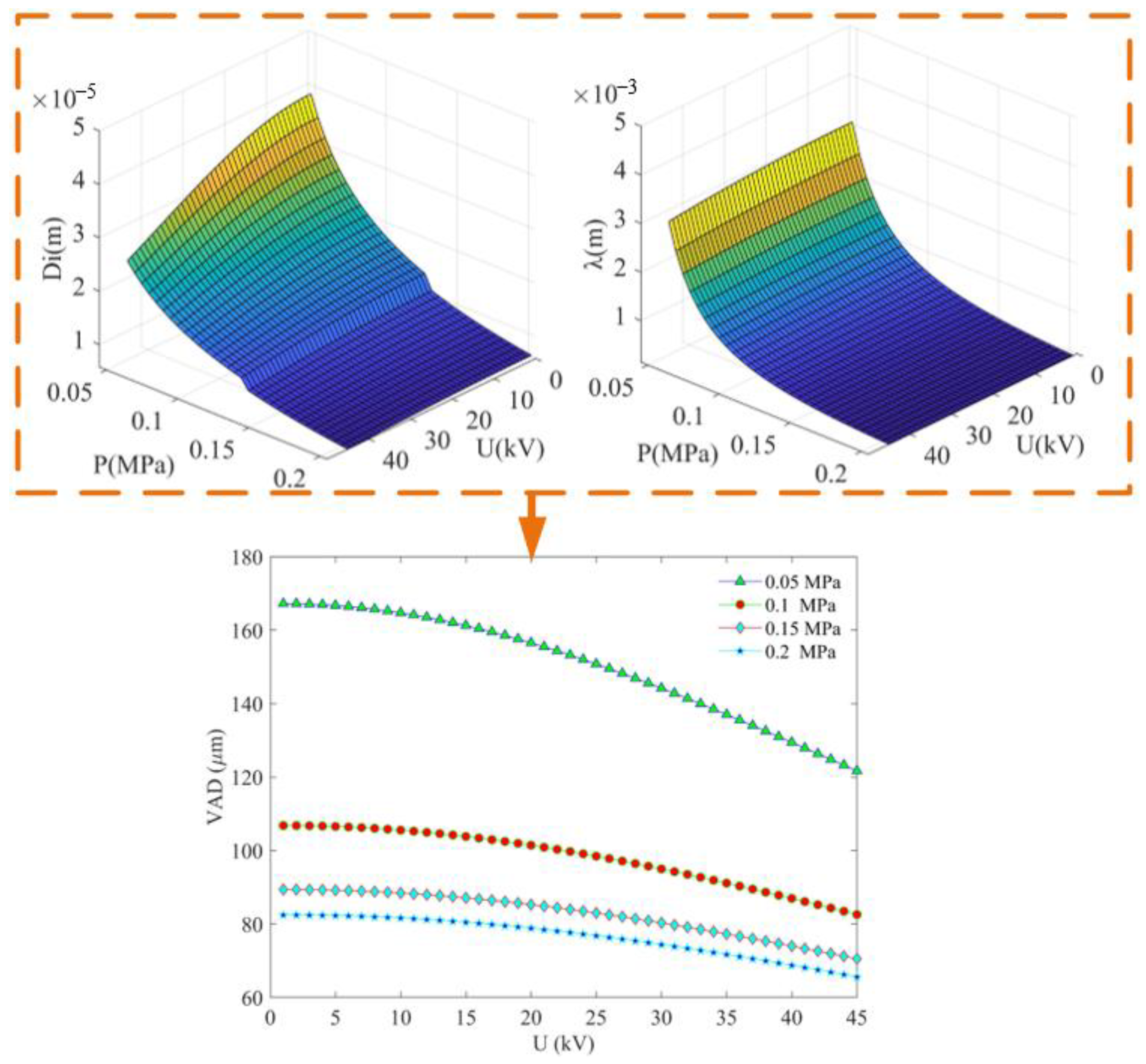

3.3. Model Prediction Results

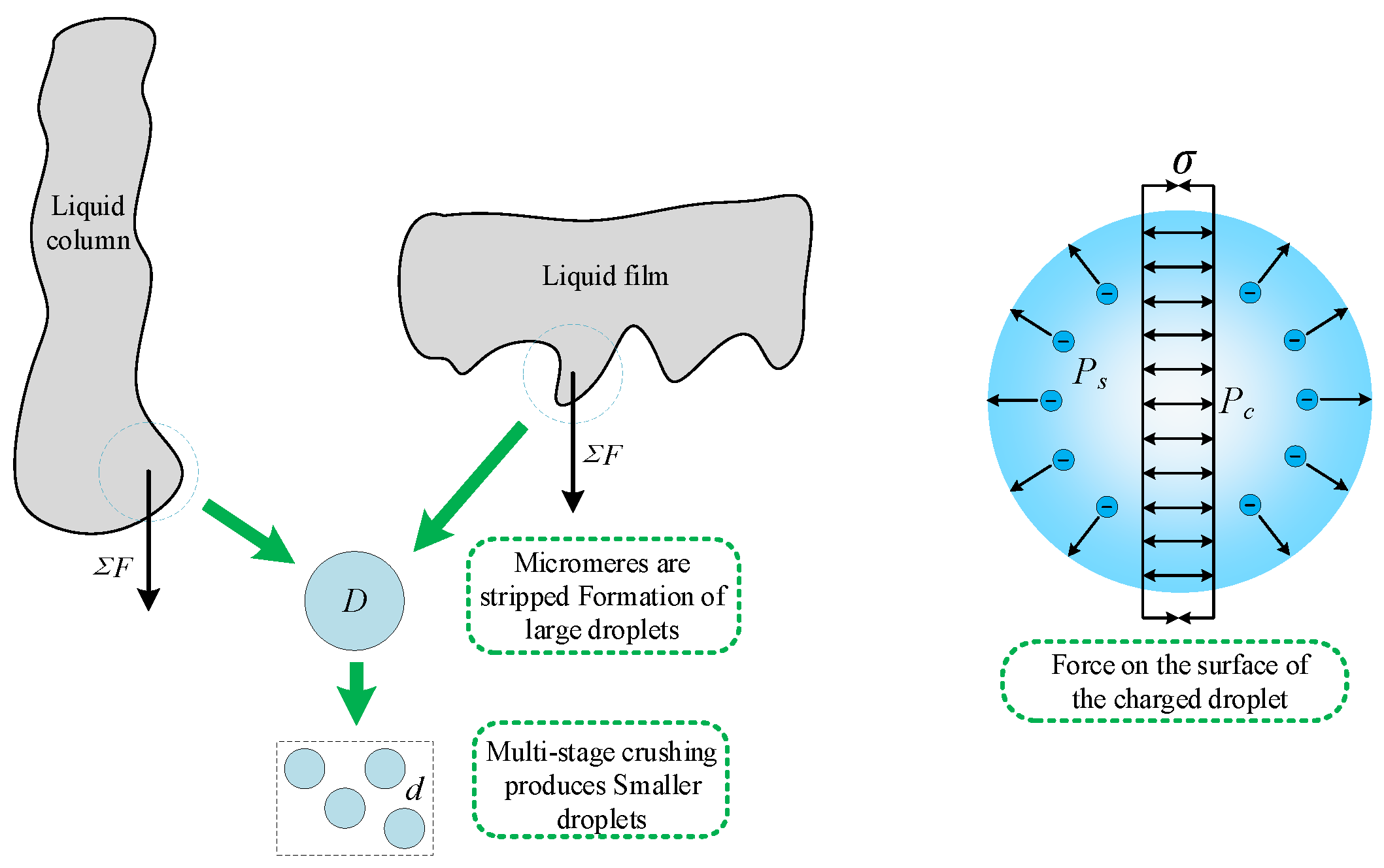

3.4. Breakup of Small Liquid Droplets

4. Experimental Setup and Materials

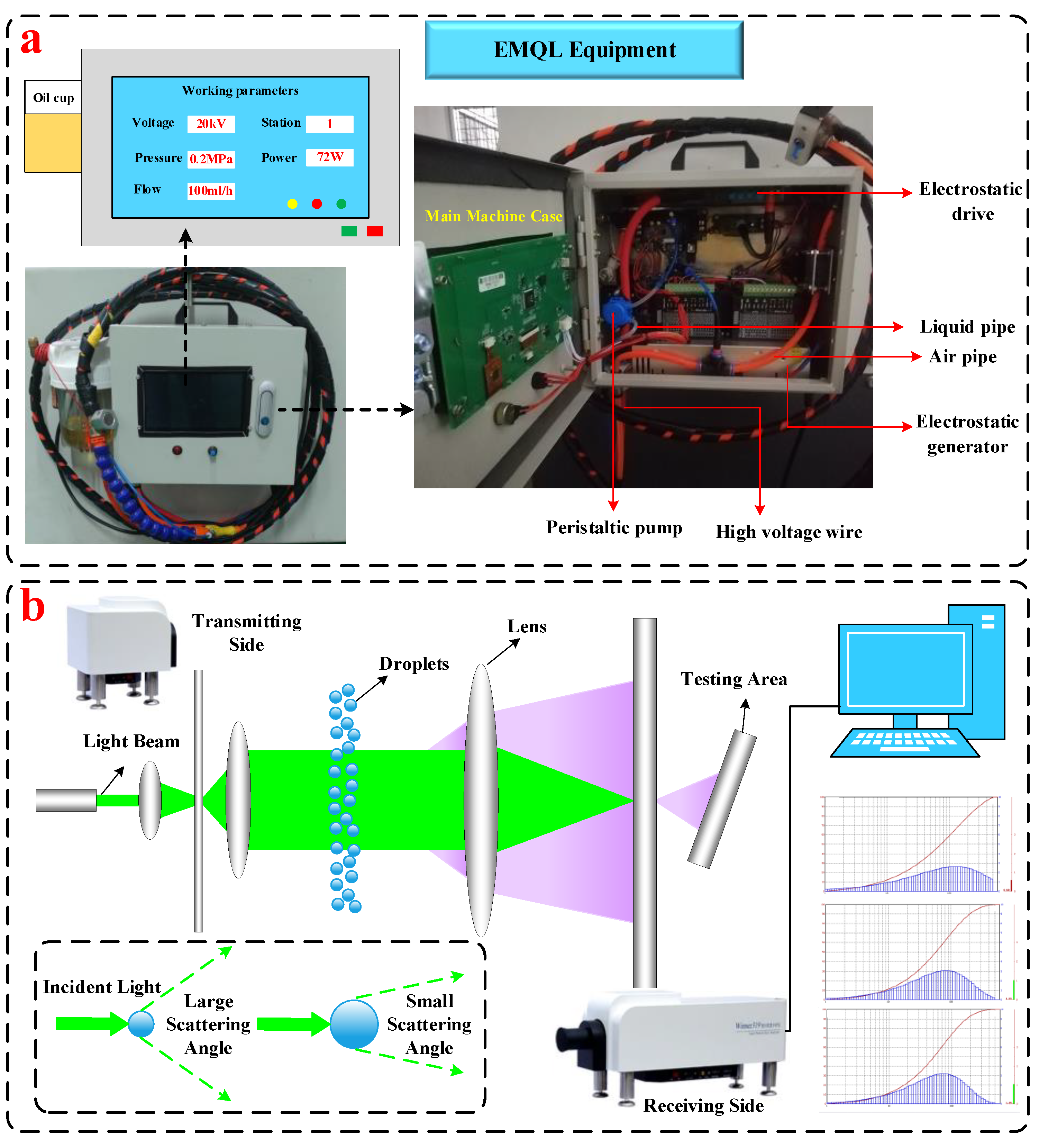

4.1. Experimental Setup

4.2. Experimental Materials

4.3. Experimental Scheme

5. Results

6. Discussion

7. Conclusions

- The charging process is mainly charge migration between the electrode and the lubricant and the droplet collision and adhesion with ions in the corona field, the charge of the lubricant depends on its own relative dielectric constant, the larger the dielectric constant the higher the charge, and the corresponding droplet surface tension is lower and easier to occur atomization;

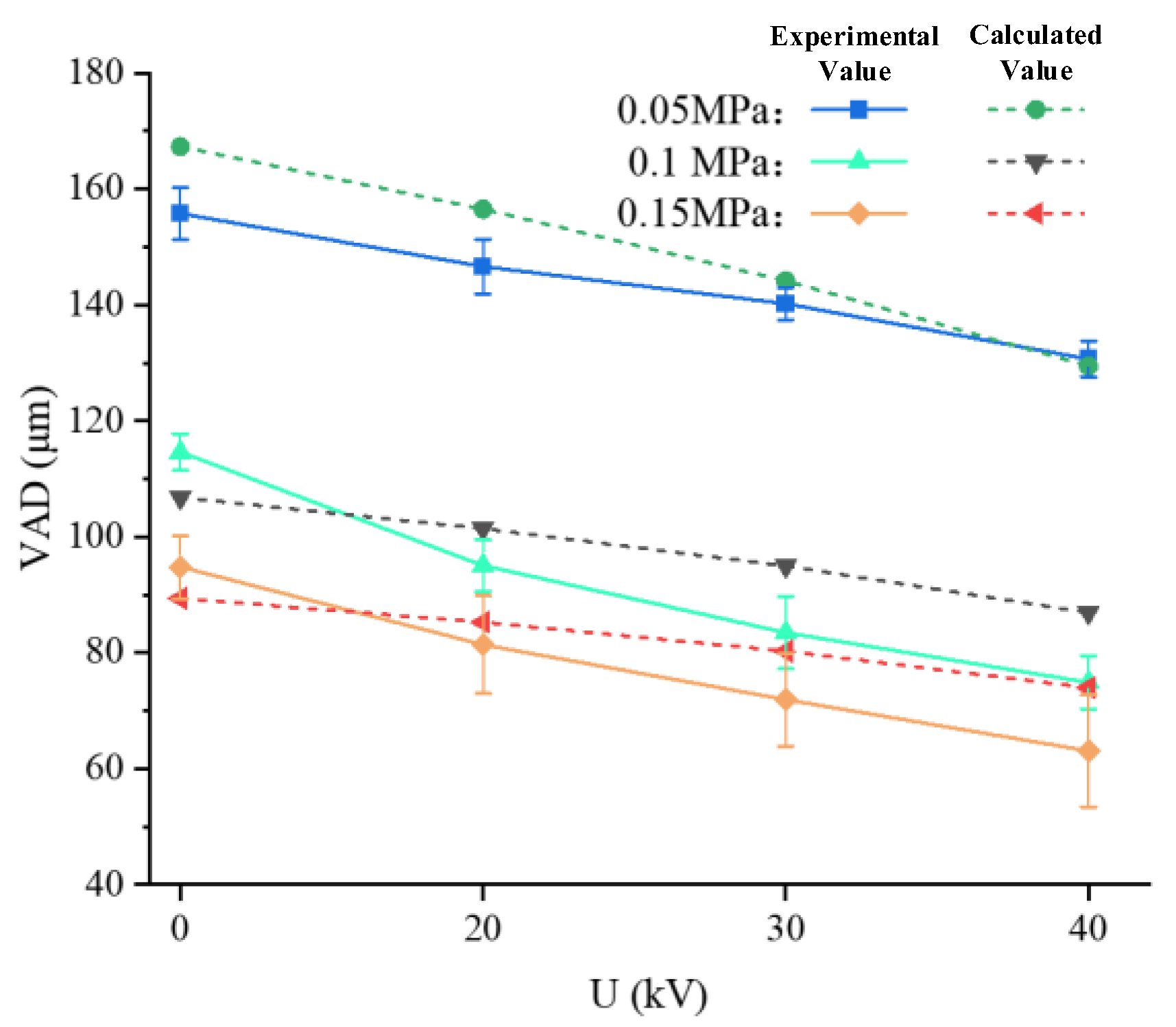

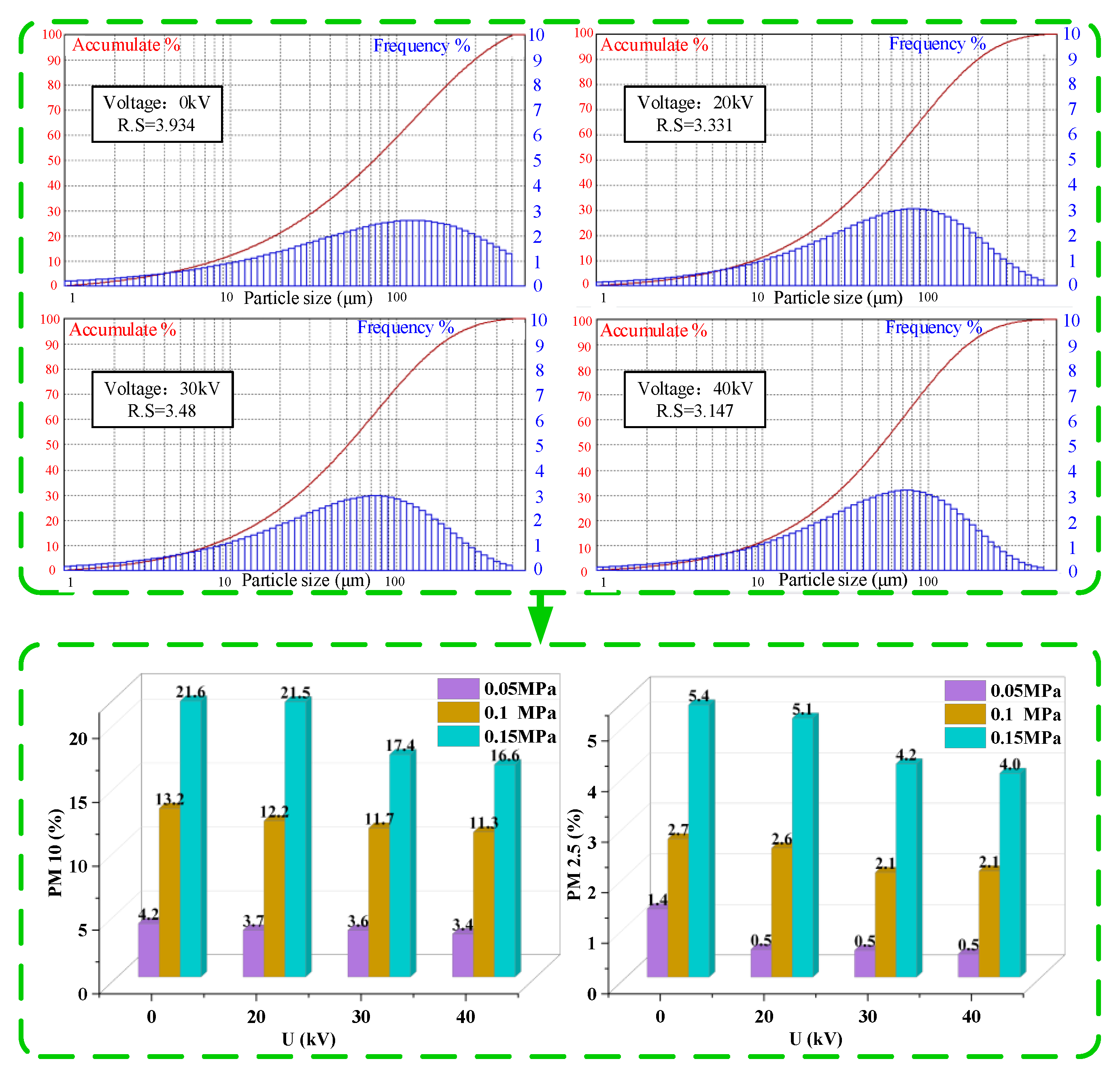

- The electrode cone jet atomization model was established. According to the model results, the volume average diameter of the droplet (VAD), the factors determining the VAD (jet diameter, wavelength) are negatively correlated with air pressure and voltage, and the jet diameter is more sensitive to voltage changes, while the wavelength is more sensitive to air pressure changes;

- The VAD under different working conditions was measured by laser particle sizer, and the VAD refinement was most obvious at 0.1 Mpa, with an overall reduction of 34.67% and a 20% reduction in the droplet group size distribution span (R.S.). Moreover, the fine particulate matter percentage concentrations were significantly reduced under different air pressure conditions;

- According to the comparison between the measured data and the results of the mathematical model, the theoretical and experimental values fit well, with an overall error of about 10%, which verifies the accuracy of the mathematical model.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Baldin, V.; Silva, L.R.R.d.; Davis, R.; Jackson, M.J.; Amorim, F.L.; Houck, C.F.; Machado, Á.R. Dry and MQL Milling of AISI 1045 Steel with Vegetable and Mineral-Based Fluids. Lubricants 2023, 11, 175. [Google Scholar] [CrossRef]

- López de Lacalle, L.N.; Angulo, C.; Lamikiz, A.; Sánchez, J.A. Experimental and numerical investigation of the effect of spray cutting fluids in high speed milling. J. Mater. Process Technol. 2006, 172, 11–15. [Google Scholar] [CrossRef]

- Özbek, O. Evaluation of Nano Fluids with Minimum Quantity Lubrication in Turning of Ni-Base Superalloy UDIMET 720. Lubricants 2023, 11, 159. [Google Scholar] [CrossRef]

- Pereira, O.; Martín-Alfonso, J.E.; Rodríguez, A.; Calleja, A.; Fernández-Valdivielso, A.; López de Lacalle, L.N. Sustainability analysis of lubricant oils for minimum quantity lubrication based on their tribo-rheological performance. J. Clean. Prod. 2017, 164, 1419–1429. [Google Scholar] [CrossRef]

- Liu, D.W.; Li, C.H.; Dong, L.; Qin, A.G.; Zhang, Y.B.; Yang, M.; Gao, T.; Wang, X.M.; Liu, M.Z.; Cui, X.; et al. Kinematics and improved surface roughness model in milling. Int. J. Adv. Manuf. Technol. 2022. [Google Scholar] [CrossRef]

- Shah, P.; Gadkari, A.; Sharma, A.D.; Shokrani, A.; Khanna, N. Comparison of machining performance under MQL and ultra-high voltage EMQL conditions based on tribological properties. Tribol. Int. 2021, 153, 106595–106601. [Google Scholar] [CrossRef]

- Lv, T.; Xu, X.F.; Yu, A.; Hu, X. Oil mist concentration and machining characteristics of SiO2 water-based nano-lubricants in electrostatic minimum quantity lubrication-EMQL milling. J. Mater. Process Technol. 2021, 290, 116964–116978. [Google Scholar] [CrossRef]

- Su, Y.; Lu, Q.; Yu, T.; Liu, Z.; Zhang, C. Machining and environmental effects of electrostatic atomization lubrication in milling operation. Int. J. Adv. Manuf. Technol. 2019, 104, 2773–2782. [Google Scholar] [CrossRef]

- Gupta, K.K.; Laubscher, R.F.; Davim, J.P.; Jain, N.K. Recent developments in sustainable manufacturing of gears: A review. J. Clean Prod. 2016, 112, 3320–3330. [Google Scholar] [CrossRef]

- Jia, D.; Li, C.; Zhang, D.; Wang, S.; Hou, Y. Investigation into the Formation Mechanism and Distribution Characteristics of Suspended Microparticles in MQL Grinding. Rec. Patents Mech. Eng. 2014, 7, 52–62. [Google Scholar] [CrossRef]

- Brentjes, A.; Jansen, B.; Pozarlik, A.K. Spray characteristics of an air-assisted electrostatic atomiser. J. Elec. 2022, 115, 103654–103661. [Google Scholar] [CrossRef]

- Xu, W.; Li, C.; Zhang, Y.; Ali, H.M.; Sharma, S.; Li, R.; Yang, M.; Gao, T.; Liu, M.; Wang, X.; et al. Electrostatic atomization minimum quantity lubrication machining: From mechanism to application. Int. J. Extrem. Manuf. 2022, 4, 042003–042046. [Google Scholar] [CrossRef]

- Huang, S.; Li, Z.; Yao, W.; Hu, J.; Xu, X. Tribological Performance of Charged Vegetable Lubricants. Tribology 2014, 34, 371–378. [Google Scholar] [CrossRef]

- Huang, S.; Wang, Z.; Yao, W.; Xu, X.F. Tribological evaluation of contact-charged electrostatic spray lubrication as a new near-dry machining technique. Tribol Int. 2015, 91, 74–84. [Google Scholar] [CrossRef]

- Quinchia, L.A.; Delgado, M.A.; Reddyhoff, T.; Gallegos, C.; Spikes, H.A. Tribological studies of potential vegetable oil-based lubricants containing environmentally friendly viscosity modifiers. Tribol. Int. 2014, 69, 110–117. [Google Scholar] [CrossRef]

- Reddy, N.S.K.; Yang, M. Development of an electro static lubrication system for drilling of SCM 440 steel. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2010, 224, 217–224. [Google Scholar] [CrossRef]

- Xu, X.F.; Huang, S.; Wang, M.; Yao, W. A study on process parameters in end milling of AISI-304 stainless steel under electrostatic minimum quantity lubrication conditions. Int. J. Adv. Manuf. Technol. 2017, 90, 979–989. [Google Scholar] [CrossRef]

- Lin, J.; Lv, T.; Huang, S.; Hu, X.; Xu, X. Experimental Investigation on Grinding Performance Based on EMQL Technology. CN Mech. Eng. 2018, 29, 2783–2791+2798. [Google Scholar]

- Huang, S.; Yao, W.; Hu, J.; Xu, X. Tribological Performance and Lubrication Mechanism of Contact-Charged Electrostatic Spray Lubrication Technique. Tribol. Lett. 2015, 59, 28–42. [Google Scholar] [CrossRef]

- Huang, S.; Lv, T.; Wang, M.; Xu, X. Effects of Machining and Oil Mist Parameters on Electrostatic Minimum Quantity Lubrication–EMQL Turning Process. Int. J. Precis. Eng. Man. 2018, 5, 317–326. [Google Scholar] [CrossRef]

- Huang, S.; Lv, T.; Wang, M.; Xu, X. Enhanced machining performance and lubrication mechanism of electrostatic minimum quantity lubrication-EMQL milling process. Int. J. Adv. Manuf. Tech. 2017, 94, 655–666. [Google Scholar] [CrossRef]

- Jia, D.; Li, C.; Zhang, Y.; Yang, M.; Cao, H.; Liu, B.; Zhou, Z. Grinding Performance and Surface Morphology Evaluation of Titanium Alloy Using Electric Traction Bio Micro Lubricant. J. Mech. Eng. 2022, 58, 198–211. [Google Scholar] [CrossRef]

- Jia, D.; Li, C.; Zhang, Y.; Zhang, D.; Zhang, X. Experimental research on the influence of the jet parameters of minimum quantity lubrication on the lubricating property of Ni-based alloy grinding. Int. J. Adv. Manuf. Technol. 2016, 82, 617–630. [Google Scholar] [CrossRef]

- Jia, D.; Zhang, Y.; Li, C.; Yang, M.; Gao, T.; Said, Z.; Sharma, S. Lubrication-enhanced mechanisms of titanium alloy grinding using lecithin biolubricant. Tribol. Int. 2022, 169, 107461. [Google Scholar] [CrossRef]

- Wang, X.; Deng, L.; Liu, Y.; Xie, P.; Yang, W. Taylor Cone Formation and Application. Comput. Appl. Chem. 2011, 11, 1387–1392. [Google Scholar]

- Li, Q.; Tan, G.; Ji, X.; Yin, Y. Factors influencing the formation and fracture of Taylor cone. J. Hebei Univ. 2018, 38, 22–27. [Google Scholar]

- Nie, Q.; Chen, H.; Li, S.; Gao, X.; An, Q.; Fang, H. Simulations for Pulsating Breakups of a Nano Taylor Cone. J. Phys. Conf. Ser. 2021, 1995, 012008–012014. [Google Scholar] [CrossRef]

- Zhang, X.; Li, C.; Zhang, Y.; Yang, M.; Jia, D.; Hou, Y.; Zhang, N.; Li, R.; Ji, H. Experimental Study of Effect of Electric Field Parameters on Atomization Characteristics and Grinding Performance of Minimal Quantity Lubrication. Manuf. Technol. Mach. Tool. 2018, 676, 105–111. [Google Scholar] [CrossRef]

- Liu, X.; He, W.; Yang, F.; Xiao, H.; Ma, J. Simulation and Analysis of Electron Transport Parameters in Air Discharge. High Volt. Eng. 2011, 37, 1614–1619. [Google Scholar] [CrossRef]

- Jia, D.; Li, C.; Liu, J.; Zhang, Y.; Yang, M.; Gao, T.; Said, Z.; Sharma, S. Prediction model of volume average diameter and analysis of atomization characteristics in electrostatic atomization minimum quantity lubrication. Friction 2023. [Google Scholar] [CrossRef]

- TIAN, B.; YANG, D.; TANG, J.; LIU, Q. Some problems of the transmission/reflection method for measuring complex permittivity of materials. CN J. Rad. Sci. 2002, 17, 10–15. [Google Scholar]

- Wang, L.; Dang, Z. Carbon Nanotube Filled Polymer-Based Dielectric Composites With High Dielectric Constant. Trans. CN. Elect. Soc. 2006, 21, 24–28. [Google Scholar]

- Jiang, Y.; Ding, X.M.; Yu, S.P.; Gao, H.Y. Density-independent microwave measurement of material moisture content. J. HIT 2007, 39, 1829–1832. [Google Scholar]

- Wang, Z.; Tian, Y.; Zhang, C.; Wang, Y.; Deng, W. Massively Multiplexed Electrohydrodynamic Tip Streaming from a Thin Disc. Phys. Rev. Lett. 2021, 126, 064502. [Google Scholar] [CrossRef] [PubMed]

- Marmottant, P.; Villermaux, E. On spray formation. J. Fluid Mech. 2004, 498, 73–111. [Google Scholar] [CrossRef]

- Varga, C.M.; Lasheras, J.C.; Hopfinger, E.J. Initial breakup of a small-diameter liquid jet by a high-speed gas stream. J. Fluid Mech. 2003, 497, 405–434. [Google Scholar] [CrossRef]

- Bian, W.; Chen, X.; Wang, J. A critical comparison of two-fluid model, discrete particle method and direct numerical simulation for modeling dense gas-solid flow of rough spheres. Chem. Eng. Sci. 2019, 210, 115233. [Google Scholar] [CrossRef]

- Pilch, M.; Erdman, C.A. Use of breakup time data and velocity history data to predict the maximum size of stable fragments for acceleration-induced breakup of a liquid drop. Int. J. Multiph. Flow 1987, 13, 741–757. [Google Scholar] [CrossRef]

- Jia, D.Z.; Li, C.H.; Zhang, Y.B.; Yang, M.; Wang, Y.G. Current status and outlook of cooling lubrication for grinding process. Mech. Eng. Auto. 2017, 202, 201–202+205. [Google Scholar]

- Singh, Y.; Sharma, A.; Singh, N.; Singla, A.; Rastogi, P.M. Prospects of inedible plant oil-driven bio-lubricants for tribological characteristics—A review. Int. J. Ambient Energy 2018, 41, 1534–1547. [Google Scholar] [CrossRef]

- Alves, S.M.; Barros, B.S.; Trajano, M.F.; Ribeiro, K.S.B.; Moura, E. Tribological behavior of vegetable oil-based lubricants with nanoparticles of oxides in boundary lubrication conditions. Tribol. Int. 2013, 65, 28–36. [Google Scholar] [CrossRef]

- Xie, Q.H.; Wu, S.X.; Liu, G.D.; Zhang, W.F. Application study of nano additives Al2O3 and MoS2 in oil-in-water drop jet cooling. Tool Eng. 2023, 57, 39–45. [Google Scholar]

| No. | Chemical Reaction | Reaction Type | Reaction Rate Constant |

|---|---|---|---|

| 1 | Collisional Ionization | [29] | |

| 2 | Adsorption Reaction | ||

| 3 | Adsorption Reaction | 2.0 × 10−41 (300/Te) | |

| 4 | Compound Reaction | 5 × 10−14 | |

| 5 | Compound Reaction | 5 × 10−12 | |

| 6 | Collisional Ionization | ||

| 7 | Adsorption Reaction | ||

| 8 | Adsorption Reaction | 2.0 × 10−41 (300/Te) | |

| 9 | Compound Reaction | 5 × 10−14 | |

| 10 | Compound Reaction | 5 × 10−14 |

| Nanoparticles | Density (g/cm3) | Relative Dielectric Constant |

|---|---|---|

| SiO2 | 2.2 | 3.9 |

| Fe2O3 | 5.27 | 14.2 |

| Al2O3 | 3.7 | 4.9 |

| CNTs | 1.3 | 205.5 |

| Density (kg/m3) | Surface Tension (N/m) | Relative Dielectric Constant | Power Viscosity (Pa·s) | Electrical Conductivity (mS/cm) |

|---|---|---|---|---|

| 916.8 | 0.032 | 3.5 | 0.061 | 0.54 |

| Atomization Parameters | Numerical Value |

|---|---|

| Liquid Flow (mL/h) | 100 |

| Gas Pressure (MPa) | 0.05–0.4 |

| Needle-plate Electrode Distance (mm) | 50 |

| Distance of Particle Size Measurement Position from Nozzle Outlet (mm) | 20 |

| Voltage Variation Range (kV) | 0–40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, H.; Yang, M. Mechanism and Experimental Study on Electrostatic Atomization Using Needle-Shaped Electrodes. Lubricants 2023, 11, 235. https://doi.org/10.3390/lubricants11060235

Ma H, Yang M. Mechanism and Experimental Study on Electrostatic Atomization Using Needle-Shaped Electrodes. Lubricants. 2023; 11(6):235. https://doi.org/10.3390/lubricants11060235

Chicago/Turabian StyleMa, Hao, and Min Yang. 2023. "Mechanism and Experimental Study on Electrostatic Atomization Using Needle-Shaped Electrodes" Lubricants 11, no. 6: 235. https://doi.org/10.3390/lubricants11060235

APA StyleMa, H., & Yang, M. (2023). Mechanism and Experimental Study on Electrostatic Atomization Using Needle-Shaped Electrodes. Lubricants, 11(6), 235. https://doi.org/10.3390/lubricants11060235