Viscosity and Friction Reduction of Double-End-Capped Polyalkylene Glycol Nanolubricants for Eco-Friendly Refrigerant

Abstract

1. Introduction

2. Materials and Methods

2.1. The Materials Specification

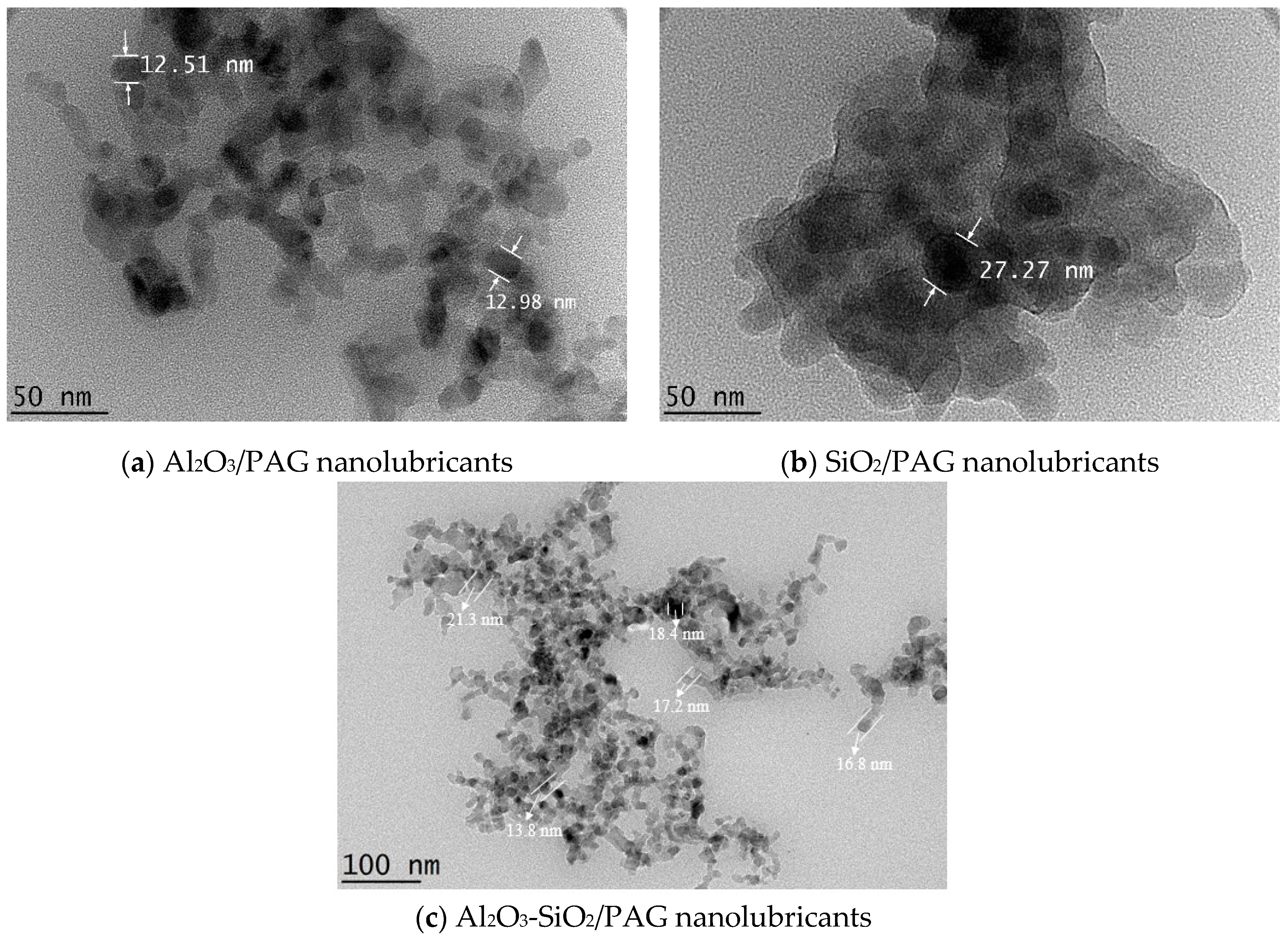

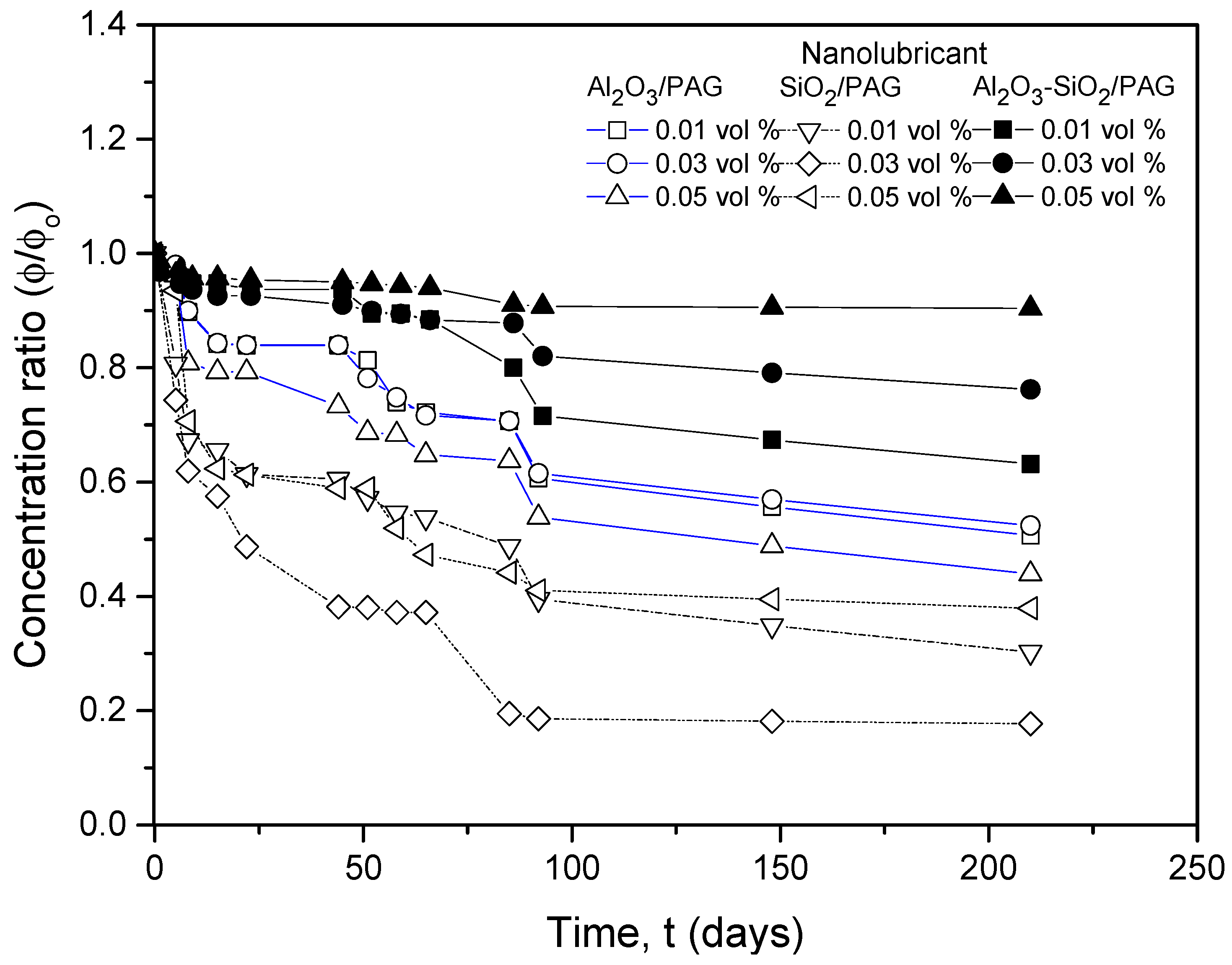

2.2. Nanolubricant Preparation and Stability

2.3. Shear Flow Curve and Viscosity Study

2.4. Tribology Study

2.5. Apparatus Reliability Analysis

3. Results and Discussion

3.1. Stability

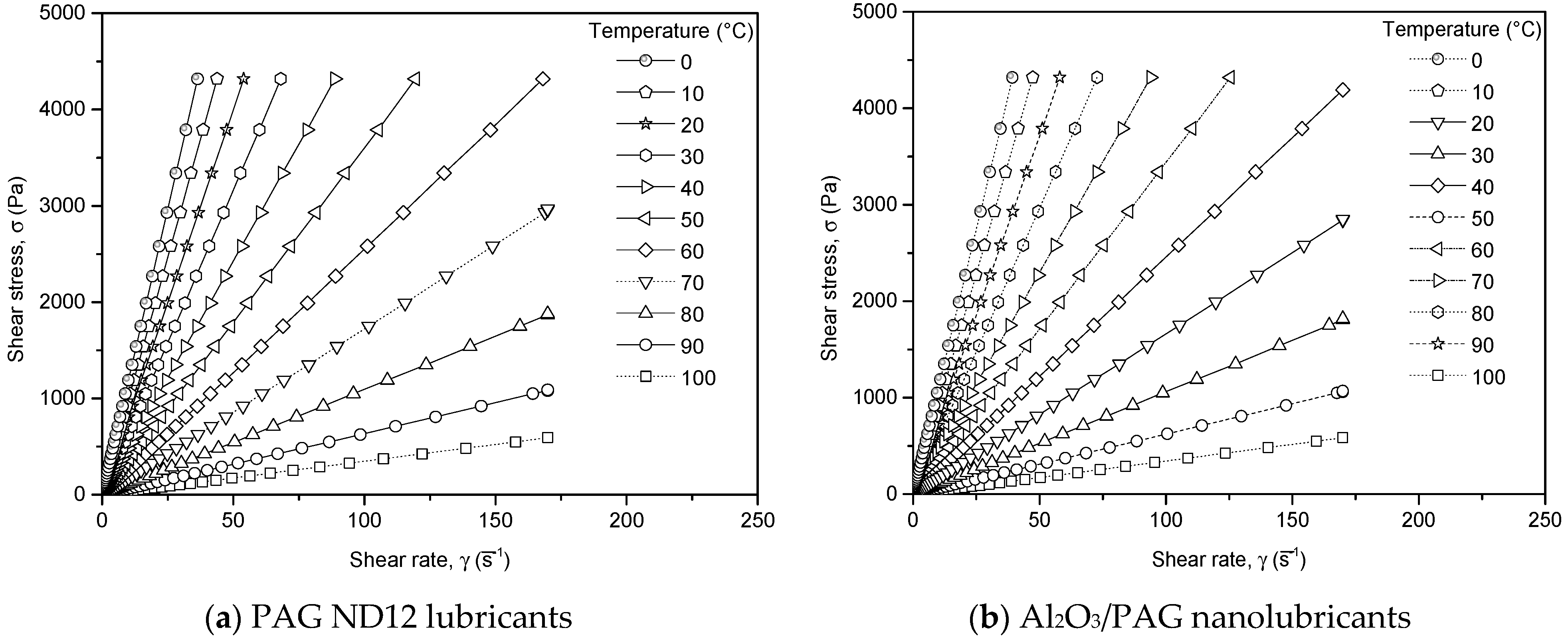

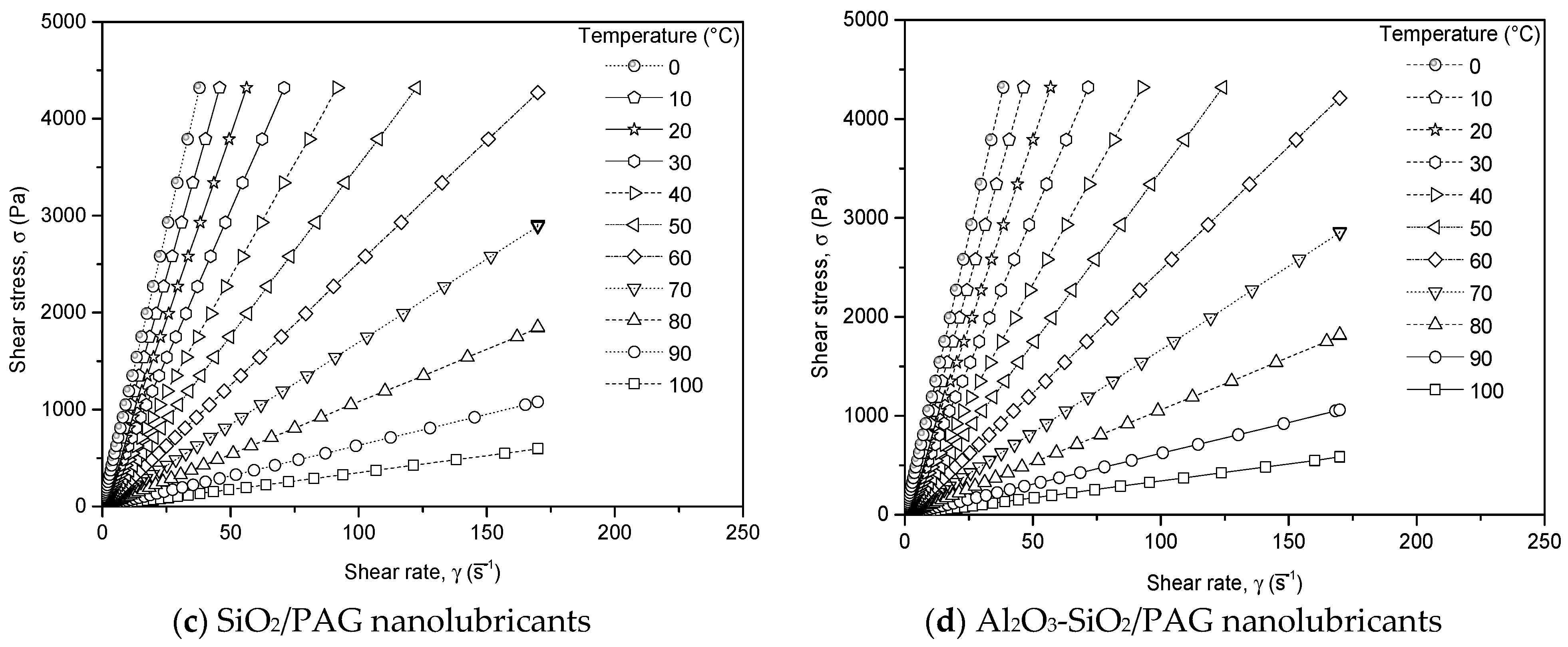

3.2. Shear Curve

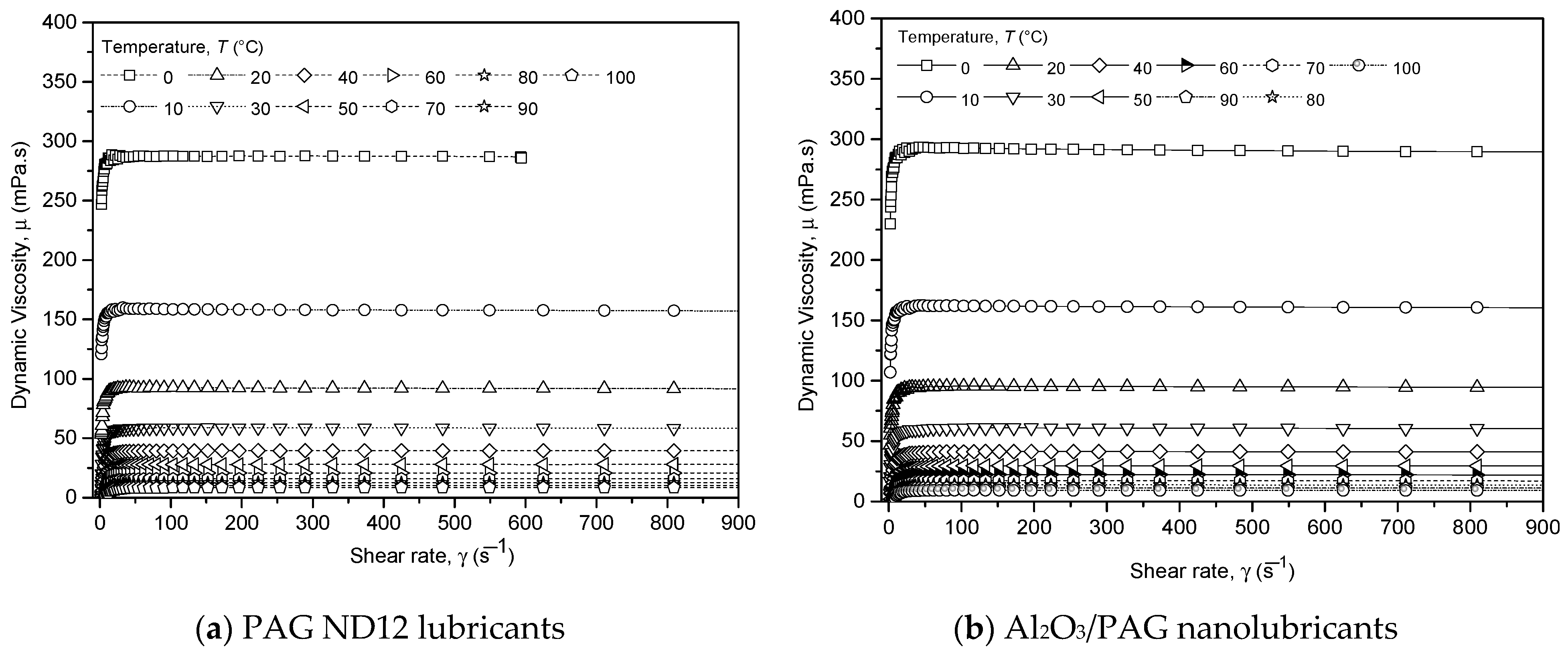

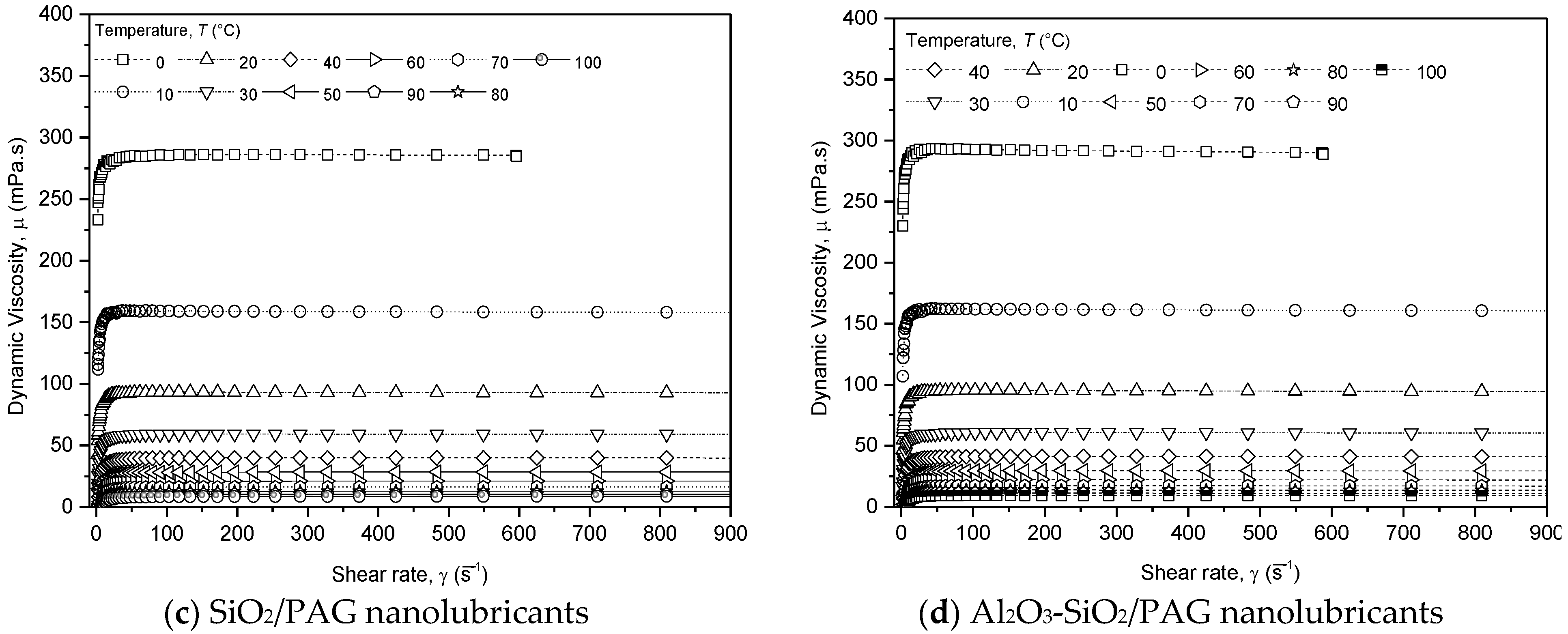

3.3. Dynamic Viscosity Evaluation

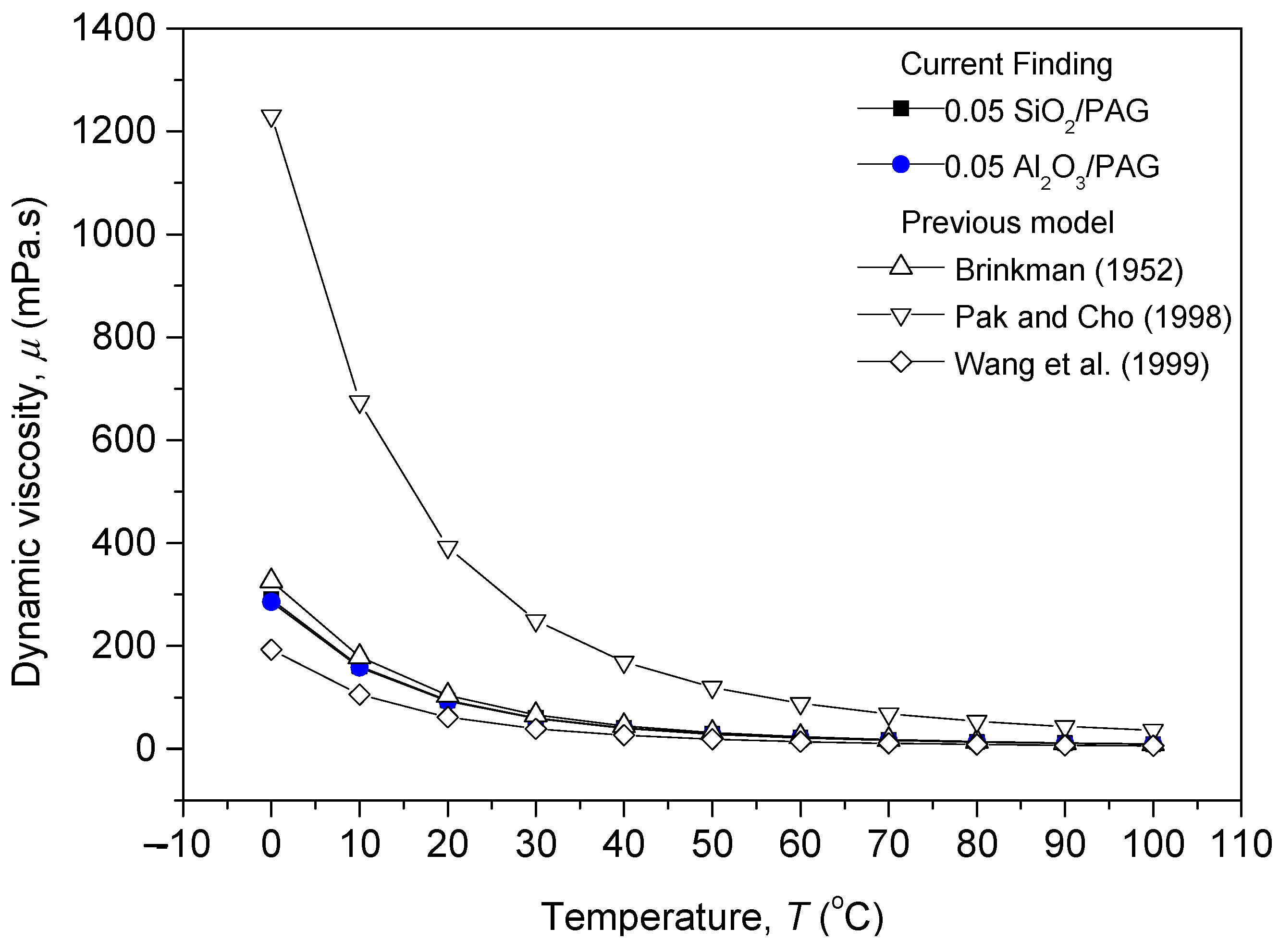

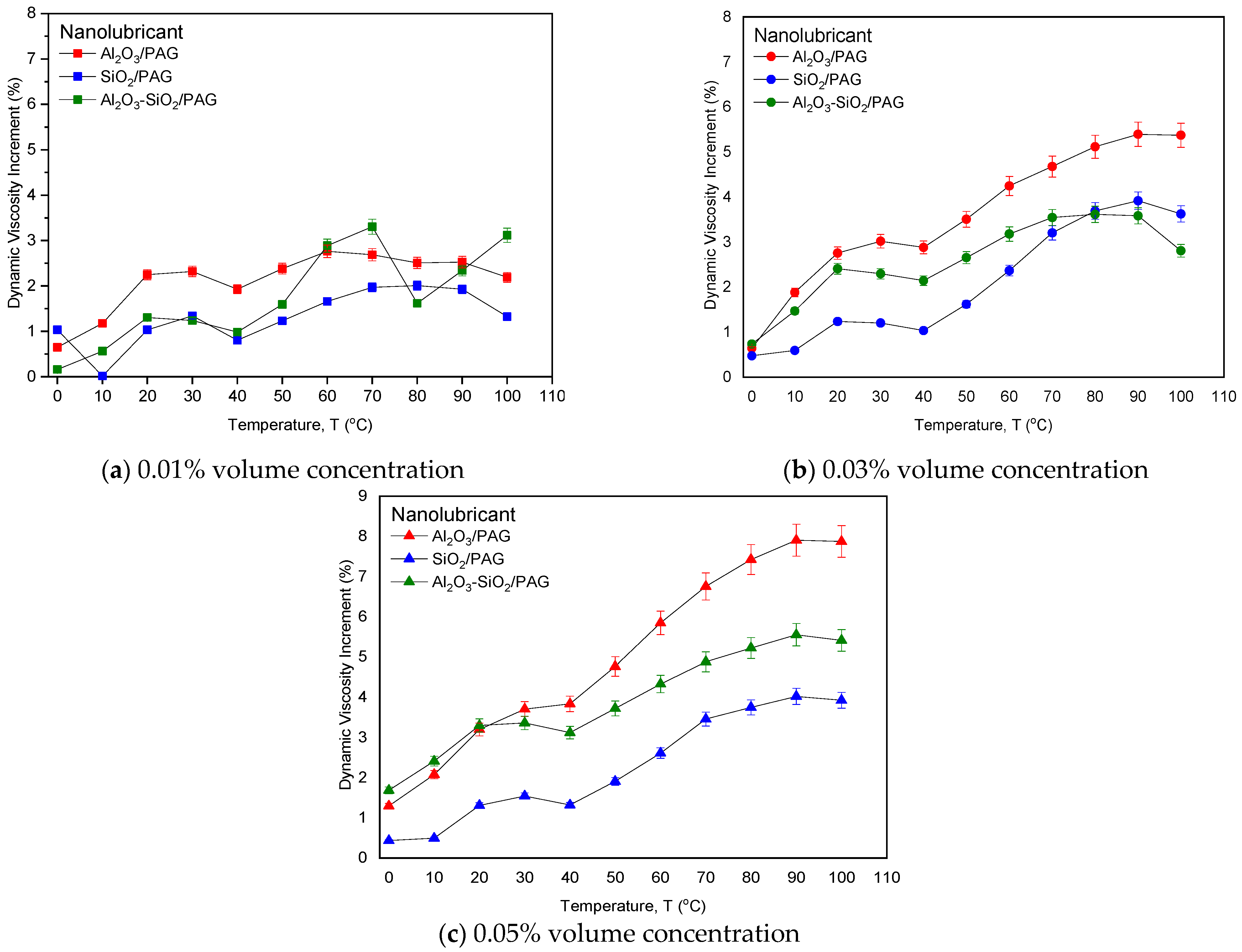

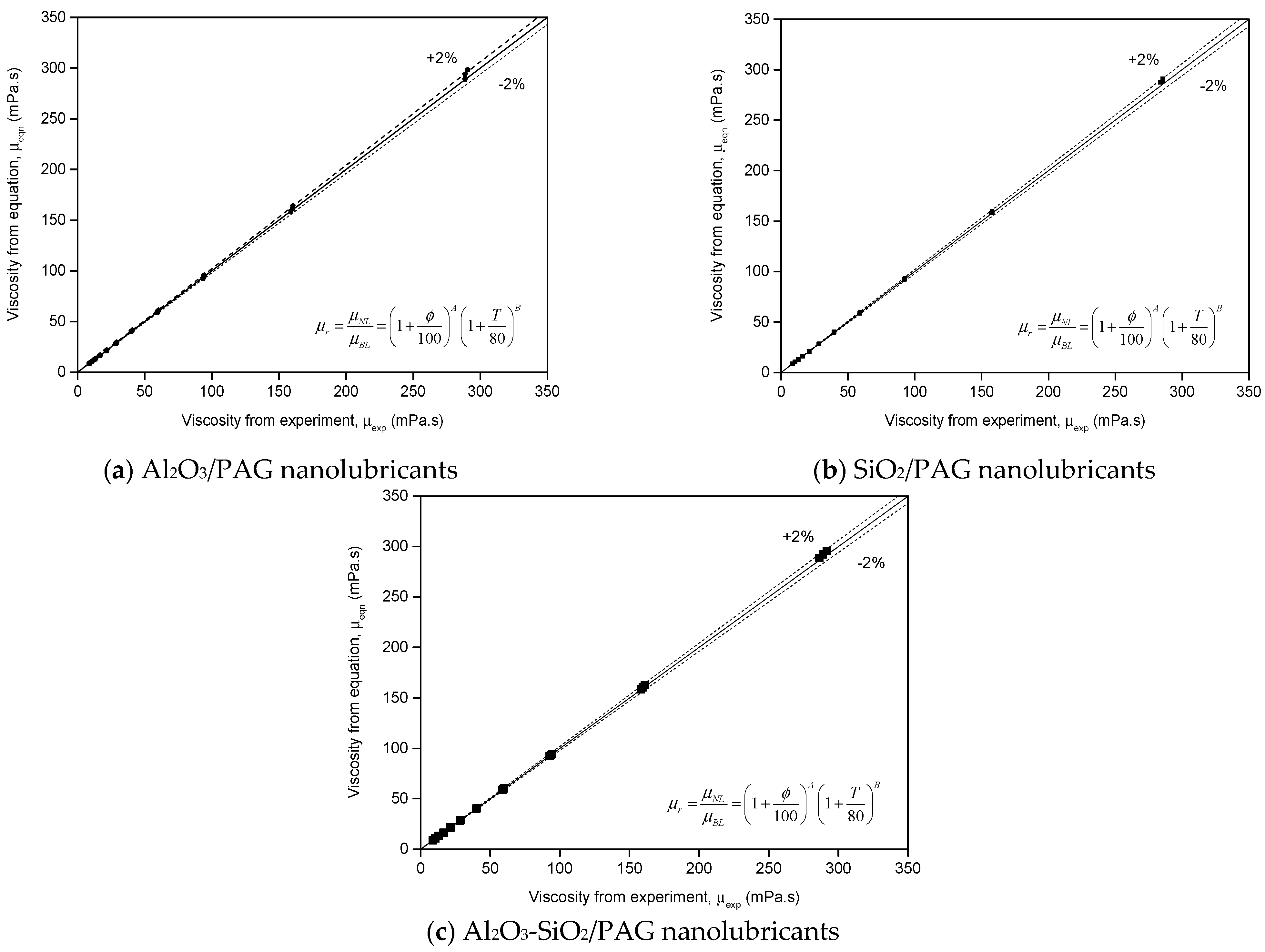

3.4. Viscosity Index Evaluation

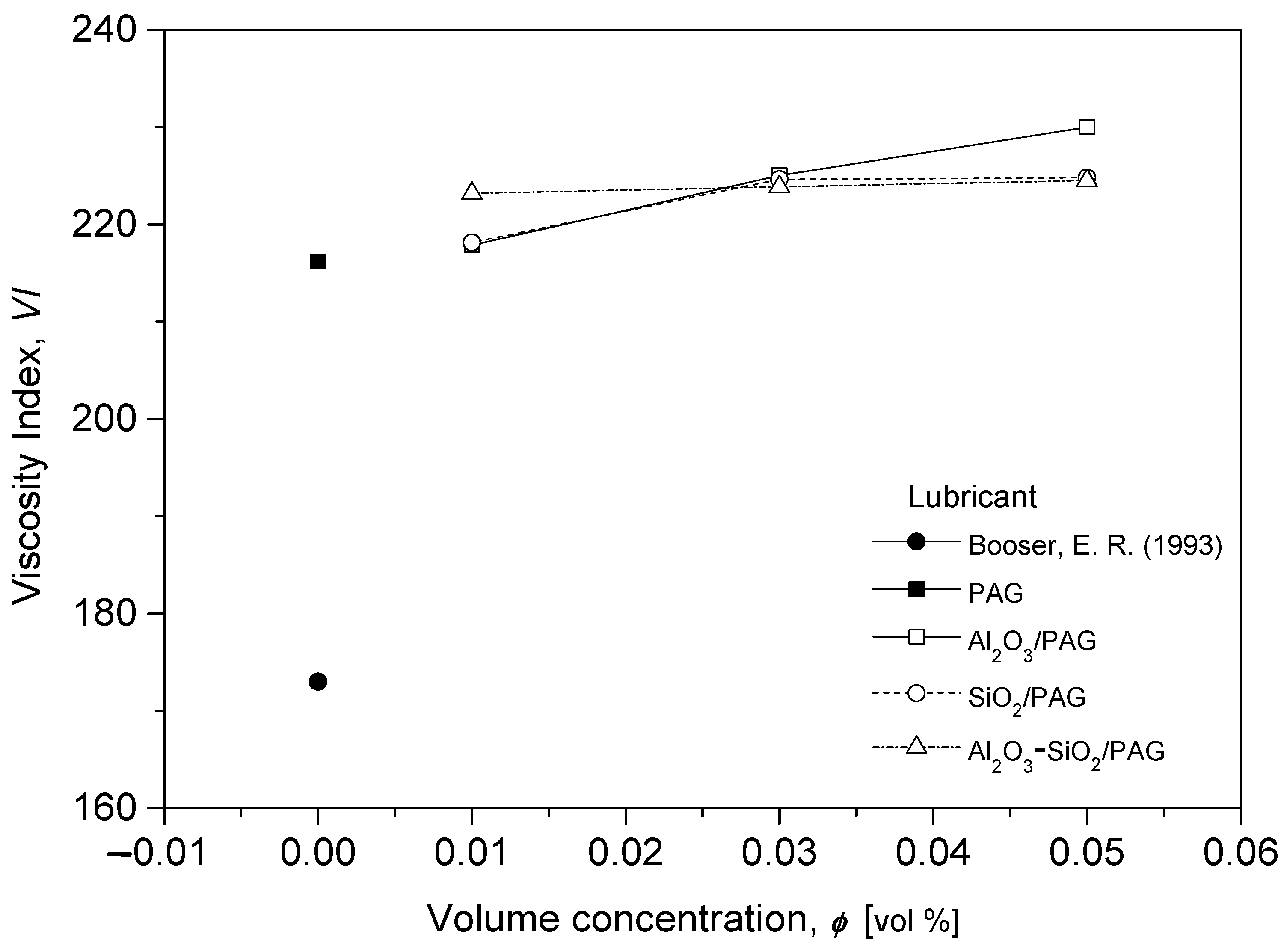

3.5. Coefficient of Friction

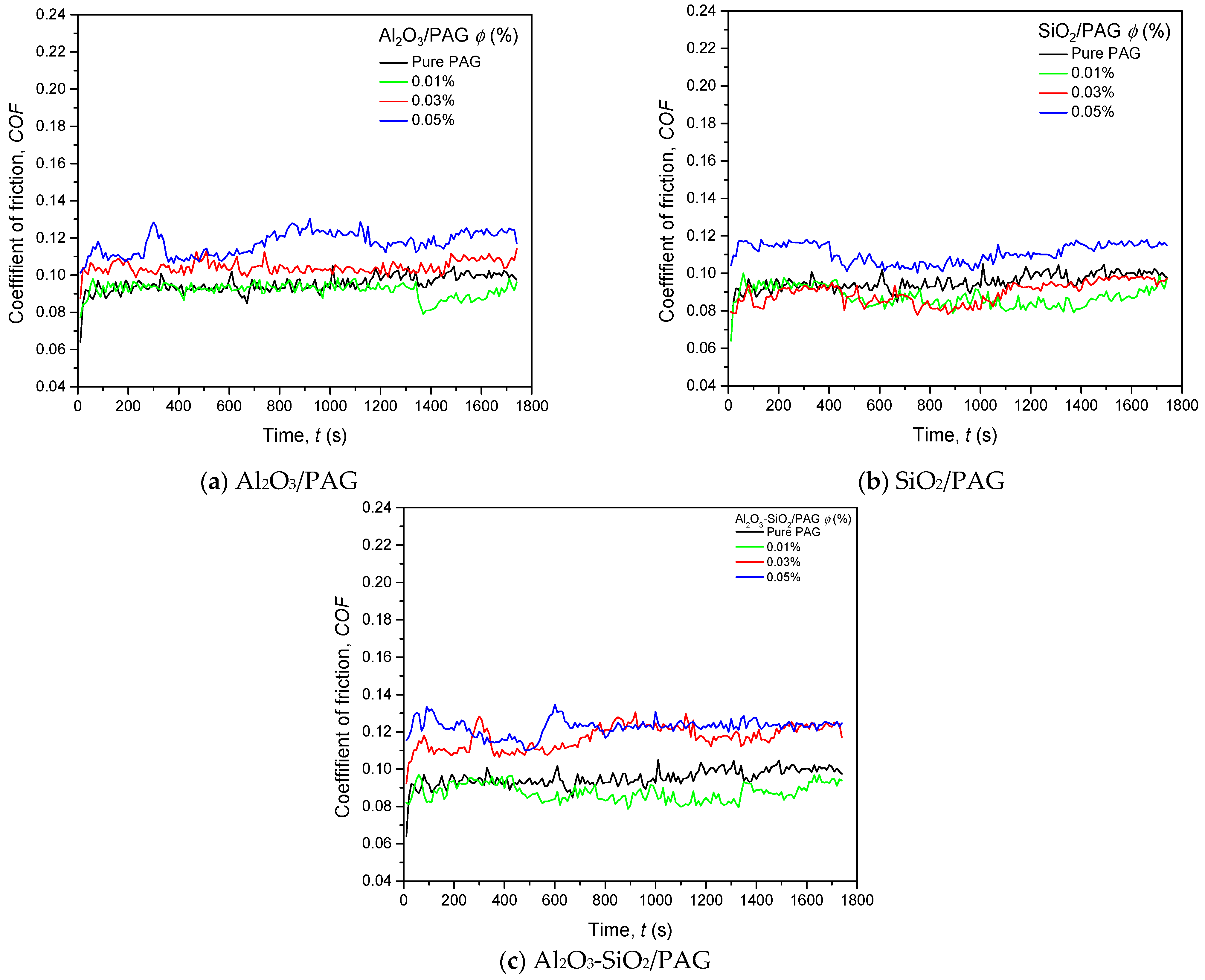

4. Conclusions

- The rheological studies showed that the nanolubricants in the present study retain Newtonian behavior similar to the original lubricants.

- The dynamic viscosity of all nanolubricants increases, although the viscosity increment is minimal. The SiO2/DEC PAG has the lowest increment of velocity (1.88%), followed by Al2O3-SiO2/DEC PAG and Al2O3-SiO2/DEC PAG (2.74% and 3.56%).

- The viscosity index of all nanolubricants was better only at higher concentrations.

- The nanoparticle additives can improve the coefficient of friction of DEC PAG lubricant. However, additional studies need to be conducted to study rheology in depth and factor in the enhancement mechanism in the tribology of the nanolubricant.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Booser, E.R. CRC Handbook of Lubrication and Tribology, Volume III: Monitoring, Materials, Synthetic Lubricants, and Applications; CRC Press: Boca Raton, FL, USA, 1993; Volume 3. [Google Scholar]

- Azmi, W.H.; Sharif, M.Z.; Yusof, T.M.; Mamat, R.; Redhwan, A.A.M. Potential of nanorefrigerant and nanolubricant on energy saving in refrigeration system—A review. Renew. Sustain. Energy Rev. 2017, 69, 415–428. [Google Scholar] [CrossRef]

- Hodnebrog, Ø.; Etminan, M.; Fuglestvedt, J.S.; Marston, G.; Myhre, G.; Nielsen, C.J.; Shine, K.P.; Wallington, T.J. Global warming potentials and radiative efficiencies of halocarbons and related compounds: A comprehensive review. Rev. Geophys. 2013, 51, 300–378. [Google Scholar] [CrossRef]

- Wang, C.C. System performance of R-1234yf refrigerant in air-conditioning and heat pump system—An overview of current status. Appl. Therm. Eng. 2014, 73, 1412–1420. [Google Scholar] [CrossRef]

- Sharif, M.Z.; Azmi, W.H.; Zawawi, N.N.M.; Ghazali, M.F. Comparative air conditioning performance using SiO2 and Al2O3 nanolubricants operating with Hydrofluoroolefin-1234yf refrigerant. Appl. Therm. Eng. 2022, 205, 118053. [Google Scholar] [CrossRef]

- Sharif, M.Z.; Azmi, W.H.; Mamat, R.; Shaiful, A.I.M. Mechanism for improvement in refrigeration system performance by using nanorefrigerants and nanolubricants—A review. Int. Commun. Heat Mass Transf. 2018, 92, 56–63. [Google Scholar] [CrossRef]

- Zawawi, N.N.M.; Azmi, W.H.; Ghazali, M.F. Tribological performance of Al2O3–SiO2/PAG composite nanolubricants for application in air-conditioning compressor. Wear 2022, 492–493, 204238. [Google Scholar] [CrossRef]

- Ma, J.; Shahsavar, A.; Al-Rashed, A.A.A.A.; Karimipour, A.; Yarmand, H.; Rostami, S. Viscosity, cloud point, freezing point and flash point of zinc oxide/SAE50 nanolubricant. J. Mol. Liq. 2020, 298, 112045. [Google Scholar] [CrossRef]

- Haldar, A.; Chatterjee, S.; Kotia, A.; Kumar, N.; Ghosh, S.K. Analysis of rheological properties of MWCNT/SiO2 hydraulic oil nanolubricants using regression and artificial neural network. Int. Commun. Heat Mass Transf. 2020, 116, 104723. [Google Scholar] [CrossRef]

- Kedzierski, M.A.; Brignoli, R.; Quine, K.T.; Brown, J.S. Viscosity, density, and thermal conductivity of aluminum oxide and zinc oxide nanolubricants. Int. J. Refrig. 2017, 74, 3–11. [Google Scholar] [CrossRef] [PubMed]

- Zawawi, N.N.M.; Azmi, W.H.; Sharif, M.Z.; Najafi, G. Experimental investigation on stability and thermo-physical properties of Al2O3–SiO2/PAG nanolubricants with different nanoparticle ratios. J. Therm. Anal. Calorim. 2019, 135, 1243–1255. [Google Scholar] [CrossRef]

- Zawawi, N.N.M.; Azmi, W.H.; Redhwan, A.A.M.; Sharif, M.Z.; Samykano, M. Experimental investigation on thermo-physical properties of metal oxide composite nanolubricants. Int. J. Refrig. 2018, 89, 11–21. [Google Scholar] [CrossRef]

- Aliasgari, M.; Maleki-Jirsaraei, N.; Rouhani, S. The effect of liquid viscosity on sliding friction coefficient of wet granular materials. In Proceedings of the EPJ Web of Conferences, Buenos Aires, Argentina, 6 August 2021; p. 08003. [Google Scholar]

- Fatehallah, H.S.; Hammoudi, Z.S.; Zidane, L.Y. Study the effect of oil viscosity on friction coefficient at point contact elasto-hydrodynamic lubrication based on experimental analysis. Diyala J. Eng. Sci. 2020, 13, 17–21. [Google Scholar] [CrossRef]

- Bhanvase, B.; Barai, D. Nanofluids for Heat and Mass Transfer: Fundamentals, Sustainable Manufacturing and Applications; Academic Press: Cambridge, MA, USA, 2021. [Google Scholar]

- Paul, G.; Hirani, H.; Kuila, T.; Murmu, N. Nanolubricants dispersed with graphene and its derivatives: An assessment and review of the tribological performance. Nanoscale 2019, 11, 3458–3483. [Google Scholar] [CrossRef]

- Gara, L.; Zou, Q. Friction and wear characteristics of water-based ZnO and Al2O3 nanofluids. Tribol. Trans. 2012, 55, 345–350. [Google Scholar] [CrossRef]

- Jeng, Y.-R.; Huang, Y.H.; Tsai, P.C.; Hwang, G.L. Tribological properties of carbon nanocapsule particles as lubricant additive. J. Tribol. 2014, 136, 041801. [Google Scholar] [CrossRef]

- Jeng, Y.R.; Huang, Y.H.; Tsai, P.C.; Hwang, G.L. Tribological performance of oil-based lubricants with carbon-Fe nanocapsules additive. Tribol. Trans. 2015, 58, 924–929. [Google Scholar] [CrossRef]

- Rapoport, L.; Bilik, Y.; Feldman, Y.; Homyonfer, M.; Cohen, S.R.; Tenne, R. Hollow nanoparticles of WS2 as potential solid-state lubricants. Nature 1997, 387, 791–793. [Google Scholar] [CrossRef]

- Karimipour, A.; Malekahmadi, O.; Karimipour, A.; Shahgholi, M.; Li, Z. Thermal conductivity enhancement via synthesis produces a new hybrid mixture composed of copper oxide and multi-walled carbon nanotube dispersed in water: Experimental characterization and artificial neural network modeling. Int. J. Thermophys. 2020, 41, 116. [Google Scholar] [CrossRef]

- Beijing-Deke-Daojin. Nano Silica. Available online: http://dknano.com/Ecplb.asp?Fid=1177&ClassId=1190&NewsId=2993 (accessed on 25 January 2023).

- Sigma-Aldrich. Aluminum Oxide (13 nm) Produced by Sigma Aldrich. Available online: https://www.sigmaaldrich.com/MY/en/product/aldrich/718475 (accessed on 19 December 2022).

- Idemitsu-Kosan. Idemitsu Hermetic Oil 1234yf ND12. Available online: https://www.idemitsulubricants.com/product/idemitsu-hermetic-oil-1234yf (accessed on 5 January 2023).

- Nayerdinzadeh, S.; Babadi Soultanzadeh, M.; Haratian, M.; Zamanimehr, A. Experimental and numerical evaluation of thermal performance of parabolic solar collector using water/Al2O3 nano-fluid: A case study. Int. J. Thermophys. 2020, 41, 1–21. [Google Scholar] [CrossRef]

- Nugroho, A.; Bo, Z.; Mamat, R.; Azmi, W.H.; Najafi, G.; Khoirunnisa, F. Extensive examination of sonication duration impact on stability of Al2O3-Polyol ester nanolubricant. Int. Commun. Heat Mass Transf. 2021, 126, 105418. [Google Scholar] [CrossRef]

- Schulz, E.F.; Wilde, R.H.; Albertson, M.L. Influence of Shape on the Fall Velocity of Sedimentary Particles. Doctoral Dissertation, Colorado State University, Fort Collins, CO, USA, 1954. [Google Scholar]

- Ghadimi, A.; Saidur, R.; Metselaar, H.S.C. A review of nanofluid stability properties and characterization in stationary conditions. Int. J. Heat Mass Transf. 2011, 54, 4051–4068. [Google Scholar] [CrossRef]

- RheolabQC, A.P. Viscometer ISO 17025 Calibration. Available online: https://www.anton-paar.com/my-en/services-support/iso-17025-calibration/ (accessed on 25 January 2023).

- Rao, Y. Nanofluids: Stability, phase diagram, rheology and applications. Particuology 2010, 8, 549–555. [Google Scholar] [CrossRef]

- Asadi, M.; Asadi, A. Dynamic viscosity of MWCNT/ZnO–engine oil hybrid nanofluid: An experimental investigation and new correlation in different temperatures and solid concentrations. Int. Commun. Heat Mass Transf. 2016, 76, 41–45. [Google Scholar] [CrossRef]

- Hamid, K.A.; Azmi, W.H.; Nabil, M.F.; Mamat, R.; Sharma, K.V. Experimental investigation of thermal conductivity and dynamic viscosity on nanoparticle mixture ratios of TiO2-SiO2 nanofluids. Int. J. Heat Mass Transf. 2018, 116, 1143–1152. [Google Scholar] [CrossRef]

- Nugroho, A.; Mamat, R.; Bo, Z.; Azmi, W.H.; Alenezi, R.; Najafi, G. An overview of vapor compression refrigeration system performance enhancement mechanism by utilizing nanolubricants. J. Therm. Anal. Calorim. 2022, 147, 9139–9161. [Google Scholar] [CrossRef]

- Sundar, L.S.; Irurueta, G.O.; Ramana, E.V.; Singh, M.K.; Sousa, A.C.M. Thermal conductivity and viscosity of hybrid nanfluids prepared with magnetic nanodiamond-cobalt oxide (ND-Co3O4) nanocomposite. Case Stud. Therm. Eng. 2016, 7, 66–77. [Google Scholar] [CrossRef]

- Azmi, W.H.; Sharma, K.V.; Mamat, R.; Najafi, G.; Mohamad, M.S. The enhancement of effective thermal conductivity and effective dynamic viscosity of nanofluids—A review. Renew. Sustain. Energy Rev. 2016, 53, 1046–1058. [Google Scholar] [CrossRef]

- Pak, B.C.; Cho, Y.I. Hydrodynamic and heat transfer study of dispersed fluids with submicron metallic oxide particles. Exp. Heat Transf. Int. J. 1998, 11, 151–170. [Google Scholar] [CrossRef]

- Brinkman, H.C. The viscosity of concentrated suspensions and solutions. J. Chem. Phys. 1952, 20, 571. [Google Scholar] [CrossRef]

- Wang, X.; Xu, X.; Choi, S.U.-S. Thermal conductivity of nanoparticle-fluid mixture. J. Thermophys. Heat Transf. 1999, 13, 474–480. [Google Scholar] [CrossRef]

- Sharma, K.V.; Sarma, P.K.; Azmi, W.H.; Mamat, R.; Kadirgama, K. Correlations to predict friction and forced convection heat transfer coefficients of water based nanofluids for turbulent flow in a tube. Int. J. Microscale Nanoscale Therm. Fluid Transp. Phenom. 2012, 3, 1–25. [Google Scholar]

- Hemmat Esfe, M.; Abbasian Arani, A.A.; Esfandeh, S. Improving engine oil lubrication in light-duty vehicles by using of dispersing MWCNT and ZnO nanoparticles in 5W50 as viscosity index improvers (VII). Appl. Therm. Eng. 2018, 143, 493–506. [Google Scholar] [CrossRef]

- Man, W.; Huang, Y.; Gou, H.; Li, Y.; Zhao, J.; Shi, Y. Synthesis of novel CuO@Graphene nanocomposites for lubrication application via a convenient and economical method. Wear 2022, 498–499, 204323. [Google Scholar] [CrossRef]

| Properties | Al2O3 | SiO2 |

|---|---|---|

| Color | White | White |

| Purity (%) | 99.9 | 99.9 |

| Density (g/cm3) | 4 | 2.22 |

| Structure | Spherical | Spherical |

| Average size (nm) | 13 | 30 |

| Molecular mass, g·mol−1 | 101.96 | 60.08 |

| Specific heat, J·(kg·K)−1 | 773 | 745 |

| Thermal conductivity, W·(m·K)−1 | 36 | 1.4 |

| n | Properties | Value |

|---|---|---|

| 1 | ISO viscosity grade | 46 |

| 2 | Dynamic viscosity at 40 °C (mPa·s) | 40.13 |

| 3 | Dynamic viscosity at 100 °C (mPa·s) | 8.25 |

| 4 | Viscosity index | 216 |

| 5 | Density at 15 °C (g/cm3) | 0.988 |

| 6 | Flash point (°C) | −45 |

| Standard | Test Conditions | |||

|---|---|---|---|---|

| Speed (rpm) | Standard | Speed (rpm) | Standard | |

| ASTM D4172 Wear characteristic Test | 1200 ± 60 | 40.0 ± 0.2 | 60 ± 1 | 75 ± 2 |

| Parameters | Range of Instrument | Values Measured | Lease Division in Instrument | Fractional Uncertainty (%) | ||

|---|---|---|---|---|---|---|

| Min | Max | Min | Max | |||

| Nanoparticle weight [g] | 0 to 200 | 0.005 | 0.1001 | ±0.0001 | 0.1 | 2 |

| Lubricant volume [mL] | 1 to 50 | 100 | 100 | ±1 | 2 | 2 |

| Volume concentration [%] | - | 0.01 | 0.05 | - | 1.41 | 1.68 |

| Zeta potential [mV] | 0 to 1000 | 80.4 | 140 | ±0.1 | 0.07 | 0.12 |

| Absorbance (UV-vis) | 0 to 3 | 0.011 | 3 | ±0.001 | 0.03 | 9.1 |

| Shear rate, ε [s−1] | 0.01 to 4000 | 2.15 | 1070 | ±0.01 | ≈0 | 0.47 |

| Temperature (°C) | Al2O3/PAG | SiO2/PAG | Al2O3-SiO2/PAG | Al2O3/PAG | SiO2/PAG | Al2O3-SiO2/PAG | Al2O3/PAG | SiO2/PAG | Al2O3-SiO2/PAG |

|---|---|---|---|---|---|---|---|---|---|

| Vol (%) | |||||||||

| 0.01 | 0.03 | 0.05 | |||||||

| 0 | 286.37 | 283.86 | 286.37 | 288.67 | 285.47 | 288.94 | 290.54 | 285.58 | 291.66 |

| 10 | 158.06 | 157.14 | 158.06 | 160.13 | 158.10 | 159.48 | 160.43 | 157.95 | 160.96 |

| 20 | 92.58 | 92.33 | 92.58 | 93.90 | 92.51 | 93.59 | 94.31 | 92.58 | 94.40 |

| 30 | 58.81 | 58.87 | 58.81 | 59.84 | 58.79 | 59.42 | 60.24 | 58.99 | 60.04 |

| 40 | 39.70 | 39.63 | 39.70 | 40.45 | 39.72 | 40.16 | 40.83 | 39.84 | 40.54 |

| 50 | 28.31 | 28.21 | 28.31 | 28.84 | 28.32 | 28.61 | 29.20 | 28.40 | 28.91 |

| 60 | 21.22 | 20.97 | 21.22 | 21.50 | 21.11 | 21.28 | 21.83 | 21.16 | 21.52 |

| 70 | 16.35 | 16.14 | 16.35 | 16.57 | 16.33 | 16.39 | 16.90 | 16.38 | 16.60 |

| 80 | 12.73 | 12.78 | 12.73 | 13.17 | 12.99 | 12.98 | 13.46 | 13.00 | 13.18 |

| 90 | 10.40 | 10.36 | 10.40 | 10.71 | 10.56 | 10.53 | 10.97 | 10.57 | 10.73 |

| 100 | 8.70 | 8.55 | 8.70 | 8.89 | 8.74 | 8.67 | 9.10 | 8.77 | 8.89 |

| Nanolubricants | A | B | Average Deviation (%) | Standard Deviation (%) |

|---|---|---|---|---|

| Al2O3 | 77.00 | 0.0250 | 0.89 | 0.67 |

| SiO2 | 28.25 | 0.0200 | 0.73 | 0.49 |

| Al2O3-SiO2/PAG | 61.07 | 0.0175 | 0.61 | 0.44 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sharif, M.Z.; Azmi, W.H.; Ghazali, M.F.; Zawawi, N.N.M.; Ali, H.M. Viscosity and Friction Reduction of Double-End-Capped Polyalkylene Glycol Nanolubricants for Eco-Friendly Refrigerant. Lubricants 2023, 11, 129. https://doi.org/10.3390/lubricants11030129

Sharif MZ, Azmi WH, Ghazali MF, Zawawi NNM, Ali HM. Viscosity and Friction Reduction of Double-End-Capped Polyalkylene Glycol Nanolubricants for Eco-Friendly Refrigerant. Lubricants. 2023; 11(3):129. https://doi.org/10.3390/lubricants11030129

Chicago/Turabian StyleSharif, Mohd Zaki, Wan Hamzah Azmi, Mohd Fairusham Ghazali, Nurul Nadia Mohd Zawawi, and Hafiz Muhammad Ali. 2023. "Viscosity and Friction Reduction of Double-End-Capped Polyalkylene Glycol Nanolubricants for Eco-Friendly Refrigerant" Lubricants 11, no. 3: 129. https://doi.org/10.3390/lubricants11030129

APA StyleSharif, M. Z., Azmi, W. H., Ghazali, M. F., Zawawi, N. N. M., & Ali, H. M. (2023). Viscosity and Friction Reduction of Double-End-Capped Polyalkylene Glycol Nanolubricants for Eco-Friendly Refrigerant. Lubricants, 11(3), 129. https://doi.org/10.3390/lubricants11030129