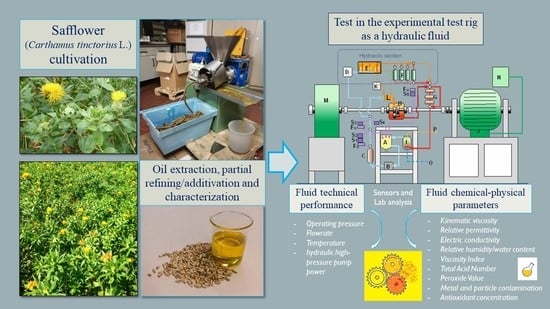

Technical Performance and Chemical–Physical Property Assessment of Safflower Oil Tested in an Experimental Hydraulic Test Rig

Abstract

1. Introduction

2. Materials and Methods

2.1. Safflower Cultivation and Oil Extraction

2.2. Oil Chemical Treatment and Additivation Studies

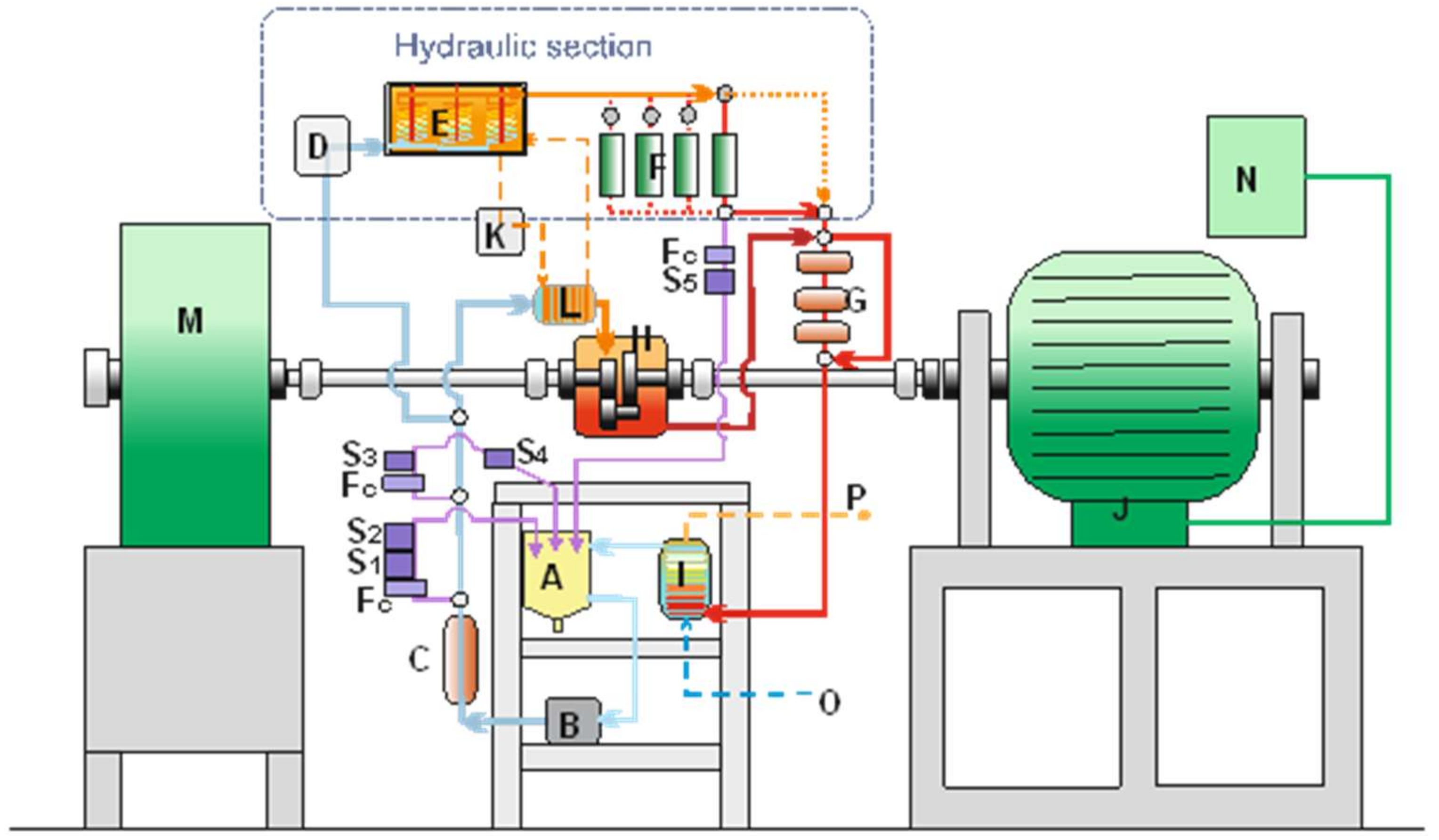

2.3. Experimental Fluid Test Rig

2.4. FTR Sensors and Fluid Chemical–Physical Parameter Acquisition

- Dynamic viscosity, VD (mPa s−1), and density, D (g cm−3), were determined by sensor S1 and S5.

- Kinematic viscosity, KVs (cSt or mm2 s−1), was provided by the ratio of VD to D. KVs was directly compared to the reference laboratory KV values measured by the viscometer according to ASTM D445-06 [29] at the reference temperatures of 40 °C (KV40) and 100 °C (KV100).

- Electric conductivity, EC (pSi m−1), was detected by sensor S3 and (for PR) was also compared to the PV and TAN determined in the laboratory.

- Relative humidity, RH (%), describes the amount of water in the fluid as a percentage of the maximum soluble amount and is a value that increases with fluid temperature. This was detected by sensor S3. In parallel, the fluid’s water content was measured in the laboratory (Karl Fisher method) by using a Karl Fischer automatic titrimeter (Metrohm, Herisau, Switzerland) according to the ISO 8534:2017 standard [32], which thus provided the absolute concentration in mg kg−1 (KF).

- Ferromagnetic particles, FMP, which could indicate the presence of wear processes, were detected by sensor S4 and their intensity is described by their amount and dimensions. S4 featured a magnetic head capable of attracting any ferromagnetic particles suspended in the fluid, with the captured particles classified as fine particles, coarse particles, or chunks. The amount of fine and coarse particles is expressed as a percentage of the occupancy rate (maximum total amount attractable by the magnetic head), while for the chunks their number is provided. When 100% of the occupancy rate was reached, the magnetic head automatically discharged, releasing the material. The detection then restarted. The trend in occupancy rate during the test was compared to that of the Fe concentration observed in fluid samples.

- Particle contamination was monitored by sensor S2. The level of contamination depends on the number of particles per fluid volume unit within certain dimensional classes, which is counted by the mean of automatic laser counters. The contamination is then expressed as “class of contamination”, which is described by numbers (codes) according to international standards such as NAS 1638 [33] and ISO 4406:2021 [34]. In this study, the latter was considered, whose classification is based on three dimensional classes: < 4 μm, < 6 μm, < 14 μm. The relative codes vary from 1 to 22 depending on the number (n) of particles per ml of oil detected in each class. Therefore, oil status is described by three numbers. Despite the ISO 4406 codes ranging from 1 to 22, the range between 7 and 22 is the most frequently considered in practical applications.

2.5. Oil and FTR Fluid Laboratory Chemical–Physical Characterization

2.6. Statistical Analysis

3. Results and Discussion

3.1. Safflower Seed Production, Oil Extraction, Characterization, and Partial Refining

3.2. Antioxidant Additivation

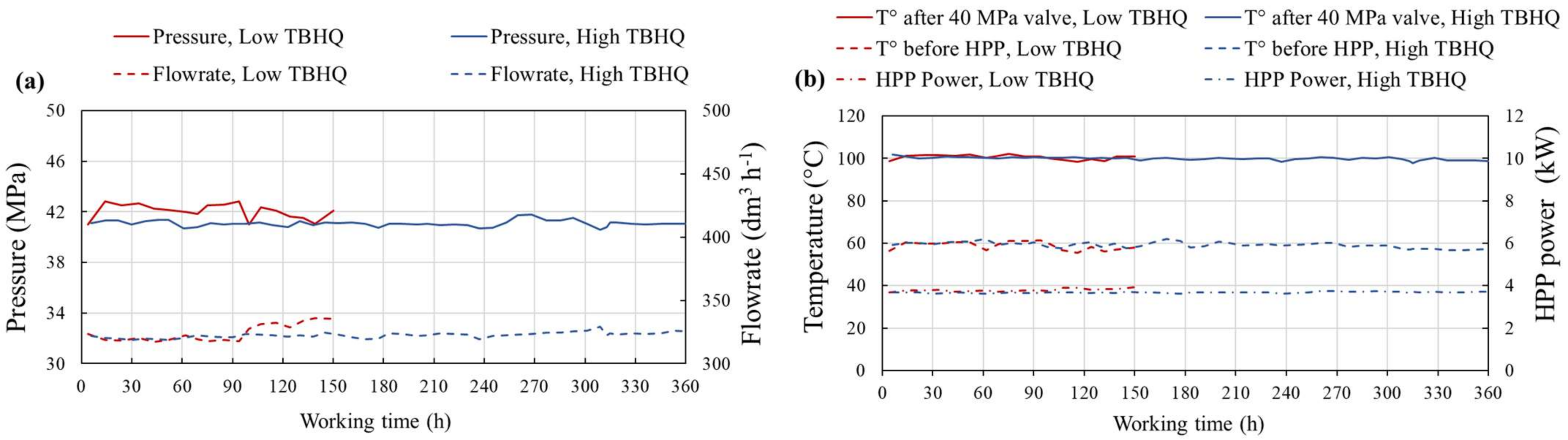

3.3. Safflower Oil Efficiency Tests

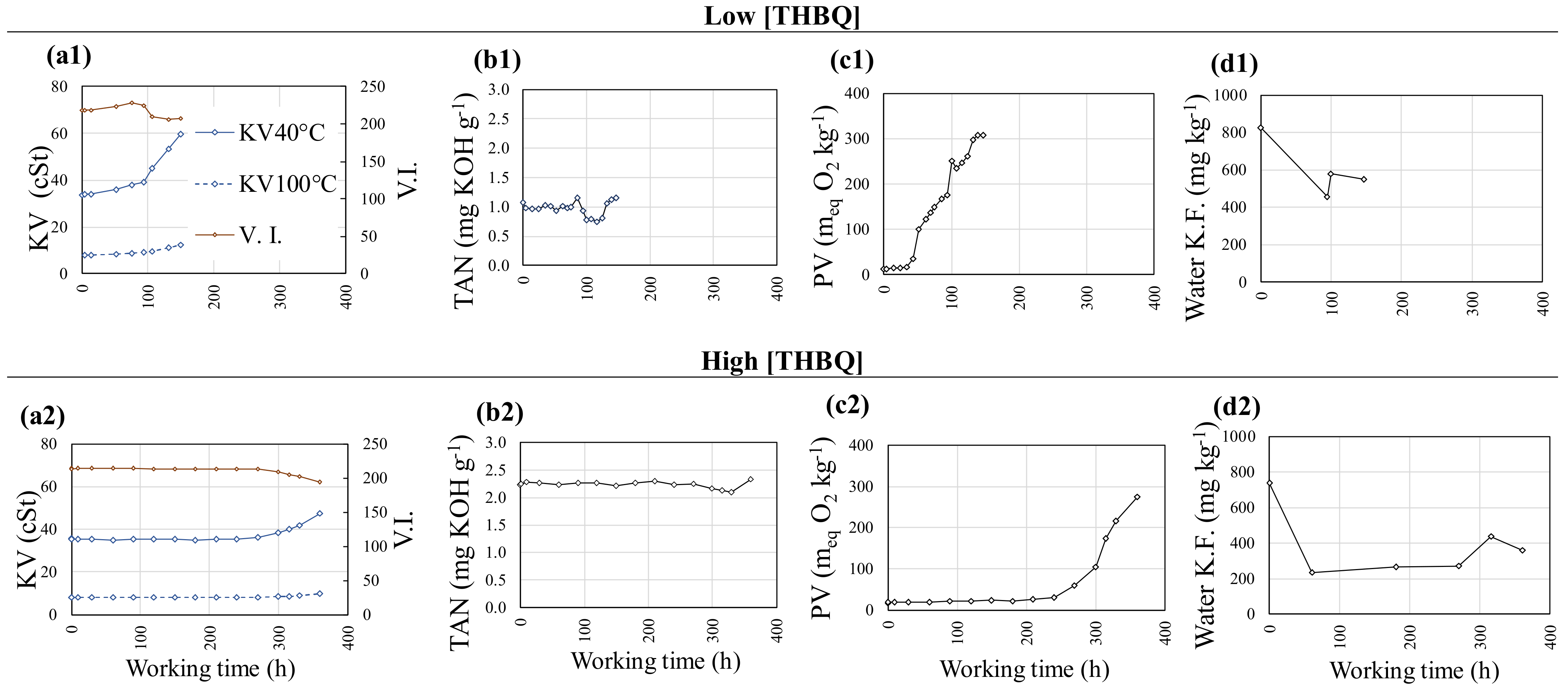

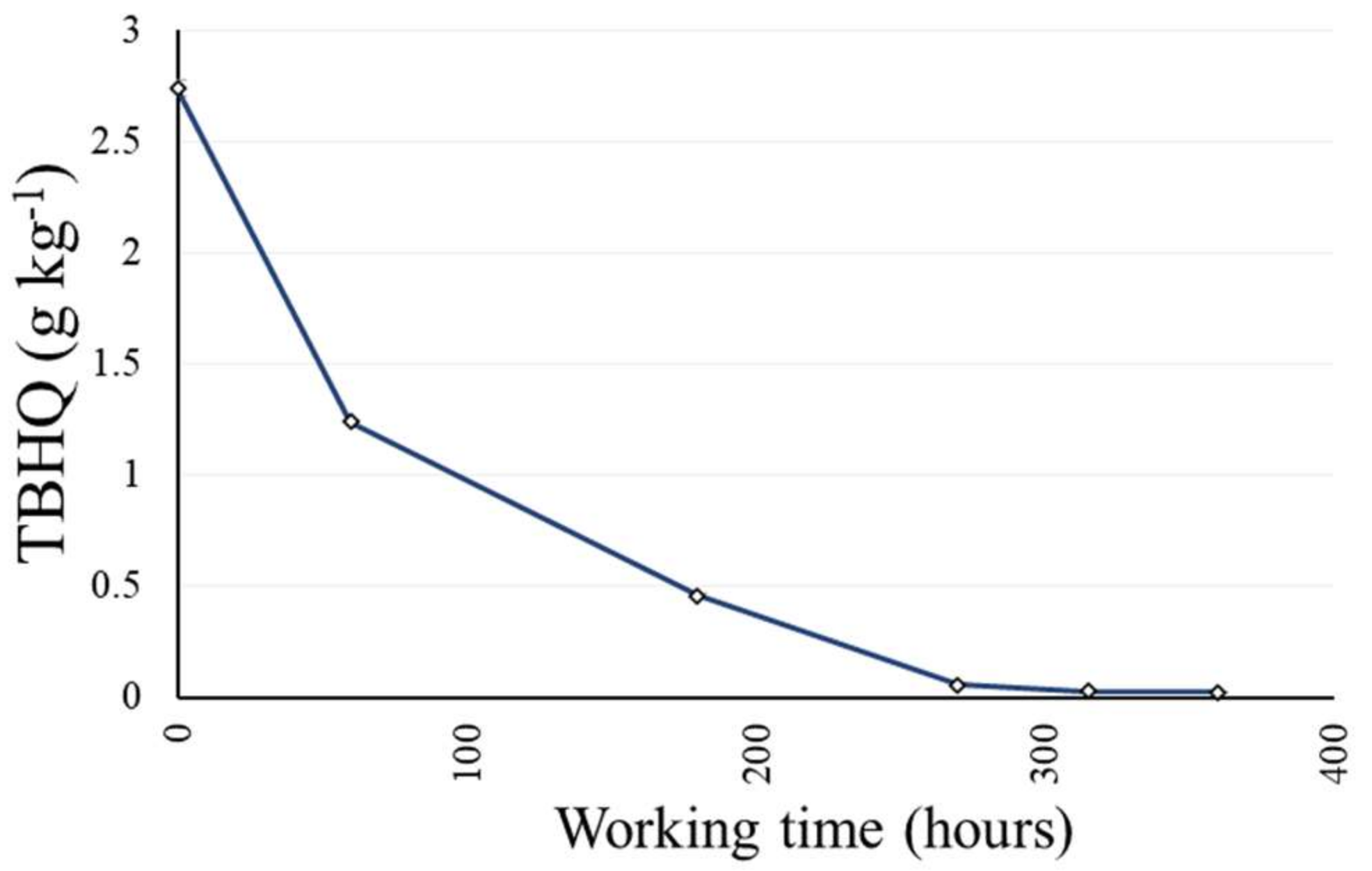

3.4. THBQ Endurance in FTR-Sampled Fluids

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Global Demand for Lubricants from 2000 to 2020, with a Forecast for 2023 and 2028. Available online: https://www.statista.com/statistics/411616/lubricants-demand-worldwide/ (accessed on 5 January 2023).

- Mendoza, G.; Igartua, A.; Fernandez-Diaz, B.; Urquiola, F.; Vivanco, S.; Arguizoniz, R. Vegetable oils as hydraulic fluids for agricultural applications. Grasas Aceites 2011, 62, 29–38. [Google Scholar] [CrossRef]

- Ohifuemen, A.; Fagbemi, E.A.; Fasina, K.A. Bio-lubricants: A renewable alternative to mineral oils. Int. J. Agric. Environ. Bioresearch 2020, 05, 22–32. [Google Scholar] [CrossRef]

- Fanigliulo, R.; Bondioli, P.; Fornaciari, L.; Folegatti, L.; Grilli, R.; Benigni, S.; Calderari, I.; Pochi, D. Bench Test of a Hydraulic Biofluid Based on Refined Pomace Oil. Eur. J. Lipid Sci. Technol. 2021, 123, 2100116. [Google Scholar] [CrossRef]

- Fanigliulo, R.; Pochi, D.; Bondioli, P.; Grilli, R.; Fornaciari, L.; Folegatti, L.; Malaguti, L.; Matteo, R.; Ugolini, L.; Lazzeri, L. Semi-refined Crambe abyssinica (Hochst. EX R.E.Fr.) oil as a biobased hydraulic fluid for agricultural applications. Biomass Convers. Biorefin. 2021. [Google Scholar] [CrossRef]

- Jabal, M.; Abdulmunem, A.; Abd, H. As a potential hydraulic fluid: Corn oil behavior characteristics examinationION. J. Therm. Eng. 2021, 7, 215–221. [Google Scholar] [CrossRef]

- Olszak, A.; Osowski, K.; Musiałek, I.; Rogoś, E.; Kęsy, A.; Kęsy, Z. Application of Plant Oils as Ecologically Friendly Hydraulic Fluids. Appl. Sci. 2020, 10, 9086. [Google Scholar] [CrossRef]

- Hilal, A.H.; Merzah, A.S.; Khadom, A.A.; Abdul-Mtaleb, M.R.; Ali, S.K. Experimental, statistical, and numerical investigations for influence of using vegetable oil with mineral oil to enhance the flow characteristics through a closed hydraulic circuit. Results Eng. 2022, 15, 100608. [Google Scholar] [CrossRef]

- Woma, T.Y.; Lawal, S.A.; Abdulrahman, A.S.; Olutoye, M.A.; Ojapah, M.M. Vegetable oil based lubricants: Challenges and prospects. Tribol. Online 2019, 14, 60–70. [Google Scholar] [CrossRef]

- Beyyavas, V.; Haliloglu, H.; Copur, O.; Yilmaz, A. Determination of seed yield and yield components of some safflower (Carthamus tinctorius L.) cultivars, lines and populations under the semi-arid conditions. Afr. J. Biotechnol. 2011, 10, 527–534. [Google Scholar]

- El-Lattief, E.A.A. Evaluation of 25 safflower genotypes for seed and oil yields under arid environment in upper Egypt. Asian J. Crop Sci. 2012, 4, 72–79. [Google Scholar] [CrossRef]

- Emongor, V.E.; Emongor, R.A. Safflower (Carthamus tinctorius L.)-Future Smart Food. In Neglected and Underutilized Crops; Muhammad, F., Kadambot, S., Eds.; Nikki P. Levy: London, UK, 2022; pp. 683–731. ISBN 978-0-323-90537-4. [Google Scholar]

- Corleto, A.; Alba, E.; Polignano, G.B.; Vonghio, G. A multipurpose species with unexploited potential and world adaptability. In Proceedings of the 4th International Safflower Conference; Corleto, A., Mündel, H.-H., Eds.; Adriatica Editrice: Bari, Italy, 1997; p. 373. [Google Scholar]

- Ekin, Z. Resurgence of safflower (Carthamus tinctorius L.) utilization: A global view. J. Agron. 2005, 4, 83–87. [Google Scholar] [CrossRef]

- Carvalho, I.S.; Miranda, I.; Pereira, H. Evaluation of oil composition of some crops suitable for human nutrition. Ind. Crops Prod. 2006, 24, 75–78. [Google Scholar] [CrossRef]

- Dajue, L.; Mündel, H. Safflower Carthamus tinctorius L. Promoting the Conservation and Use of Underutilized and Neglected Crops; IPGRI; IPK: Rome, Italy, 1996; ISBN 9290432977. [Google Scholar]

- Emongor, V. Safflower (Carthamus tinctorius L.) the underutilized and neglected crop: A review. Asian J. Plant Sci. 2010, 9, 299–306. [Google Scholar] [CrossRef]

- Steberl, K.; Hartung, J.; Munz, S.; Graeff-Hönninger, S. Effect of row spacing, sowing density, and harvest time on floret yield and yield components of two safflower cultivars grown in southwestern Germany. Agronomy 2020, 10, 664. [Google Scholar] [CrossRef]

- La Bella, S.; Tuttolomondo, T.; Lazzeri, L.; Matteo, R.; Leto, C.; Licata, M. An agronomic evaluation of new safflower (Carthamus tinctorius L.) germplasm for seed and oil yields under mediterranean climate conditions. Agronomy 2019, 9, 468. [Google Scholar] [CrossRef]

- Zanetti, F.; Angelini, L.G.; Berzuini, S.; Foschi, L.; Clemente, C.; Ferioli, F.; Vecchi, A.; Rossi, A.; Monti, A.; Tavarini, S. Safflower (Carthamus tinctorius L.) a winter multipurpose oilseed crop for the Mediterranean region: Lesson learnt from on-farm trials. Ind. Crops Prod. 2022, 184, 115042. [Google Scholar] [CrossRef]

- Shyurova, N.; Dubrovin, V.; Narushev, V.; Kozhevnikov, A.; Milovanov, I. Biofuel as an Alternative Energy Source for the Automobile Industry: The Experience of the Lower Volga Region (Russia). J. Ecol. Eng. 2020, 21, 29–35. [Google Scholar] [CrossRef]

- Nogales-Delgado, S.; Encinar, J.M.; González Cortés, Á. High oleic safflower oil as a feedstock for stable biodiesel and biolubricant production. Ind. Crops Prod. 2021, 170, 113701. [Google Scholar] [CrossRef]

- Hudson, D.; Richards, R. Super High Oleic Safflower—A Game Changer for Grain Growers. Available online: https://grdc.com.au/resources-and-publications/grdc-update-papers/tab-content/grdc-update-papers/2019/08/super-high-oleic-safflower-a-game-changer-for-grain-growers (accessed on 5 January 2023).

- Pochi, D.; Fanigliulo, R.; Bisaglia, C.; Cutini, M.; Grilli, R.; Fornaciari, L.; Betto, M.; Pari, L.; Gallucci, F.; Capuzzi, L.; et al. Test rig and method for comparative evaluation of conventional and bio-based hydraulic fluids and lubricants for agricultural transmissions. Sustainability 2020, 12, 8564. [Google Scholar] [CrossRef]

- Pochi, D.; Fanigliulo, R.; Grilli, R.; Fornaciari, L.; Bisaglia, C.; Cutini, M.; Brambilla, M.; Sagliano, A.; Capuzzi, L.; Palmieri, F.; et al. Design and assessment of a test rig for hydrodynamic tests on hydraulic fluids. In Innovative Biosystems Engineering fo Sustainable Agriculture, Forestry and Food Production, MID-TERM AIIA 2019. “Lecture Note in Civil Engineering” Book Series; Coppola, A., Di Renzo, G., Altieri, G., D’Antonio, P., Eds.; Springer Nature: Cham, Switzerland, 2020; Volume 67, pp. 419–429. [Google Scholar]

- Pochi, D.; Fanigliulo, R.; Pagano, M.; Grilli, R.; Fedrizzi, M.; Fornaciari, L. Dynamic-energetic balance of agricultural tractors: Active systems for the measurement of the power requirements in static tests and under field conditions. J. Agric. Eng. 2013, 44, 415–420. [Google Scholar] [CrossRef]

- Pochi, D.; Fanigliulo, R.; Bisaglia, C.; Cutini, M.; Grilli, R.; Betto, M.; Fornaciari, L. Vegetable-based oil as UTTO fluid for agricultural tractors application. Appl. Eng. Agric. 2020, 36, 79–88. [Google Scholar] [CrossRef]

- Pochi, D.; Grilli, R.; Fornaciari, L.; Betto, M.; Benigni, S.; Fanigliulo, R. Bench testing of sensors utilized for in-line monitoring of lubricants and hydraulic fluids properties. Sensors 2021, 21, 8201. [Google Scholar] [CrossRef] [PubMed]

- ASTM D445-06; Standard Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (and Calculation of Dynamic Viscosity). American Society for Testing and Materials: West Conshohocken, PA, USA, 2006.

- ISO 3960:2017; Animal and Vegetable Fats and Oils-Determination of Peroxide Value-Iodometric (Visual) Endpoint Determination. The International Organization for Standardization: Geneva, Switzerland, 2017.

- ISO 660:2020; Animal and Vegetable Fats and Oils-Determination of Acid Value and Acidity. The International Organization for Standardization: Geneva, Switzerland, 2020.

- ISO 8534:2017; Animal and Vegetable Fats and Oils-Determination of Water Content-Karl Fischer Method (Pyridine Free). The International Organization for Standardization: Geneva, Switzerland, 2017.

- NAS 1638; Cleanliness Requirements of Parts Used in Hydraulic System. National Aerospace Standard. Aerospace Industries of America: Washington, DC, USA, 2001.

- ISO 4406:2021; Hydraulic Fluid Power-Fluids-Method for Coding the Level of Contamination by Solid Particles. The International Organization for Standardization: Geneva, Switzerland, 2021.

- Abou Chehade, L.; Angelini, L.G.; Tavarini, S. Genotype and seasonal variation affect yield and oil quality of safflower (Carthamus tinctorius L.) under mediterranean conditions. Agronomy 2022, 12, 122. [Google Scholar] [CrossRef]

- Arslan, B. The determination of oil content and fatty acid compositions of domestic and exotic safflower (Carthamus tinctorius L.) genotypes and their interactions. J. Agron. 2007, 6, 415–420. [Google Scholar] [CrossRef]

- Gupta, M.K. Degumming. In Practical Guide to Vegetable Oil Processing; Elsevier Inc.: Lynnwood, TX, USA, 2017; pp. 41–78. [Google Scholar]

- Ugolini, L.; Cinti, S.; Righetti, L.; Stefan, A.; Matteo, R.; D’Avino, L.; Lazzeri, L. Production of an enzymatic protein hydrolyzate from defatted sunflower seed meal for potential application as a plant biostimulant. Ind. Crops Prod. 2015, 75, 15–23. [Google Scholar] [CrossRef]

- Canistro, D.; Vivarelli, F.; Ugolini, L.; Pinna, C.; Grandi, M.; Antonazzo, I.C.; Cirillo, S.; Sapone, A.; Cinti, S.; Lazzeri, L.; et al. Digestibility, toxicity and metabolic effects of rapeseed and sunflower protein hydrolysates in mice. Ital. J. Anim. Sci. 2017, 16, 462–473. [Google Scholar] [CrossRef]

- Meijer, G.C.M. Smart Sensor Systems; Meijer, G., Ed.; John Wiley & Sons: West Sussex, UK, 2008. [Google Scholar]

- ISO 4263-1:2003; Petroleum and related products-Determination of the ageing behavior of inhibited oils and fluids-TOST test-Part 1. Procedure for Mineral Oils. The International Organization for Standardization: Geneva, Switzerland, 2003.

- Renius, K. Tractors: Technology and Its Application; BLV Publishing Society: Munchen, Germany, 1985. [Google Scholar]

- Osinenko, P. Optimal Slip Control for Tractors with Feedback of Drive Torque; Technische Universität Dresden: Dresden, Germany, 2014. [Google Scholar]

- ASTM D7043-17; Standard Test Method for Indicating Wear Characteristics of Non-Petroleum and Petroleum Hydraulic Fluids in a Constant Volume Vane Pump. American Society for Testing and Materials: West Conshohocken, PA, USA, 2017.

- IP 281; Methods of Test for Petroleum and Its Products Part 281: Determination of Anti-Wear Properties of Hydraulic Fluids-Vane Pump Method. The Institute of Petroleum: London, UK, 2000.

| FTR Section | Component | Manufacturer | Model | Measurement Range/Setting |

|---|---|---|---|---|

| Low pressure | Oil reservoir | Self-made at CREA | - | Volume: 30 dm3 |

| Horizontal multistage pump | Ebara Pumps Europe (Vicenza, Italy) | MATRIX3 5T/0.75M HT | Max flowrate: 80 dm3 min−1; max pressure: 0.5 MPa; power: 0.75 kW | |

| Digital pressure gauge | Kobold Instruments (Milano, Italy) | SEN-329701/2B065 | Measurement range: 0–6 MPa | |

| Flow meter | Kobold Instruments (Milano, Italy) | DON-215H | Measurement range: 15–550 dm3 h−1 | |

| Main filter | Donaldson Company (Minneapolis, USA) | P171533 | Cartridge filtration mesh: 23 μm | |

| Oil-to-water heat exchanger | Pacetti S.r.l. (Ferrara, Italy) | BV 50–40 plate | Fluid operating temperature: 60 °C | |

| High pressure | High-pressure radial piston pump | Atos Group (Sesto Calende, Italy) | PFR203 | Displacement: 3.5 dm3; max speed: 1800 min−1; max pressure: 50 MPa; max power: 5 kW |

| Digital inverter | Toshiba (Tokyo, Japan) | VF-AS1 4055 PL-WP | - | |

| Fluid heating unit | Self-made at CREA | - | Thermal leap up to 40 °C | |

| Distributor with four solenoid valves | Self-made at CREA | - | - | |

| Four overpressure valves | Bosch Rexroth (Lohr am Main, Germany) | DBDS 6G 1X | 10, 20, 30, 40 MPa | |

| Digital pressure gauge | Kobold Instruments (Milano, Italy) | SEN-329701/2A165 | Measurement range: 0–60 MPa |

| Technical Parameters | Unit | FTR Working Conditions |

|---|---|---|

| Tested oil volume | dm3 | 22 |

| Pressure in the low-pressure section | MPa | 0.15 |

| Oil temperature in the reservoir 1 | °C | ≤60 |

| Oil temperature after lamination 2 | °C | ≅100 |

| Flow rate | dm3 min−1 | 5.4 |

| Pressure applicable in the HP section 3 | MPa | 40 |

| HPP maximum speed | min−1 | 1800 |

| Hydraulic power | kW | 3.8 |

| Sensor | Measured Parameters | Laboratory Parameters | Possible Fluid Alterations | ||

|---|---|---|---|---|---|

| Manufacturer | Model | Symbol | |||

| Parker | FPS 2810 | S1–S5 | VD | KV40, KV100 | Primary oxidation, secondary oxidation |

| D | |||||

| PR | PV, TAN | Oxidation | |||

| T | - | Thermal stress | |||

| Parker | i-Count | S2 | Particles | ISO 4406:2021 | Contamination with particles of various origin |

| Argo-Hytos | LubCos H2O plus | S3 | RH | KF [H2O] | Contamination with water |

| PR | PV, TAN | Primary oxidation, secondary oxidation | |||

| EC | PV, TAN, KF [H2O] | Primary oxidation, secondary oxidation, polar products, contamination with water and/or other substances | |||

| T | - | Thermal stress | |||

| Argo-Hytos | OPCom FerroS | S4 | Fine FMP occ. rate | [Fe]; other metals | Wear of materials |

| Coarse FMP | |||||

| Chunk | |||||

| Fatty Acids | M ± Ue % | |

|---|---|---|

| Miristic acid | C 14:0 | 0.09 ± 0.01 |

| Pentadecanoic acid | C 15:0 | 0.01 ± 0.02 |

| Palmitic acid | C 16:0 | 5.86 ± 0.24 |

| Palmitoleic acid | C 16:1 | 0.13 ± 0.02 |

| Eptadecanoic acid | C 17:0 | 0.03 ± 0.01 |

| Stearic acid | C 18:0 | 2.23 ± 0.16 |

| Oleic acid | C 18:1 | 54.24 ± 2.44 |

| Linoleic acid | C 18:2 | 36.07 ± 2.41 |

| Linolenic acid | C 18:3 | 0.08 ± 0.05 |

| Arachidic acid | C 20:0 | 0.40 ± 0.03 |

| Eicosenoic acid | C 20:1 | 0.25 ± 0.03 |

| Beenic acid | C 22:0 | 0.28 ± 0.03 |

| Elements | Crude Oil 1st | Crude Oil 2nd | Degummed Oil 1st | Degummed Oil 2nd | |

|---|---|---|---|---|---|

| Wear metals | |||||

| Fe | mg kg−1 | <1.0 | <1.0 | <1.0 | <1.0 |

| Ag, Al, Cr, Cu, Mn, Ni, Ti, Sn, Pb | mg kg−1 | <1.0 | <1.0 | <1.0 | <1.0 |

| Contaminant elements | |||||

| K | mg kg−1 | 6.6 ± 1.6 | 14.0 ± 2.5 | <1.0 | <1.0 |

| Na | mg kg−1 | <1.0 | 2.0 ± 0.5 | <1.0 | <1.0 |

| V | mg kg−1 | <1.0 | <1.0 | <1.0 | <1.0 |

| Si | mg kg−1 | <1.0 | <1.0 | 3.1 ± 0.1 | <1.0 |

| Additive elements | |||||

| P | mg kg−1 | 23.1 ± 0.9 | 60 ± 6.3 | 5.0 ± 0.7 | <4.0 |

| Ca | mg kg−1 | 9.6 ± 0.2 | 18 ± 0.2 | 1.7 ± 0.2 | <1.0 |

| Mg | mg kg−1 | 5.6 ± 0.5 | 13 ± 0.5 | <1.0 | <1.0 |

| Mo, Zn, Ba | mg kg−1 | <1.0 | <1.0 | <1.0 | <1.0 |

| Free fatty acids | % oleic acid | 0.57 ± 0.07 | 1.4 ± 0.05 | 0.55 ± 0.07 | 1.13 ± 0.05 |

| Test | Statistical Indices | Pressure (MPa) | Flowrate (dm3 h−1) | HPP Power (kW) | T° before 40 MPa Valve (°C) | T° after 40 MPa Valve (°C) |

|---|---|---|---|---|---|---|

| Low-THBQ | Average | 42.10 | 324.40 | 4.46 | 58.80 | 100.50 |

| SD | 3.00 | 2.87 | 0.08 | 1.32 | 0.47 | |

| CV | 0.71 | 0.89 | 1.75 | 2.24 | 0.47 | |

| SE | 0.05 | 0.04 | 0.02 | 0.02 | 0.01 | |

| Max value | 43.30 | 340.40 | 4.61 | 61.40 | 101.70 | |

| Min value | 40.90 | 310.10 | 4.34 | 54.40 | 98.50 | |

| High-THBQ | Average | 41.10 | 322.50 | 4.33 | 58.40 | 100.00 |

| SD | 2.35 | 2.46 | 0.04 | 1.26 | 0.51 | |

| CV | 0.57 | 0.76 | 0.89 | 2.16 | 0.51 | |

| SE | 0.03 | 0.02 | 0.01 | 0.02 | 0.01 | |

| Max value | 42.50 | 339.40 | 4.41 | 62.00 | 101.40 | |

| Min value | 40.60 | 314.50 | 4.25 | 53.60 | 98.80 |

| Properties | T0 | T150 | Differences (T150 − T0) |

|---|---|---|---|

| KV40 (cSt) | 33.48 | 59.65 | 26.17 (78%) |

| KV100 (cSt) | 7.87 | 12.26 | 4.39 (56%) |

| VI | 219.00 | 208.00 | −11.00 (−5%) |

| TAN (mg KOH g−1) | 1.08 | 1.16 | 0.08 (7%) |

| PV (meq O2 kg−1) | 13.69 | 308.38 | 294.69 (2152%) |

| D at 20 °C (g cm−3) | 0.90 | 0.91 | 0.01 |

| Properties | T0 | T360 | Differences (T360 − T0) |

|---|---|---|---|

| KV40 (cSt) | 35.55 | 47.29 | 11.74 (33%) |

| KV100 (cSt) | 8.15 | 9.62 | 1.48 (18%) |

| VI | 214.00 | 194.00 | −20.00 (9%) |

| TAN (mg KOH g−1) | 2.24 | 2.33 | 0.09 (4%) |

| PV (meq O2 kg−1) | 17.00 | 275.30 | 258.30 (1521%) |

| D at 20 °C (g cm−3) | 0.91 | 0.92 | 0.01 |

| Test | Statistical Indices | KV40 (cSt) | KV100 (cSt) | VI (N) | TAN (mg KOH g−1) | PV (meq O2 kg−1) |

|---|---|---|---|---|---|---|

| TBHQ 0.25 g kg−1 | Average | 41.50 | 9.27 | 217.00 | 0.97 | 151.00 |

| SD | 8.45 | 1.52 | 7.75 | 0.12 | 110.61 | |

| CV | 20.37 | 16.45 | 3.56 | 12.53 | 73.25 | |

| SE | 1.94 | 0.51 | 2.58 | 0.03 | 25.38 | |

| Max value | 59.65 | 12.26 | 228.00 | 1.16 | 308.69 | |

| Min value | 33.48 | 7.87 | 206.00 | 0.75 | 13.69 | |

| THBQ 3.00 g kg−1 | Average | 36.94 | 8.31 | 211.00 | 2.24 | 71.35 |

| SD | 3.43 | 0.44 | 5.67 | 0.06 | 86.18 | |

| CV | 9.27 | 5.34 | 2.69 | 2.71 | 120.74 | |

| SE | 0.86 | 0.11 | 1.42 | 0.02 | 21.55 | |

| Max value | 47.29 | 9.62 | 214.00 | 2.33 | 275.32 | |

| Min value | 35.06 | 8.04 | 194.00 | 2.10 | 16.98 |

| TBHQ Concentration | Fluid T (C°) | Δ KV (cSt) | Δ KV (%) | Correlation Lab/S1 | |||

|---|---|---|---|---|---|---|---|

| Lab. | S1 | Lab. | S1 | r | p | ||

| Low (0.25 g kg−1) | 40 | 26.17 | 19.82 | 75.39 | 62.00 | 0.99 | 1.2 × 10−6 |

| 100 | 4.39 | 4.23 | 53.70 | 44.60 | 0.95 | 3.2 × 10−4 | |

| High (3.00 g kg−1) | 40 | 12.23 | 12.91 | 33.04 | 38.89 | 0.96 | 3.1 × 10−9 |

| 100 | 1.58 | 1.72 | 18.12 | 19.49 | 0.88 | 6.9 × 10−6 | |

| TBHQ Concentration | Lab Parameters | PR–S1 (40 °C) | PR–S5 (87 °C) | PR–S3 (60 °C) | PR–S3 (40 °C) | ||||

|---|---|---|---|---|---|---|---|---|---|

| r | p | r | p | r | p | r | p | ||

| Low (0.25 g kg−1) | TAN | 0.072 | 7.8 × 10−1 | 0.187 | 4.7 × 10−1 | −0.057 | 8.2 × 10−1 | −0.068 | 7.9 × 10−1 |

| PV | 0.95 | 8.3 × 10−10 | 0.92 | 1.8 × 10−8 | 0.96 | 2.7 × 10−9 | 0.96 | 3.4 × 10−11 | |

| High (3.00 g kg−1) | TAN | −0.119 | 6.7 × 10−1 | −0.203 | 4.7 × 10−1 | −0.177 | 5.3 × 10−1 | −0.205 | 4.6 × 10−1 |

| PV | 0.96 | 7.4 × 10−9 | 0.98 | 1.9 × 10−10 | 0.97 | 2.5 × 10−9 | 0.96 | 2.0 × 10−8 | |

| TBHQ Concentration | r/p | EC (S3)–TAN | EC(S3)–PV | ||

|---|---|---|---|---|---|

| EC (60 °C) | EC (40 °C) | EC (60 °C) | EC (40 °C) | ||

| Low (0.25 g kg−1) | r | −0.08 | −0.05 | 0.94 | −0.62 |

| p | 7.8 × 10−1 | 8.4 × 10−1 | 1.2 × 10−8 | 4.7 × 10−3 | |

| High (3.00 g kg−1) | r | −0.24 | −0.14 | 0.95 | 0.97 |

| p | 3.9 × 10−1 | 6.2 × 10−1 | 4.5 × 10−8 | 3.7 × 10−9 | |

| TBHQ Concentration | r/p | RH (S3)–TAN | RH (S3)–PV | RH (S3)–KF | RH (S3)–EC (S3) | |

|---|---|---|---|---|---|---|

| RH–EC (60 °C) | RH–EC (40 °C) | |||||

| Low (0.25 g kg−1) | r | −0.336 | 0.202 | 0.724 | 0.160 | 0.100 |

| p | 0.203 | 0.454 | 0.104 | 0.531 | 0.690 | |

| High (3.00 g kg−1) | r | −0.825 | 0.590 | −0.426 | −0.150 | −0.080 |

| p | 0.175 | 0.411 | 0.574 | 0.580 | 0.770 | |

| Elements | T0 | T93 | T100 | T150 | |

|---|---|---|---|---|---|

| Wear metals | |||||

| Cu | mg kg−1 | <1.0 | 1.7 ± 0.2 | 14.4 ± 0.9 | 6.3 ± 0.9 |

| Ag, Al, Cr, Fe, Mn, Ni, Ti, Sn, Pb | mg kg−1 | <1.0 | <1.0 | <1.0 | <1.0 |

| Contaminant elements | |||||

| K, Na, V | mg kg−1 | <1.0 | <1.0 | <1.0 | <1.0 |

| Si | mg kg−1 | 3.1 ± 0.1 | 3.1 ± 0.1 | 2.9 ± 0.1 | 2.8 ± 0.1 |

| Additive elements | |||||

| P | mg kg−1 | 5.0 ± 0.7 | 19.6 ± 0.9 | 18.1 ± 0.9 | 17.9 ± 0.7 |

| Ca | mg kg−1 | 1.7 ± 0.2 | 37.6 ± 2.6 | 37.5 ± 2.6 | 35.9 ± 2.6 |

| Mg | mg kg−1 | <1.0 | <1.0 | <1.0 | <1.0 |

| Zn | mg kg−1 | <1.0 | 101.0 ± 0.1 | 114.0 ± 0.1 | 108.0 ± 0.1 |

| Ba, Mo | mg kg−1 | <1.0 | <1.0 | <1.0 | <1.0 |

| Elements | T0 | T60 | T180 | T270 | T315 | T360 | |

|---|---|---|---|---|---|---|---|

| Wear metals | |||||||

| Cu | mg kg−1 | <1.0 | <1.0 | <1.0 | <1.0 | 2.0 | 2.0 |

| Ag, Al, Cr, Fe, Mn, Ni, Ti, Sn, Pb | mg kg−1 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 |

| Contaminant elements | |||||||

| K, Na, V | mg kg−1 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 |

| Si | mg kg−1 | <5.0 | <5.0 | <5.0 | <5.0 | <5.0 | <5.0 |

| Additive elements | |||||||

| P | mg kg−1 | 6.2 ± 0.9 | 5.9 ± 0.9 | 6.0 ± 0.9 | 6.1 ± 0.9 | 6.7 ± 0.9 | 6.3 ± 0.9 |

| Ca | mg kg−1 | 1.0 ± 0.2 | 1.0 ± 0.2 | 1.0 ± 0.2 | 1.0 ± 0.2 | 1.0 ± 2.6 | 1.0 ± 2.6 |

| Mg | mg kg−1 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 |

| Zn | mg kg−1 | 1.0 ± 0.1 | 9.0 ± 0.1 | 22.0 ± 0.1 | 35.0 ± 0.1 | 54.0 ± 0.1 | 74.0 ± 0.1 |

| Ba, Mo | mg kg−1 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ugolini, L.; Matteo, R.; Lazzeri, L.; Malaguti, L.; Folegatti, L.; Bondioli, P.; Pochi, D.; Grilli, R.; Fornaciari, L.; Benigni, S.; et al. Technical Performance and Chemical–Physical Property Assessment of Safflower Oil Tested in an Experimental Hydraulic Test Rig. Lubricants 2023, 11, 39. https://doi.org/10.3390/lubricants11020039

Ugolini L, Matteo R, Lazzeri L, Malaguti L, Folegatti L, Bondioli P, Pochi D, Grilli R, Fornaciari L, Benigni S, et al. Technical Performance and Chemical–Physical Property Assessment of Safflower Oil Tested in an Experimental Hydraulic Test Rig. Lubricants. 2023; 11(2):39. https://doi.org/10.3390/lubricants11020039

Chicago/Turabian StyleUgolini, Luisa, Roberto Matteo, Luca Lazzeri, Lorena Malaguti, Liliana Folegatti, Paolo Bondioli, Daniele Pochi, Renato Grilli, Laura Fornaciari, Stefano Benigni, and et al. 2023. "Technical Performance and Chemical–Physical Property Assessment of Safflower Oil Tested in an Experimental Hydraulic Test Rig" Lubricants 11, no. 2: 39. https://doi.org/10.3390/lubricants11020039

APA StyleUgolini, L., Matteo, R., Lazzeri, L., Malaguti, L., Folegatti, L., Bondioli, P., Pochi, D., Grilli, R., Fornaciari, L., Benigni, S., & Fanigliulo, R. (2023). Technical Performance and Chemical–Physical Property Assessment of Safflower Oil Tested in an Experimental Hydraulic Test Rig. Lubricants, 11(2), 39. https://doi.org/10.3390/lubricants11020039