Method for On-Line Remaining Useful Life and Wear Prediction for Adjustable Journal Bearings Utilizing a Combination of Physics-Based and Data-Driven Models: A Numerical Investigation

Abstract

1. Introduction

2. Materials and Methods

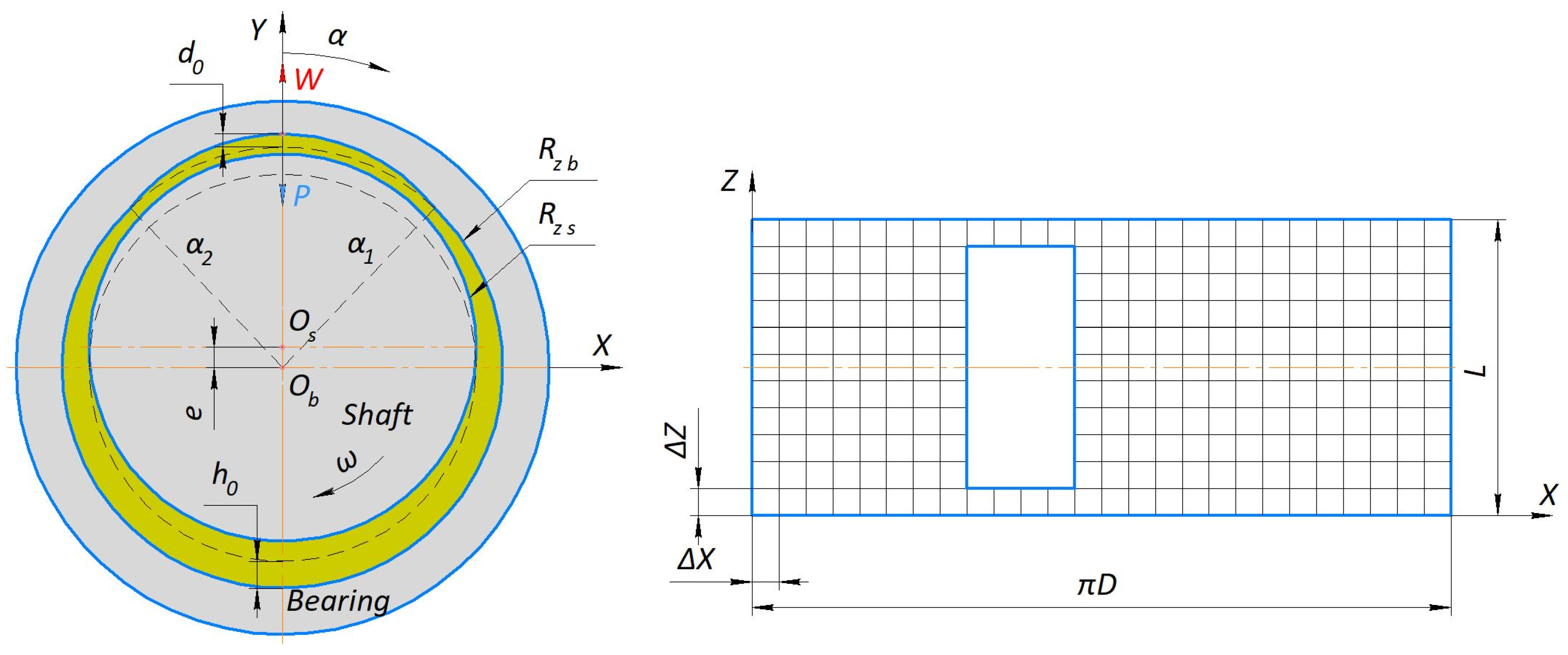

2.1. Subject Description

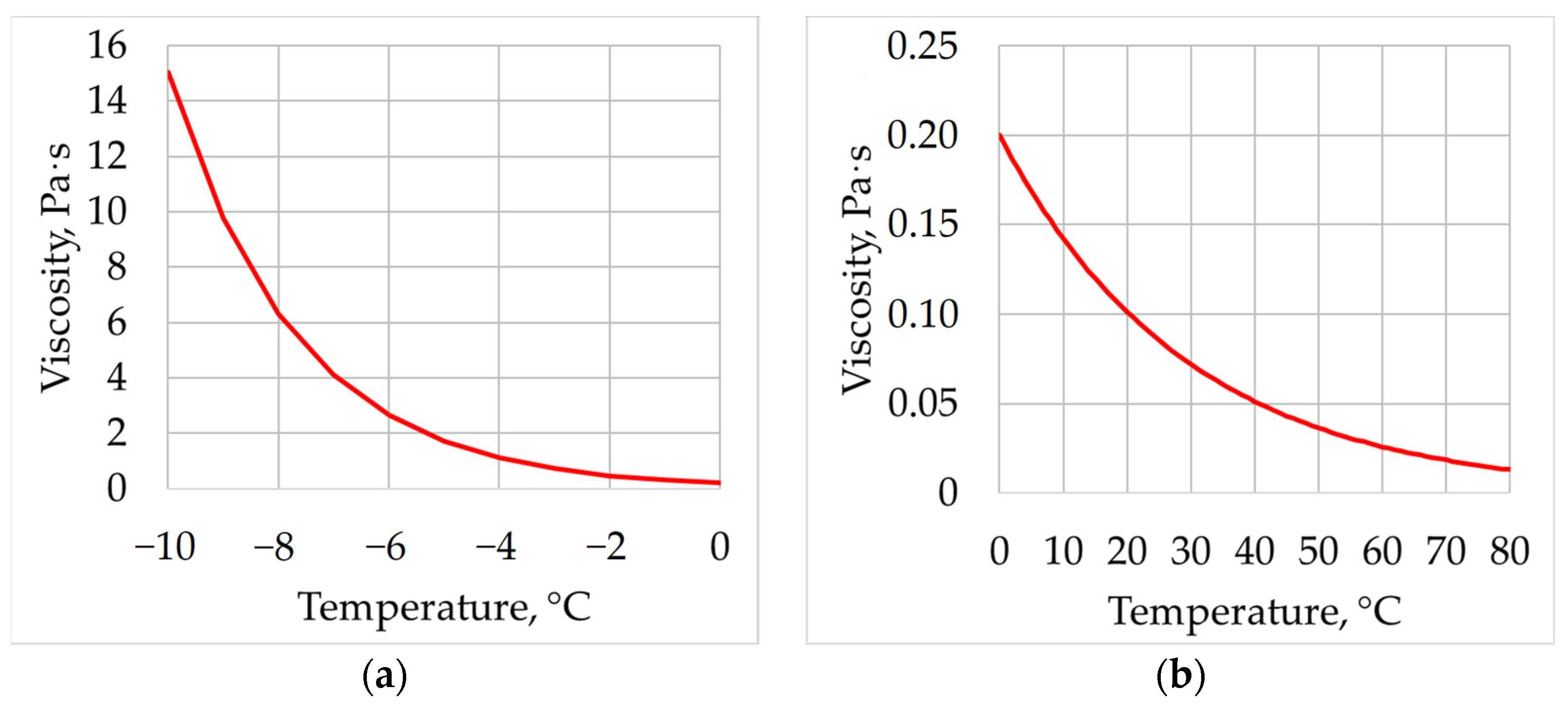

2.2. Wear Model

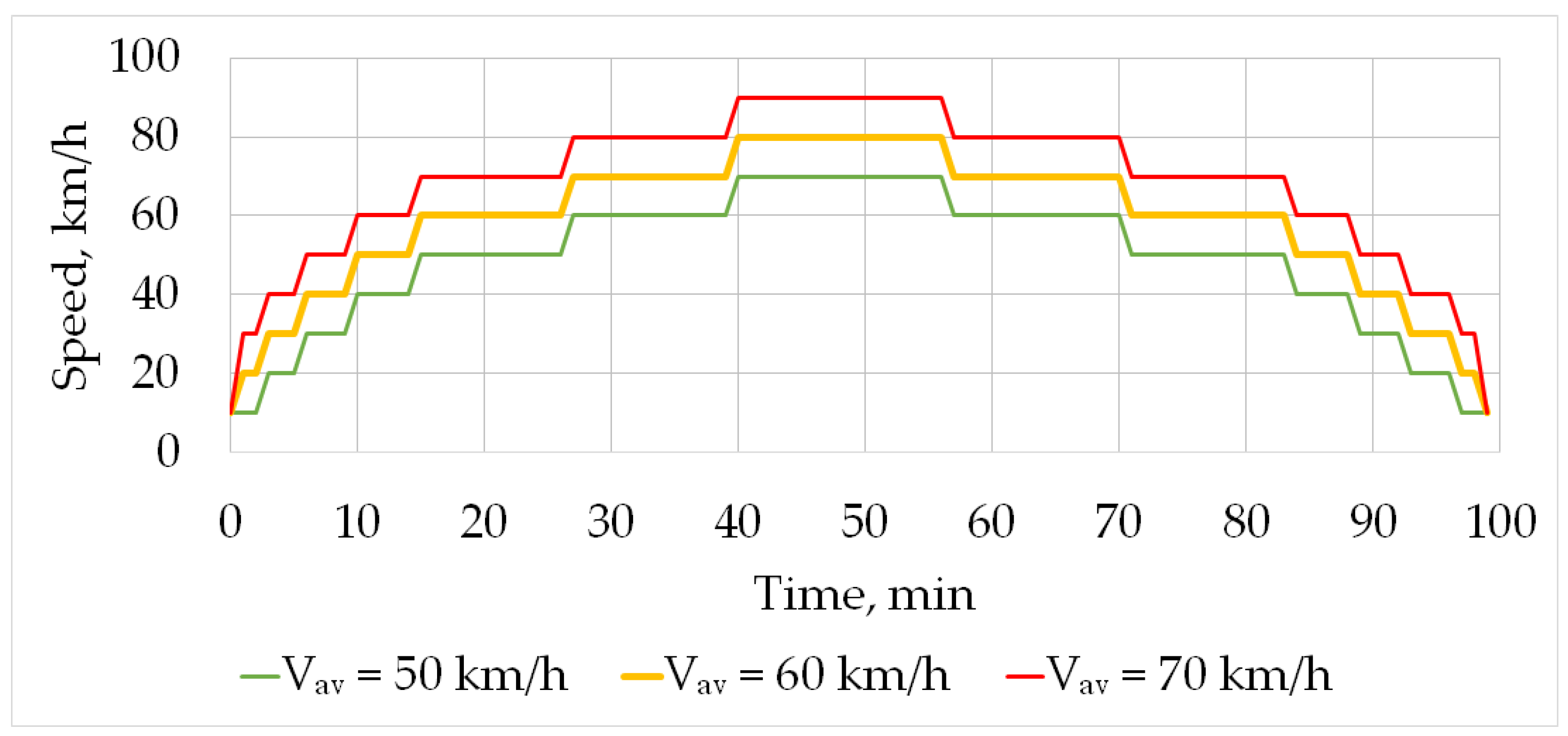

2.3. Operating Conditions

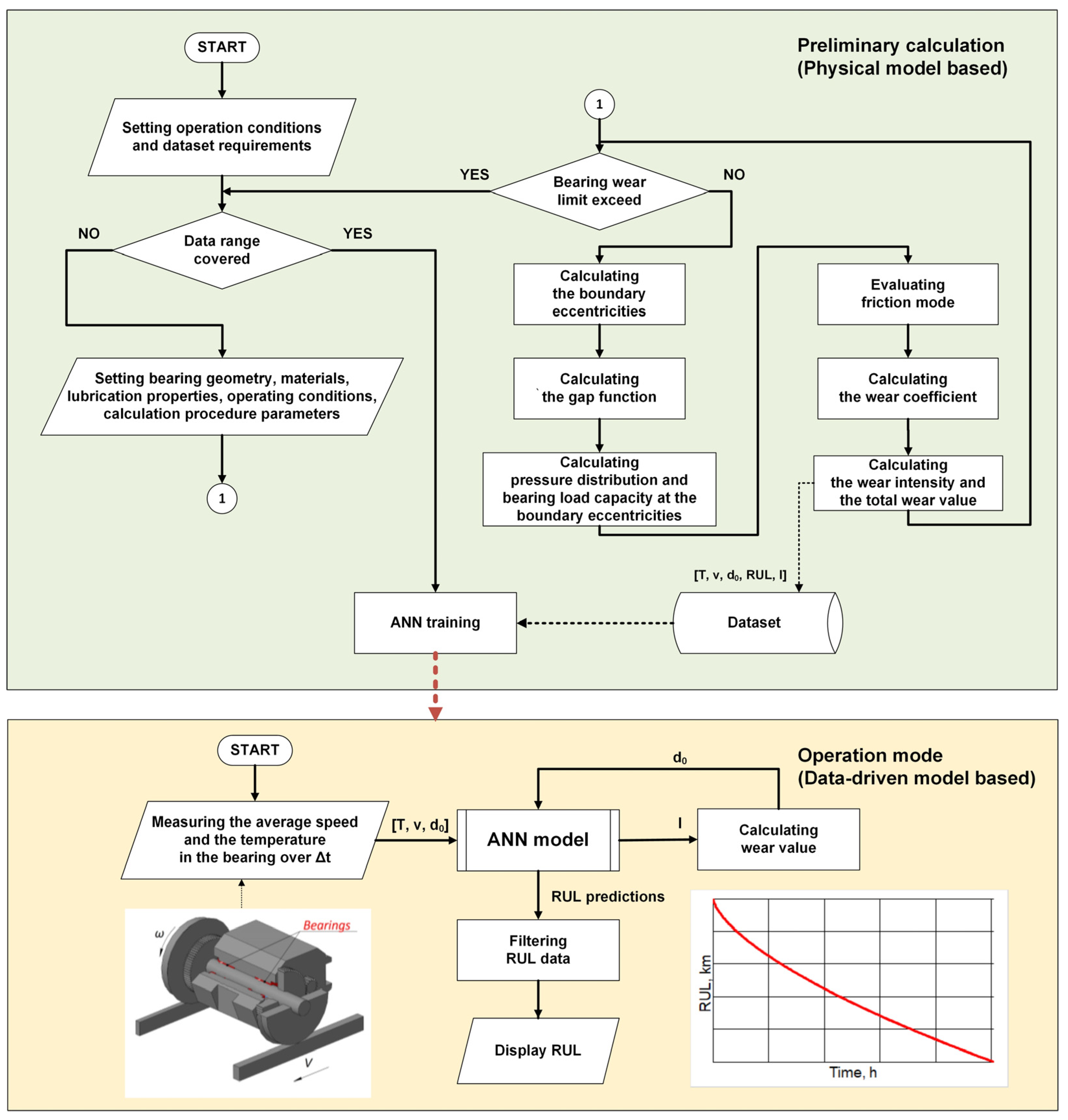

2.4. General Algorithm of RUL and Wear calculation

3. Results and Discussion

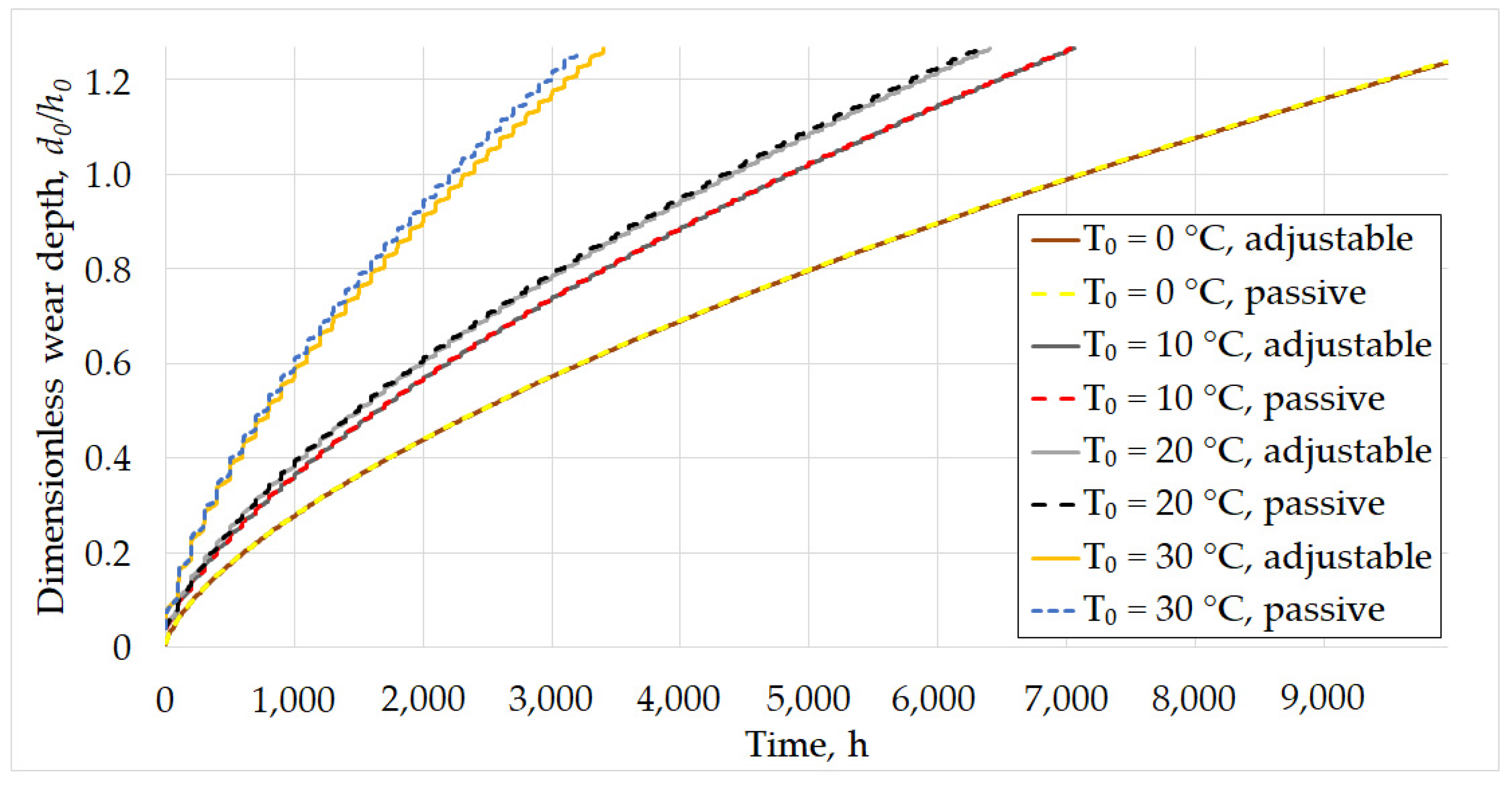

3.1. Wear Calculation

3.1.1. Passive Bearings

3.1.2. Adjustable Bearings

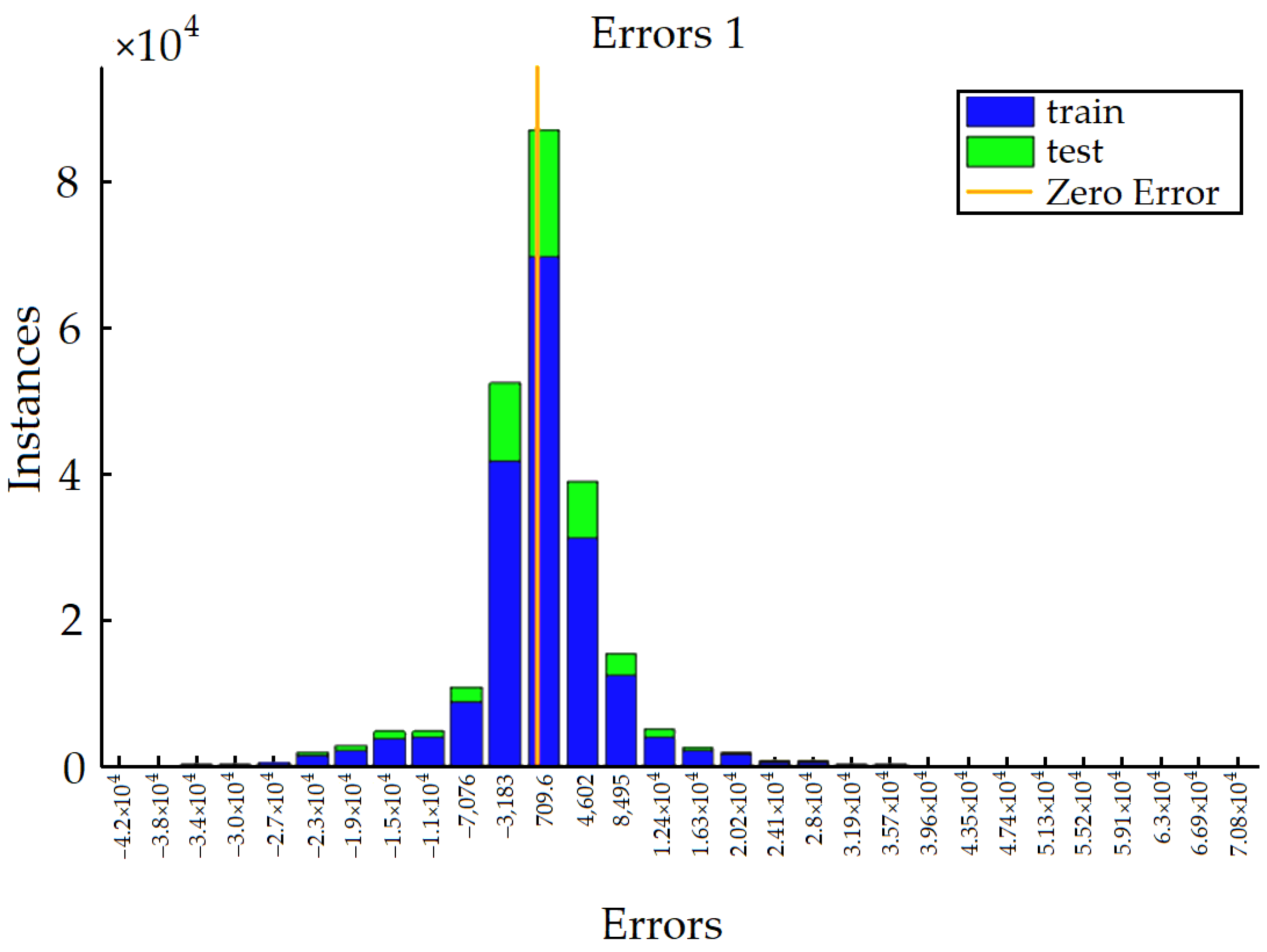

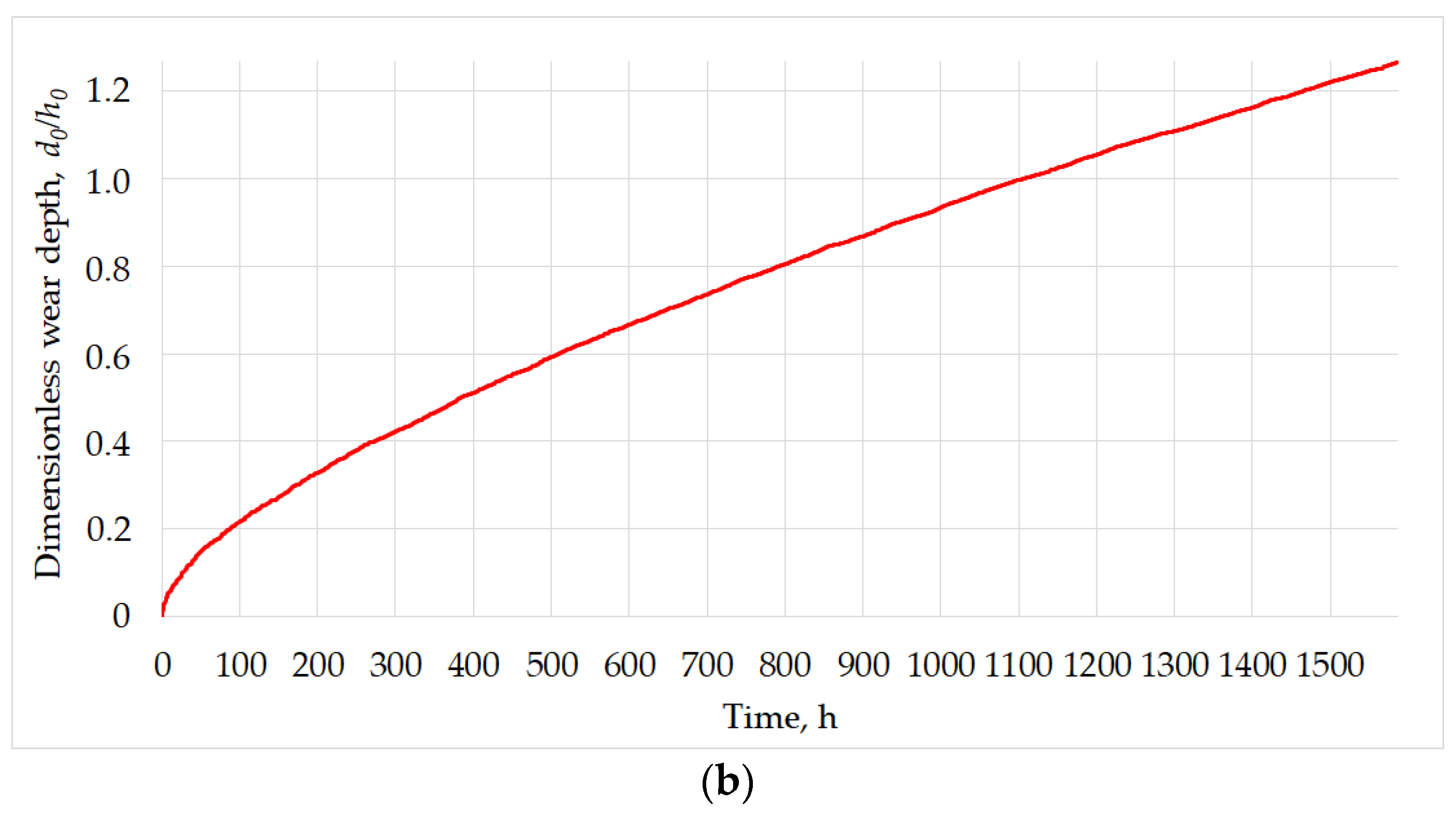

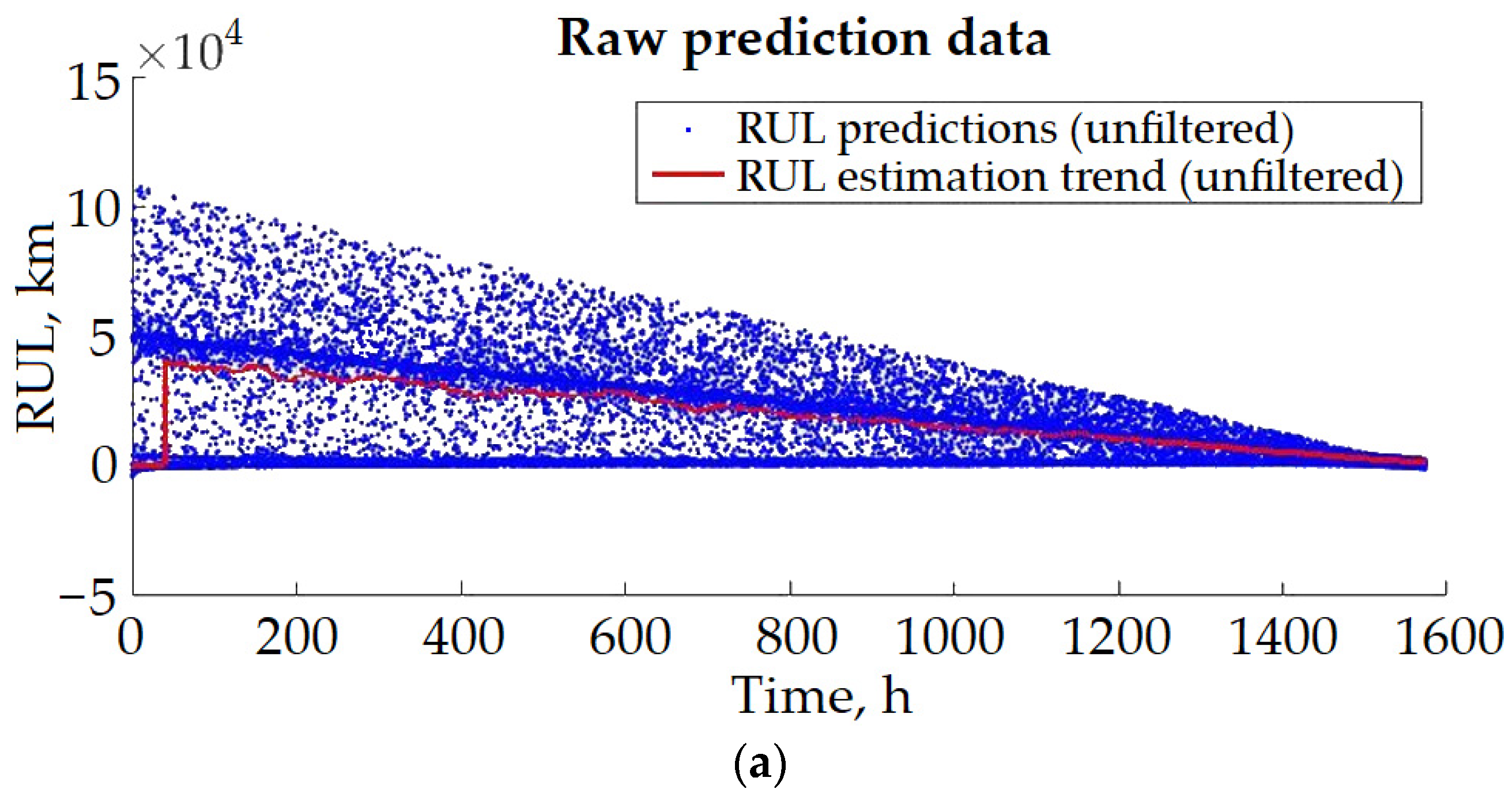

3.2. Prediction of RUL and Wear Rate

3.3. Discussion

- Differences in bearing loading schemes. In the considered case, the mechanical loads applied to the bearing are described mainly by the speed of the locomotive. In other applications, the sources and types of bearing loads may be more diverse. If the existing loads cannot be described by a single generalized parameter, one or more additional parameters should be introduced to the dataset. Such parameters should together give a complete assessment of the loads based either on their direct measurements or on indirect estimates using other types of sensors.

- Differences in the schemes of adjustment of the bearing parameters. As in the previous case, if the control scheme implies adjusting more than one of the independent parameters considered in the physics-based model, one or more additional generalized parameters should be introduced that reflect the magnitude of the control action. When generating a dataset, the range of change of introduced parameters should be divided into steps in the same way as described in Section 3.2.

- By analogy with points 1 and 2, in the case of any other differences, it is recommended to parameterize them, making sure that their values can be estimated using the measurement data in the system, and introducing them to the dataset among the variables that have a significant impact on the estimated parameters.

- Increasing approximation accuracy. The practice of applying machine learning methods shows that the choice of the methods themselves and their hyperparameters in most cases should be made individually, even including the elements of an heuristic approach. The variety of machine learning techniques gives a wide scope for tests and possible improvements. The dataset can also be optimized, including the reduction of its dimensionality, if possible, as well as adjusting the discretization step of the independent variables, including the use of adaptive grids.

- Using advanced techniques of data processing to refine the RUL prediction. The RUL value still significantly depends on the behavior of independent factors, such as the locomotive speed in the considered example. Implementing the predictive analysis of independent variables, when possible, could improve the accuracy of long-term prediction.

- Create and verify a physics-based bearing model for calculation wear, taking into account the variability of adjustable and non-adjustable parameters.

- Analyze the system using the model and ensure that the power margin of the control action allows the bearing operating modes to be adjusted to the desired extent and the desired performance in the required range of conditions to be obtained.

- Add all the independent factors that affect the wear rate and which cannot be fully compensated by the control system to the dataset generated by the physics-based model. The input data for the data-driven model will include the values of the corresponding independent variables. The output data will be the estimations of RUL and the wear rate.

- Train a predictive model utilizing the obtained dataset using machine learning with subsequent validation of the results and the choice of relevant methods for post-processing the predictive data.

4. Conclusions

- The proposed method allows on-line prediction of RUL and wear of sliding bearings with high speed and good accuracy. In the case of adjustable bearing design, the influence of the control system is taken into account by introducing appropriate variables into the dataset for training the predictive model. However, the set of the variables depends on the bearing design and should be chosen for each case individually.

- The accuracy of the prediction primarily depends on the accuracy of the physics-based model as well as on the methods of data processing and post-processing. Despite the good qualitative agreement between the simulation results obtained for the considered case and the corresponding results of other authors, the practical application of wear models requires careful verification before use. Primarily, the preliminary refinement of wear coefficients for specific materials and the conditions of their interaction is required to obtain fairly accurate simulation models.

- Active adjustment of parameters in sliding bearings allows reduction of wear and increase in the service life compared with the conventional passive design. However, the sufficient margins of control action should be provided in order to obtain a significant improvement in the mentioned parameters.

- Approximation and prediction inaccuracies can be compensated by post-processing the prediction data, taking into account the type of error distribution, as well as a priori information regarding the behavior of the predicted parameters. Pre- and post-processing of forecasting data, together with optimization of datasets and applied methods, can significantly improve the quality of predictive analytics.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ding, H.; Yang, L.; Cheng, Z.; Yang, Z. A Remaining Useful Life Prediction Method for Bearing Based on Deep Neural Networks. Measurement 2021, 172, 108878. [Google Scholar] [CrossRef]

- Ding, N.; Li, H.; Yin, Z.; Zhong, N.; Zhang, L. Journal Bearing Seizure Degradation Assessment and Remaining Useful Life Prediction Based on Long Short-Term Memory Neural Network. Measurement 2020, 166, 108215. [Google Scholar] [CrossRef]

- Chen, X.; van Hillegersberg, J.; Topan, E.; Smith, S.; Roberts, M. Application of Data-Driven Models to Predictive Maintenance: Bearing Wear Prediction at TATA Steel. Expert Syst. Appl. 2021, 186, 115699. [Google Scholar] [CrossRef]

- Suh, S.; Jang, J.; Won, S.; Jha, M.S.; Lee, Y.O. Supervised Health Stage Prediction Using Convolutional Neural Networks for Bearing Wear. Sensors 2020, 20, 5846. [Google Scholar] [CrossRef]

- Li, N.; Lei, Y.; Gebraeel, N.; Wang, Z.; Cai, X.; Xu, P.; Wang, B. Multi-Sensor Data-Driven Remaining Useful Life Prediction of Semi-Observable Systems. IEEE Trans. Ind. Electron. 2021, 68, 11482–11491. [Google Scholar] [CrossRef]

- Wen, P.; Li, Y.; Chen, S.; Zhao, S. Remaining Useful Life Prediction of IIoT-Enabled Complex Industrial Systems with Hybrid Fusion of Multiple Information Sources. IEEE Internet Things J. 2021, 8, 9045–9058. [Google Scholar] [CrossRef]

- Feng, K.; Ji, J.C.; Zhang, Y.; Ni, Q.; Liu, Z.; Beer, M. Digital Twin-Driven Intelligent Assessment of Gear Surface Degradation. Mech. Syst. Signal Process. 2023, 186, 109896. [Google Scholar] [CrossRef]

- Li, Y.; Xiang, Y.; Pan, B.; Shi, L. A Hybrid Remaining Useful Life Prediction Method for Cutting Tool Considering the Wear State. Int. J. Adv. Manuf. Technol. 2022, 121, 3583–3596. [Google Scholar] [CrossRef]

- Sun, B.; Li, Y.; Wang, Z.; Ren, Y.; Feng, Q.; Yang, D.; Lu, M.; Chen, X. Remaining Useful Life Prediction of Aviation Circular Electrical Connectors Using Vibration-Induced Physical Model and Particle Filtering Method. Microelectron. Reliab. 2019, 92, 114–122. [Google Scholar] [CrossRef]

- Djeziri, M.A.; Benmoussa, S.; Mouchaweh, M.S.; Lughofer, E. Fault Diagnosis and Prognosis Based on Physical Knowledge and Reliability Data: Application to MOS Field-Effect Transistor. Microelectron. Reliab. 2020, 110, 113682. [Google Scholar] [CrossRef]

- Cai, J.; Han, Y.; Xiang, G.; Wang, J.; Wang, L. Effects of Wear and Shaft-Shape Error Defects on the Tribo-Dynamic Response of Water-Lubricated Bearings under Propeller Disturbance. Phys. Fluids 2022, 34, 077118. [Google Scholar] [CrossRef]

- Chasalevris, A.C.; Nikolakopoulos, P.G.; Papadopoulos, C.A. Dynamic Effect of Bearing Wear on Rotor-Bearing System Response. J. Vib. Acoust. Trans. ASME 2013, 135, 011008. [Google Scholar] [CrossRef]

- Ali, A.A.H.; Jamil, A.N. Study the Dynamic Behavior of Rotor Supported on a Worn Journal Bearings. J. Eng. 2015, 21, 1–18. [Google Scholar]

- Dargaiah, K.; Kamalam, P. Steady State, Dynamic and Stability Analysis of a Loading Arc (Worn) Journal Bearing Used in Turbo-Generator. In Proceedings of the 2006 SEM Annual Conference and Exposition on Experimental and Applied Mechanics 2006, Saint Louis, MO, USA, 4–6 June 2006; pp. 1454–1466. [Google Scholar]

- Machado, T.H.; Cavalca, K.L. Modeling of Hydrodynamic Bearing Wear in Rotor-Bearing Systems. Mech. Res. Commun. 2015, 69, 15–23. [Google Scholar] [CrossRef]

- Machado, T.H.; Alves, D.S.; Cavalca, K.L. Investigation about Journal Bearing Wear Effect on Rotating System Dynamic Response in Time Domain. Tribol. Int. 2019, 129, 124–136. [Google Scholar] [CrossRef]

- Alves, D.S.; Fieux, G.; Machado, T.H.; Keogh, P.S.; Cavalca, K.L. A Parametric Model to Identify Hydrodynamic Bearing Wear at a Single Rotating Speed. Tribol. Int. 2021, 153, 106640. [Google Scholar] [CrossRef]

- Saridakis, K.M.; Nikolakopoulos, P.G.; Papadopoulos, C.A.; Dentsoras, A.J. Identification of Wear and Misalignment on Journal Bearings Using Artificial Neural Networks. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2012, 226, 46–56. [Google Scholar] [CrossRef]

- Chun, S.M.; Khonsari, M.M. Wear Simulation for the Journal Bearings Operating under Aligned Shaft and Steady Load during Start-up and Coast-down Conditions. Tribol. Int. 2016, 97, 440–466. [Google Scholar] [CrossRef]

- Gertzos, K.P.; Nikolakopoulos, P.G.; Chasalevris, A.C.; Papadopoulos, C.A. Wear Identification in Rotor-Bearing Systems by Measurements of Dynamic Bearing Characteristics. Comput. Struct. 2011, 89, 55–66. [Google Scholar] [CrossRef]

- Pang, X.; Xue, X.; Jin, X. Experimental Study on Wear Life of Journal Bearings in the Rotor System Subjected to Torque. Trans. Can. Soc. Mech. Eng. 2019, 44, 272–278. [Google Scholar] [CrossRef]

- Du, X.; Jia, W.; Yu, P.; Shi, Y.; Cheng, S. A Remaining Useful Life Prediction Method Based on Time–Frequency Images of the Mechanical Vibration Signals. Measurement 2022, 202, 111782. [Google Scholar] [CrossRef]

- Yan, J.; He, Z.; He, S. A Deep Learning Framework for Sensor-Equipped Machine Health Indicator Construction and Remaining Useful Life Prediction. Comput. Ind. Eng. 2022, 172, 108559. [Google Scholar] [CrossRef]

- Li, T.; Si, X.; Pei, H.; Sun, L. Data-Model Interactive Prognosis for Multi-Sensor Monitored Stochastic Degrading Devices. Mech. Syst. Signal Process. 2022, 167, 108526. [Google Scholar] [CrossRef]

- Yu, W.; Shao, Y.; Xu, J.; Mechefske, C. An Adaptive and Generalized Wiener Process Model with a Recursive Filtering Algorithm for Remaining Useful Life Estimation. Reliab. Eng. Syst. Saf. 2022, 217, 111424. [Google Scholar] [CrossRef]

- Wang, R.; Shi, R.; Hu, X.; Shen, C. Remaining Useful Life Prediction of Rolling Bearings Based on Multiscale Convolutional Neural Network with Integrated Dilated Convolution Blocks. Shock Vib. 2021, 2021, 6616861. [Google Scholar] [CrossRef]

- Wen, J.; Gao, H. Remaining Useful Life Prediction of Bearings with the Unscented Particle Filter Approach. J. Vib. Shock 2018, 37, 208–213. [Google Scholar] [CrossRef]

- Wang, R.; Yan, F.; Shi, R.; Yu, L.; Deng, Y. Uncertainty-Controlled Remaining Useful Life Prediction of Bearings with a New Data-Augmentation Strategy. Appl. Sci. 2022, 12, 11086. [Google Scholar] [CrossRef]

- Guan, H.Q.; Feng, K.; Yu, K.; Cao, Y.L.; Wu, Y.H. Nonlinear Dynamic Responses of a Rigid Rotor Supported by Active Bump-Type Foil Bearings. Nonlinear Dyn. 2020, 100, 2241–2264. [Google Scholar] [CrossRef]

- Jensen, K.M.; Santos, I.F. Design of Actively-Controlled Oil Lubrication to Reduce Rotor-Bearing-Foundation Coupled Vibrations—Theory & Experiment. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2022, 236, 1493–1510. [Google Scholar] [CrossRef]

- Aibers, A.; Nguyen, H.T.; Burger, W. Steigerung Der Energieeffizienz Stationär Belasteter Hydrodynamischer Gleitlager Durch Aktive Regelung Des Schmiermitteldurchflusses Und Condition Monitoring Mittels Körperschallanalyse. Tribol. Schmier. 2012, 59, 5–8. [Google Scholar]

- Fieux, G.A.; Bailey, N.Y.; Keogh, P.S. Internal Rotor Actuation and Magnetic Bearings for the Active Control of Rotating Machines. Actuators 2022, 11, 57. [Google Scholar] [CrossRef]

- Zhang, D.; Ho, J.K.L.; Dong, G.; Zhang, H.; Hua, M. Tribological Properties of Tin-Based Babbitt Bearing Alloy with Polyurethane Coating under Dry and Starved Lubrication Conditions. Tribol. Int. 2015, 90, 22–31. [Google Scholar] [CrossRef]

- Kwang-Hua, C.R. Temperature-Dependent Negative Friction Coefficients in Superlubric Molybdenum Disulfide Thin Films. J. Phys. Chem. Solids 2020, 143, 109526. [Google Scholar] [CrossRef]

- Zhou, G.; Wu, K.; Pu, W.; Li, P.; Han, Y. Tribological Modification of Hydrogenated Nitrile Rubber Nanocomposites for Water-Lubricated Bearing of Ship Stern Shaft. Wear 2022, 504–505, 204432. [Google Scholar] [CrossRef]

- Estupinan, E.A.; Santos, I.F. Feasibility of Applying Active Lubrication to Dynamically Loaded Fluid Film Bearings. In Proceedings of the Society of Tribologists and Lubrication Engineers Annual Meeting and Exhibition 2009, Orlando, FL, USA, 17–21 May 2009; pp. 261–263. [Google Scholar]

- Zeng, W.; Yi, J.; Lin, R.; Lu, W. Statistical Tolerance-Cost-Service Life Optimization of Blade Bearing of Controllable Pitch Propeller Considering the Marine Environment Conditions through Meta-Heuristic Algorithm. J. Comput. Des. Eng. 2022, 9, 689–705. [Google Scholar] [CrossRef]

- Huang, W.; Zhang, X.; Wu, C.; Cao, S.; Zhou, Q. Tool Wear Prediction in Ultrasonic Vibration-Assisted Drilling of CFRP: A Hybrid Data-Driven Physics Model-Based Framework. Tribol. Int. 2022, 174, 107755. [Google Scholar] [CrossRef]

- Shen, S.; Lu, H.; Sadoughi, M.; Hu, C.; Nemani, V.; Thelen, A.; Webster, K.; Darr, M.; Sidon, J.; Kenny, S. A Physics-Informed Deep Learning Approach for Bearing Fault Detection. Eng. Appl. Artif. Intell. 2021, 103, 104295. [Google Scholar] [CrossRef]

- He, G.Y.; Zhao, Y.X.; Yan, C.L. MFLP-PINN: A Physics-Informed Neural Network for Multiaxial Fatigue Life Prediction. Eur. J. Mech. A Solids 2023, 98, 104889. [Google Scholar] [CrossRef]

- Yang, K.; Duan, W.; Huang, L.; Zhang, P.; Ma, S. A Prediction Method for Ship Added Resistance Based on Symbiosis of Data-Driven and Physics-Based Models. Ocean Eng. 2022, 260, 112012. [Google Scholar] [CrossRef]

- Ye, S.; Wang, C.; Wang, Y.; Lei, X.; Wang, X.; Yang, G. Real-Time Model Predictive Control Study of Run-of-River Hydropower Plants with Data-Driven and Physics-Based Coupled Model. J. Hydrol. 2023, 617, 128942. [Google Scholar] [CrossRef]

- Regis, A.; Linares, J.M.; Arroyave-Tobon, S.; Mermoz, E. Numerical Model to Predict Wear of Dynamically Loaded Plain Bearings. Wear 2022, 508–509, 204467. [Google Scholar] [CrossRef]

- Schmidt, A.A.; Schmidt, T.; Grabherr, O.; Bartel, D. Transient Wear Simulation Based on Three-Dimensional Finite Element Analysis for a Dry Running Tilted Shaft-Bushing Bearing. Wear 2018, 408–409, 171–179. [Google Scholar] [CrossRef]

- König, F.; Ouald Chaib, A.; Jacobs, G.; Sous, C. A Multiscale-Approach for Wear Prediction in Journal Bearing Systems—From Wearing-in towards Steady-State Wear. Wear 2019, 426–427, 1203–1211. [Google Scholar] [CrossRef]

- Fu, X.; Wei, L.; Zhang, Y.; Li, S. Comparative Study of Bearing Wear in Spindle System at Different Working Conditions. Mech. Based Des. Struct. Mach. 2022, 1–20. [Google Scholar] [CrossRef]

- Acar, N.; Franco, J.M.; Kuhn, E.; Gonçalves, D.E.P.; Seabra, J.H.O. Tribological Investigation on the Friction and Wear Behaviors of Biogenic Lubricating Greases in Steel-Steel Contact. Appl. Sci. 2020, 10, 1477. [Google Scholar] [CrossRef]

- Fleischer, K. Stratified Sampling Using Double Samples. Stat. Pap. 1990, 31, 55–63. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and Rubbing of Flat Surfaces. J. Appl. Phys. 2004, 24, 981. [Google Scholar] [CrossRef]

- Reichert, S.; Lorentz, B.; Heldmaier, S.; Albers, A. Wear Simulation in Non-Lubricated and Mixed Lubricated Contacts Taking into Account the Microscale Roughness. Tribol. Int. 2016, 100, 272–279. [Google Scholar] [CrossRef]

- Aghdam, A.B.; Khonsari, M.M. Prediction of Wear in Grease-Lubricated Oscillatory Journal Bearings via Energy-Based Approach. Wear 2014, 318, 188–201. [Google Scholar] [CrossRef]

- Xiang, G.; Yang, T.; Guo, J.; Wang, J.; Liu, B.; Chen, S. Optimization Transient Wear and Contact Performances of Water-Lubricated Bearings under Fluid-Solid-Thermal Coupling Condition Using Profile Modification. Wear 2022, 502–503, 204379. [Google Scholar] [CrossRef]

- Xiang, W.W.K.; Yan, S.Z.; Wu, J.N. A Comprehensive Method for Joint Wear Prediction in Planar Mechanical Systems with Clearances Considering Complex Contact Conditions. Sci. China Technol. Sci. 2015, 58, 86–96. [Google Scholar] [CrossRef]

- Xiang, G.; Han, Y.; Wang, J.; Wang, J.; Ni, X. Coupling Transient Mixed Lubrication and Wear for Journal Bearing Modeling. Tribol. Int. 2019, 138, 1–15. [Google Scholar] [CrossRef]

- Czichos, H. Tribology. A Systems Approach to the Science and Technology of Friction, Lubrication and Wear; Elsevier Scientific Publishing Company: Amsterdam, The Netherlands, 1978; pp. 166–175. ISBN 0-444-41676-5. [Google Scholar]

- Bhushan, B. Introduction to Tribology, 2nd ed.; John Wiley & Sons: Chichester, UK, 2002. [Google Scholar]

- Greenwood, J.A.; Kauzlarich, J.J. Inlet Shear Leafing in Elastohydrodynamic Lubrication. Lubr. Technol. 1973, 95, 246–417. [Google Scholar]

- Mokhtari, N.; Pelham, J.G.; Nowoisky, S.; Bote-Garcia, J.L.; Gühmann, C. Friction and Wear Monitoring Methods for Journal Bearings of Geared Turbofans Based on Acoustic Emission Signals and Machine Learning. Lubricants 2020, 8, 29. [Google Scholar] [CrossRef]

- Kauzlarich, J.J.; Williams, J.A. Archard wear and component geometry. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2001, 215, 387–403. [Google Scholar] [CrossRef]

- Kushniruk, A.S. Diagnosis of Traction Motor Axle Bearings of a Wheel-Motor Unit with a Neural Network Reference Model. Ph.D. Thesis, Far Eastern State Transport University, Khabarovsk, Russia, 2021. [Google Scholar]

- Eckle, K.; Schmidt-Hieber, J. A Comparison of Deep Networks with ReLU Activation Function and Linear Spline-Type Methods. Neural Netw. 2019, 110, 232–242. [Google Scholar] [CrossRef]

- Haugaard, A.M.; Santos, I.F. Multi-Orifice Active Tilting-Pad Journal Bearings-Harnessing of Synergetic Coupling Effects. Tribol. Int. 2010, 43, 1374–1391. [Google Scholar] [CrossRef]

- Breńkacz, Ł.; Witanowski, Ł.; Drosińska-Komor, M.; Szewczuk-Krypa, N. Research and Applications of Active Bearings: A State-of-the-Art Review. Mech. Syst. Signal Process. 2021, 151, 107423. [Google Scholar] [CrossRef]

| Parameter | Notation | Value | Unit |

|---|---|---|---|

| Diameter of bearing | D | 0.20575 | m |

| Length of bearing | L | 0.275 | m |

| Diameter of journal | d | 0.20496 | m |

| Clearance | h0 | 395 | μm |

| Maximum wear depth | d0 | 500 | μm |

| Roughness of bearing | Rzb | 8 | μm |

| Roughness of journal | Rzj | 6.3 | μm |

| Material of bearing | - | Steel OS | - |

| Material of journal | - | Babbitt B16 | - |

| Wear coefficient | K | 3 × 10−10–3 × 10−8 | - |

| Maximum external load | P | 48 | kN |

| Maximum rotational speed | ω | 44.4 | rad/s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shutin, D.; Bondarenko, M.; Polyakov, R.; Stebakov, I.; Savin, L. Method for On-Line Remaining Useful Life and Wear Prediction for Adjustable Journal Bearings Utilizing a Combination of Physics-Based and Data-Driven Models: A Numerical Investigation. Lubricants 2023, 11, 33. https://doi.org/10.3390/lubricants11010033

Shutin D, Bondarenko M, Polyakov R, Stebakov I, Savin L. Method for On-Line Remaining Useful Life and Wear Prediction for Adjustable Journal Bearings Utilizing a Combination of Physics-Based and Data-Driven Models: A Numerical Investigation. Lubricants. 2023; 11(1):33. https://doi.org/10.3390/lubricants11010033

Chicago/Turabian StyleShutin, Denis, Maxim Bondarenko, Roman Polyakov, Ivan Stebakov, and Leonid Savin. 2023. "Method for On-Line Remaining Useful Life and Wear Prediction for Adjustable Journal Bearings Utilizing a Combination of Physics-Based and Data-Driven Models: A Numerical Investigation" Lubricants 11, no. 1: 33. https://doi.org/10.3390/lubricants11010033

APA StyleShutin, D., Bondarenko, M., Polyakov, R., Stebakov, I., & Savin, L. (2023). Method for On-Line Remaining Useful Life and Wear Prediction for Adjustable Journal Bearings Utilizing a Combination of Physics-Based and Data-Driven Models: A Numerical Investigation. Lubricants, 11(1), 33. https://doi.org/10.3390/lubricants11010033