The Influence of Mullite Shape and Amount on the Tribological Properties of Non-Asbestos Brake Friction Composites

Abstract

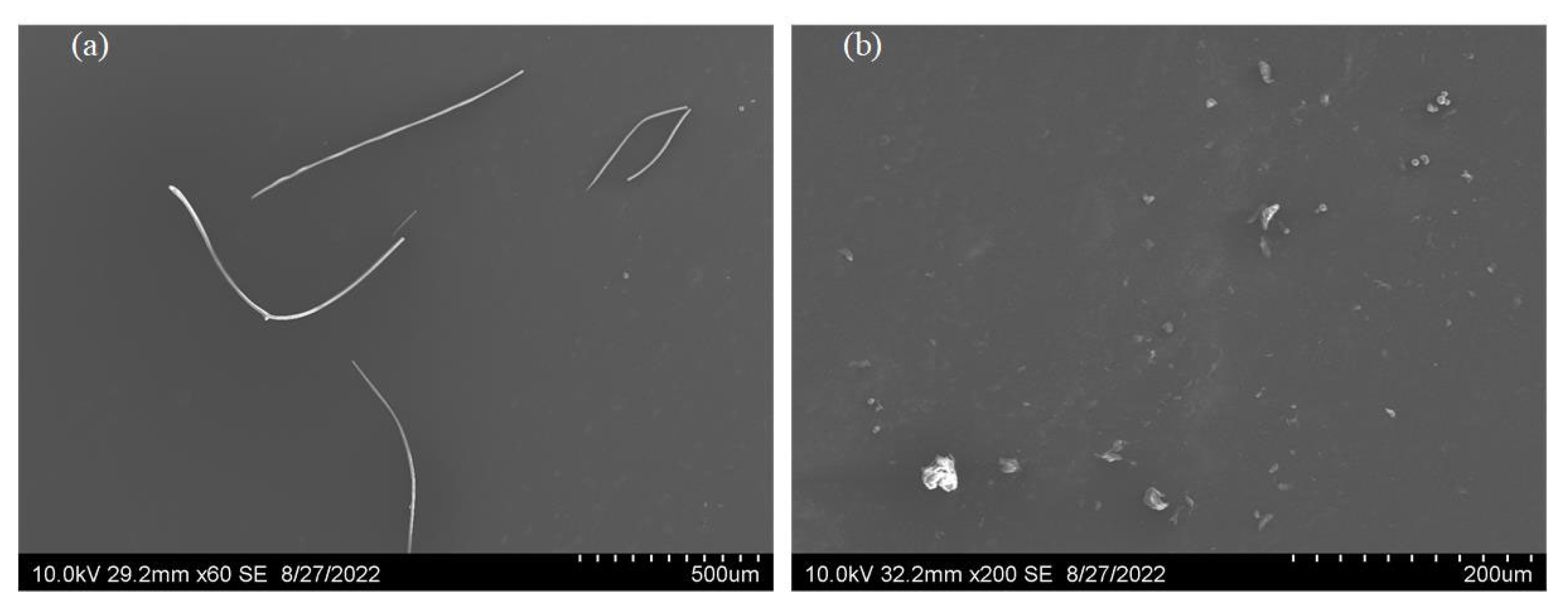

:1. Introduction

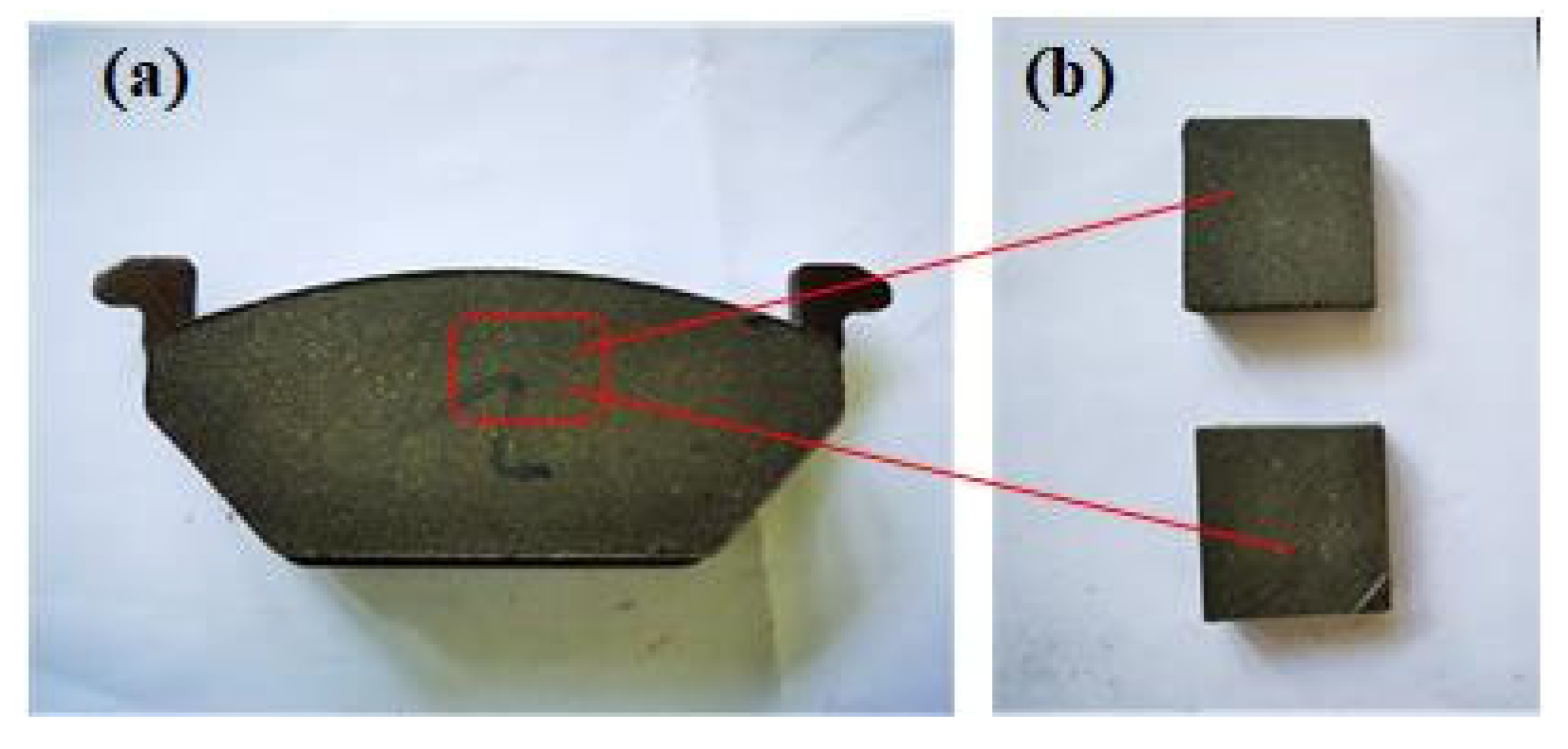

2. Materials and Methods

2.1. Materials and Fabrication

- (1)

- Mix the mullite, rock wool, and lapinus fiber in the plough harrow mixer for 10 min and then add other ingredients to keep stirring for another 10 min;

- (2)

- Heat curing under a pressure of 14.4 MPa at a temperature of 155 °C with four breathings to expel volatile gas and then maintain the pressure of 14.4 MPa for 400 s;

- (3)

- Heat the samples in an oven at 130 °C for 2 h, then raise the temperature to 160 °C for 20 min and then keeping the temperature at 160 °C for 6 h.

2.2. Characterization of Physical, Mechanical and Thermal Properties

2.3. Friction and Wear Testing

3. Results and Discussions

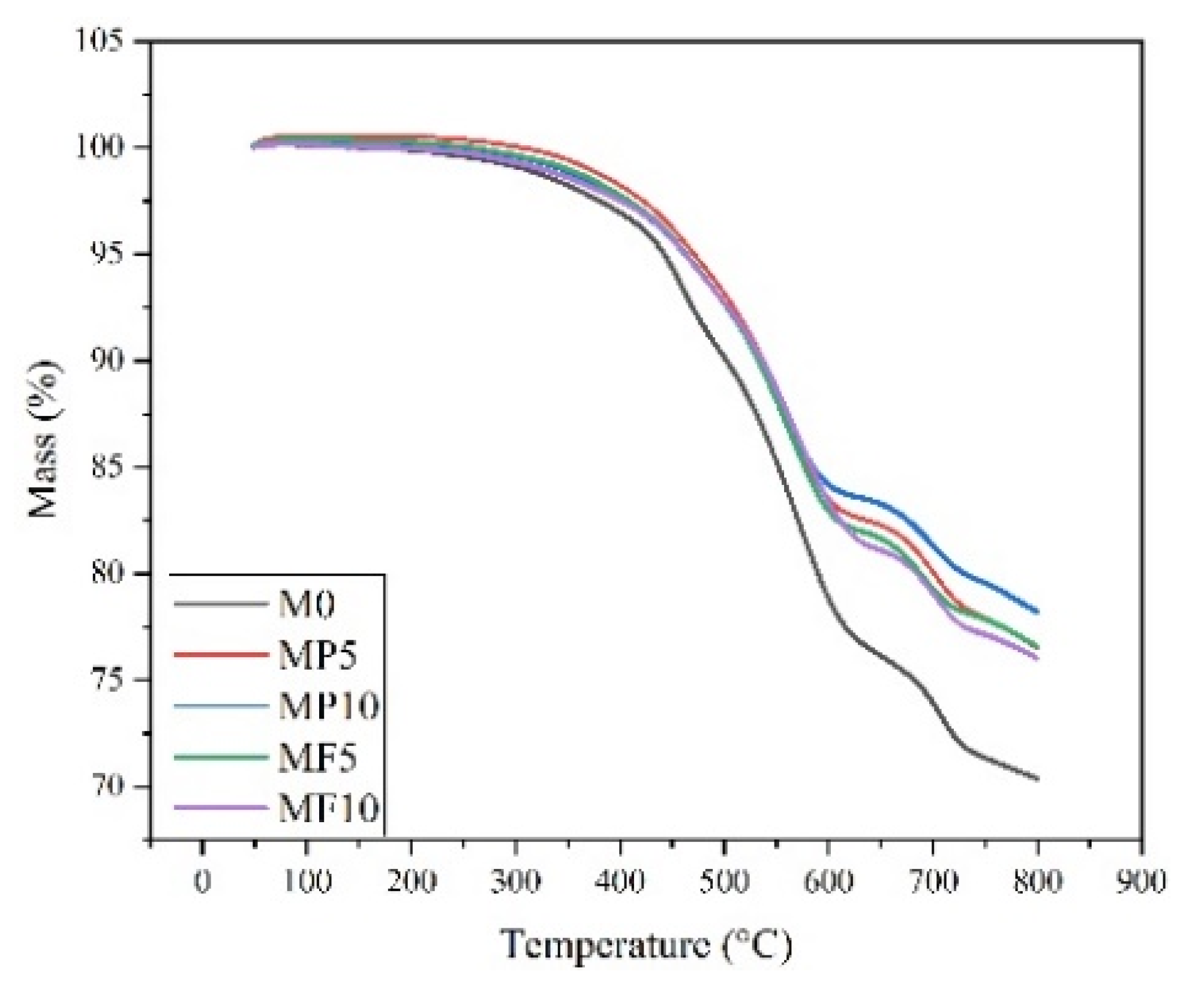

3.1. Physical, Mechanical, and Thermal Properties of Composites

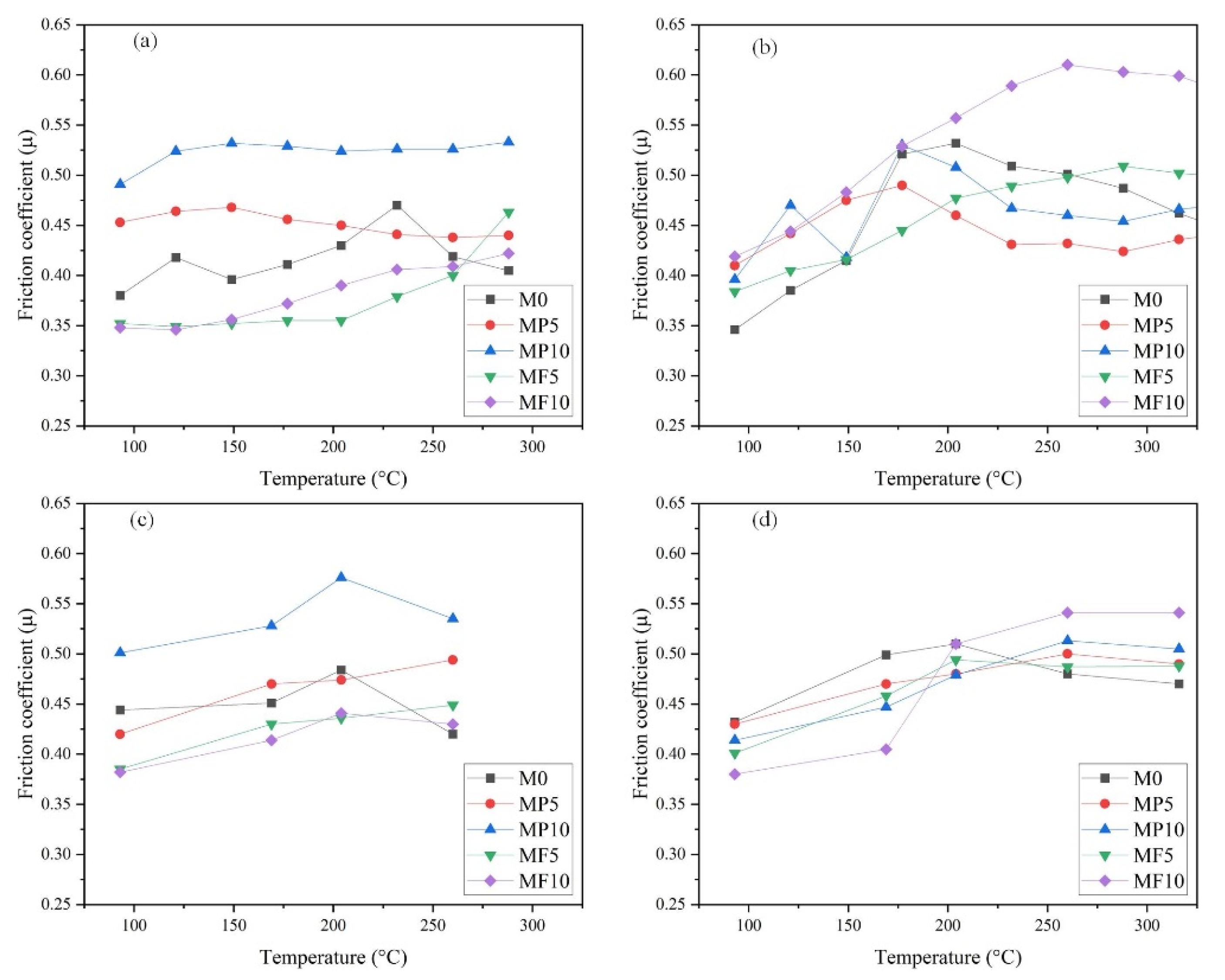

3.2. Tribological Performance of the Composites

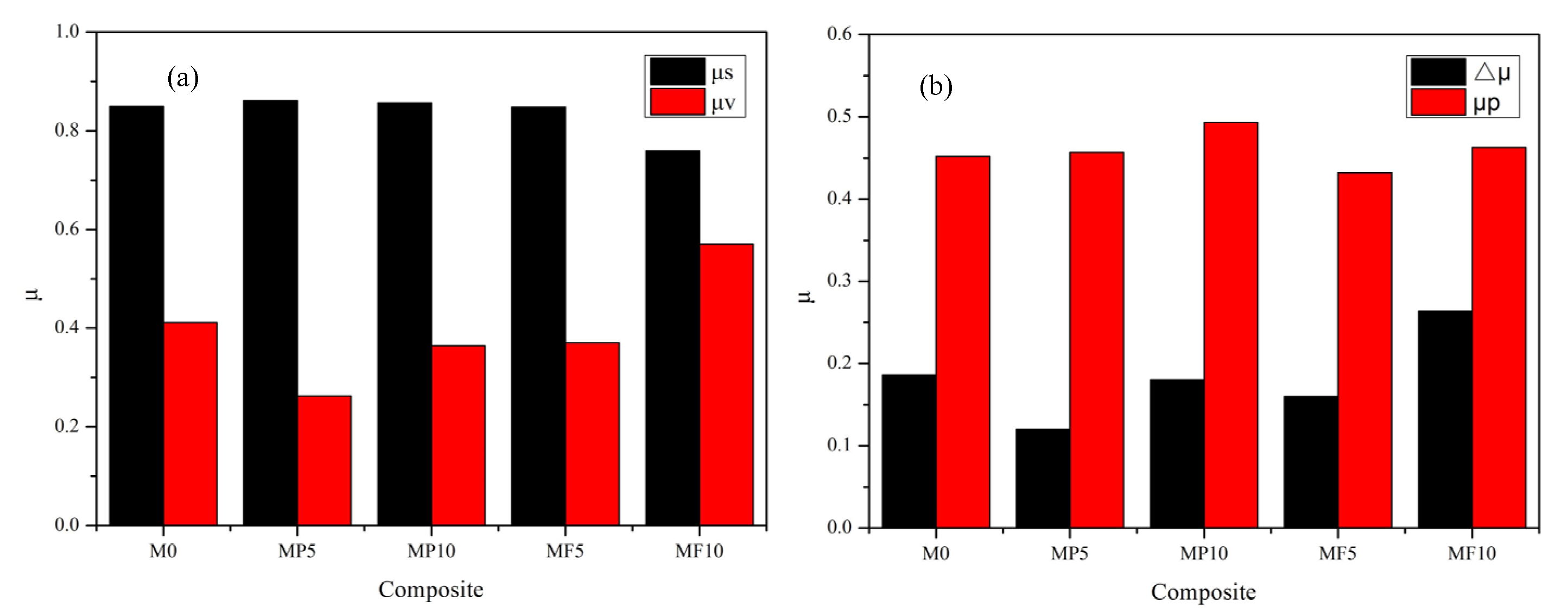

3.2.1. Friction Performance of the Formulations

3.2.2. , , , Performance of the Composites

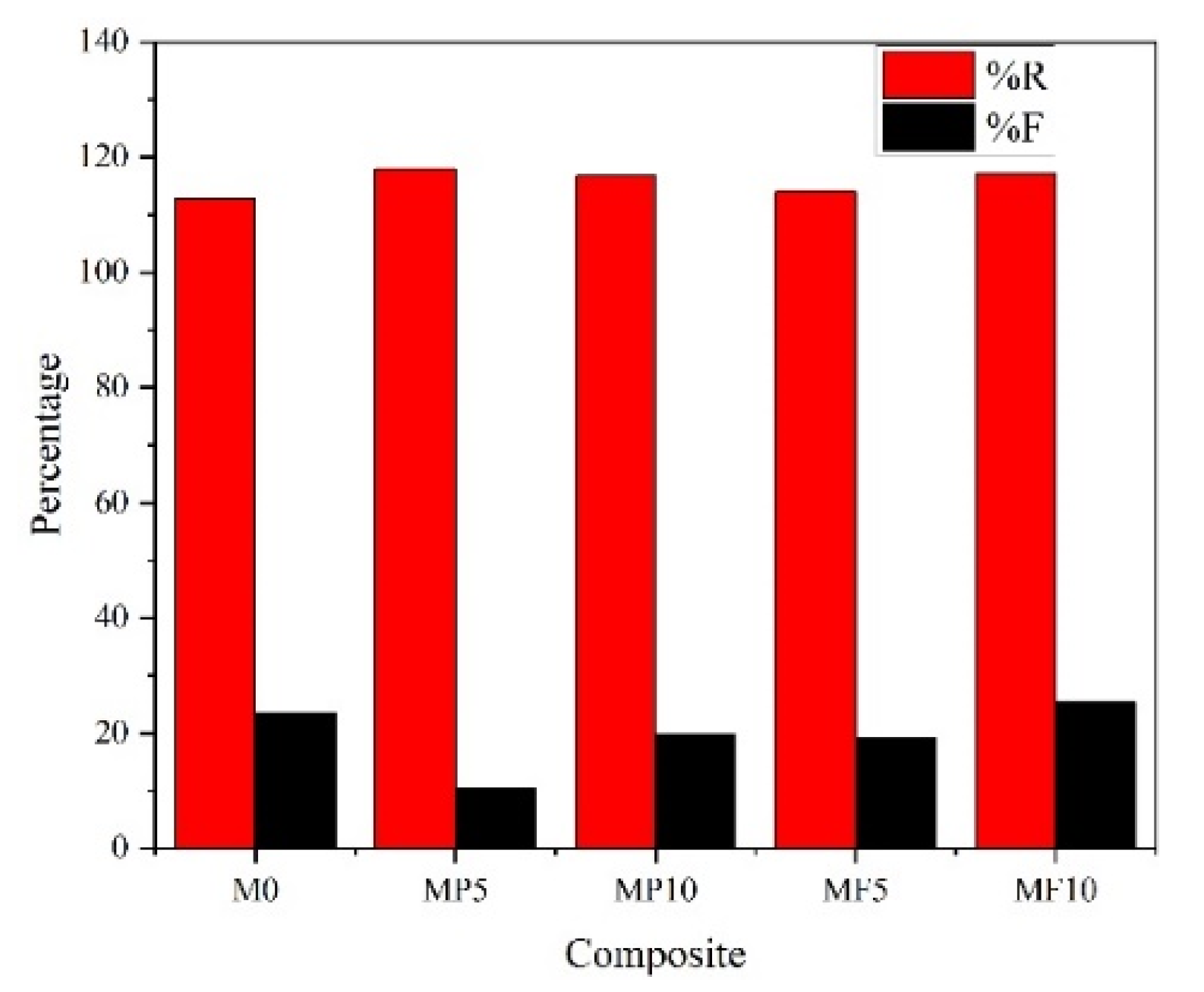

3.2.3. Fade and Recovery Performance of the Composites

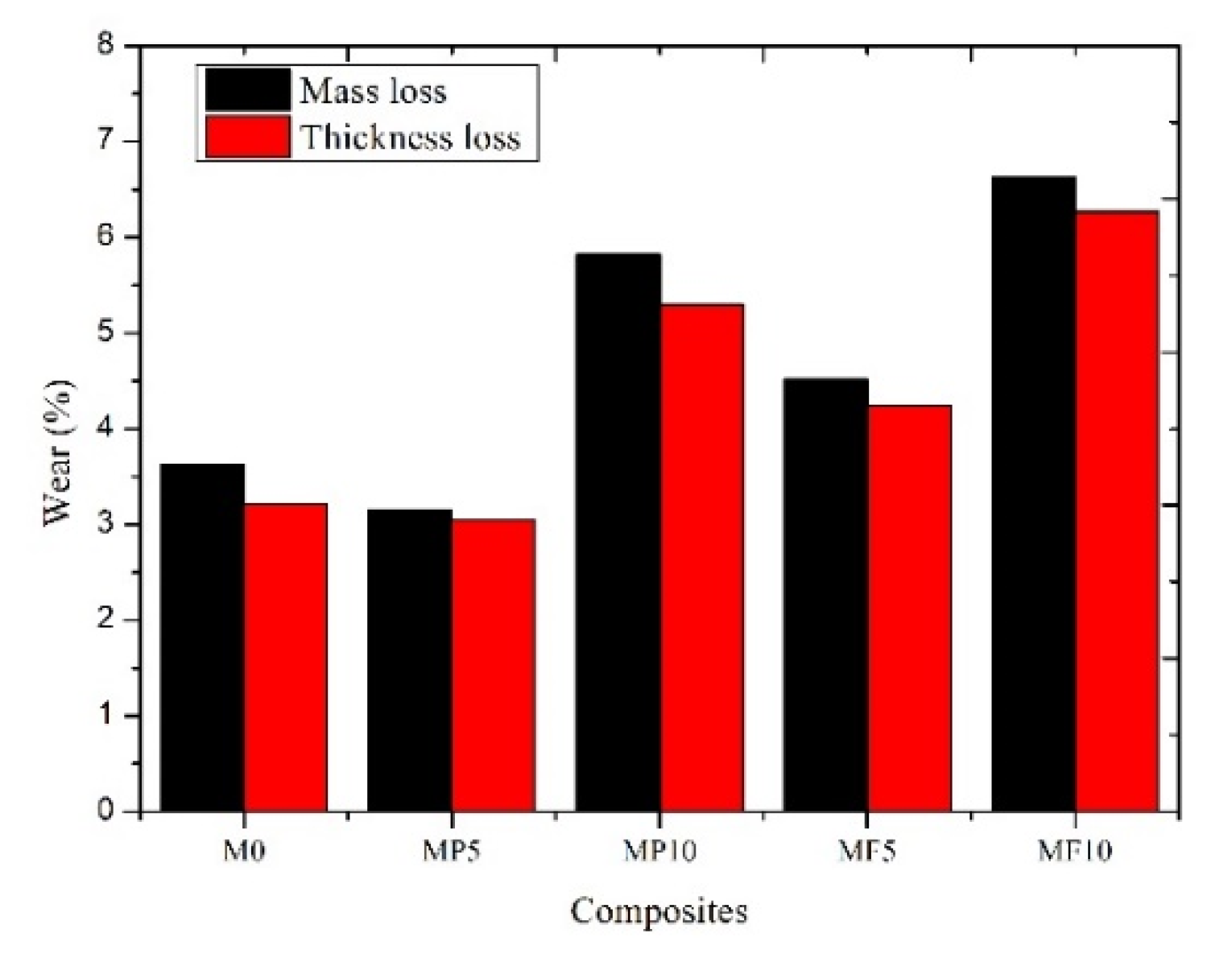

3.3. Wear Performance of the Composites

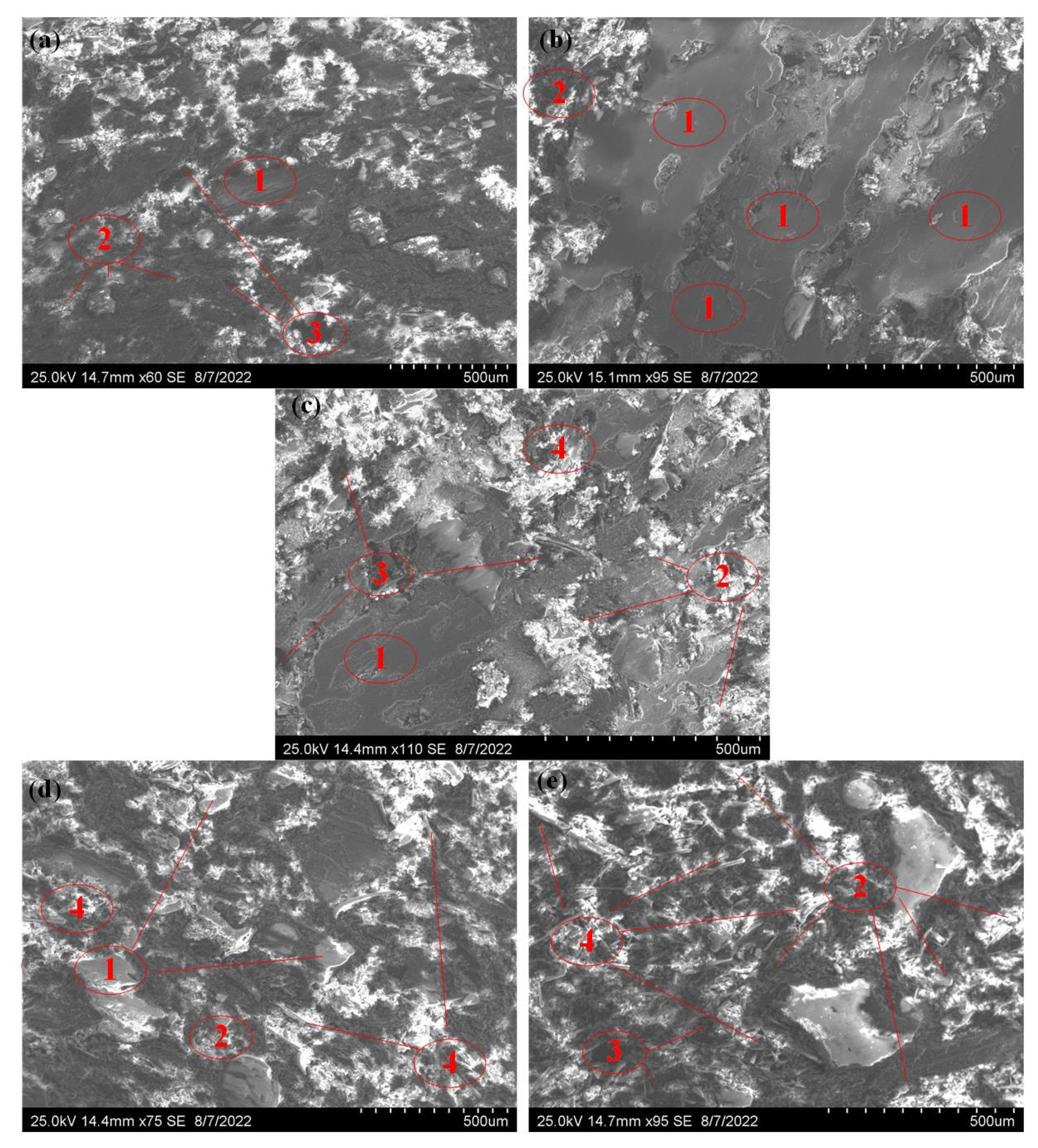

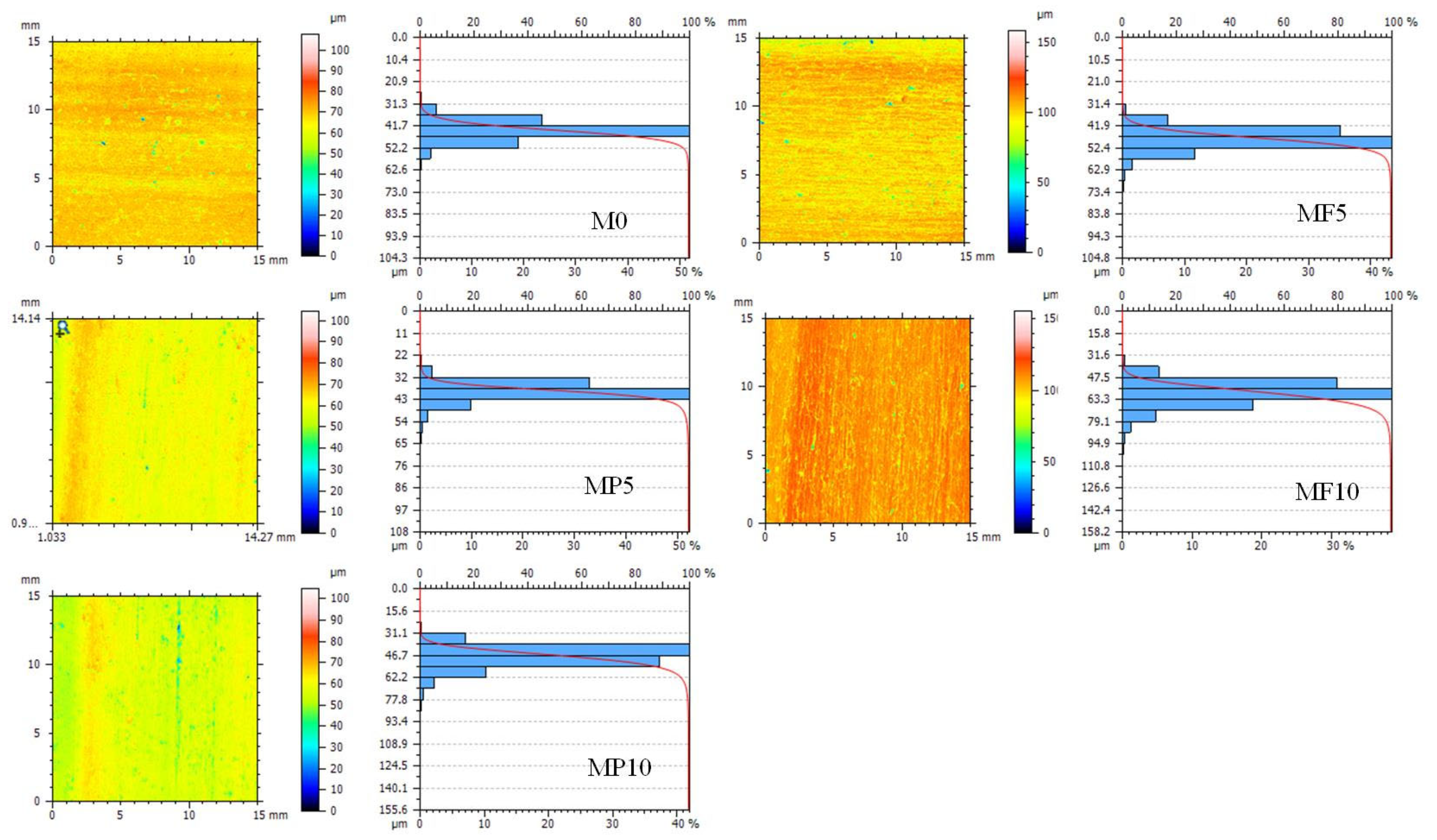

3.4. Worn Surface Study

4. Conclusions

- (1)

- Fibrous mullite brake friction materials have a higher shear strength and hardness and a lower density compared to powdered mullite composites, as mullite content increases, hardness, and shear strength increase and density decreases. Mullite content and shape have less of an effect on water absorption properties;

- (2)

- The stability coefficient of the composites decreases, while the variability coefficient, wear, and frictional fluctuations increase with the increased mullite content; meanwhile, the powder-based mullite composites perform better than that of fiber-based composites;

- (3)

- As the mullite content increases, the fade and recovery performance of the composites become worse, and the powder-based composites perform better than fiber-based composites;

- (4)

- The worn surface of the composites showed typical wear characteristics, the powdered composites present a completely continuous contact platform and small roughness on the surface, yet more spalling and wear debris on the surface of the fibrous composites and increased surface damage as the mullite content increased;

- (5)

- The brake friction material with 5% powdered mullite has the highest stable friction performance (0.86), the lowest wear rate (3%), the highest %R (118), the lowest %F (10.4), and the lowest friction variation performance (0.263), which is considered to be the optimal formulation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Baskara Sethupathi, P.; Chandradass, J. Comparative study of different solid lubricants towards friction stability in a non-asbestos disc brake pad. Ind. Lubr. Tribol. 2021, 73, 897–903. [Google Scholar]

- Jubsilp, C.; Jantaramaha, J.; Mora, P.; Rimdusit, S. Tribological Performance and Thermal Stability of Nanorubber-Modified Polybenzoxazine Composites for Non-Asbestos Friction Materials. Polymers 2021, 13, 2435. [Google Scholar] [CrossRef]

- Wongpayakyotin, A.; Jubsilp, C.; Tiptipakorn, S.; Mora, P.; Bielawski, C.W.; Rimdusit, S. Effects of Alkyl-Substituted Polybenzoxazines on Tribological Properties of Non-Asbestos Composite Friction Materials. Polymers 2021, 13, 567. [Google Scholar] [CrossRef]

- Kalel, N.; Bhatt, B.; Darpe, A.; Bijwe, J. Suppression of Brake Noise and Vibration Using Aramid and Zylon Fibers: Experimental and Numerical Study. ACS Omega 2022, 7, 21946. [Google Scholar] [CrossRef]

- Shen, M.-X.; Li, H.-X.; Du, J.-H.; Ji, D.-H.; Liu, S.-P.; Xiao, Y.-L. New insights into reducing airborne particle emissions from brake materials: Grooved textures on brake disc surface. Tribol. Int. 2022, 174, 107721. [Google Scholar] [CrossRef]

- Ahdy, M.A.; Ali MK, A.; Mourad, M.; Abd-El-Tawwab, A.M. Review of automotive brake lining materials and their tribological properties. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2022, 236, 1445–1465. [Google Scholar] [CrossRef]

- Singh, T.; Tiwari, A.; Patnaik, A.; Chauhan, R.; Ali, S. Influence of wollastonite shape and amount on tribo-performance of non-asbestos organic brake friction composites. Wear 2017, 386, 157–164. [Google Scholar] [CrossRef]

- Sinha, A.; Ischia, G.; Menapace, C.; Gialanella, S. Experimental characterization protocols for wear products from disc brake materials. Atmosphere 2020, 11, 1102. [Google Scholar] [CrossRef]

- Wang, X.; Bao, J.; Liu, J.; Yin, Y.; Liu, T.; Zhao, S. Preparation and optimization of a soft magnetic brake friction material based on permalloy additive. Industrial Lubr. Tribol. 2021, 73, 308–315. [Google Scholar] [CrossRef]

- Kim, S.-H.; Jeong, M.H.; Kim, J.; Shim, W.; Kwon, S.-U.; Lee, J.-J.; Huh, S.H.; Pee, J.-H.; Kim, J.-Y. Dynamometric Investigation on Airborne Particulate Matter (PM) from Friction Materials for Automobile: Impact of Abrasive and Lubricant on PM Emission Factor. Lubricants 2021, 9, 118. [Google Scholar] [CrossRef]

- Kumar, N.; Kumar, S.; Grewal, J.S.; Mehta, V.; Ali, S. Comparative study of Abaca fiber and Kevlar fibers based brake friction composites. Polym. Compos. 2022, 43, 730–740. [Google Scholar] [CrossRef]

- Karaca, F.; Can, İ. Effects of grain size on the performance of brake linings with Al2O3 additives. Mater. Test. 2021, 63, 822–828. [Google Scholar] [CrossRef]

- Shinde, D.; Bulsara, M.; Patil, J. Wear analysis of eco-friendly non-asbestos friction-lining material applied in an automotive drum brake: Experimental and finite-element analysis. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2022, 236, 552–562. [Google Scholar] [CrossRef]

- Kumar, N.; Grewal, J.S.; Kumar, N.; Kumar, S. A novel Pinus roxburghii natural leaves fiber used as reinforcement polymer composite: As asbestos-free brake friction material. Polym. Compos. 2022, 43, 566–573. [Google Scholar] [CrossRef]

- Monreal-Pérez, P.; González, J.; Iraizoz, A.; Bilbao, U.; Clavería, I. Effect of the steel fiber length on the friction performance and wear mechanism of railway brake shoes. Tribol. Int. 2022, 172, 107589. [Google Scholar] [CrossRef]

- Wei, L.; Choy, Y.S.; Cheung, C.S.; Jin, D. Tribology performance, airborne particle emissions and brake squeal noise of copper-free friction materials. Wear 2020, 448–449, 203215. [Google Scholar] [CrossRef]

- Zaquen, N.; Tegels, D.; Kerssemakers, A.; Persoon, F. Establishing a Correlation Between Friction Performance and Tribolayer Formation Using Engineered Mineral Fibers. J. Tribol. 2021, 143, 101701. [Google Scholar] [CrossRef]

- Irawan, A.P.; Fitriyana, D.F.; Tezara, C.; Siregar, J.P. Overview of the Important Factors Influencing the Performance of Eco-Friendly Brake Pads. Polymers 2022, 14, 1180. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, L.; Song, Q.; Zhang, R.; Zhao, F.; Li, W.; Sheng, H.; Hou, X.; Li, H. Simultaneously enhancing mechanical and tribological properties of carbon fiber composites by grafting SiC hexagonal nanopyramids for brake disk application. J. Mater. Sci. Technol. 2022, 121, 1–8. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Di Bella, G.; Valenza, A. A review on basalt fibre and its composites. Compos. Part B Eng. 2015, 74, 74–94. [Google Scholar] [CrossRef]

- Pucci, M.F.; Seghini, M.C.; Liotier, P.J.; Sarasini, F.; Tirilló, J.; Drapier, S. Surface characterisation and wetting properties of single basalt fibres. Compos. Part B Eng. 2017, 109, 72–81. [Google Scholar] [CrossRef]

- Cui, G.; Han, J. Resin Matrix Brake Materials Reinforced by Nano-Al2O3 for Mining Equipment. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2019, 34, 75–81. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, Y.; Lv, X.; Yu, J.; Zhuang, J.; Tong, J. Mineral fibre reinforced friction composites: Effect of rockwool fibre on mechanical and tribological behaviour. Mater. Res. Express 2018, 5, 095308. [Google Scholar] [CrossRef]

- Baskara Sethupathi, P.; Chandradass, J. Effect of zirconium silicate and mullite with three different particle sizes on tribo performance in a non-asbestos brake pad. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2022, 236, 314–325. [Google Scholar] [CrossRef]

- Raj, J.S.; Christy, T.V.; Gnanaraj, S.D.; Sugozu, B. Influence of calcium sulfate whiskers on the tribological characteristics of automotive brake friction materials. Eng. Sci. Technol. Int. J. 2020, 23, 445–451. [Google Scholar]

- Jara, D.C.; Jang, H. Synergistic effects of the ingredients of brake friction materials on friction and wear: A case study on phenolic resin and potassium titanate. Wear 2019, 430, 222–232. [Google Scholar] [CrossRef]

- Huang, Y.-Q.; Li, Z.; Liu, P.-F.; Huang, T.-X.; Li, Y.; Xiao, P. Tribological properties of Mullite/3Y-TZP ceramics with different content of mullite fabricated by gel-casting. Appl. Surf. Sci. 2019, 476, 232–241. [Google Scholar] [CrossRef]

- Schneider, H.; Schreuer, J.; Hildmann, B. Structure and properties of mullite—A review. J. Eur. Ceram. Soc. 2008, 28, 329–344. [Google Scholar] [CrossRef]

- Ji, Z.; Luo, W.; Zhou, K.; Hou, S.; Zhang, Q.; Li, J.; Jin, H. Effects of the shapes and dimensions of mullite whisker on the friction and wear behaviors of resin-based friction materials. Wear 2018, 406, 118–125. [Google Scholar] [CrossRef]

- Cai, P.; Wang, Y.; Wang, T.; Wang, Q. Improving tribological behaviors of friction material by mullite. Tribol. Int. 2016, 93, 282–288. [Google Scholar] [CrossRef]

- Vineeth Kumar, V.; Senthil Kumaran, S.; Dhanalakshmi, S.; Sivaramakrishnan, R. Tribological performance evaluation of fused mullite-reinforced hybrid composite brake pad for defence application. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 179. [Google Scholar] [CrossRef]

- Zhu, J.; Yan, H. Fabrication of an A356/fly-ash-mullite interpenetrating composite and its wear properties. Ceram. Int. 2017, 43, 12996–13003. [Google Scholar] [CrossRef]

- Singh, T.; Pattnaik, P.; Pruncu, C.I.; Tiwari, A.; Fekete, G. Selection of natural fibers based brake friction composites using hybrid ELECTRE-entropy optimization technique. Polym. Test. 2020, 89, 106614. [Google Scholar] [CrossRef]

- Amirjan, M. Microstructure, wear and friction behavior of nanocomposite materials with natural ingredients. Tribol. Int. 2019, 131, 184–190. [Google Scholar] [CrossRef]

- Pai, A.; Subramanian, S.; Sood, T. Tribological response of waste tire rubber as micro-fillers in automotive brake lining materials. Friction 2020, 8, 16. [Google Scholar] [CrossRef]

- Wang, F.; Ying, L. Mechanical and tribological properties of ceramic-matrix friction materials with steel fiber and mullite fiber. Mater. Des. 2014, 57, 449–455. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Huang, B.Y.; Di, S.U. Relationship Between Fiber Content and Properties of Automotive Friction Materials. Tribology 1999, 32, 32–36. [Google Scholar]

- Kumar, N.; Singh, T.; Grewal, J.S.; Patnaik, A.; Fekete, G. Experimental investigation on the physical, mechanical and tribological properties of hemp fiber-based non-asbestos organic brake friction composites. Mater. Res. Express 2019, 6, 1–11. [Google Scholar] [CrossRef]

- Kumar, N.; Grewal, J.S.; Kumar, S.; Ali, S.; Kumar, N. A novel Himachal’s Bagar (Sabai) grass fiber used as a brake friction material in brake polymer composite and compared to standard brake friction material. Polym. Compos. 2022, 43, 215–224. [Google Scholar] [CrossRef]

| Ingredient (wt%) | M0 | MP5 | MP10 | MF5 | MF10 |

|---|---|---|---|---|---|

| Resin | 10 | 10 | 10 | 10 | 10 |

| Rubber | 3 | 3 | 3 | 3 | 3 |

| Friction powder | 3 | 3 | 3 | 3 | 3 |

| Mullite | 0 | 5 | 10 | 5 | 10 |

| Rock wool | 15 | 15 | 15 | 15 | 15 |

| Lapinus fiber | 10 | 10 | 10 | 10 | 10 |

| Graphite | 7 | 7 | 7 | 7 | 7 |

| Vermiculite | 7 | 7 | 7 | 7 | 7 |

| Barite | 45 | 40 | 35 | 40 | 35 |

| Cycle | Speed (rpm) | Load (N) | Time | Temp. (°C) | Applications | Heater | ||

|---|---|---|---|---|---|---|---|---|

| on | off | min | max | |||||

| Burnish | 312 | 440 | 20 min | - | - | 93 | 1 | off |

| Baseline | 417 | 667 | 10 s | - | 82 | 104 | 20 | off |

| Fade-I | 417 | 667 | 10 min | - | 93 | 288 | 1 | on |

| Recovery-I | 417 | 667 | 10 s | - | 260 | 93 | 1 | off |

| Wear | 417 | 667 | 20 s | 10 s | 193 | 204 | 100 | off |

| Fade-II | 417 | 667 | 10 min | - | 93 | 343 | 1 | on |

| Recovery-II | 417 | 667 | 10 s | - | 316 | 93 | 1 | off |

| Baseline | 417 | 667 | 10 s | 20 s | 82 | 104 | 20 | off |

| Properties | M0 | MP5 | MP10 | MF5 | MF10 |

|---|---|---|---|---|---|

| Density (g/cm3) | 2.34 | 2.29 | 2.21 | 2.19 | 2.10 |

| Hardness (HRR) | 83.1 | 83.8 | 84.8 | 82.6 | 83.3 |

| Water absorption (%) | 0.9 | 0.82 | 0.93 | 0.85 | 0.97 |

| Shear strength (MPa) | 7.3 | 7.4 | 7.1 | 8.2 | 7.6 |

| Sample | %F | %R | Mass Loss | Thickness Loss | ||||

|---|---|---|---|---|---|---|---|---|

| M0 | 0.452 | 0.186 | 0.85 | 0.411 | 23.5 | 112.8 | 3.57% | 3.24% |

| MP5 | 0.457 | 0.12 | 0.862 | 0.263 | 10.2 | 116.0 | 3.19% | 3.05% |

| MP10 | 0.493 | 0.18 | 0.857 | 0.365 | 19.7 | 116.7 | 5.75% | 5.36% |

| MF5 | 0.432 | 0.16 | 0.848 | 0.371 | 19.1 | 114.4 | 4.51% | 4.21% |

| MF10 | 0.463 | 0.264 | 0.759 | 0.57 | 25.3 | 116.8 | 6.59% | 6.27% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, N.; Yin, Z. The Influence of Mullite Shape and Amount on the Tribological Properties of Non-Asbestos Brake Friction Composites. Lubricants 2022, 10, 220. https://doi.org/10.3390/lubricants10090220

Wang N, Yin Z. The Influence of Mullite Shape and Amount on the Tribological Properties of Non-Asbestos Brake Friction Composites. Lubricants. 2022; 10(9):220. https://doi.org/10.3390/lubricants10090220

Chicago/Turabian StyleWang, Nan, and Zixin Yin. 2022. "The Influence of Mullite Shape and Amount on the Tribological Properties of Non-Asbestos Brake Friction Composites" Lubricants 10, no. 9: 220. https://doi.org/10.3390/lubricants10090220

APA StyleWang, N., & Yin, Z. (2022). The Influence of Mullite Shape and Amount on the Tribological Properties of Non-Asbestos Brake Friction Composites. Lubricants, 10(9), 220. https://doi.org/10.3390/lubricants10090220