Influence of Test Parameters on the Evaluation of Chocolate Silkiness Using the Tribological Method

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

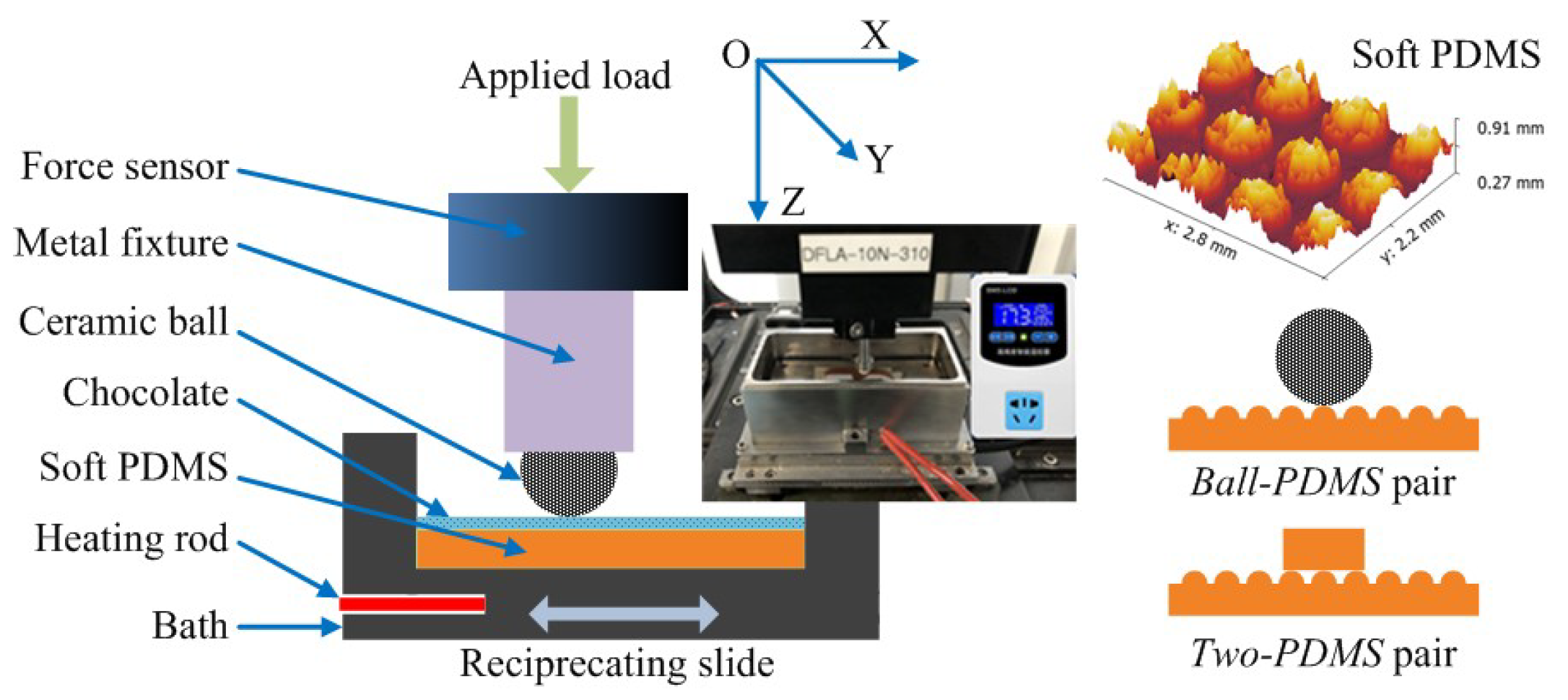

2.2. Evaluation Process of Chocolate Silkiness

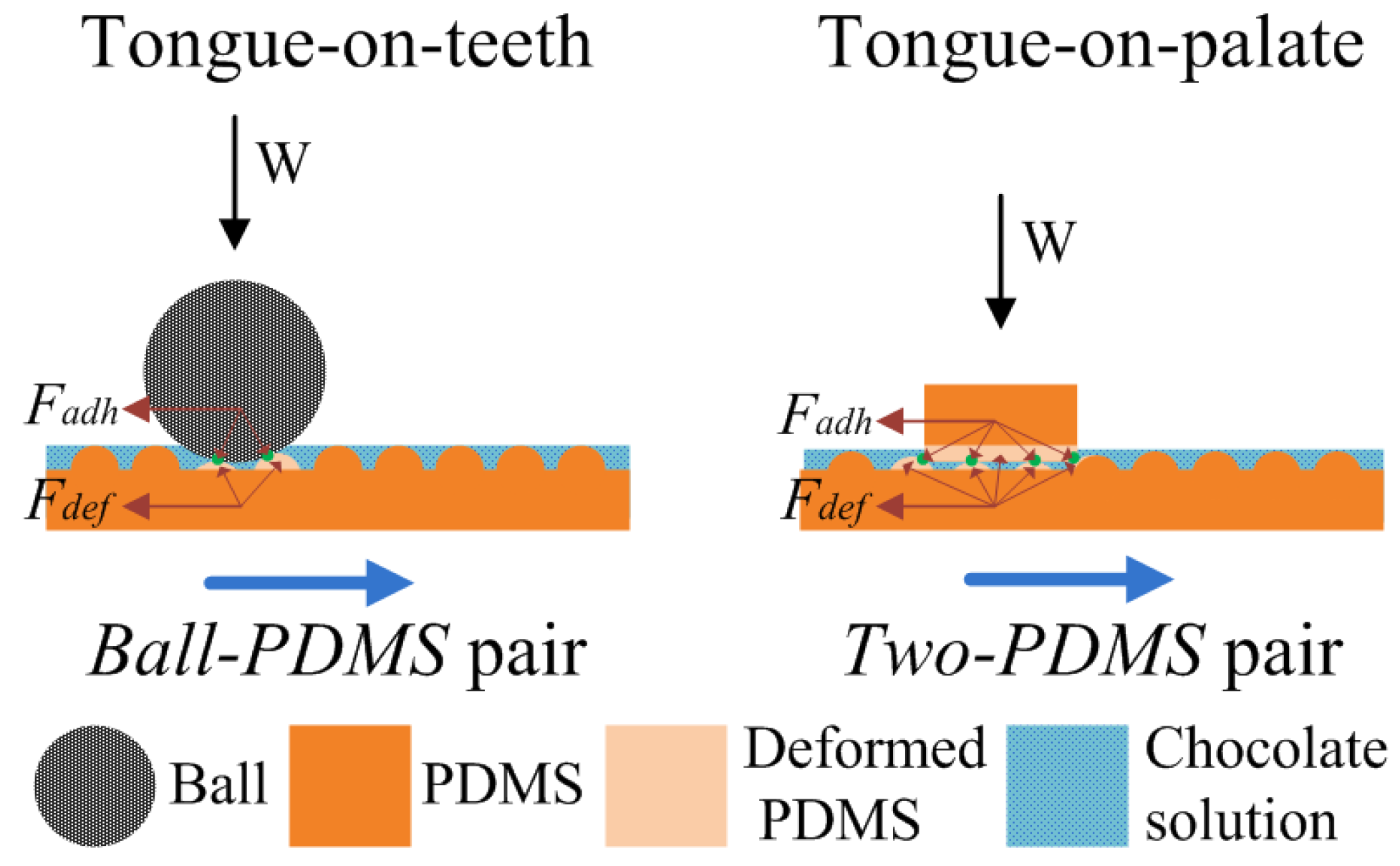

2.3. Testing Method for Friction Properties of Mixed Chocolate Solution

2.4. Correlation Coefficient

3. Results and Discussion

3.1. Effect of Cocoa Concentration on Chocolate Silkiness

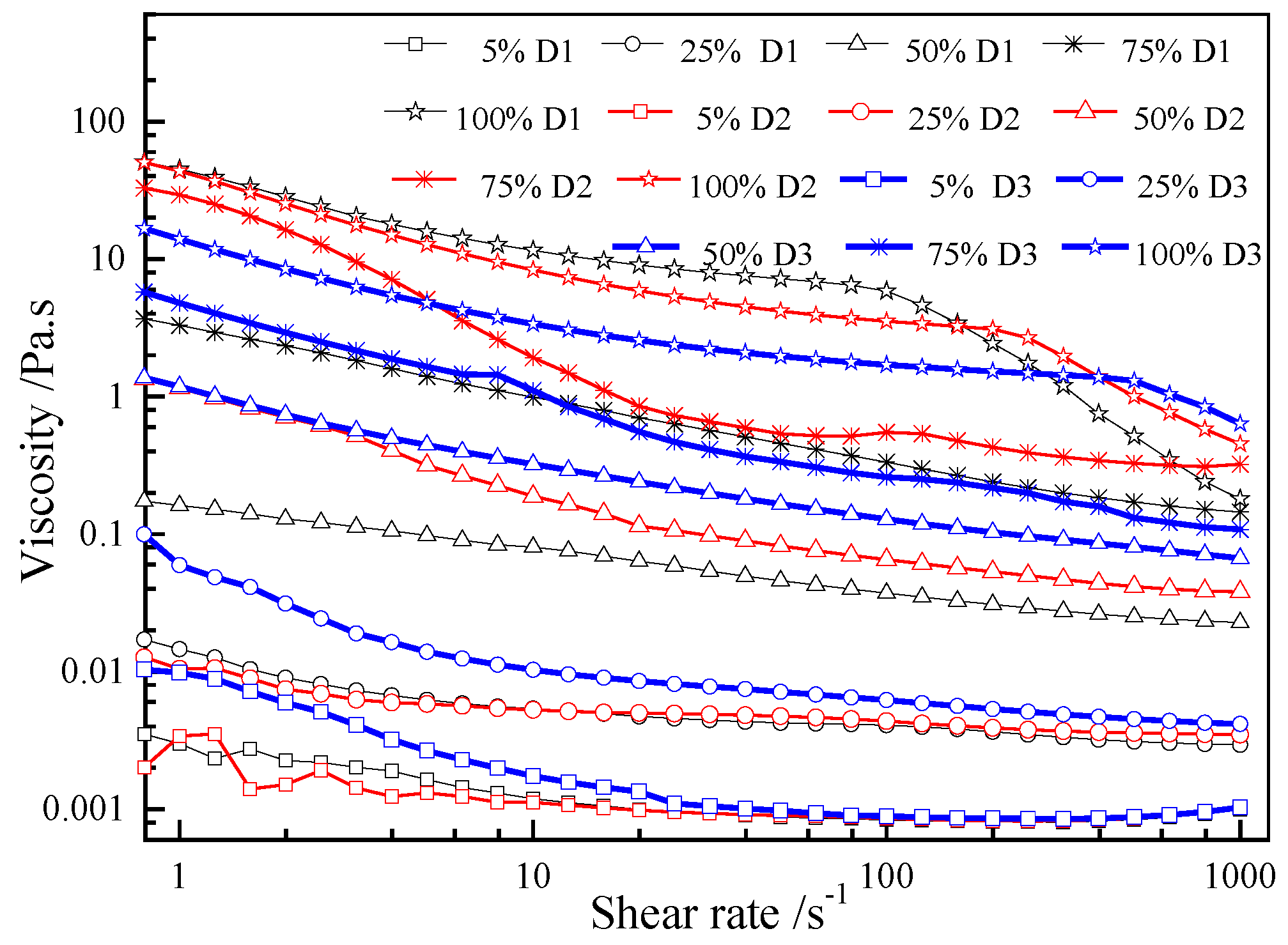

3.2. Effect of Cocoa Concentration on Viscosity

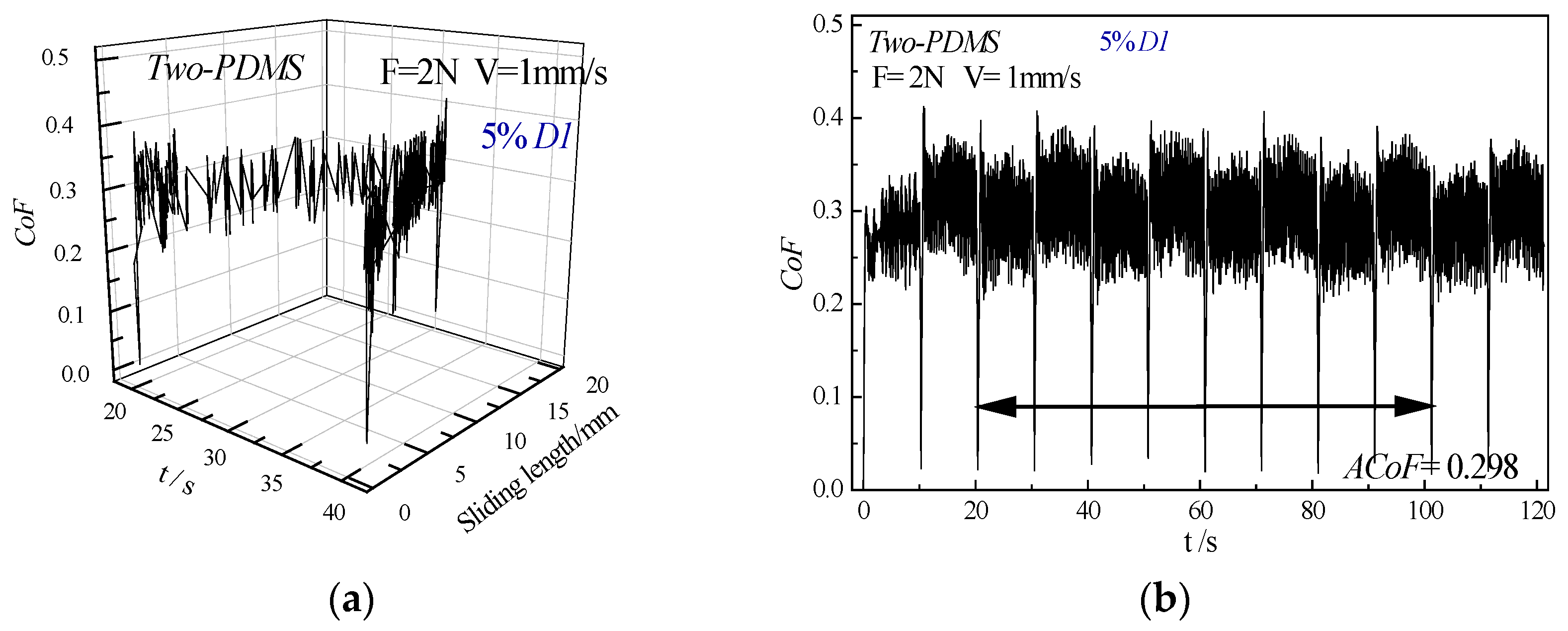

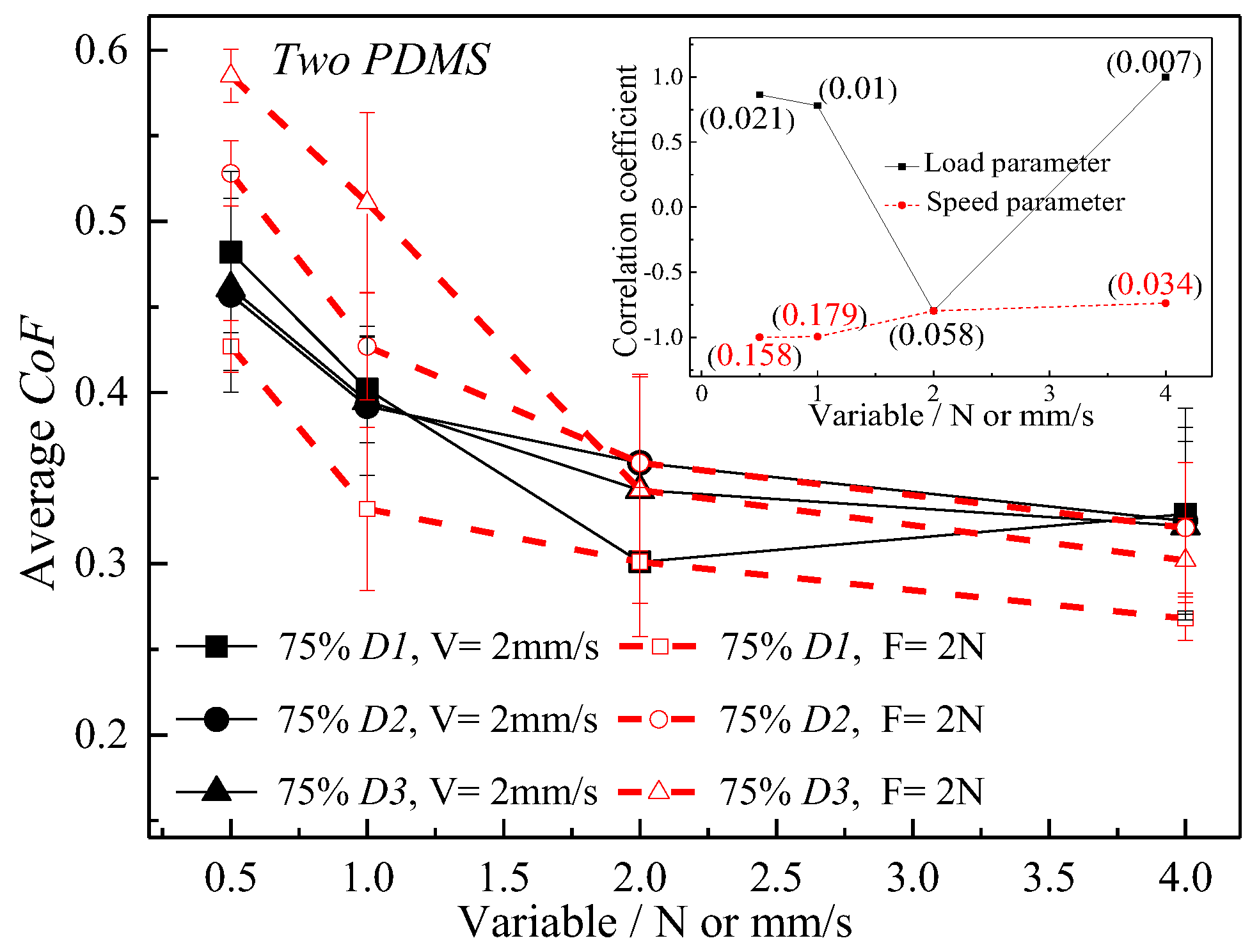

3.3. Effects of Cocoa Concentration on the Friction Property

3.4. Discussions

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lonchampt, P.; Hartel, R.W. Fat bloom in chocolate and compound coatings. Eur. J. Lipid Sci. Technol. 2004, 106, 241–274. [Google Scholar] [CrossRef]

- Fernandes, V.A.; Muller, A.J.; Sandoval, A.J. Thermal, structural and rheological characteristics of dark chocolate with different compositions. J. Food Eng. 2013, 116, 97–108. [Google Scholar] [CrossRef]

- Glicerina, V.; Balestra, F.; Dalla Rosa, M.; Romani, S. Microstructural and rheological characteristics of dark, milk and white chocolate: A comparative study. J. Food Eng. 2016, 169, 165–171. [Google Scholar] [CrossRef]

- Vasquez, C.; Henriquez, G.; Lopez, J.V.; Penott-Chang, E.K.; Sandoval, A.J.; Muller, A.J. The effect of composition on the rheological behavior of commercial chocolates. Lwt-Food Sci. Technol. 2019, 111, 744–750. [Google Scholar] [CrossRef]

- Ren, S.; Barringer, S. Electrohydrodynamic spraying quality of different chocolate formulations. J. Electrost. 2016, 84, 121–127. [Google Scholar] [CrossRef]

- Rodrigues, S.A.; Selway, N.; Morgenstern, M.P.; Motoi, L.; Stokes, J.R.; James, B.J. Lubrication of chocolate during oral processing. Food Funct. 2017, 8, 533–544. [Google Scholar] [CrossRef]

- Silva, G.D.J.; Ferreira Goncalves, B.H.R.; De Jesus, J.C.; Teixeira Ribeiro Vidigal, M.C.; Minim, L.A.; Ferreira, S.O.; Ferreira Bonomo, R.C.; Barbosa Ferrao, S.P. Study of the structural properties of goat’s milk chocolates with different concentrations of cocoa mass. J. Texture Stud. 2019, 50, 547–555. [Google Scholar] [CrossRef]

- Parsons, J.G.; Keeney, P.G. Phospholipid concentration in cocoa butter and its relationship to viscosity in dark chocolate. J. Am. Oil Chem. Soc. 1969, 46, 425–427. [Google Scholar] [CrossRef]

- Lee, S.; Biresaw, G.; Kinney, M.P.; Inglett, G.E. Effect of cocoa butter replacement with a beta-glucan-rich hydrocolloid (C-trim30) on the rheological and tribological properties of chocolates. J. Sci. Food Agric. 2009, 89, 163–167. [Google Scholar] [CrossRef]

- Kokini, J.L.; Kadane, J.B.; Cussler, E.L. Liquid texture perceived in the mouth. J. Texture Stud. 1977, 8, 195–218. [Google Scholar] [CrossRef]

- Wijk, R.A.D.; Prinz, J.F. The role of friction in perceived oral texture. Food Qual. Prefer. 2005, 16, 121–129. [Google Scholar] [CrossRef]

- De Wijk, R.A.; Prinz, J.F. Mechanisms underlying the role of friction in oral texture. J. Texture Stud. 2006, 37, 413–427. [Google Scholar] [CrossRef]

- Subramanian, S.; Viswanathan, R. Bulk density and friction coefficients of selected minor millet grains and flours. J. Food Eng. 2007, 81, 18–126. [Google Scholar] [CrossRef]

- Dresselhuis, D.M.; De Hoog, E.H.A.; Stuart, M.A.C.; Van Aken, G.A. Application of oral tissue in tribological measurements in an emulsion perception context. Food Hydrocoll. 2008, 22, 323–335. [Google Scholar] [CrossRef]

- Meyer, D.; Vermulst, J.; Tromp, R.H.; De Hoog, E.H.A. The effect of inulin on tribology and sensory profiles of skimmed milk. J. Texture Stud. 2011, 42, 387–393. [Google Scholar] [CrossRef]

- Luengo, G.; Tsuchiya, M.; Heuberger, M.; Israelachvili, J. Thin film rheology and tribology of chocolate. J. Food Sci. 1997, 62, 767–812. [Google Scholar] [CrossRef]

- Carvalho-da-Silva, A.M.; Van Damme, I.; Taylor, W.; Hort, J.; Wolf, B. Oral processing of two milk chocolate samples. Food Funct. 2013, 4, 461–469. [Google Scholar] [CrossRef]

- Taylor, B.L.; Mills, T.B. Using a three-ball-on-plate configuration for soft tribology applications. J. Food Eng. 2020, 274, 109838. [Google Scholar] [CrossRef]

- Joyner, H.S.; Pernell, C.W.; Daubert, C.R. Impact of parameter settings on normal force and gap height during tribological measurements. J. Food Eng. 2014, 137, 51–63. [Google Scholar] [CrossRef]

- Chen, J.; Liu, Z.; Prakash, S. Lubrication studies of fluid food using a simple experimental set up. Food Hydrocoll. 2014, 42, 100–105. [Google Scholar] [CrossRef]

- Mo, L.; Chen, J.; Wang, X. A novel experimental set up for in situ oral lubrication measurements. Food Hydrocoll. 2019, 95, 396–405. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, J.; Zhong, M.; Xu, W. A novel, simple and rapid method for the detection of melamine from milk based on tribology measurements. Tribol. Int. 2018, 119, 66–72. [Google Scholar] [CrossRef]

- Liu, Y.; Qu, F.; Luo, L.; Xu, W.; Zhong, M. Detection of rice syrup from acacia honey based on lubrication properties measured by tribology technique. Tribol. Int. 2019, 129, 239–245. [Google Scholar] [CrossRef]

- Masen, M.; Cann, P.M.E. Friction measurements with molten chocolate. Tribol. Lett. 2018, 66, 24. [Google Scholar] [CrossRef]

- Mantihal, S.; Prakash, S.; Godoi, F.C.; Bhandari, B. Effect of additives on thermal, rheological and tribological properties of 3D printed dark chocolate. Food Res. Int. 2019, 119, 161–169. [Google Scholar] [CrossRef] [PubMed]

- He, Q.; Bramante, F.; Davies, A.; Elleman, C.; Fourtouni, K.; Wolf, B. Material properties of ex vivo milk chocolate boluses examined in relation to texture perception. Food Funct. 2018, 9, 3532–3546. [Google Scholar] [CrossRef] [PubMed]

- Bongaerts, J.H.H.; Rossetti, D.; Stokes, J.R. The lubricating properties of human whole saliva. Tribol. Lett. 2007, 27, 277–287. [Google Scholar] [CrossRef]

- Lee, S.; Heuberger, M.; Rousset, P.; Spencer, N.D. A tribological model for chocolate in the mouth: General implications for slurry-lubricated hard/soft sliding counterfaces. Tribol. Lett. 2004, 16, 239–249. [Google Scholar] [CrossRef]

- Segovia, C.; Hutchinson, I.; Laing, D.G.; Jinks, A.L. A quantitative study of fungiform papillae and taste pore density in adults and children. Dev. Brain Res. 2002, 138, 135–146. [Google Scholar] [CrossRef]

- Essick, G.K.; Chopra, A.; Guest, S.; McGlone, F. Lingual tactile acuity, taste perception, and the density and diameter of fungiform papillae in female subjects. Physiol. Behav. 2003, 80, 289–302. [Google Scholar] [CrossRef]

- Just, T.; Stave, J.; Pau, H.W.; Guthoff, R. In vivo observation of papillae of the human tongue using confocal laser scanning microscopy. ORL J. Otorhinolaryngol. Relat. Spec. 2005, 67, 207–212. [Google Scholar] [CrossRef] [PubMed]

- Chen, N.; Yang, X.; Zuniga, J.R. Quantitative studies of taste and fungiform papillae on the anterior human tongue. Chin. J. Stomatol. 1998, 33, 140–142. [Google Scholar]

- Correa, M.; Hutchinson, I.; Laing, D.G.; Jinks, A.L. Changes in fungiform papillae density during development in humans. Chem. Senses 2013, 38, 519–527. [Google Scholar] [CrossRef] [PubMed]

- Xie, K.W.; Zebin Li, Z.B.; Deng, Y.; Zhang, Q.; Zhong, S.Y.; Cai, J.J.; Chang, L.X. Stress-laser composite fabrication of right-angle microgrooves on polydimethylsiloxane flexible substrate. Polym. Mater. Sci. Eng. 2022, 38, 106–112. [Google Scholar]

- Qian, S.H.; Cheng, S.; Liu, Z.; Xu, F.F.; Yu, J.H. A rapid method to evaluate the chocolate smoothness based on the tribological measurement. J. Texture Stud. 2020, 51, 882–890. [Google Scholar] [CrossRef] [PubMed]

- Qian, S.; Zhang, L.; Ni, Z.F.; Huang, C.; Zhang, D. Investigation of contact characteristics and frictional properties of natural articular cartilage at two different surface configurations. J. Mater. Sci. Mater. Med. 2017, 28, 84. [Google Scholar] [CrossRef]

- Qian, S.; Liu, L.; Ni, Z.; Luo, Y. Experimental investigation of the dynamic properties of natural cartilage under reciprocating sliding at two typical rubbing pairs. J. Eng. Tribol. 2019, 233, 1318–1326. [Google Scholar] [CrossRef]

- Moore, D.F. The Friction and Lubrication of Elastomers; Pergamon Press: Oxford, UK, 1972. [Google Scholar]

- Guo, Y.; Wang, J.; Li, F.; Pan, D.; Li, K. Theory of adhesion-hysteresis-fatigue of elastomeric tribology and experimental demonstration. Tribology 2013, 33, 443–448. [Google Scholar]

- Su, B.; Huang, W.; Wang, X. Distribution effect of surface texture on the elastic deformation in soft contacts. Ind. Lubr. Tribol. 2019, 71, 1194–1199. [Google Scholar] [CrossRef]

- Peng, C.L.; Jost-Brinkmann, P.G.; Miethke, R.R.; Lin, C.T. Ultrasonographic measurement of tongue movement during swallowing. J. Ultrasound Med. 2000, 19, 15–20. [Google Scholar] [CrossRef] [Green Version]

| Chocolate | Energy (kJ) | Cocoa (%) | Protein (g) | Fat (g) | Carbohydrates (g) |

|---|---|---|---|---|---|

| D1 | 2270 | 25 | 6.3 | 31.6 | 57 |

| D2 | 2177 | 48 | 5.7 | 33.5 | 59.1 |

| D3 | 2388 | 66 | 7.1 | 44.8 | 48.1 |

| Load Group | Speed Group | |||||

|---|---|---|---|---|---|---|

| Variable | Load (N) | Speed (mm/s) | Time (s) | Load (N) | Speed (mm/s) | Time (s) |

| Value | 0.5 | 2 | 120 | 2 | 0.5 | 480 |

| 1 | 1 | 240 | ||||

| 2 | 2 | 120 | ||||

| 4 | 4 | 60 | ||||

| Affected Attributes | Evaluated Criterion | Involved Subjects |

|---|---|---|

| Melting speed | Higher melting speed produced more silkiness | 20 (62.5%) |

| Hardness | Lower hardness produced more silkiness | 10 (31.2%) |

| Viscosity | Lower viscosity produced more silkiness | 8 (25%) |

| Particle sensation | Lower particle sensation produced more silkiness | 7 (21.9%) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ni, Z.; Qian, S.; Cheng, S.; Wang, L.; Xu, F. Influence of Test Parameters on the Evaluation of Chocolate Silkiness Using the Tribological Method. Lubricants 2022, 10, 217. https://doi.org/10.3390/lubricants10090217

Ni Z, Qian S, Cheng S, Wang L, Xu F. Influence of Test Parameters on the Evaluation of Chocolate Silkiness Using the Tribological Method. Lubricants. 2022; 10(9):217. https://doi.org/10.3390/lubricants10090217

Chicago/Turabian StyleNi, Zifeng, Shanhua Qian, Shuai Cheng, Liang Wang, and Feifei Xu. 2022. "Influence of Test Parameters on the Evaluation of Chocolate Silkiness Using the Tribological Method" Lubricants 10, no. 9: 217. https://doi.org/10.3390/lubricants10090217

APA StyleNi, Z., Qian, S., Cheng, S., Wang, L., & Xu, F. (2022). Influence of Test Parameters on the Evaluation of Chocolate Silkiness Using the Tribological Method. Lubricants, 10(9), 217. https://doi.org/10.3390/lubricants10090217