1. Introduction

Reducing wear and friction under high-temperature sliding conditions, for example, inside internal combustion or jet engines, during the high-speed processing of metals, etc., requires the use of metal–ceramic composites that are resistant to high-temperature tribo-oxidizing [

1,

2,

3,

4,

5]. However, tribo-oxidizing of the composite components can offer an adaptation mechanism that may provide a generation of oxidized mechanically mixed layers on the worn surfaces. These smooth tribological layers are capable of shielding the underlying material from fracture, deformation and adhesion wear. Sometimes, the generation of these mechanically mixed layers may mean enhancing the wear due to a sliding-assisted unfavorable phase or chemical transformations on the worn surfaces [

1,

2,

3,

4,

5].

A positive approach in such a situation could be the adaptive, in situ generation of anti-friction oxide compounds on the worn surfaces in high-speed (high-temperature) sliding [

1,

2,

3,

4,

5]. Retaining the composites’ good tribological characteristics in a wide temperature range is an issue discussed in many papers devoted to high-temperature tribological applications [

1,

2,

3,

4,

5]. Oxides possessing a low shear strength may be good candidates for the preparation of solid lubricants as components of anti-friction composites. These candidates may include, for example, tungsten trioxide WO

3 or oxygen-lean W

nO

3n−1 or W

nO

3n−2 Magneli phases [

6]. Alternative materials may be double- and triple-mixed oxides formed on the worn surfaces during sliding, which are capable of friction reduction [

7,

8,

9,

10,

11,

12]. Many compounds are known at present, such as Cs

2WOS

3, Ag

2MoO

4, ZnMoO

4, etc., which can be used as high-temperature anti-friction components [

7,

8,

9,

10,

11,

12]. These or other compounds may form on the worn surfaces as films by means of tribo-oxidation from the components that were transferred or added to the sliding zone under specific speed and loading conditions, and then allow for a reduction in wear and friction.

The potential use of the Magneli phases or mixed oxides as anti-friction components in composites is a widely discussed issue. The first approach is to synthesize these phases while sintering the composite, as reported in the example of WO

2.9 and ZrO

2 + WO

2.9 [

6]. The second approach involves the in situ tribological synthesis of the self-lubrication compounds, such as, for example, in the case of the high-speed sliding WC/Hadfield steel composite against a HSS disk when smooth glassy films covered the worn surface and could reach a coefficient of friction (CoF) of as low as 0.07 due to the tribological in situ synthesis of anti-friction compound FeWO

4 [

13,

14].

WC-Fe composites possess good strength and wear resistance, as well as mechanical processability [

13,

14,

15,

16,

17,

18], and can be used as a base material for the preparation of hybrid composites whose initially metallic matrix is reinforced by ceramic compounds. Additional reinforcement of the metallic matrix can be achieved by the formation of extra phases. For example, alloying the steel with 4 and 20 wt. % Mn allowed γ + α’ and pure γ matrices to be obtained, respectively [

17]. Compared to the single γ-phase one, the heterophase γ + α’ matrix allowed for improvements in a composite’s compression strength and wear resistance due to the strain-induced γ → α’ transformation [

17]. Under sliding conditions at 7–37 m/s, a mechanically mixed layer was generated on both composites, was composed of fine WC fragments, and oxidized binder and FeWO

4 mixed oxide, whose lubrication characteristics were not studied in detail [

18]. Generally speaking, FeWO

4 should demonstrate lubrication properties as well as other tungstates, such as ZnWO

4 CuWO

4, etc. [

7,

8,

11,

12]. At the same time, with the exclusion of a few references [

13,

14,

18,

19,

20], the literature search provided almost no results relating to the tribological performance of these compounds, although a lot of experiments were reported where both W and Fe were present in the rubbed materials.

This research is focused on studying the tribological behavior of WC-(Fe-Mn-C) composites with γ-iron (WC-Mn20) and γ + α’ (WC-Mn4) matrices as future base for the preparation of metal–ceramic composites that can demonstrating the lubricating effect of FeWO4 in high-speed (high-temperature) applications.

2. Materials and Methods

Metal matrix composites (MMC) WC-(Fe-Mn-C) were produced using melt infiltration of porous WC preforms in vacuum at

T = 1350 °C, as described elsewhere [

17]. The resulting MMCs were thus composed of 80 wt. % WC grains and 20 wt. % (Fe-Mn-C) matrix. The matrix was deliberately alloyed with Mn to obtain the resulting samples with Fe-Mn-C matrices that contained either 4 wt. % (WC-Mn4) or 20 wt. % of Mn (WC-Mn20).

The total amount of carbon in the matrix was about 0.8 wt. % for all samples. On infiltration, the samples were withdrawn from the vacuum furnace, heated to 1150 °C and then quenched in oil. The final sample dimensions were 5 × 5 × 7 mm

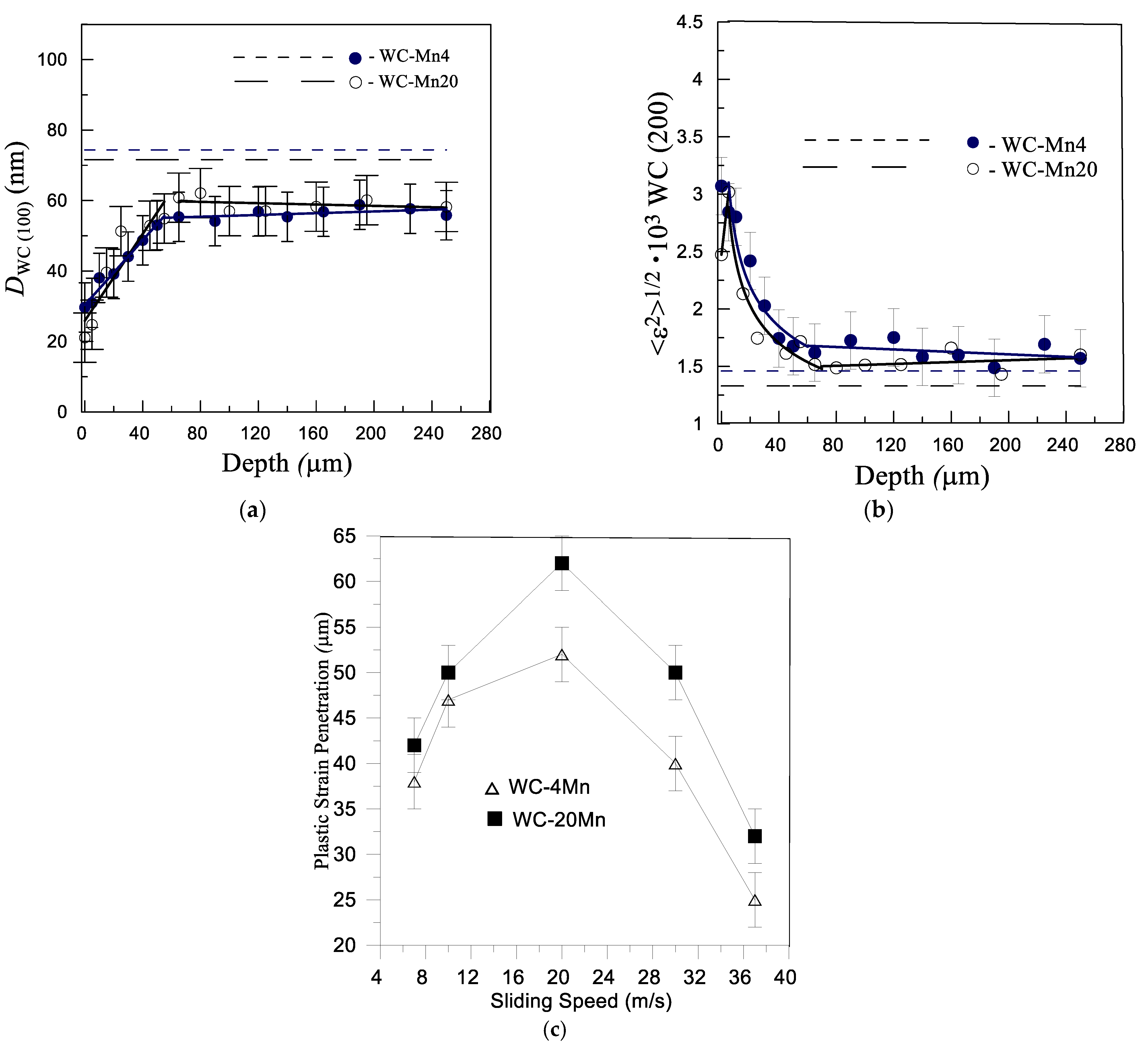

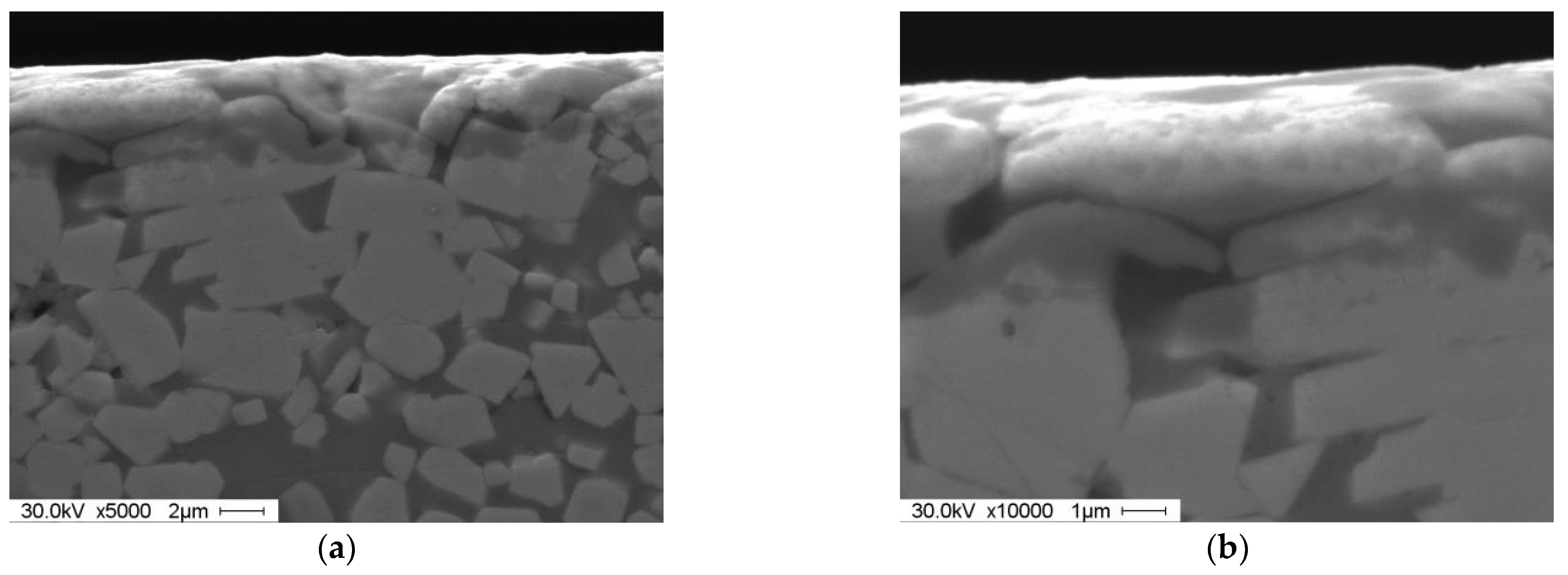

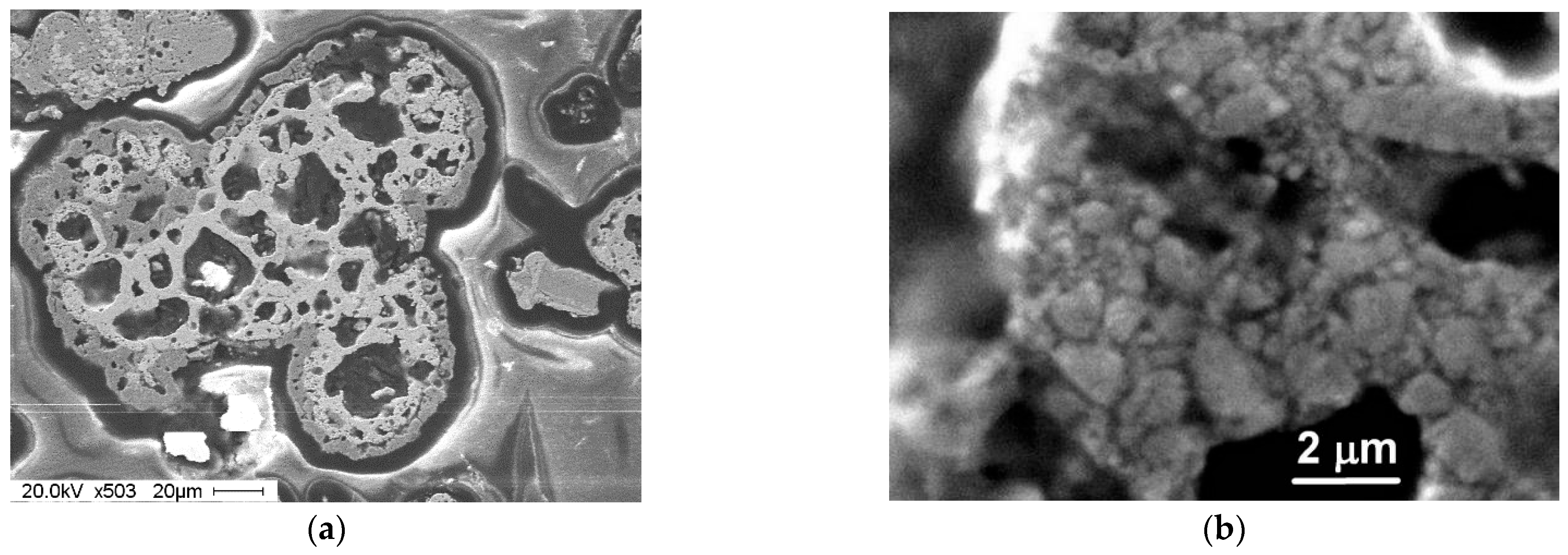

3. Both MMCs shared the same microstructure type, with mean carbide grain size and interparticle space 2.7 ± 0.5 μm and 1.2 ± 0.2 μm, respectively (

Figure 1a,c). The residual porosity was not higher 0.5%.

The XRD phase analysis showed the presence of HCP WC and FCC γ-iron in WC-Mn20, while, in WC-Mn4, the matrix additionally contained about 20 ± 5% of α’-martensite (

Figure 1e).

Mechanical characteristics of the composites are given in

Table 1. As follows from the

Table 1, the compression strength and ductility of the WC-Mn4 composite were higher than those of WC-Mn20, which had higher microhardness.

Tribological pin-on-disk testing of the composites was carried out using a sliding test machine UMT-1 (Tochpribor, Ivanovo, Russia). A disk made of as-cast high-speed steel (HSS) 63–65 HRC steel disk was used as a counterbody. Microstructurally, the disk was composed of martensite with M12C carbides and small amount of the retained austenite. Chemical composition of the HSS M2 was as follows (wt. %): 15 V, 4.5 W, 3.6 Cr, 3.6 Mo, 1.8 Ni, 1.4 C, 1.0 Mn, Fe-balance). The disk track diameter was 240 mm. Tests were conducted at nominal contact pressure of 5 MPa (normal load 375 N divided by total three pins’ contact area 75 mm2 in the speed range of 7–37 m/s (7 m/s, 10 m/s, 20 m/s, 30 m/s, 37 m/s) at ambient conditions of approximately 25 °C and 40–50% relative humidity. Total three experiments (9 pins) each with wear path length 1000 m were conducted at each of the sliding speed values. Test duration diminished with the sliding speed growth so that, at 7, 10, 20, 30 and 37 m/s, test durations were 143 s, 100 s, 50 s, 33 s and 27 s, respectively.

Wear was evaluated by measuring the sample’s height before and after the test and then calculating the wear rate as volume loss (mm3) divided by sliding path length (m)-mm3/m. Coefficient of friction (CoF) vs. time dependencies were obtained from experiments that demonstrated a steady sliding stage with moderate friction force oscillation amplitudes. These steady sliding portions of the curves were used to calculate the mean CoF values for each experiment.

Wear rate of the HSS disk was not evaluated but, given that the wear track length was about ~750 mm and tests’ durations ranged from 143 s to 27 s depending on the sliding speed, we may see that the wear rate of the disk was negligible compared to that of a pin.

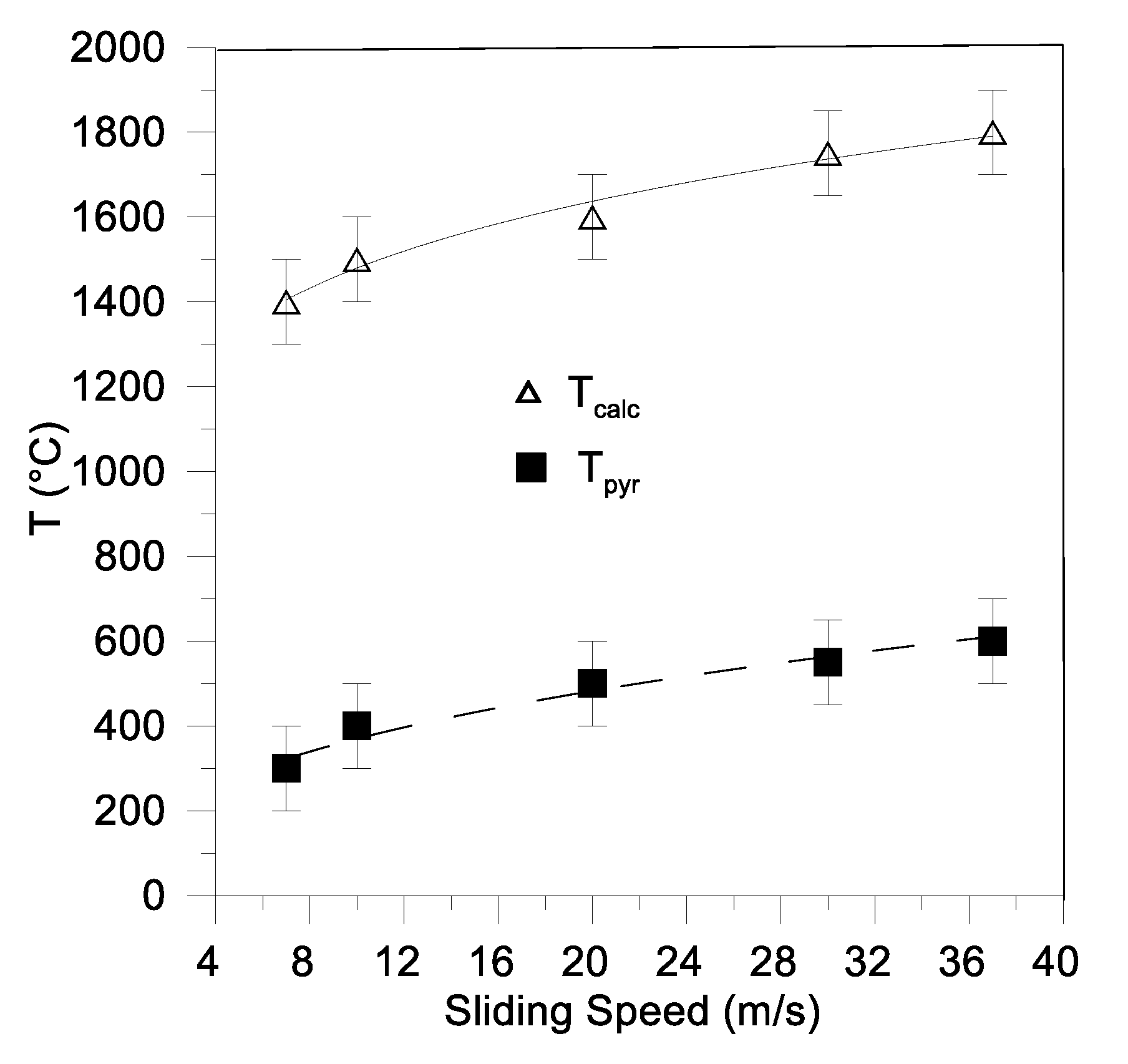

Flash temperatures on the worn surfaces were estimated using the well-known equation [

21]:

where

μ is the CoF,

P and

V are the normal load and sliding speed, respectively,

Ksample and

Kdisk are thermal conductivities of the pin and disk, respectively.

J is the Joule’s constant (in this case,

J = 1), and α is the contact radius of the real contact area to be determined from the following Equation (2):

is the sample’s hardness.

The results of this estimation are represented in

Figure 2, together with the real temperatures of the sliding zone, as measured using a pyrometer. Really high flash temperatures occur on the real contact spots, and then the heat is dissipated to the bulk of the sample, somewhat increasing its average temperature. The latter can be measured using the pyrometer.

Both worn surfaces and wear debris were examined using a SEM instrument Philips SEM-515 attached with an EDS analyzer EDAX ECON IV (Koninklijke Philips Electronics N.V., Amsterdam, The Netherlands). XRD was carried out using X-ray diffractometer DRON-7 (Burevestnik, Saint-Petersburg, Russia), Cu-Kα obtained at 40 kV and 22 mA with a scan range of 15–102° with (2θ) step size of 0.05° and counting time of 10 s. XRD peak. Identification of the XRD reflections was performed using Crystal Impact’s software “Match!” (version 3.9, Crystal Impact, Bonn, Germany).

4. Discussion

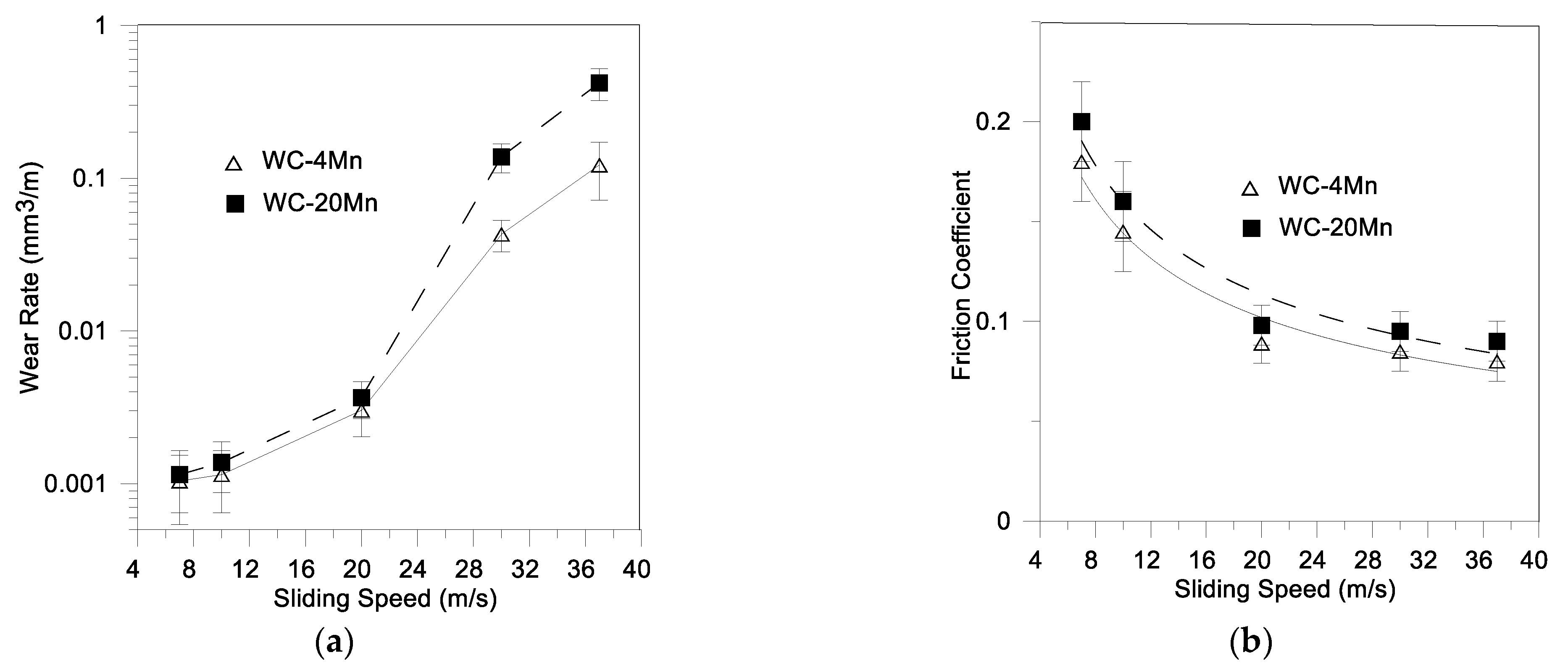

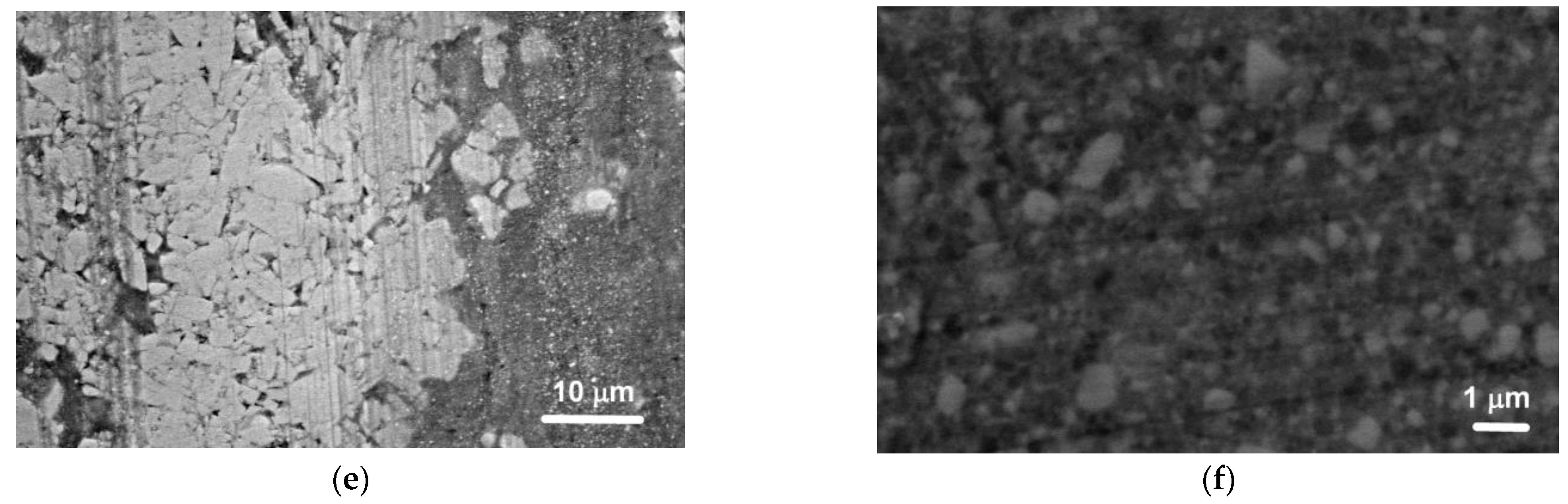

The results of this work clearly show that the coefficient of friction is reduced with increasing sliding speed and, correspondingly, the sliding zone temperatures. On the other side, the WC-(Fe-Mn-C) composites produce iron tungstate over the course of high-speed sliding against a HSS disk. The tungstate can serve as a high-temperature lubricant and, therefore, reduce friction between the pin and disk. When sliding the WC-(Fe-Mn-C) composites at 30 and 37 m/s with a contact pressure of 5 MPa against the steel counter-body, it was possible to generate a tribological transfer layer composed of fine WC fragments and iron-rich particles, cemented by mechanochemically formed FeWO

4. Such a composite layer can absorb dynamic loads, reducing friction (

Figure 3b) and forming a smooth protection for the underlying composite grains against deformation and fracture (

Figure 4a,c,e,f)

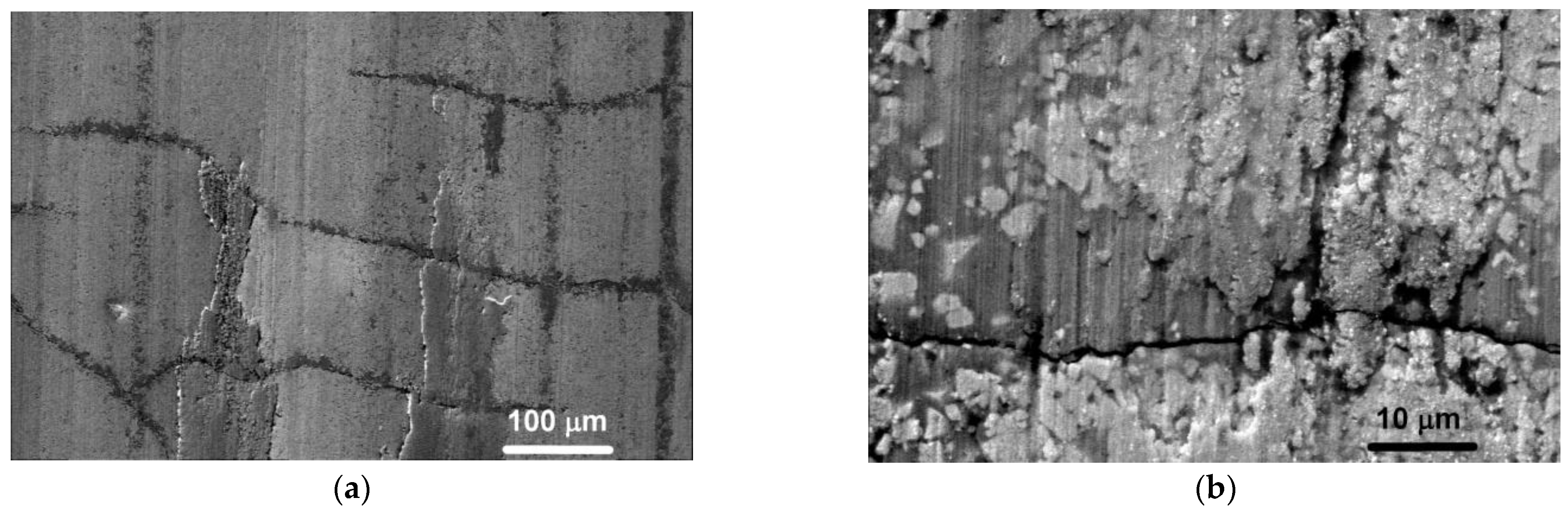

. Such an effective protection layer could not appear in sliding at lower speeds (lower temperatures); therefore, the worn surfaces of both composites experienced subsurface fractures (

Figure 5) and deformation (

Figure 7).

Let us consider the mechanochemical aspects and conditions that could facilitate the iron tungstate synthesis during the high-speed sliding of WC-(Fe-Mn-C) composites. Tungsten carbide becomes prone to intense oxidizing at temperatures above 800 °C [

22]. This oxidizing can occur according to the reactions, as follows:

The presence of Fe-Mn-C matrix and the transferred HSS components may also oxidize their main component, iron, according to the following reaction:

The occurrence of this reaction can be facilitated by accumulating structural defects and plastic strain in the subsurface of the composite matrix. The higher the plastic deformation penetration into the sample, the more intense the tribooxidation. The preferable reaction to produce iron tungstate over the course of high-speed sliding could be as follows [

20]:

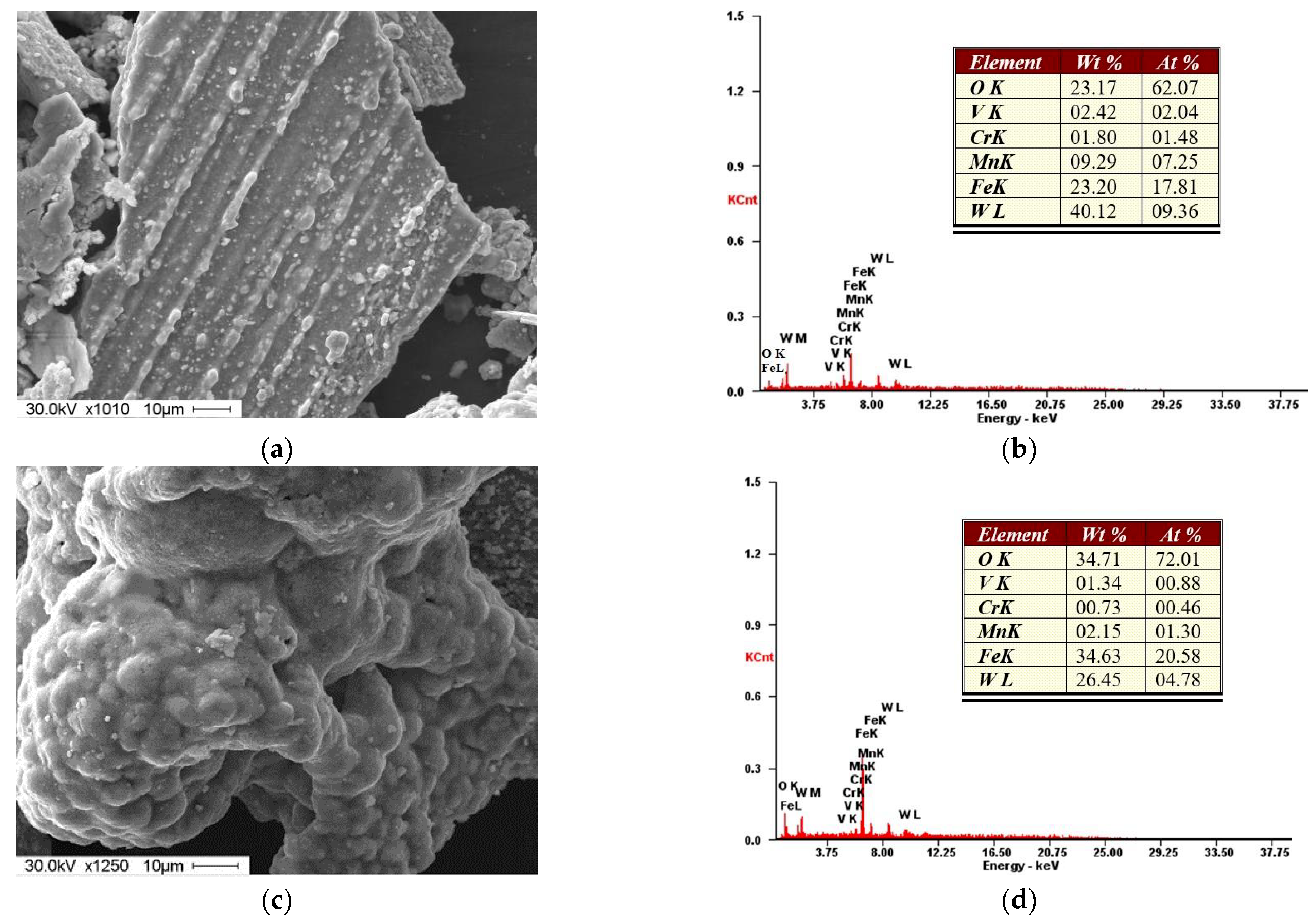

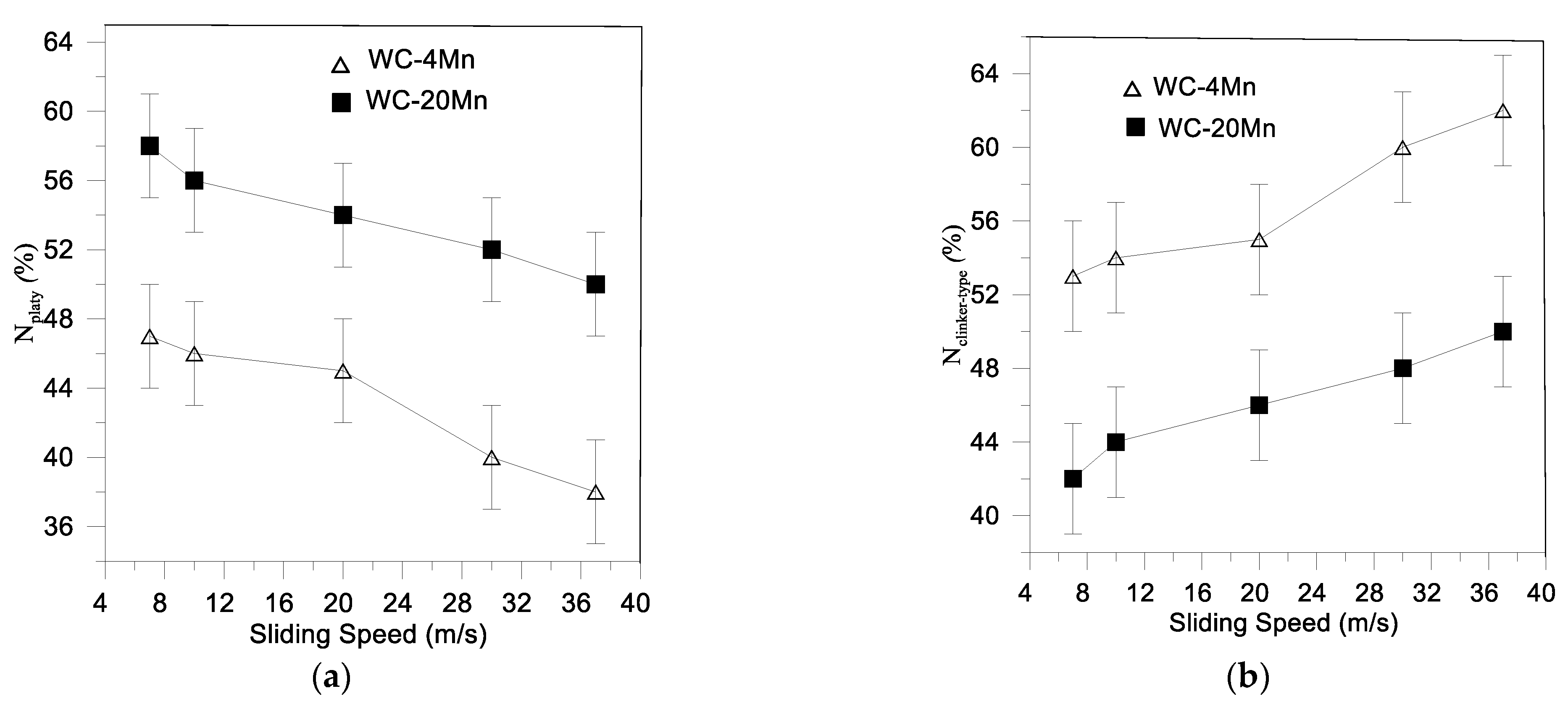

The amount of iron tungstate depends on the sliding speed and type of WC-(Fe-Mn-C) composite. According to the results obtained from semi-quantitative XRD, the amount of iron tungstate on the worn surface is lower than that detected in wear debris (

Figure 6b). This finding can be explained by the fact that the tungstate produced by tribo-oxidation is increased with the sliding speed and temperature, along with the intensification of wear, so that more tungstate is carried away with the debris and solidify there as porous particulates. Simultaneously, effective friction reduction occurs with increases in the sliding speed (

Figure 3b).

The cross-section views of the clinker-type particles with their thin inner walls (

Figure 11a,b) suggest that these particles could not originate directly from mechanical wear as wear debris. They are instead the product of tribo-chemical reactions when hot crushed WC fragments react with oxygen and oxidized iron, according to reactions (3), (4), and (5). The gaseous reaction product CO may form bubbles with the FeWO

4, intermixed with the WC fragments and transferred iron oxide particles.

A corresponding tribology literature search was carried out to look for similar types of hollow particles; however, no relevant references were found. However, numerous papers are devoted to studying tribo-chemical alloying or even the synthesis of compounds in attritors [

23]. It is not inconceivable that this type of particle can be formed by tribo-chemical synthesis, but the interests of researchers specializing in this field lie more with studying the phases and compositions of the compounds, rather than their particle structure and morphology. Therefore, to the best of our knowledge, we could not find any descriptions of these specific particulates in the literature.

A higher amount of Mn was detected in wear debris (

Figure 9b,d and

Figure 11c) than in the steel counter-body. This finding suggests that a steel matrix of the WC-(Fe-Mn-C) plays the main role in the tribooxidation and generation of FeWO

4.

There were no qualitative differences between the worn surfaces on WC-Mn4 and WCMn20 composites obtained at the same sliding speed (

Figure 4a,c) despite the difference in wear rate, which, in fact, increased with the sliding speed (

Figure 3a). The worn surface cracking was less or not noticeable on samples tested at higher speeds, irrespective of the composite matrix (

Figure 4c and

Figure 5a), i.e., sliding speed was the main factor defining the worn surface morphology.

It was shown earlier [

17] that the WC-Mn4 composite had a lower wear rate when sliding at the 1–4 m/s speed range as compared to that of WC-Mn20, and this difference was related to the fact that the WC-Mn4 had a meta-stable double phase (γ + α’) matrix that experienced strain-induced γ → α’ transformation and hardening during sliding. Such a suggestion can be true only in the case of low frictional heating, while high-speed sliding generates much more heat, so the α’ → γ transformation becomes more real. Under these conditions, the double-phase WC-Mn4 matrix would demonstrate a higher resistance to plastic deformation, and thus more effectively retain the carbide grains until the moment of complete α’ → γ transformation. By this time, however, the γ-phase matrix of the WC-Mn20 composite would be thermally softened and not capable of retaining the WC grains in place.

The EDS data obtained from the worn surfaces (

Figure 4d) and wear debris (

Figure 9b,d) of the WC-Mn20 composite demonstrate that the worn surfaces are enriched with WC as compared to the base metal (

Figure 1d), while wear debris contain more metallic components.

As follows from

Figure 10b, the clinker/platy particle ratio grows with the sliding speed. Additionally, the number of clinker-type particles is higher for the WC-Mn4. Considering the dependence of FeWO

4 on sliding speed (

Figure 6b), one may suggest that the clinker-type particles are mainly formed of FeWO

4. It seems that the worn surface of WC-Mn4 is more successful in synthesizing and retaining the iron tungstate film at high sliding speeds.

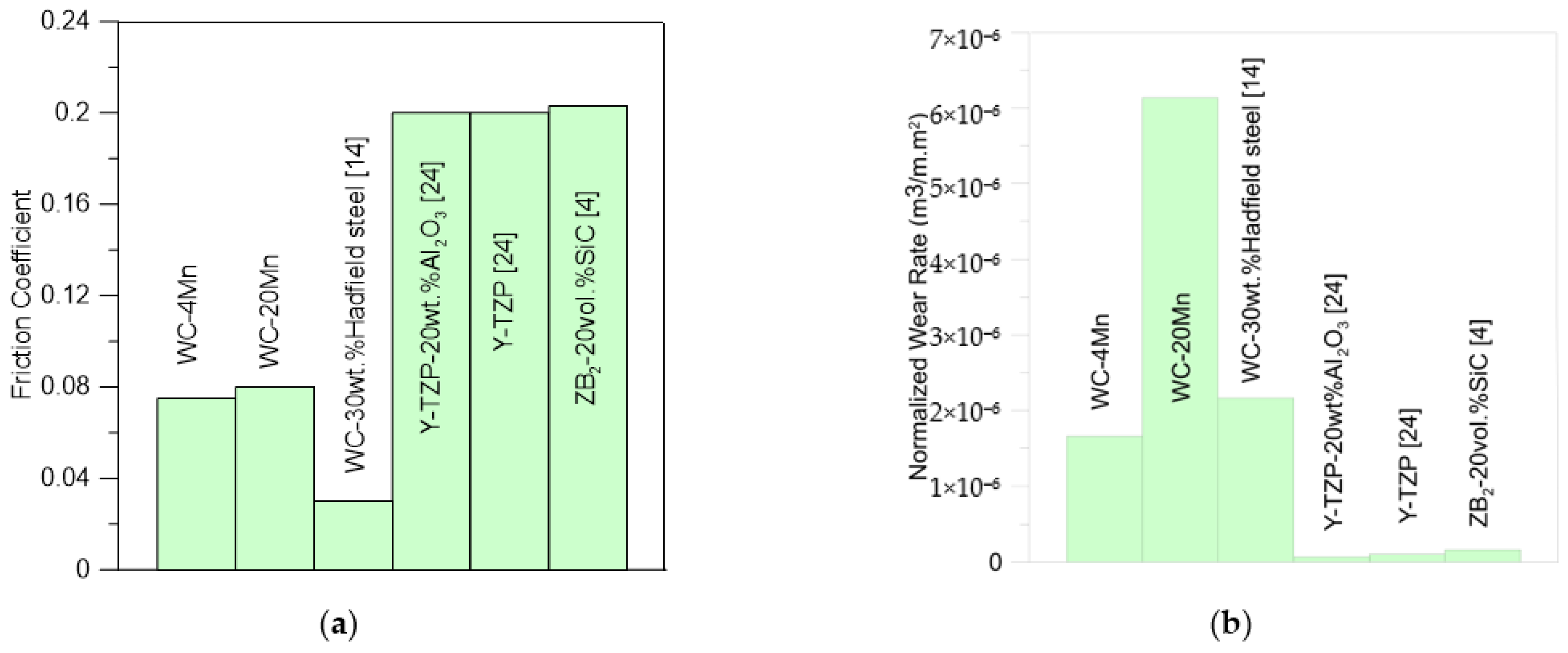

It was mentioned above that both WC-Mn4 and WC-Mn20 composites are intended for the preparation of hybrid ceramic–metal matrix composites and, therefore, their wear resistance should be considered and compared with those of other candidates, such as WC-30 wt. % Hadfield steel [

14], Y-TZP [

24], Y-TZP + 20 wt. % Al

2O

3, and ZrB

2 + 20 vol.% SiC [

4].

For that purpose, the wear rate and CoF values of all these composites were obtained in sliding at 37 m/s and contact pressure 5 MPa against the HSS disk, with other tribological experiment conditions kept identical to those used in the present work [

4,

14,

24].

A reduction in friction was achieved for ZrB

2 + 20 vol.% SiC due to the formation of a liquid phase that served as a liquid lubricant at high temperatures [

4,

5]. The Y-TZP-base ceramics such as Y-TZP and Y-TZP 20 wt. % Al

2O

3 demonstrated a relatively high wear resistance due to subsurface deformation by means of ferroelasticity mechanism, accompanied by the subsurface layer deformation texturing and generation of a protection transfer layer [

24,

25].

The CoF values for both WC-Mn4 and WC-Mn20 at 30 m/s and 37 m/s were at the level of ~0.08 i.e., almost twice as low as ~0.2 inherent with Y-TZP, Y-TZP + 20 wt. % Al

2O

3 and ZrB

2 + 20 vol.% SiC ceramics but comparable to the CoF value demonstrated by WC-30 wt. % Hadfield steel metal ceramic composites discussed above (

Figure 12a) [

4,

14,

25].

A series of works were published regarding the sliding of the MAX-phase composites over steel counter-bodies when CoF values were obtained under the following conditions: f~0.15 at 30 m/s and 30 N [

26]; f~0.22 at 30 m/s and 20 N [

27]; f~0.13 at 30 m/s and 80 N [

28]; f~0.25 at 30 m/s and 60 N [

29]. A comparison between the above data and CoF values obtained in the present study, namely, ~0.08, shows that both WC-Mn4 and WC-Mn20 are good candidates for the hybrid composites.

To provide a correct comparison between the wear rate values obtained on WC-Mn4 and WC-Mn20 and those obtained on the above-mentioned materials (

Figure 12b), the normalized wear rate values were calculated as wear rate divided by the apparent contact area [

30]. It was also impossible to overlook the high wear rate of the metal ceramic composites such as WC-30 wt. %Hadfield steel, WC-Mn4 and WC-Mn20 during sliding at high speeds (

Figure 12b). A relatively high content of metal matrix in the composite may result in the selective wear of the thermally softened and even partly melted matrix.

It could be suggested that FeWO

4 is effective for high-speed (temperature) lubrication in sliding against steel. This result may be used for to develop self-lubricating composites by replacing part of the metal matrix with ceramics in an attempt to reduce wear in the base ductile WC-reinforced ferrous matrix composites. Y-TZP)/alumina-reinforced ceramic matrix could be a good candidate, since all the components, such as WC, ZrO

2, Al

2O

3 and steel, can be consolidated into a bulk composite [

31]. The Y-TZP-Al

2O

3 can also be additionally reinforced by adding WC cemented by high-manganese steel. These approaches would allow for the use of both mechanical reinforcement and tribological adaptation by the in situ synthesis of FeWO

4 of the bulk composites for high-temperature tribological applications.