Abstract

Scientists and tribologists are currently exploring sustainable and inexhaustible lubricants as a result of increased awareness of environmental and health-related issues. Vegetable oils are being investigated as a potential form of environmentally friendly cutting fluids due to their excellent renewability, biodegradability, and lubricating performance. This report provides an overview of different vegetable oils used as cutting fluids in the machining of engineering materials. The effects of virgin vegetable oils, emulsified vegetable-based oils, and vegetable-oil-based nano-cutting fluids on the cutting force, the surface finish of machined parts, the tool wear, and the temperature of the cutting area were surveyed critically. Compared to mineral-oil-based cutting fluids, studies have demonstrated that vegetable-oil-based cutting fluids meet cleaner manufacturing standards with good or better efficiency.

1. Introduction

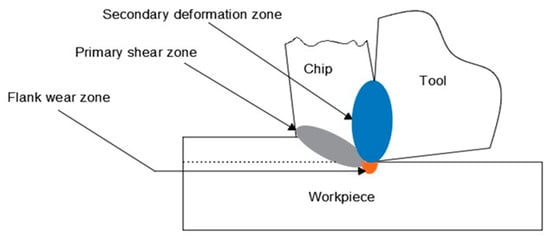

Machining is a very necessary aspect of manufacturing. It involves a group of processes that consist of material removal and surface modifications of a workpiece after different methods have been used [1,2]. Almost all the energy generated during metal cutting is transformed into heat [3]. Heat is produced at the cutting point from three sources: (i) the primary cutting areas, in which much of the energy is transferred to heat; the (ii) secondary deformation area at the tool-chip interface, where additional heat is produced by rubbing or shearing; and (iii) the strained flanks, owing to rubbing between the tool and the finished surfaces [4,5,6]. Figure 1 shows the heat dispersion in the workpiece, cutting tool and chip during an orthogonal cutting operation. The heat deposits are destructive to the tool, the workpiece, and the machine tool [7]. In addition, the heat produced while cutting metal leads to tool wear, resulting in higher workpiece surface roughness [8,9]. Another reason for cutting tool failure is thermal cracking due to expansion and cracking induced by extreme temperatures [10,11]. Moreover, crater and flank wearing on the face after some time reduces the weight of the cutting tool [12]. High temperatures during and after machining eventually cause damage to the surface due to oxidation, burns, and rapid corrosion at the cutting area, resulting in dimensional inaccuracy of the workpiece due to thermal distortion and expansion-contraction [13,14,15]. The friction or wear between the tool and work is minimized by lubricants, and coolants transport the heat produced during metal deformation [16].

Figure 1.

Schematic diagram of the heat generation region during an orthogonal cutting operation.

The suitable selection and application of cutting fluids have become one of the approaches to reducing heat at the cutting area [17,18]. Researchers have already shown that cutting fluids gain entry to the tool–chip boundary by seeping from the edges of the chip through the capillary action of the interlocking surface asperity network in the interface. Cutting fluid has small intermolecular interactions and exhibits adequate wetting (surface tension) characteristics due to the limited size of this capillary network [19,20]. Cutting fluid encompasses lubricants and coolants [21,22]. Lubricants lessen the friction or wear between tool and work, while the heat generated during metal deformation is transported by the coolants [23,24,25]. Moreover, cutting fluid helps to enhance surface finish and provides stronger dimensional control [26]. It reduces the energy consumption of removing the material. In addition, it keeps hot chips out of the cutting region [27,28]. Thus, it causes chips to break up into small pieces. More significantly, cutting fluids protect the machined surface against environmental degradation [13,29]. There are diverse kinds of cutting fluids that could be used to accomplish machining activities [30,31]. Mineral-oil-based cutting fluids (MOCFs) are by far the most common cutting fluid and these fluids improve the efficiency and quality of production processes during forming and cutting [32,33].

Roughly 85% of the machining fluids used globally are MOCF. In the machining industry, the use of MOCF is increasing [34]. It is estimated that the European Union exclusively expends almost 320,000 metric tons of cutting fluids each year, from which two-thirds or more will be discarded [35,36]. Reports on occupational exposures to mineral oil have shown that operators in the manufacturing sector are in danger of experiencing allergens and diseases [37]. Because machine tool operators are close to cutting fluids, the health impact of operator interaction with fluids is a top consideration [38]. Fumes, smoke, mist, and odors from cutting fluids can potentially cause severe respiratory problems and allergic conditions, especially with mineral oil that contains chemical constituents such as biocides, phosphorus, sulfur, hydrocarbon, chlorine, and other additives [38,39]. Approximately 80% of all workplace hazards of operators have been reported as linked to skin exposure with cutting fluids [37,40]. Researchers estimate that between 700,000–1,000,000 workers in the United States alone are vulnerable to cutting fluid. Airborne and allergies to cutting fluids have been associated with health complications such as infections of the throat, nose, lungs, eyes, and skin [41]. Mineral-based cutting fluids have a lot of advantages, but also have a lot of drawbacks in terms of health and the environment. Technicians in the machining industry are at danger of getting allergic disorders and diseases, according to studies on job exposures to mineral oil-based cutting fluids. Exposure to cutting fluids through the skin and in the air has been related to health problems such as throat, lungs, nose, as well as skin inflammation. Other diseases like upper respiratory tract inflammation, asthma, cancers, obesity as well as dermatitis can be contracted when exposed to mineral oil-based cutting fluids [42]. Particularly, the key problem of MOCFs is related to their improper handling that ultimately results in surface and groundwater contamination as a result of food toxicity and agricultural products [43].

Various replacements for MOCFs are actively being explored by tribologists and scientists to deal with these problems. These replacements encompass using solid lubricants, vegetable oils, and organic lubricants [39,44]. Increasing adoption for undeletable natural resources has paved the way for the use of vegetable oils as a replacement for petroleum-based polymeric materials, especially in production processes [45]. Vegetable oils are typically highly desirable alternatives to petroleum-derived oils because they are eco-friendly, sustainable, and less toxic [46,47]. They are often more likely to be used in the lubricants / cutting fluid industries. Several studies have been undertaken to establish new bio-based lubricants from different plant oils available in the world. Environmentally friendly issues, rising pollution, and degradation legislation mean that increased need for renewables and biodegradable lubricants is very much envisaged [48]. Productivity growth for eco-sustainable oils is expected to be 7–10% in the US economy over the next few years, compared to just 2% in the aggregate lubricant sectors [49]. Vegetable oils are a feasible and environmentally benign source of renewable oils [50].

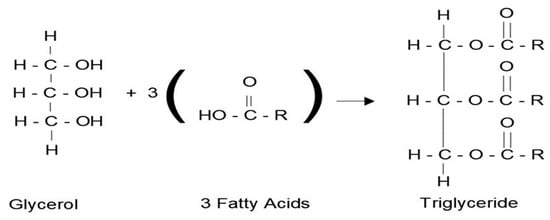

The molecules of vegetable oils are composed of glycerol and fatty acids [51]. A glycerol molecule is bound to three long chains of carbon atoms to make one vegetable oil molecule, as shown in Figure 2 [52,53,54]. In almost all vegetable oils, the component alcohol (glycerine) is the same. The free formation of fatty acids in vegetable oils tends to provide a desirable quality for the lubricant [55]. The R classes of polar fatty acids give high-strength adhesive films that bind strongly with metal parts, reducing wear and friction [56,57]. Powerful intermolecular forces are often resistant to variations in temperature that provide a steadier viscosity or a higher viscosity coefficient [58]. The similarity of all vegetable oil structures ensures that a small range of viscosities can be obtained for their possible use as lubricating oils [59]. Intermolecular forces interactions thus supplying a long-lasting lubricant film often contribute to low-temperature characteristics [58]. Vegetable oils often have a high flash point, which eliminates smoke and fire risks. The high flash point enables the use of the cutting fluid under elevated temperatures [13,34]. As a consequence, vegetable-oil-based fluid meets the criteria for lubrication properties and holds great potential for application [60]. Table 1 shows the comparison of two base oils’ properties.

Figure 2.

The structure of a vegetable oil molecule [52,53,54].

Table 1.

Comparison of base oil properties.

Vegetable oils as cutting fluids have been widely used in many machining operations, such as drilling, milling, turning, and grinding [33,40]. Vegetable oils often demonstrate very good efficiency as lubricants. Onuoha et al. [61] explored the impacts on the surface finish of novel vegetable oils produced from groundnut and false walnut oils and an industrial MOCF during annealed AISI 1330 alloy steel turning with HSS tool. It was reported that the optimal cutting conditions for the part were achieved when using groundnut oil. Rahim and Sasahara [62] evaluated the potency of synthetic ester and palm oil as cutting fluids during minimum quantity lubrication (MQL) turning of GH169 alloy in terms of surface quality. Improved surface defect, microhardness, surface roughness, sub-surface deformation, and other workpiece properties were obtained after processing with palm oil as base oil rather than with synthetic ester. Belluco and Chiffre [63] utilized rapeseed-oil-based cutting fluids in drilling austenitic stainless steel. The comparison was performed with industrial MOCF in terms of cutting forces and tool life. They concluded that vegetable oil was stronger than conventional oil, with an approximately 117% increase in tool life. Elmunafi et al. [64] researched the use of castor oil as a lubricant in turning hardened stainless-steel material using the MQL approach. They noted that the tool life increased appreciably, and this was due to the high castor oil lubricating value. In another report Ozcelik et al. [65] compared the cutting fluids from sunflower and canola oils with conventional mineral oil during machining of AISI 304 austenitic stainless steel. Cutting fluid derived from canola oil provided lower tool wear compared to equivalent sunflower oil. Some other researchers have established in previous research that vegetable oils can be used as cutting fluids in turning, drilling, and other metal machining methods and achieve good cooling and lubrication results. The basic physicochemical qualities, cost, availability, and applications of some selected vegetable oils as reported by Sankaranarayanan and Krolczyk [66] is depicted in Table 2. Vegetable oil has a high flash point, which is a requirement for use in machining activities. Vegetable oils have a greater flash point, making them easier to use in harsh machining applications where high temperatures are involved. It also decreases the risk of smoke and fire. Higher flashpoints of vegetable oils provide further benefits for these eco-friendly coolants when replacing traditional cutting fluid, significantly reducing smoke and fire safety issues. Vegetable oils’ high viscosity index enables consistent lubrication, implying that the rate of viscosity reduction is lower than in the case of temperature build-up. For cooling and lubrication, the density of eco-friendly cutting fluids is equivalent to that of synthetic and mineral coolants. In most circumstances, however, the kinematic viscosity values of chemically synthesized cutting fluids are highly comparable. Vegetable oils have sufficient kinematic viscosity to provide optimum lubrication without neglecting cooling properties. Vegetable oils’ physical and chemical qualities are proving to be adequate for use as cutting fluids. Table 2 also shows the market pricing of various vegetable oils employed in machining operations. Vegetable oil prices range from USD 1178.75 to 4441.54 per metric ton. Of all the prices presented, palm oil is the cheapest. The expenditure incurred on metal cutting fluids varies between 16 and 30%, emphasizing the significance of cutting fluids on both economic and technical levels. These expenditures span the entire life cycle of the product, from procurement to disposal. Considering their high purchasing cost, vegetable oils outperform mineral oils in this circumstance. Considering the costs of maintenance, recycling, and disposal, as well as the severe environmental requirements, investing in vegetable oils will yield only profitable outcomes. Furthermore, large-scale planting of vegetable-oil-based plants, trees, or crops would minimize long-term purchase price. When vegetable oils are improperly extracted, handled, and stored, they can become rancid, losing antioxidant properties and quality [67]. Moisture, microorganisms, air, antioxidants, and sunshine exposure are all elements that influence the oil’s rancidity or deterioration time [68].

Table 2.

Basic physicochemical qualities, cost, availability, and applications of selected cutting fluids as reported by Sankaranarayanan and Krolczyk [66].

Within this report, the use of vegetable-oil-based cutting fluids in machining different engineering materials is described in depth and their applications as a substitute to mineral-based oil are outlined.

2. Review of Research Progress in Machining with Vegetable-Oil-Based Machining Fluids

Several researchers have attempted to take advantage of vegetable-oil-based cutting fluids in different machining procedures, for example turning, grinding, drilling, and milling. The impact of vegetable-oil-based machining fluids on the surface roughness, tool life, cutting forces and tool wear, surface hardness, and temperature has been studied in detail by various researchers.

2.1. Utilization of Vegetable Oils as Machining Fluids in Turning Operations

When turning AISI 1018 steel with TiAlN-coated inserts, Kumar et al. [69] studied the impacts of hybrid biodegradable nanofluids (CuO-ZnO) on surface roughness; different classes of biodegradable fluids, in particular palm oil and coconut oil, were studied as base fluids and mixed in a blend of CuO-ZnO (50:50) mixture nanoparticles. During dry cutting, MQL/coconut oil and MQL/palm oil with CuO-ZnO mixture of hybrid nanofluid blended environments, the contribution of cutting parameters, and volume concentration of fluid were examined. The Taguchi orthogonal array of L9 and L18 was chosen exclusively to contrast dry and a blend of palm oil MQL and coconut oil MQL, separately. They argued that the incorporation of CuO-ZnO hybrid nanoparticles into the base cutting fluids prompted a significant decrease in surface roughness when contrasted with regular dry machining. ZnO nanoparticles serve as lubricating oils which decrease friction between the workpiece and the tool. Analysis of variance (ANOVA) has demonstrated that feed rate is the largest contributor of surface roughness, trailed by the depth of cut and speed.

Kıvak et al. [70] explored the turning output of PVD TiN-covered Al2O3 + TiCN ceramic tool on Ni-Hard 4 material under dry, unadulterated MQL and nanofluid-MQL strengthened by nano-sized solid particles, for example, graphene nanoplatelets (GnPs) and multi-walled carbon nanotubes (MWCNTs). Two distinctive test structures were arranged in this review. In the underlying structure, they evaluated the impact of cutting boundaries (depth of cut, feed rate, cutting speed, and environmental condition) and cooling/oil condition on surface roughness, tool life as well as the extreme temperature of the chip. Taguchi L16 (34) was hence determined for the plan. In the subsequent plan, four assays were directed to observe the effect of the cooling/oil condition on surface roughness and wear conduct of the ceramic cutting tool by setting working boundaries, such as cutting velocity of 120 m/min, feed rate of 0.1 mm/rev, and depth of cut (DOC) of 1 mm. Unadulterated MQL in this way assisted with lessening nose wear by about 69% contrasted with dry machining, while GnP-based nanofluid MQL added to decreasing surface roughness by 19.42%. The drop in chip greatest temperature was 7.47%, 8.74%, and 9.59%, respectively, in MQL, MWCNTs nanofluid MQL, and GnP-based nanofluid MQL contrasted with dry cutting. Through the examinations of scanning electron microscope (SEM) and energy dispersive X-ray (EDX), the modes of failure of the cutting tool were confirmed to be triggered by the wear and crack of tools. Nose, crater, attrition wears and notching at the depth of cut line, stripping of the coating, and built-up layer were the principal kinds of wear, while chipping and cataclysmic crack of the edge prompted the tool fracture.

Courbon et al. [71] addressed the use of high-pressure jet assistance (HPJA) with a carbide-coated tool for rough turning of Inconel 718. The operational parameters, which set control factors constraints, were demonstrated experimentally using tool material pair (TMP) techniques. They noted that HPJA was an effective alternative lubrication approach that improved chip brittleness, reduced cutting forces, and provided the benefits of lubrication and thermal loads connected to the tool.

The influence of nanofluids as cutting fluids on surface roughness was observed by Kumar et al. [72] while turning AISI 1018 steel under dry and MQL conditions. A mixture of CuO and Al2O3 hybrid nanofluids was formed in situ in different weight ratios (50:50, 25:75, and 75:25), with coconut oil as the base fluid. Taguchi L9 trial arrangement was regarded for the dry condition with process parameters (depth of cut, feed rate, and speed) while L18 orthogonal array was utilized for MQL/nanofluid tests, with process parameters (volume of fluid, speed, depth of cut, and feed rate). Their results showed that adding hybrid nanoparticles to the base fluid decreases the surface roughness contrasted with the dry machining. Feed rate was the most significant contributor for surface roughness, followed by speed and depth of cut.

Ramana et al. [73] conducted evaluations of three different conditions, e.g., dry, palm oil, palm oil mixture and boric acid lubricant, during the process of turning Ti-6Al-4V alloy with uncoated tungsten carbide, CVD-coated, and PVD-coated carbide tools in terms of surface roughness. The Taguchi L27 (35) strategy was then used to reveal the ideal cutting parameters for surface roughness. The study selected five control variables, namely, type of machining environment, depth of cut, feed rate, cutting speed, and type of carbide tool material. The results showed that palm oil was stronger when applied, compared to dry and palm oil, with boric acid cutting fluids. Palm oil, cutting speed at 79 m/min, feed rate at 0.206 mm/rev, cutting depth at 1.0 mm, and CVD-coated tool are the optimum and safest combination values for reducing surface roughness.

An L9 (34) Taguchi design was utilized to compare an experimental soybean-based cutting fluid in turning operations of E52100 chromium-alloy steel against dry and petroleum-based cutting fluids [74]. The trial data analysis showed that the soya-based cutting fluid performed better than the alternative petroleum product as regards tool wear, and both cutting fluids worked equally well in reducing surface roughness.

Dhar and Islam [75] developed an MQL conveyance framework and led an investigation to determine the impact of MQL by vegetable-oil-based cutting fluid (VBCF) in turning of AISI 1040 steel with uncoated carbide insert as regards surface finish, dimensional deviation, tool wear, and cutting temperature. The adequacy of MQL was contrasted with dry and wet machining conditions. MQL was focused on the flank and rake surfaces along the auxiliary cutting edge at the pace of 200 mL/h and an air pressure of 2.5 bar. They observed that with MQL, the cutting temperature was diminished up to 10% because of the direct application of fluid to the heat generation areas by the MQL jet. With the concept of economical MQL, the authors presented a notable improvement in tool life. The lubrication impact and effective cooling of MQL assist with decreasing flank wear and built-up edges on the material. Moreover, dimensional accuracy was generally improved with MQL due to a notable decrease in wear and damage at the tooltip. Additionally, surface finish in the order for effectiveness (worst to best) is wet cooling, dry cutting, and MQL. They concluded that the cutting efficiency of MQL machining is higher than that of traditional flood machining.

Revankar et al. [76] examined the impact of various cooling strategies, namely, dry, MQL, and flooding, on surface roughness and surface hardness during turning of Ti-6Al-4V alloy. The experimentation work depended on a Taguchi plan with L27 orthogonal arrangement utilizing feed rate, depth of cut, cutting speed, nose radius, and method of application as the critical input parameters. The MQL conveyed palm oil through a flimsy pulsed jet framework of 0.40 cc/stroke and conveyance pressure of 4 kgf/cm3, while for flood cooling the emulsion metal cutting fluids were acquired by blending the concentrates with water at a proportion of 1:20 soluble oil and provided through three nozzles at the pace of 8000 mL/min. To ascertain the contributing factor affecting roughness and hardness, ANOVA was utilized. In light of the optimization, corresponding optimal values of surface hardness and surface roughness are shown in Table 3.

Table 3.

Optimal control factor settings and the corresponding optimal values of surface roughness and surface hardness [76].

Diminished surface roughness was accounted for with MQL when contrasted with dry and flood cooling. The better performance of MQL was ascribed to its cooling action, which was more effective due to the convective and evaporative mode of heat transfer. Additionally, surface hardness is greater in dry lubrication because of the large measure of heat generated when contrasted with MQL and flood cooling.

Xavior and Adithan [77] led an exploratory examination on determining the impact of cutting fluids on surface roughness and tool wear during AISI 304 austenitic stainless steel turning with a cemented carbide tool, CNMG120408 inserts as the cutting tool. Taguchi L27 (34) orthogonal array was adopted for the test plan. The factors and levels (low, medium, and high) considered were depth of cut (1.2, 1.0, and 0.5 mm); cutting speed (97.38, 61.35, and 38.95 m/min); feed rates (0.28, 0.25, and 0.20 mm/rev); and type of cutting fluids (coconut oil, straight cutting oil, and soluble oil), respectively. Numerical models for cutting parameters and cutting fluids (considering the viscosity of each cutting fluids as 40 °C) were obtained from regression analysis to estimate tool wear and surface roughness. ANOVA and signal-to-noise (S/N) ratio were carried out to ascertain the significant parameter affecting tool wear and surface roughness. Surface roughness and tool wear model equations established in the study are shown in Equations (1) and (2) [77].

where Vb is flank wear in millimeters, Vc is the cutting speed in meters/minutes, d is the depth of cut in millimeters, f is the feed rate in meters/revolution, Ra is the surface roughness in micrometers, and is the viscosity in millipascal-second. The finding indicated that feed rate had a greater impact on surface roughness with a contribution of 61.54% while cutting speed had a greater impact on tool wear, with a contribution of 46.49%. Cutting fluids have been discovered to have a substantial impact on both tool wear and surface roughness. The viscosity of coconut oil was between that of soluble oil and the straight cutting oil, which increases the effective transition of the cutting fluids in a relatively low oil condition.

Singh et al. [1] directed analyses on the capability of mineral and vegetable oils on surface roughness during turning of EN31 steel under MQL and dry environments using three typical cutting inserts (CNMG120412, CNMG120408, and SNMG120408). Both mineral oil and vegetable oil (soybean) were conveyed as mist MQL targeted at the rake face of the tool at a specific pressure of 5 bar. It was noted that vegetable oil was superior to mineral oil as concerns surface finish. The decrease in surface roughness owing to vegetable oil was around 1–10% contrasted with mineral oil. The report revealed that with MQL the surface roughness was diminished by 20–40% when contrasted with dry machining due to the lubricity, evaporative cooling, and hydrogen embrittlement activity of vegetable oil.

Majak et al. [78] considered AISI 304 stainless steel as the processing material in a test to analyze chip compression ratio and surface finish in MQL turning with three kinds of vegetable oils to be specific: palm, sunflower, and coconut oils. The experimentation work depended on the Taguchi design of experiment (DOE) method with an L9 (3)4 orthogonal array and employed feed rate, depth of cut, cutting speed, and kinds of cutting liquids (using the particular viscosity of each oil for investigation) as basic input parameters. The parameter level is presented in Table 4. MQL was operated at 8-bar pressure and a fluid flow rate of 100 mL/hr. Chip compression ratio was determined with Equation (3) [78].

where Z = chip compression ratio, a1 = thickness of the uncut layer equivalent to the feed rate in turning, and a2 = thickness of the chip after the cut. S/N ratio and ANOVA were likewise performed to recognize the critical parameters affecting chip compression ratio and surface roughness.

Table 4.

Experimental factors and their levels [78].

The authors observed that (i) depth of cut had a more prominent impact on surface roughness with 34.63% contribution, followed by the viscosity of cutting fluid (33.10%) and spindle speed (24.77%); (ii) viscosity of cutting liquid has the most critical impact on chip compression ratio with a contribution of 59.13%, followed by feed rate and depth of cut with contributions of 29.69% and 15.99%, respectively; (iii) the general performance of the cutting oils in decreasing the chip compression ratio and improving the surface roughness was better when sunflower oil as opposed to palm or coconut oil was applied.

Rohit and Kuppa [79] considered an investigation on two distinctive vegetable cutting oils produced from processed sunflower and rapeseed oils, and an industrial mineral machining fluid to establish the least surface roughness, cutting forces, and tool wear during turning of SS316. Cutting speed, feed rate, cutting fluid, and depth of cut were considered as parameters in the machining. Multiple linear regression models were obtained to predict the output parameters. Vegetable oils were blended with water in an oil proportion of 1:100. Vegetable oils were discovered to be more beneficial than mineral oil when all the yield parameters were considered.

Gong et al. [80] assessed the impact of MQL during cylindrical turning of Inconel 718 with respect to surface integrity and chip morphology and contrasted its potential with dry and flood conditions. The practicality of utilizing graphene nanoplatelets as added substances to vegetable oil to form mist MQL was surveyed. Five cooling conditions that were adopted include dry, flooding, MQL with unadulterated vegetable oil (MQL_Pure), nanofluid with graphene platelets of 5 μm size (MQL_5), and nanofluid with graphene platelets of 15 μm size (MQL_15). The MQL framework was utilized by choosing an air pressure of 7 bar and an oil flow of 1320 mL/h. Surface roughness and chip morphology were estimated with an optical profiler and scanning electron microscope, respectively. The chip compression ratio was determined using Equation (4) [80] and estimations of λ as a component of the cutting speed and lubricating-cooling conditions are accounted for in Table 5.

where tc = chip thickness, λ = chip compression ratio, and to = uncut chip thickness. The analysts reasoned that the utilization of the MQL_5 brought about the best surface roughness. On the contrary, the MQL_15 did not improve the surface finish contrasted with the MQL_Pure, which also worsened it compared with the traditional flood condition. The chip compression ratio data demonstrated that the thinnest chips were obtained while applying the MQL_5, though the most elevated were acquired on account of MQL_15. In addition, all the samples demonstrated a grain size refinement and the presence of an extreme plastic deformed layer.

Table 5.

Chip compression ratio as a function of the cutting speed and lubricating cooling condition [80].

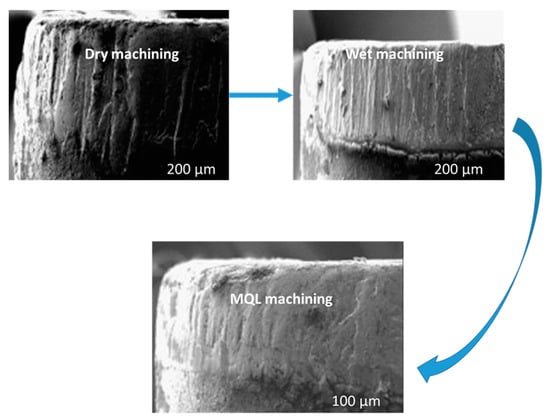

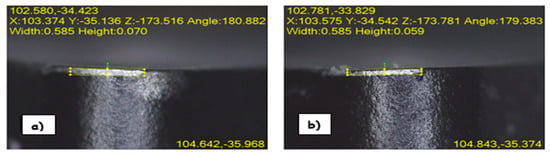

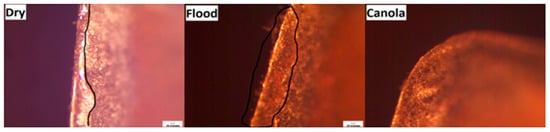

Khan et al. [81] employed an MQL metal-cutting strategy in turning AISI 9310 steel with non-coated tool material while contrasting with flood cooling and dry conditions with respect to chip tool boundary temperature, chip forming mode, surface roughness, and tool wear. MQL was supplied with a mist of food-grade vegetable oil and air at a flow rate of 100 mL/h and air pressure of 6 bar while flooding was operated at 6 L/min and 0.5 bar using Eco cut San 220 coolant. Lower surface roughness decreased cutting temperature and better chip formation was reported for with MQL when contrasted with dry and flood cooling. The chips formed with MQL using vegetable oil were constantly observed to be better than flood and dry cutting at any chosen feed rate. The desired continuous chips with MQL application were due to the drop in temperature, the existence of an enabled chip–tool interface and the removal of even traces of built-up edge formation. The pattern and level of wear formed at different tool-tip surfaces after being used for a moderately long period under SEM were likewise observed to see the impacts of various conditions on the wear of the SNMG-type carbide insert. Abrasive scratch marks appeared in the flanks under all the environments (see Figure 3). The insert contained several indicators of adhesive wear. Under dry and wet conditions, severe groove wear on the flank surfaces was found in the insert. Under dry machining, plastic distortion and micro-chipping were found to have occurred. Effective temperature control with MQL through vegetable oil almost decreased groove wear development at the main cutting edge just as well as the auxiliary cutting edges. Moreover, the image clearly demonstrates diminished average wear on the primary flank and average wear on the auxiliary flank under MQL by the vegetable oil condition.

Figure 3.

SEM views of principal flank wear of the worn-out insert after machining 43 min under dry, wet, and MQL conditions [81], License Number: 5287320091190.

The effectiveness of six cutting fluids, four typical vegetable oils from canola and sunflower oils with a various proportions of extreme pressure (EP) added substances, and two commercial kinds of fluids (mineral and semi-synthetic oils) were assessed for diminishing surface roughness, feed, and cutting forces during AISI 304L austenitic stainless steel turning with a carbide insert tool [82]. The DOE (Taguchi L18, to be specific) was utilized for the trial. Spindle speed, cutting fluid, feed rate, and cutting depth were observed as parameters. In predicting the surface roughness and the forces generated during machining, a regression model was considered. ANOVA determined the impacts of the machining parameters and cutting fluids on the output parameters. The results revealed that the cutting fluids were less effective compared to the depth of cut and feed rate in lowering forces and enhancing the surface roughness. The potential of vegetable and commercial cutting fluids was also analyzed, and the results established that the two vegetable oils performed better than the others.

Paul and Pal [83] conducted a study on mild steel turning with an HSS tooltip. They measured the cutting temperature and surface roughness of dry, MQL, and flooding cooling conditions. A universal water-miscible coolant SOL-CUT-1000 was utilized as the flood coolant. The MQL was run using neem and karanja oils. It was found that surface roughness was better compared to dry and flood operating conditions, using both neem and Karanja oils with increasing feed rate or depth of cut variance. The cooling results of vegetable oils are comparable with flood cooling for a lower depth of cut. For a high depth of cut, the performance varied slightly, and the effectiveness of neem oil was better than that of karanja oil between the two types of vegetable oil.

Venkatesan et al. [84] explored the work efficiency and multi-response enhancement of tool wear, surface roughness, and cutting forces in Inconel 617 super alloy CNC turning using a blend of aluminum oxide (Al2O3) nanofluids in coconut oil with a PVD (AlTiN)-covered cutting device under the MQL condition. The compacted air and flow rate were kept constant at 4 MPa and 20 mL/min for every cutting trial. Taguchi L9 was specified for the trial. Cutting velocity (40, 60, and 100 m/min), percentage concentration (0.25, 0.50, and 1.00%), and feed rate (0.14, 0.17, and 0.20 mm/rev) were fixed as parameters. It was noticed that a feed rate increase escalates the force, wear of the tool, and surface roughness. The surface roughness and tool wear values were intensified as cutting speed increased and diminished for cutting force. Both cutting forces and tool wear were elevated with an increase in the weight level of nanoparticles in coconut oil while reducing surface roughness. The least surface roughness and tool wear were achieved with feed rate and cutting speed of 0.14 mm/rev and 60 mm/min, respectively, with a magnitude of 0.58 μm and 1.58 μm at 0.25% (tool wear) and 1.00% (surface roughness). Optimum cutting force is attainable at 0.25% concentration, 100 m/min cutting speed, and 0.14 mm/rev feed rate for a decrease in cutting force of 169N. Tool wear investigation revealed the presence of scraped area (abrasion), diffusion, and adhesion wear. Fewer scraped spot marks and less adhesion were noticed at 0.25% as it has a higher removal of heat and diminished friction force at the chip/tool border. In view of the analysis of chip structure, the optical chip image showed an increase in curly rates due to higher rubbings and a reduction in lubricity in the MQL setting.

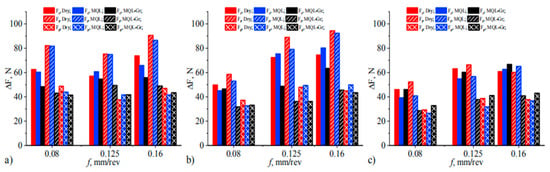

Gutnichenko et al. [85] showed through a test the impact of MQL aided with solid lubricant on an Alloy 718 workpiece material with a cemented carbide cutting tool. Nanosized (~30) powder of graphite nanoplatelets was scattered (0.2% vol.) in rapeseed oil. The influence of cutting conditions on the process parameters (surface finish, vibration rates, tool wear, and cutting forces) was scrutinized. During machining, the depth of cut was kept consistent for all tests (0.3 mm) while feed rate and cutting speed were set as 0.08, 0.125, and 0.160 mm/rev and 40, 50, and 60 m/min, respectively. An experiment was carried out under dry conditions, plain rapeseed, and altered GnPs rapeseed oil as a cooling/lubricating medium for minimum quantity cooling lubrication (MQCL). Mist lubricant flow rate was set at 15 mL/h, while pressure was kept steady at 0.5 MPa. The results showed a disparity between feed and cutting force because of the chip-forming action, while the passive component was stiffer and affected by the development of flank wear.

Furthermore, the amplitude in the force variation of the cutting part, as well as the segment and chip-forming action, was subject to adhesive measures on the flank. The result of pure oil machining is generally critical at low feed rate values and has almost no adverse effect on other cutting environments in contrast to dry conditions. This results in a somewhat more effective impact of oil as a cooling medium and, to a lesser degree, as an oil. The addition of GnPs has had a far greater influence on the outcome within the region of cutting speeds of 40–50 m/min within the ranges of all feed rates. The comparative findings for the f = 0.08 mm/rev feed may have been due to the prevalence of a tool-edge radius and size of chamfer of approximately 0.1 mm. Speed increase prevents graphite nanomaterials from entering the cutting region. The influence of graphite on top speeds (60 m/min), as shown by Figure 4, was evident on the force disparity intensity in the direction of the feed owing to the partly open radial portion of the tool nose, which is accessible for lubrication. Diffusion and abrasion are the key wear mechanisms found in conjunction with notch forming, chipping of cutting edge, adhesion, and rake flaking. They found that the development of grooves is common for the initial formation of flank wearing. The GnP particles in cutting oil hinder or restrict the production of flank wear. GnP additives of 0.2% (vol.) to vegetable oil will substantially boost the process efficiency of the workpiece in terms of tool life, process stability, and surface finish.

Figure 4.

Average values of cutting force variation at different cooling conditions: (a) (b) ; (c) [85], License Number: 5287320340171.

Rapeti et al. [86] dealt with the utilization of a vegetable oil and nanoparticle blend as cutting fluids while turning AISI 1040 steel, taking into account eco-friendly machining. Cutting fluids were planned by dissolving nanosuspensions of molybdenum disulfide (MoS2), in canola, coconut, and sesame oils, and were supplied to the cutting area at different cutting conditions, as recommended by L27 Taguchi DOE. Nanoparticle inclusion, feed rate, base fluid, and cutting speed were assessed statistically as four factors at three levels each. Surface roughness, cutting temperature, flank wear on the tool, and cutting forces were studied as four responses that reflect performance records of machining. Multi-objective optimization was accomplished using Taguchi-based gray relational analysis (GRA). Statistical analysis revealed that coconut oil + 0.5% nMoS2 prompts the least surface roughness, cutting forces, tool wear, and cutting temperatures in contrast to other conditions. The optimal conditions of cutting were discovered to be 0.14 mm/rev and 40 m/min for decreases in cutting temperature, tool wear, and cutting force. Surface roughness was observed to be least at 0.14 mm/rev feed rate and 100 m/min speed. The optimal conditions for superior absolute cutting performance were ascertained with GRA. It was shown that coconut oil + 0.5% nano molybdenum sulfide when deployed at 0.5% nanoparticle inclusions, 40 m/min cutting speed, and 0.14 mm/rev feed rate enhanced cutting efficiency.

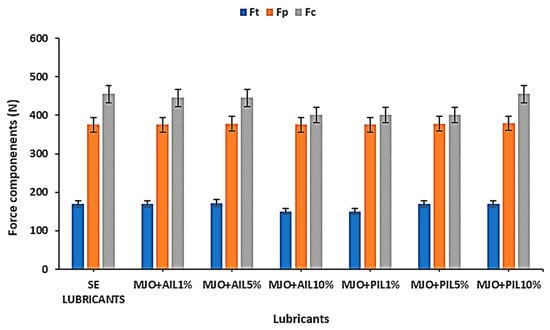

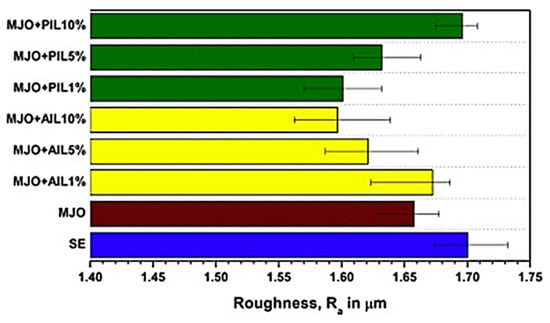

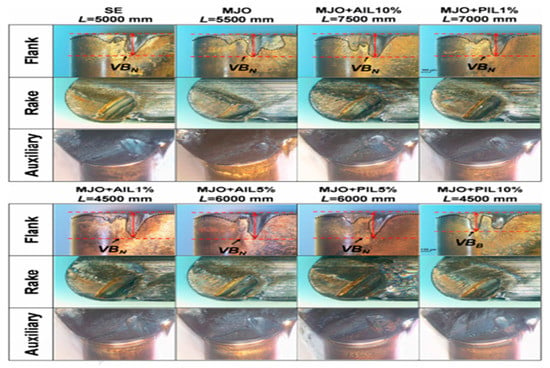

Sani et al. [87] researched the impact of modified Jatropha oils (MJO) during AISI 1045 steel turning with uncoated inserts (cermet) using the MQL procedure. The machining executions of the newly evolved vegetable-oil-based metal cutting fluids were assessed with respect to tool life, cutting temperature, surface roughness, and wear action. The findings were contrasted with a commercially engineered ester-based fluid under a similar cutting context. In their investigation, two biocompatible and oil-miscible ionic liquids (ILs) ([N1888] [NTf2], AIL and [P66614] [1(C8)2 PO2], PIL) were applied as fluid-form added substances (additives) into the processed, synthesized modified-Jatropha-oil-based ester. The added substances were blended to form MJO with three unique concentrations (1.0, 5.0, and 10.0 wt.%). A variability in cutting forces and surface roughness, along with the related modes of tool failure found during the machining at a certain set of feed rate, cutting speed, and depth of cut under MQL, is shown clearly in Figure 5, Figure 6 and Figure 7. The authors inferred that among the ILs included, MJO +AIL10%, MJOs had superior lubricity with excessive viscosity.

Figure 5.

Results of force components at the machining region adapted from [87], License Number: 5287300872221.

Figure 6.

Arithmetic average of surface roughness profile on machined surfaces lubricated with all lubricant samples [87].

Figure 7.

Typical tool failure modes under MQL turning lubricated with all lubricant samples. The allowable tool wear mode according to ISO-3685 standards is shown with notch wear dominating most of the measured tool life [87].

The potency of nano solid lubricant suspensions in vegetable oils was examined by Krishna et al. [88] during AISI 1040 steel turning with cemented carbide cutting tools. Boric acid particles with a particle thickness of 100 nm were used as dispersions in coconut, castor, sesame, sunflower, and canola oils. An analysis of basic properties by taking nanoboric acid suspensions in all the oils was conducted, and then machining was performed using coconut and canola oils in order to save time and lower the cost of the experiments. The machining was based on different amounts of solid lubricant suspensions, i.e., 1.00, 0.50, and 0.25% by weight and with a flow rate of 10 mL/min. The influence of the newly formulated lubricants on machining temperatures, surface roughness, and tool flank wear was examined. Basic properties were computed from the empirical relations (Equation (5)) [88].

where Pr = Prandtl number, h = heat transfer coefficient, Re = Reynolds number, D = workpiece diameter, and m and C are constants that are dependent on the Re value. Among all the oils selected, coconut and canola oils were selected due to their consistent improvements in basic properties. For the comparison, cutting temperature, surface roughness, and flank wear were selected. The report indicated that 0.5% boric acid suspension in vegetable oils resulted in reductions in temperature and flank wear. The greatest reductions were achieved with coconut oil. In terms of surface roughness, coconut oil performed well at lower feed rates and speeds, while at higher feed rates and speeds canola oil performed better compared to other conditions.

Saikiran and Kumar [89] considered the potential of groundnut and cottonseed oils during copper alloy turning with a high-speed steel tool. Material removal rate, machining forces, and surface roughness were selected as responses. Three test pieces of copper alloys with different compositions and hardness were employed in the trial. The Taguchi-based DOE adopted was an L54 orthogonal array. Therefore, 54 experiments were performed according to Equation (6) [89].

where m and n are the number of levels and q and p are the number of factors. This was applied on the three-test piece at different depths of cut, machining speeds, and feed rates. Table 6 shows the process parameters and their respective levels. It was shown that a decrease or increase in surface roughness was dependent on the kind of machining fluid. Additionally, the resultant cutting forces were elevated with speed. The set of optimal process parameters was found to be 0.0916 mm/rev feed rate, 835 rpm spindle speed, 1.5 mm depth of cut, 80.89 m/min cutting speed, and groundnut oil to optimize the cutting conditions such as maximum metal removal rate and minimal surface roughness and cutting forces.

Table 6.

Cutting parameters and machining conditions [89].

Shaikh and Sidhu [90] determined the efficacy of three metalworking fluids (cottonseed, servo cut, and soybean oils) with reference to material removal rates and surface roughness during a flood turning operation of AISI D2 steel. They reported that all the three metalworking fluids were relatively close to each other as there was only a little difference of 1–10%. The findings indicated that soya bean and cottonseed oils should replace servo cut oil due to their user-friendly ability, availability, and cost.

In MQL machining of aluminum bronze (150HB) with an uncoated cemented carbide tool, rapeseed-based cutting oil was used as a lubricant (50 mL/h water flow rate, 50 mL/h oil flow rate, and at 2 bar). The cutting forces were lower by 16% compared to dry cutting. No such difference was observed in the frequency segmentation of the chips produced. Segments of chip occurred randomly in dry cutting irrespective of the process parameters, whereas in the MQL condition, chip segments were uniform with the same geometrical parameters. Strain hardening was found to be higher under dry cutting. The average chip thickness during MQL turning was 0.4 mm, which was lower than the 0.6 mm from dry cutting. The reduction of chip thickness with MQL was attributed to the reduced force of friction in the tool–chip interface [91].

It’s worth noting that most industrial cutting fluids contain additives like biocides, dispersants, colourants, dispersants, as well as corrosion inhibitors and so on. In the production of cutting fluids, 1H-indole can be a useful addition. Furthermore, cyclopropane, another component of the oil, does not irritate the respiratory organs and hence does not prevent breathing [92].

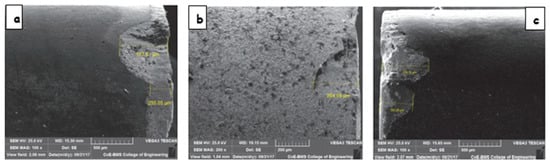

In a study by Jeevan anda Jayaram [93], non-edible modified Jatropha and Pongamia oils were investigated analytically and contrasted with mineral oil using an L27 Taguchi experiment concept for their feasibility as machining fluids in AA6061 turning with an uncoated carbide cutting tool using a minimal quantity lubrication technique. Vegetable oils were chemically synthesized by the epoxidation process (a known oil volume is mixed with hydrogen peroxide and acetic/formic acid). The statistical analysis of the results based on the Taguchi procedure indicated that the force produced was optimal for 0.5 mm cutting depth, 1600 rpm cutting speed, and 0.1 mm/rev feed rate when modified Jatropha was used. Modified Pongamia oil was shown to have reduced wear with respect to adopted machining parameters, followed by mineral and modified Jatropha oils. As for the existence of vegetable oils as cutting fluids, it is observable from Figure 8a,b that cutting tool wear was caused by an abrasion between the workpiece and the tool. In the case of mineral oil, erosion or peeling away from the carbide insert was observed in Figure 8c. The processes of chemical modification greatly improve the polarity of vegetable oils. In both Pongamia and Jatropha molecules, the bonds between ester chains became stronger, thereby increasing metal adsorption. As a result of the polar shape of the oil extracts, tool wear was reduced in versions modified with vegetable oils by producing a protective shield on the contact area that decreased friction and wear. For modified Pongamia oil, a good surface finish was reported with low-speed cutting fluid and for modified Jatropha oil with high-speed cutting fluid.

Figure 8.

SEM images for flank wear for different oil conditions: (a) Jatropha, (b) Pongamia, (c) mineral oil [93].

Ghatge et al. [94] studied the impacts of nano mixtures of plant oils (neem and coconut oils) and mineral oil as coolants in enhancing the processability of duplex stainless steel in turning operation with covered carbide inserts (TiN-Al2O3-TICN-TiN). Studies were designed using the orthogonal array of Taguchi’s L27 by adjusting four parameters at three main levels. Cutting speed (200, 150, 100 m/min), feed rate (0.3, 0.2, 0.1 mm/rev), DOC (1.2, 0.8, 0.4 mm), and cutting fluids (coconut, neem and mineral) were the process parameters used. Cutting force, wear of the tool, and surface roughness were tested and evaluated through the main effects plot for optimal operational parameters. Eco-sustainable nanoemulsions were formulated by blending every vegetable oil with water, base oil, and non-ionic Tween80 (HLB-15) surfactant. The authors stated that the optimal tool wear, surface roughness, and tool temperature values were, for neem oil, 0.4 mm, 0.3 mm/rev, and 100 m/min, and for coconut oil, 0.8 mm, 0.1 mm/rev, and 100 m/min, respectively. The experimental outcome showed abrasive wear in the worn structure. This abrasive wear was on the tool flank surface, thereby causing flank wear. The images of tool wear generated while machining are shown in Figure 9. The two images displayed are for machining levels (7 and 25, respectively).

Figure 9.

Tool wear pattern at (a) Level 7 and (b) Level 25 [94], License Number: 5287311337135.

The cutting speed alone differs in these machining ranges (100–200 m/min), cutting fluid (neem oil), DOC (0.4 mm) with a fixed feed rate (0.294 mm/rev). Therefore, it is apparent from the findings that when the cutting speed increases the flank wear is reduced as the cutting time of the required cutting length is decreased. This in turn decreases the cutting tool contact time with the workpiece. The authors inferred that the sequence of importance to enhance surface roughness and tool wear is cutting fluid, feed rate, and DOC, respectively, and that the selected vegetable oils (neem and coconut oils) may provide a superior choice to mineral oil to improve sustainability and machinability.

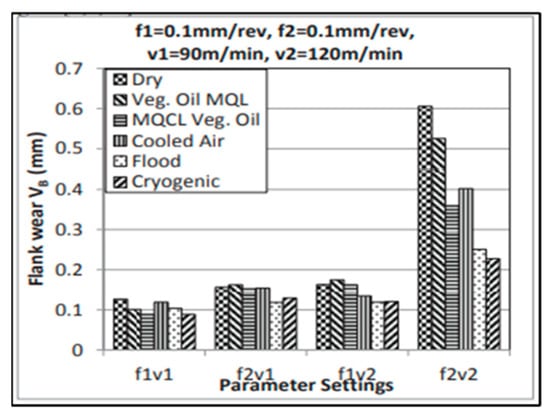

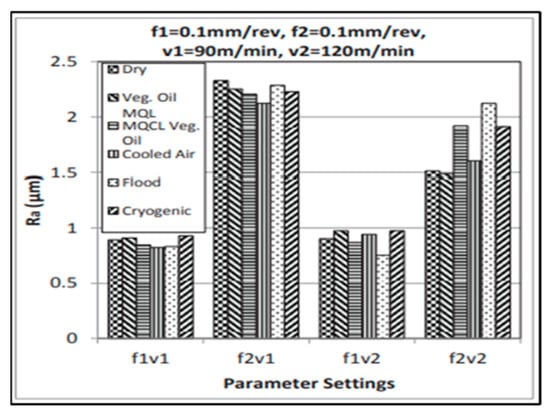

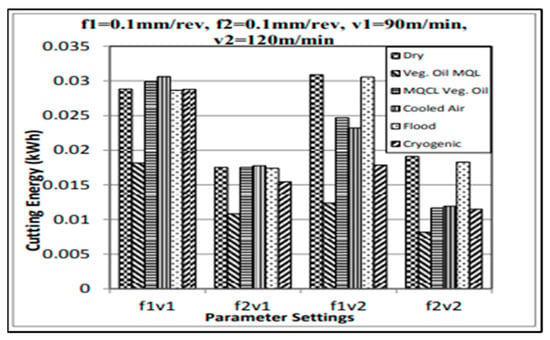

Deiab et al. [95] worked on tool wear, cutting energy, and surface roughness in titanium alloy turning with different coolant environments. The results were compared under the following conditions: dry, flood cooling with synthetic emulsion, MQL with rapeseed vegetable oil, MQCL (rapeseed oil and cooled air), cooled air, and cryogenic cooling with liquid nitrogen. Figure 10, Figure 11 and Figure 12 show the average performance of the lubrication strategies. The interventions of vegetable oil MQCL and MQL provided good outcomes in terms of surface roughness and tool wear and often improved in terms of minimizing energy usage. Sustainable effects such as improved surface quality, reduced energy usage, and less tool wear resulted due to the effective supply of coolant and strong lubricity in these techniques. MQCL (rapeseed oil and cooled air) is extremely encouraging, particularly at lower speeds and feeds, thereby indicating that the use of vegetable oil in machining is a safe method compared to others. The authors concluded that MQCL with vegetable oil provided the best potential in terms of flank wear at low speed and low feed. Vegetable oil (MQCL) has emerged as a viable option together with cryogenic machining.

Figure 10.

Tool wear with lubrication techniques [95], License Number: 5287311103641.

Figure 11.

Surface roughness with lubrication techniques [95], License Number: 5287311103641.

Figure 12.

Cutting energy consumption with lubrication techniques [95], License Number: 5287311103641.

The author and co-authors formulated a new white type of coconut oil cutting fluid during AISI 304 and mild steel turning operations with T9325 indexable lathe tool inserts via the MQL technique [96]. The cutting variables that were selected included: spindle speed (96, 32, 0.1 ms−1), pressure of the compressed air (3.0, 2.5, 2.0 bar) with fixed depth of cut (1.0 mm), and feed rate (0.05 mm/rev). Considering mild steel machining with mineral and coconut oils under an MQL environment, the latter exhibited the best surface roughness. However, the mineral oil metalworking fluid (MWF) showed a lower surface roughness value when contrasted with a similar cutting method of AISI 304. Extensive experiments have shown that the innovative vegetable oil MWF provides a higher cooling approach for mild steel than austenitic steel to obtain better dimensional accuracy. The lowest temperature value for mild steel was observed while machining with mineral oil. In addition, the novel coconut oil showed characteristics different from those of the mineral oil. Furthermore, with contrasting temperatures provided from two metalworking fluids, turning mild steel with mineral oil may significantly improve temperature differences during the implementation procedure. Vegetable metalworking fluid provided the lowest temperature difference for the same process with AISI 304. To achieve a more appropriate temperature of the tooltip, white coconut oil was preferable for AISI 304 rather than mineral oil. It has been shown empirically that the new coconut oil was capable of absorbing heat at the cutting area for AISI 304 contrasted with mineral oil. The flank wear achieved in cutting AISI 304 with new coconut oil was reduced as contrasted with mineral oil. AISI 304 has a much lower thermal conductivity compared to mild steel. AISI 304 failed to rapidly disperse the heat produced, while mild steel quickly disseminated the heat to the face of the flank.

Ekinović et al. [97] investigated the turning of two difficult-to-cut workpiece materials (nickel-based super alloy Nimonic 263 and low-carbon steel St52-3 steel) with titanium PVD-coated cutting inserts. They experimentally studied the tool temperature, machining force, and machined surface roughness to compare the effects of MQL and dry cutting conditions. Biodegradable rapeseed oil was supplied as lubricant at a rate of 50 mL/h (oil), 250 mL/h (water), and compressed air pressure of 2 bar. From the results obtained, MQL reduced the cutting force by about 25% over dry cutting depending on the process parameters considered. MQL machining achieves greater efficiency of the machined surface compared to dry cutting. Lower cutting zone temperature was reported due to effectual cooling in MQL cutting, which in turn resulted in less tool wear and better cutting stability.

Yazid et al. [98] utilized MQL at an application rate of 100 mL/h and 50 mL/h in finish turning of Inconel 718 alloy with a PVD-covered TiAlN carbide tool. Vegetable oil (coolube) was considered for the MQL approach. The use of MQL 100 mL/h and 50 mL/h produced about 50% and 38% enhancements, respectively, in tool life. The tool life for MQL 100 mL/h and 50 m/h was superior to dry cutting. A lower heat effect was observed for MQL (100 mL/h and 50 mL/h) when contrasted with the dry condition because of diminished friction from the cooling and lubrication impact of the compacted air. It was observed that flank wear was the main dominant wear of the cutting tool. Further, adhesion and abrasion were the wear mechanisms detected on the flank side and diffusion wear was noticed on the rake side.

Lawal et al. [99] tested the effectiveness of three vegetable oils, two distinct vegetable oils, palm kernel and cotton seeds, and one industrial type of cutting fluid (mineral) for the reduction of surface roughness and cutting forces during AISI 4340 steel turning with a coated carbide tool. With a water-to-oil ratio of 9:1, the cutting fluids were processed and supplied using a flood cooling approach. For the experimental design, a Taguchi mixed-level parameter (L27) was used. ANOVA was used to assess the impact on surface roughness and cutting forces of the cutting fluids and cutting variables. Regression analysis was used to model cutting force and surface roughness. The effects of depth of cut and feed rate were considered to be more effective than spindle speed and cutting fluids in minimizing forces and maximizing surface finish. Overall performance of seed oils and mineral oils was measured, and the findings generally revealed that cottonseed and palm kernel cutting fluids performed much better than mineral oils.

Ansari and Kotiveerachary [100] investigated the turning of Incoloy 800 in different cutting environments by uncoated tungsten carbide. The experiments were conducted under the effects of MQL (for Q = 150, 300 mL/h) and compared with dry and flood (600 mL/h) environments with respect to surface roughness. The lubricant used in the experimentation was sunflower seed oil and it was supplied at a compressed pressure of 4 bar. The Taguchi technique was used to optimize the cutting variables to determine the minimum surface roughness between the various combinations of feed, depth of cut, and cutting speed. The findings were evaluated through ANOVA. The evaluation showed that feed played a significant role in achieving lower surface roughness accompanied by speed, although the depth of cut had minimal significance in developing lower surface roughness. The authors reported that MQL (150 mL/h) showed the least surface roughness in contrast to MQL (300 mL/h), dry, and flood coolant conditions.

Ojolo and Ohunakin [101] explored the role of the cutting variables (rake angle, cutting speed, feed, and DOC) on the dominant cutting force when turning the aluminum rod, brass, and mild steel with a high-speed steel cutting tool in a dry and wet (palm kernel oil) setting. The influence of lubricating oil on the coefficient of friction between both the face of the rake and the chip was determined. The results showed that, in view of the coefficient of friction, the impact of palm kernel oil as a coolant was completely reliant on the cutting conditions. However, aluminum demonstrated a strong lubrication effect with quite a significant reduction of 33% in the coefficient of friction and a variation in rake angle, while mild steel and brass showed no effect of lubrication, with 13.8% and 7.9% increases in the coefficient of friction, respectively. Moreover, higher values of cutting forces were achieved by dry conditions for all the workpiece materials due to the absence of lubricant at the cutting region.

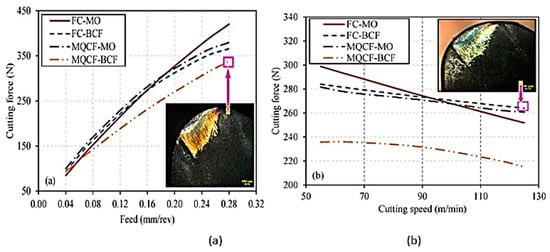

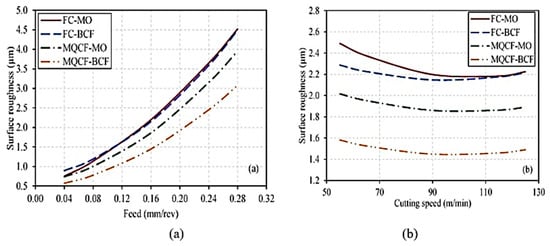

Gajrani et al. [102] discussed the significance and sustainable prospects of bio-cutting fluids (BCFs) and commonly available mineral oils (MOs) in hard material cutting of AISI H-13 steel. The impact of minimum quantity cutting lubrication (MQCL) and flood cooling (FC) strategies on the feed force, machined part surface roughness, coefficient of friction, and cutting forces was examined during the metal cutting with speed-feed variations. Each of the cutting fluids was examined individually under FO and MQCL. The difference of cutting force against cutting speed and feed for MQCF and FC in Figure 13 indicates that feed rate had a substantial influence on machining force. The angle of shear was reduced as feed increased and the thickness of the chip increased. Increased chip thickness increased the chip load and friction on the tool rake face. Thus, the force increases with feed (see Figure 13a). The tool-work component interaction time during cutting decreased with increasing cutting speed, but the MRR increased. Thus, heat increases in both primary and secondary shear areas. The possibility of preheating adjacent to the cutting area increased due to the enhanced temperature conductivity of AISI H-13 steel. Thus, workpiece surface thermal softening develops. Increasing heat in the secondary shear area caused stress distribution to reduce in the machined surface, thus decreasing cutting force with increasing cutting speed (see Figure 13b).

Figure 13.

Variation of cutting force with (a) feed and (b) cutting speed for FC and MQCF [102], License Number: 5287301340048.

The pressurized mist was forcefully pumped into the chip–tool interface after the steady blending of cutting fluid and compressed air in MQCF. The study findings showed that the efficiency of the MQCF mist is better compared to that of FC, due to the increased capacity of mist cutting fluid in the tool–chip boundary. The surface roughness resulted in an increment with increasing feed, regardless of the cutting fluid application procedure (Figure 14a,b). On account of FC, due to high friction and adhesion at the tool–chip boundary, the machined part produced a higher surface roughness. Surface roughness of the workpiece was lower when machined with MQCF, in view of the reduced feed and cutting forces. This may cause similarly less tool chatter, prompting better surface finish, i.e., low surface roughness. From the trial results, coefficient of friction, cutting force, surface roughness, and feed force were diminished with MQCF (for both cutting liquids) compared with FC. Because of its better lubrication and cooling properties, BCF produced preferred outcomes over MO. The authors concluded that BCF emulsion performed better than MO regarding its high specific heat, higher temperature conductivity, and better capacity to infiltrate the tool–chip boundary.

Figure 14.

Variations in feed force with (a) feed and (b) cutting speed under FC and MQCF [102], License Number: 5287301340048.

Ojolo et al. [103] investigated turning of aluminum alloy, copper alloy, and mild steel with a tungsten carbide tool in a wet environment. The impact of four oils, namely shea butter, coconut, palm kernel, and groundnut oils, was tested on the force of the cutting process. The authors observed a better performance with groundnut oil. Groundnut oil showed the greatest cutting force reduction when aluminum was machined accordingly at feed rates and speed. When copper was turned on feeds less than 0.15 mm/rev, palm kernel oil had the best performance. However, the optimum condition for copper was associated with higher feeds. In all three materials machined, coconut oil experienced the highest cutting force, followed by shea butter, and as such it is very moderate in minimizing cutting force during cylindrical machining.

Bhowmik et al. [104] performed experimental research on the performances of three environmentally friendly oils (groundnut oil, neem oil and soya oil) and one industrial mineral oil (supa oil) in a mild steel turning operation in wet and dry environments. The cutting fluids were applied manually with a bottle by flooding. Cutting fluid efficiency was contrasted with the surface finish of the materials. The authors stated that the workpiece machined with vegetable oil produced a fine surface morphology in contrast with mineral oil. Among all vegetable oils, groundnut oil provided better lubricating ability, especially at elevated temperatures. Chip thickness formed using groundnut oil was the highest compared to other cutting oils. The viscosity of groundnut oil was the least and the variation was the closest, even at extreme temperatures. The authors also reported that dry cutting was more time-consuming compared to any form of cutting fluid due to reduced tool performance in the unavailability of cutting fluid.

Bruni et al. [105] investigated surface roughness and tool wear in AISI 420B stainless steel turning using a triple-coated carbide insert (TiCN outer layer, a Al2O3 intermediate layer, and a TiN inner layer) in MQL, flooding, and dry cutting environments. The industrial vegetable oil Vascomill MKS 42 was adopted as an MQL lubricant and was applied at a fluid flow rate of 10 mL/h. Flood cooling trials were operated with chemical-soluble cutting oil (XPS synth, castrol) with 1:20 oil-to-water proportions. Observational findings suggested that lubrication and cooling did not greatly impact tool wear, whereas flood cooling produced the highest surface roughness. It was also found that MQL technology was not superior to dry cutting based on the tool wear and surface roughness values measured.

In their design, Dhar and Khan [106] manufactured an advanced testing technology for the supply of fluid and successfully used AISI 1060 steel in MQL and dry environments in terms of dimensional deviation, tool wear, cutting temperature, and surface roughness. The MQL was supplied with spraying of air with food-grade vegetable oil at an oil flow rate of 6.0 mL/h and air pressure of 7 bar. MQL cutting forces were found to be significantly lower than dry cutting by 5–15% due to a decrease in the temperature of the cutting field. The authors reported decreased surface roughness, tool wear rate, and dimensional accuracy by MQL. They also reported a decrease in surface roughness, dimensional inaccuracy, and tool wear rate by MQL primarily due to lower cutting temperature and desirable change in tool–chip and tool–work interaction.

Klocke et al. [107] tested the influence of dry cutting and various cooling strategies such as high-pressure coolant supply, flooding method, MQL, and cryogenic-cooling-utilizing liquid nitrogen on the machined surface roughness and wear of the cutting tool during gamma titanium aluminide turning operations. The MQL with vegetable oil was supplied through two external nozzles at 7.0 mL/h and 5.5 bar, flood cooling at 6 bar and 10 L/min, and cryogenic at a supply pressure of 2 bar and 2.3 kg/min; high-pressure coolant considered three different levels of supply pressures (80, 150, and 300 bar at a flow rate of 42, 31, and 23 L/min, respectively). The results indicate that surface finish gained by MQL allowed for classifying MQL as an intermediary between flood and cryogenic cooling. In terms of tool wear, the most efficient (best to worst) cooling methods were cryogenic cooling, high-pressure coolants, MQL, and flood cooling. In contrast to flood lubrication, cryogenic cooling reduced tool wear by up to 61%. The authors concluded that cryogenic cooling is the most preferred technology to increase cutting efficiency by reducing tool wear and improving surface quality.

Pusavec et al. [108] studied tool wear, cutting forces, and surface roughness during an Inconel 718 alloy turning procedure under conditions of cryogenic cooling, MQL, cryo-lubrication (cryogenic + MQL), and dryness. In MQL, UNIST coolube 2210 EP oil mist was supplied to the tool rake face at 60 mL/h lubricant flow rate and 0.5 MPa air pressure. The rake surface was supplied with liquid nitrogen (LN) at 1.5 MPa pressure and with a mass flow rate of around 10 g/s. LN was provided to the flank surface when cryo-lubricating and the oil spray was supplied to the rake surface. The studies were conducted with the Taguchi experimental design method by operating an L16 orthogonal arrangement for all lubrication environments. ANOVA and response surface methodology (RSM) were employed for the analysis and modeling, respectively. Cryo-lubrication produced the lowest cutting forces, and the feed force component could be substantially reduced by up to 50% with cryo-lubrication machining in contrast to any of the other scenarios. The cryo-lubricating case scenario demonstrated the most advantageous results from the point of view of flank and rake wear. Cryo-lubrication greatly increased the surface quality of the component being machined.

To analyze the impact of various cooling channels and cutting conditions on machined surface roughness during hardened AISI 52100 steel (60–62 HRC) turning operations, Chinchanikar et al. [109] performed an experimental study via numerical techniques. Tests were conducted under dry conditions and with different cooling mediums, namely, water-based and vegetable oils. Coconut oil and servo cut oil were used as machining fluids. A 5% concentration of oil in water made the servo cut oil. The flow rates for both machining fluids were kept constant at 1.0 L/min. RSM was employed to analyze the experimental results and ANOVA determined the major parameters on surface roughness. The authors established that machining fluids do not greatly enhance the surface finish compared to dry cutting. Coconut oil was found to produce lower values of surface roughness compared with dry and servo cut oil, especially at higher values of the cutting parameters.

In a study with AISI 1045 steel, Kramar et al. [110] investigated the ability of dry, high-pressure, and flood cooling in turning at speeds up to 160 m/min with an Al2O3-covered carbide tool. The cooling performances were monitored for cutting forces, tool life, cooling efficiency, tool wear, and regions of operability. HPC was supplied by providing an emulsion vegetable oil as a cooling system. The findings revealed that dry machining could not be carried out due to long ductile chips that were shaped under all conditions of cutting. A 25% increase in the highest attainable feed rate and a roughly 45% increase in the maximum attainable cutting speed were observed with high-pressure cooling compared to traditional cooling. Increased tool life, reduced coolant consumption, and improved coolant breakability were recorded with high-pressure machining.

Bruni et al. [111] studied the tool wear mechanism and surface roughness while turning 39-NiCrMo-3 alloy steel (HRC = 58) using ceramic and polycrystalline cubic boron nitride (PCBN) inserts in flood, MQL, and dry environments. Vascomill MKS-42 vegetable-typed cutting oil was considered as MQL lubricant with a flow rate of 10 mL/h. The flooding state was made of synthetic soluble cutting fluid with an oil-water ratio of 1:20. In this study, the authors ascertained that dry machining contributed to the lowest surface roughness and tool wear, whereas the MQL technique did not provide turning operation benefits. Consequently, the PCBN inserts were characterized by a longer tool life than the ceramic inserts.

Saleem et al. [112] compared the efficacy, with respect to the cutting temperature of mild steel with a high-speed stainless-steel cutting tool, of mustard oil using an MQL technique and two regular mineral oils (SAE 40 base oil + 10% of boric acid and SAE 40 base oil + 10% molybdenum disulfide). Their findings showed that vegetable oil, compared to other coolants, had a great lubrication and cooling effect. They noted that mustard oil was successful at low as well as high feed rates.

The impact of two different vegetable oils produced from groundnut and false walnut oils, and industrial mineral oil on surface roughness during turning of annealed AISI 1330 alloy steel was investigated by Onuoha et al. [61]. The flooding mode of the cutting fluids application technique was considered. Experiments were performed with the Taguchi L27 (34) orthogonal line-up. To test the relationship between feed rate, DOC, and cutting speed on surface roughness under various cutting fluids, the ANOVA and signal-to-noise ratio statistical methods were used. The best parameter to attain a superior surface roughness of machined parts was obtained when groundnut oil was considered as machining fluid.

During the CNC turning of aluminum alloy-AA 1050 workpiece material, Kumar et al. [113] assessed the efficiency of neat vegetable oils as lubricating oils. The comprehensive study on surface roughness was performed with the same machining conditions between vegetable (coconut and castor) and mineral oils. The mineral-oil-based machining fluid was used using the conventional fluid application method, while the MQL concept was used for the vegetable oils. The results showed that the efficiency of vegetable lubricants is comparable to that of mineral oil.

Kumar et al. [114] assessed the effect of vegetable oils with EP additive in terms of cutting tool temperature, machined surface roughness, cutting forces, and flank wear when turning AISI 1040 steel. The cutting process was conducted with sesame oil with 5% of EP additive, coconut oil with 5% of EP additive, soluble oil and coconut oil with 0% of EP additive, and sesame oil with 0% of EP additive. All cutting fluids were delivered by means of flood cooling. The machining efficiency of vegetable oils with EP additives was compared with soluble oil and vegetable oils without EP additives. The findings showed that vegetables had an EP-additive-enhanced machining efficiency relative to other lubricating environments. Coconut oil with an EP additive reduced the tool temperature by 7% and the feed force by 31%, and improved the surface quality by 33%, the cutting force by 20%, the thrust force by 28%, and the flank wear by 34%, in contrast with sesame oil with an EP additive.

Elmunafi et al. [64] investigated the application of castor oil in the metal cutting of AISI 420 stainless steel using the MQL mechanism. MQL performance was compared with that of dry cutting. The measured parameters were cutting forces, tool life, and surface roughness. Machining variables selected include a fixed DOC (0.2 mm), feed rate (0.24, 0.2, 0.16 mm/rev) and cutting speeds (170, 135, 100 m/min). It was published that the use of a small quantity of oil of 50 mL/h provided more accurate results than dry cuts in terms of more extended tool life. Owing to a decrease in the cutting temperature in the cutting area, the surface roughness and cutting forces improved marginally. The authors clarified that by using carbide-coated tools up to 0.24 mm/rev and 170 m/min, MQL could be a better process for turning the workpiece considered.

Kazeem et al. [31] researched the presentation of a vegetable oil, less frequently used, derived from Jatropha as machining fluid. The Jatropha oil was used to establish lubricity, phytochemical, and physiochemical properties. In turning low-carbon steel alloy AISI 1525 with a covered carbide tool, the impact of emulsion Jatropha oil on machining temperature, chip shape, and surface roughness was tested and compared with mineral oil. Factors and levels (high, medium, and low) considered were cutting velocities (710, 500, and 355 rpm), feed rates (0.2, 0.15, and 0.1 mm/rev), and DOC (1.25, 1.0, and 0.75 mm), respectively. For the experimental scheme, a Taguchi L9 (33) orthogonal array was utilized. In addition, using gray relational analysis, multi-response optimization was performed. In most machining environments, Jatropha oil achieved better efficiency than mineral oil. The GRA solution showed that the appropriate multi-response efficiency of the industrial mineral oil and Jatropha oil could be achieved using the same feed rate (0.10 mm /rev) and cutting velocity (355 m/min) but with DOCs of 1.25 and 1.00 mm, respectively.

Chang et al. [115] studied the cutting fluid output of emulsified and virgin vegetable oil when turning titanium alloy with ceramic inserts. With some input variables such as cutting speed, lubricant type, depth of cut and feed rate, the performances of coconut and palm oils were assessed using signal-to-noise (S/N) ratio. To develop emulsified oil, virgin oil was mixed with a small amount of water. All through the experiment, MQL was used in the machining procedure. To achieve the best cutting condition, the performance of each type of oil was assessed using the S/N ratio for chip reduction coefficient, cutting temperature and percentage of tool wear. The virgin palm oil outperformed the other oils in terms of tool wear, cutting temperature and chip reduction coefficient. Moreover, virgin coconut oil performed better than emulsified coconut oil. As a result, it was concluded that virgin vegetable oils outperformed emulsified vegetable oils as cutting fluids.

Saleem and Mehmood [116] observed the performance of an environmentally friendly spray-based technique on precision-machine nickel-based super alloy Inconel 718 using vegetable oils. Two vegetable oils, castor and sunflower oils, were evaluated for turning operations using a Taguchi L9 (33) orthogonal array, and their performance was compared to the dry machining mode. Air pressure (5, 3.5, 2 bar), cutting speed (70, 50, 30 m/min) and feed rate (0.393, 0,281, 0.168 mm/rev) were varied while maintaining the depth of cut (1.0 mm) and spray standoff settings (50 mm). Response parameters included surface roughness, tool wear, and machined surface integrity. Scanning electron microscopy was used to supplement the tool wear analysis (SEM). ANOVA was used to quantify the impact of the input factors on response parameters. The most important component for surface roughness was determined to be feed rate, which contributed 95.71%, 97.86%, and 93.19% for MQL sunflower oil (MQLSO), MQL castor oil (MQLCO), and dry machining conditions, respectively. Sunflower oil combined with the lowest cutting speed (30 m/min) and feed rate (0.168 mm/rev) resulted in the least tool wear. SEM images provide detailed information into circumstances leading to the worst or the least tool wear, and reveal grooving, adherent material occurrences, and chipping/attrition for dry machining settings.

Kazeem et al. [117] investigated the efficiency of lesser-known vegetable oil (watermelon oil) as a machining cutting fluid. The developed watermelon oil was mechanically compared to the traditional mineral oil in turning AISI 1525 steel based on cutting temperature, surface roughness, and chip formation mode. The experiment depended on the Taguchi plan with an L9 orthogonal arrangement utilizing feed rate, depth of cut, and cutting speed as critical input parameters. Moreover, the grey relational analysis optimization approach was employed to analyze the parameter impacts and achieve the best possible cutting parameters. The optimization showed that the best combinations of cutting parameters for cutting speed, feed rate, and depth of cut were 355 rev/min, 0.1 mm/rev, and 1 mm for watermelon, and 355 rev/min, 0.1 mm/rev, and 1.25 mm for mineral oils.

Arul et al. [118] investigated the machinability of duplex stainless steel during the turning of various wet coolants, such as water (mustard, coconut, and soya bean oil). Cutting speed, depth of cut, feed, pressure, nozzle inclination angle, and standoff distance were all input process factors. Thrust force, tool wear, machining zone temperature, and surface roughness were all considered as output response factors. The Taguchi approach was applied to design the experimental runs in this investigation under three different levels of process parameter combinations. The turning rate was increased with coconut oil over the other coolant conditions, and it generated a uniform surface finish along the length of the workpiece, according to the trial results.

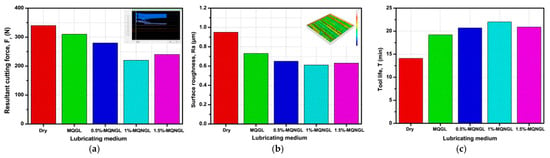

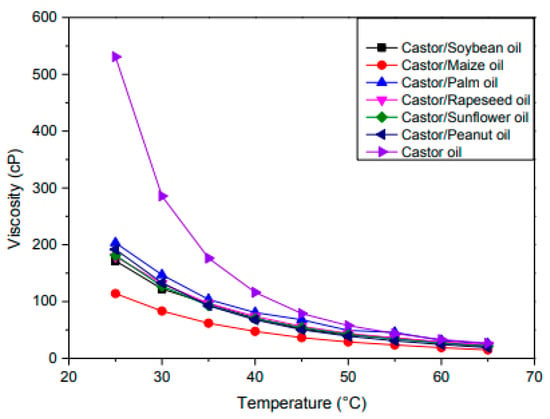

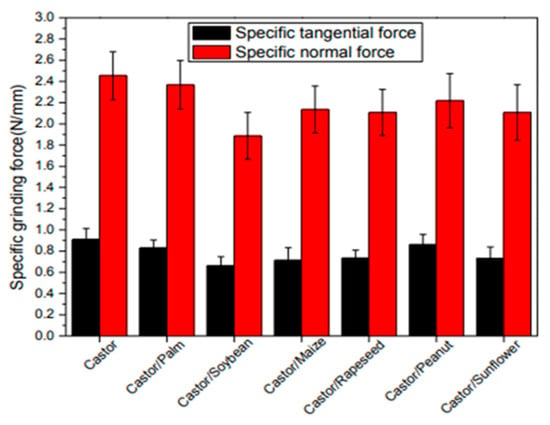

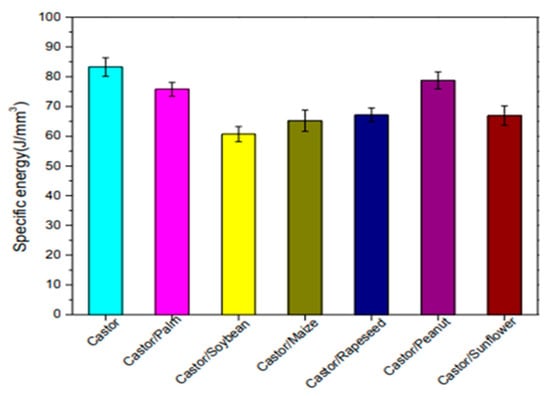

Sani et al. [119] used a minimum quality lubrication technique to investigate the machining performance of a novel crude tamanu oil, crude Jatropha oil, synthetic ester, and bleached, deodorized, and refined palm olein during the turning process of an AISI 316L stainless-steel disc. Process factors included deformed chip thickness, cutting forces, elemental compositions on the surface morphology of the cutting inserts, and chip curling effect. According to the findings of the tests, crude Jatropha oil was the best plant-based lubricant, outperforming all other lubricant samples. The crude tamanu oil has a high viscosity index value and kinematic viscosity, which means that there is much room for improvement in its lubricating qualities, which could increase its anti-wear and anti-friction behaviors.