Modified Ni Nanoparticles as Additives in Various Greases: Assessment of Comparative Performance Potential

Abstract

1. Introduction

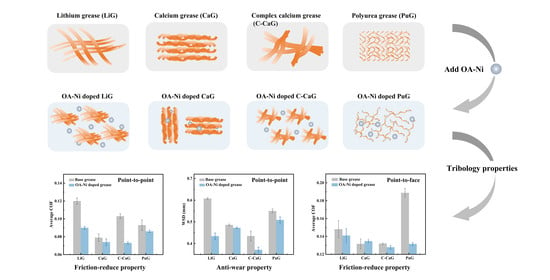

2. Materials and Methods

2.1. Materials

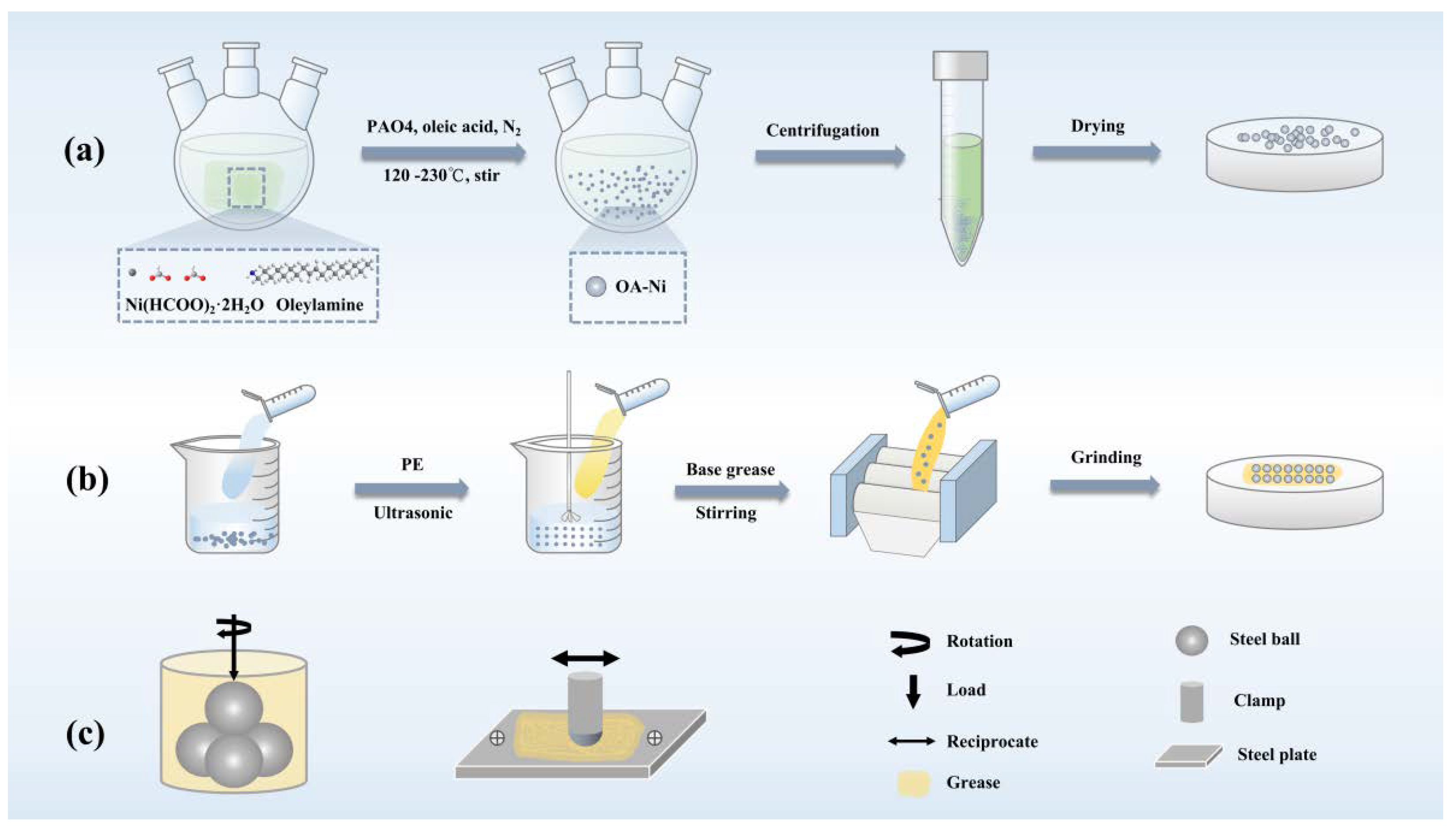

2.2. Preparation of OA-Ni and Doped Greases

2.2.1. Synthesis of OA-Ni

2.2.2. Preparation of Greases Containing OA-Ni

2.3. Physicochemical and Tribological Properties Characterization

2.3.1. Physicochemical Characterization Tests

2.3.2. Tribological Properties Tests

2.4. Characterization

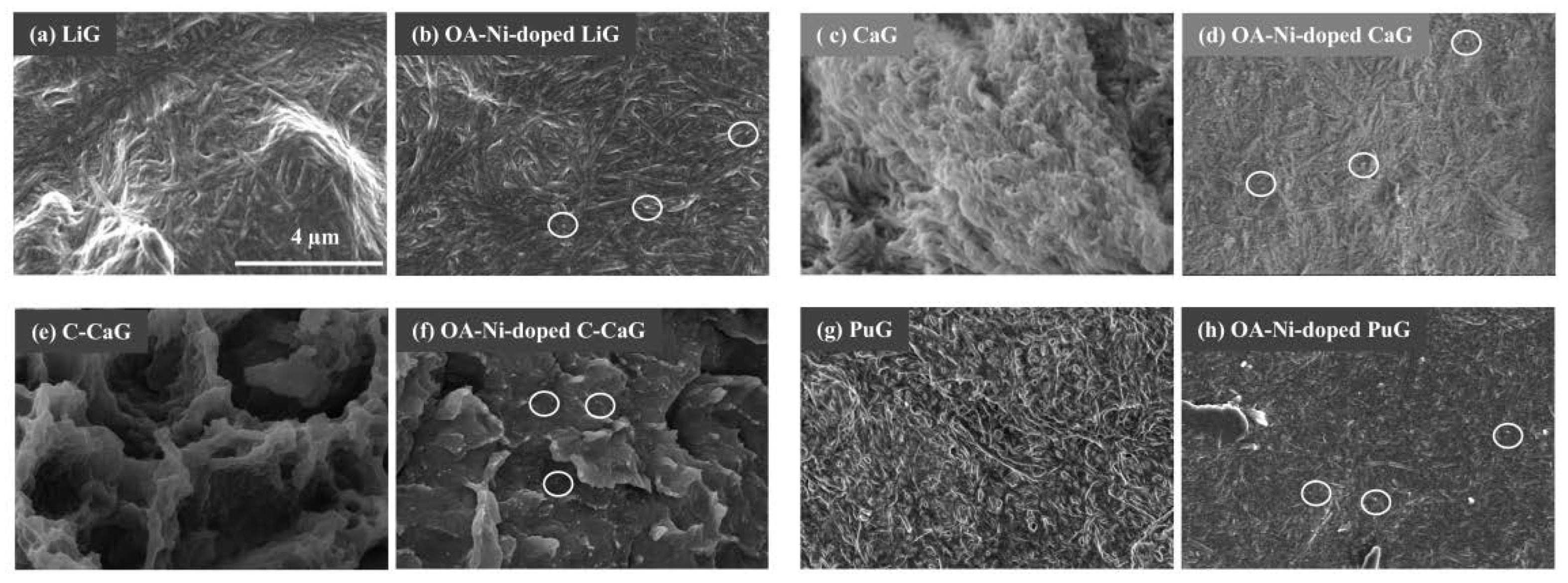

2.4.1. Characterization of OA-Ni and Doped Greases

2.4.2. Characterization of Worn Surfaces

3. Results

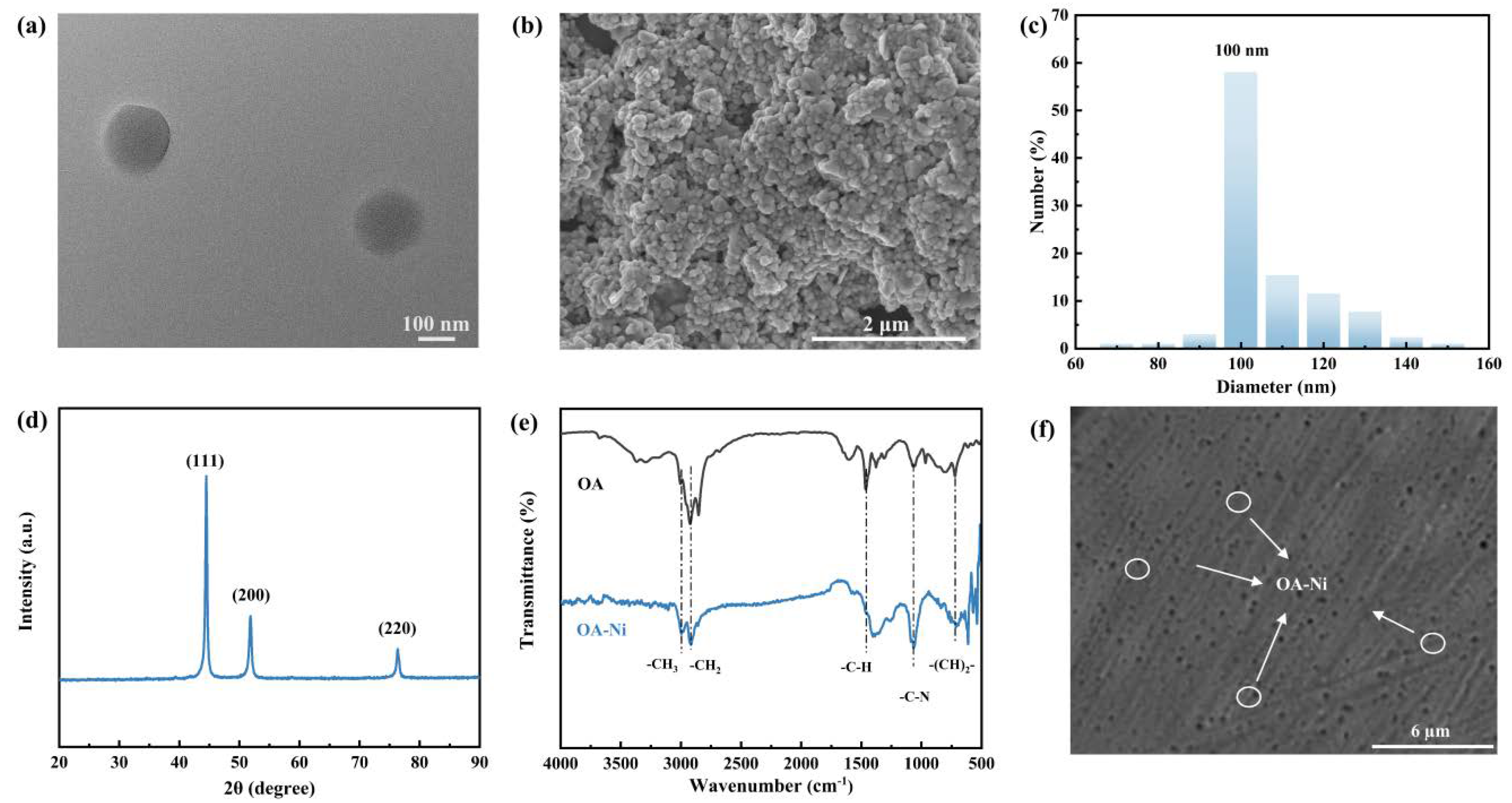

3.1. Characterization Results of OA-Ni

3.2. Characterization of Greases

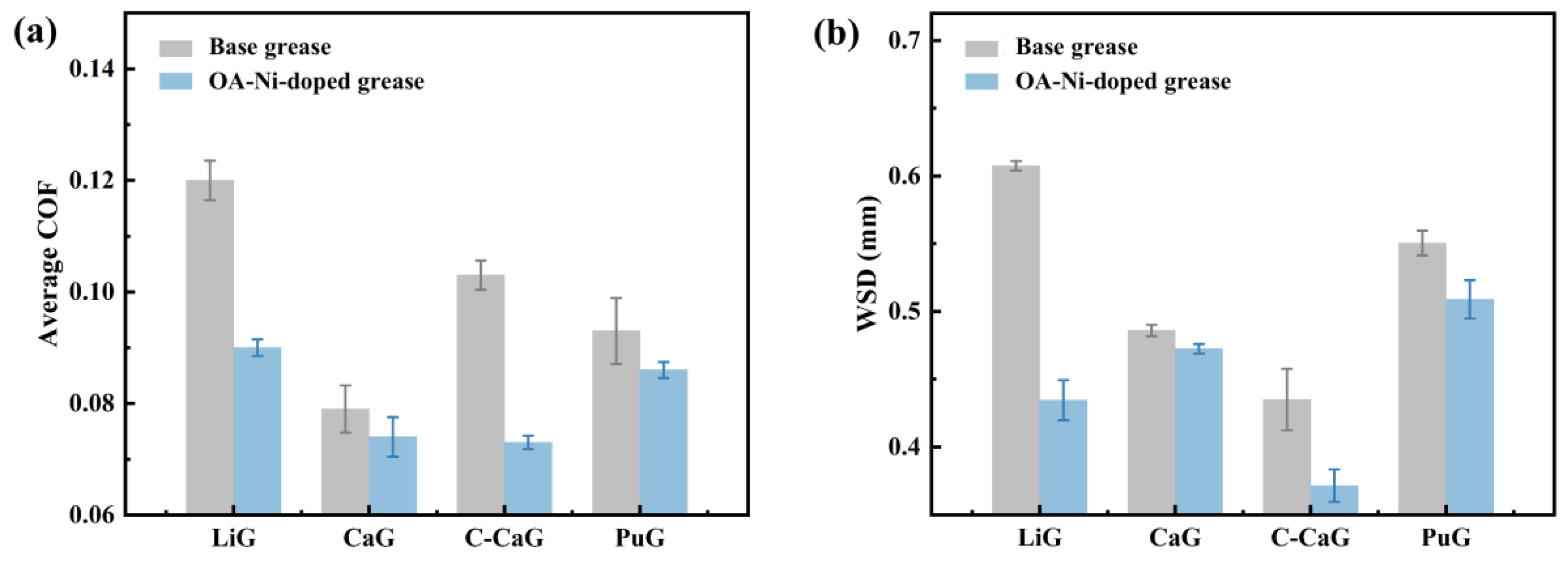

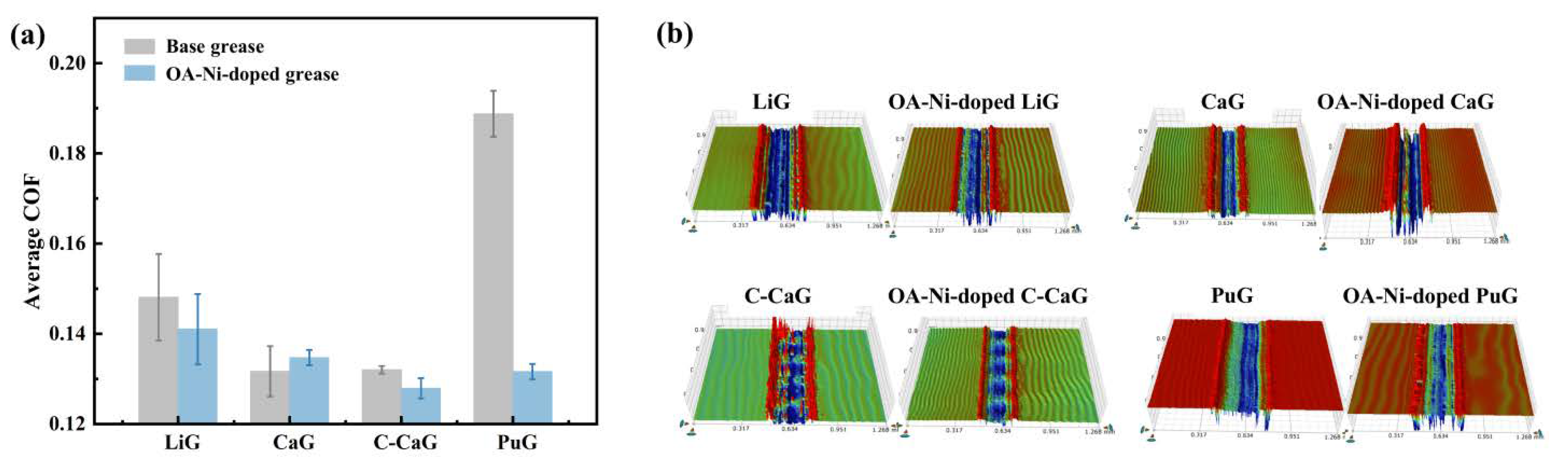

3.3. Results of Tribological Tests

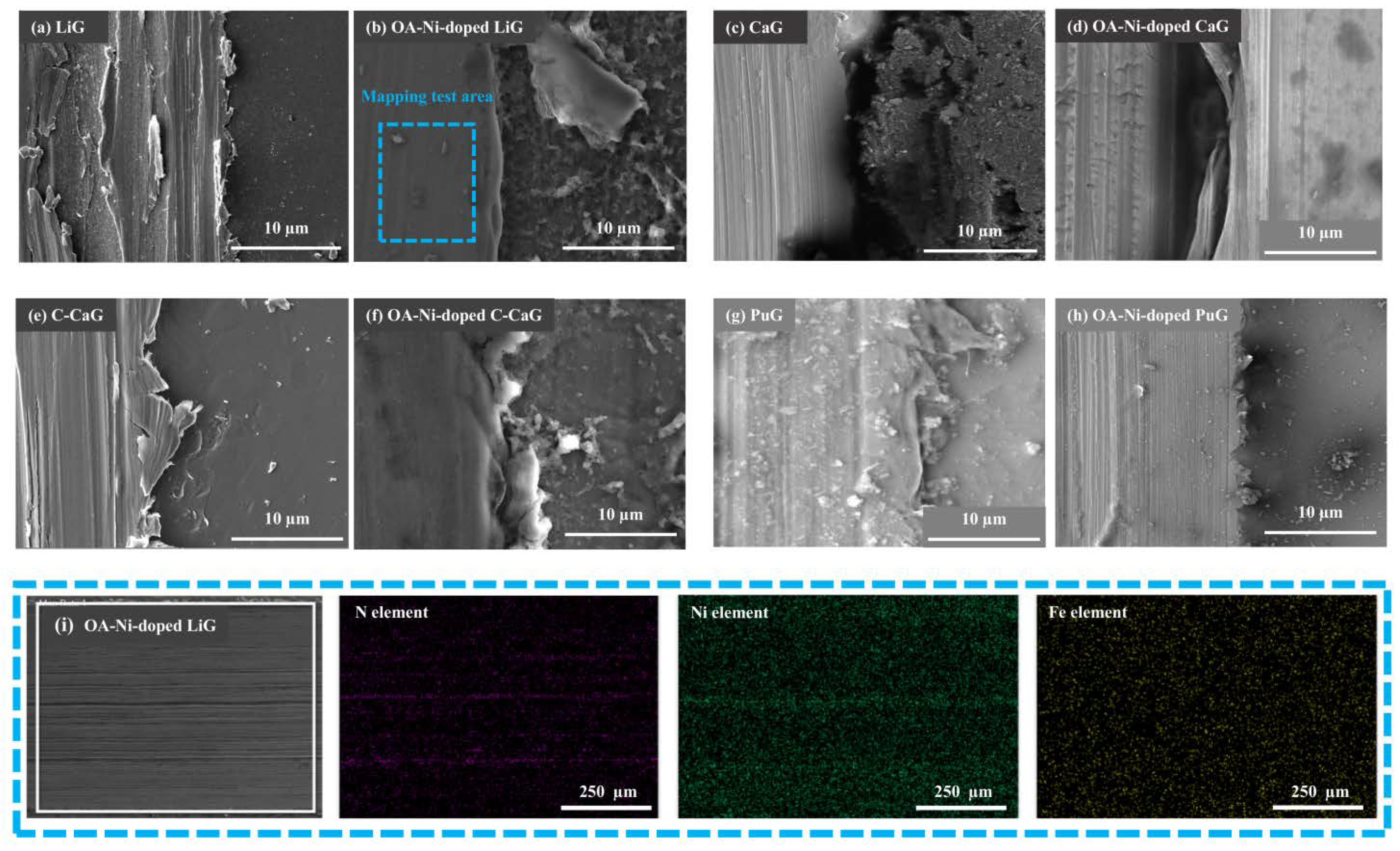

3.4. SEM and EDS Analysis of Worn Surface

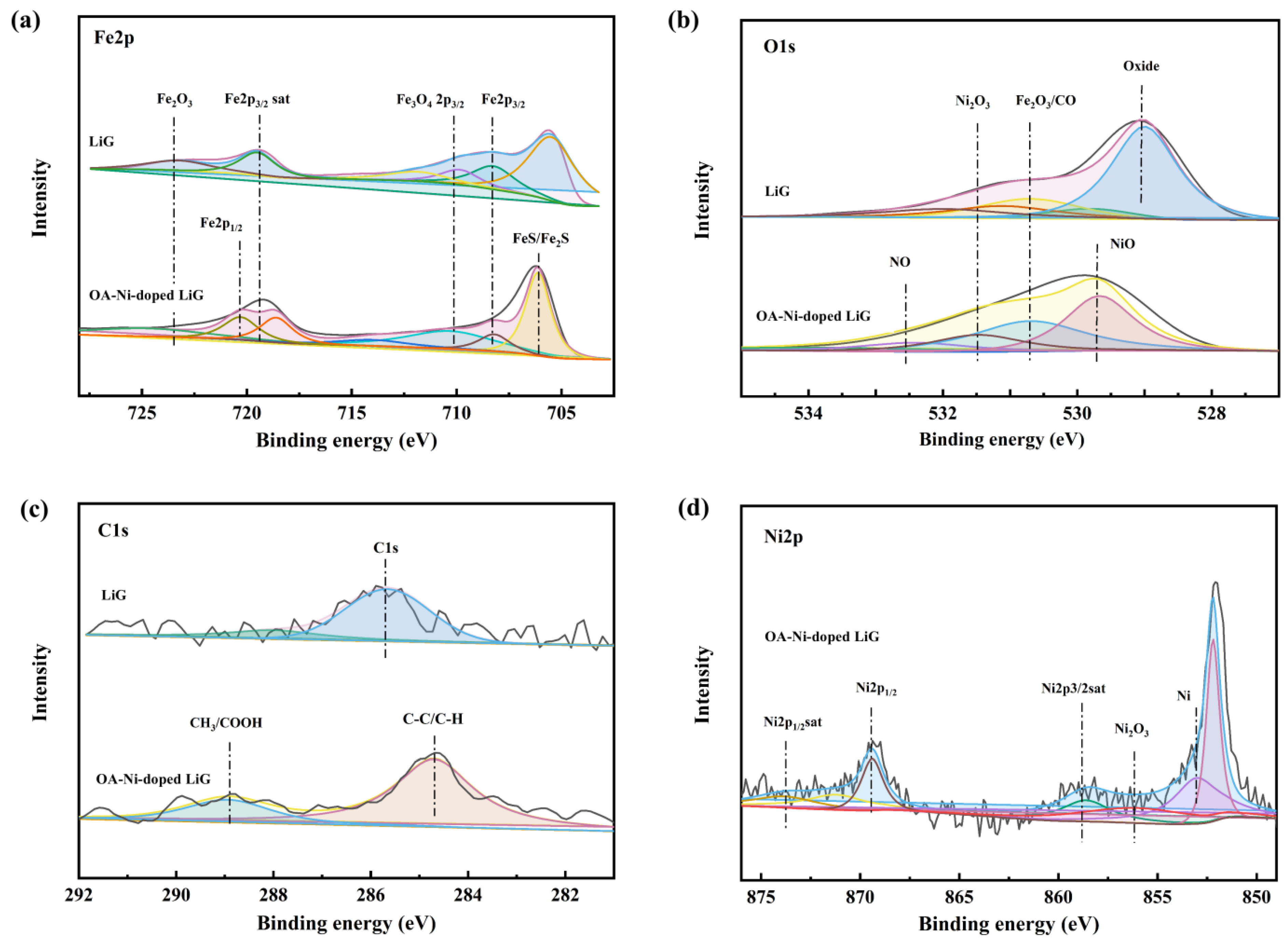

3.5. XPS Analysis of the Worn Surface

3.6. Possible Mechanism

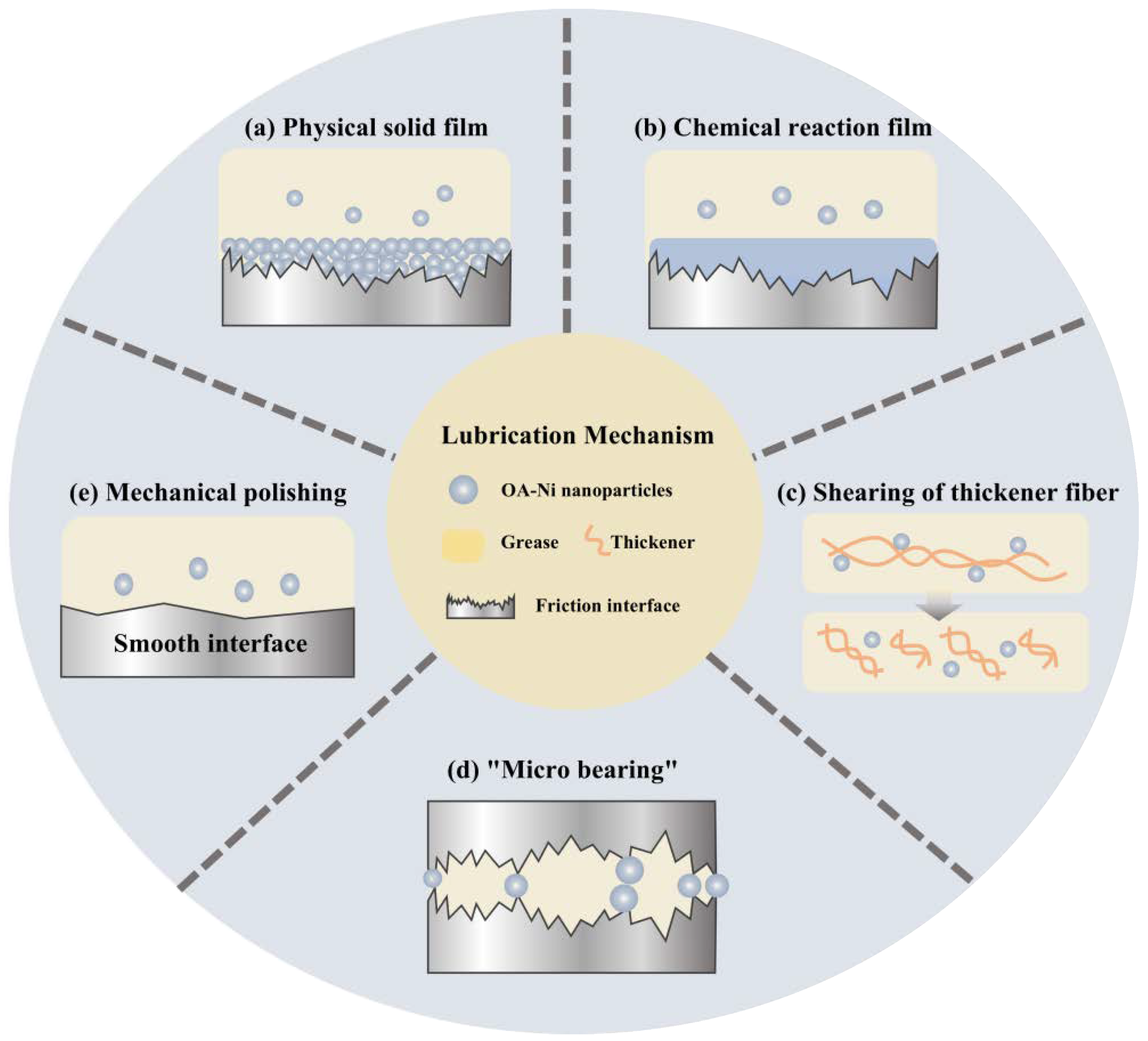

- Chemical reaction film (Figure 6 and Figure 7). The organic chain on OA-Ni reacts with the friction material, while, to a certain extent, the high temperature promotes the chemical reaction; this temperature originates from the thermal energy induced by the friction. Accordingly, the chemical reaction film is formed on the contact area [32];

- Polishing effect (Figure 6). OA-Ni mechanically polishes the nanoscale protrusion of the rough surface, while a smooth surface increases the friction area and, thus, avoids severe wear.

4. Conclusions

- (1)

- The introduction of OA-Ni has a constructive effect on all four types of greases. Under point-to-point conduct, LiG and C-CaG exhibit the most sensitive response to OA-Ni. In contrast, CaG and PuG samples demonstrate only insignificant responses. Under point-to-face conduct, the tribological properties of PuG show the most obvious improvement, while the performance of other greases is not significantly enhanced;

- (2)

- The lubrication mechanism of OA-Ni offers the following benefits: it generates a physically solid film and a chemical-reaction film, it shears the thickener fiber, and it uses mechanical polishing as “micro bearing”. The synergy of these functions greatly broadens working conditions and prolongs serving life in comparison with pure grease.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- He, B.; Liu, S.; Zhao, X.; Liu, J.; Ye, Q.; Liu, S.; Liu, W. Dialkyl dithiophosphate-functionalized gallium-based liquid-metal nanodroplets as lubricant additives for antiwear and friction reduction. ACS Appl. Nano Mater. 2020, 3, 10115–10122. [Google Scholar] [CrossRef]

- Li, Z.; He, Q.; Du, S.; Zhang, Y. Effect of few layer graphene additive on the tribological properties of lithium grease. Lubr. Sci. 2020, 32, 333–343. [Google Scholar] [CrossRef]

- Yu, H.; Xu, Y.; Shi, P.; Wang, H.; Wei, M.; Zhao, K.; Xu, B. Microstructure, mechanical properties and tribological behavior of tribofilm generated from natural serpentine mineral powders as lubricant additive. Wear 2013, 297, 802–810. [Google Scholar] [CrossRef]

- Furukawa, H.; Cordova, K.E.; O’Keeffe, M.; Yaghi, O.M. The chemistry and applications of metal-organic frameworks. Science 2013, 341, 1230444. [Google Scholar] [CrossRef]

- Rahman, M.; Hayat, T.; Khan, S.A.; Alsaedi, A. Entropy generation in sutterby nanomaterials flow due to rotating disk with radiation and magnetic effects. Math. Comput. Simul. 2022, 197, 151–165. [Google Scholar] [CrossRef]

- Bakunin, V.N.; Suslov, A.Y.; Kuzmina, G.N.; Parenago, O.P. Synthesis and application of inorganic nanoparticles as lubricant components-a review. J. Nanopart. Res. 2004, 6, 273–284. [Google Scholar] [CrossRef]

- Krawiec, S. On the mechanism of the synergistic effect of PTFE and copper in a lithium grease lubricant. Ind. Lubr. Tribol. 2011, 63, 171. [Google Scholar] [CrossRef]

- Sanchez, C.; Chen, Y.; Parkinson, D.Y.; Liang, H. In situ probing of stress-induced nanoparticle dispersion and friction reduction in lubricating grease. Tribol. Int. 2017, 111, 66–72. [Google Scholar] [CrossRef]

- Mariño, F.; López, E.R.; Arnosa, Á.; González Gómez, M.A.; Piñeiro, Y.; Rivas, J.; Alvarez-Lorenzo, C.; Fernández, J. ZnO nanoparticles coated with oleic acid as additives for a polyalphaolefin lubricant. J. Mol. Liq. 2022, 348, 118401. [Google Scholar] [CrossRef]

- Zhao, J.; Yang, G.; Zhang, C.; Zhang, Y.; Zhang, S.; Zhang, P. Synthesis of water-soluble Cu nanoparticles and evaluation of their tribological properties and thermal conductivity as a water-based additive. Friction 2019, 7, 246–259. [Google Scholar] [CrossRef]

- Guo, J.; Cheng, J.; Tan, H.; Sun, Q.; Yang, J.; Liu, W. Constructing a novel and high-performance liquid nanoparticle additive from a Ga-based liquid metal. Nanoscale 2020, 12, 9208–9218. [Google Scholar] [CrossRef] [PubMed]

- Salah, N.; Abdel-Wahab, M.S.; Alshahrie, A.; Alharbi, N.D.; Khan, Z.H. Carbon nanotubes of oil fly ash as lubricant additives for different base oils and their tribology performance. RSC Adv. 2017, 7, 40295–40302. [Google Scholar] [CrossRef]

- Hu, J.; Wang, C.; Zhang, P.; Zhang, S.; Zhang, Y. Diisooctyl sebacate-containing Nickel nanoparticles for lubrication of steel sliding parts under magnetic fields. ACS Appl. Nano Mater. 2021, 4, 7007–7016. [Google Scholar] [CrossRef]

- Maksimova, Y.M.; Shakhmatova, A.S.; Ilyin, S.O.; Pakhmanova, O.A.; Lyadov, A.S.; Antonov, S.V.; Parenago, O.P. Rheological and tribological properties of lubricating greases based on esters and polyurea thickeners. Rheol. Tribol. Prop. 2018, 58, 1064–1069. [Google Scholar] [CrossRef]

- Kumara, C.; Luo, H.; Leonard, D.N.; Meyer, H.M.; Qu, J. Organic-modified silver nanoparticles as lubricant additives. ACS Appl. Mater. Interfaces 2017, 9, 37227–37237. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, J.; Xue, Q. Synthesis and characterization of a molybdenum disulfide nanocluster. J. Phys. Chem. 1994, 98, 12973–12977. [Google Scholar] [CrossRef]

- Meng, Y.; Su, F.; Chen, Y. Nickel/Multi-walled ncarbon nanotube nanocomposite synthesized in supercritical fluid as efficient lubricant additive for mineral oil. Tribol. Lett. 2018, 66, 134. [Google Scholar] [CrossRef]

- Reinert, L.; Varenbery, M.; Mücklich, F.; Suárez, S. Dry friction and wear of self-lubricating carbon-nanotube-containing surfaces. Wear 2018, 406–407, 33–42. [Google Scholar] [CrossRef]

- Ahmad, U.; Raza Naqvi, S.; Ali, I.; Saleem, F.; Taqi Mehran, M.; Sikandar, U.; Juchelková, D. Biolubricant production from castor oil using iron oxide nanoparticles as an additive: Experimental, modelling and tribological assessment. Fuel 2022, 324, 124565. [Google Scholar] [CrossRef]

- Tóth, Á.D.; Szabó, Á.I.; Leskó, M.Z.; Rohde-Brandenburger, J.; Kuti, R. Tribological Properties of the Nanoscale Spherical Y2O3 Particles as Lubricant Additives in Automotive Application. Lubricants 2022, 10, 28. [Google Scholar] [CrossRef]

- Qiu, S.; Zhou, Z.; Dong, J.; Chen, G. Preparation of Ni nanoparticles and evaluation of their tribological performance as potential additives in Oils. ASME J. Tribol. 2001, 123, 441–443. [Google Scholar] [CrossRef]

- Shu, J.; Harris, K.; Munavirov, B.; Westbroek, R.; Leckner, J.; Glavatskih, S. Tribology of polypropylene and Li-complex greases with ZDDP and MoDTC additives. Tribol. Int. 2018, 118, 189–195. [Google Scholar] [CrossRef]

- Li, D.; Xie, Y.; Yong, H.; Sun, D. Surfactant-assisted preparation of Y2O3-stabilized ZrO2 nanoparticles and their tribological performance in mineral and commercial lubricating oils. RSC Adv. 2017, 7, 3727–3735. [Google Scholar] [CrossRef]

- Singh, Y.; Rahim, E.A.; Singh, N.K.; Sharma, A.; Singla, A.; Palamanit, A. Friction and wear characteristics of chemically modified mahua (madhuca indica) oil based lubricant with SiO2 nanoparticles as additives. Wear 2022, 508–509, 204463. [Google Scholar] [CrossRef]

- Ye, X.; Wang, J.; Fan, M. Evaluating tribological properties of the stearic acid-based organic nanomaterials as additives for aqueous lubricants. Tribol. Int. 2019, 140, 105848. [Google Scholar] [CrossRef]

- Wu, H.; Wei, D.; Hee, A.C.; Huang, S.; Xing, Z.; Jiao, S.; Huang, H.; Jiang, Z. The influence of water-based nanolubrication on mill load and friction during hot rolling of 304 stainless steel. Int. J. Adv. Manuf. Technol. 2022, 121, 7779–7792. [Google Scholar] [CrossRef]

- Szabó, Á.I.; Tóth, Á.D.; Leskó, M.Z.; Hargitai, H. Investigation of the Applicability of Y2O3–ZrO2 spherical nanoparticles as tribological lubricant additives. Lubricants 2022, 10, 152. [Google Scholar] [CrossRef]

- Wang, X.; Wei, X.; Zhang, J.; Li, R.; Hua, M.; Wang, W. formation of nanocrystallized structure in worn surface layer of T10 steel against 20CrMnTi steel during dry rubbing. J. Nanomater. 2016, 2016, 4631851. [Google Scholar] [CrossRef]

- Thampi, A.D.; Prasanth, M.A.; Anandu, A.P.; Sneha, E.; Sasidharan, B.; Rani, S. The effect of nanoparticle additives on the tribological properties of various lubricating oils—Review. Mater. Today Proc. 2021, 47, 4919–4924. [Google Scholar] [CrossRef]

- Bhushan, B.; Israelachvill, J.N.; Landman, U. Nanotribology: Friction, wear and lubrication at the atomic scale. Nature 1995, 374, 607–616. [Google Scholar] [CrossRef]

- Gundarneeya, T.P.; Vakharia, D.P. Performance analysis of journal bearing operating on nanolubricants with TiO2, CuO and Al2O3 nanoparticles as lubricant additives. Mater. Today Proc. 2021, 45, 5624–5630. [Google Scholar] [CrossRef]

- Zhang, R.; Liu, X.; Guo, Z.; Cai, M.; Shi, L. Effective suger-derived organic gelator for three different types of lubricant oils to improve tribological performance. Friction 2020, 8, 1025–1038. [Google Scholar] [CrossRef]

- Radulescu, A.V.; Radulescu, I. Rheological models for lithium and calcium greases. Mechanics 2016, 59, 67. [Google Scholar]

- Ali, Z.A.A.A.; Takhakh, A.M.; Al-Waily, M. A review of use of nanoparticle additives in lubricants to improve its tribological properties. Mater. Today Proc. 2022, 52, 1442–1450. [Google Scholar] [CrossRef]

| National Standard | LiG | OA-Ni- Doped LiG | CaG | OA-Ni- Doped CaG | C-CaG | OA-Ni- Doped C-CaG | PuG | OA-Ni- Doped PuG | |

|---|---|---|---|---|---|---|---|---|---|

| Dropping point (°C) | GB/T 4929 | 188.3 | 187.0 | 172.9 | 170.2 | 177.4 | 177.9 | 182.5 | 186.3 |

| Penetration | GB/T 269 | 365.6 | 368.2 | 305.3 | 309.5 | 338.1 | 340.6 | 420.5 | 434.9 |

| Cone penetration (0.1 mm) | GB/T 392 | 0.6 | 1.7 | 0.2 | 0.8 | 0.4 | 1.3 | 1.1 | 2.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Zhang, H.; Hu, W.; Li, J. Modified Ni Nanoparticles as Additives in Various Greases: Assessment of Comparative Performance Potential. Lubricants 2022, 10, 367. https://doi.org/10.3390/lubricants10120367

Wang J, Zhang H, Hu W, Li J. Modified Ni Nanoparticles as Additives in Various Greases: Assessment of Comparative Performance Potential. Lubricants. 2022; 10(12):367. https://doi.org/10.3390/lubricants10120367

Chicago/Turabian StyleWang, Jiabei, Hong Zhang, Wenjing Hu, and Jiusheng Li. 2022. "Modified Ni Nanoparticles as Additives in Various Greases: Assessment of Comparative Performance Potential" Lubricants 10, no. 12: 367. https://doi.org/10.3390/lubricants10120367

APA StyleWang, J., Zhang, H., Hu, W., & Li, J. (2022). Modified Ni Nanoparticles as Additives in Various Greases: Assessment of Comparative Performance Potential. Lubricants, 10(12), 367. https://doi.org/10.3390/lubricants10120367