Performance of Al2O3/TiO2 Hybrid Nano-Cutting Fluid in MQL Turning Operation via RSM Approach

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Properties of Hybrid Nanofluid

2.2. Workpiece Preparation

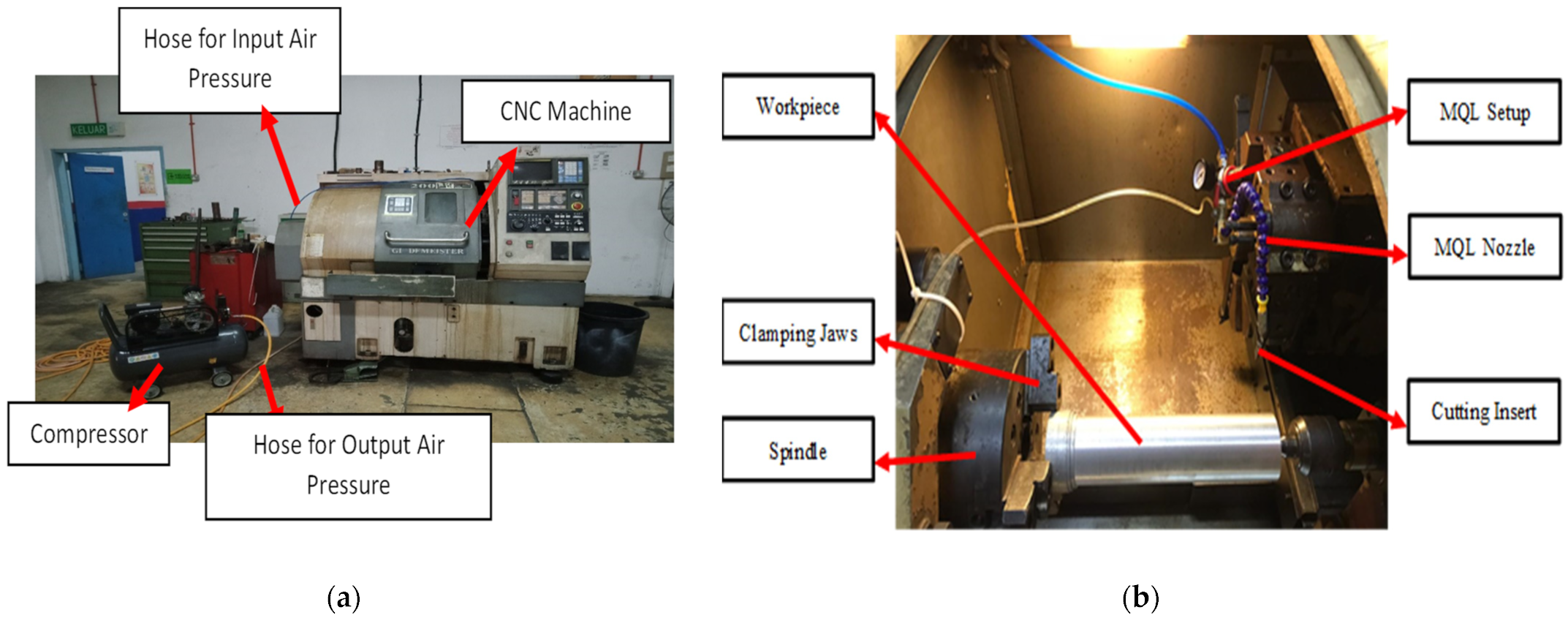

2.3. The Turning Process with MQL-Hybrid Nano-Cutting Fluid

2.4. Response Surface Method (RSM)

2.4.1. DOE

2.4.2. RSM Analysis

3. Results and Discussion

3.1. The Investigation of Hybrid Nano-Cutting Fluid Stability

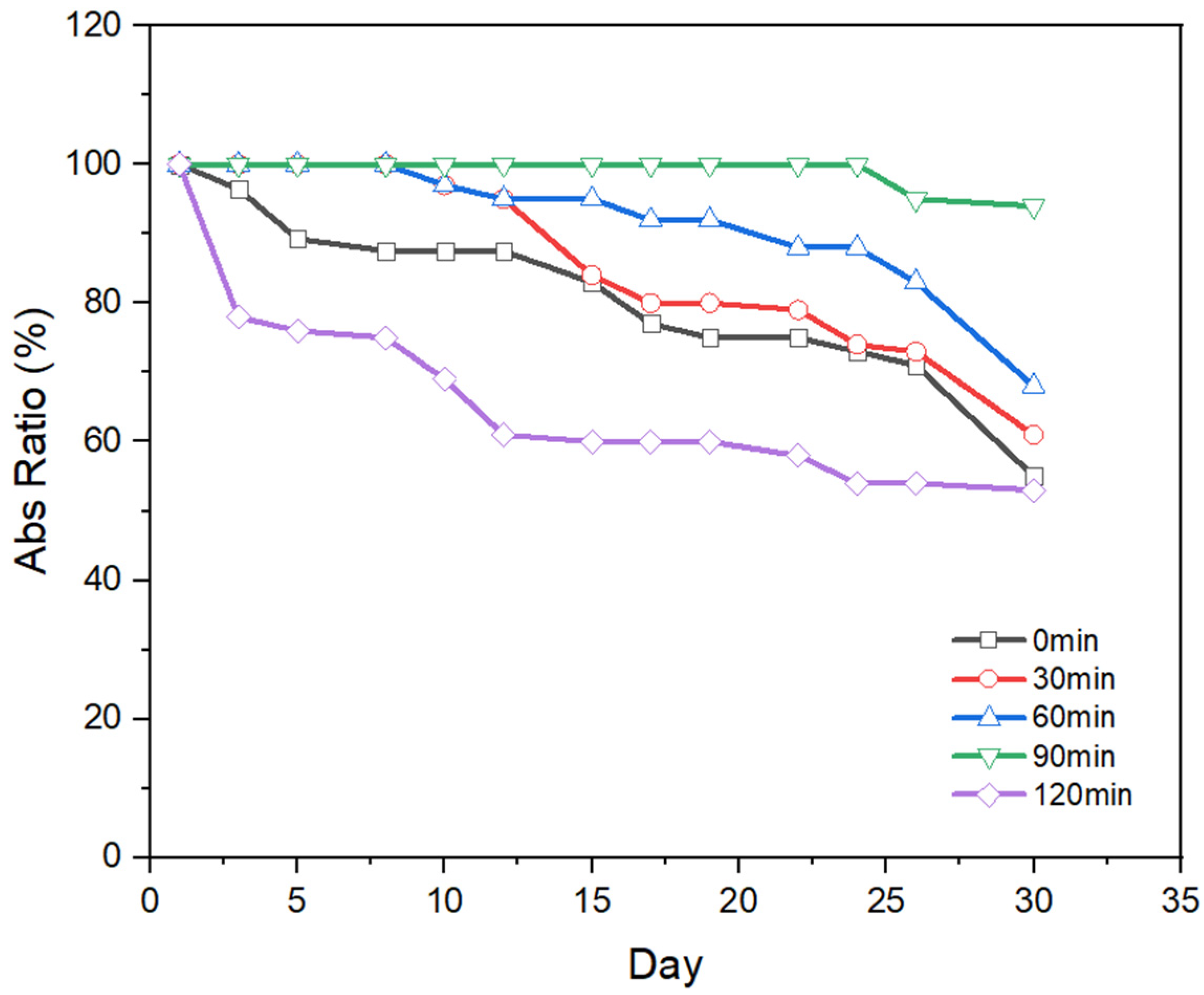

3.1.1. Via UV-Vis Spectrophotometer

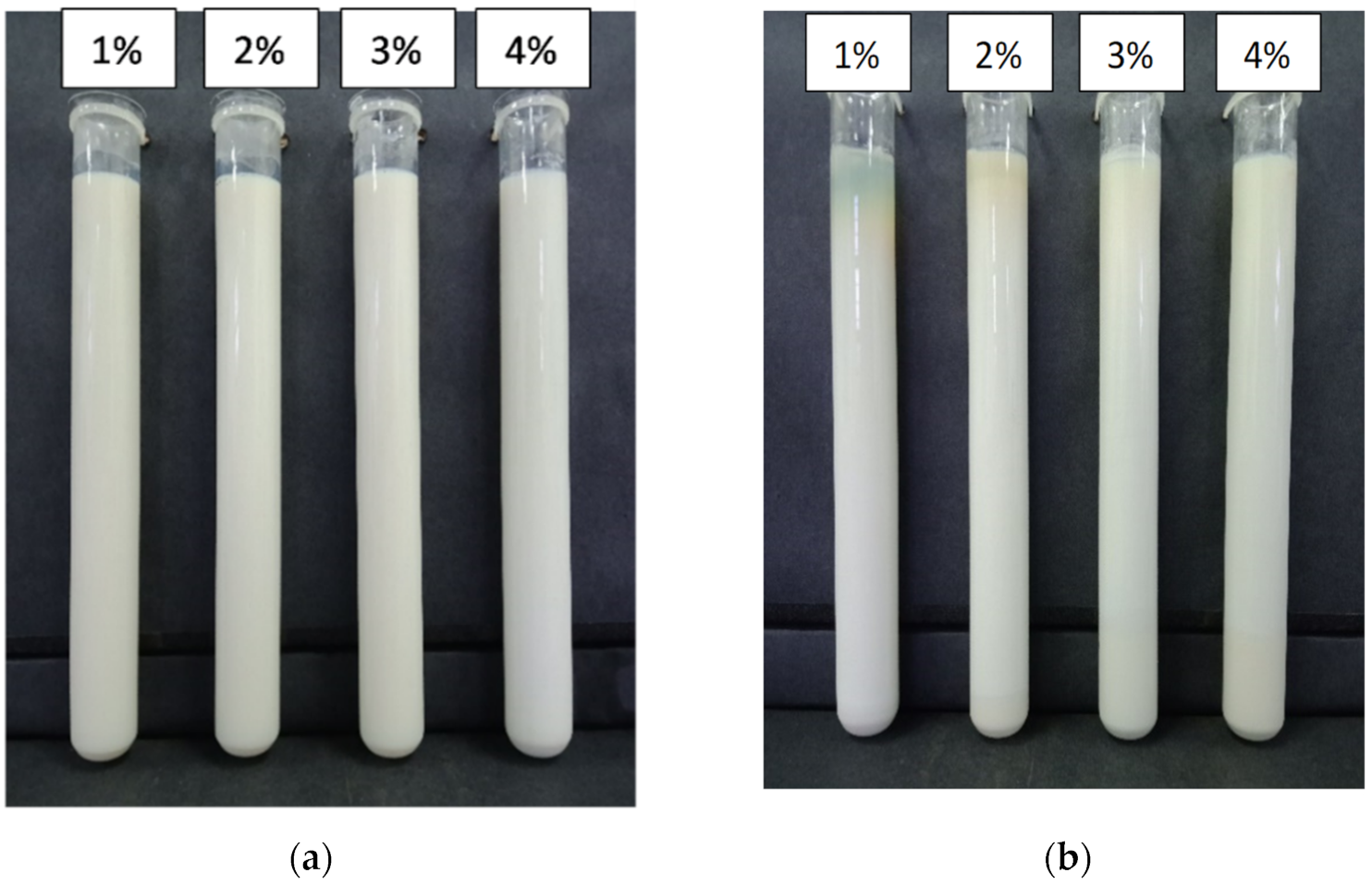

3.1.2. Via Visual Sedimentation

3.1.3. Via Zeta Potential

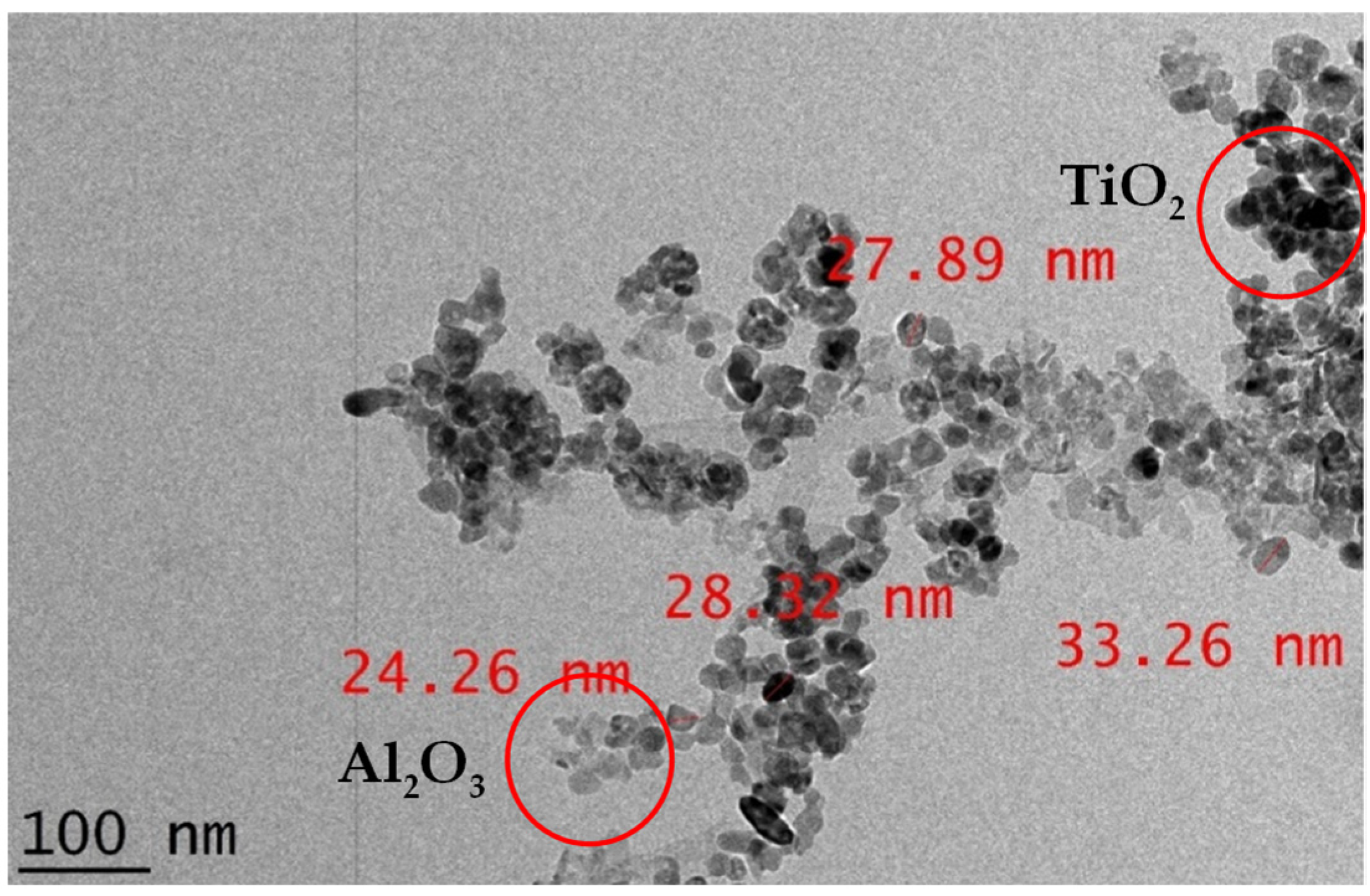

3.1.4. Via TEM Analysis

3.2. Machining with Hybrid Nano-Cutting and MQL

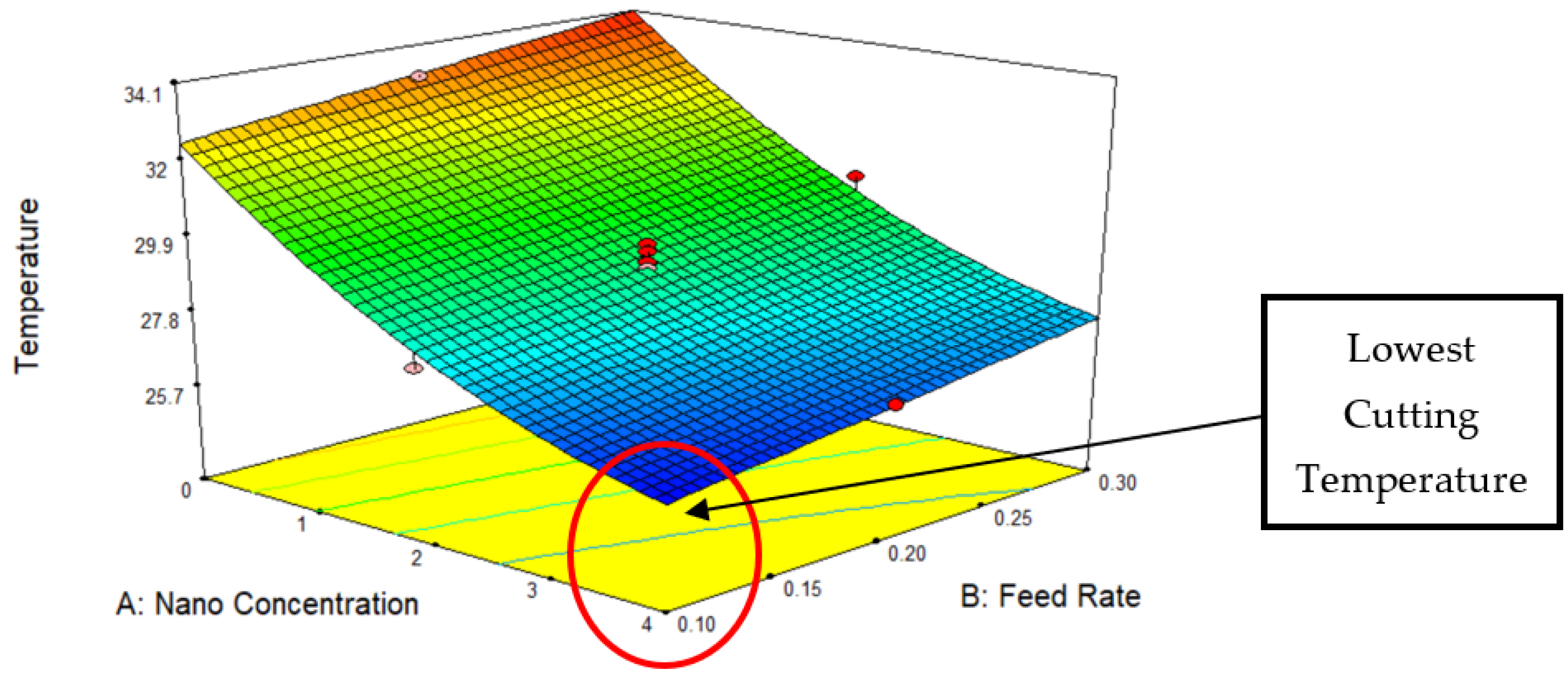

3.3. Analysis of Cutting Temperature

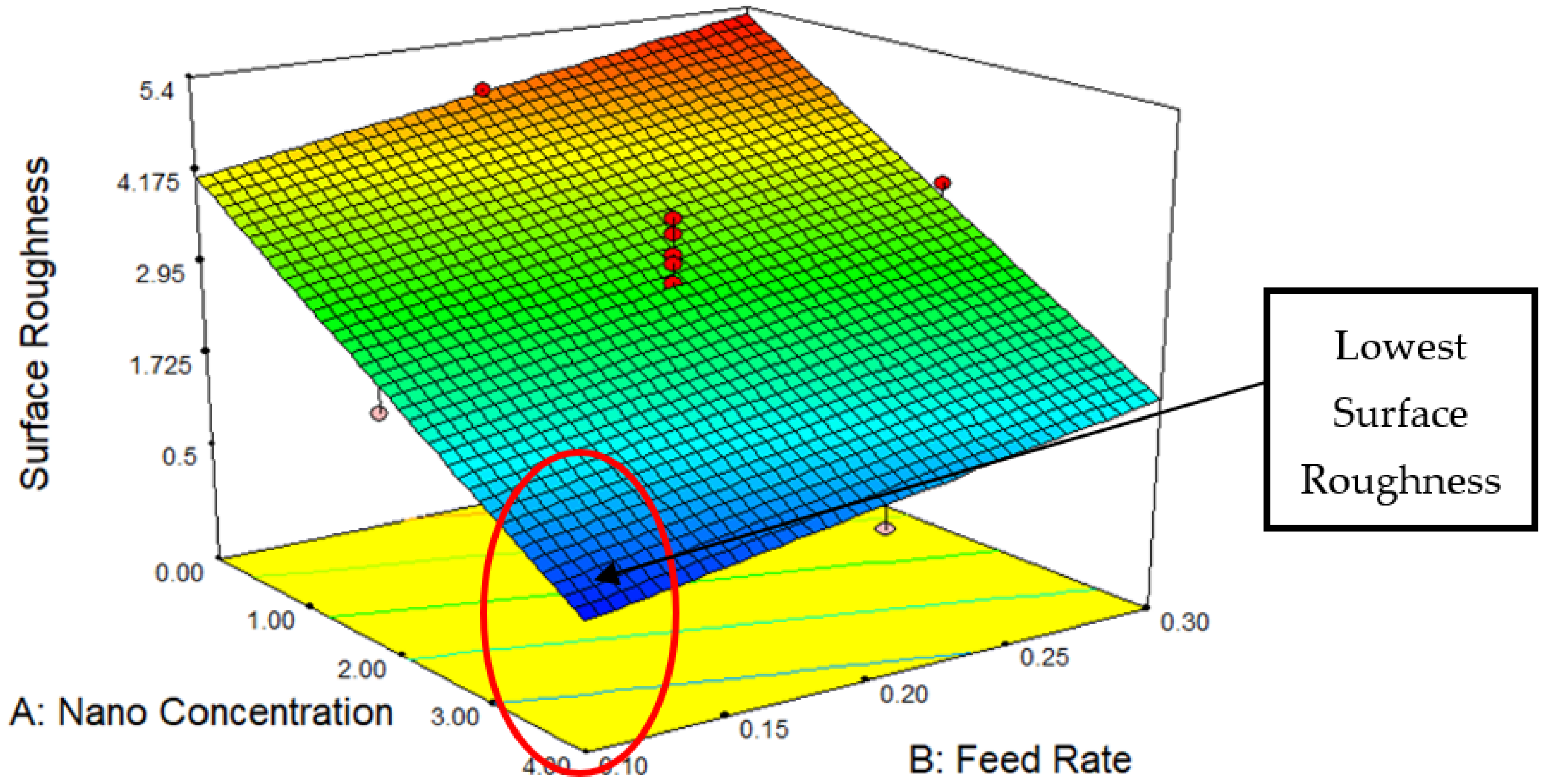

3.4. Analysis of Surface Roughness

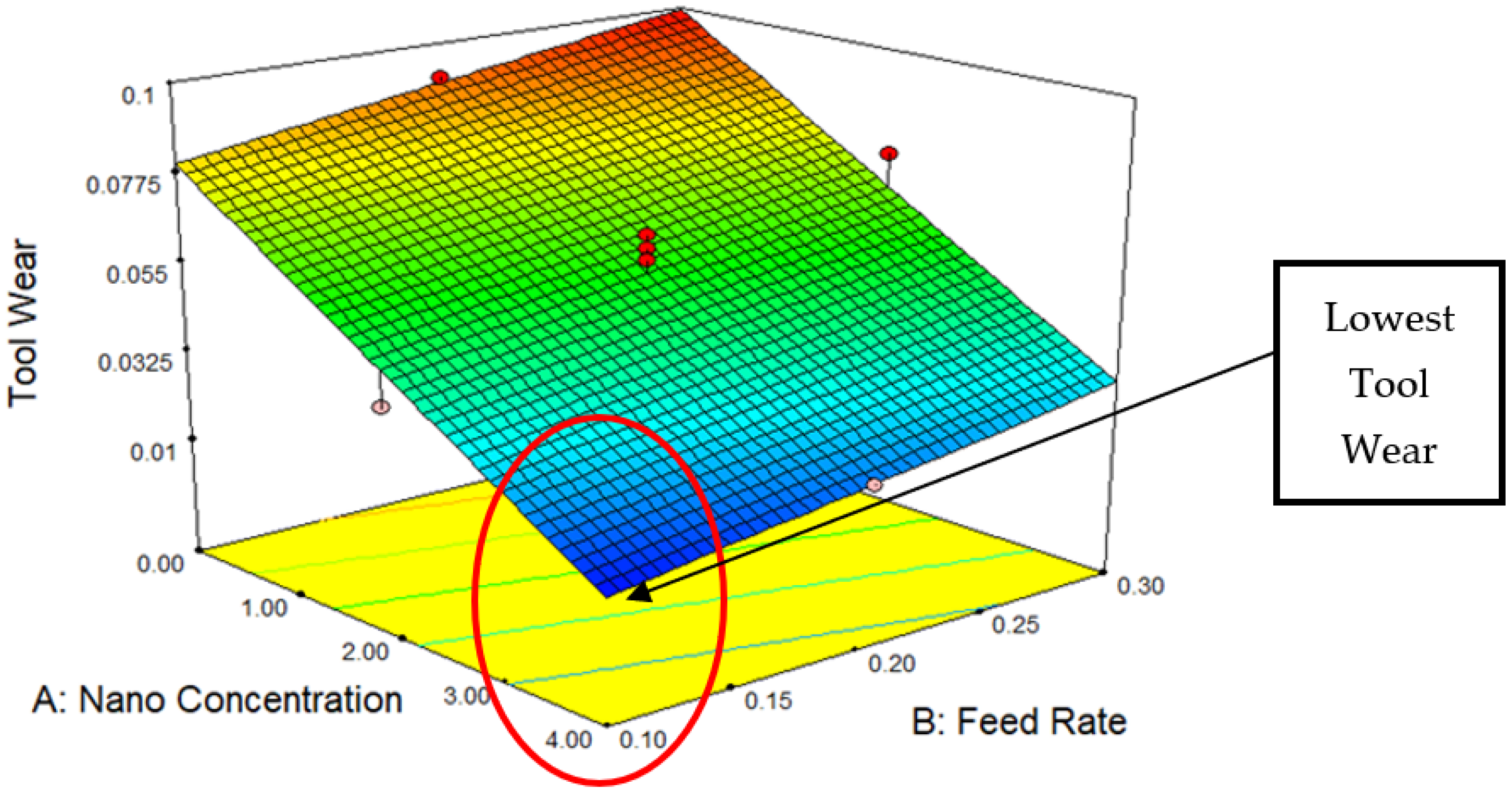

3.5. Analysis of Tool Wear

3.6. Regression Analysis

3.7. Optimization and Validations

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| AISI | American Iron and Steel Institute |

| Al2O3 | Aluminum Oxide |

| Al7075 | Aluminum 7075 |

| ATX224 | An Electronic Balance Model |

| CCD | Center Composite Design |

| CNC | Computer Numerical Control |

| Cr | Chromium |

| CT-200 | Turning Machine Brand |

| Cu | Copper |

| doc | depth of cut |

| DOE | Design of Experiment |

| Err | Error |

| f | feedrate |

| FCD | Face Centered Design |

| Fe | Iron |

| H13 | chromium-molybdenum hot work steel |

| HRB | Hardness Rockwell B |

| IR 42545 | A Thermometer Model |

| kg/m3 | kilogram per meter cube |

| ksi | kilopound per square inch |

| LoF | Lack of Fit |

| Mg | Magnesium |

| ml | mililiter |

| mm | milimeter |

| mm/rev | milimeter per revolution |

| Mn | Manganese |

| MPa | Mega Pascal |

| MQL | Minimum Quantity Lubricant |

| mV | mili Volt |

| nm | nanometer |

| Ra | Arithmetic Average Roughness |

| Res | Residual |

| RSM | Response Surface Method |

| Si | Silicon |

| SJ-210 | A Rougness Tester Model |

| TEM | Transmission Electron Microscopy |

| Ti | Titanium |

| TiO2 | Titanium Oxide |

| Tot | Total |

| UTS | Ultimate Tensile Strength |

| UV-Vis | Ultra Violet Visible |

| vol% | volume percentage |

| wt% | weight percentage |

| YTS | Yield Tensile Strength |

| Zn | Zinc |

| °C | Degree Celcius |

| % | Percentage |

| µm | micrometer |

| ϕ | nanoconcentration |

References

- Vishnu, A.V.; Kumar, P.J.; Ramana, M.V. Comparison among dry, flooded and MQL conditions in machining of EN 353 steel alloys-an experimental investigation. Mater. Today Proc. 2018, 5, 24954–24962. [Google Scholar] [CrossRef]

- Khan, N.S.; Shah, Q.; Sohail, A.; Ullah, Z.; Kaewkhao, A.; Kumam, P.; Zubair, S.; Ullah, N.; Thounthong, P. Rotating flow assessment of magnetized mixture fluid suspended with hybrid nanoparticles and chemical reactions of species. Sci. Rep. 2021, 11, 11277. [Google Scholar] [CrossRef] [PubMed]

- Debnath, S.; Anwar, M.; Pramanik, A.; Basak, A.K. Nanofluid-Minimum Quantity Lubrication System in Machining: Towards Clean Manufacturing. In Sustainable Manufacturing; Elsevier: Amsterdam, The Netherlands, 2021; pp. 109–135. [Google Scholar]

- Sharma, A.K.; Tiwari, A.K.; Singh, R.K.; Dixit, A.R. Tribological investigation of TiO2 nanoparticle based cutting fluid in machining under minimum quantity lubrication (MQL). Mater. Today Proc. 2016, 3, 2155–2162. [Google Scholar] [CrossRef]

- Shao, Y.; Fergani, O.; Ding, Z.; Li, B.; Liang, S.Y. Experimental investigation of residual stress in minimum quantity lubrication grinding of AISI 1018 steel. J. Manuf. Sci. Eng. 2016, 138, 011009. [Google Scholar] [CrossRef]

- Mulyadi, I.H.; Balogun, V.A.; Mativenga, P.T. Environmental performance evaluation of different cutting environments when milling H13 tool steel. J. Clean. Prod. 2015, 108, 110–120. [Google Scholar] [CrossRef]

- Zhang, T.; Zou, Q.; Cheng, Z.; Chen, Z.; Liu, Y.; Jiang, Z. Effect of particle concentration on the stability of water-based SiO2 nanofluid. Powder Technol. 2021, 379, 457–465. [Google Scholar] [CrossRef]

- Sharma, A.K.; Singh, R.K.; Dixit, A.R.; Tiwari, A.K. Characterization and experimental investigation of Al2O3 nanoparticle based cutting fluid in turning of AISI 1040 steel under minimum quantity lubrication (MQL). Mater. Today Proc. 2016, 3, 1899–1906. [Google Scholar] [CrossRef]

- Singh, R.K.; Sharma, A.K.; Dixit, A.R.; Tiwari, A.K.; Pramanik, A.; Mandal, A. Performance evaluation of alumina-graphene hybrid nano-cutting fluid in hard turning. J. Clean. Prod. 2017, 162, 830–845. [Google Scholar] [CrossRef]

- Thakur, A.; Manna, A.; Samir, S. Experimental investigation of nanofluids in minimum quantity lubrication during turning of EN-24 steel. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2020, 234, 712–729. [Google Scholar] [CrossRef]

- Musavi, S.H.; Davoodi, B.; Niknam, S.A. Effects of reinforced nanoparticles with surfactant on surface quality and chip formation morphology in MQL-turning of superalloys. J. Manuf. Processes 2019, 40, 128–139. [Google Scholar] [CrossRef]

- Gupta, M.K.; Sood, P.K.; Sharma, V.S. Optimization of machining parameters and cutting fluids during nano-fluid based minimum quantity lubrication turning of titanium alloy by using evolutionary techniques. J. Clean. Prod. 2016, 135, 1276–1288. [Google Scholar] [CrossRef]

- Zawawi, N.N.M.; Azmi, W.H.; Ghazali, M.F.; Ramadhan, A.I. Performance optimization of automotive air-conditioning system operating with Al2O3-SiO2/PAG composite nanolubricants using Taguchi Method. Automot. Exp. 2022, 5, 121–136. [Google Scholar] [CrossRef]

- Yu, W.; Xie, H. A review on nanofluids: Preparation, stability mechanisms, and applications. J. Nanomater. 2012, 2012, 1–17. [Google Scholar] [CrossRef]

- Zawawi, N.N.M.; Azmi, W.H.; Ghazali, M.F. Performance of Al2O3-SiO2/PAG composite nanolubricants in automotive air-conditioning system. Appl. Therm. Eng. 2022, 204, 117998. [Google Scholar] [CrossRef]

- Zawawi, N.N.M.; Azmi, W.H.; Ghazali, M.F. Tribological performance of Al2O3–SiO2/PAG composite nanolubricants for application in air-conditioning compressor. Wear 2022, 492–493, 204238. [Google Scholar] [CrossRef]

- Singh, T.; Singh, P.; Dureja, J.; Dogra, M.; Singh, H.; Bhatti, M.S. A review of near dry machining/minimum quantity lubrication machining of difficult to machine alloys. Int. J. Mach. Mach. Mater. 2016, 18, 213–251. [Google Scholar] [CrossRef]

- Kopac, J. Achievements of sustainable manufacturing by machining. J. Achiev. Mater. Manuf. Eng. 2009, 34, 180–187. [Google Scholar]

- Cetin, M.H.; Kabave Kilincarslan, S. Effects of cutting fluids with nano-silver and borax additives on milling performance of aluminium alloys. J. Manuf. Processes 2020, 50, 170–182. [Google Scholar] [CrossRef]

- Faheem, A.; Husain, T.; Hasan, F.; Murtaza, Q. Effect of nanoparticles in cutting fluid for structural machining of Inconel 718. Adv. Mater. Process. Technol. 2020, 8, 259–276. [Google Scholar] [CrossRef]

- Abdullah, M.I.H.C.; Othman, A.; Abdullah, R.; Abdollah, M.F. Optimization on the nanoparticles stability in liquid phased condition by using Taguchi analysis. J. Adv. Res. Fluid Mech. Therm. Sci. 2019, 61, 129–139. [Google Scholar]

- Mukesh Kumar, P.C.; Palanisamy, K.; Vijayan, V. Stability analysis of heat transfer hybrid/water nanofluids. Mater. Today Proc. 2020, 21, 708–712. [Google Scholar] [CrossRef]

- Mahbubul, I.M. Stability and Dispersion Characterization of Nanofluid. In Preparation, Characterization, Properties and Application of Nanofluid; William Andrew Publishing: Gazipur, Bangladesh, 2019; pp. 47–112. [Google Scholar] [CrossRef]

- Lee, J.H.; Hwang, K.S.; Jang, S.P.; Lee, B.H.; Kim, J.H.; Choi, S.U.S.; Choi, C.J. Effective viscosities and thermal conductivities of aqueous nanofluids containing low volume concentrations of Al2O3 nanoparticles. Int. J. Heat Mass Transf. 2008, 51, 2651–2656. [Google Scholar] [CrossRef]

- Sharif, S.; Sadiq, I.O.; Yusof, N.M.; Mohruni, A.S. A review of minimum quantity lubrication technique with nanofluids application in metal cutting operations. Int. J. Adv. Sci. Eng. Inf. Technol. 2017, 7, 587–593. [Google Scholar] [CrossRef][Green Version]

- Şirin, Ş.; Kıvak, T. Performances of different eco-friendly nanofluid lubricants in the milling of Inconel X-750 superalloy. Tribol. Int. 2019, 137, 180–192. [Google Scholar] [CrossRef]

- Viswanathan, R.; Ramesh, S.; Subburam, V. Measurement and optimization of performance characteristics in turning of Mg alloy under dry and MQL conditions. Measurement 2018, 120, 107–113. [Google Scholar] [CrossRef]

- Sinha, M.K.; Madarkar, R.; Ghosh, S.; Rao, P.V. Application of eco-friendly nanofluids during grinding of Inconel 718 through small quantity lubrication. J. Clean. Prod. 2017, 141, 1359–1375. [Google Scholar] [CrossRef]

- Prasad, M.M.S.; Srikant, R.R. Performance evaluation of nano graphite inclusions in cutting fluids with MQL technique in turning of AISI 1040 steel. Int. J. Res. Eng. Technol. 2013, 2, 381–393. [Google Scholar]

- Sarfraz, M.H.; Jahanzaib, M.; Ahmed, W.; Hussain, S. Multi-response parametric optimization of squeeze casting process for fabricating Al 6061-SiC composite. Int. J. Adv. Manuf. Technol. 2019, 102, 759–773. [Google Scholar] [CrossRef]

- Derdour, F.Z.; Kezzar, M.; Khochemane, L. Optimization of penetration rate in rotary percussive drilling using two techniques: Taguchi analysis and response surface methodology (RSM). Powder Technol. 2018, 339, 846–853. [Google Scholar] [CrossRef]

- Cetin, M.H.; Ozcelik, B.; Kuram, E.; Demirbas, E. Evaluation of vegetable based cutting fluids with extreme pressure and cutting parameters in turning of AISI 304L by Taguchi method. J. Clean. Prod. 2011, 19, 2049–2056. [Google Scholar] [CrossRef]

| Property | Aluminum Oxide | Titanium Oxide |

|---|---|---|

| Molecular Formula | Al2O3 | TiO2 |

| Form | are liquid | are liquid |

| Diameter (nm) | 30 nm | 30–50 nm |

| Weight concentration (wt%) | 20 | 40 |

| Density (kg/m3) | 4000 | 4230 |

| Property/Information | Coolant Oil | Distilled Water |

|---|---|---|

| Density | 700–950 kg/m3 | 1000 kg/m3 |

| Type (Brand) | Semi-synthetic(Beiling X-Ten 150) | - |

| Ratio | 5% | 95% |

| Elements | Max | Min | Actual |

|---|---|---|---|

| Si | 0.40 | 0.00 | 0.0713 |

| Fe | 0.50 | 0.00 | 0.1350 |

| Cu | 2.00 | 1.20 | 1.6100 |

| Mn | 0.30 | 0.00 | 0.1010 |

| Mg | 2.90 | 2.10 | 2.3100 |

| Cr | 0.28 | 0.18 | 0.2360 |

| Zn | 6.10 | 5.10 | 5.5400 |

| Ti | 0.20 | 0.00 | 0.0225 |

| Test | Ultimate Tensile Strength (UTS) | Yield Tensile Strength (YTS) | Elongation | Hardness |

|---|---|---|---|---|

| Requirement | ≥81 | ≥71 | ≥7 | |

| Actual | 89.19/6.15 × 102 | 81.49/5.62 × 102 | 10.0 | 84.7 |

| Unit | ksi/MPa | ksi/MPa | % | HRB |

| Control Factor | Depth of Cut, Doc (mm) | Feed Rate (mm/rev) | Volume Concentration, ϕ (%) |

|---|---|---|---|

| Level 1 | 0.3 | 0.1 | 0 |

| Level 2 | 0.6 | 0.2 | 2 |

| Level 3 | 0.9 | 0.3 | 4 |

| Run | ϕ (%) | doc (mm) | F (mm/rev) |

|---|---|---|---|

| 1 | 0.00 | 0.20 | 0.60 |

| 2 | 4.00 | 0.30 | 0.90 |

| 3 | 2.00 | 0.20 | 0.60 |

| 4 | 2.00 | 0.30 | 0.60 |

| 5 | 2.00 | 0.20 | 0.60 |

| 6 | 2.00 | 0.10 | 0.60 |

| 7 | 2.00 | 0.20 | 0.30 |

| 8 | 4.00 | 0.10 | 0.30 |

| 9 | 2.00 | 0.20 | 0.60 |

| 10 | 2.00 | 0.20 | 0.60 |

| 11 | 2.00 | 0.20 | 0.60 |

| 12 | 0.00 | 0.10 | 0.90 |

| 13 | 0.00 | 0.30 | 0.90 |

| 14 | 4.00 | 0.10 | 0.90 |

| 15 | 0.00 | 0.10 | 0.30 |

| 16 | 2.00 | 0.20 | 0.90 |

| 17 | 0.00 | 0.30 | 0.30 |

| 18 | 2.00 | 0.20 | 0.60 |

| 19 | 4.00 | 0.20 | 0.60 |

| 20 | 4.00 | 0.30 | 0.30 |

| Run | Input Parameter | Responses Studied | ||||

|---|---|---|---|---|---|---|

| Nano Concentration (%) | Depth of Cut (mm) | Feed Rate (mm/rev) | Cutting Temperature (°C) | Surface Roughness (μm) | Tool Wear (%) | |

| 1 | 0.00 | 0.20 | 0.60 | 33.2 | 4.726 | 0.0911 |

| 2 | 4.00 | 0.30 | 0.90 | 27.5 | 1.799 | 0.0308 |

| 3 | 2.00 | 0.20 | 0.60 | 28.3 | 2.841 | 0.0456 |

| 4 | 2.00 | 0.30 | 0.60 | 30.2 | 3.687 | 0.0733 |

| 5 | 2.00 | 0.20 | 0.60 | 28.7 | 2.953 | 0.0498 |

| 6 | 2.00 | 0.10 | 0.60 | 27.7 | 1.958 | 0.0362 |

| 7 | 2.00 | 0.20 | 0.30 | 28.0 | 2.195 | 0.0405 |

| 8 | 4.00 | 0.10 | 0.30 | 25.8 | 0.494 | 0.0107 |

| 9 | 2.00 | 0.20 | 0.60 | 28.9 | 3.206 | 0.0523 |

| 10 | 2.00 | 0.20 | 0.60 | 29.1 | 3.326 | 0.0582 |

| 11 | 2.00 | 0.20 | 0.60 | 29.4 | 3.794 | 0.0612 |

| 12 | 0.00 | 0.10 | 0.90 | 32.9 | 3.816 | 0.0852 |

| 13 | 0.00 | 0.30 | 0.90 | 34.4 | 5.316 | 0.1005 |

| 14 | 4.00 | 0.10 | 0.90 | 26.1 | 0.517 | 0.0162 |

| 15 | 0.00 | 0.10 | 0.30 | 32.2 | 3.705 | 0.0797 |

| 16 | 2.00 | 0.20 | 0.90 | 29.9 | 3.619 | 0.0676 |

| 17 | 0.00 | 0.30 | 0.30 | 33.7 | 4.854 | 0.0941 |

| 18 | 2.00 | 0.20 | 0.60 | 29.6 | 3.591 | 0.0646 |

| 19 | 4.00 | 0.20 | 0.60 | 26.6 | 0.795 | 0.0201 |

| 20 | 4.00 | 0.30 | 0.30 | 27.0 | 0.851 | 0.0257 |

| Source | Sum of Squares | F Value | p-Value | Remarks |

|---|---|---|---|---|

| Model | 124.41 | 192.62 | <0.0001 | significant |

| A- ϕ | 111.56 | 690.89 | <0.0001 | significant |

| B- f | 6.56 | 40.63 | <0.0001 | significant |

| C-doc | 1.68 | 10.41 | 0.0056 | - |

| A2 | 4.61 | 28.54 | <0.0001 | significant |

| Res. | 2.42 | - | - | - |

| LoF | 1.30 | 0.58 | 0.7825 | not significant |

| Pure Err | 1.12 | - | - | - |

| Cor Tot | 126.83 | - | - | - |

| Source | Sum of Squares | F Value | p-Value | Remarks |

|---|---|---|---|---|

| Model | 36.76 | 63.18 | <0.0001 | significant |

| A- ϕ | 32.26 | 166.32 | <0.0001 | significant |

| B- f | 3.62 | 18.67 | 0.0005 | significant |

| C-doc | 0.88 | 4.54 | 0.0489 | significant |

| Res. | 3.10 | - | - | - |

| LoF | 2.44 | 1.66 | 0.3009 | not significant |

| Pure Err | 0.67 | - | - | - |

| Cor Tot | 39.86 | - | - | - |

| Source | Sum of Squares | F Value | p-Value | Remarks |

|---|---|---|---|---|

| Model | 0.013 | 108.23 | <0.0001 | significant |

| A-ϕ | 0.012 | 295.83 | <0.0001 | significant |

| B-f | 9.293 × 10−4 | 22.82 | 0.0002 | significant |

| C-doc | 2.460 × 10−4 | 6.04 | 0.0258 | significant |

| Res. | 6.516 × 10−4 | - | - | - |

| LoF | 3.886 × 10−4 | 0.67 | 0.7302 | not significant |

| Pure Err | 2.630 × 10−4 | - | - | - |

| Cor Tot | 0.014 | - | - | - |

| Cutting Parameters | Nanoconcentration (%) | Feed Rate (mm/rev) | Depth of Cut (mm) |

|---|---|---|---|

| Suggested Parameter | 4.0 | 0.1 | 0.55 |

| Responses Studied | Cutting Temperature (°C) | Surface Roughness (Ra, µm) | Tool Wear (%) |

| Prediction Results | 25.3 | 0.480 | 0.0104 |

| Validation Results | 24.9 | 0.455 | 0.0094 |

| Percentage Deviation (%) | 1.58 | 5.21 | 9.62 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arifuddin, A.; Redhwan, A.A.M.; Azmi, W.H.; Zawawi, N.N.M. Performance of Al2O3/TiO2 Hybrid Nano-Cutting Fluid in MQL Turning Operation via RSM Approach. Lubricants 2022, 10, 366. https://doi.org/10.3390/lubricants10120366

Arifuddin A, Redhwan AAM, Azmi WH, Zawawi NNM. Performance of Al2O3/TiO2 Hybrid Nano-Cutting Fluid in MQL Turning Operation via RSM Approach. Lubricants. 2022; 10(12):366. https://doi.org/10.3390/lubricants10120366

Chicago/Turabian StyleArifuddin, Ariffin, Abd Aziz Mohammad Redhwan, Wan Hamzah Azmi, and Nurul Nadia Mohd Zawawi. 2022. "Performance of Al2O3/TiO2 Hybrid Nano-Cutting Fluid in MQL Turning Operation via RSM Approach" Lubricants 10, no. 12: 366. https://doi.org/10.3390/lubricants10120366

APA StyleArifuddin, A., Redhwan, A. A. M., Azmi, W. H., & Zawawi, N. N. M. (2022). Performance of Al2O3/TiO2 Hybrid Nano-Cutting Fluid in MQL Turning Operation via RSM Approach. Lubricants, 10(12), 366. https://doi.org/10.3390/lubricants10120366