Three-Body Abrasive Wear Performance of High Chromium White Cast Iron with Different Ti and C Content

Abstract

1. Introduction

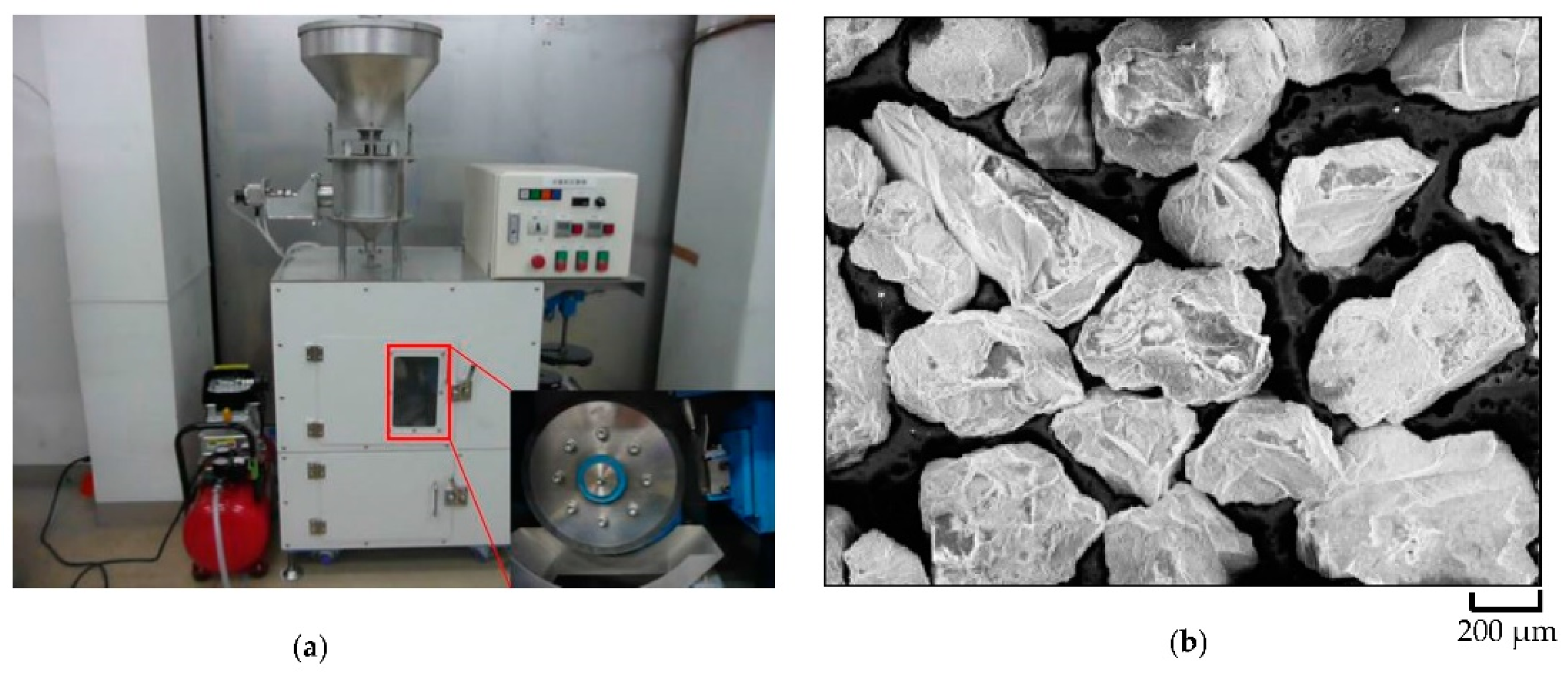

2. Experimental Procedures

2.1. Materials Preparation

2.2. Three-Body Abrasive Wear Testing

2.3. Vickers Hardness Test

3. Results and Discussion

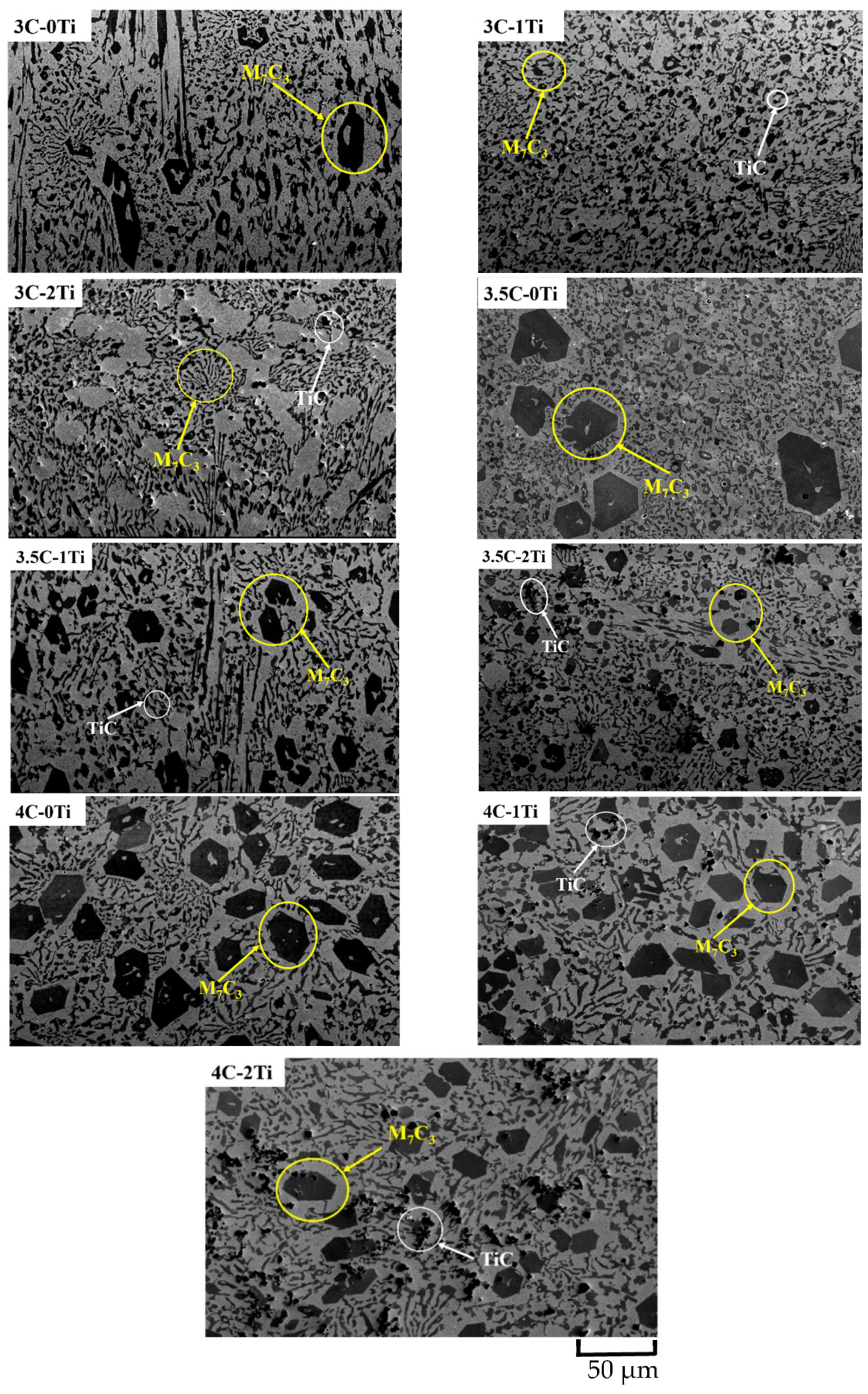

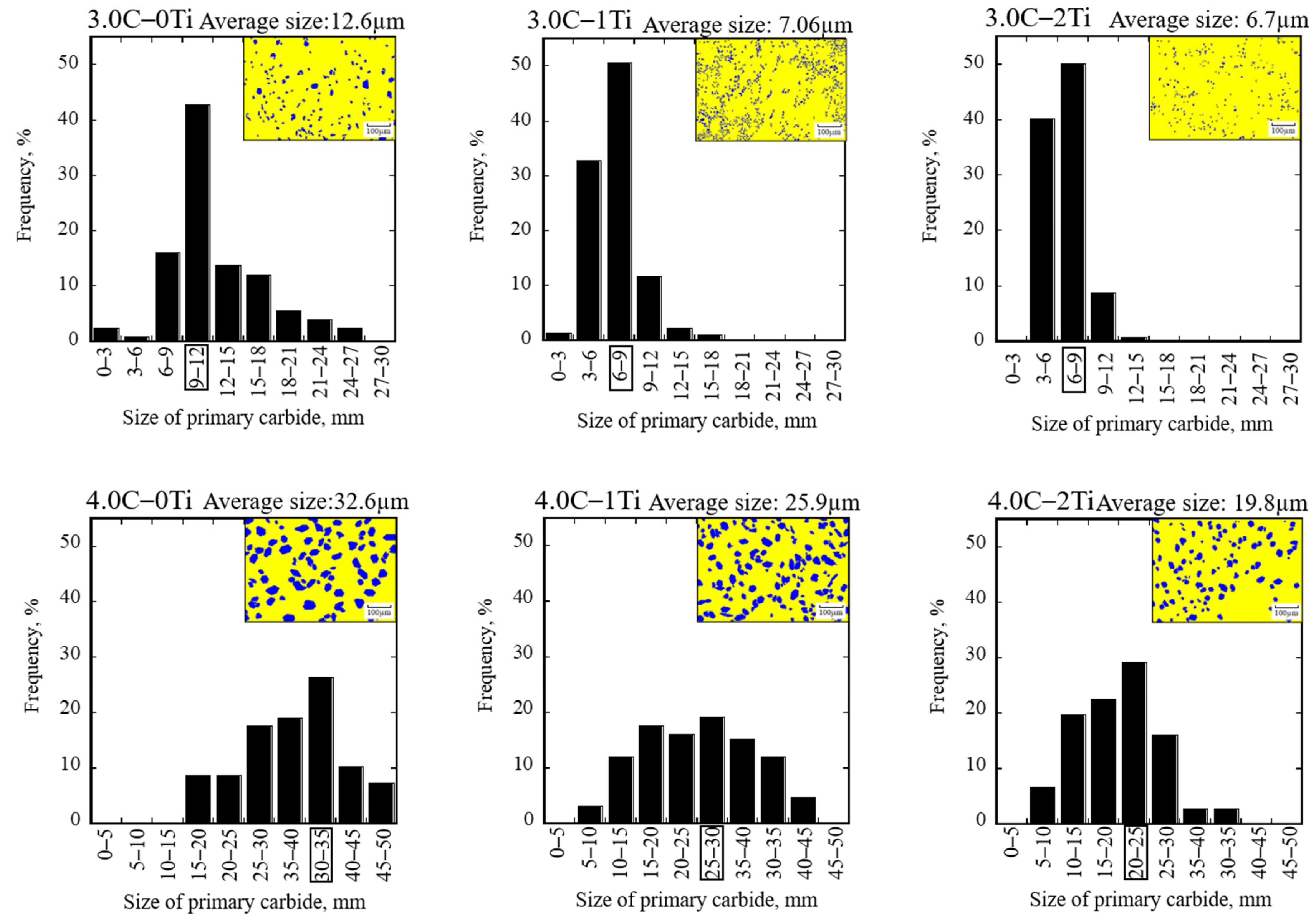

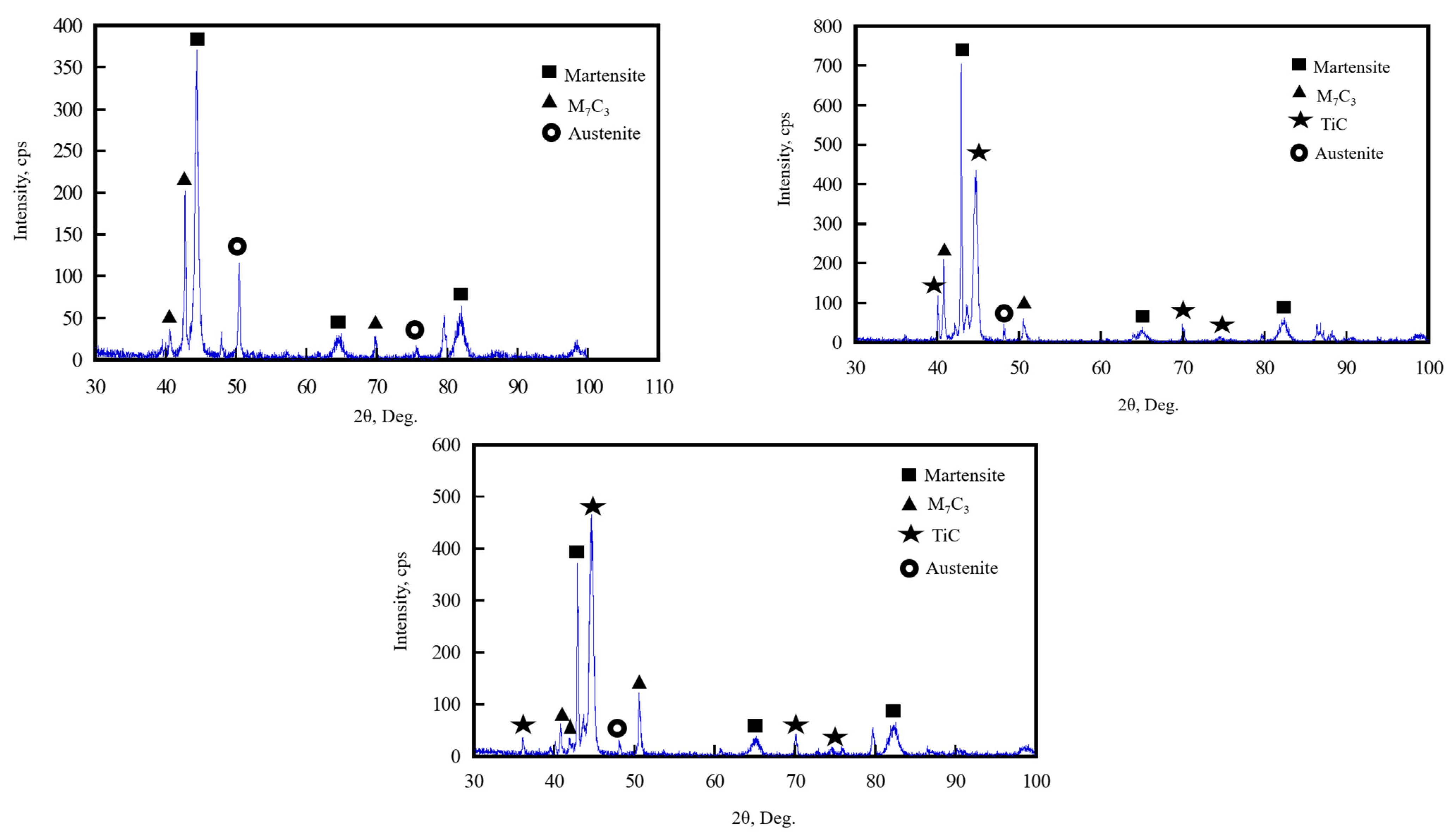

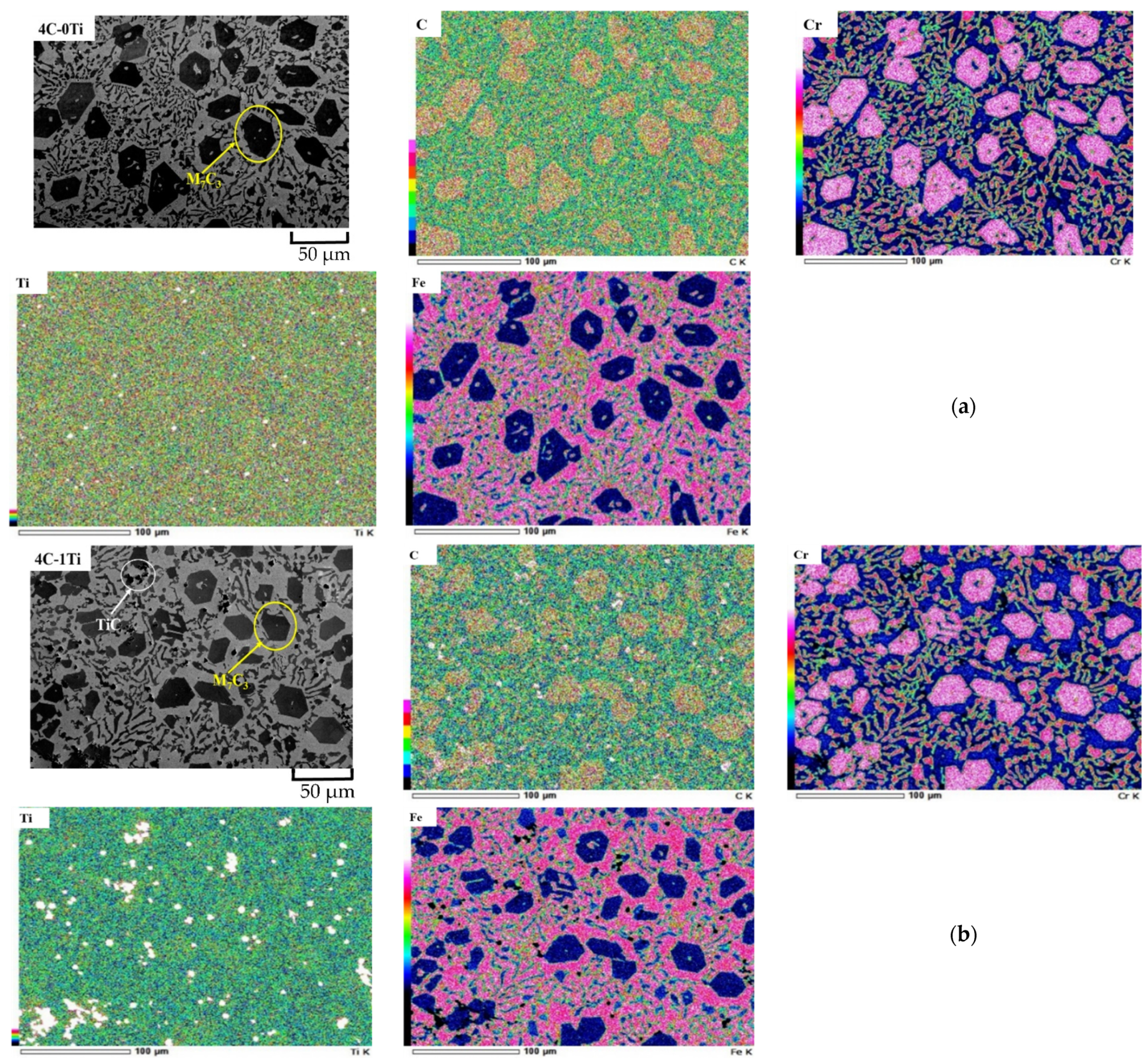

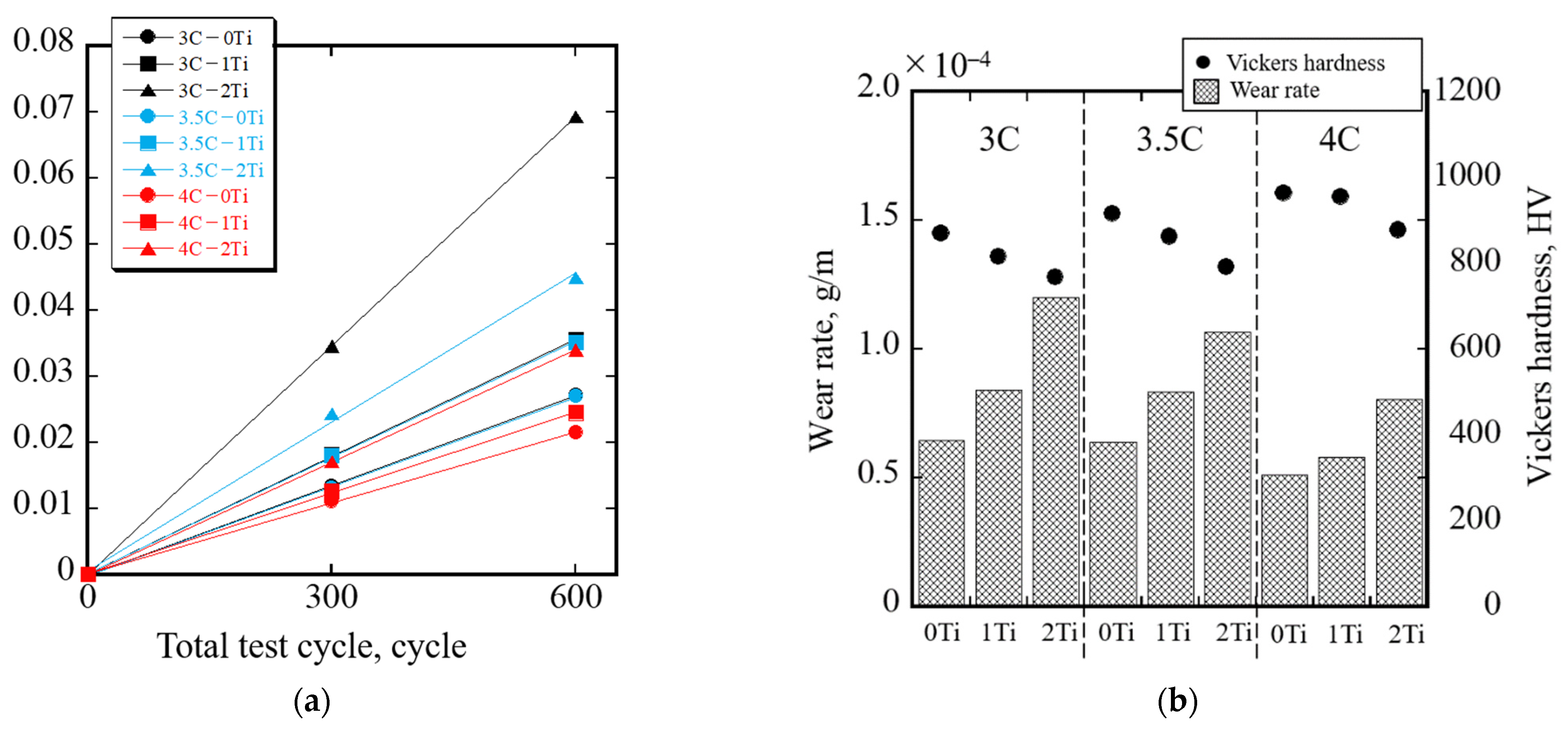

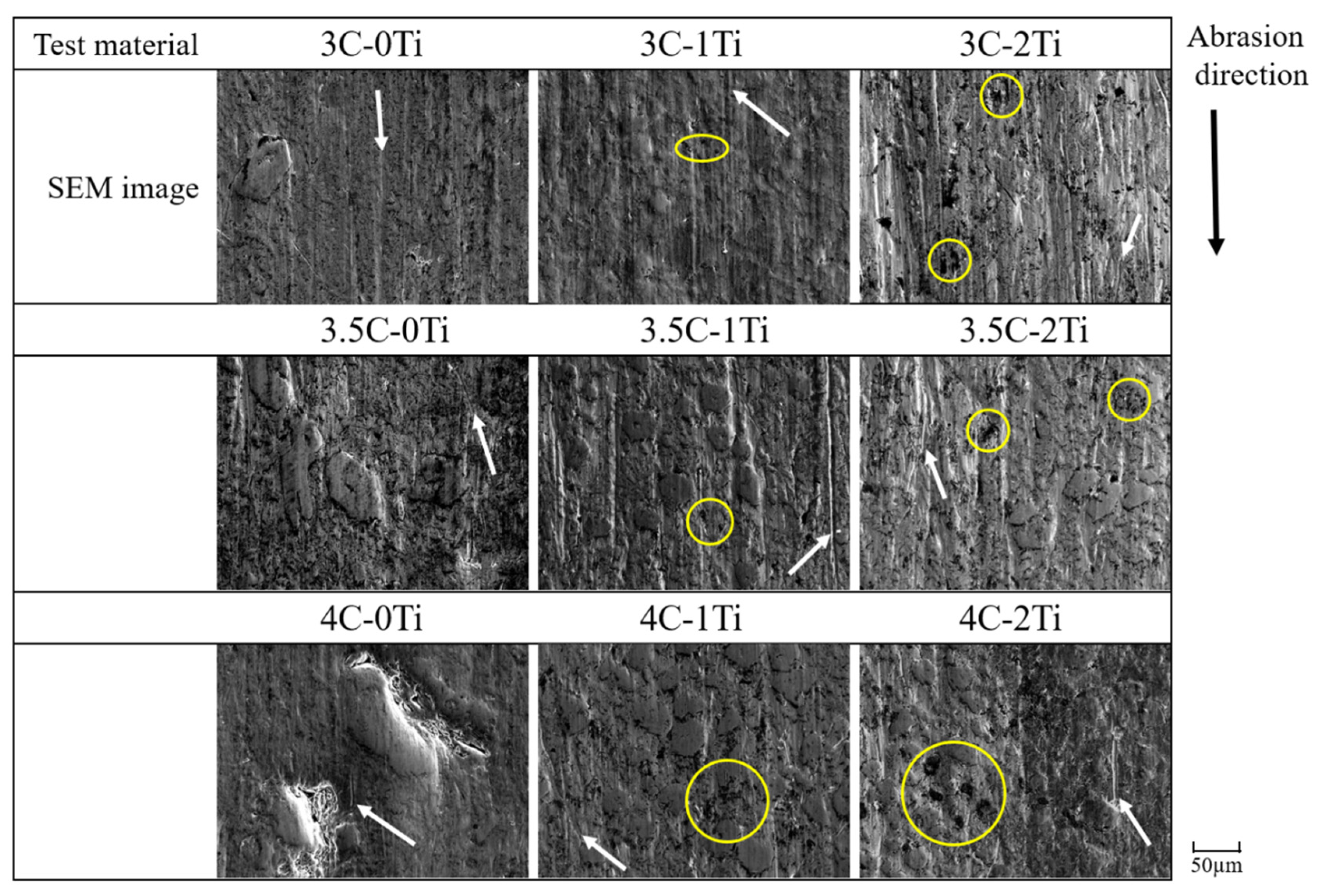

3.1. Microstructural Characterization

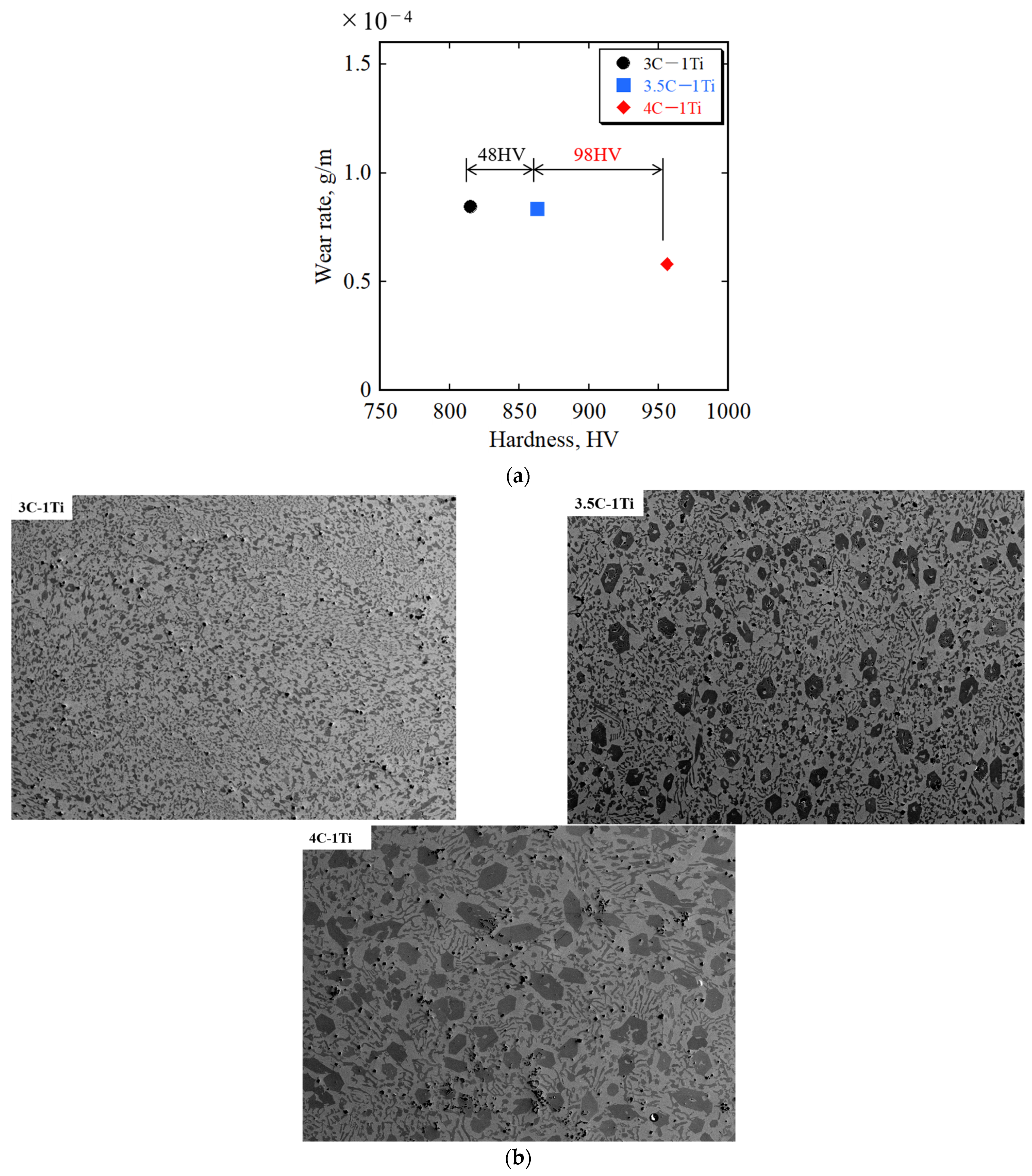

3.2. Hardness of Materials

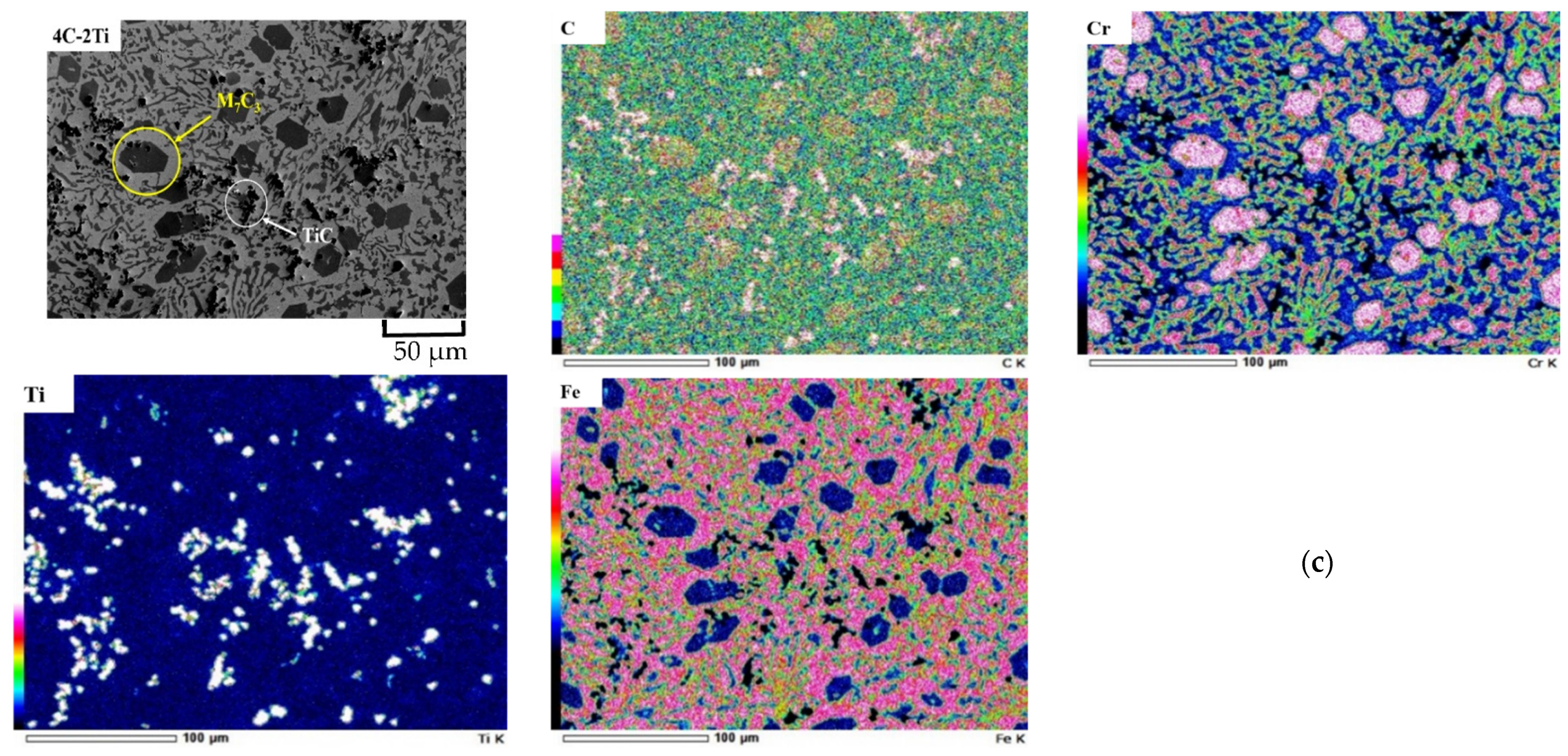

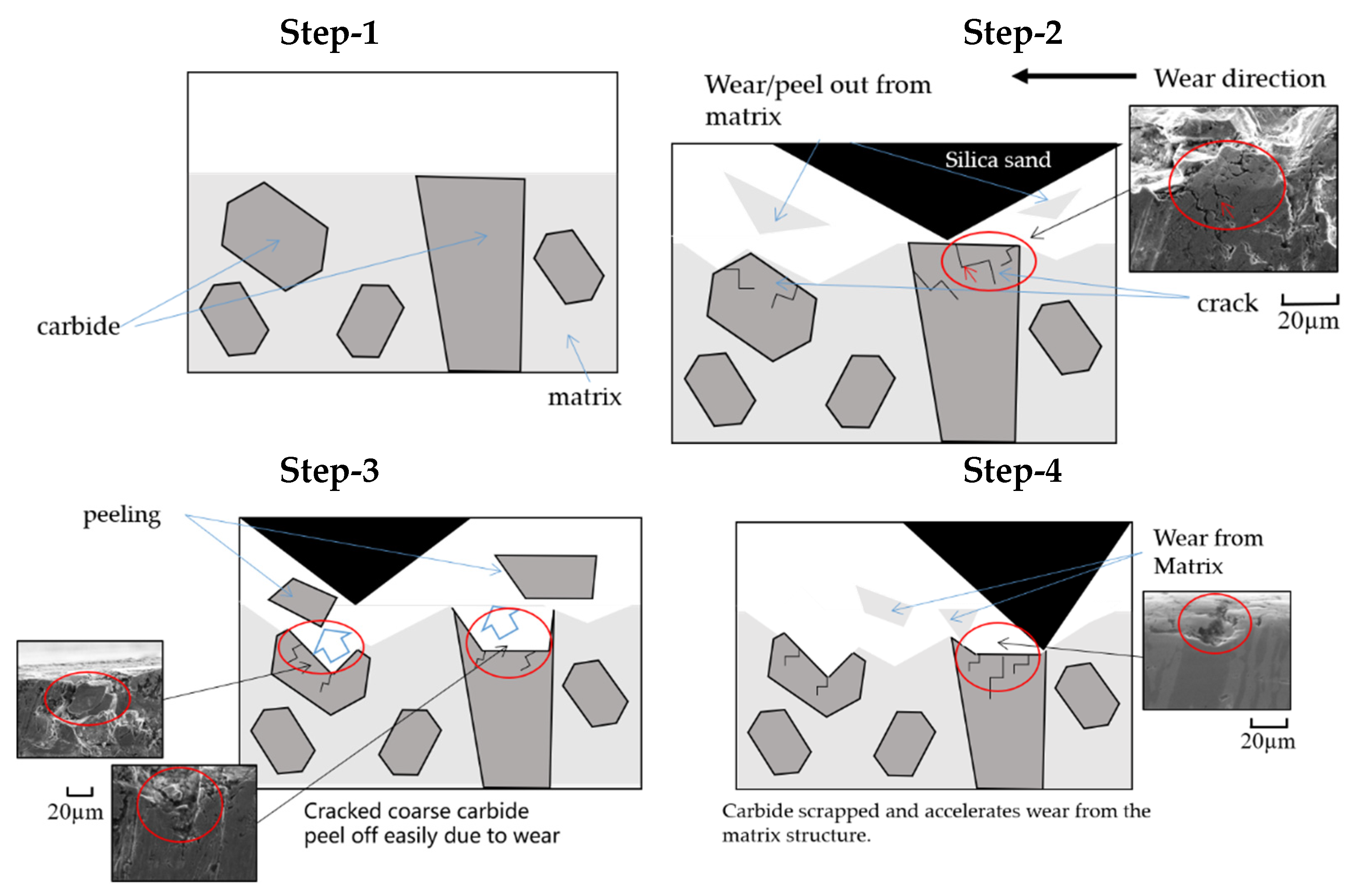

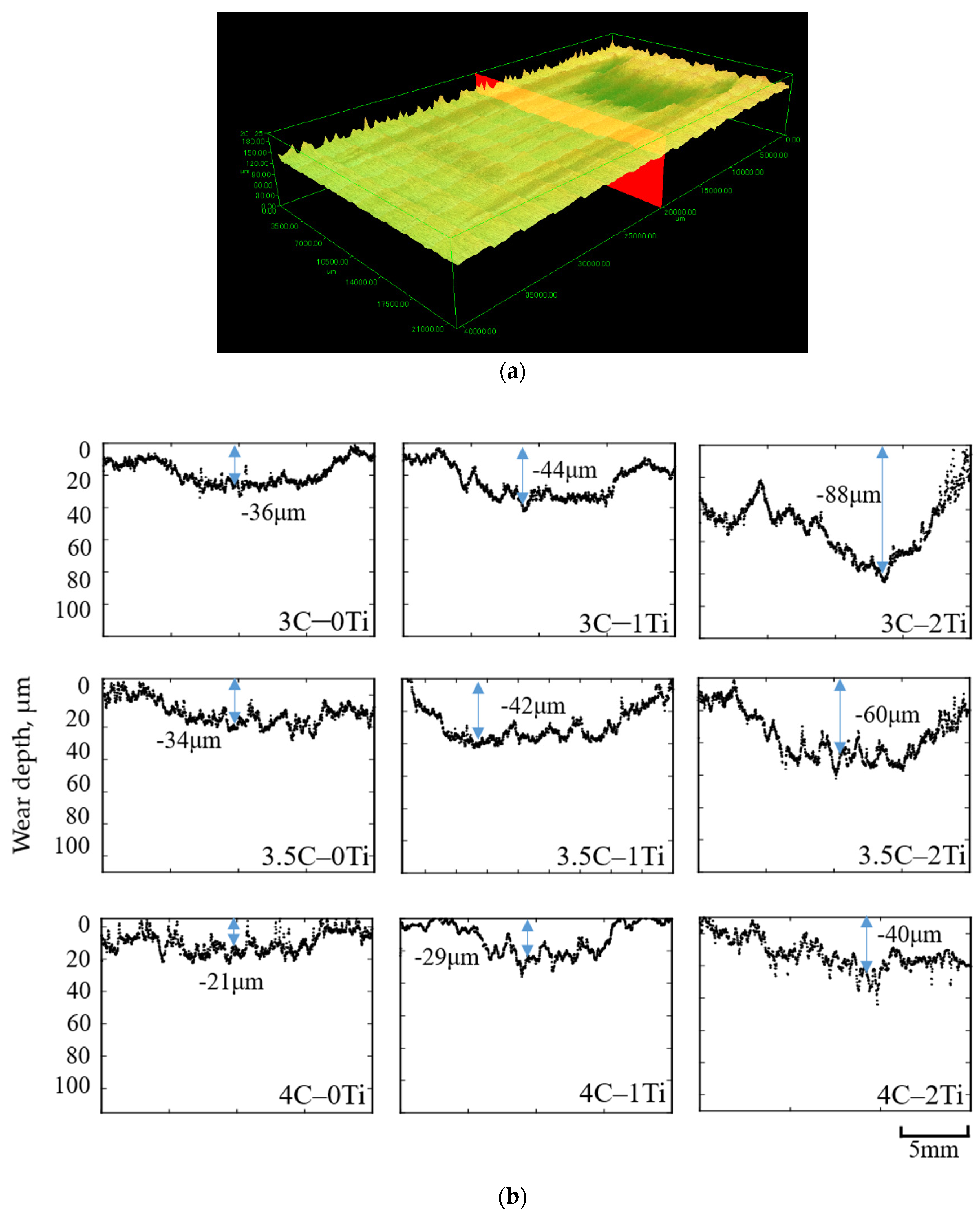

3.3. Three-Body Abrasive Wear Characteristics

4. Conclusions

- The addition of Ti causes the M7C3 carbides in the microstructure to become finer and TiC to crystallize. The hike in Ti content results in a decrease in the microstructure hardness.

- From the rubber wheel abrasive test, it can be concluded that the overall hardness of the microstructure increases, leading to a lower wear volume and improved abrasive wear resistance.

- The hardness of the microstructure, hardness of the matrix, and morphology of carbide crystallization have a notable effect on the abrasive wear resistance.

- The highest C results in better wear resistance, while the 4C-0Ti composition exhibits better hardness, a lower wear rate, and a shallower wear depth.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gahr, K.-H.Z. Microstructure and Wear of Materials, 1st ed.; Elsevier S: New York, NY, USA, 1987. [Google Scholar]

- Tylczak, J.H. Abrasive Wear ASM Handbook; ASM International: Tokyo, Japan, 1992. [Google Scholar]

- Eyre, T.S. Wear Characteristics of Magnesium; SAE Technical Papers; SAE International: Warrendale, PA, USA, 1953. [Google Scholar]

- Li, H.; Tong, W.; Ma, C.; Chen, L.; Zuo, L. Abrasive wear behaviors of high-vanadium alloy steel using the dry sand/rubber wheel apparatus. J. Eng. Tribol. 2019, 233, 1800–1809. [Google Scholar] [CrossRef]

- Holmberg, K.; Erdemir, A. Influence of tribology on global energy consumption, costs and emissions. Friction 2017, 5, 263. [Google Scholar] [CrossRef]

- Mang, T.; Bobzin, K.; Bartels, T. Industrial Tribology: Tribosystems, Friction, Wear and Surface Engineering, Lubrication; WileyVCH: Weinheim, Germany, 2011; p. 1. [Google Scholar]

- Gahr, K.H.Z.; Scholz, W.G. Fracture Toughness of White Cast Irons. JOM 1980, 32, 38–44. [Google Scholar] [CrossRef]

- Francisco Vapeani Guerra, C.P.; Tabrett, I.R.; Sare, M.R. Ghomashchi, Microstructure property relationships in high chromium white iron alloys. Int. Mater. Rev. 1996, 41, 59. [Google Scholar]

- Ono, Y.; Murai, M.; Ogi, K. Partition Coefficients of Alloying Elements to Primary Austenite and Eutectic Phases of Chromium Irons of Rolls. ISIJ Int. 1992, 32, 1150. [Google Scholar] [CrossRef]

- Laird, G. Microstructures of Ni-Hard I, Ni-Hard IV, and High Cr White Cast Irons. AFS Trans. 1991, 99, 339. [Google Scholar]

- Todaka, T.; Shimizu, K.; Kusumoto, K.; Purba, R.H.; Gaqi, Y. Effect of Carbon Content on Three-body Abrasive Wear Characteristics of 28Cr-3Ni Cast Alloys. ISIJ Int. 2021, 61, 2274–2283. [Google Scholar] [CrossRef]

- Bedolla-Jacuinde, A.; Correa, R.; Quezada, J.G.; Maldonado, C. Effect of titanium on the as-cast microstructure of a 16% chromium white iron. Mater. Sci. Eng. A 2005, 398, 297. [Google Scholar] [CrossRef]

- Bedolla-Jacuinde, A.; Guerra, F.V.; Mejía, I.; Zuno-Silva, J.; Rainforth, M. Abrasive wear of V-Nb-Ti alloyed high-chromium white irons. Wear 2015, 332–333, 1006. [Google Scholar] [CrossRef]

- Gahr, K.-H.Z.; Doane, D.V. Optimizing fracture toughness and abrasion resistance in white cast irons. Met. Mater. Trans. A 1980, 11, 613. [Google Scholar] [CrossRef]

- Pearce, J.T.H. Examination of M7C3 carbides in high chromium cast irons using thin foil transmission electron microscopy. J. Mater. Sci. Lett. 1983, 2, 428–432. [Google Scholar] [CrossRef]

- Peev, K.; Radulovic, M.; Fiset, M. Modification of FeCr-C alloys using mischmetal. J. Mater. Sci. Lett. 1994, 13, 112–114. [Google Scholar] [CrossRef]

- Kibble, K.A.; Pearce, J.T.H. An examination of the effects of annealing heat treatment on secondary carbide formation in 25%Cr high chromium irons. Cast Met. 1995, 8, 123–127. [Google Scholar] [CrossRef]

- Powell, G.L.F.; Laird, G., II. Structure, nucleation, growth and morphology of secondary carbides in high chromium and Cr-Ni white cast irons. J. Mater. Sci. 1992, 27, 29–35. [Google Scholar] [CrossRef]

- Powell, G. Improved wear-resistant high-alloyed white irons—A historical perspective. In Proceedings of the International Congress on Abrasion Wear Resistance Alloyed White Cast Iron for Rolling and Pulverizing Mills, Fukuoka, Japan, 16–20 August 2002. [Google Scholar]

- Bedolla-Jacuinde, A. Microstructure of vanadium-, niobium and titanium-alloyed high-chromium white cast irons. Int. J. Cast Met. Res. 2001, 13, 343. [Google Scholar] [CrossRef]

- Wu, X.; Xing, J.; Fu, H.; Zhi, X. Effect of titanium on the morphology of primary M7C3 carbides in hypereutectic high chromium white iron. Mater. Sci. Eng. A 2007, 457, 180–185. [Google Scholar] [CrossRef]

- Dogan, O.N.; Hawk, J.A.; Laird, G., II. Solidification structure and abrasion resistance of high chromium white irons. Metall. Mater. Trans. A 1997, 28, 1315–1327. [Google Scholar] [CrossRef]

- Huang, Z.F.; Huang, W.D.; Zhang, A.F.; Xing, J.D. Study on impact and wear properties of semi-solid hypereutectic high-chromium cast iron. J. Xi’an Jiaotong Univ. 2005, 39, 775–778. [Google Scholar]

- Llewellyn, R.J.; Yick, S.K.; Dolmanb, K.F. Scouring erosion resistance of metallic materials used in slurry pump service. Wear 2004, 256, 592–599. [Google Scholar] [CrossRef]

- Qin, Z.R.; Nie, L.W. Effect of RE-Mg alloy modification on high chromium cast iron. Chin. Pet. Mach. 1998, 26, 20–23. [Google Scholar]

- Schneider, C.; Rasband, W.; Eliceiri, K. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef] [PubMed]

- Karantzalis, A.E.; Lakatou, A.; Diavati, E. Effect of Destabilization Heat Treatments on the Microstructure of High Chromium Cast Iron: A Microscopy Examination Approach. J. Mater. Eng. Perform. 2009, 18, 1078–1085. [Google Scholar] [CrossRef]

- Kishore, K.; Kumar, U.; Dinesh, N.; Adhikary, M. Effect of Soaking Temperature on Carbide Precipitation, Hardness, and Wear Resistance of High-Chromium White Cast Iron. J. Fail. Anal. Prev. 2020, 20, 249–260. [Google Scholar] [CrossRef]

- Purba, R.H.; Shimizu, K.; Kusumoto, K.; Todaka, T.; Shirai, M.; Hara, H.; Ito, J. Erosive Wear Characteristics of High-Chromium Based Multi-Component White Cast Irons. Tribol. Int. 2021, 159, 106982. [Google Scholar] [CrossRef]

- Yu, S.K.; Sasaguri, N.; Matsubara, Y. Effects of Retained Austenite on Abrasion Wear Resistance and Hardness of Hypoeutectic High Cr White Cast Iron. Int. J. Cast Met. Res. 1999, 11, 561–566. [Google Scholar] [CrossRef]

- Sun, J.; Hao, Y. Microstructure Development and Mechanical Properties of Quenching and Partitioning (Q&P) Steel and an Incorporation of Hot-Dipping Galvanization during Q&P Process. Mater. Sci. Eng. A. 2013, 586, 100–107. [Google Scholar]

- Ma, S.; Xing, J.; He, Y.; Li, Y.; Huang, Z.; Liu, G.; Geng, Q. Microstructure and Crystallography of M7C3 Carbide in High Chromium Cast Iron. Mater. Chem. Phys. 2015, 161, 65–73. [Google Scholar] [CrossRef]

- Liu, S.; Zhou, Y.; Xing, X.; Wang, J.; Yang, Y.; Yang, Q. Agglomeration Model of (Fe, Cr)7C3 Carbide in Hypereutectic FeCr-C Alloy. Mater. Lett. 2016, 183, 272–276. [Google Scholar] [CrossRef]

- Geng, B.; Li, Y.; Zhou, R.; Wang, Q.; Jiang, Y. Formation Mechanism of Stacting Faults and its Effect on Hardness in M7C3 Carbides. Mater. Charact. 2020, 170, 110691. [Google Scholar] [CrossRef]

- Laird, G.; Gundlach, R.; Rohrig, K. Abrasion-Resistant Cast Iron Handbook; AFS: Oakland, CA, USA, 2000. [Google Scholar]

- Gahr, K.-H.Z. Recent developments in wear-mechanism maps. Tribol. Int. 1998, 31, 587. [Google Scholar] [CrossRef]

- Sare, I.R. Abrasion resistance and fracture toughness of white cast irons. Met. Technol. 1979, 6, 412. [Google Scholar] [CrossRef]

- Berns, H.; Fischer, A.; Theisen, W. Fracture Toughness and Microstructure of Fe-Cr-C-B Hard Facing Alloys. In Mechanical Behaviour of Materials V, Proceedings of the Fifth International Conference, Beijing, China, 3–6 June 1987; Pergamon Press: Beijing, China, 1987; pp. 285–294. [Google Scholar] [CrossRef]

- Ibrahim, K.M.; Nofal, A.A. Effect of titanium addition on structure and properties of the as-cast high Cr–Mo white iron. Int. J. Mater. Res. 2012, 103, 362–370. [Google Scholar] [CrossRef]

- Purba, R.H.; Shimizu, K.; Kusumoto, K.; Gaqi, Y. Comparison of Three-Body Abrasion Behaviors of High-Cr-Mo- and High-Cr-Based Multicomponent White Cast Irons. J. Mater. Eng. Perform. 2022. [Google Scholar] [CrossRef]

- Banadkouki, S.S.G.; Mehranfar, S. Wear Behavior of a Modified Low Alloy as Cast Hardening White Iron. ISIJ Int. 2012, 52, 2096–2099. [Google Scholar] [CrossRef][Green Version]

| Test Material | C | Si | Mn | Cr | Ti | Fe |

|---|---|---|---|---|---|---|

| 3C-0Ti | 3.07 | 0.48 | 0.43 | 27.18 | 0.01 | Bal. |

| 3C-1Ti | 3.02 | 0.49 | 0.44 | 27.10 | 1.09 | Bal. |

| 3C-2Ti | 3.02 | 0.51 | 0.44 | 26.92 | 1.87 | Bal. |

| 3.5C-0Ti | 3.48 | 0.45 | 0.44 | 27.34 | 0.06 | Bal. |

| 3.5C-1Ti | 3.48 | 0.46 | 0.45 | 27.18 | 1.18 | Bal. |

| 3.5C-2Ti | 3.49 | 0.47 | 0.45 | 27.02 | 2.09 | Bal. |

| 4C-0Ti | 3.88 | 0.49 | 0.41 | 27.50 | 0.07 | Bal. |

| 4C-1Ti | 3.82 | 0.51 | 0.42 | 27.18 | 1.24 | Bal. |

| 4C-2Ti | 3.88 | 0.52 | 0.42 | 26.91 | 2.35 | Bal. |

| Test Material | 3C-0Ti | 3C-1Ti | 3C-2Ti |

| Macro hardness | 870HV | 815HV | 768HV |

| Matrix hardness | 643HV | 558HV | 524HV |

| CVF | 41.2% | 39.0% | 39.2% |

| Test material | 3.5C-0Ti | 3.5C-1Ti | 3.5C-2Ti |

| Macro hardness | 916HV | 863HV | 792HV |

| Matrix hardness | 665HV | 612HV | 549HV |

| CVF | 42.3% | 39.3% | 39.1% |

| Test material | 4C-0Ti | 4C-1Ti | 4C-2Ti |

| Macro hardness | 964HV | 956HV | 878HV |

| Matrix hardness | 748HV | 672HV | 623HV |

| CVF | 39.4% | 41.0% | 40.5% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huq, M.J.; Shimizu, K.; Kusumoto, K.; Purba, R.H. Three-Body Abrasive Wear Performance of High Chromium White Cast Iron with Different Ti and C Content. Lubricants 2022, 10, 348. https://doi.org/10.3390/lubricants10120348

Huq MJ, Shimizu K, Kusumoto K, Purba RH. Three-Body Abrasive Wear Performance of High Chromium White Cast Iron with Different Ti and C Content. Lubricants. 2022; 10(12):348. https://doi.org/10.3390/lubricants10120348

Chicago/Turabian StyleHuq, Mohammad Jobayer, Kazumichi Shimizu, Kenta Kusumoto, and Riki Hendra Purba. 2022. "Three-Body Abrasive Wear Performance of High Chromium White Cast Iron with Different Ti and C Content" Lubricants 10, no. 12: 348. https://doi.org/10.3390/lubricants10120348

APA StyleHuq, M. J., Shimizu, K., Kusumoto, K., & Purba, R. H. (2022). Three-Body Abrasive Wear Performance of High Chromium White Cast Iron with Different Ti and C Content. Lubricants, 10(12), 348. https://doi.org/10.3390/lubricants10120348