1. Introduction

In general, journal bearings are used to support high-speed rotors in turbo engines, which often operate above the critical speed acting on the rotor. These bearings provide lateral support and dynamic coefficients in the form of stiffness, damping, and mass terms, which are related to engine vibration [

1]. Machining, heat treatment, assembly, destructive testing, washing, and packing are all part of the bearings’ manufacturing process. Customer satisfaction, top quality, and reliable bearing products are the primary responsibilities of any organized or disorganized bearing manufacturing unit in the current market scenario. Industry 4.0, often known as the Fourth Industrial Revolution, is a new paradigm in the digitalization of manufacturing that affords businesses a variety of benefits. Industry 4.0, which integrates numerous advancements, is an intriguing topic for nearly everyone engaged in the manufacturing sector. Future Industry 4.0 production ideas must include the development of bearing technology to maximize the added value of intelligent processes over the next decade. In order to improve the quality of a bearing, technological intervention and advancement have become essential in the manufacturing sector.

In operation, the role of lubrication in bearings is very important; one example is the selection of the lubricant. When selecting a lubricant, several criteria must be considered, including thermal properties and flow rate, both of which are mechanical parameters of the lubricating oil analyzed under different operating conditions. In general, the viscosity of the lubricant decreases with increasing temperature. For operation at high speeds and under heavy loads, oils containing highly polymeric molecules are used as viscosity index enhancers to prevent changes in viscosity with increasing temperatures. Increasing the viscosity of the lubricant also increases the bearing capacity of the modified lubricant, but the viscosity decreases with increasing shear rates. This phenomenon is called pseudoplasticity. In general, fluids that are not bound by Newton’s law of viscosity are called non-Newtonian fluids. At present, many studies in lubrication use non-Newtonian fluids. Wada et al. [

2] were the first to present a significant lubrication theory for Bingham plastics in 2D lubricating films. They found that the film pressure, load-bearing capacity, and friction force of Bingham plastics were greater than those of Newtonian fluids, and that these values increased with increasing yield stress. Silva et al. [

3] analyzed infinitely large plain bearings, using lubricating oils with characteristic index rheology. This index was obtained by analytical resolution of the Reynolds equation in one dimension. They showed that liquid dilatants increase the load-bearing capacity and pressure. Wang and Zhu [

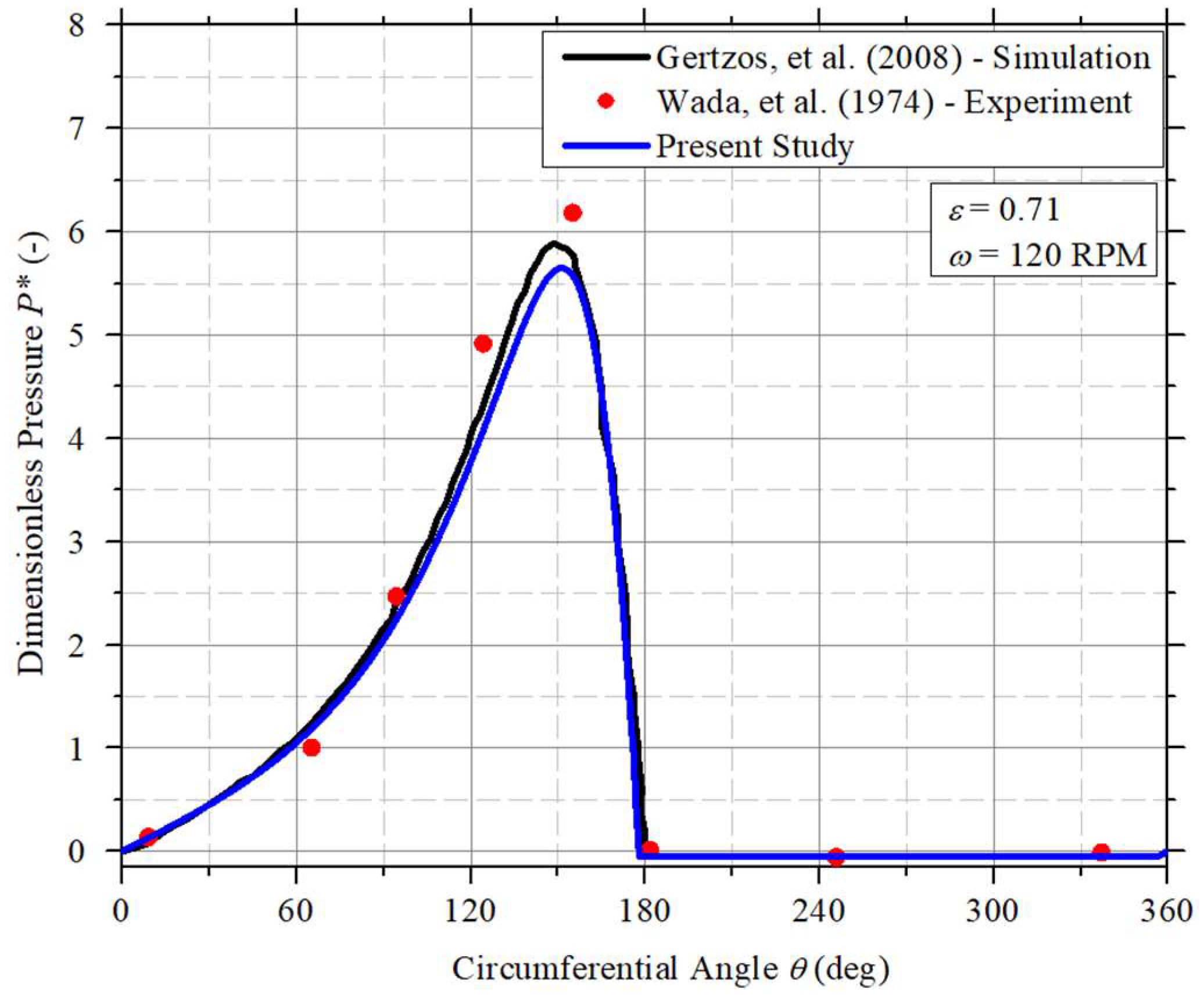

4] conducted a numerical study of finite journal bearings lubricated with micropolar liquids, taking into account thermal and cavitation effects. It was found that increases in load-bearing capacity and temperature values occurred in finite journal bearings compared to the use of Newtonian fluids. Gertzos et al. [

5] presented a CFD analysis of the performance characteristics of Bingham-fluid-lubricated journal bearings using different parameters. From their analysis, it can be concluded that the load-bearing capacity, film pressure, and frictional force of Bingham solids are greater than those of Newtonian fluids, and that these values increase with increasing yield stress. For low eccentricity ratios, the magnitude of the yield has little effect on the journal behavior. In electrorheological and magnetorheological fluids, the yield stress increases with changes in the electric and magnetic fields. In addition, the resulting graph can be presented in the form of a Raimondi–Boyd graph, which can be easily used in the design and analysis of Bingham-fluid-lubricated journal bearings. Garg et al. [

6] investigated the thermal and rheological effects of lubricants on the performance of slot-entry hybrid journal bearing systems. Finite element analysis was used to solve the governing equations. The calculation results showed that variations in viscosity due to temperature increases and the non-Newtonian properties of the lubricant affected the bearing performance. Lin et al. [

7] presented a micropolar fluid analysis of the dynamic stiffness and damping properties of parabolic-film slider bearings. The authors concluded that the non-Newtonian effect of the micropolar fluid exerts a greater influence on the increased load-bearing capacity and higher dynamic coefficient compared to Newtonian lubricants. Kango et al. [

8] presented an investigation on the effects of viscous heat dissipation and non-Newtonian fluids on the performance of microtextured journal bearings with JFO (Jakobsson, Floberg, and Olsson) as the boundary condition. The authors concluded that with the presence of a micro surface texture, the average lubricant temperature decreases at low and high eccentricity ratio values. Bompos and Nikolakopoulos [

9] demonstrated the use of the CFD model to analyze the effects of texture with Bingham plastic lubricants. They used two types of textures, namely, egg area and rectangular. They concluded that the egg area is promising because an increase in depth causes a 4.8% increase in eccentricity, while the performance of a rectangular area decreases. Chandra et al. [

10] analyzed the performance of plain bearings with and without textures lubricated with non-Newtonian lubricants. The authors compared the characteristics of the two bearings and concluded that textured bearings provide increased stability parameters compared to journal bearings without texture. Budheeja and Verma [

11] studied the stability behavior of hole-entry bearings lubricated with micropolar liquids. The influence of linear and nonlinear trajectories related to the journal motion was also studied. It was observed that micropolarity had a substantial effect on performance as a stability margin in bearings, while a fast response was achieved by nonlinear analysis. Das and Roy [

12] investigated the performance parameters of four different bearing configurations and compared the results with plain journal bearings, and the analysis was carried out by considering the non-Newtonian fluids associated with the power-law model. Lambha et al. [

13] considered the effects of the couple stress together with the flexibility of the bearing for elastohydrodynamic analysis of cylindrical bearings. The combined effect showed an increase in the load-bearing capacity and dynamic characteristics of JB, while the stiffness coefficient value directly increased with the increase in the variable of the couple stress. Kumar and Kakoty [

14] analyzed the impact of a couple-stress lubricant on the performance of two lobe bearings by applying the Krieger–Dougherty model for viscosity calculation. The results showed a large increase in the load-bearing capacity and flow coefficient and a decrease in the friction variable. The results of the analyses conducted by the researchers mentioned above show that non-Newtonian fluids are good for improving the performance of journal bearings, with various models of approaches used—such as power-law models, Bingham, couple stress, and other performance aspects of journal bearings lubricated with non-Newtonian fluids—able to increase the load-bearing capacity and reduce the coefficient of friction in journal bearings. This is because non-Newtonian fluids have anti-wear, low-friction, and extreme pressure properties [

15]. In addition, Bingham plastic lubricants were also proven to be able to enhance the stability of the bearing system and the minimum film thickness [

16]. Lampaert and Ostayen [

17] simulated precise thin-film lubrication for Bingham plastic fluids. The model was validated by comparing the results obtained for finite- and infinite-length journal bearings with those published in the literature, which showed good agreement. All of these studies have made significant contributions to the state of the art of non-Newtonian lubricants. However, research on Bingham plastics for journal bearings with roughness is still lacking.

Surface roughness is crucial to journal bearings’ performance and cannot be disregarded. As a result, many researchers have investigated how surface roughness affects bearings’ surfaces. The effect of surface roughness on short and long porous journal bearings lubricated with Newtonian fluids was studied by Gururajan and Prakash [

18,

19]. They found that there was a strong interaction between the roughness and the slip effect. Then, Naduvinamani et al. [

20] studied the effects of surface roughness on porous journal bearings with couple-stress fluids. It was noted that couple-stress fluids exhibited more pronounced effects of surface roughness on the bearing characteristics than Newtonian fluids. Rahmatabadi et al. [

21] conducted a study on two-lobe, three-lobe, and four-lobe hydrodynamic bearings operated with micropolar lubricants. They reported that the use of micropolar lubricants improved the static performance characteristics. The combined effects of surface roughness and non-Newtonian fluids have been studied by several authors, such as Naduvinamani et al. [

22] and Ramesh et al. [

23]. They found that the performance characteristics of the bearings increased with increasing roughness parameters and Hartmann number. In a study conducted by Bhaskar et al. [

24], which analyzed the static characteristics of finite bearings for various L/D ratios with three types of surface roughness orientations, it was found that longitudinal surface roughness has a greater effect on the Sommerfeld number. Then, they found that the load-bearing capacity increased by 52.57% compared to journal bearings without surface roughness. Sander et al. [

25] analyzed the effects of surface roughness on the dynamic properties of journal bearings ranging from hydrodynamic lubrication to mixed lubrication. They found that compared to the rough surface of the new bearing, the run-in roughness reduces the maximum contact pressure and contact area. Later, the effect of surface roughness on the transient behavior of hydrodynamic journal bearings during startup was explored by Cui et al. [

26], who found that the longitudinal roughness surface configuration had a significant effect on the decrease in hydrodynamic forces. Al-Samieh [

27] explored the effects of surface roughness in terms of sinusoidal waves for Newtonian and non-Newtonian lubricants. It was observed that as the wave amplitude increases, more fluctuations in the pressure distribution occur. Then, Tauviqirrahman et al. [

28] revealed that the hydrodynamic pressure and load-bearing capacity decrease with surface roughness. In their case, it was assumed that the roughness was applied to the entire bushing surface. Gu et al. [

29] reported that surface roughness should be taken into account in the optimization of surface texture. A study on conical hybrid journal bearings lubricated with Bingham plastics was presented by Sharma and Kumar [

30]. They observed that using Bingham plastic lubricants in journal bearings enhanced the bearing performance, but at the expense of frictional power loss. Recently, Skaltsas et al. [

31] demonstrated that in the case of journal bearings with stochastic roughness on the stator and rotor, the load-bearing capacity of rough bearings increases significantly—up to 14% and 10%, respectively. Furthermore, the friction coefficient of a rough bearing—defined as the ratio of friction force to load-bearing capacity—was lower than that of a smooth bearing, with a decrease reaching 5% at higher loads. The same conclusion was reached by Angadi and Naduvinamani [

32], who noticed that the load-bearing capacity was enhanced by the presence of the surface roughness structure. Experimentally, it was also revealed that surface roughness has a strong effect on the friction coefficient [

33]. Furthermore, by introducing the longitudinal roughness surface pattern, the bearing stability could be enhanced [

34]. In general, a review of the relevant literature revealed that roughness characteristics have a significant impact on the tribological behavior of bearings. In addition, none of the studies on roughened journal bearings lubricated with Bingham plastics have examined acoustic behavior (noise). It remains to be seen whether engineered roughness can simultaneously achieve low noise and good tribological performance for a journal bearing.

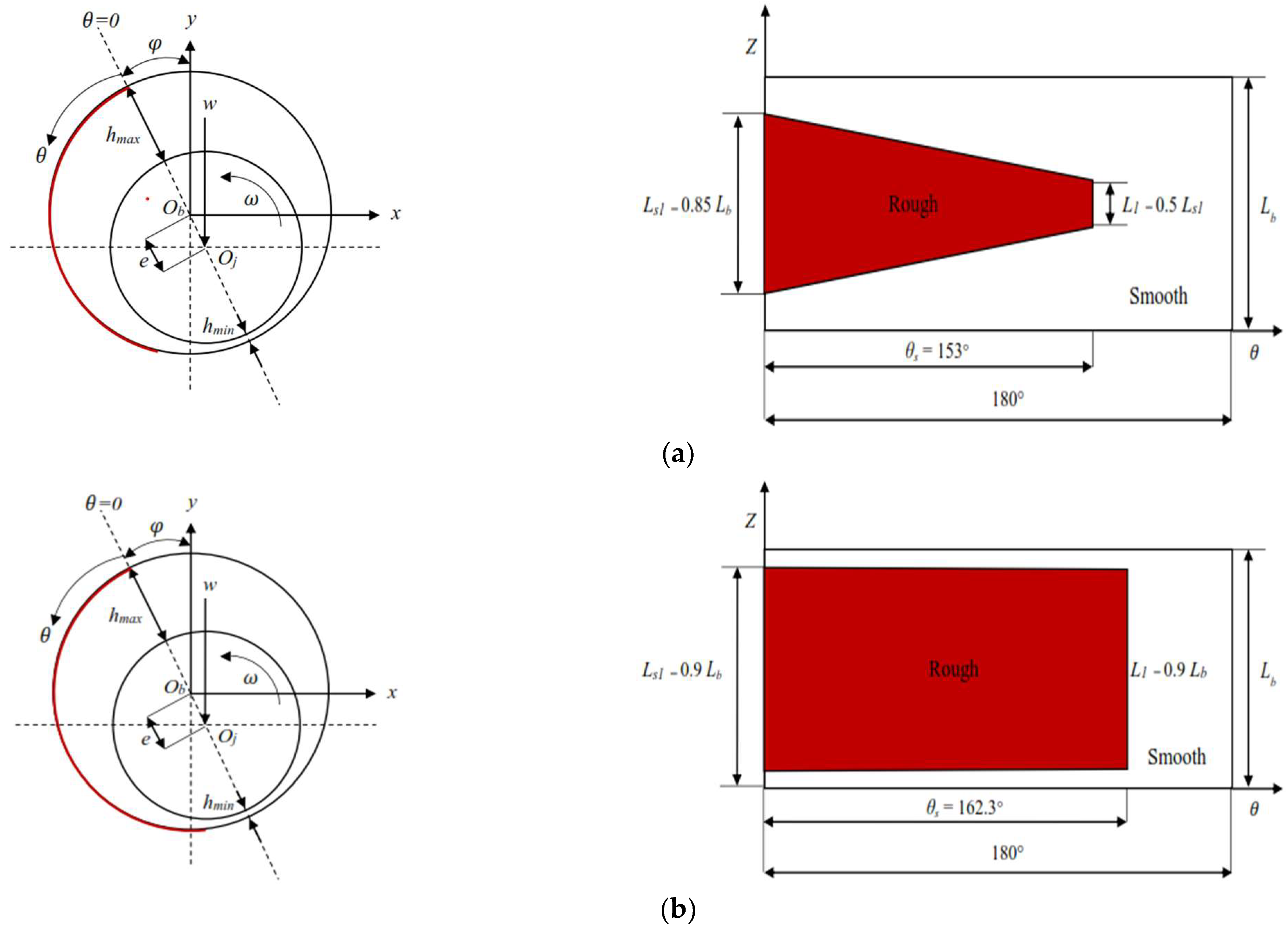

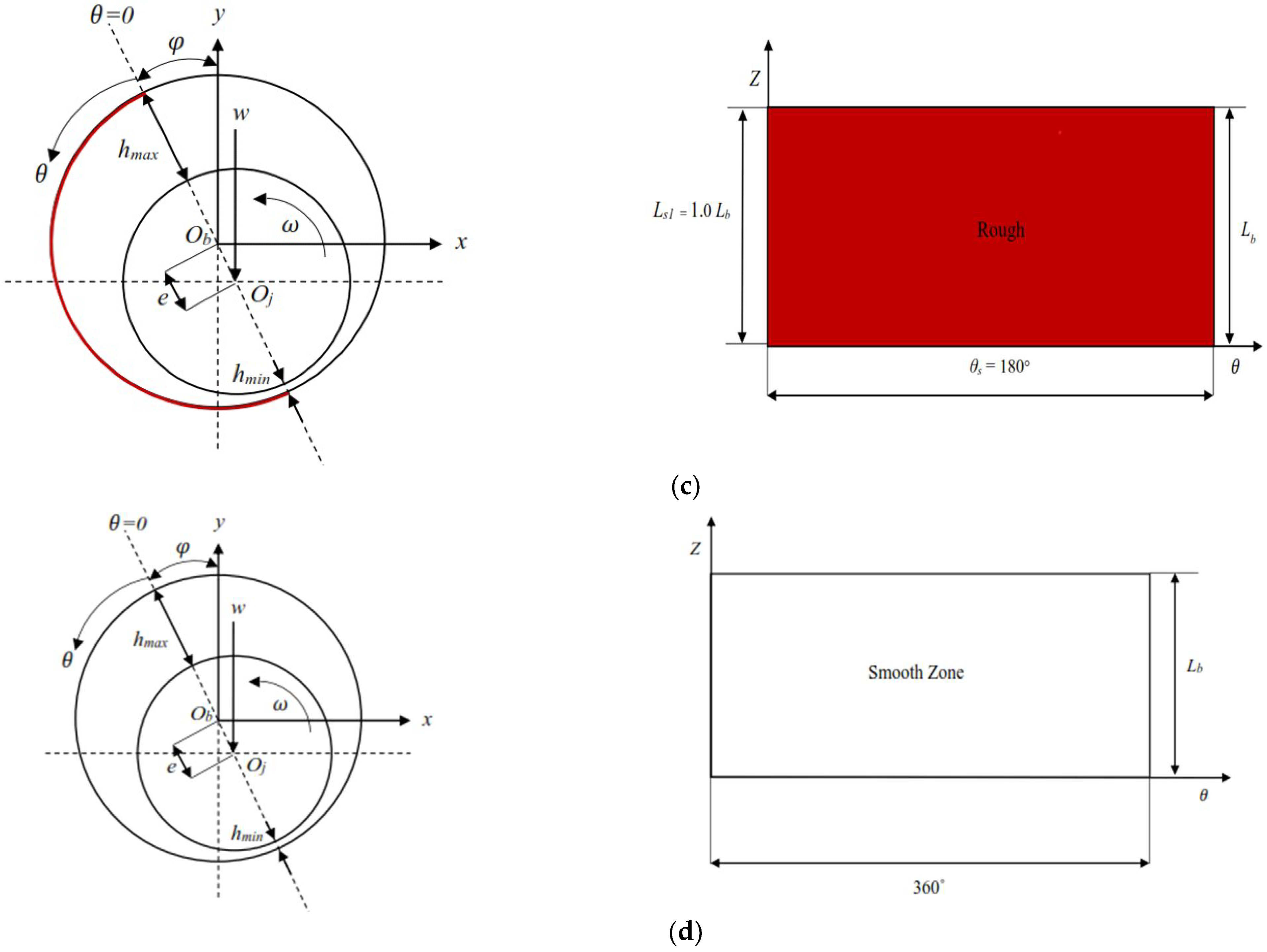

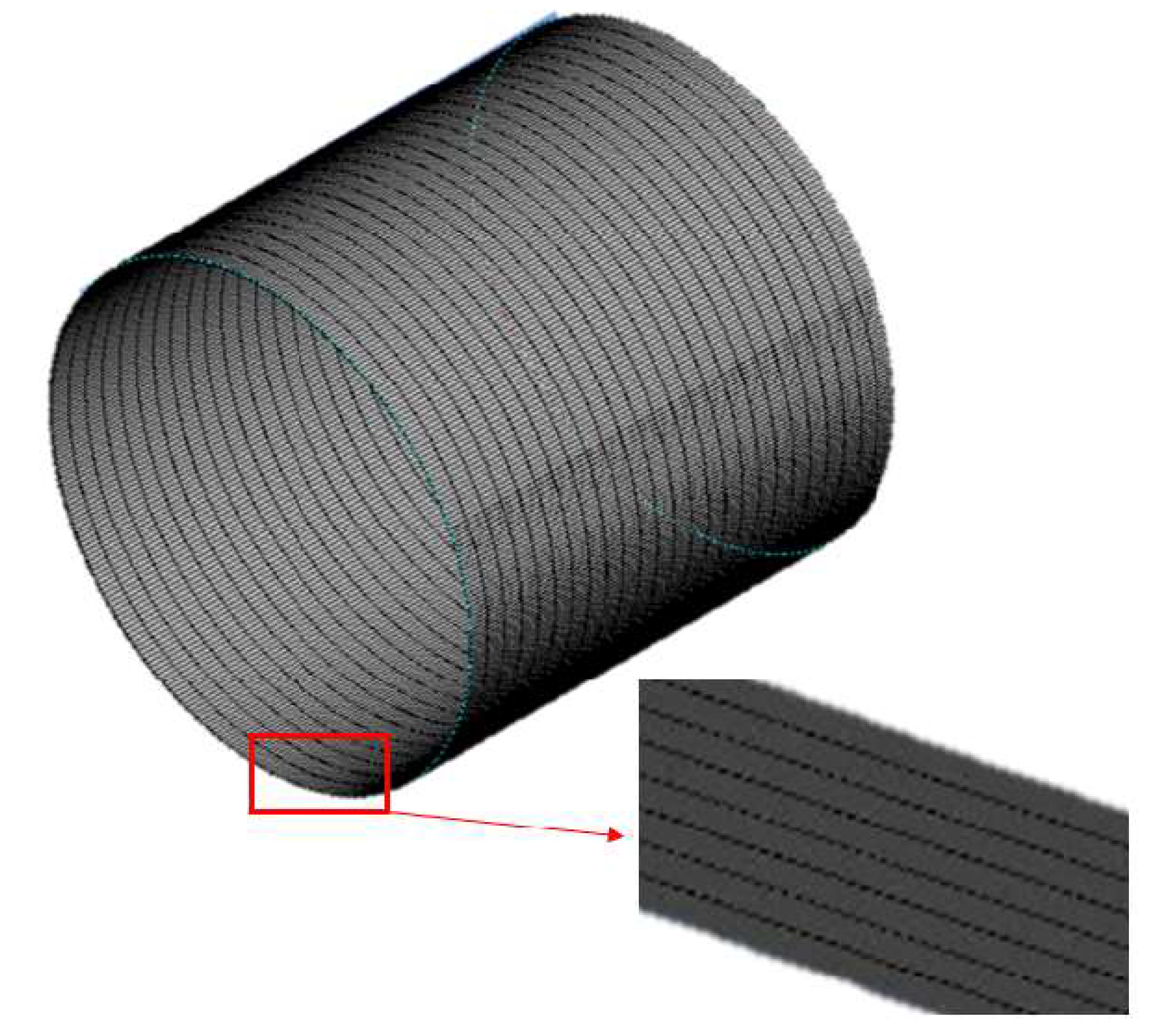

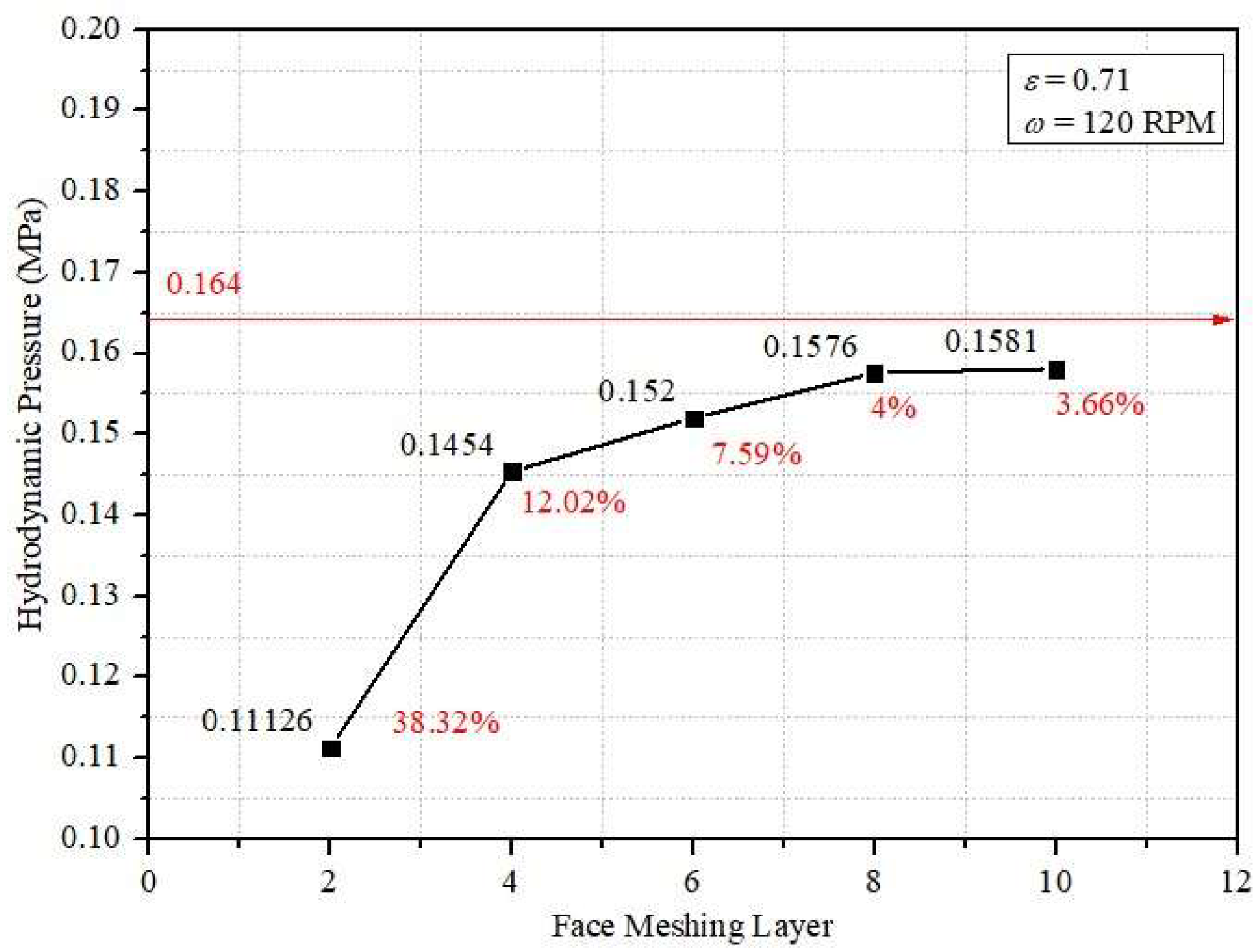

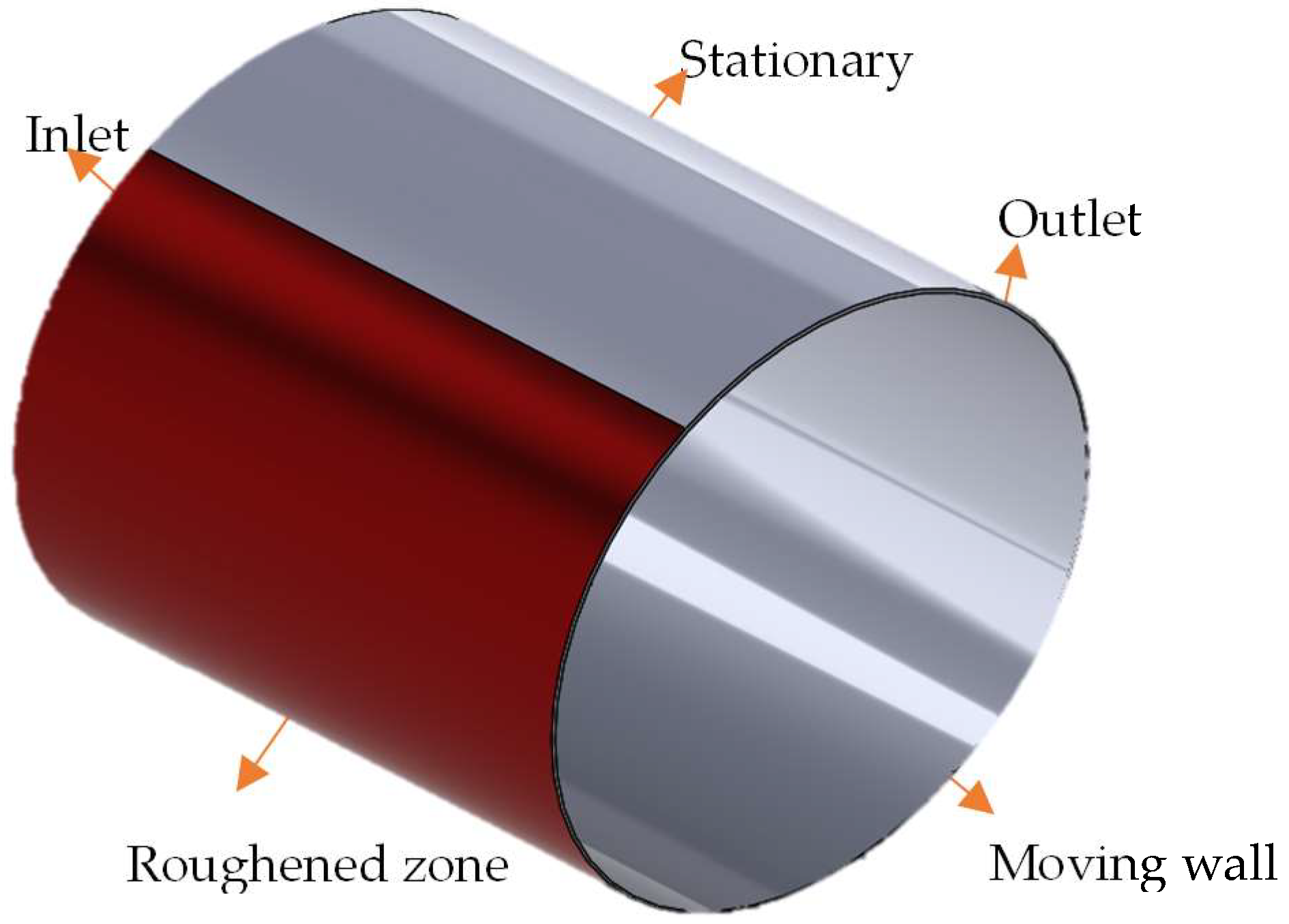

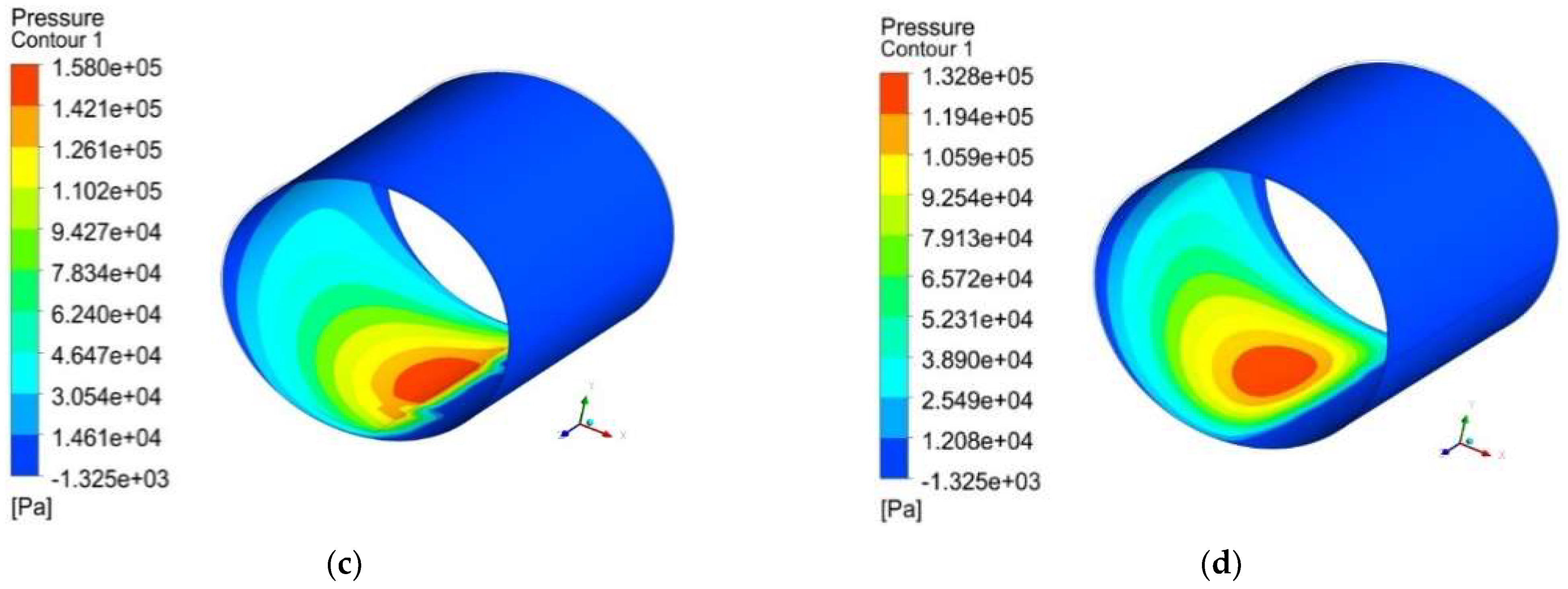

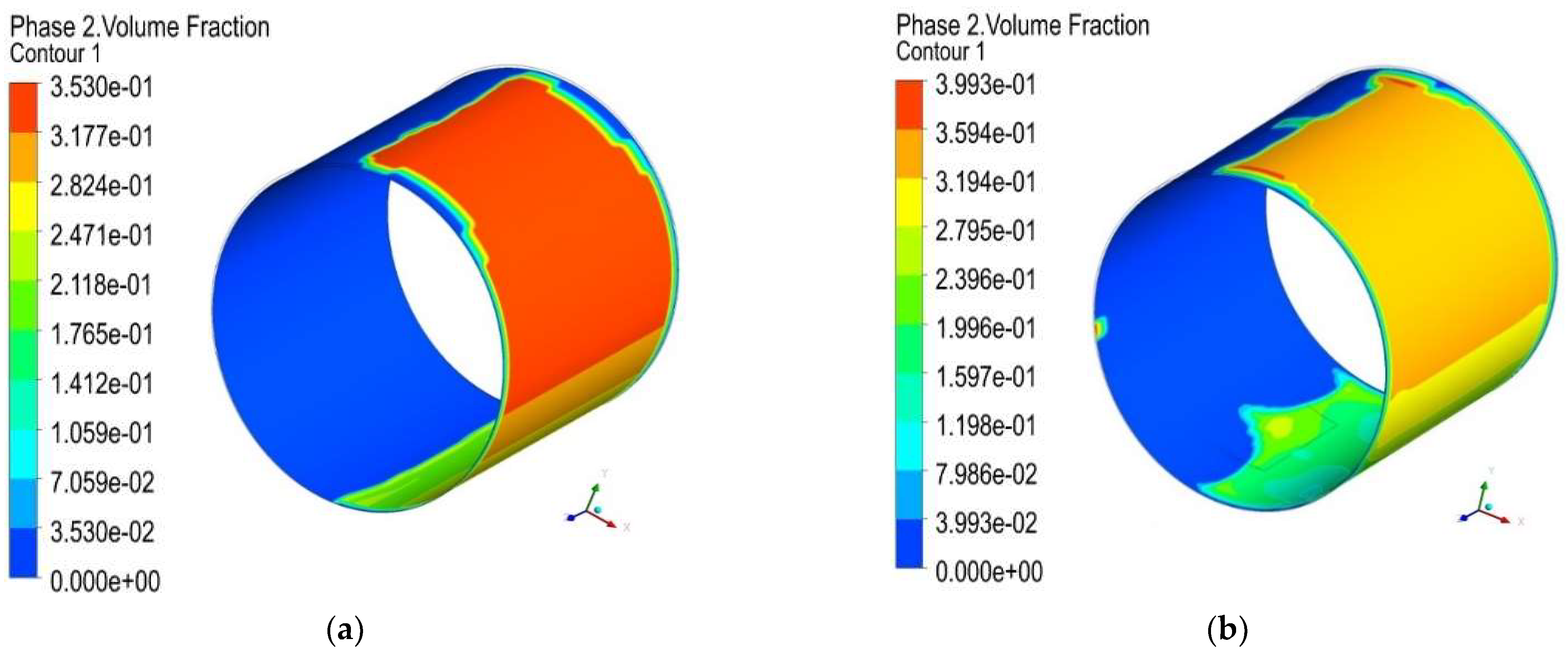

Therefore, the novelty of this study lies in the in-depth investigation of the tribological and acoustic properties of a bearing lubricated with Bingham fluids while considering roughness and cavitation. Here, in order to predict the bearing’s performance more precisely, a more thorough computational model is required. In this study, a comprehensive analysis of journal bearings lubricated with Bingham fluids with different patterns of the engineered roughness area of the bearing was carried out. Furthermore, in this work, the multiphase cavitation and turbulence were also considered to capture more realistic conditions.