Influence of Friction on the Formability of Fe-Zn-Coated IF Steels for Car Body Parts

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

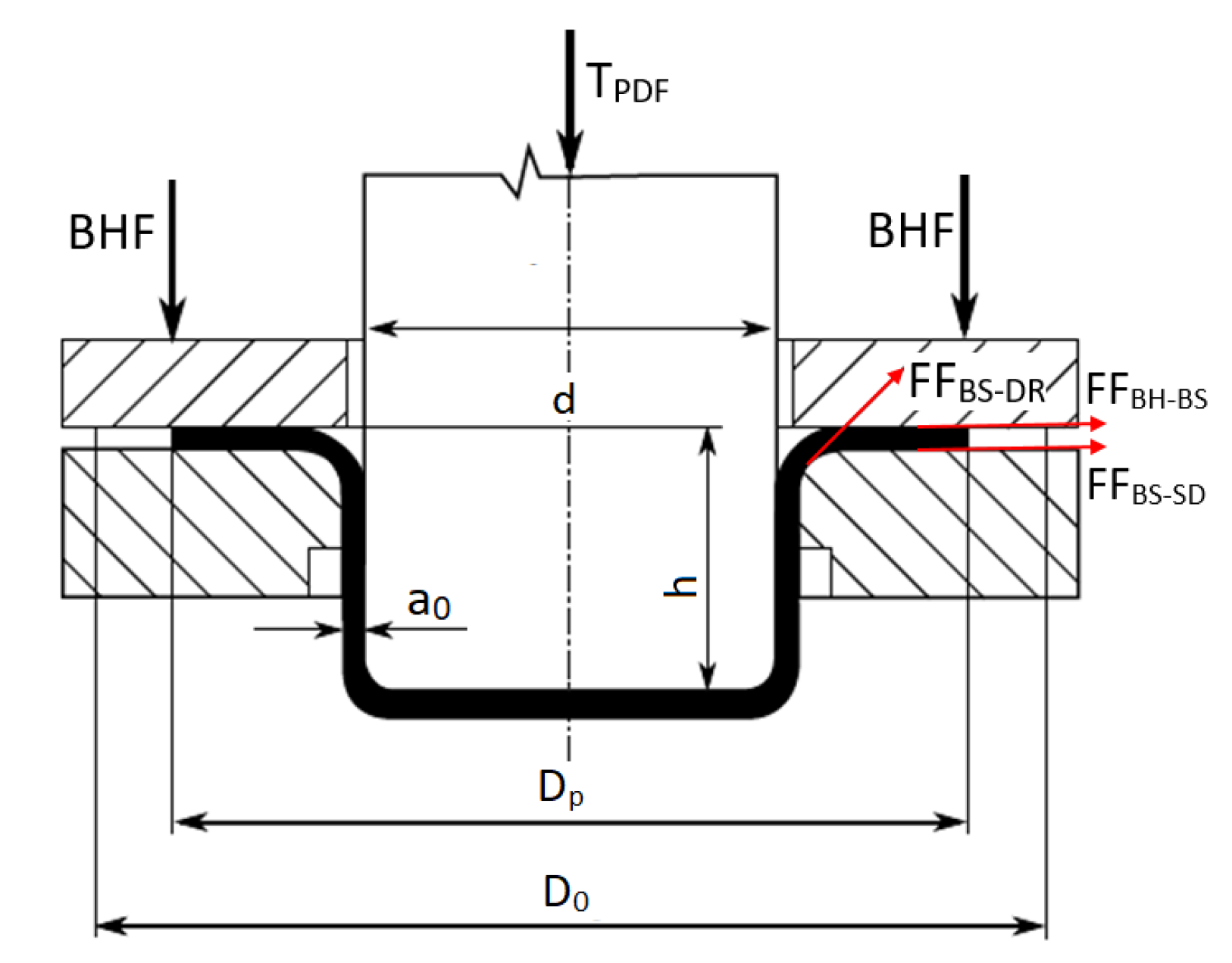

- CF is constant, i.e., in the area under the blank holder, and CFBH is the same as on the drawing edge of the die (CF = CFBH = CFDR);

- CF is not constant, i.e., it changes depending on the used lubricant, pressure on the contact surfaces, drawing speed, surface morphology of the contact surfaces, etc. (CFBH ≠ CFDR).

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Akafuah, N.K.; Poozesh, S.; Salaimeh, A.; Gabriela Patrick, P.; Lawler, K.; Saito, K. Evolution of the Automotive Body Coating Process—A Review. Coatinngs 2016, 6, 24. [Google Scholar] [CrossRef]

- Evin, E.; Kollárová, M. The Tribology Properties of Zinc Coated Steel Sheets for Auto Body. Chem. Listy 2011, 105, 465–467. [Google Scholar]

- Graban, J.; Kohúteková, V.; Hollý, F.; Tarhaničová, R. Evaluation of Galvanized Sheets with Thin Organic Coating with Antifingerprint properties. In Proceedings of the 17th International Conference on Metallurgy and Materials Proceedings—METAL 2008, Hradec nad Moravicí, Czech Republic, 24–26 May 2008. [Google Scholar]

- Kolnerová, M.; Solfronk, P. Morphology of sheet metal of zinc coated sheet metal surface used in car industry. In Proceedings of the 10th International Metallurgical Conference Proceedings—METAL 2001, Ostrava, Czech Republic, 15–17 May 2001. [Google Scholar]

- Evin, E.; Tomáš, M.; Graban, J.; Kundracík, V.; Hollý, F.; Toth, M. Analysis of coated steel sheets resistance to corrosion after plastic deformation. MM Sci. J. 2016, 5, 1415–1419. [Google Scholar] [CrossRef]

- Evin, E.; Tomáš, M.; Kollárová, M.; Antoszewski, B. Some Tribological aspects of Fe-Zn Coated steel sheets at Stamping Processes. Acta Metall. Slovaca 2014, 2, 189–199. [Google Scholar] [CrossRef]

- Tanaka, S.; Honda, K.; Takahashi, A.; Morimoto, Y.; Kurosaki, M.; Shindo, H.; Nishimura, K.; Sugiyama, M. The performance of Zn-Al-Mg-Si hot-dip galvanized steel sheet. In Proceedings of the 5th International Conference on Zinc and Zinc Alloy Coated Steel, GALVATECH, Brussels, Belgium, 26–28 June 2001; pp. 153–160. [Google Scholar]

- Tsujimura, T.; Komatsu, A.; Andoh, A. Influence of Mg content in coating layer and coating structure on corrosion resistance of hot-dip Zn-Al-Mg alloy coated steel sheet. In Proceedings of the 5th International Conference on Zinc and Zinc Alloy Coated Steel, GALVATECH, Brussels, Belgium, 26–28 June 2001; pp. 145–152. [Google Scholar]

- Pradhan, D.; Kumar, A.; Pankaj Raju, G.; Manna, M.; Dutta, M.; Venugopalan, T. Fe-Zn Alloy Coating on Galvannealed (GA) Steel Sheet to Improve Product Qualities. J. Mater. Eng. Perform. 2014, 23, 3336–3346. [Google Scholar] [CrossRef]

- Miranda, W.J.; Carneiro, J.R.G.; Brito, P.P. Formability evaluation of Galvannealed (GA), Hot-Dip Pure ZN Galvanized (GI), Electrogalvanized (EG) and Electrgalvanized Prephosphated (EGP) Intersticial Free Steelaluation. In Proceedings of the IMECE2005 2005 ASME International Mechanical Engineering Congress and Exposition, Orlando, FL, USA, 5–11 November 2005. [Google Scholar]

- Sigvant, M.; Pilthammar, J.; Hol, J.; Wiebenga, J.H.; Chezan, T.; Carleer, B.; van den Boogaard, A.H. Friction in sheet metal forming influence of surface roughness and strain rate on sheet metal forming simulation results. Procedia Manuf. 2019, 29, 512–519. [Google Scholar] [CrossRef]

- Ajayi, O.O.; Erck, R.A.; Lorenzo-Martin, C.; Fenske, G.R. Frictional anisotropy under boundary lubrication: Effect of surface texture. Wear 2009, 267, 1214–1219. [Google Scholar] [CrossRef]

- Hrivňák, A.; Evin, E. Formability of Steel Sheets, 1st ed.; Elfa: Košice, Slovakia, 2004. [Google Scholar]

- Gorbunov, A.V.; Belov, V.K.; Begletsov, D.O. Texturing of Rollers for the Production of Auto-Industry Sheet. Steel Transl. 2009, 39, 696–699. [Google Scholar] [CrossRef]

- Çolak, B.; Basglu, F.; Kurgan, N. Texturing Methods for Cold Mill Work Rolls. In Proceedings of the UDCS’19 Fourth International Iron and Steel Symposium, Karabuk, Turkey, 4–6 April 2019. [Google Scholar]

- Müll, K.; Routschek, T. Topocrom Texturing: Technology and Advantages. Available online: http://www.topocrom.com/content/pdf/Baosteel_BAC_Topocrom.pdf (accessed on 27 November 2019).

- Evin, E.; Tomáš, M.; Kmec, J. Optimization of Electro-Discharge Texturing Parameters for Steel Sheets’ Finishing Rollers. Materials 2020, 13, 1223. [Google Scholar] [CrossRef]

- Manabe, K.; Soeda, K.; Shibata, A. Effects of Variable Punch Speed and Blank Holder Force in Warm Superplastic Deep Drawing Process. Metals 2021, 11, 493. [Google Scholar] [CrossRef]

- Lange, K. Lehrbuch der Umformtechnik: Band 3: Blechumformung; Springer: Berlin/Heidelberg, Germany, 1975. [Google Scholar]

- Tigrinho, L.M.V.; Santos, R.A.; Filho, A.A.C.; Marcondes, P.V.P. Experimental Investigation on the influence of the lubricant Type in the Punch Stretching of Extra Deep-Drawing Steel. J. Braz. Soc. Mech. Sci. Eng. 2008, 30, 29–294. [Google Scholar] [CrossRef]

- Zein, H.; Irfan, O.M. Optimization and Mapping of the Deep Drawing Force Considering Friction Combination. Appl. Sci. 2021, 11, 9235. [Google Scholar] [CrossRef]

- Evin, E.; Ábel, M.; Vinaš, J.; Tkáčová, J.; Antoszewski, B. Tribological characteristics of stamping dies with coatings. Mechanika 2013, 2, 129–137. [Google Scholar] [CrossRef]

- Choudhury, I.A.; Lai, O.H.; Wong, L.T. PAM-STAP in the simulation of stamping process of an automotive component. Simul. Model. Pract. Theory 2006, 14, 71–81. [Google Scholar] [CrossRef]

- Adnan, I.O. Zaid. Effect of Different Lubricants on Deep Drawing of Galvanized Steel. Int. J. Sci. Eng. Res. 2017, 8, 1584. [Google Scholar]

- Mohan Krishna, K.; Kumara Swamy, M. Prediction of Draw Ratio in Deep Drawing through Software Simulations. Int. Refereed J. Eng. Sci. (IRJES) 2014, 3, 24–29. [Google Scholar]

- Hou, J.; Wang, B.; Xu, D.; Cui, L.; Sun, J. Effect of Surfactants on the Corrosion Protectability of Calcium Phosphate Conversion Coatings on Duplex StructuredMg-8Li (in wt.%) Alloy. Coatings 2022, 12, 1182. [Google Scholar] [CrossRef]

- Karupannasamy, D.K.; Hol, J.; de Rooij, M.B.; Meinders, T.; Schipper, D.J. Modelling mixed lubrication for deep drawing processes. Wear 2012, 294–295, 296–304. [Google Scholar] [CrossRef]

- Roizarda, X.; Pothiera, J.M.; Hih, J.Y.; Monteila, G. Experimental device for tribological measurement aspects in deep drawing process. J. Mater. Process. Technol. 2009, 209, 1220–1230. [Google Scholar] [CrossRef]

- Shisode, M.; Hazrati, J.; Mishra, T.; de Rooij, M.; ten Horn, C.; van Beeck, J.; van den Boogaard, T. Modeling boundary friction of coated sheets in sheet metal forming. Tribol. Int. 2021, 153, 106554. [Google Scholar] [CrossRef]

- Wu, W.; Zhao, C.; Cao, M. Effect of ultrasonic and low frequency vibrations on friction coefficient at die radius in deep drawing process. J. Manuf. Process. 2021, 71, 56–69. [Google Scholar] [CrossRef]

- Xia, J.; Zhao, J.; Dou, S.; Shen, X. A Novel Method for Friction Coefficient Calculation in Metal Sheet Forming of Axis-Symmetric Deep Drawing Parts. Symmetry 2022, 14, 414. [Google Scholar] [CrossRef]

- Trzepieciński, T. Polynomial Multiple Regression Analysis of the Lubrication Effectiveness of Deep Drawing Quality Steel Sheets by Eco-Friendly Vegetable Oils. Materials 2022, 15, 1151. [Google Scholar] [CrossRef] [PubMed]

- Trzepiecinski, T.; Lemu, G.H. Recent Developments and Trends in the Friction Testing for Conventional Sheet Metal Forming and Incremental Sheet Forming. Metals 2020, 10, 47. [Google Scholar] [CrossRef]

- Bay, N.; Olsson, D.D.; Andreasen, J.O. Lubricant test methods for sheet metal forming. Tribol. Int. 2008, 41, 844–853. [Google Scholar] [CrossRef]

- Folle, L.; Schaeffer, L. New Proposal to Calculate the Friction in Sheet Metal Forming Through Bending Under Tension Test. Mater. Res. 2019, 22, 1–11. [Google Scholar] [CrossRef]

- Pöhlandt, K. Materials Testing for the Metal Forming Industry; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

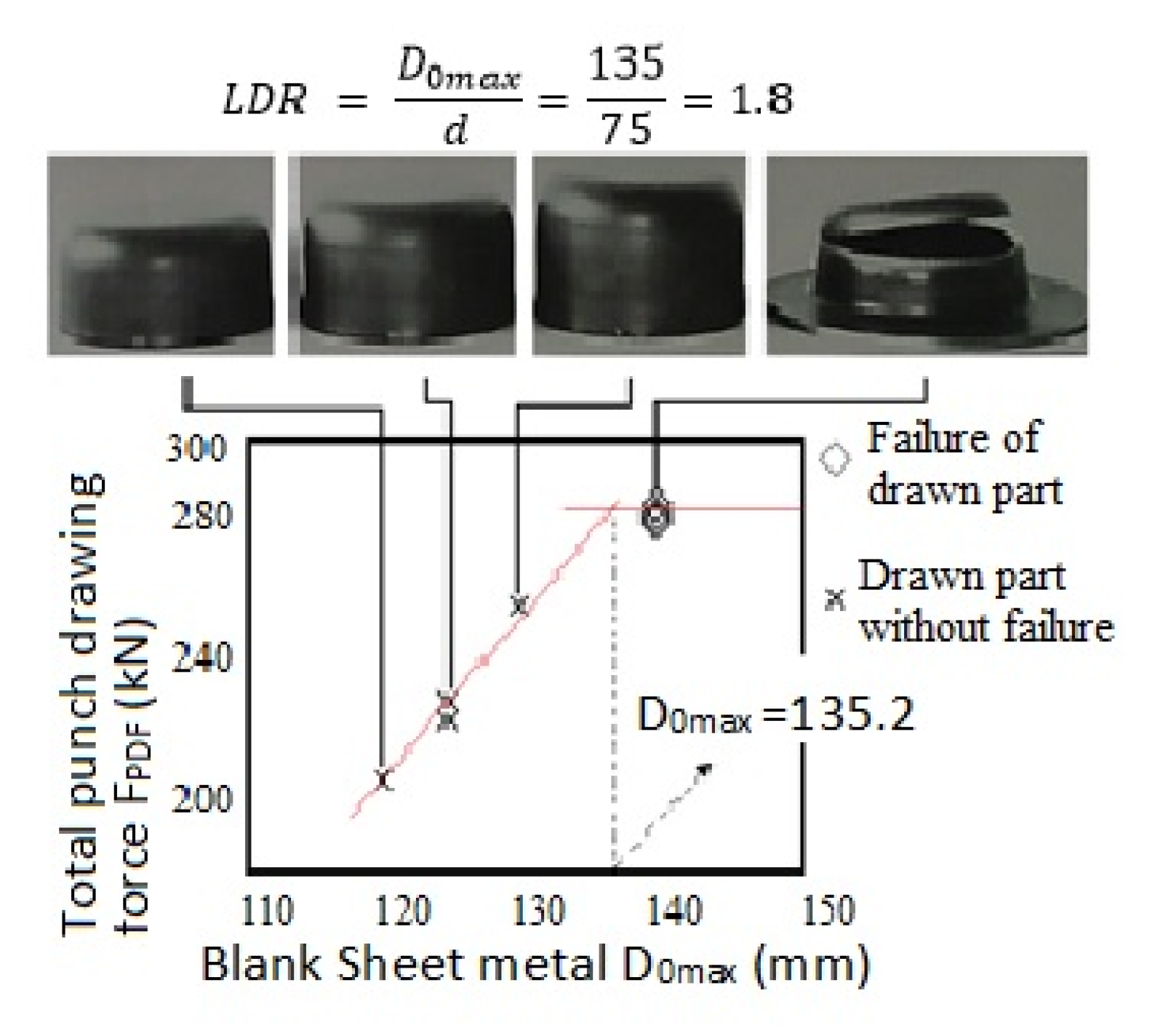

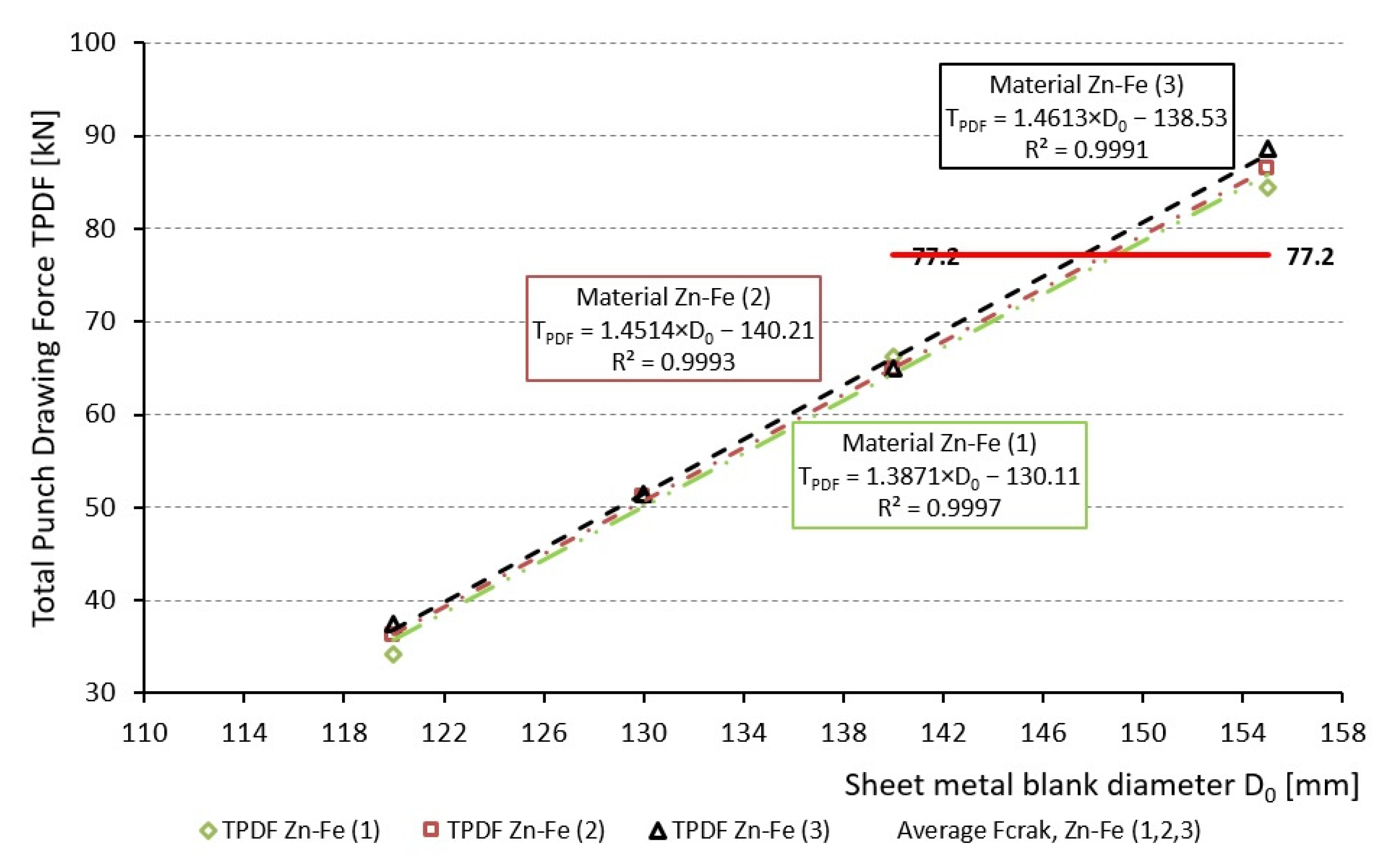

- Rahul, K.; Verma, R.K.; Chandra, S. An improved model for predicting limiting drawing ratio. J. Mater. Process. Technol. 2006, 172, 218–224. [Google Scholar]

- Evin, E.; Jakubeczyová, D.; Kollárová, M.; Hrabčáková, L. The influence of Fe-Zn coatings phase composition on friction characteristics under forming. In Proceedings of the 17th International Conference on Metallurgy and Materials Proceedings—METAL 2008, Hradec nad Moravicí, Czech Republic, 24–26 May 2008. [Google Scholar]

- Čada, R. Evaluation of Strain and Material Flow in Sheet-Metal Forming. J. Mater. Process. Technol. 2003, 138, 170–175. [Google Scholar] [CrossRef]

- Novák, V.; Valeš, M.; Tatíček, T.; Šanovec, J.; Chrášťanský, L. Analysis of forming capacity of HCT490X and DX57D depending on strain rate. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1178, 012045. [Google Scholar] [CrossRef]

- Mulidrán, P.; Spišák, E.; Tomáš, M.; Slota, J.; Majerníková, J. Numerical Prediction and Reduction of Hat-Shaped Part Springback Made of Dual-Phase AHSS Steel. Metals 2020, 10, 1119. [Google Scholar] [CrossRef]

- Schrek, A.; Gajdošová, V.; Švec, P. Deformation Properties of Tailor Welded Blank Made of Dual Phase Steels. Acta Mech. Autom. 2016, 10, 38–42. [Google Scholar] [CrossRef]

- Rusz, S.; Hilšer, O.; Ochodek, V.; Čada, R.; Švec, J.; Szkandera, P. Influence of SPD Process on Low-Carbon Steel Mechanical Properties. Mod. Mach. Sci. J. 2019, 12, 2910–2914. [Google Scholar] [CrossRef]

- Gupta, A.K.; Kumar, D.R. Formability of galvanized interstitial-free steel sheets. J. Mater. Process. Technol. 2006, 172, 225–237. [Google Scholar] [CrossRef]

- Dallin, G.W. Galvanizing—2014: Continuous Hot-Dip Galvanizing—Process and Products; Galvinfo center—A Program of the International Zinc Association; 2014. Available online: https://www.galvinfo.com/wp-content/uploads/sites/8/2017/05/Galvanizing-2014.pdf (accessed on 3 November 2022).

- Teixeira, E.L.S.; Dias, T.S.; Andrade, M.O.; Oliveira, A.B.S. Statistical process control application in automotive industry. In Proceedings of the 24th ABCM International Congress of Mechanical Engineering, Curitiba, Brazil, 3–8 December 2017. [Google Scholar]

- Godina, R.; Matias, J.C.O.; Azevedo, S.G. Quality Improvement With Statistical Process Control in the Automotive Industry. Int. J. Ind. Eng. Manag. (IJIEM) 2016, 7, 1–8. [Google Scholar]

- Verma, V.; Vinay Sharma, V.; Badar, M.A. Improving Sigma Level of Galvanization Process by Zinc Over-Coating Reduction Using an Integrated Six Sigma and Design-of-Experiments Approach. Arab. J. Acience Eng. 2022, 47, 8535–8549. [Google Scholar] [CrossRef]

- Li, G.; Long, X.; Yang, P.; Liang, Z. Advance on friction of stamping forming. Int. J. Adv. Manuf. Technol. 2018, 96, 21–38. [Google Scholar] [CrossRef]

- Garza, L.G.; Van Tyne, C.J. Friction and formability of galvannealed interstitial free sheet steel. J. Mater. Process. Technol. 2007, 187–188, 164–168. [Google Scholar] [CrossRef]

- Cristino, V.A.M.; Rosa, P.A.R.; Martins, P.A.F. Surface roughness and material strength of tribo-pairs in ring compression tests. Tribol. Int. 2011, 44, 134–143. [Google Scholar] [CrossRef]

- Feng, D.; Shen, M.X.; Peng, X.D.; Meng, X.K. Surface roughness effect on the friction and wear behaviour of acrylonitrile-butadiene rubber (NBR) under oil lubrication. Tribol. Lett. 2017, 65, 10. [Google Scholar] [CrossRef]

- Podgornik, B.; Jerina, J. Surface topography effect on galling resistance of coated and uncoated tool steel. Surf. Coat. Technol. 2012, 206, 2792–2800. [Google Scholar] [CrossRef]

- Leu, D.K. Modeling of surface roughness effect on dry contact friction in metal forming. Int. J. Adv. Manuf. Technol. 2011, 57, 575–584. [Google Scholar] [CrossRef]

- Sriram, S.; Krishnardula, V.; Hahn, H. Influence of Delta Phase Morphology in Galvannealed Coated Steels on Formability. IOP Conf. Ser. Mater. Sci. Eng. 2018, 418, 012094. [Google Scholar] [CrossRef]

- Dalton, G.M.; Zaccone, D.C. Oil Migration on Sheet Steels and the Effect on Performance in Metal Stamping. J. Mater. Manuf. 1999, 108, 661–666. [Google Scholar]

- Booser, E.R. Tribology Data Handbook, 1st ed.; CRC Press: Boca Raton, FL, USA, 1997. [Google Scholar]

| C Max | Mn Max | P Max | S Max | Al Min | Ti | N Max |

|---|---|---|---|---|---|---|

| 0.015 | 0.20 | 0.015 | 0.015 | 0.02 | 0.06–0.14 | 0.006 |

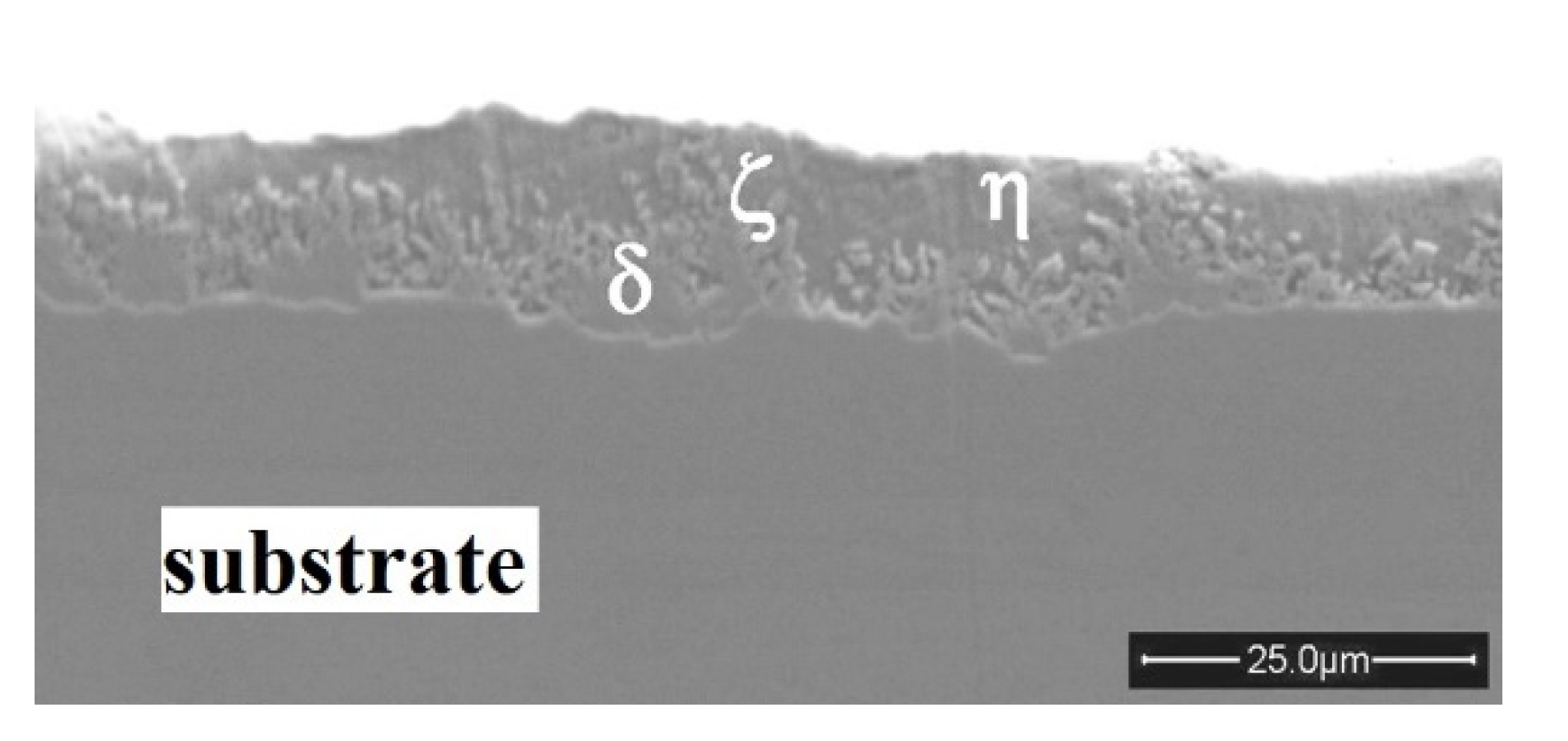

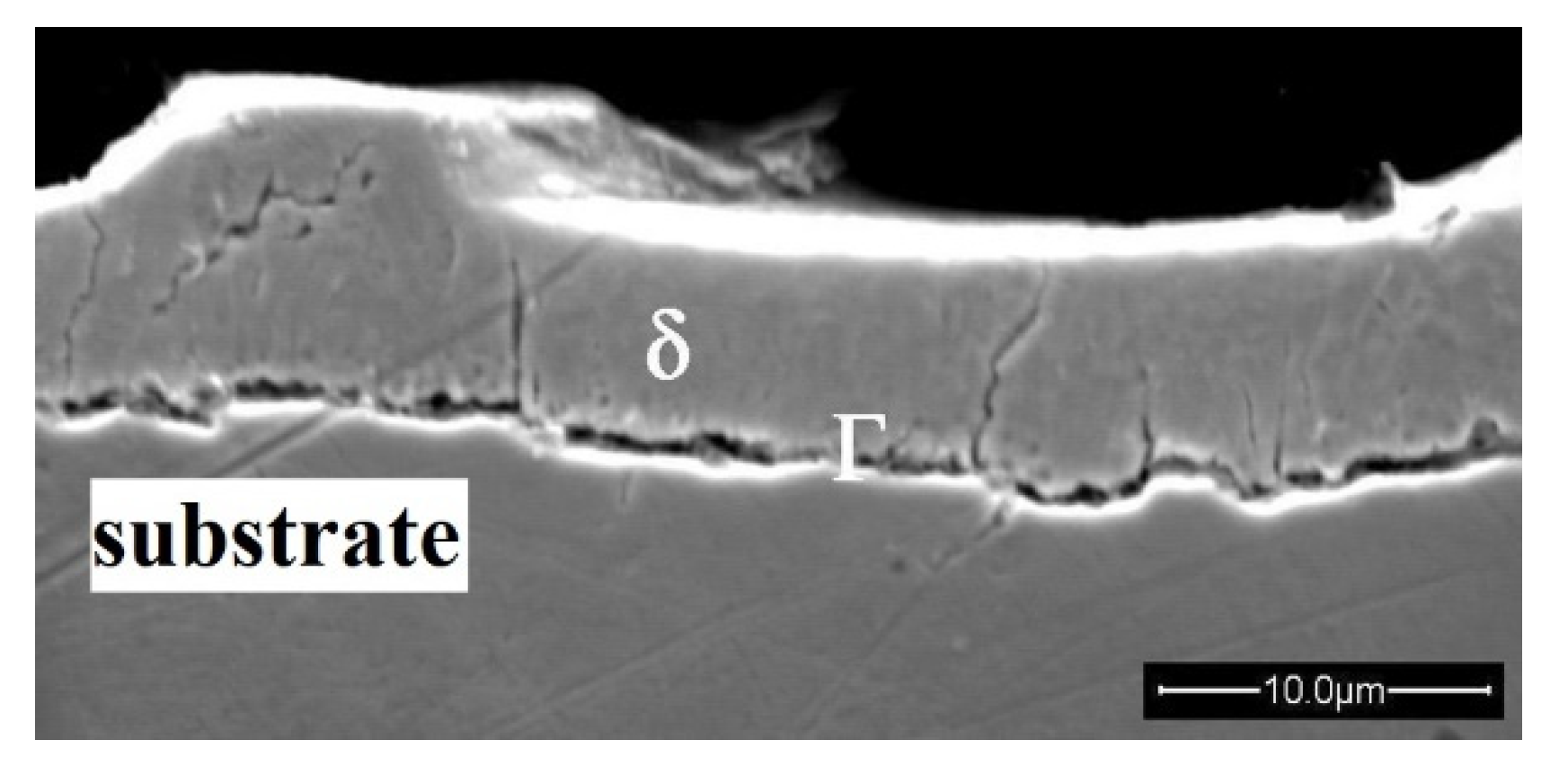

| Coating | Thickness [µm] | Fe Volume [%] | Alloying | Phase Composition | Phase Microhardness HV | |

|---|---|---|---|---|---|---|

| Inside | Surface | |||||

| Zn-Fe (1) | 11.6 | 5.5 | No | η, ζ, δ | η | η (52 to 72) |

| Zn-Fe (2) | 7.6 | 12.6 | Yes | δ, Γ | δ | δ (240 to 300) |

| Zn-Fe (3) | 8.0 | 14.4 | Yes | δ, Γ | δ | |

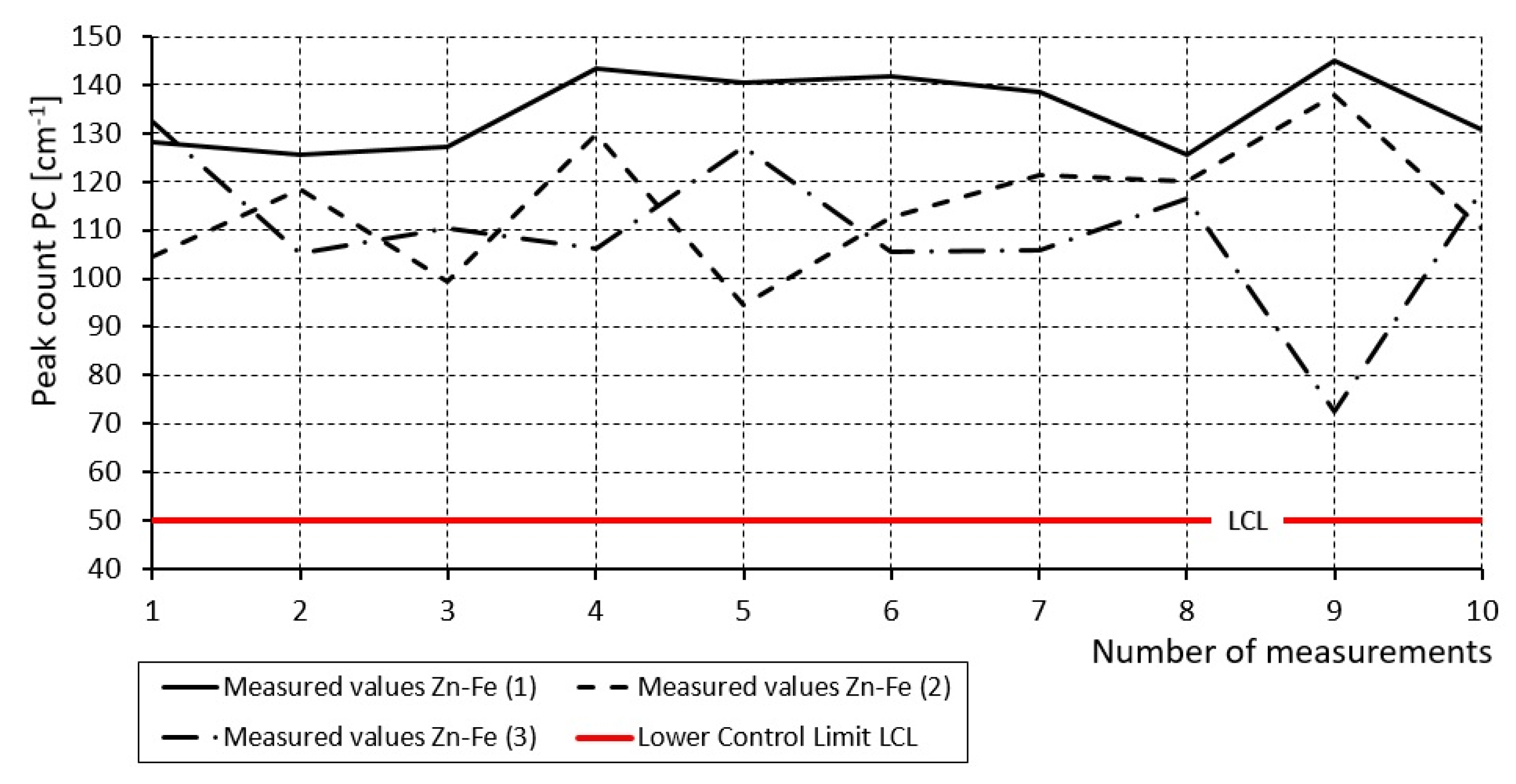

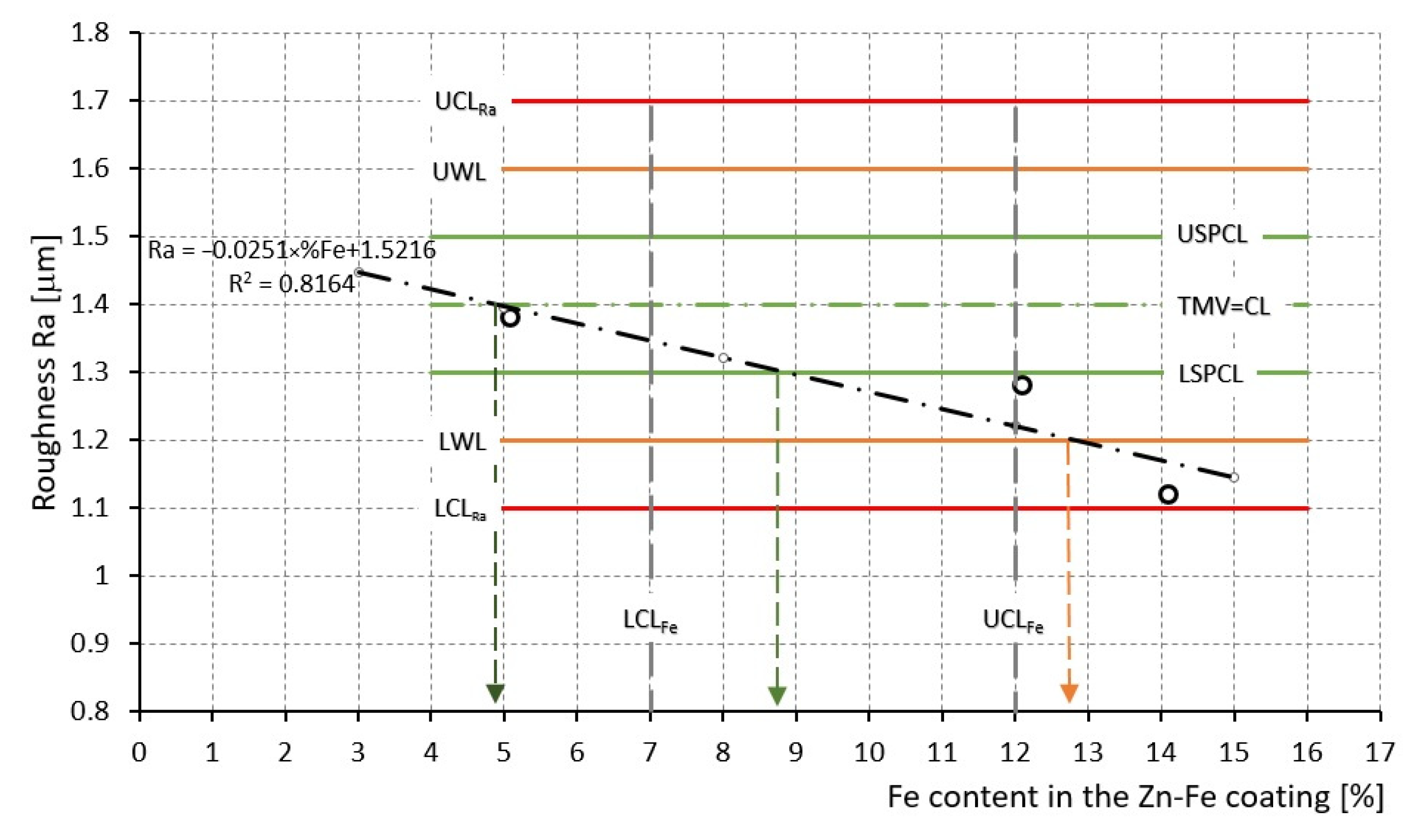

| Coating | Measured Values Ra and Pc | Ford Requirements | Cpk,Ra Indexes | Cpk,Pc Index | |||||

|---|---|---|---|---|---|---|---|---|---|

| Ra [µm] | Pc [cm−1] | бRa [µm] | бPc [cm−1] | Ra [µm] | Pc [cm−1] | Cpk,USL | Cpk,LSL | ||

| Zn-Fe (1) | 1.38 | 134 | 0.07 | 7.5 | 1.1 to 1.6 | >60 | 1.54 | 1.34 | 5.97 |

| Zn-Fe (2) | 1.27 | 115 | 0.061 | 12.8 | 2.3 | 0.96 | 2.97 | ||

| Zn-Fe (3) | 1.12 | 110 | 0.034 | 15.5 | 5.73 | 0.2 | 2.34 | ||

| Coating | Rolling Dir. [°] | RP0.2 [MPa] | Rm [MPa] | Ag [%] | A80 [%] | K [MPa] | n [-] | φ0 [-] | r [-] |

|---|---|---|---|---|---|---|---|---|---|

| Zn-Fe (1) | 90° | 166 | 293 | 27.5 | 40.7 | 509 | 0.215 | 0.005 | 2.19 |

| Zn-Fe (2) | 175 | 296 | 26.7 | 39.0 | 514 | 0.210 | 0.010 | 2.02 | |

| Zn-Fe (3) | 170 | 294 | 26.0 | 38.2 | 498 | 0.205 | 0.010 | 1.93 |

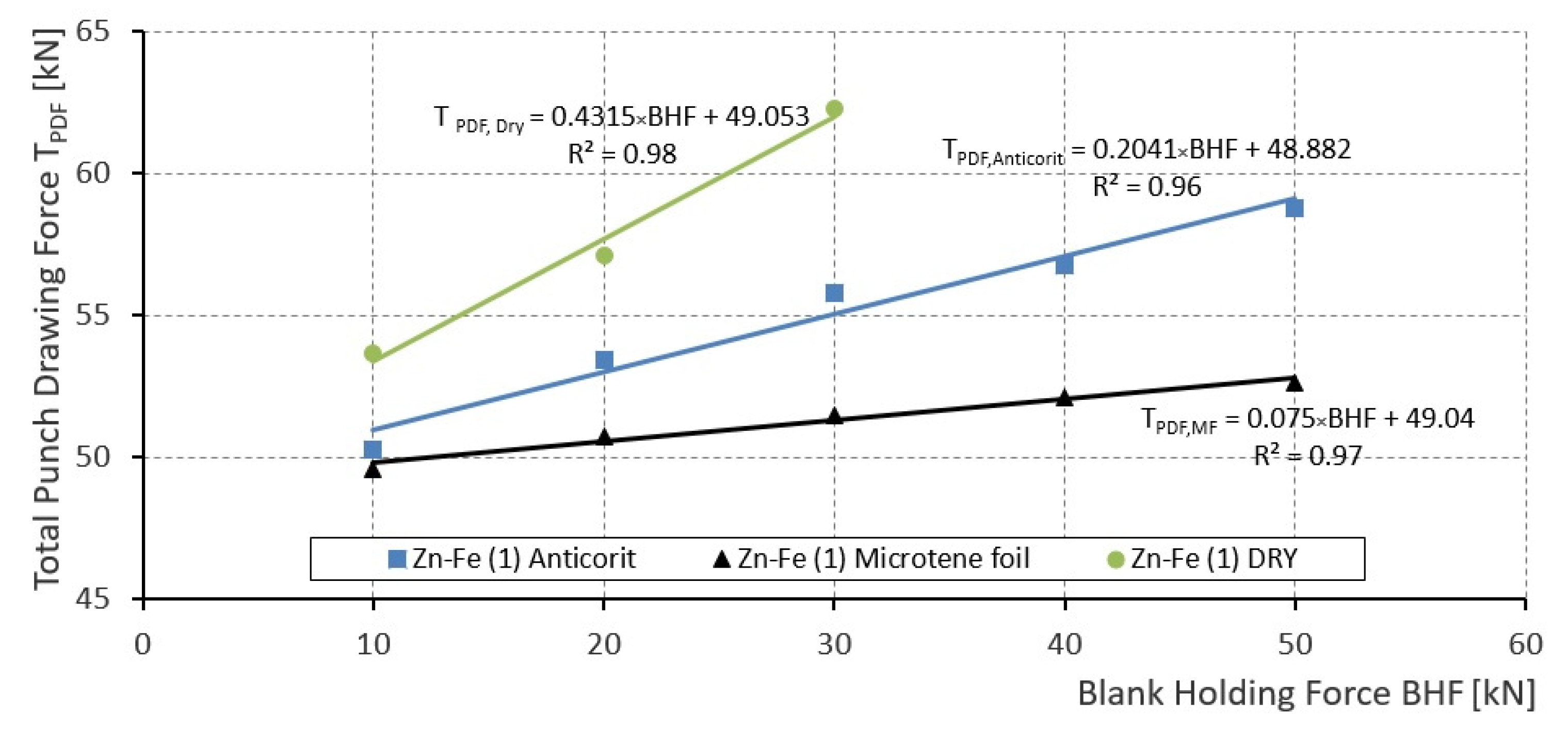

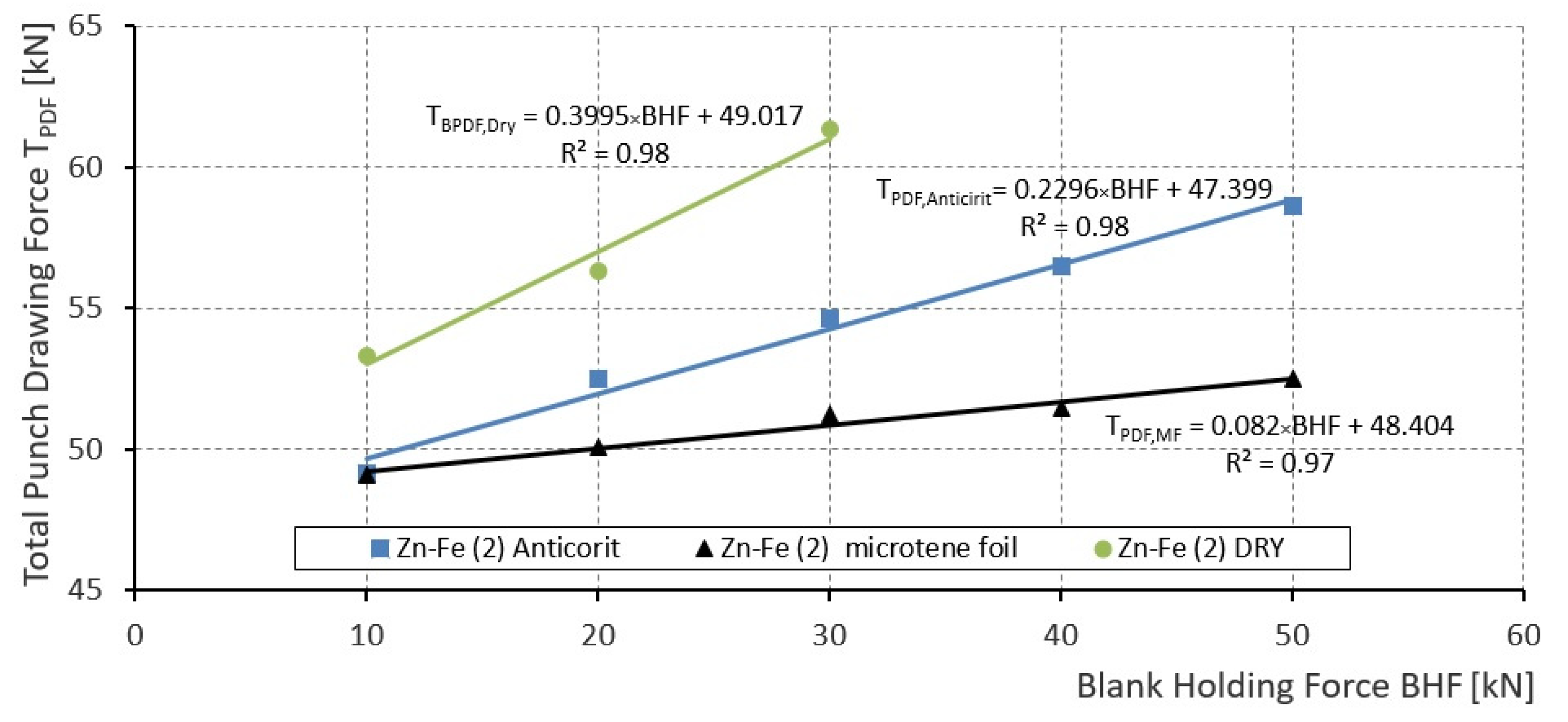

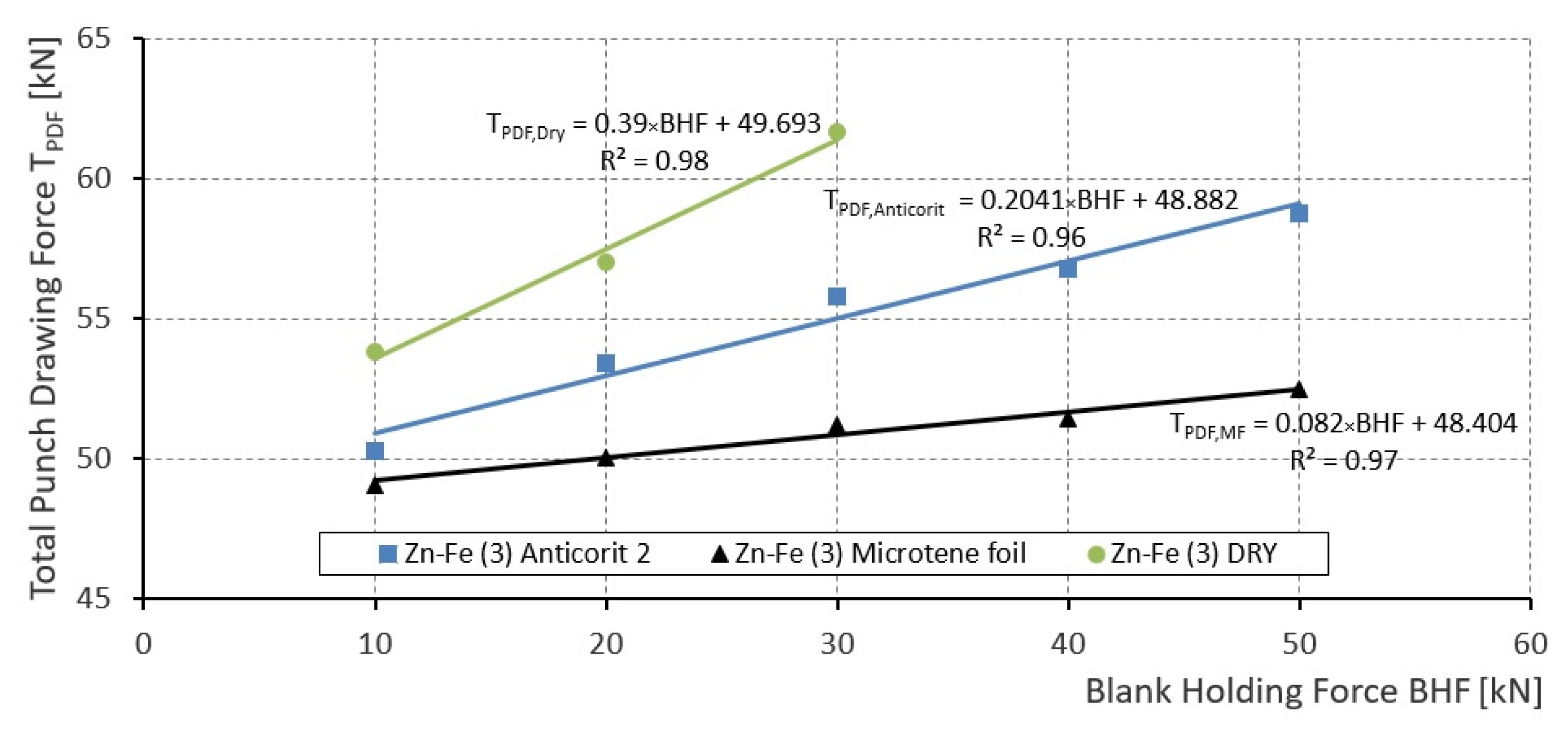

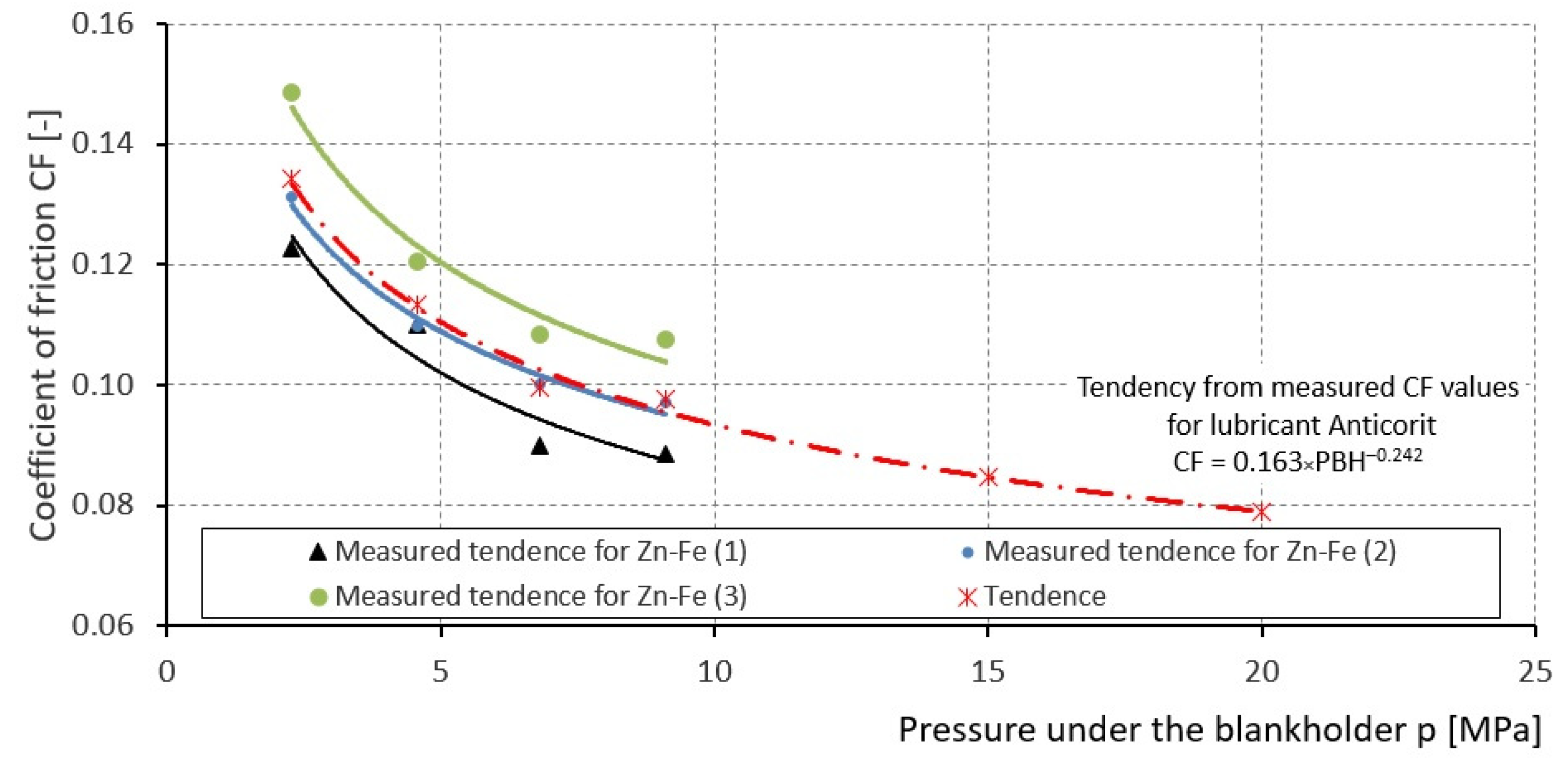

| Material | Blankholder Force BHF [kN] | Coefficient of Friction CFAntic. [-] | Coefficient of Friction CFmf. [-] | Coefficient of Friction CFDry. [-] | Pressure under the Blank Holder [MPa] |

|---|---|---|---|---|---|

| Zn-Fe (1) | 10 | - | - | - | 2.27 |

| 20 | 0.123 | 0.052 | 0.133 | 4.56 | |

| 30 | 0.100 | 0.045 | 0.161 | 6.84 | |

| 40 | 0.090 | 0.040 | Fracture | 9.12 | |

| 50 | 0.088 | 0.037 | - | 13.68 | |

| Zn-Fe (2) | 10 | - | - | - | 2.27 |

| 20 | 0.131 | 0.046 | 0.119 | 4.56 | |

| 30 | 0.110 | 0.049 | 0.151 | 6.84 | |

| 40 | 0.100 | 0.038 | Fracture | 9.12 | |

| 50 | 0.097 | 0.041 | - | 13.68 | |

| Zn-Fe (3) | 10 | - | - | - | 2.27 |

| 20 | 0.149 | 0.052 | 0.124 | 4.56 | |

| 30 | 0.120 | 0.053 | 0.148 | 6.84 | |

| 40 | 0.108 | 0.060 | Fracture | 9.12 | |

| 50 | 0.107 | 0.051 | - | 13.68 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Evin, E.; Tomáš, M. Influence of Friction on the Formability of Fe-Zn-Coated IF Steels for Car Body Parts. Lubricants 2022, 10, 297. https://doi.org/10.3390/lubricants10110297

Evin E, Tomáš M. Influence of Friction on the Formability of Fe-Zn-Coated IF Steels for Car Body Parts. Lubricants. 2022; 10(11):297. https://doi.org/10.3390/lubricants10110297

Chicago/Turabian StyleEvin, Emil, and Miroslav Tomáš. 2022. "Influence of Friction on the Formability of Fe-Zn-Coated IF Steels for Car Body Parts" Lubricants 10, no. 11: 297. https://doi.org/10.3390/lubricants10110297

APA StyleEvin, E., & Tomáš, M. (2022). Influence of Friction on the Formability of Fe-Zn-Coated IF Steels for Car Body Parts. Lubricants, 10(11), 297. https://doi.org/10.3390/lubricants10110297