Carbon Nanomaterial-Based Lubricants: Review of Recent Developments

Abstract

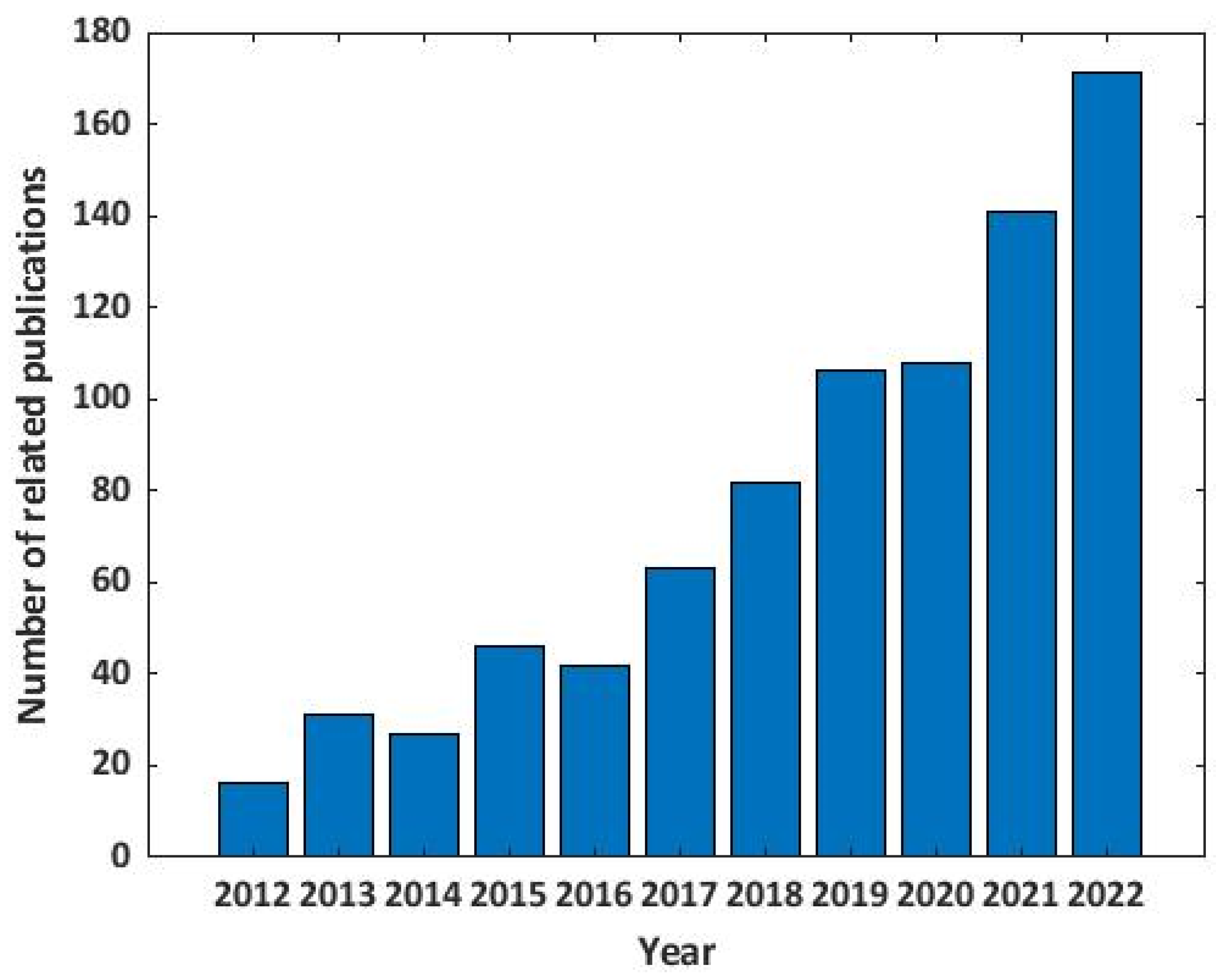

1. Introduction

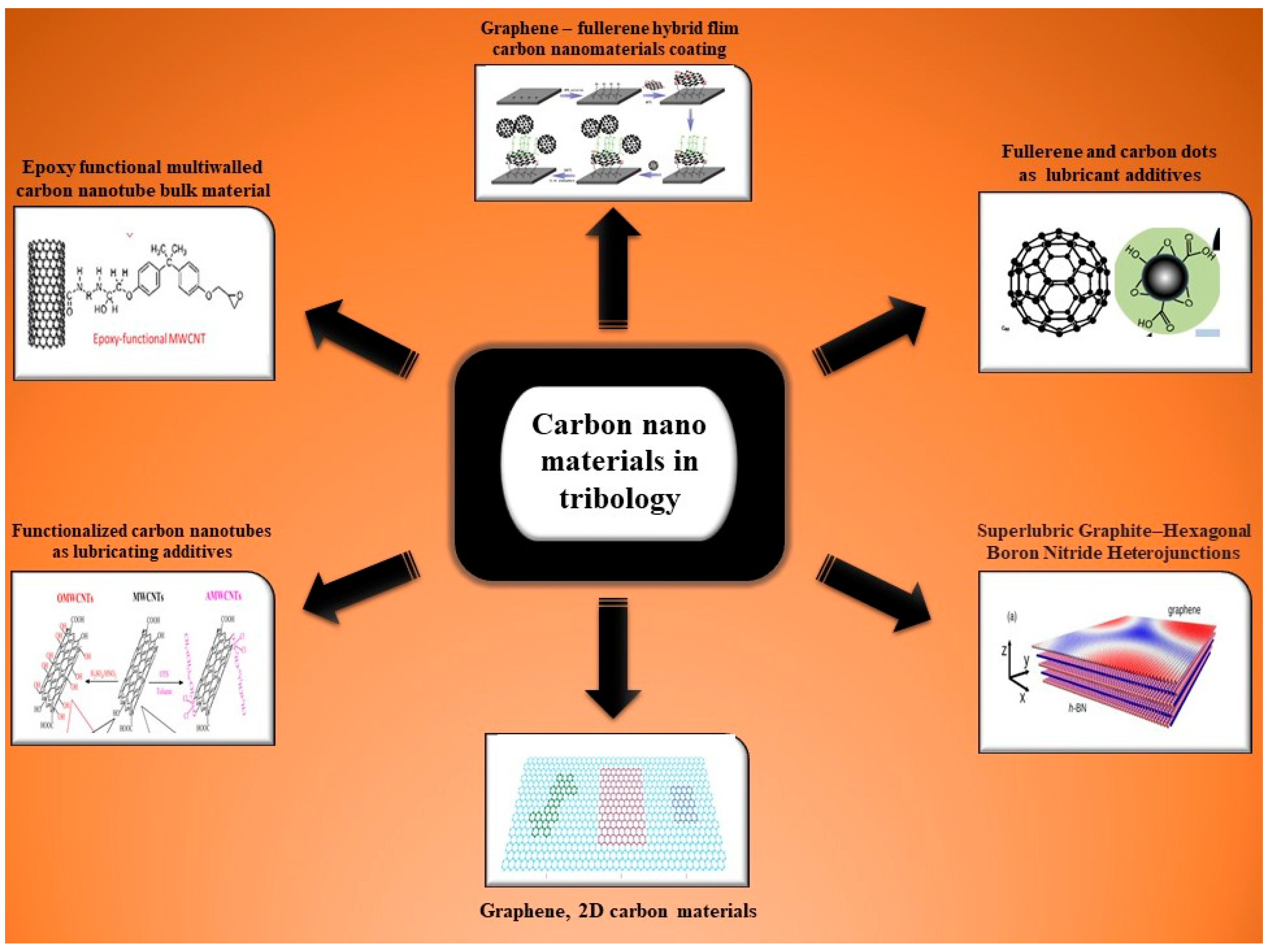

2. Lubricity Mechanism of Carbon Nanomaterials

3. Carbon Nanomaterials as a Solid Lubricant

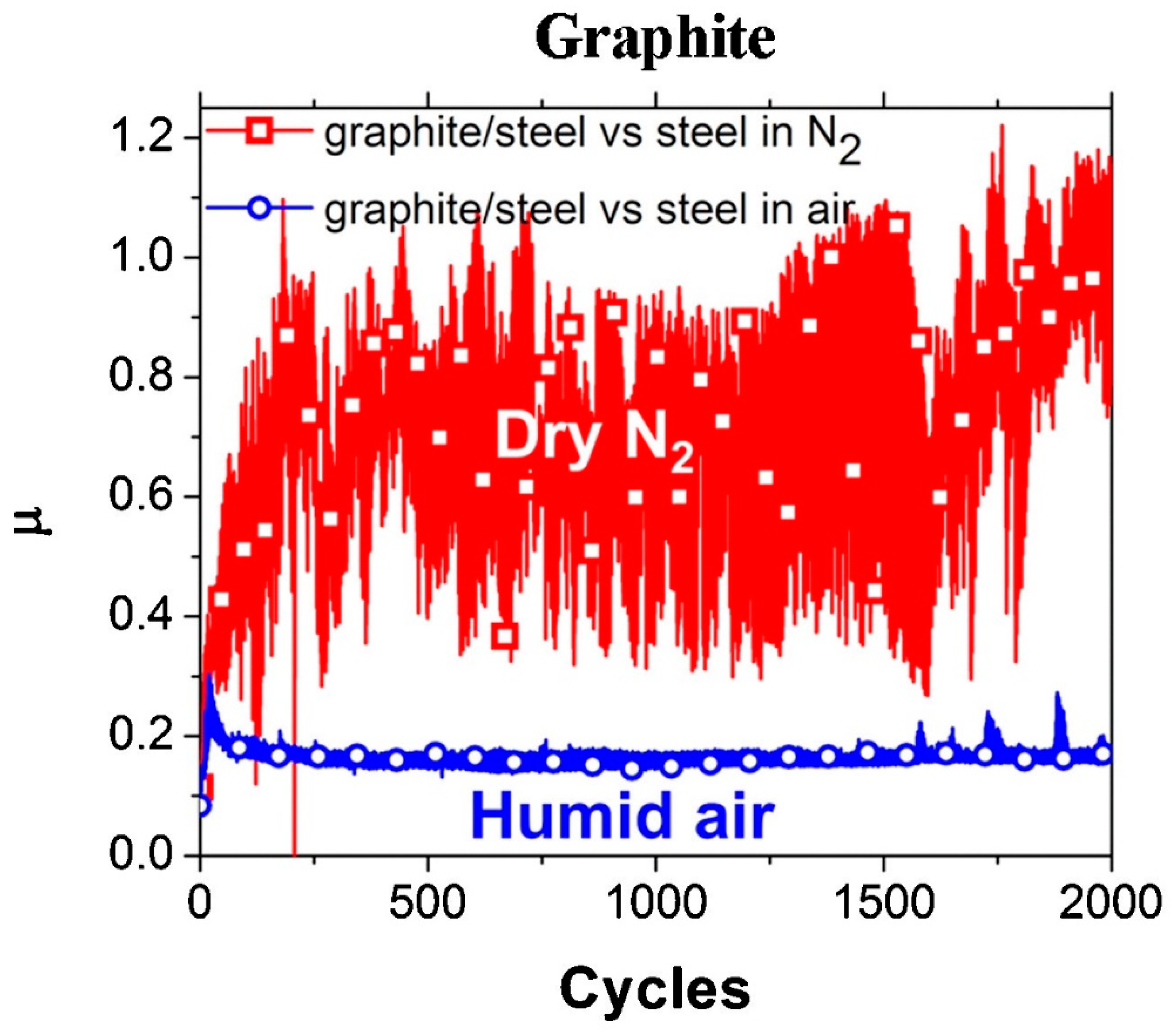

3.1. Graphite

3.2. Graphene

3.3. Graphene-Based Coatings

3.4. Diamond-like Carbon (DLC)-Based Coatings

4. Carbon Nanomaterials as Additives in Lubricants

4.1. Graphene as Lubricating Additives

4.2. Carbon Nanotubes (CNTs) as Lubricating Additives

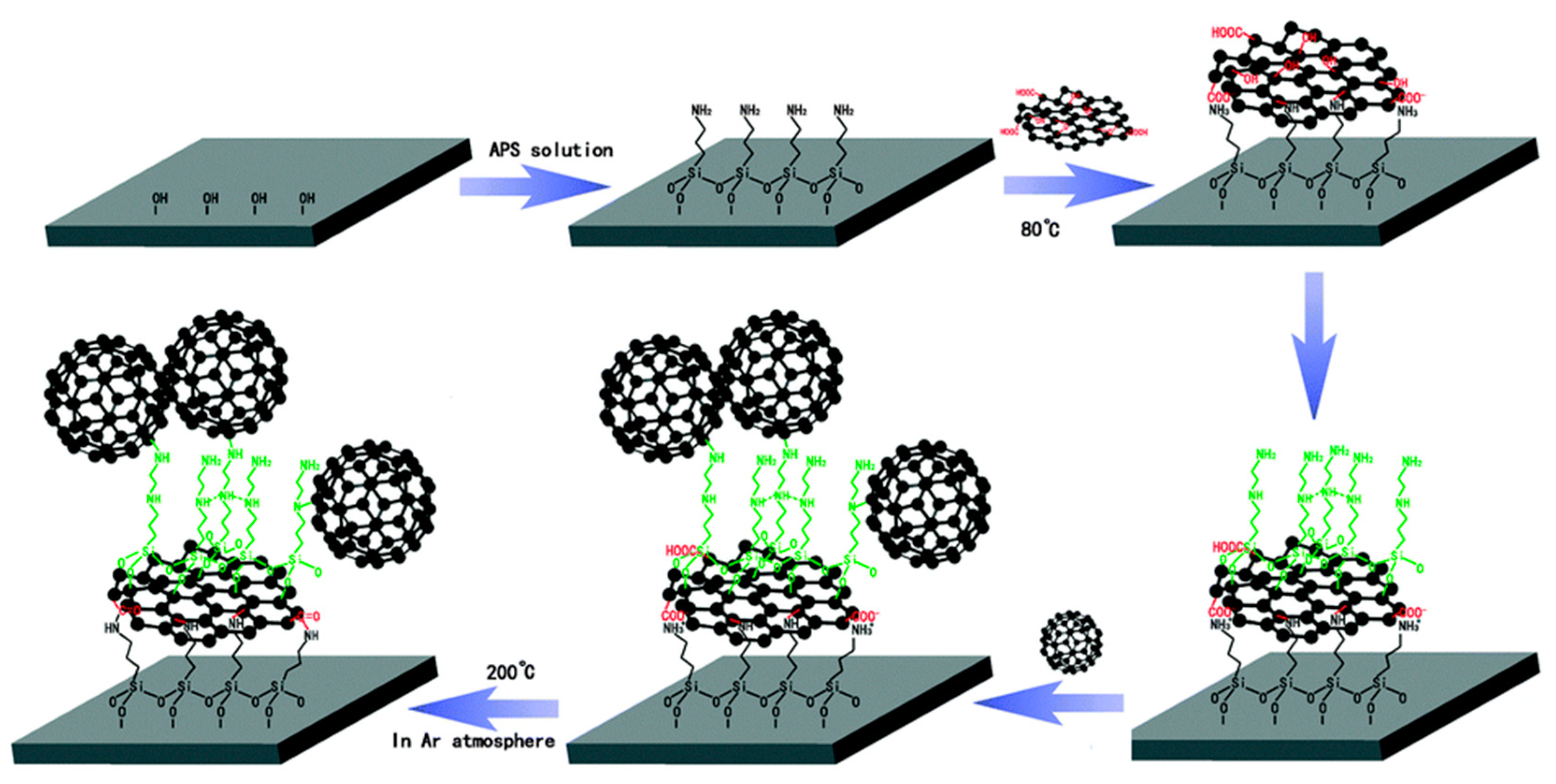

4.3. Fullerene as an Additive in Lubricant

4.4. Carbon Nanodiamonds as an Additive in Lubricant

4.5. Carbon Nano-Onions as an Additive in Lubricant

4.6. Carbon Nanohorns and Carbon Spheres as an Additive in Lubricant

5. Carbon Nanomaterial-Reinforced Bulk Material as Lubricants

5.1. Graphene Reinforced Bulk Material

5.2. Carbon Nanotube-Reinforced (CNTs) Bulk Material

5.3. Carbon Nanodiamonds as Bulk Material

6. Superlubricity of Carbon Nanomaterial(CNM)-Based Lubricants

6.1. Carbon Nanotubes (CNTs) in Superlubricity

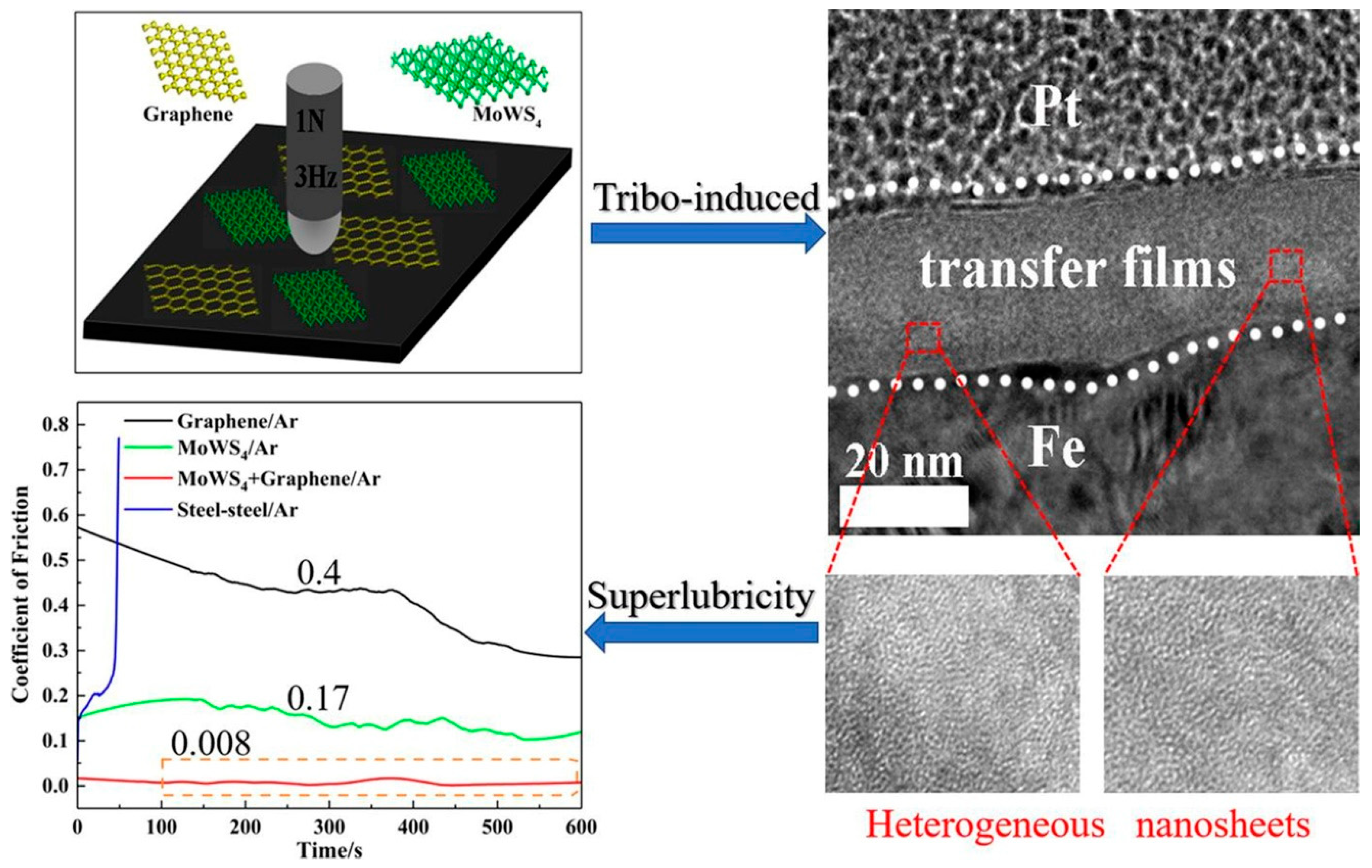

6.2. Graphene in Superlubricity

| CNM Lubricant | Experimental Method, Conditions | Friction Coefficient (µ) | Ref |

|---|---|---|---|

| C60 Fullerene | The friction coefficients obtained by linear fitting for all the cases are presented in C60 bearing system µ C60 (ϴ) and graphite system µ G (ϴ); friction coefficients of the C60 bearing and graphite systems for the scan directions ϴ = 0, 15 and 30; 10.27 nN. | µ = <0.001 | [233] |

| Carbon quantum dots | Rotating ball-on-disc tester. Steel and Al2O3 balls (u = 3 nm); 200 r min−1, 20 mN. | µ = 0.0066 | [217] |

| Nanodiamonds | CETR UMT-3 ball on disk test; 0.15 m s−1, 3 N; glycerol colloidal solution 30 wt%. | µ = 0.006 | [234] |

| Graphene | 0.5–3 N | µ = 0.004 | [2] |

| Bilayer graphene | The sliding force exhibits a fractal structure with distinct area correlations. Zero scaling of the sliding force is demonstrated for a geometric sequence of dodecagonal elements. | Sliding force: 10 pN | [229] |

| Graphene flake | Graphene flake sliding on a graphite substrate, using molecular dynamics test. 100–600 m s−1. | Sliding force: 0–4 nN | [235] |

| CNT | 1–10 nN/µm | Sliding force: 1.37–1.64 nN | [2] |

7. Conclusions and Outlook

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Manu, B.R.; Gupta, A.; Jayatissa, A.H. Tribological Properties of 2D Materials and Composites—A Review of Recent Advances. Materials 2021, 14, 1630. [Google Scholar] [CrossRef] [PubMed]

- Zhai, W.; Srikanth, N.; Kong, L.B.; Zhou, K. Carbon nanomaterials in tribology. Carbon 2017, 119, 150–171. [Google Scholar] [CrossRef]

- Mosey, N.J.; Muser, M.H.; Woo, T.K. Molecular mechanisms for the functionality of lubricant additives. Science 2005, 307, 1612–1615. [Google Scholar] [CrossRef]

- Senatore, A.; Hong, H.; D’Urso, V.; Younes, H. Tribological Behavior of Novel CNTs-Based Lubricant Grease in Steady-State and Fretting Sliding Conditions. Lubricants 2021, 9, 107. [Google Scholar] [CrossRef]

- Taylor, R.; Dixon, R.; Wayne, F.; Gunsel, S. Lubricants & energy efficiency: Life-cycle analysis. In Tribology and Interface Engineering Series; Elsevier: Amsterdam, The Netherlands, 2005; Volume 48, pp. 565–572. [Google Scholar]

- Persson, B.J.E.o.L. Lubrication. In History of Tribology; Springer: Berlin/Heidelberg, Germany, 2014; pp. 791–797. [Google Scholar]

- Sawyer, W.G. Leonardo da Vinci on Wear. Biotribology 2021, 26, 100160. [Google Scholar] [CrossRef]

- Agarwal, S. Lubricant, Engineering Chemistry_ Fundamentals and Applications, 2nd ed.; Cambridge University Press: Cambridge, UK, 2019. [Google Scholar]

- Rasheed, A.; Khalid, M.; Rashmi, W.; Gupta, T.; Chan, A. Graphene based nanofluids and nanolubricants–Review of recent developments. Renew. Sustain. Energy Rev. 2016, 63, 346–362. [Google Scholar] [CrossRef]

- Lutz Lindemann, D.T.R.; Ralph Rheinboldt, D.S. Fuchs Capital Markets Day 2022; Fuchs Petrolub SE: Mannheim, Germany, 2022. [Google Scholar]

- Holmberg, K.; Erdemir, A. Influence of tribology on global energy consumption, costs and emissions. Friction 2017, 5, 263–284. [Google Scholar] [CrossRef]

- Younes, H.; Hong, H.; Peterson, G. A novel approach to fabricate carbon nanomaterials–nanoparticle solids through aqueous solutions and their applications. Nanomanuf. Metrol. 2021, 4, 226–236. [Google Scholar] [CrossRef]

- Ku, B.-C.; Han, Y.-C.; Lee, J.-E.; Lee, J.-K.; Park, S.-H.; Hwang, Y.-J. Tribological effects of fullerene (C60) nanoparticles added in mineral lubricants according to its viscosity. Int. J. Precis. Eng. Manuf. 2010, 11, 607–611. [Google Scholar] [CrossRef]

- Kinoshita, H.; Nishina, Y.; Alias, A.A.; Fujii, M. Tribological properties of monolayer graphene oxide sheets as water-based lubricant additives. Carbon 2014, 66, 720–723. [Google Scholar] [CrossRef]

- Alves, S.M.; Mello, V.; Faria, E.; Camargo, A. Nanolubricants developed from tiny CuO nanoparticles. Tribol. Int. 2016, 100, 263–271. [Google Scholar] [CrossRef]

- Wang, J.; Wang, J.; Li, C.; Zhao, G.; Wang, X. A study of 2, 5-dimercapto-1, 3, 4-thiadiazole derivatives as multifunctional additives in water-based hydraulic fluid. Ind. Lubr. Tribol. 2014, 66, 402–410. [Google Scholar] [CrossRef]

- Rahman, M.M.; Younes, H.; Lu, J.Y.; Ni, G.; Yuan, S.; Fang, N.X.; Zhang, T.; Al Ghaferi, A. Broadband light absorption by silver nanoparticle decorated silica nanospheres. RSC Adv. 2016, 6, 107951–107959. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Graphene: A new emerging lubricant. Mater. Today 2014, 17, 31–42. [Google Scholar] [CrossRef]

- Gupta, B.; Kumar, N.; Panda, K.; Dash, S.; Tyagi, A. Energy efficient reduced graphene oxide additives: Mechanism of effective lubrication and antiwear properties. Sci. Rep. 2016, 6, 1–10. [Google Scholar] [CrossRef]

- Jansson, N. Carbon Nanostructures as Lubricant Additives; NTNU: Trondheim, Norway, 2021. [Google Scholar]

- Kumar, V.B.; Sahu, A.K.; Rao, K.B.S. Development of Doped Carbon Quantum Dot-Based Nanomaterials for Lubricant Additive Applications. Lubricants 2022, 10, 144. [Google Scholar] [CrossRef]

- Rahman, M.M.; Younes, H.; Ni, G.; Zhang, T.; Al Ghaferi, A. Synthesis and optical characterization of carbon nanotube arrays. Mater. Res. Bull. 2016, 77, 243–252. [Google Scholar] [CrossRef]

- Younes, H.; Al-Rub, R.A.; Rahman, M.M.; Dalaq, A.; Al Ghaferi, A.; Shah, T. Processing and property investigation of high-density carbon nanostructured papers with superior conductive and mechanical properties. Diam. Relat. Mater. 2016, 68, 109–117. [Google Scholar] [CrossRef]

- Younes, H.; Shoaib, N.; Rahman, M.M.; Al-Rub, R.A.; Hong, H.; Christensen, G.; Chen, H.; Younes, A.B.; Al Ghaferi, A. Thin carbon nanostructure mat with high electromagnetic interference shielding performance. Synth. Met. 2019, 253, 48–56. [Google Scholar] [CrossRef]

- Ali, I.; Kucherova, A.; Memetov, N.; Pasko, T.; Ovchinnikov, K.; Pershin, V.; Kuznetsov, D.; Galunin, E.; Grachev, V.; Tkachev, A. Advances in carbon nanomaterials as lubricants modifiers. J. Mol. Liq. 2019, 279, 251–266. [Google Scholar] [CrossRef]

- Grablander, T.; Christensen, G.; Bailey, C.; Lou, D.; Hong, H.; Younes, H. CPU Performance Improvement Using Novel Thermally Conductive Carbon Nano Grease. Lubricants 2022, 10, 172. [Google Scholar] [CrossRef]

- Bhushan, B.; Gupta, B.K.; Van Cleef, G.W.; Capp, C.; Coe, J.V. Fullerene (C60) Films for Solid Lubrication. Tribol. Trans. 1993, 36, 573–580. [Google Scholar] [CrossRef]

- Geim, A.K.; Novoselov, K.S. The rise of graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef] [PubMed]

- Kausar, A. Nanocarbon and macrocarbonaceous filler–reinforced epoxy/polyamide: A review. J. Thermoplast. Compos. Mater. 2020. [Google Scholar] [CrossRef]

- Tang, J.; Chen, S.; Jia, Y.; Ma, Y.; Xie, H.; Quan, X.; Ding, Q. Carbon dots as an additive for improving performance in water-based lubricants for amorphous carbon (a-C) coatings. Carbon 2020, 156, 272–281. [Google Scholar] [CrossRef]

- Ye, X.; Songfeng, E.; Fan, M. The influences of functionalized carbon nanotubes as lubricating additives: Length and diameter. Diam. Relat. Mater. 2019, 100, 107548. [Google Scholar] [CrossRef]

- Pu, J.; Mo, Y.; Wan, S.; Wang, L. Fabrication of novel graphene–fullerene hybrid lubricating films based on self-assembly for MEMS applications. Chem. Commun. 2014, 50, 469–471. [Google Scholar] [CrossRef]

- Martin, J.M.; Ohmae, N. Nanolubricants; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Rudnick, L.R. Lubricant Additives: Chemistry and Applications; CRC press: Boca Raton, FL, USA, 2009. [Google Scholar]

- Morstein, C.; Dienwiebel, M. Graphite lubrication mechanisms under high mechanical load. Wear 2021, 477, 203794. [Google Scholar] [CrossRef]

- Kroto, H.W.; Heath, J.R.; O’Brien, S.C.; Curl, R.F.; Smalley, R.E. C60: Buckminsterfullerene. Nature 1985, 318, 162–163. [Google Scholar] [CrossRef]

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Ugarte, D. Curling and closure of graphitic networks under electron-beam irradiation. Nature 1992, 359, 707–709. [Google Scholar] [CrossRef] [PubMed]

- Shenderova, O.; Vargas, A.; Turner, S.; Ivanov, D.; Ivanov, M. Nanodiamond-based nanolubricants: Investigation of friction surfaces. Tribol. Trans. 2014, 57, 1051–1057. [Google Scholar] [CrossRef]

- Ivanov, M.; Ivanov, D.; Pavlyshko, S.; Petrov, I.; Vargas, A.; McGuire, G.; Shenderova, O.J.F.; Nanotubes; Nanostructures, C. Nanodiamond-based nanolubricants. Curr. Opin. Solid State Mater. Sci. 2012, 20, 606–610. [Google Scholar] [CrossRef]

- Yin, X.; Jin, J.; Chen, X.; Rosenkranz, A.; Luo, J. Interfacial nanostructure of 2D Ti3C2/graphene quantum dots hybrid multicoating for ultralow wear. Adv. Eng. Mater. 2020, 22, 1901369. [Google Scholar] [CrossRef]

- Rahman, M.; Younes, H.; Subramanian, N.; Al Ghaferi, A. Optimizing the dispersion conditions of SWCNTs in aqueous solution of surfactants and organic solvents. J. Nanomater. 2014, 2014, 145. [Google Scholar] [CrossRef]

- Shah, S.; Chiou, Y.-C.; Lai, C.Y.; Apostoleris, H.; Rahman, M.M.; Younes, H.; Almansouri, I.; Al Ghaferi, A.; Chiesa, M. Impact of short duration, high-flow H2 annealing on graphene synthesis and surface morphology with high spatial resolution assessment of coverage. Carbon 2017, 125, 318–326. [Google Scholar] [CrossRef]

- Azman, S.S.N.; Zulkifli, N.W.M.; Masjuki, H.; Gulzar, M.; Zahid, R. Study of tribological properties of lubricating oil blend added with graphene nanoplatelets. J. Mater. Res. 2016, 31, 1932–1938. [Google Scholar] [CrossRef]

- Xiao, H.; Liu, S. 2D nanomaterials as lubricant additive: A review. Mater. Des. 2017, 135, 319–332. [Google Scholar] [CrossRef]

- Bhowmick, S.; Banerji, A.; Alpas, A.T. Role of humidity in reducing sliding friction of multilayered graphene. Carbon 2015, 87, 374–384. [Google Scholar] [CrossRef]

- Rahman, M.M.; Raza, A.; Younes, H.; AlGhaferi, A.; Chiesa, M.; Lu, J. Hybrid graphene metasurface for near-infrared absorbers. Opt. Express 2019, 27, 24866–24876. [Google Scholar] [CrossRef]

- Sun, J.; Du, S. Application of graphene derivatives and their nanocomposites in tribology and lubrication: A review. RSC Adv. 2019, 9, 40642–40661. [Google Scholar] [CrossRef] [PubMed]

- Klemenz, A.; Pastewka, L.; Balakrishna, S.G.; Caron, A.; Bennewitz, R.; Moseler, M. Atomic Scale Mechanisms of Friction Reduction and Wear Protection by Graphene. Nano Lett. 2014, 14, 7145–7152. [Google Scholar] [CrossRef] [PubMed]

- Lei, Y.; Yan, Y.; Lv, J. Atomistic study of the strengthening mechanisms of graphene coated aluminum. Nanotechnology 2019, 31, 055708. [Google Scholar] [CrossRef] [PubMed]

- Peng, W.; Sun, K.; Abdullah, R.; Zhang, M.; Chen, J.; Shi, J. Strengthening mechanisms of graphene coatings on Cu film under nanoindentation: A molecular dynamics simulation. Appl. Surf. Sci. 2019, 487, 22–31. [Google Scholar] [CrossRef]

- Zhao, Y.; Peng, X.; Fu, T.; Zhu, X.; Hu, N.; Yan, C. Strengthening mechanisms of graphene coated copper under nanoindentation. Comput. Mater. Sci. 2018, 144, 42–49. [Google Scholar] [CrossRef]

- Chen, W.; Yu, Y.; Cheng, J.; Wang, S.; Zhu, S.; Liu, W.; Yang, J. Microstructure, Mechanical Properties and Dry Sliding Wear Behavior of Cu-Al2O3-Graphite Solid-Lubricating Coatings Deposited by Low-Pressure Cold Spraying. J. Therm. Spray Technol. 2018, 27, 1652–1663. [Google Scholar] [CrossRef]

- Kim, K.-S.; Lee, H.-J.; Lee, C.; Lee, S.-K.; Jang, H.; Ahn, J.-H.; Kim, J.-H.; Lee, H.-J. Chemical vapor deposition-grown graphene: The thinnest solid lubricant. ACS Nano 2011, 5, 5107–5114. [Google Scholar] [CrossRef]

- Algul, H.; Tokur, M.; Ozcan, S.; Uysal, M.; Cetinkaya, T.; Akbulut, H.; Alp, A. The effect of graphene content and sliding speed on the wear mechanism of nickel–graphene nanocomposites. Appl. Surf. Sci. 2015, 359, 340–348. [Google Scholar] [CrossRef]

- Liang, H.; Bu, Y.; Zhang, J. Graphene Oxide Film as Solid Lubricant. ACS Appl. Mater. Interfaces 2013, 5, 6369–6375. [Google Scholar] [CrossRef]

- Jiang, B.; Zhao, Z.; Gong, Z.; Wang, D.; Yu, G.; Zhang, J. Superlubricity of metal-metal interface enabled by graphene and MoWS4 nanosheets. Appl. Surf. Sci. 2020, 520, 146303. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Graphene as a protective coating and superior lubricant for electrical contacts. Appl. Phys. Lett. 2014, 105, 231907. [Google Scholar] [CrossRef]

- Lang, H.; Xu, Y.; Zhu, P.; Peng, Y.; Zou, K.; Yu, K.; Huang, Y. Superior lubrication and electrical stability of graphene as highly effective solid lubricant at sliding electrical contact interface. Carbon 2021, 183, 53–61. [Google Scholar] [CrossRef]

- Qi, S.; Wei, X.; Chen, L.; Geng, Z.; Luo, J.; Lu, Z.; Zhang, G. 3D graphene/hexagonal boron nitride composite nanomaterials synergistically reduce the friction and wear of Steel-DLC contacts. Nano Sel. 2021, 2, 791–801. [Google Scholar] [CrossRef]

- Donnet, C.; Grill, A. Friction control of diamond-like carbon coatings. Surf. Coat. Technol. 1997, 94-95, 456–462. [Google Scholar] [CrossRef]

- Bryant, P.; Gutshall, P.; Taylor, L. A study of mechanisms of graphite friction and wear. Wear 1964, 7, 118–126. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Reduced wear and friction enabled by graphene layers on sliding steel surfaces in dry nitrogen. Carbon 2013, 59, 167–175. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Few layer graphene to reduce wear and friction on sliding steel surfaces. Carbon 2013, 54, 454–459. [Google Scholar] [CrossRef]

- Menezes, P.L.; Reeves, C.J.; Rohatgi, P.K.; Lovell, M.R. Self-Lubricating Behavior of Graphite-Reinforced Composites. In Tribology for Scientists and Engineers: From Basics to Advanced Concepts; Menezes, P.L., Nosonovsky, M., Ingole, S.P., Kailas, S.V., Lovell, M.R., Eds.; Springer: New York, NY, USA, 2013; pp. 341–389. [Google Scholar] [CrossRef]

- Menezes, P.L.; Rohatgi, P.K.; Lovell, M.R. Self-Lubricating Behavior of Graphite Reinforced Metal Matrix Composites. In Green Tribology: Biomimetics, Energy Conservation and Sustainability; Nosonovsky, M., Bhushan, B., Eds.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 445–480. [Google Scholar] [CrossRef]

- Omrani, E.; Moghadam, A.D.; Menezes, P.L.; Rohatgi, P.K. Influences of graphite reinforcement on the tribological properties of self-lubricating aluminum matrix composites for green tribology, sustainability, and energy efficiency—A review. Int. J. Adv. Manuf. Technol. 2016, 83, 325–346. [Google Scholar] [CrossRef]

- Ravindran, P.; Manisekar, K.; Narayanasamy, R.; Narayanasamy, P. Tribological behaviour of powder metallurgy-processed aluminium hybrid composites with the addition of graphite solid lubricant. Ceram. Int. 2013, 39, 1169–1182. [Google Scholar] [CrossRef]

- Spreadborough, J. The frictional behaviour of graphite. Wear 1962, 5, 18–30. [Google Scholar] [CrossRef]

- Bollmann, W.; Spreadborough, J. Action of graphite as a lubricant. Nature 1960, 186, 29–30. [Google Scholar] [CrossRef]

- Sánchez Egea, A.J.; Martynenko, V.; Abate, G.; Deferrari, N.; Martinez Krahmer, D.; López de Lacalle, L.N. Friction capabilities of graphite-based lubricants at room and over 1400 K temperatures. Int. J. Adv. Manuf. Technol. 2019, 102, 1623–1633. [Google Scholar] [CrossRef]

- Fasihi, P.; Kendall, O.; Abrahams, R.; Mutton, P.; Lai, Q.; Qiu, C.; Yan, W. Effect of graphite and MoS2 based solid lubricants for application at wheel-rail interface on the wear mechanism and surface morphology of hypereutectoid rails. Tribol. Int. 2021, 157, 106886. [Google Scholar] [CrossRef]

- Su, Y.; Gong, L.; Chen, D. An investigation on tribological properties and lubrication mechanism of graphite nanoparticles as vegetable based oil additive. J. Nanomater. 2015, 2015, 203. [Google Scholar] [CrossRef]

- Hod, O.; Meyer, E.; Zheng, Q.; Urbakh, M. Structural superlubricity and ultralow friction across the length scales. Nature 2018, 563, 485–492. [Google Scholar] [CrossRef]

- Martin, D.; Gertjan, S.V.; Namboodiri, P.; Joost, W.; Jennifer, A.H.; Henny, W.Z. Superlubricity of graphite. Phys. Rev. Lett. 2004, 92, 126101. [Google Scholar]

- El Mansori, M.; Schmitt, M.; Paulmier, D.J.S.; Technology, C. Role of transferred layers in friction and wear for magnetized dry frictional applications. Surf. Coat. Technol. 1998, 108, 479–483. [Google Scholar] [CrossRef]

- Li, J.; Ge, X.; Luo, J. Random occurrence of macroscale superlubricity of graphite enabled by tribo-transfer of multilayer graphene nanoflakes. Carbon 2018, 138, 154–160. [Google Scholar] [CrossRef]

- Merkle, A.; Marks, L. Friction in full view. Appl. Phys. Lett. 2007, 90, 064101. [Google Scholar] [CrossRef]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the Elastic Properties and Intrinsic Strength of Monolayer Graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef]

- Muley, S.V.; Ravindra, N.M. Thermoelectric Properties of Pristine and Doped Graphene Nanosheets and Graphene Nanoribbons: Part I. JOM 2016, 68, 1653–1659. [Google Scholar] [CrossRef]

- Suk, J.W.; Piner, R.D.; An, J.; Ruoff, R.S. Mechanical Properties of Monolayer Graphene Oxide. ACS Nano 2010, 4, 6557–6564. [Google Scholar] [CrossRef] [PubMed]

- Xiong, G.; Meng, C.; Reifenberger, R.G.; Irazoqui, P.P.; Fisher, T.S. A Review of Graphene-Based Electrochemical Microsupercapacitors. Electroanalysis 2014, 26, 30–51. [Google Scholar] [CrossRef]

- Torres, T. Graphene chemistry. Chem. Soc. Rev. 2017, 46, 4385–4386. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Shen, B.; Zhang, F.; Hong, H.; Pan, J. Mussel-Inspired Graphene Film with Enhanced Durability as a Macroscale Solid Lubricant. ACS Appl. Mater Interfaces 2019, 11, 31386–31392. [Google Scholar] [CrossRef]

- Chen, Z.; Kim, S.H. Measuring nanoscale friction at graphene step edges. Friction 2019, 8, 802–811. [Google Scholar] [CrossRef]

- Fan, X.; Xue, Q.; Wang, L. Carbon-based solid-liquid lubricating coatings for space applications—A review. Friction 2015, 3, 191–207. [Google Scholar] [CrossRef]

- He, X.; Bai, Q.; Shen, R. Atomistic perspective of how graphene protects metal substrate from surface damage in rough contacts. Carbon 2018, 130, 672–679. [Google Scholar] [CrossRef]

- Kim, H.J.; Kim, D.E. Water Lubrication of Stainless Steel using Reduced Graphene Oxide Coating. Sci. Rep. 2015, 5, 17034. [Google Scholar] [CrossRef]

- Liu, Y.; Ge, X.; Li, J. Graphene lubrication. Appl. Mater. Today 2020, 20. [Google Scholar] [CrossRef]

- Robert, F. Investigation on Graphene-Coated Silver-Palladium Microelectrical Contact and Effect of Coating Thickness. IEEE Trans. Compon. Packag. Manuf. Technol. 2020, 10, 1821–1828. [Google Scholar] [CrossRef]

- Robert, F.; Sharma, A.; Katare, H.; Fredo, A.R.J. Investigation of graphene as a material for electrical contacts in the application of microrelays using finite element modeling. Mater. Res. Express 2019, 6, 094008. [Google Scholar] [CrossRef]

- Sarath, P.S.; Moni, G.; George, J.J.; Haponiuk, J.T.; Thomas, S.; George, S.C. A study on the influence of reduced graphene oxide on the mechanical, dynamic mechanical and tribological properties of silicone rubber nanocomposites. J. Compos. Mater. 2020, 55, 2011–2024. [Google Scholar] [CrossRef]

- Xu, J.; Luo, T.; Chen, X.; Zhang, C.; Luo, J. Nanostructured tribolayer-dependent lubricity of graphene and modified graphene nanoflakes on sliding steel surfaces in humid air. Tribol. Int. 2020, 145, 106203. [Google Scholar] [CrossRef]

- Kwon, S.; Ko, J.-H.; Jeon, K.-J.; Kim, Y.-H.; Park, J.Y. Enhanced Nanoscale Friction on Fluorinated Graphene. Nano Lett. 2012, 12, 6043–6048. [Google Scholar] [CrossRef]

- Choi, J.S.; Kim, J.-S.; Byun, I.-S.; Lee, D.H.; Lee, M.J.; Park, B.H.; Lee, C.; Yoon, D.; Cheong, H.; Lee, K.H.; et al. Friction anisotropy-driven domain imaging on exfoliated monolayer graphene. Science 2011, 333, 607–610. [Google Scholar] [CrossRef] [PubMed]

- Balog, R.; Jørgensen, B.; Nilsson, L.; Andersen, M.; Rienks, E.; Bianchi, M.; Fanetti, M.; Lægsgaard, E.; Baraldi, A.; Lizzit, S.; et al. Bandgap opening in graphene induced by patterned hydrogen adsorption. Nat. Mater. 2010, 9, 315–319. [Google Scholar] [CrossRef]

- Elias, D.C.; Nair, R.R.; Mohiuddin, T.M.G.; Morozov, S.V.; Blake, P.; Halsall, M.P.; Ferrari, A.C.; Boukhvalov, D.W.; Katsnelson, M.I.; Geim, A.K.; et al. Control of Graphene’s Properties by Reversible Hydrogenation: Evidence for Graphane. Science 2009, 323, 610–613. [Google Scholar] [CrossRef]

- Berman, D.; Deshmukh, S.A.; Sankaranarayanan, S.K.R.S.; Erdemir, A.; Sumant, A.V. Extraordinary Macroscale Wear Resistance of One Atom Thick Graphene Layer. Adv. Funct. Mater. 2014, 24, 6640–6646. [Google Scholar] [CrossRef]

- Filleter, T.; McChesney, J.L.; Bostwick, A.; Rotenberg, E.; Emtsev, K.V.; Seyller, T.; Horn, K.; Bennewitz, R. Friction and Dissipation in Epitaxial Graphene Films. Phys. Rev. Lett. 2009, 102, 086102. [Google Scholar] [CrossRef]

- Bhowmick, S.; Banerji, A.; Alpas, A.T. Friction reduction mechanisms in multilayer graphene sliding against hydrogenated diamond-like carbon. Carbon 2016, 109, 795–804. [Google Scholar] [CrossRef]

- Cho, D.-H.; Wang, L.; Kim, J.-S.; Lee, G.-H.; Kim, E.S.; Lee, S.; Lee, S.Y.; Hone, J.; Lee, C. Effect of surface morphology on friction of graphene on various substrates. Nanoscale 2013, 5, 3063–3069. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.; Li, Q.; Kalb, W.; Liu, X.-Z.; Berger, H.; Carpick, R.W.; Hone, J. Frictional Characteristics of Atomically Thin Sheets. Science 2010, 328, 76–80. [Google Scholar] [CrossRef]

- Lee, H.; Lee, N.; Seo, Y.; Eom, J.; Lee, S. Comparison of frictional forces on graphene and graphite. Nanotechnology 2009, 20, 325701. [Google Scholar] [CrossRef] [PubMed]

- Yeldose, B.C.; Ramamoorthy, B. Characterization of DC magnetron sputtered diamond-like carbon (DLC) nano coating. Int. J. Adv. Manuf. Technol. 2008, 38, 705–717. [Google Scholar] [CrossRef]

- De Barros Bouchet, M.I.; Martin, J.M.; Avila, J.; Kano, M.; Yoshida, K.; Tsuruda, T.; Bai, S.; Higuchi, Y.; Ozawa, N.; Kubo, M.; et al. Diamond-like carbon coating under oleic acid lubrication: Evidence for graphene oxide formation in superlow friction. Sci. Rep. 2017, 7, 46394. [Google Scholar] [CrossRef]

- Dolmatov, V.; Fujimura, T.; Burkat, G.; Orlova, E. Preparation of Wear-Resistant Chromium Coatings Using Different Types of Nanodiamonds. Powder Metall. Met. Ceram. 2003, 42, 587–591. [Google Scholar] [CrossRef]

- Kim, H.-S.; Park, J.-W.; Park, S.-M.; Lee, J.-S.; Lee, Y.-Z. Tribological characteristics of paraffin liquid with nanodiamond based on the scuffing life and wear amount. Wear 2013, 301, 763–767. [Google Scholar] [CrossRef]

- Kim, S.-T.; Woo, J.-Y.; Lee, Y.-Z. Friction, Wear, and Scuffing Characteristics of Marine Engine Lubricants with Nanodiamond Particles. Tribol. Trans. 2016, 59, 1098–1103. [Google Scholar] [CrossRef]

- Koumoulos, E.P.; Jagadale, P.; Lorenzi, A.; Tagliaferro, A.; Charitidis, C.A. Evaluation of surface properties of epoxy–nanodiamonds composites. Compos. Part B Eng. 2015, 80, 27–36. [Google Scholar] [CrossRef]

- Marko, M.; Kyle, J.; Branson, B.; Terrell, E. Tribological Improvements of Dispersed Nanodiamond Additives in Lubricating Mineral Oil. J. Tribol. 2014, 137, 011802. [Google Scholar] [CrossRef]

- Novak, C.; Kingman, D.; Stern, K.; Zou, Q.; Gara, L. Tribological Properties of Paraffinic Oil with Nanodiamond Particles. Tribol. Trans. 2014, 57, 831–837. [Google Scholar] [CrossRef]

- Shirvani, K.A.; Mosleh, M.; Smith, S.T. Nanopolishing by colloidal nanodiamond in elastohydrodynamic lubrication. J. Nanoparticle Res. 2016, 18, 248. [Google Scholar] [CrossRef]

- Grill, A. Diamond-like carbon: State of the art. Diam. Relat. Mater. 1999, 8, 428–434. [Google Scholar] [CrossRef]

- Robertson, J. Diamond-like amorphous carbon. Mater. Sci. Eng. R Rep. 2002, 37, 129–281. [Google Scholar] [CrossRef]

- Vetter, J.D.-I. 60 years of DLC coatings: Historical highlights and technical review of cathodic arc processes to synthesize various DLC types, and their evolution for industrial applications. Surf. Coat. Technol. 2014, 257, 213–240. [Google Scholar] [CrossRef]

- Zhou, Y.; Ma, W.; Geng, J.; Wang, Q.; Rao, L.; Qian, Z.; Xing, X.; Yang, Q. Exploring long-run reciprocating Wear of diamond-like carbon coatings: Microstructural, morphological and tribological evolution. Surf. Coat. Technol. 2021, 405, 126581. [Google Scholar] [CrossRef]

- Wang, F.; Shang, L.; Zhang, G.; Wang, Z. Polyethylene glycol derived carbon quantum dots nanofluids: An excellent lubricant for diamond-like carbon film/bearing steel contact. Friction 2022, 10, 1393–1404. [Google Scholar] [CrossRef]

- Andersson, J.; Erck, R.A.; Erdemir, A. Friction of diamond-like carbon films in different atmospheres. Wear 2003, 254, 1070–1075. [Google Scholar] [CrossRef]

- Erdemir, A. The role of hydrogen in tribological properties of diamond-like carbon films. Surf. Coat. Technol. 2001, 146–147, 292–297. [Google Scholar] [CrossRef]

- Eryilmaz, O.L.; Erdemir, A. Surface analytical investigation of nearly-frictionless carbon films after tests in dry and humid nitrogen. Surf. Coat. Technol. 2007, 201, 7401–7407. [Google Scholar] [CrossRef]

- Kim, H.I.; Lince, J.R.; Eryilmaz, O.L.; Erdemir, A. Environmental effects on the friction of hydrogenated DLC films. Tribol. Lett. 2006, 21, 51–56. [Google Scholar] [CrossRef]

- Andersson, J.; Erck, R.A.; Erdemir, A. Frictional behavior of diamondlike carbon films in vacuum and under varying water vapor pressure. Surf. Coat. Technol. 2003, 163–164, 535–540. [Google Scholar] [CrossRef]

- Sniderman, D.J.T.; Technology, L. The chemistry and function of lubricant additives. Tribol. Lubr. Technol. 2017, 73, 18–29. [Google Scholar]

- Zhao, J.; Li, Y.; He, Y.; Luo, J. In situ green synthesis of the new sandwichlike nanostructure of Mn3O4/graphene as lubricant additives. ACS Appl. Mater. Interfaces 2019, 11, 36931–36938. [Google Scholar] [CrossRef]

- Paul, G.; Hirani, H.; Kuila, T.; Murmu, N.C. Nanolubricants dispersed with graphene and its derivatives: An assessment and review of the tribological performance. Nanoscale 2019, 11, 3458–3483. [Google Scholar] [CrossRef]

- Zin, V.; Agresti, F.; Barison, S.; Colla, L.; Fabrizio, M. Influence of Cu, TiO2 nanoparticles and carbon nano-horns on tribological properties of engine oil. J. Nanosci. Nanotechnol. 2015, 15, 3590–3598. [Google Scholar] [CrossRef]

- Wu, P.; Chen, X.; Zhang, C.; Zhang, J.; Luo, J.; Zhang, J. Modified graphene as novel lubricating additive with high dispersion stability in oil. Friction 2021, 9, 143–154. [Google Scholar] [CrossRef]

- Elomaa, O.; Singh, V.K.; Iyer, A.; Hakala, T.J.; Koskinen, J. Graphene oxide in water lubrication on diamond-like carbon vs. stainless steel high-load contacts. Diam. Relat. Mater. 2015, 52, 43–48. [Google Scholar] [CrossRef]

- Liang, S.; Shen, Z.; Yi, M.; Liu, L.; Zhang, X.; Ma, S. In-situ exfoliated graphene for high-performance water-based lubricants. Carbon 2016, 96, 1181–1190. [Google Scholar] [CrossRef]

- Wu, P.; Chen, X.; Zhang, C.; Luo, J. Synergistic tribological behaviors of graphene oxide and nanodiamond as lubricating additives in water. Tribol. Int. 2019, 132, 177–184. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, Y.; Yin, Z.; Su, Y.; Zhang, Y.; Cao, J. Experimental research on tribological properties of liquid phase exfoliated graphene as an additive in SAE 10W-30 lubricating oil. Tribol. Int. 2019, 135, 29–37. [Google Scholar] [CrossRef]

- Xu, Y.; Peng, Y.; Dearn, K.D.; Zheng, X.; Yao, L.; Hu, X. Synergistic lubricating behaviors of graphene and MoS2 dispersed in esterified bio-oil for steel/steel contact. Wear 2015, 342–343, 297–309. [Google Scholar] [CrossRef]

- Zhao, S.; Niu, M.; Peng, P.; Cheng, Y.; Zhao, Y. Edge Oleylaminated Graphene as Ultra-Stable Lubricant Additive for Friction and Wear Reduction. Eng. Sci. 2020, 9, 77–83. [Google Scholar] [CrossRef]

- Liu, X.; Chen, Y. Synthesis of polyethylene glycol modified carbon dots as a kind of excellent water-based lubricant additives. Fuller. Nanotub. Carbon Nanostruct. 2019, 27, 400–409. [Google Scholar] [CrossRef]

- Vardhaman, B.S.A.; Amarnath, M.; Ramkumar, J.; Mondal, K. Enhanced tribological performances of zinc oxide/MWCNTs hybrid nanomaterials as the effective lubricant additive in engine oil. Mater. Chem. Phys. 2020, 253, 123447. [Google Scholar] [CrossRef]

- Zhao, J.; Mao, J.; Li, Y.; He, Y.; Luo, J. Friction-induced nano-structural evolution of graphene as a lubrication additive. Appl. Surf. Sci. 2018, 434, 21–27. [Google Scholar] [CrossRef]

- Mao, J.; Zhao, J.; Wang, W.; He, Y.; Luo, J. Influence of the micromorphology of reduced graphene oxide sheets on lubrication properties as a lubrication additive. Tribol. Int. 2018, 119, 614–621. [Google Scholar] [CrossRef]

- Gan, C.; Liang, T.; Li, W.; Fan, X.; Li, X.; Li, D.; Zhu, M. Hydroxyl-terminated ionic liquids functionalized graphene oxide with good dispersion and lubrication function. Tribol. Int. 2020, 148, 106350. [Google Scholar] [CrossRef]

- Mao, J.; Chen, G.; Zhao, J.; He, Y.; Luo, J. An investigation on the tribological behaviors of steel/copper and steel/steel friction pairs via lubrication with a graphene additive. Friction 2020, 9, 228–238. [Google Scholar] [CrossRef]

- Wu, L.; Gu, L.; Jian, R. Lubrication mechanism of graphene nanoplates as oil additives for ceramics/steel sliding components. Ceram. Int. 2021, 47, 16935–16942. [Google Scholar] [CrossRef]

- Kogovšek, J.; Kalin, M. Lubrication performance of graphene-containing oil on steel and DLC-coated surfaces. Tribol. Int. 2019, 138, 59–67. [Google Scholar] [CrossRef]

- Alqahtani, B.; Hoziefa, W.; Abdel Moneam, H.M.; Hamoud, M.; Salunkhe, S.; Elshalakany, A.B.; Abdel-Mottaleb, M.; Davim, J.P. Tribological Performance and Rheological Properties of Engine Oil with Graphene Nano-Additives. Lubricants 2022, 10, 137. [Google Scholar] [CrossRef]

- Mistry, K.K.; Pol, V.G.; Thackeray, M.M.; Wen, J.; Miller, D.J.; Erdemir, A. Synthesis and Tribology of Micro-Carbon Sphere Additives for Enhanced Lubrication. Tribol. Trans. 2015, 58, 474–480. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, J.; Tang, C.; He, Y.; Wang, Y.; Chen, J.; Mao, J.; Zhou, Q.; Wang, B.; Wei, F.; et al. Highly Exfoliated Reduced Graphite Oxide Powders as Efficient Lubricant Oil Additives. Adv. Mater. Interfaces 2016, 3, 1600700. [Google Scholar] [CrossRef]

- Omrani, E.; Menezes, P.; Rohatgi, P. Effect of Micro- and Nano-Sized Carbonous Solid Lubricants as Oil Additives in Nanofluid on Tribological Properties. Lubricants 2019, 7, 25. [Google Scholar] [CrossRef]

- Lv, X.; Cao, L.; Yang, T.; Wan, Y.; Gao, J. Lubricating behavior of Submicrometer carbon spheres as lubricant additives. Part. Sci. Technol. 2020, 38, 568–572. [Google Scholar] [CrossRef]

- Liu, B.; Li, H.J.F.; Nanotubes; Nanostructures, C. Alkylated fullerene as lubricant additive in paraffin oil for steel/steel contacts. Fuller. Nanotub. Carbon Nanostruct. 2016, 24, 712–719. [Google Scholar] [CrossRef]

- Lee, J.; Cho, S.; Hwang, Y.; Lee, C.; Kim, S.H. Enhancement of Lubrication Properties of Nano-oil by Controlling the Amount of Fullerene Nanoparticle Additives. Tribol. Lett. 2007, 28, 203–208. [Google Scholar] [CrossRef]

- Zhao, J.; Gao, T.; Li, Y.; He, Y.; Shi, Y. Two-dimensional (2D) graphene nanosheets as advanced lubricant additives: A critical review and prospect. Mater. Today Commun. 2021, 29, 102755. [Google Scholar] [CrossRef]

- Chouhan, A.; Kumari, S.; Sarkar, T.K.; Rawat, S.S.; Khatri, O.P. Graphene-Based Aqueous Lubricants: Dispersion Stability to the Enhancement of Tribological Properties. ACS Appl. Mater. Interfaces 2020, 12, 51785–51796. [Google Scholar] [CrossRef] [PubMed]

- Gu, Y.; Ma, L.; Yan, M.; He, C.; Zhang, J.; Mou, J.; Wu, D.; Ren, Y. Strategies for Improving Friction Behavior Based on Carbon Nanotube Additive Materials. Tribol. Int. 2022, 176, 107875. [Google Scholar] [CrossRef]

- Gao, T.; Li, C.; Zhang, Y.; Yang, M.; Jia, D.; Jin, T.; Hou, Y.; Li, R. Dispersing mechanism and tribological performance of vegetable oil-based CNT nanofluids with different surfactants. Tribol. Int. 2019, 131, 51–63. [Google Scholar] [CrossRef]

- Xie, H.; Wei, Y.; Jiang, B.; Tang, C.; Nie, C. Tribological properties of carbon nanotube/SiO2 combinations as water-based lubricant additives for magnesium alloy. J. Mater. Res. Technol. 2021, 12, 138–149. [Google Scholar] [CrossRef]

- Fan, X.; Wang, L. Ionic liquids gels with in situ modified multiwall carbon nanotubes towards high-performance lubricants. Tribol. Int. 2015, 88, 179–188. [Google Scholar] [CrossRef]

- Zhang, L.; Pu, J.; Wang, L.; Xue, Q.J. Synergistic effect of hybrid carbon nanotube–graphene oxide as nanoadditive enhancing the frictional properties of ionic liquids in high vacuum. ACS Appl. Mater. Interfaces 2015, 7, 8592–8600. [Google Scholar] [CrossRef]

- Krätschmer, W.; Lamb, L.D.; Fostiropoulos, K.; Huffman, D.R. Solid C60: A new form of carbon. Nature 1990, 347, 354–358. [Google Scholar] [CrossRef]

- Blau, P.J.; Haberlin, C.E. An investigation of the microfrictional behavior of C60 particle layers on aluminum. Thin Solid Film. 1992, 219, 129–134. [Google Scholar] [CrossRef]

- Bo, F. Relationship between the structure of C60 and its lubricity: A review. Lubr. Sci. 1997, 9, 181–193. [Google Scholar] [CrossRef]

- Gupta, B.K.; Bhushan, B.; Capp, C.; Coe, J.V. Materials characterization and effect of purity and ion implantation on the friction and wear of sublimed fullerene films. J. Mater. Res. 1994, 9, 2823–2838. [Google Scholar] [CrossRef]

- Cataldo, F. Solubility of Fullerenes in Fatty Acids Esters: A New Way to Deliver In Vivo Fullerenes. Theoretical Calculations and Experimental Results. In Medicinal Chemistry and Pharmacological Potential of Fullerenes and Carbon Nanotubes; Cataldo, F., Da Ros, T., Eds.; Springer: Dordrecht, The Netherlands, 2008; pp. 317–335. [Google Scholar] [CrossRef]

- Gupta, B.K.; Bhushan, B. Fullerence particles as an additive to liquid lubricants and greases for low friction and wear. Lubr. Eng. 1994, 50. [Google Scholar]

- Lee, K.; Hwang, Y.; Cheong, S.; Kwon, L.; Kim, S.; Lee, J. Performance evaluation of nano-lubricants of fullerene nanoparticles in refrigeration mineral oil. Curr. Appl. Phys. 2009, 9, e128–e131. [Google Scholar] [CrossRef]

- Shahnazar, S.; Bagheri, S.; Abd Hamid, S.B. Enhancing lubricant properties by nanoparticle additives. Int. J. Hydrogen Energy 2016, 41, 3153–3170. [Google Scholar] [CrossRef]

- Chu, H.Y.; Hsu, W.C.; Lin, J.F. The anti-scuffing performance of diamond nano-particles as an oil additive. Wear 2010, 268, 960–967. [Google Scholar] [CrossRef]

- Tao, X.; Jiazheng, Z.; Kang, X. The ball-bearing effect of diamond nanoparticles as an oil additive. J. Phys. D Appl. Phys. 1996, 29, 2932–2937. [Google Scholar] [CrossRef]

- Peng, D.X.; Kang, Y.; Hwang, R.M.; Shyr, S.S.; Chang, Y.P. Tribological properties of diamond and SiO2 nanoparticles added in paraffin. Tribol. Int. 2009, 42, 911–917. [Google Scholar] [CrossRef]

- Chu, H.Y.; Hsu, W.C.; Lin, J.F. Scuffing mechanism during oil-lubricated block-on-ring test with diamond nanoparticles as oil additive. Wear 2010, 268, 1423–1433. [Google Scholar] [CrossRef]

- Chou, C.-C.; Lee, S.-H. Tribological behavior of nanodiamond-dispersed lubricants on carbon steels and aluminum alloy. Wear 2010, 269, 757–762. [Google Scholar] [CrossRef]

- Chou, C.-C.; Lee, S. Rheological behavior and tribological performance of a nanodiamond-dispersed lubricant. J. Mater. Process. Technol. 2008, 201, 542–547. [Google Scholar] [CrossRef]

- Wu, Y.; Tsui, W.; Liu, T. Experimental analysis of tribological properties of lubricating oils with nanoparticle additives. Wear 2007, 262, 819–825. [Google Scholar] [CrossRef]

- Krueger, A. Carbon Materials and Nanotechnology; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Zhai, W.; Lu, W.; Liu, X.; Zhou, L. Nanodiamond as an effective additive in oil to dramatically reduce friction and wear for fretting steel/copper interfaces. Tribol. Int. 2019, 129, 75–81. [Google Scholar] [CrossRef]

- Elomaa, O.; Hakala, T.J.; Myllymäki, V.; Oksanen, J.; Ronkainen, H.; Singh, V.K.; Koskinen, J. Diamond nanoparticles in ethylene glycol lubrication on steel–steel high load contact. Diam. Relat. Mater. 2013, 34, 89–94. [Google Scholar] [CrossRef]

- Tomita, S.; Burian, A.; Dore, J.C.; LeBolloch, D.; Fujii, M.; Hayashi, S. Diamond nanoparticles to carbon onions transformation: X-ray diffraction studies. Carbon 2002, 40, 1469–1474. [Google Scholar] [CrossRef]

- Joly-Pottuz, L.; Matsumoto, N.; Kinoshita, H.; Vacher, B.; Belin, M.; Montagnac, G.; Martin, J.M.; Ohmae, N. Diamond-derived carbon onions as lubricant additives. Tribol. Int. 2008, 41, 69–78. [Google Scholar] [CrossRef]

- Matsumoto, N.; Mistry, K.; Kim, J.H.; Eryilmaz, O.; Erdemir, A.; Kinoshita, H.; Ohmae, N. Friction reducing properties of onion-like carbon based lubricant under high contact pressure. Tribol. Mater. Surf. Interfaces 2012, 6, 116–120. [Google Scholar] [CrossRef]

- Tsang, S.C.; Harris, P.J.; Claridge, J.B.; Green, M.L. A microporous carbon produced by arc-evaporation. J. Chem. Soc. Chem. Commun. 1993, 1519–1522. [Google Scholar] [CrossRef]

- Kim, K.T.; Cha, S.I.; Hong, S.H. Hardness and wear resistance of carbon nanotube reinforced Cu matrix nanocomposites. Mater. Sci. Eng. A 2007, 449–451, 46–50. [Google Scholar] [CrossRef]

- Li, Y.; Wang, S.; He, E.; Wang, Q. The effect of sliding velocity on the tribological properties of polymer/carbon nanotube composites. Carbon 2016, 106, 106–109. [Google Scholar] [CrossRef]

- Li, Y.; Wang, S.; Wang, Q. A molecular dynamics simulation study on enhancement of mechanical and tribological properties of polymer composites by introduction of graphene. Carbon 2017, 111, 538–545. [Google Scholar] [CrossRef]

- Li, Z.; Khun, N.W.; Tang, X.-Z.; Liu, E.; Khor, K.A. Mechanical, tribological and biological properties of novel 45S5 Bioglass® composites reinforced with in situ reduced graphene oxide. J. Mech. Behav. Biomed. Mater. 2017, 65, 77–89. [Google Scholar] [CrossRef]

- Liu, C.-F.; Huang, C.P.; Hu, C.-C.; Juang, Y.; Huang, C. Photoelectrochemical degradation of dye wastewater on TiO2-coated titanium electrode prepared by electrophoretic deposition. Sep. Purif. Technol. 2016, 165, 145–153. [Google Scholar] [CrossRef]

- Papadopoulos, A.; Gkikas, G.; Paipetis, A.S.; Barkoula, N.M. Effect of CNTs addition on the erosive wear response of epoxy resin and carbon fibre composites. Compos. Part A Appl. Sci. Manuf. 2016, 84, 299–307. [Google Scholar] [CrossRef]

- Radha, A.; Vijayakumar, K.R. An investigation of mechanical and wear properties of AA6061 reinforced with silicon carbide and graphene nano particles-Particulate composites. Mater. Today Proc. 2016, 3, 2247–2253. [Google Scholar] [CrossRef]

- Zhai, W.; Shi, X.; Xu, Z.; Zhang, Q. Formation of friction layer of Ni3Al matrix composites with micro- and nano-structure during sliding friction under different loads. Mater. Chem. Phys. 2014, 147, 850–859. [Google Scholar] [CrossRef]

- Zhang, X.; Dong, P.; Chen, Y.; Yang, W.; Zhan, Y.; Wu, K.; Chao, Y. Fabrication and tribological properties of copper matrix composite with short carbon fiber/reduced graphene oxide filler. Tribol. Int. 2016, 103, 406–411. [Google Scholar] [CrossRef]

- Atlukhanova, L.B.; Kozlov, G.V.; Dolbin, I.V. Structural Model of Frictional Processes for Polymer/Carbon Nanotube Nanocomposites. J. Frict. Wear 2019, 40, 475–479. [Google Scholar] [CrossRef]

- Jin, B.; Chen, G.; Zhao, J.; He, Y.; Huang, Y.; Luo, J. Improvement of the lubrication properties of grease with Mn3O4/graphene (Mn3O4#G) nanocomposite additive. Friction 2020, 9, 1361–1377. [Google Scholar] [CrossRef]

- Kesavulu, A.; Mohanty, A. Tribological investigation of alumina/graphene nanoplatelets reinforced epoxy nanocomposites. Mater. Res. Express 2020, 6, 125379. [Google Scholar] [CrossRef]

- Neitzel, I.; Mochalin, V.; Bares, J.A.; Carpick, R.W.; Erdemir, A.; Gogotsi, Y. Tribological Properties of Nanodiamond-Epoxy Composites. Tribol. Lett. 2012, 47, 195–202. [Google Scholar] [CrossRef]

- Sahu, S.K.; Badgayan, N.D.; Rama Sreekanth, P.S. Understanding the influence of contact pressure on the wear performance of HDPE/multi-dimensional carbon filler based hybrid polymer nanocomposites. Wear 2019, 438-439, 438–439. [Google Scholar] [CrossRef]

- Sawyer, W.G.; Argibay, N.; Burris, D.L.; Krick, B.A. Mechanistic Studies in Friction and Wear of Bulk Materials. Annu. Rev. Mater. Res. 2014, 44, 395–427. [Google Scholar] [CrossRef]

- Upadhyay, R.K.; Kumar, A. Effect of particle weight concentration on the lubrication properties of graphene based epoxy composites. Colloid Interface Sci. Commun. 2019, 33, 100206. [Google Scholar] [CrossRef]

- Voznyakovskii, A.P.; Ginzburg, B.M.; Rashidov, D.; Tochil’nikov, D.G.; Tuichiev, S. Structure, mechanical, and tribological characteristics of polyurethane modified with nanodiamonds. Polym. Sci. Ser. A 2010, 52, 1044–1050. [Google Scholar] [CrossRef]

- Zhai, W.; Shi, X.; Wang, M.; Xu, Z.; Yao, J.; Song, S.; Wang, Y.; Zhang, Q. Effect of graphene nanoplate addition on the tribological performance of Ni3Al matrix composites. J. Compos. Mater. 2014, 48, 3727–3733. [Google Scholar] [CrossRef]

- Lin, C.B.; Chang, Z.-C.; Tung, Y.H.; Ko, Y.-Y. Manufacturing and tribological properties of copper matrix/carbon nanotubes composites. Wear 2011, 270, 382–394. [Google Scholar] [CrossRef]

- Xu, Z.; Zhang, Q.; Shi, X.; Zhai, W.; Zhu, Q. Comparison of Tribological Properties of NiAl Matrix Composites Containing Graphite, Carbon Nanotubes, or Graphene. J. Mater. Eng. Perform. 2015, 24, 1926–1936. [Google Scholar] [CrossRef]

- Bhargava, S.; Koratkar, N.; Blanchet, T.A. Effect of Platelet Thickness on Wear of Graphene–Polytetrafluoroethylene (PTFE) Composites. Tribol. Lett. 2015, 59, 17. [Google Scholar] [CrossRef]

- Lahiri, D.; Hec, F.; Thiesse, M.; Durygin, A.; Zhang, C.; Agarwal, A. Nanotribological behavior of graphene nanoplatelet reinforced ultra high molecular weight polyethylene composites. Tribol. Int. 2014, 70, 165–169. [Google Scholar] [CrossRef]

- Rajkumar, K.; Aravindan, S. Tribological studies on microwave sintered copper–carbon nanotube composites. Wear 2011, 270, 613–621. [Google Scholar] [CrossRef]

- Ahmad, I.; Kennedy, A.; Zhu, Y.Q. Wear resistant properties of multi-walled carbon nanotubes reinforced Al2O3 nanocomposites. Wear 2010, 269, 71–78. [Google Scholar] [CrossRef]

- Manikandan, P.; Sieh, R.; Elayaperumal, A.; Le, H.R.; Basu, S. Micro/Nanostructure and Tribological Characteristics of Pressureless Sintered Carbon Nanotubes Reinforced Aluminium Matrix Composites. J. Nanomater. 2016, 2016, 9843019. [Google Scholar] [CrossRef]

- Fang, J.; Dong, L.; Dong, W.; Chiang, S.W.; Makimattila, S.; Du, H.; Li, J.; Kang, F. Freeze-drying method prepared UHMWPE/CNT s composites with optimized micromorphologies and improved tribological performance. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef]

- Campo, M.; Jiménez-Suárez, A.; Ureña, A.J.W. Effect of type, percentage and dispersion method of multi-walled carbon nanotubes on tribological properties of epoxy composites. Wear 2015, 324, 100–108. [Google Scholar] [CrossRef]

- Bastwros, M.M.H.; Esawi, A.M.K.; Wifi, A. Friction and wear behavior of Al–CNT composites. Wear 2013, 307, 164–173. [Google Scholar] [CrossRef]

- Dong, B.; Yang, Z.; Huang, Y.; Li, H.L. Study on Tribological Properties of Multi-walled CarbonNanotubes/Epoxy Resin Nanocomposites. Tribol. Lett. 2005, 20, 251–254. [Google Scholar] [CrossRef]

- Cui, L.-J.; Geng, H.-Z.; Wang, W.-Y.; Chen, L.-T.; Gao, J. Functionalization of multi-wall carbon nanotubes to reduce the coefficient of the friction and improve the wear resistance of multi-wall carbon nanotube/epoxy composites. Carbon 2013, 54, 277–282. [Google Scholar] [CrossRef]

- Liu, Z.; Yang, J.; Grey, F.; Liu, J.Z.; Liu, Y.; Wang, Y.; Yang, Y.; Cheng, Y.; Zheng, Q. Observation of Microscale Superlubricity in Graphite. Phys. Rev. Lett. 2012, 108, 205503. [Google Scholar] [CrossRef]

- Bhushan, B. Nanotribology and nanomechanics. Wear 2005, 259, 1507–1531. [Google Scholar] [CrossRef]

- Bhushan, B.; Israelachvili, J.N.; Landman, U. Nanotribology: Friction, wear and lubrication at the atomic scale. Nature 1995, 374, 607–616. [Google Scholar] [CrossRef]

- Luan, B.; Robbins, M.O. The breakdown of continuum models for mechanical contacts. Nature 2005, 435, 929–932. [Google Scholar] [CrossRef]

- Yoon, E.S.; Singh, R.A.; Kong, H.; Kim, B.; Kim, D.H.; Jeong, H.E.; Suh, K.Y. Tribological properties of bio-mimetic nano-patterned polymeric surfaces on silicon wafer. Tribol. Lett. 2006, 21, 31–37. [Google Scholar] [CrossRef]

- Yang, J.; Liu, Z.; Grey, F.; Xu, Z.; Li, X.; Liu, Y.; Urbakh, M.; Cheng, Y.; Zheng, Q. Observation of High-Speed Microscale Superlubricity in Graphite. Phys. Rev. Lett. 2013, 110, 255504. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Q.; Jiang, B.; Liu, S.; Weng, Y.; Lu, L.; Xue, Q.; Zhu, J.; Jiang, Q.; Wang, S.; Peng, L. Self-Retracting Motion of Graphite Microflakes. Phys. Rev. Lett. 2008, 100, 067205. [Google Scholar] [CrossRef] [PubMed]

- Legoas, S.B.; Coluci, V.R.; Braga, S.F.; Coura, P.Z.; Dantas, S.O.; Galvão, D.S. Molecular-Dynamics Simulations of Carbon Nanotubes as Gigahertz Oscillators. Phys. Rev. Lett. 2003, 90, 055504. [Google Scholar] [CrossRef] [PubMed]

- Haerens, K.; Matthijs, E.; Binnemans, K.; Van der Bruggen, B. Electrochemical decomposition of choline chloride based ionic liquid analogues. Green Chem. 2009, 11, 1357–1365. [Google Scholar] [CrossRef]

- Ma, W.; Gong, Z.; Gao, K.; Qiang, L.; Zhang, J.; Yu, S. Superlubricity achieved by carbon quantum dots in ionic liquid. Mater. Lett. 2017, 195, 220–223. [Google Scholar]

- Urbakh, M. Towards macroscale superlubricity. Nat. Nanotechnol. 2013, 8, 893–894. [Google Scholar] [CrossRef]

- Falk, K.; Sedlmeier, F.; Joly, L.; Netz, R.R.; Bocquet, L. Molecular Origin of Fast Water Transport in Carbon Nanotube Membranes: Superlubricity versus Curvature Dependent Friction. Nano Lett. 2010, 10, 4067–4073. [Google Scholar] [CrossRef]

- Zhang, R.; Ning, Z.; Zhang, Y.; Zheng, Q.; Chen, Q.; Xie, H.; Zhang, Q.; Qian, W.; Wei, F. Superlubricity in centimetres-long double-walled carbon nanotubes under ambient conditions. Nat. Nanotechnol. 2013, 8, 912–916. [Google Scholar] [CrossRef]

- Kis, A.; Jensen, K.; Aloni, S.; Mickelson, W.; Zettl, A. Interlayer forces and ultralow sliding friction in multiwalled carbon nanotubes. Phys. Rev. Lett. 2006, 97, 025501. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Wen, Q.; Qian, W.; Su, D.S.; Zhang, Q.; Wei, F. Superstrong Ultralong Carbon Nanotubes for Mechanical Energy Storage. Adv. Mater. 2011, 23, 3387–3391. [Google Scholar] [CrossRef] [PubMed]

- Bian, J.; Nicola, L. On the lubrication of rough copper surfaces with graphene. Tribol. Int. 2021, 156, 106837. [Google Scholar] [CrossRef]

- Han, E.; Yu, J.; Annevelink, E.; Son, J.; Kang, D.A.; Watanabe, K.; Taniguchi, T.; Ertekin, E.; Huang, P.Y.; van der Zande, A.M. Ultrasoft slip-mediated bending in few-layer graphene. Nat. Mater. 2020, 19, 305–309. [Google Scholar] [CrossRef]

- Liu, L.; Zhou, M.; Jin, L.; Li, L.; Mo, Y.; Su, G.; Li, X.; Zhu, H.; Tian, Y. Recent advances in friction and lubrication of graphene and other 2D materials: Mechanisms and applications. Friction 2019, 7, 199–216. [Google Scholar] [CrossRef]

- Müser, M.H. Are There Limits to Superlubricity of Graphene in Hard, Rough Contacts? Front. Mech. Eng. 2019, 5, 28. [Google Scholar] [CrossRef]

- Xu, Y.; Cheng, Z.; Zhu, X.; Lu, Z.; Zhang, G. Ultra-Low Friction of Graphene/Honeycomb Borophene Heterojunction. Tribol. Lett. 2021, 69, 44. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Approaches for Achieving Superlubricity in Two-Dimensional Materials. ACS Nano 2018, 12, 2122–2137. [Google Scholar] [CrossRef] [PubMed]

- Koren, E.; Duerig, U. Superlubricity in quasicrystalline twisted bilayer graphene. Phys. Rev. B 2016, 93, 201404. [Google Scholar] [CrossRef]

- Hirano, M.; Shinjo, K. Superlubricity and frictional anisotropy. Wear 1993, 168, 121–125. [Google Scholar] [CrossRef]

- Hirano, M.; Shinjo, K.; Kaneko, R.; Murata, Y. Anisotropy of frictional forces in muscovite mica. Phys. Rev. Lett. 1991, 67, 2642–2645. [Google Scholar] [CrossRef] [PubMed]

- Koren, E.; Lörtscher, E.; Rawlings, C.; Knoll, A.W.; Duerig, U. Adhesion and friction in mesoscopic graphite contacts. Science 2015, 348, 679–683. [Google Scholar] [CrossRef] [PubMed]

- Itamura, N.; Miura, K.; Sasaki, N. Simulation of Scan-Directional Dependence of Superlubricity of C60 Molecular Bearings and Graphite. Jpn. J. Appl. Phys. 2009, 48, 060207. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, Y.; Luo, J. Superlubricity of nanodiamonds glycerol colloidal solution between steel surfaces. Colloids Surf. A Physicochem. Eng. Asp. 2016, 489, 400–406. [Google Scholar] [CrossRef]

- Liu, Y.; Grey, F.; Zheng, Q.-S. The high-speed sliding friction of graphene and novel routes to persistent superlubricity. Sci. Rep. 2014, 4, 4875. [Google Scholar] [CrossRef] [PubMed]

- McKinnon, A.; Browne, M.; Whiteing, A.; Piecyk, M. Green Logistics: Improving the Environmental Sustainability of Logistics; Kogan Page Publishers: London, UK, 2015. [Google Scholar]

| Solid Lubricant | Experimental Method, Conditions, Materials and Application | Tribological Properties | Ref | |

|---|---|---|---|---|

| Friction Coefficient (µ) | Wear Rate | |||

| Graphite | Steel–steel pair test; 1 N, dry N2 humid air; ethanol solution; solid lubricant coating on steel. | Dry N2 µ = 0.8 Humid air µ = 0.17 | Dry N2: 5.07 × 10−7 mm3/Nm Humid air: 4.94 × 10−8 mm3/Nm | [18] |

| Cu-coated graphite/Al2O3/Cu | HT-1000 ball-on-disk tribo-meter; 5 N, 360 rpm; electrolytic copper, ethanol; deposited on the 304 stainless steel substrate | 10 wt% Cu-coated graphite/10 wt% Al2O3 µ = 0.29 | 2.2 × 10−4 mm3/Nm | [53] |

| Ni-grown graphene | Home-built micro tribometer; 5–70 mN, 50 μm/s; poly (methyl methacrylate) (PMMA); deposited onto the SiO2 substrate. | µ = 0.12 | - | [54] |

| 500 mg/L graphene/Ni | Tested by a reciprocating ball-on disk method; 1 N, 150 mm/s; mixture of H2SO4, NaNO3 and KMnO4; composite coatings sliding against an M50 steel balls. | µ = 0.10 | 8.6 × 10−4 mm3/Nm | [55] |

| Graphene oxide | Reciprocating ball-on-plate tester (MFT-R4000); 400 mN, 25 mm/s; N-type polished single-crystal silicon, ultra-pure water; film as solid lubricant fabricated onto silicon wafer. | µ = 0.05 | - | [56] |

| MoWS4/graphene heterogeneous composite | Steel ball as counterpart ball and with the loads of 1 N under 3 Hz reciprocating motion mode in dry argon; N-methyl-2-pyrrolidone, ethanol; composite coatings on steel–steel interface. | µ = 0.008 | 1.6 × 10−6 ± 1.1 × 10−6 mm3/Nm | [57] |

| Graphene coating/Au vs. TiN | High vacuum tribometer with a ball on disk contact geometry method in dry nitrogen (900 mbar) at room temperature; 1 µm thick gold film; graphene coatings with Au vs. TiN substrates. | µ = 0.15 | - | [58] |

| Graphene coating | AFM (MFP-3D) tester; spring constant 2.8 N/m, resonance frequency of 75 kHz; pyrolytic graphite, 5 nm thick Cr and 95 nm thick Au thin film on Si wafer; graphene coatings at electrical contact interface. | µ = 0.028 | - | [59] |

| 3D graphene/hexagonal boron nitride composite coating | Ball-disc tribological test with friction pair GCr15 bearing steel and DLC films at load 5 N, 5 hz; 0.1 wt% h-BN ethanol solution; composite coating at steel-DLC contact. | µ = 0.01 | 3.0 × 10−7 mm3/Nm | [60] |

| Diamond-like carbon (DLC) film with hydrogen content | Tribological test in ultra-high vacuum with a reciprocating pin-on-flat configuration; sliding speed of 1 mm/s and 1 Gpa; thin amorphous silicon layer (<5 nm); deposited on polished 440 C steel or silicon substrates. | µ = 0.02 | - | [61] |

| Lubricant | Additive | Experimental Method, Conditions and Application | Tribological Properties | Ref | |

|---|---|---|---|---|---|

| Friction Coefficient (µ) | Wear | ||||

| Polyalphaolefin 6 oil (PAO-6) | Modified graphene (0.5 wt%)/dispersant (1 wt%) | Reciprocating tribotester (UMT-5, Brucker) with a ball-on-disk bearing steel mode. Load 2 N, sliding speed 5 mm/s. Modified graphene/dispersant in PAO6 oil. | µ = 0.10 | Wear track depth 21 nm | [127] |

| Pure water | Graphene oxide (1 wt%) | Diamond-like carbon vs. stainless steel contact by a pin-on-disk tribometer. Load 10 N. Graphene oxide in pure water. | µ = 0.06 | - | [128] |

| Graphene enhanced | Graphene dispersion (110 µg/mL) | Reciprocating tribotester (UMT-3) with a ball-plate bearing steel mode. Load 2 N. Graphene enhanced lubricant | µ = 0.105 | Wear volume 0.8 × 10−5 mm3 | [129] |

| Pure water | Graphene oxide (0.1 wt%) and nano diamond (0.5 wt%) concentration | The tribotester ball on plate tribopairs employed were Si3N4 balls and Si wafers. Load 5 mN. Graphene oxide and nano diamond in water. | µ = 0.03 | Wear track depth 5 nm | [130] |

| Deionized water | Carbon dots (0.1 wt%) concentration | Reciprocating tribotester (UMT-3) with a ball on disk. Load 15 N, 5 Hz, 25 °C. Carbon dots in water-based lubricants for amorphous carbon (a-C) coatings. | µ = 0.03 | Wear volume 0.9 × 10−5 mm3 | [30] |

| SAE 10 W-30 lubricating oil | Liquid phase exfoliated graphene (0.05 wt%) concentration | The pin-on-disk tribometer test. Pressure 10 Mpa, Speed 0.3 m/s. Liquid phase exfoliated graphene in SAE 10 W-30 lubricating oil. | µ = 0.033 | Wear rate 2.91 × 10−7 mm3/Nm | [131] |

| Esterified bio-oil | Graphene/MoS2 (0.5 wt%) mass ratio 3:2 | MQ-800 four-ball tribometer test. Load 300 N, 1000 rpm. Graphene and MoS2 dispersed in esterified bio-oil for steel–steel contact. | µ = 0.017 | Wear scar diameter 0.43 mm | [132] |

| Refined oil | Edge-oleylaminated graphene (0.1 wt%) concentration | Ball milling method. Load 396 N, 75 °C. Edge oleylaminated graphene as ultra-stable lubricant additive for friction and wear reduction. | µ = 0.05 | Wear scar diameter 0.35 mm | [133] |

| Base liquid | Polyethylene glycol 200 modified carbon dots (CDs-PEG200) (0.2 wt%) concentration | The universal friction and wear tester (MMW-1) with steel balls. Load 40 N, 600 rpm. Synthesis of polyethylene glycol modified carbon dots as a kind of water-based lubricant additive. | µ = 0.045 | Wear volume 0.4 × 10−6 mm3 | [134] |

| 10 W40 engine oil | (Zinc oxide) ZnO/MWCNTs (multiwalled carbon nanotubes) hybrid nanomaterial (0.25 wt%), mix 3:2 | Bronze alloy-steel contacts using linear reciprocating ball-on-disk tribotester. Load 35 N. Zinc oxide/MWCNTs hybrid nanomaterials in engine oil. | µ = 0.044 | Wear volume 0.09 mm3 | [135] |

| Lubricant | Additive | Experimental Method, Conditions and Application | Tribological Properties | Ref | |

|---|---|---|---|---|---|

| Friction Coefficient (µ) | Wear | ||||

| PEG200 oil | Reduced graphene oxide (0.2 mg mL−1) concentration | Ball-on-disc nanotribometer. Load 500 mN. Reduced graphene oxide (rGO) in PEG200 oil. | µ = 0.06 | - | [19] |

| Base oil | Few-layer graphene larger interlayer spacing (FLG-Ls) (0.5 wt%) concentration | Reciprocating sliding tester (UMT-3 CETR, USA). Load 2 N. Graphene oxide in pure water. | µ = 0.08 | - | [136] |

| Hydraulic oil | Graphene oxide sheets include regular edges (RG) (1 wt%) | Reciprocating tribotester (UMT-3) with a ball on disk mode. Load 2 N, 0.5 Hz. Reduced graphene oxide sheets on lubrication properties as a lubrication additive. | µ = 0.0614 | Wear scar depth 0.151 µm | [137] |

| water | 1-hydroxyethyl-3-methyl imidazolium tetrafluoroborate functionalized graphene oxide (ILCAs-GO) 0.8 mg/mL concentration | CETR UMT-3 multi-function sliding test. Load 5 N. Hydroxyl-terminated ionic liquids functionalized graphene oxide in water. | µ = 0.172 | Wear volume 0.6×105 mm3 | [138] |

| Hydraulic oil | Graphene (TRGO) | UMT-3 (CETR, USA) tribometer in a ball-on-disk reciprocating friction and wear mode. Load 3 N. The graphene (TRGO) as additive in hydraulic oil. | µ = 0.081 | Wear scar depth 0.68 µm | [139] |

| 4010 aviation lubricant (4010 AL) | Graphene (0.075 wt%) concentration | Four-ball tester. Si3N4 ceramics/GCr15 steel tribo-pairs. Load 392 N and 1450 r/min. Graphene nanoplates as oil additives for ceramics/steel sliding components | µ = 0.068 | Wear scar depth 0.516 µm | [140] |

| Polyalphaolefin oil | Graphene platelets (5 wt%) concentration | The ball-on-disk tribometer test. Load 35 N. Graphene-containing polyalphaolefin oil on DLC-coated surfaces. | µ = 0.025 | - | [141] |

| SAE 5W-30 oil | Graphene nanoplate (GN) (0.12 wt%) concentration | Four ball tribo tester method Load 800 N, 10,050 rpm. Engine oil with graphene nano-additives. | µ = 0.0425 | Wear scar depth 0.75 mm | [142] |

| Polyalphaolefin 4 oil (PAO-4) | Carbon spheres (CS-700) + SMO surfactant | High-frequency reciprocating rig tribotester. The test relative humidity was 35–40%., the oil temperature 100 C, the contact pressure 1 GPa and the sliding speed 0.06 m/s. Micro-carbon sphere additives for enhanced lubrication in PAO-4 oil. | µ = 0.10 | Wear coefficient 49 × 10−18 m3/Nm | [143] |

| Polyalphaolefin 6 oil (PAO-6) | Highly exfoliated reduced graphite oxide (heRGO-4) (0.5 wt%) concentration | Reciprocating tribotester (UMT-3 CETR, USA) with a ball-on-disk mode. Load 2 N. Highly exfoliated reduced graphite oxide powders as efficient lubricant oil additives in PAO-6 oil. | µ = 0.084 ± 0.005 | Wear scar depth 31.6 ± 12.6 nm | [144] |

| canola oil | Graphene sheets (0.7 wt%) concentration | Pin-on-disk tribometer. Load 10 N, contact pressure 700 MPa, sliding speed, 20 mm/s. Graphene in canola oil. | µ = 0.064 | Wear rate 1.5 × 10−5 mm3/Nm | [145] |

| 5W30 engine oil | Carbon spheres (CS) (0.5 wt%) concentration | Ball-on-disk tribometer. Relative humidity, 35–40%; oil temperature, 100 C; load 10 N. Submicrometer carbon spheres in engine oil. | µ = 0.04 | Wear volume 0.9 mm3 | [146] |

| paraffin oil (PO) | Alkylated fullerene which bears three eicosyl chains (3,4,5-C20C60,1) (1.0 wt%) concentration | Steel–steel contacts using an Optimol SRV-IV oscillating reciprocating friction and wear tester. Load 200 N, 25 Hz. Alkylated fullerene in paraffin oil. | µ = 0.16 | - | [147] |

| Mineral oil | Fullerene nanoparticle (0.5 wt%) concentration | Disk-on-disk type tester. Load 200 N. Fullerene nanoparticle in mineral oil. | µ = 0.02 | Surface roughness 0.048 µm | [148] |

| pure calcium grease | Two-dimensional (2D) graphene nanosheets (3 wt%) concentration | Four-ball tester. Load 200 N, 1200 rpm, 60 min. Graphene nanosheets in grease. | µ = 0.01 | Wear scar depth 0.40 µm | [149] |

| Water | Aminoborate-functionalized reduced graphene oxide (rGO-AmB) (0.2 w/v %) | The ball-on-disk tribometer test. Load 0.5 N, 50 rpm. rGO-AmB as additive in water. | µ = 0.12 | Wear scar width 98 µm | [150] |

| Bulk Material Lubricant | Experimental Method, Conditions and Application | Tribological Properties | Ref | |

|---|---|---|---|---|

| Friction Coefficient (µ) | Wear Rate mm3/Nm | |||

| 10 vol% graphene/Cu | Ultrasonic dispersing and hot-press (HP) sintering. HT-1000 ball-on-disk high temperature tribometer. Load 2 N, 1 m/s. Graphene/Cu graphene-reinforced bulk material as lubricant. | µ = 0.17 | 1.8 × 10−4 | [197] |

| 4.0 wt% graphene/ polytetrafluoroethylene | Compression at room temperature and sintering. Inidirectional two-pin-on plate tribometer; 20 N, 0.1 m/s. Graphene/polytetrafluoroethylene graphene-reinforced bulk material as lubricant. | µ = 0.18 | 7.5 × 10−6 | [198] |

| 1.0 wt% graphene/polyethylene | Hot compression, 2D transducer of the triboindenter. 100 µN, 0.333 µm/s. Graphene/polyethylene graphene-reinforced bulk material as lubricant. | µ = 0.24 | - | [199] |

| 15 vol% multi-walled CNTs/copper | Pin-on-disc test. 24 N, 2.77 m/s. Electrolytic copper powder. Multi-walled CNTs/copper metal and ceramic matrix composite material as lubricant. | µ = 0.10 | 1.2 × 10−4 | [200] |

| 10 wt% multi-walled CNTs/Al2O3 | Ball-on-reciprocating flat geometry test. 14 N, 10 mm/s. Multi-walled CNTs/Al2O3 metal and ceramic matrix composite material as lubricant. | µ = 0.11 | - | [201] |

| 1.0 wt% multi-walled CNTs/Al | Pin-on-disc test. 1 N, 0.5 m/s. Multi-walled CNTs/Al metal and ceramic matrix composite material as lubricant. | µ = 0.25 | 2.00 mm3/Kg m | [202] |

| 1.0 wt% multi-walled CNTs/polyphenylene | Reciprocating-type ball-on-disc tribometer (HSR-2M). 20 N, 0.20 m/s. Multi-walled CNTs/polyphenylene polymer composite material as lubricant. | µ = 0.09 | 3.15 × 10−6 | [203] |

| 0.5 wt% multi-walled CNTs/epoxy | Pin-on-disc tribometer test. 10 N, 0.09 m/s. Multi-walled CNTs/epoxy polymer composite material as lubricant. | µ = 0.06 | 3.0 × 10−5 | [204] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahman, M.M.; Islam, M.; Roy, R.; Younis, H.; AlNahyan, M.; Younes, H. Carbon Nanomaterial-Based Lubricants: Review of Recent Developments. Lubricants 2022, 10, 281. https://doi.org/10.3390/lubricants10110281

Rahman MM, Islam M, Roy R, Younis H, AlNahyan M, Younes H. Carbon Nanomaterial-Based Lubricants: Review of Recent Developments. Lubricants. 2022; 10(11):281. https://doi.org/10.3390/lubricants10110281

Chicago/Turabian StyleRahman, Md Mahfuzur, Mohaiminul Islam, Rakesh Roy, Hassan Younis, Maryam AlNahyan, and Hammad Younes. 2022. "Carbon Nanomaterial-Based Lubricants: Review of Recent Developments" Lubricants 10, no. 11: 281. https://doi.org/10.3390/lubricants10110281

APA StyleRahman, M. M., Islam, M., Roy, R., Younis, H., AlNahyan, M., & Younes, H. (2022). Carbon Nanomaterial-Based Lubricants: Review of Recent Developments. Lubricants, 10(11), 281. https://doi.org/10.3390/lubricants10110281