Role of Nanofluid Minimum Quantity Lubrication (NMQL) in Machining Application

Abstract

:1. Introduction

2. Minimum Quantity Lubrication (MQL)

3. Nanofluids

4. Machining Application

4.1. Turning

4.2. Milling

4.3. Drilling

4.4. Grinding

5. Future Work

5.1. Computational Fluid Dynamics to Study Nanofluid MQL

5.2. Multiphase Flow Distribution in MQL Machining

6. Conclusions

- enhance the cooling performance and lubricating effects

- enhance tribological property of the fluid

- increase the cutting performance

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lee, Y.; Resiga, A.; Yi, S.; Wern, C. The Optimization of Machining Parameters for Milling Operations by Using the Nelder–Mead Simplex Method. J. Manuf. Mater. Process. 2020, 4, 66. [Google Scholar] [CrossRef]

- Cutting Fluids for Machining. Available online: https://www.thomasnet.com/articles/process-equipment/cutting-fluids-for-machining/ (accessed on 28 February 2022).

- Difference between Flood Cooling and Minimum Quantity Lubrication (MQL). Available online: https://www.difference.minaprem.com/machining/difference-between-flood-cooling-and-minimum-quantity-lubrication-mql/ (accessed on 28 February 2022).

- Rifat, M.; Rahman, M.; Das, D. A review on application of nanofluid MQL in machining. AIP Conf. Proc. 2017, 1919, 020015. [Google Scholar] [CrossRef] [Green Version]

- Said, Z.; Gupta, M.; Hegab, H.; Arora, N.; Khan, A.; Jamil, M.; Bellos, E. A comprehensive review on minimum quantity lubrication (MQL) in machining processes using nano-cutting fluids. Int. J. Adv. Manuf. Technol. 2019, 105, 2057–2086. [Google Scholar] [CrossRef]

- Sharma, A.; Tiwari, A.; Dixit, A. Progress of Nanofluid Application in Machining: A Review. Mater. Manuf. Process. 2015, 30, 813–828. [Google Scholar] [CrossRef]

- Woon, K. High Performance Machining of Metal Matrix Composites. Encycl. Mater. Compos. 2021, 1, 512–524. [Google Scholar] [CrossRef]

- Haider, J.; Hashmi, M. Health and Environmental Impacts in Metal Machining Processes. Compr. Mater. Process. 2014, 8, 7–33. [Google Scholar] [CrossRef]

- Khan, M.; Mia, M.; Dhar, N. High-pressure coolant on flank and rake surfaces of tool in turning of Ti-6Al-4V: Investigations on forces, temperature, and chips. Int. J. Adv. Manuf. Technol. 2016, 90, 1977–1991. [Google Scholar] [CrossRef]

- Ezugwu, E.; Bonney, J.; Da Silva, R.; Çakir, O. Surface integrity of finished turned Ti–6Al–4V alloy with PCD tools using conventional and high pressure coolant supplies. Int. J. Mach. Tools Manuf. 2007, 47, 884–891. [Google Scholar] [CrossRef]

- Gajrani, K.; Sankar, M. Sustainable Cutting Fluids: Thermal, Rheological, Biodegradation, Anti-Corrosion, Storage Stability Studies and its Machining Performance. Encycl. Renew. Sustain. Mater. 2020, 1, 839–852. [Google Scholar] [CrossRef]

- Debnath, S.; Reddy, M.; Yi, Q. Environmental friendly cutting fluids and cooling techniques in machining: A review. J. Clean. Prod. 2014, 83, 33–47. [Google Scholar] [CrossRef]

- Kalpakjian, S.; Schmid, S.R. Cutting-Tool Materials and Cutting Fluids. In Manufacturing Engineering and Technology, 6th ed.; Pearson Education: London, UK, 2009; pp. 590–614. [Google Scholar]

- Dudzinski, D.; Devillez, A.; Moufki, A.; Larrouquère, D.; Zerrouki, V.; Vigneau, J. A review of developments towards dry and high speed machining of Inconel 718 alloy. Int. J. Mach. Tools Manuf. 2004, 44, 439–456. [Google Scholar] [CrossRef]

- Jayal, A.; Balaji, A.; Sesek, R.; Gaul, A.; Lillquist, D. Machining Performance and Health Effects of Cutting Fluid Application in Drilling of A390.0 Cast Aluminum Alloy. J. Manuf. Process. 2007, 9, 137–146. [Google Scholar] [CrossRef]

- Yan, L.; Yuan, S.; Liu, Q. Influence of minimum quantity lubrication parameters on tool wear and surface roughness in milling of forged steel. Chin. J. Mech. Eng. 2012, 25, 419–429. [Google Scholar] [CrossRef]

- Boswell, B.; Islam, M.; Davies, I.; Ginting, Y.; Ong, A. A review identifying the effectiveness of minimum quantity lubrication (MQL) during conventional machining. Int. J. Adv. Manuf. Technol. 2017, 92, 321–340. [Google Scholar] [CrossRef] [Green Version]

- The Long, T.; Minh Duc, T. The Characteristics and Application of Nanofluids in MQL and MQCL for Sustainable Cutting Processes. In Advances in Microfluidic Technologies for Energy and Environmental Applications; IntechOpen: London, UK, 2020. [Google Scholar]

- Minh, D.; The, L.; Bao, N. Performance of Al2O3 nanofluids in minimum quantity lubrication in hard milling of 60 Si2Mn steel using cemented carbide tools. Adv. Mech. Eng. 2017, 9, 1687814017710618. [Google Scholar] [CrossRef] [Green Version]

- Long, T.T.; Duc, T.M. Micro/Nanofluids in Sustainable Machining. In Microfluidics and Nanofluidics; Kandelousi, M.S., Ed.; IntechOpen: London, UK, 2018. [Google Scholar]

- Krajnik, P.; Franci, P.; Amir, R. Nanofluids: Properties, Applications and Sustainability Aspects in Materials Processing Technologies. In Advances in Sustainable Manufacturing; Springer: Berlin, Germany, 2011; pp. 107–113. [Google Scholar]

- Vanderbilt University. Cheap, Small Carbon Nanotubes. 2018. Available online: https://www.sciencedaily.com/releases/2018/05/180523160148.htm (accessed on 1 June 2022).

- Shanmugam, K.; Sahadevan, R. Bioceramics—An introductory overview. In Fundamental Biomaterials: Ceramics; Woodhead Publishing: Thorston, UK, 2018; pp. 1–46. [Google Scholar] [CrossRef]

- Sahoo, S.P.; Datta, S. Dry, MQL, and Nanofluid MQL Machining of Ti–6Al–4V Using Uncoated WC–Co Insert: Application of Jatropha Oil as Base Cutting Fluid and Graphene Nanoplatelets as Additives. Arab. J. Sci. Eng. 2020, 45, 9599–9618. [Google Scholar] [CrossRef]

- Cui, X.; Li, C.; Ding, W.; Chen, Y.; Mao, C.; Xu, X.; Liu, B.; Wang, D.; Li, H.N.; Zhang, Y.; et al. Minimum quantity lubrication machining of aeronautical materials using carbon group nanolubricant: From mechanisms to application. Chin. J. Aeronaut. 2021, 35, 85–112. [Google Scholar] [CrossRef]

- Zainali, A.; Tofighi, N.; Shadloo, M.; Yildiz, M. Numerical investigation of Newtonian and non-Newtonian multiphase flows using ISPH method. Comput. Methods Appl. Mech. Eng. 2013, 254, 99–113. [Google Scholar] [CrossRef]

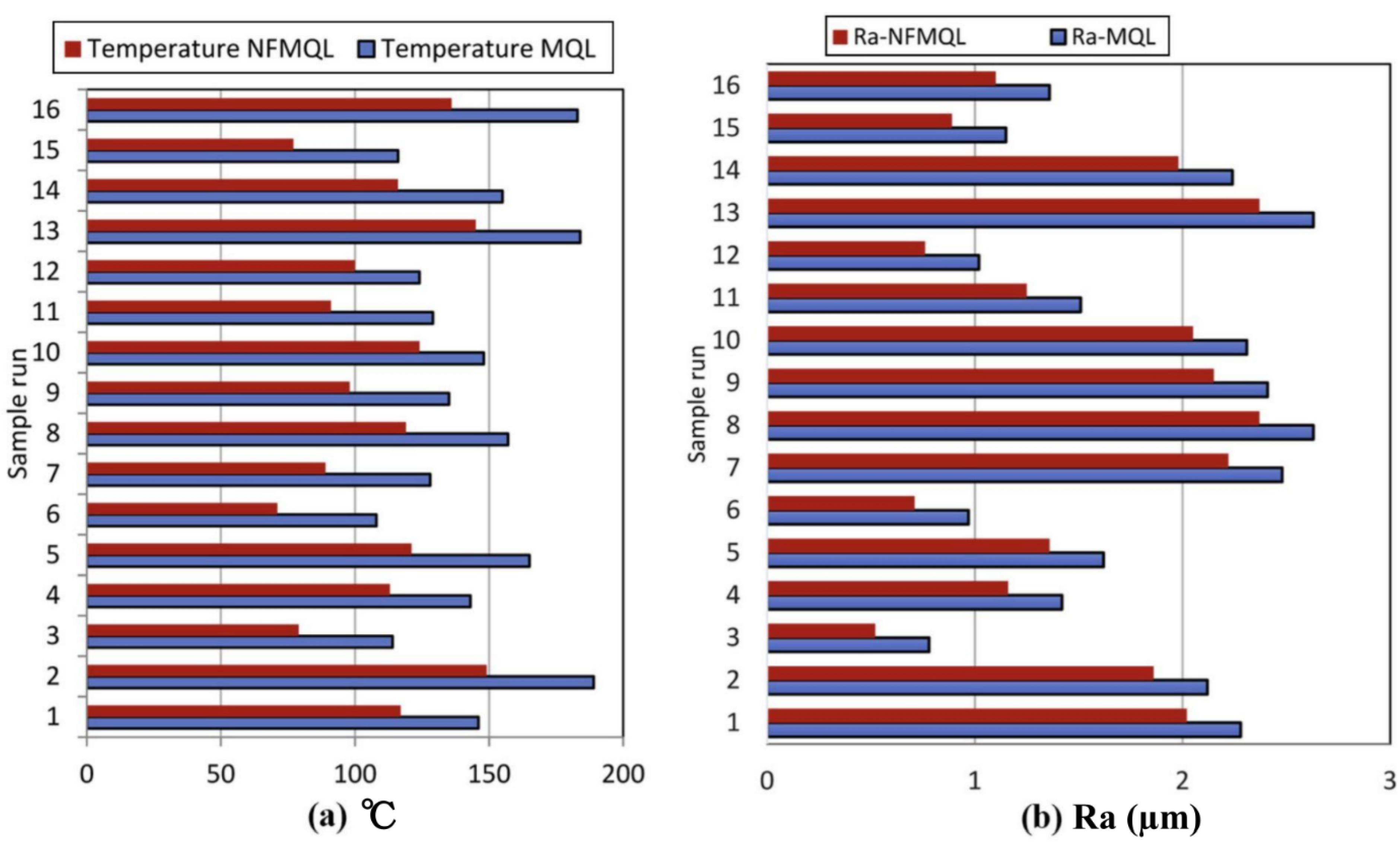

- Khan, A.; Jamil, M.; Ul Haq, A.; Hussain, S.; Meng, L.; He, N. Sustainable machining. Modeling and optimization of temperature and surface roughness in the milling of AISI D2 steel. Ind. Lubr. Tribol. 2018, 71, 267–277. [Google Scholar] [CrossRef]

- Ibrahim, A.M.M.; Omer, M.A.E.; Das, S.R.; Li, W.; Alsoufi, M.S.; Elsheikh, A. Evaluating the effect of minimum quantity lubrication during hard turning of AISI D3 steel using vegetable oil enriched with nano-additives. Alex. Eng. J. 2022, 61, 10925–10938. [Google Scholar] [CrossRef]

- Sharma, A.; Tiwari, A.; Dixit, A. Effects of Minimum Quantity Lubrication (MQL) in machining processes using conventional and nanofluid based cutting fluids: A comprehensive review. J. Clean. Prod. 2016, 127, 1–18. [Google Scholar] [CrossRef]

- Bruni, C.; Forcellese, A.; Gabrielli, F.; Simoncini, M. Effect of the lubrication-cooling technique, insert technology and machine bed material on the workpart surface finish and tool wear in finish turning of AISI 420B. Int. J. Mach. Tools Manuf. 2006, 46, 1547–1554. [Google Scholar] [CrossRef]

- Le Coz, G.; Marinescu, M.; Devillez, A.; Dudzinski, D.; Velnom, L. Measuring temperature of rotating cutting tools: Application to MQL drilling and dry milling of aerospace alloys. Appl. Therm. Eng. 2012, 36, 434–441. [Google Scholar] [CrossRef]

- Brinksmeier, E.; Janssen, R. Drilling of multi-layer composite materials consisting of carbon fiber reinforced plastics (CFRP), titanium and aluminum alloys. CIRP Ann-Manuf. Technol. 2002, 51, 87–90. [Google Scholar] [CrossRef]

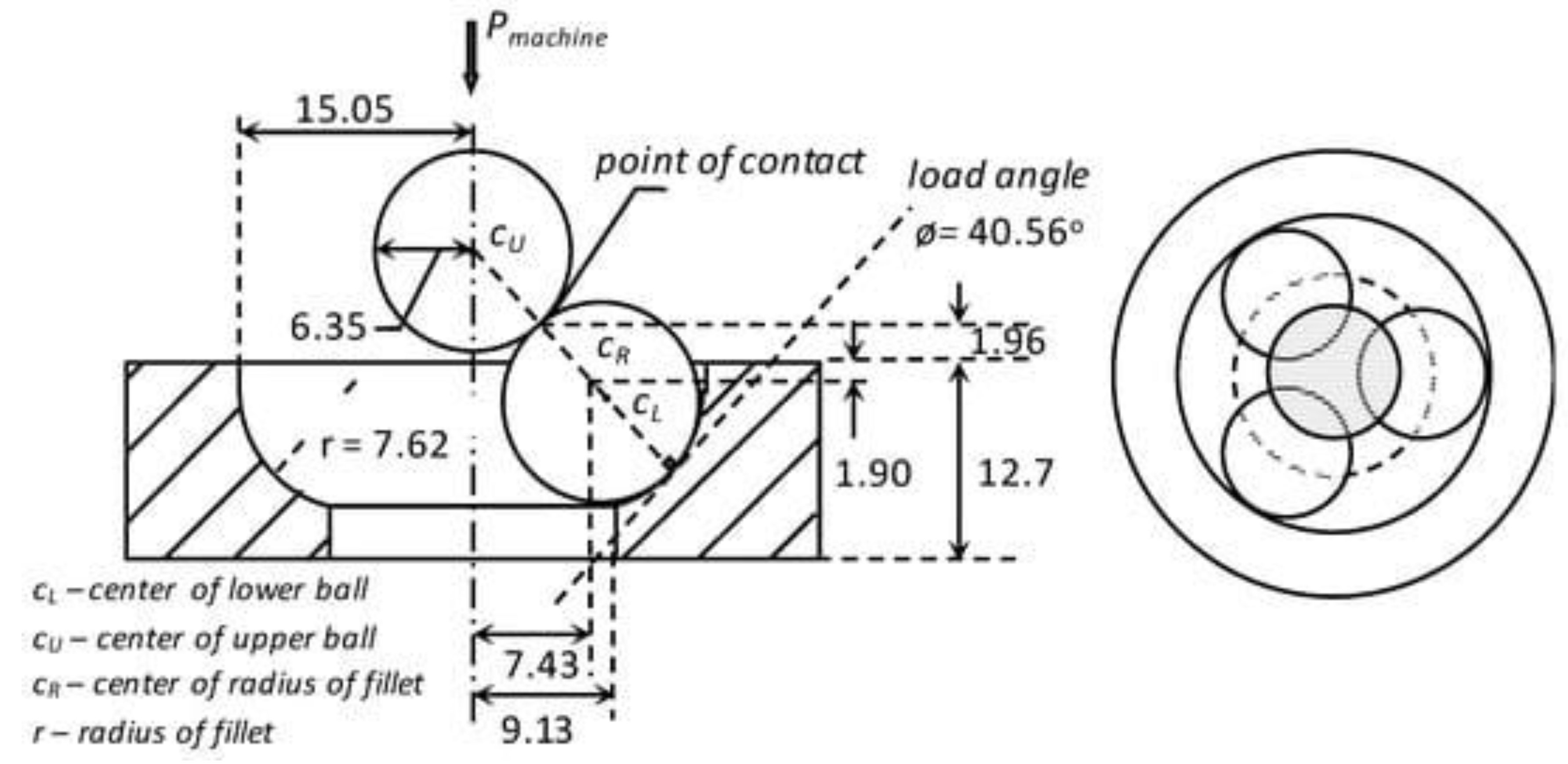

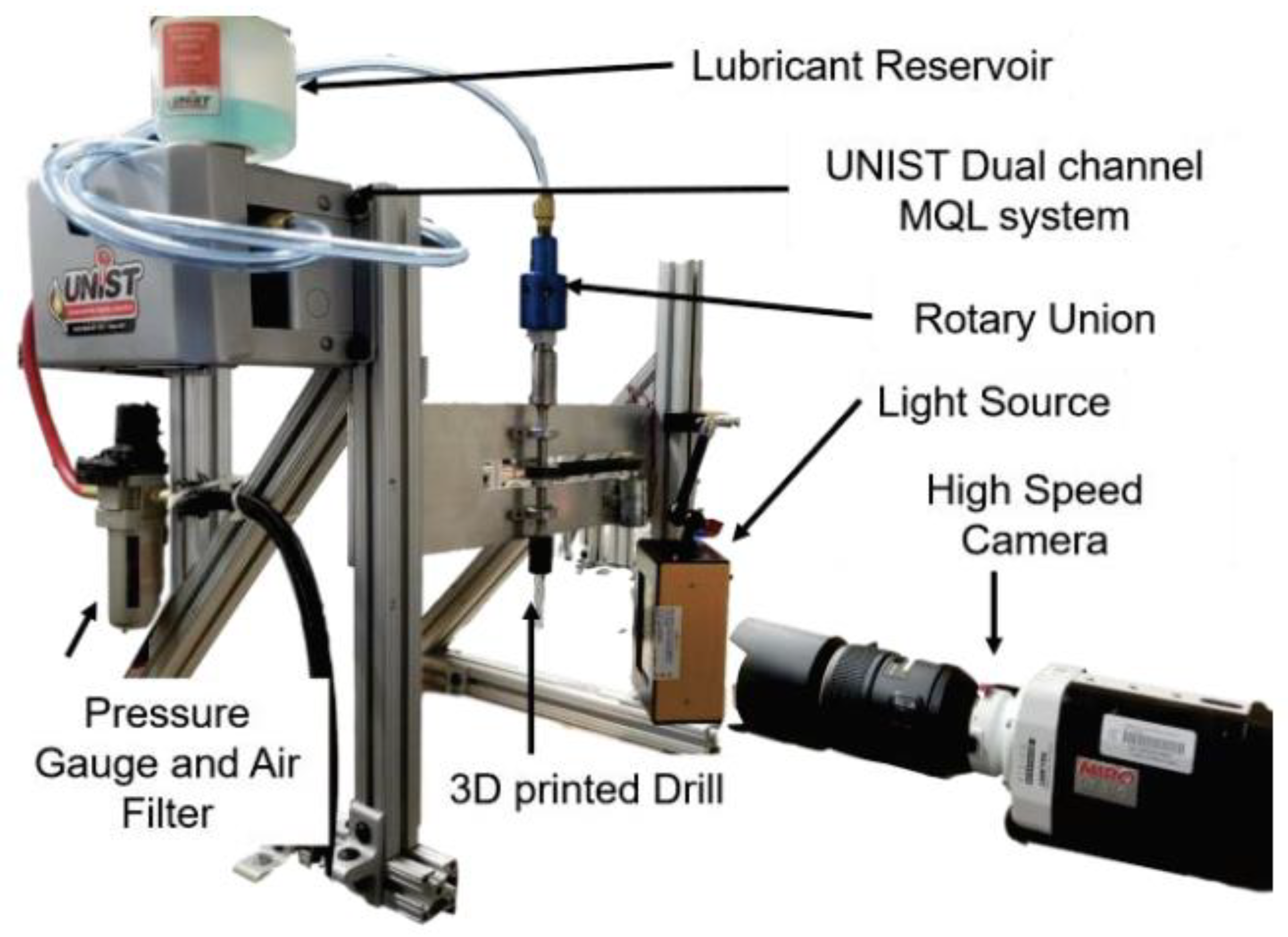

- Mosleh, M.; Shirvani, K.; Smith, S.; Belk, J.H.; Lipczynski, G. A Study of Minimum Quantity Lubrication (MQL) by Nanofluids in Orbital Drilling and Tribological Testing. J. Manuf. Mater. Process. 2019, 3, 5. [Google Scholar] [CrossRef] [Green Version]

- Turning Process, Defects, Equipment. Available online: http://www.custompartnet.com/wu/turning?newwindow=true (accessed on 1 March 2022).

- Behera, B.C.; Ghosh, S.; Rao, P.V. Application of nanofluids during minimum quantity lubrication: A case study in turning process. Tribol. Int. 2016, 101, 234–246. [Google Scholar]

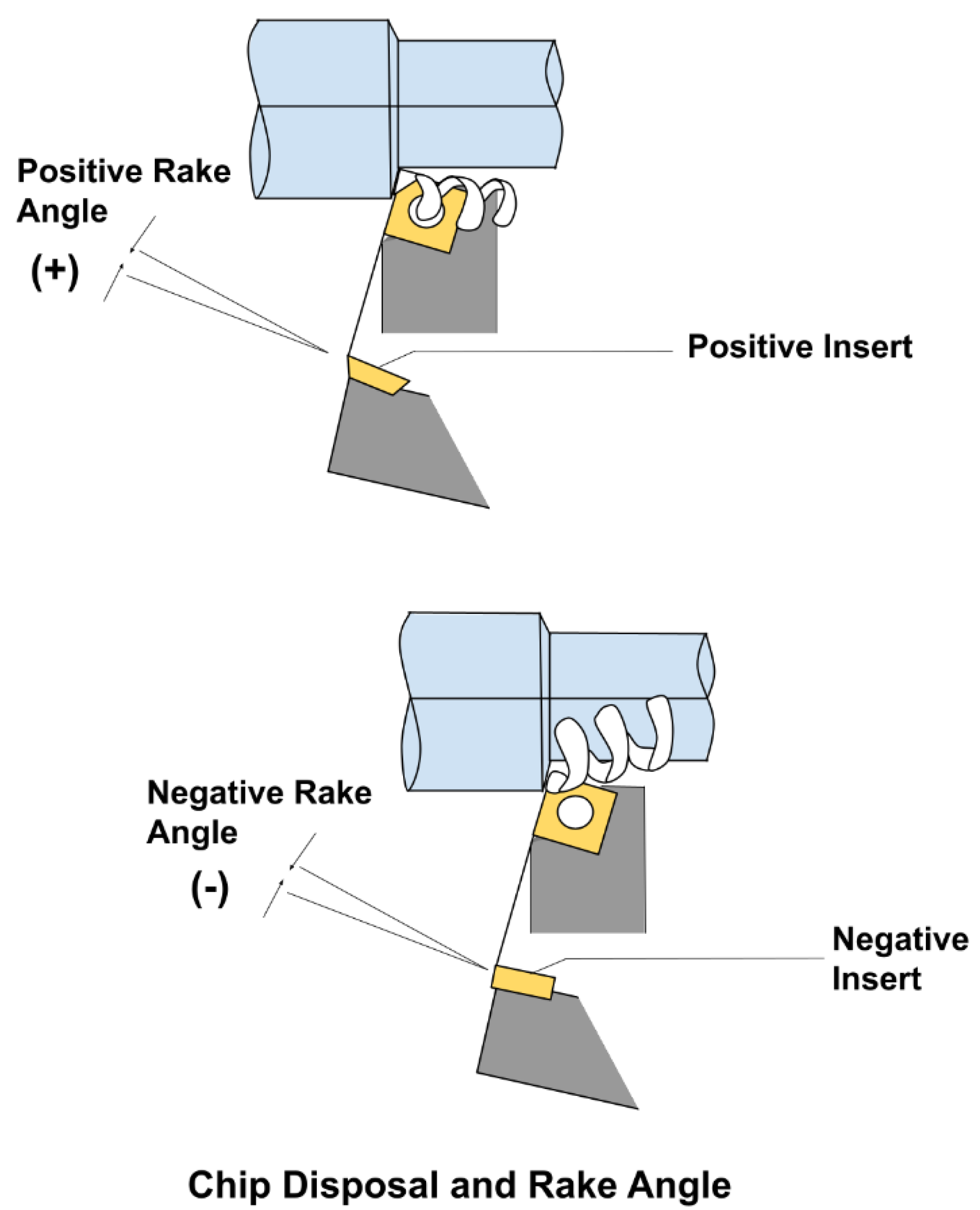

- Mitsubishi Materials Corporation Function of Tool Features for Face Turning. Available online: http://www.mitsubishicarbide.net/contents/mmus/enus/html/product/technical_information/information/t_sukui.html (accessed on 1 March 2022).

- Patole, P.; Kulkarni, V.; Bhatwadekar, S. MQL Machining with nano fluid: A review. Manuf. Rev. 2021, 8, 13. [Google Scholar] [CrossRef]

- Hegab, H.; Umer, U.; Deiab, I.; Kishawy, H. Performance evaluation of Ti–6Al–4V machining using nano-cutting fluids under minimum quantity lubrication. Int. J. Adv. Manuf. Technol. 2018, 95, 4229–4241. [Google Scholar] [CrossRef]

- Das, A.; Patel, S.; Das, S. Performance comparison of vegetable oil based nanofluids towards machinability improvement in hard turning of HSLA steel using minimum quantity lubrication. Mech. Ind. 2019, 20, 506. [Google Scholar] [CrossRef]

- Milling Machine Definition, Process & Types-Engineering Articles. Available online: https://www.engineeringarticles.org/milling-machine-definition-process-types/ (accessed on 1 March 2022).

- What Is High-Speed Machining-Grainger Know How. Available online: https://www.grainger.com/know-how/industry/metalworking/kh-what-is-high-speed-machining#:~:text=A%20process%20that%20combines%20lighter,life%20and%20increase%20shop%20productivity (accessed on 1 March 2022).

- Frances, B. High Speed Machining: Disadvantages. Available online: https://www.bandbprecision.co.uk/high-speed-machining-disadvantages (accessed on 1 March 2022).

- Bai, X.; Li, C.; Dong, L.; Yin, Q. Experimental evaluation of the lubrication performances of different nanofluids for minimum quantity lubrication (MQL) in milling Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2018, 101, 2621–2632. [Google Scholar] [CrossRef]

- Sarhan, A.; Sayuti, M.; Hamdi, M. Reduction of power and lubricant oil consumption in milling process using a new SiO2 nanolubrication system. Int. J. Adv. Manuf. Technol. 2012, 63, 505–512. [Google Scholar] [CrossRef]

- Sayuti, M.; Sarhan, A.; Hamdi, M. An investigation of optimum SiO2 nanolubrication parameters in end milling of aerospace Al6061-T6 alloy. Int. J. Adv. Manuf. Technol. 2012, 67, 833–849. [Google Scholar] [CrossRef]

- Eltaggaz, A.; Deiab, I. Comparison of between direct and peck drilling for large aspect ratio in Ti-6Al-4V alloy. Int. J. Adv. Manuf. Technol. 2019, 102, 2797–2805. [Google Scholar] [CrossRef]

- Baksi, S. Drilling Machine: Definition, Parts, Types, and Operations (With PDF). Available online: https://learnmechanical.com/drilling-machine/ (accessed on 1 March 2022).

- Drilling Introduction, Drill Press Work Area. Available online: https://www.efunda.com/processes/machining/drill.cfm (accessed on 1 March 2022).

- Salimi-Yasar, H.; Zeinali Heris, S.; Shanbedi, M. Influence of soluble oil-based TiO2 nanofluid on heat transfer performance of cutting fluid. Tribol. Int. 2017, 112, 147–154. [Google Scholar] [CrossRef]

- Chatha, S.; Pal, A.; Singh, T. Performance evaluation of aluminium 6063 drilling under the influence of nanofluid minimum quantity lubrication. J. Clean. Prod. 2016, 137, 537–545. [Google Scholar] [CrossRef]

- Zelinski, P. The Fast Track to High Speed Drilling. Available online: https://www.mmsonline.com/articles/the-fast-track-to-high-speed-drilling (accessed on 1 March 2022).

- Milling vs. Grinding: What’s the Difference? Available online: https://monroeengineering.com/blog/milling-vs-grinding-whats-the-difference/ (accessed on 1 March 2022).

- Shen, B.; Shih, A.; Tung, S. Application of Nanofluids in Minimum Quantity Lubrication Grinding. Tribol. Trans. 2008, 51, 730–737. [Google Scholar] [CrossRef]

- Bhargavi, A.; Prashantha, S.T. Application of Nano Cutting Fluid under Minimum Quantity Lubrication (MQL) Technique to Improve Grinding of Ti–6Al–4V Alloy. Int. J. Eng. Res. Technol. (IJERT) Icesmart 2015, 3. [Google Scholar] [CrossRef]

- Cui, X.; Li, C.; Zhang, Y.; Said, Z.; Debnath, S.; Sharma, S.; Ali, H.M.; Yang, M.; Gao, T.; Li, R. Grindability of titanium alloy using cryogenic nanolubricant minimum quantity lubrication. J. Manuf. Process. 2022, 80, 273–286. [Google Scholar] [CrossRef]

- Hegab, H.; Darras, B.; Kishawy, H. Sustainability Assessment of Machining with Nano-Cutting Fluids. Procedia Manuf. 2018, 26, 245–254. [Google Scholar] [CrossRef]

- Hanson, A. The Benefits of Using Computational Fluid Dynamics as a Tool for Innovation. Available online: https://www.pddinnovation.com/computational-fluid-dynamics/ (accessed on 1 March 2022).

- El-Bouri, W.K. Investigation of Minimum Quantity Lubrication Coolant Strategy for the Machining of Austempered Ductile Iron (ADI). Mater. Sci. 2018. [Google Scholar]

- Byrne, G.; Dornfeld, D.; Denkena, B. Advancing Cutting Technology. CIRP Ann. 2003, 52, 483–507. [Google Scholar] [CrossRef]

- Hegab, H.; Kishawy, H.; Umer, U.; Mohany, A. A model for machining with nano-additives based minimum quantity lubrication. Int. J. Adv. Manuf. Technol. 2019, 102, 2013–2028. [Google Scholar] [CrossRef]

- Rohit, J.; Surendra Kumar, K.; Sura Reddy, N.; Kuppan, P.; Balan, A. Computational Fluid Dynamics Analysis of MQL Spray Parameters and Its Influence on MQL Milling of SS304. In Simulations for Design and Manufacturing; Lecture Notes on Multidisciplinary Industrial Engineering; Springer: Singapore, 2018; pp. 45–78. [Google Scholar]

- Milling Troubleshooting. Available online: https://www.sandvik.coromant.com/en-us/knowledge/milling/pages/troubleshooting.aspx (accessed on 1 March 2022).

- López de Lacalle, L.; Angulo, C.; Lamikiz, A.; Sánchez, J. Experimental and numerical investigation of the effect of spray cutting fluids in high speed milling. J. Mater. Process. Technol. 2006, 172, 11–15. [Google Scholar] [CrossRef]

- Balan, A.; Kullarwar, T.; Vijayaraghavan, L.; Krishnamurthy, R. Computational fluid dynamics analysis of MQL spray parameters and its influence on superalloy grinding. Mach. Sci. Technol. 2017, 21, 603–616. [Google Scholar] [CrossRef]

- Raval, J.; Hung, W.; Tai, B. Multiphase Flow Distribution in MQL Drilling Using Optical Intensity Distribution Based Approach. In Proceedings of the 14th International Manufacturing Science and Engineering Conference, Erie, PA, USA, 10–14 June 2019. [Google Scholar]

- Eltaggaz, A.; Said, Z.; Deiab, I. An integrated numerical study for using minimum quantity lubrication (MQL) when machining austempered ductile iron (ADI). Int. J. Interact. Des. Manuf. 2020, 14, 747–758. [Google Scholar] [CrossRef]

- Ammar, H.E.; Elaziz, M.A.; Das, S.R.; Muthuramalingam, T.; Lu, S. A new optimized predictive model based on political optimizer for eco-friendly MQL-turning of AISI 4340 alloy with nano-lubricants. J. Manuf. Process. 2021, 67, 562–578. [Google Scholar] [CrossRef]

- Abrão, B.S.; Pereira, M.F.; da Silva, L.R.R.; Machado, Á.R.; Gelamo, R.V.; de Freitas, F.M.C.; Mia, M.; da Silva, R.B. Improvements of the MQL Cooling-Lubrication Condition by the Addition of Multilayer Graphene Platelets in Peripheral Grinding of SAE 52100 Steel. Lubricants 2021, 9, 79. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, H.N.; Li, C.; Huang, C.; Ali, H.M.; Xu, X.; Mao, C.; Ding, W.; Cui, X.; Yang, M.; et al. Nano-enhanced biolubricant in sustainable manufacturing: From processability to mechanisms. Friction 2022, 10, 803–841. [Google Scholar] [CrossRef]

| Material | Thermal Conductivity (W/mK) |

|---|---|

| Carbon nanotubes | 3000 |

| Aluminum oxide | 40 |

| Water | 0.60 |

| Vegetable oils | 0.18 |

| Work-Piece | Tool | Nanofluid (Diameter = 70 nm) | Tribological Performance Observation (Milling Force, Surface Roughness, etc.) |

|---|---|---|---|

| Ti-6AL-4V (40 mm × 30 mm × 30 mm) | Dema ML1060B |

| |

| |||

| |||

| |||

| |||

|

| Test Levels | Control Factors and Levels (i) | The Measured Values | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nanoparticle Suspended Concentration (A) | Air Pressure (B) | Nozzle Orientation (C) | Cutting Force (N) | Cutting Temperature (°C) | Surface Roughness (µm) | ||||||||||

| Reading | Average | Reading | Average | Reading | Average | ||||||||||

| 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 | |||||||

| 1 | i = 1 | 1 | 1 | 132.11 | 135.23 | 135.14 | 134.16 | 56.80 | 57.50 | 57.30 | 57.20 | 3.21 | 3.11 | 3.10 | 3.14 |

| 2 | i = 1 | 2 | 2 | 199.56 | 195.44 | 198.73 | 197.91 | 70.90 | 71.80 | 70.90 | 71.20 | 0.78 | 0.82 | 0.66 | 0.75 |

| 3 | i = 1 | 3 | 3 | 127.82 | 133.64 | 130.88 | 130.78 | 55.70 | 56.90 | 55.70 | 56.10 | 1.39 | 1.38 | 1.48 | 1.42 |

| 4 | i = 1 | 4 | 4 | 183.9 | 182.63 | 186.76 | 184.43 | 48.80 | 49.50 | 48.10 | 48.80 | 1.47 | 1.51 | 1.60 | 1.53 |

| 5 | i = 2 | 1 | 2 | 56.98 | 51.14 | 53.31 | 53.81 | 43.10 | 43.80 | 43.60 | 43.50 | 0.79 | 0.77 | 0.65 | 0.74 |

| 6 | i = 2 | 2 | 1 | 145.31 | 149.77 | 155.85 | 150.31 | 53.60 | 54.20 | 52.70 | 53.50 | 1.59 | 1.55 | 1.71 | 1.62 |

| 7 | i = 2 | 3 | 4 | 165.48 | 157.69 | 162.8 | 161.99 | 73.90 | 72.90 | 72.50 | 73.10 | 0.87 | 0.84 | 0.93 | 0.88 |

| 8 | i = 2 | 4 | 3 | 153.56 | 155.87 | 163.46 | 157.63 | 70.60 | 71.10 | 67.40 | 69.70 | 1.30 | 1.30 | 1.42 | 1.34 |

| 9 | i = 3 | 1 | 3 | 172.75 | 173.33 | 169.35 | 171.81 | 68.40 | 67.20 | 67.80 | 67.80 | 1.09 | 1.13 | 0.99 | 1.07 |

| 10 | i = 3 | 2 | 4 | 109.45 | 113.32 | 100.33 | 107.70 | 61.80 | 61.30 | 61.40 | 61.50 | 0.95 | 0.99 | 0.85 | 0.93 |

| 11 | i = 3 | 3 | 1 | 120.56 | 122.87 | 122.33 | 121.92 | 51.80 | 52.40 | 49.70 | 51.30 | 0.83 | 0.72 | 0.84 | 0.80 |

| 12 | i = 3 | 4 | 2 | 186.73 | 190.21 | 187.18 | 188.04 | 64.70 | 63.80 | 66.50 | 65.00 | 1.54 | 1.59 | 1.61 | 1.58 |

| 13 | i = 4 | 1 | 4 | 112.85 | 111.73 | 109.71 | 111.43 | 56.60 | 57.80 | 60.90 | 58.10 | 0.79 | 0.77 | 0.69 | 0.75 |

| 14 | i = 4 | 2 | 3 | 146.76 | 144.45 | 145.77 | 145.66 | 57.30 | 56.10 | 57.30 | 56.90 | 0.69 | 0.70 | 0.64 | 0.68 |

| 15 | i = 4 | 3 | 2 | 188.22 | 185.38 | 186.68 | 186.76 | 67.20 | 65.30 | 64.00 | 65.50 | 0.32 | 0.32 | 0.37 | 0.34 |

| 16 | i = 4 | 4 | 1 | 175.07 | 179.37 | 177.49 | 177.31 | 67.90 | 68.20 | 68.50 | 68.20 | 0.74 | 0.76 | 0.73 | 0.74 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shah, R.; Shirvani, K.A.; Przyborowski, A.; Pai, N.; Mosleh, M. Role of Nanofluid Minimum Quantity Lubrication (NMQL) in Machining Application. Lubricants 2022, 10, 266. https://doi.org/10.3390/lubricants10100266

Shah R, Shirvani KA, Przyborowski A, Pai N, Mosleh M. Role of Nanofluid Minimum Quantity Lubrication (NMQL) in Machining Application. Lubricants. 2022; 10(10):266. https://doi.org/10.3390/lubricants10100266

Chicago/Turabian StyleShah, Raj, Khosro A. Shirvani, Alexandra Przyborowski, Nikhil Pai, and Mohsen Mosleh. 2022. "Role of Nanofluid Minimum Quantity Lubrication (NMQL) in Machining Application" Lubricants 10, no. 10: 266. https://doi.org/10.3390/lubricants10100266

APA StyleShah, R., Shirvani, K. A., Przyborowski, A., Pai, N., & Mosleh, M. (2022). Role of Nanofluid Minimum Quantity Lubrication (NMQL) in Machining Application. Lubricants, 10(10), 266. https://doi.org/10.3390/lubricants10100266