Experimental Measurement of Ice-Curling Stone Friction Coefficient Based on Computer Vision Technology: A Case Study of “Ice Cube” for 2022 Beijing Winter Olympics

Abstract

1. Introduction

- (1)

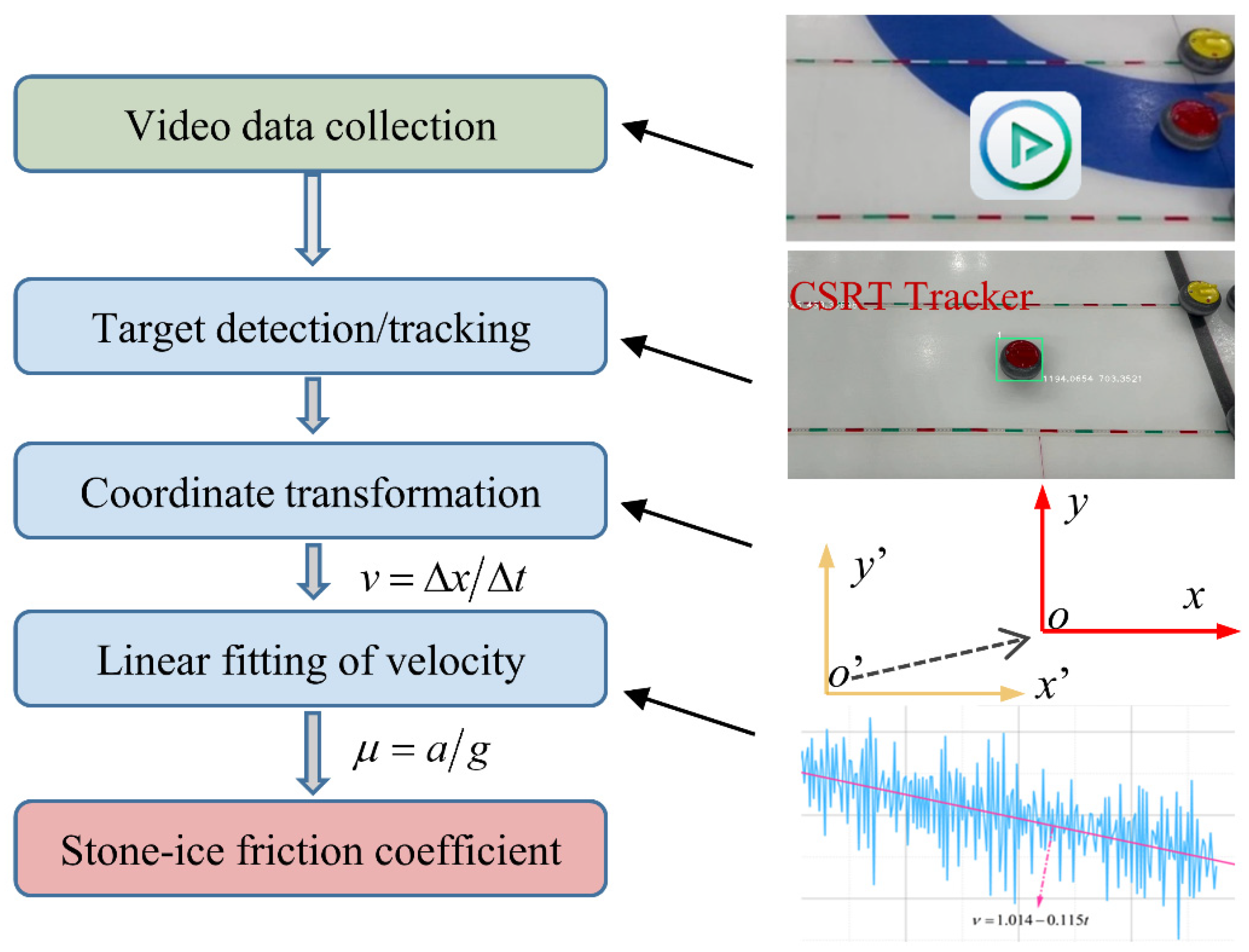

- The friction coefficient of a curling stone sliding on pebbled ice in an actual rink for the Beijing Winter Olympics was obtained, based on on-site measurement.

- (2)

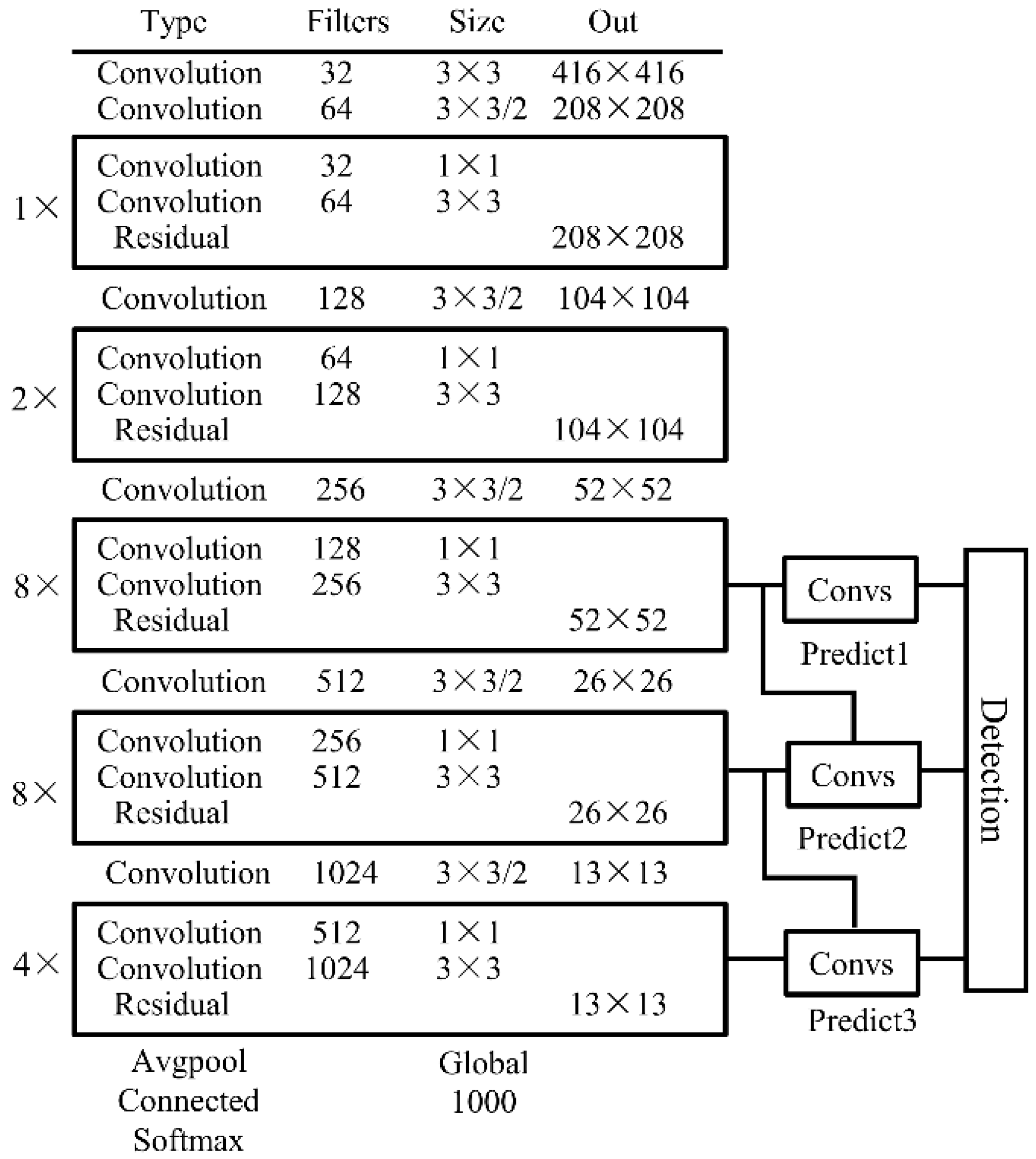

- A procedure to determine the location of the curling stone was proposed, based on YOLO-V3 deep neural networks and the CSRT tracker. The method may be further applied to actual competitions without the ethical issues of competition, which may contribute to revealing the complex friction mechanism of stone–ice.

- (3)

- A curling stone dataset containing 1000 images was created to supply the data for the study of curling stone object recognition.

2. Methodologies

2.1. Image Dataset Description

2.1.1. Video Data Acquisition

2.1.2. Image Acquisition, Annotation and Dataset Production

2.2. YOLO-V3 Deep Neural Network

2.3. Object Tracking Algorithms

2.4. Computer Hardware Parameters

3. Experiments

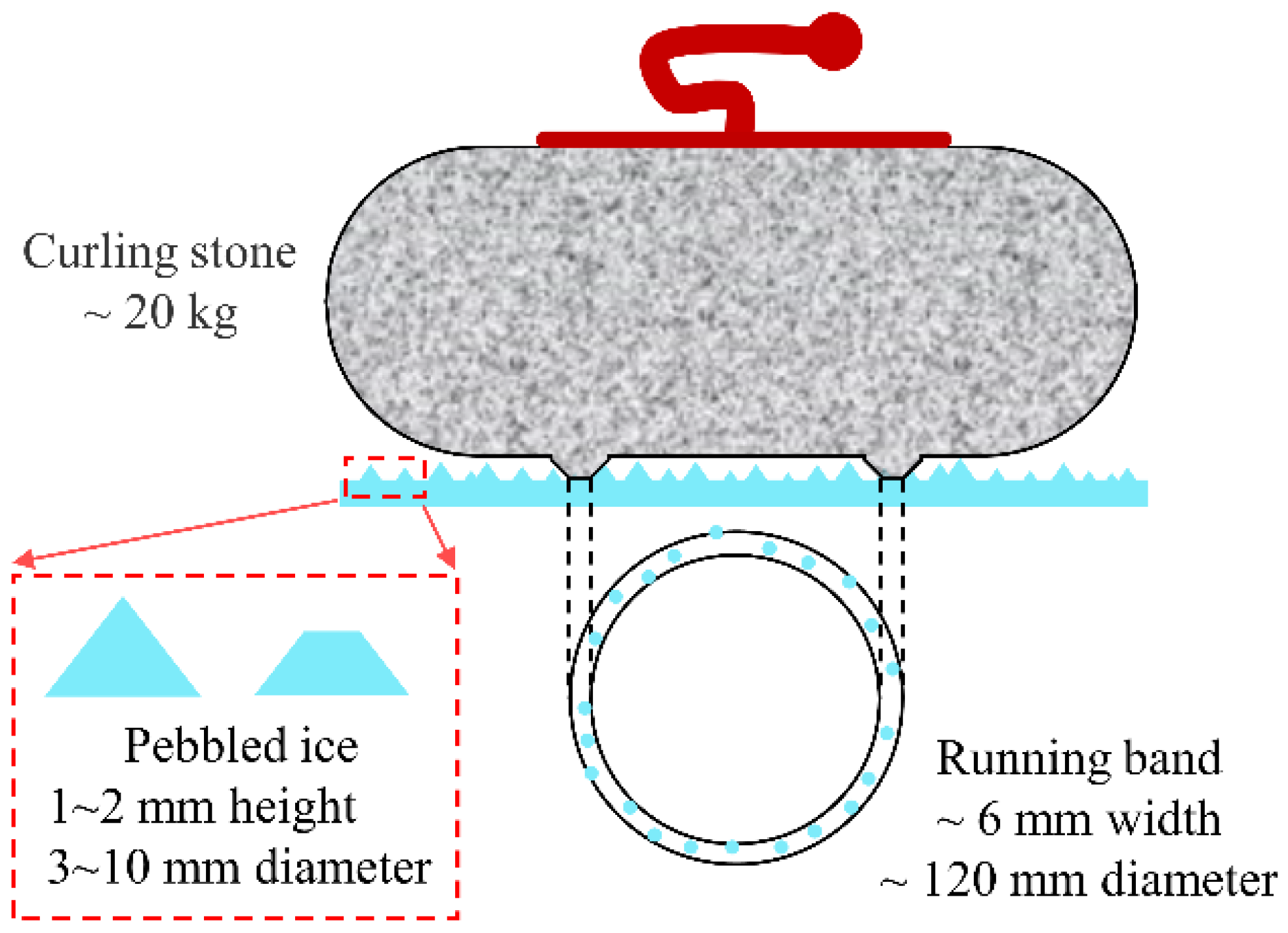

3.1. Experimental Description

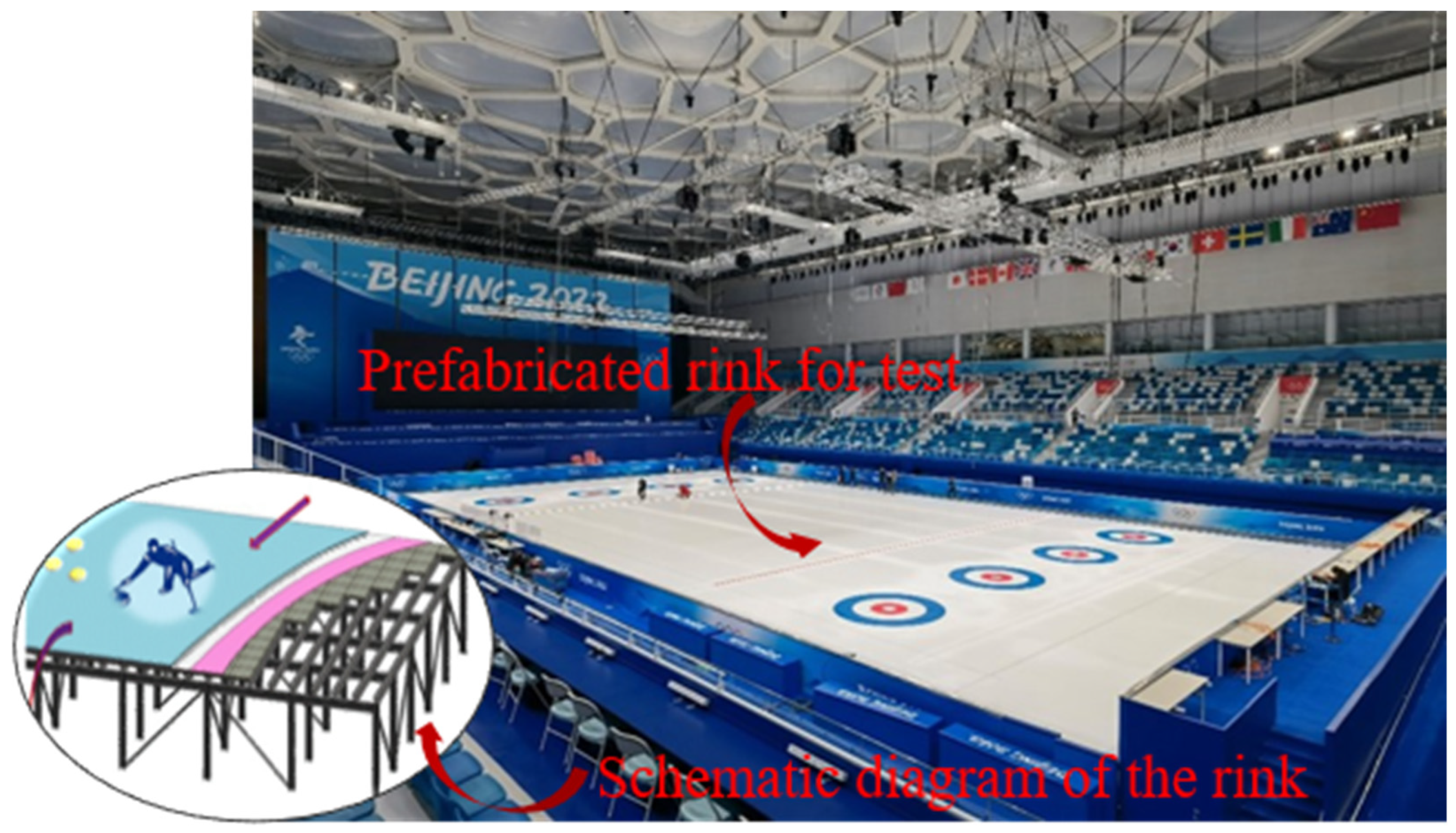

3.1.1. Curling Ice Rink for Beijing Winter Olympics

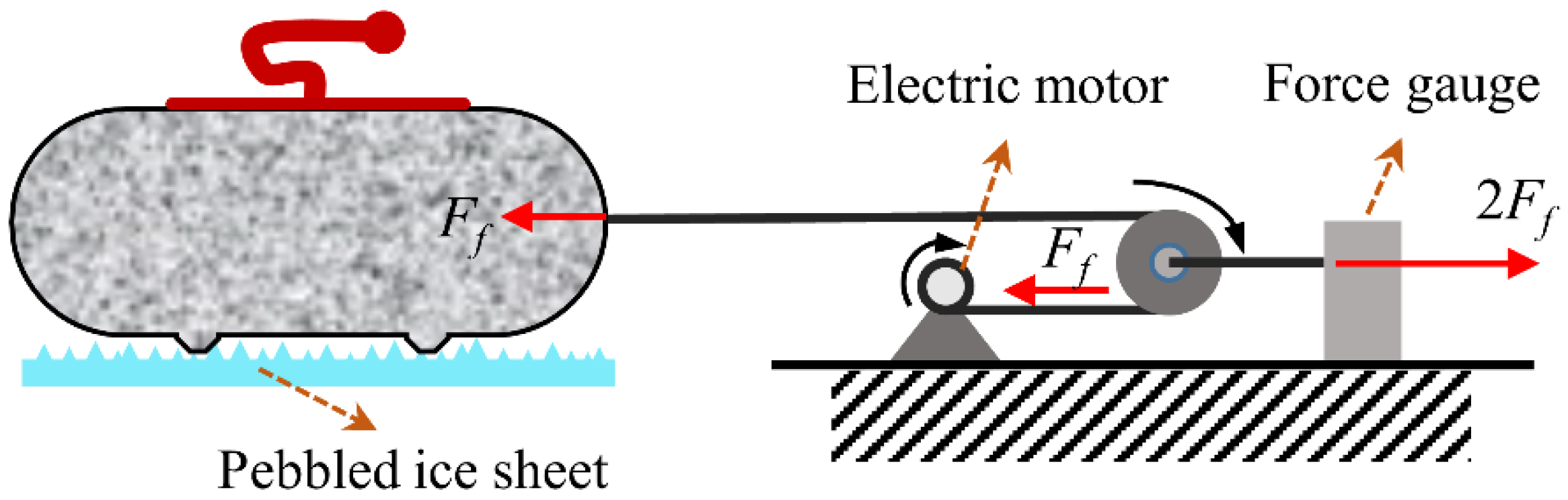

3.1.2. Methods of Measurements

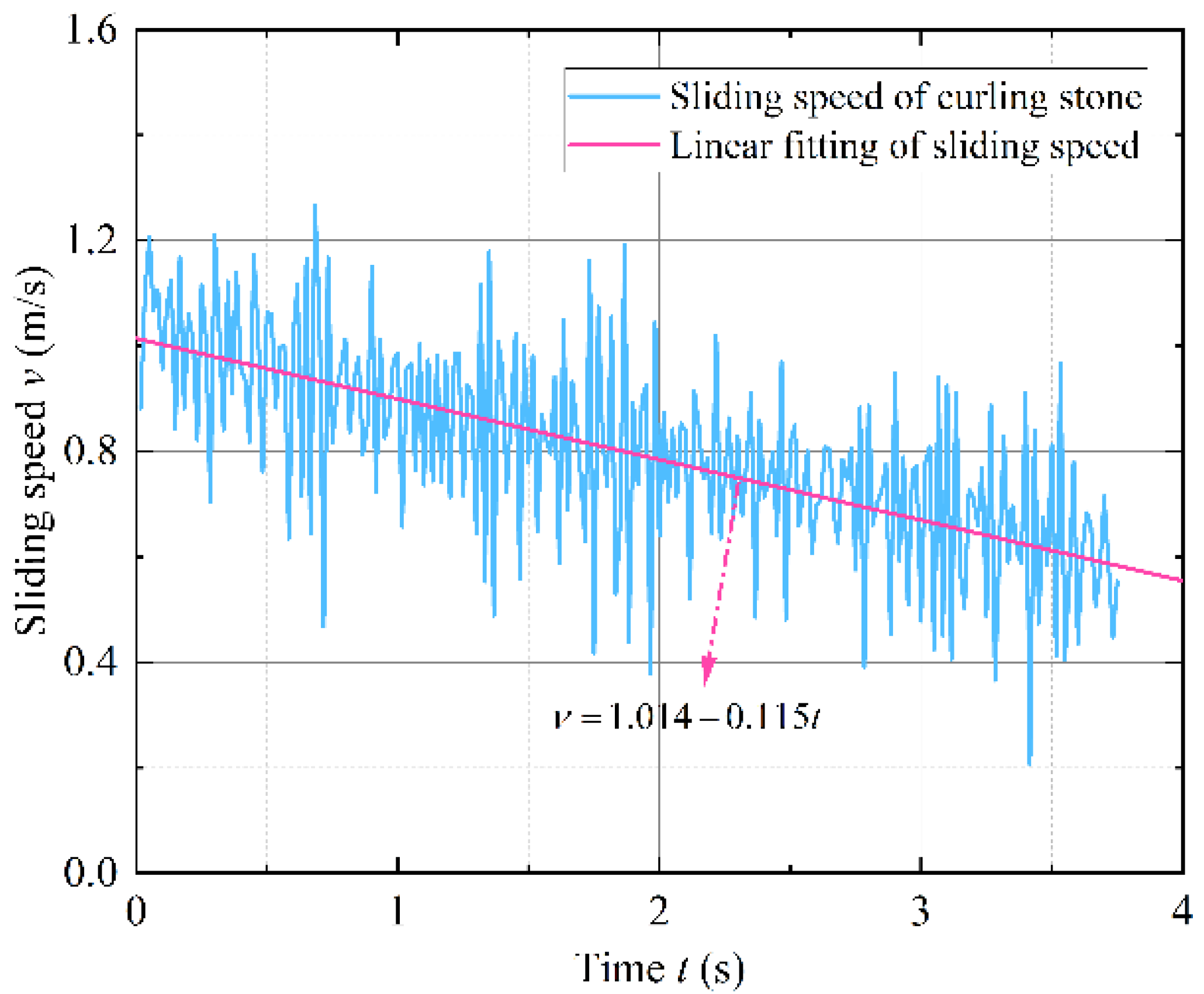

3.2. Data Processing

4. Results and Discussion

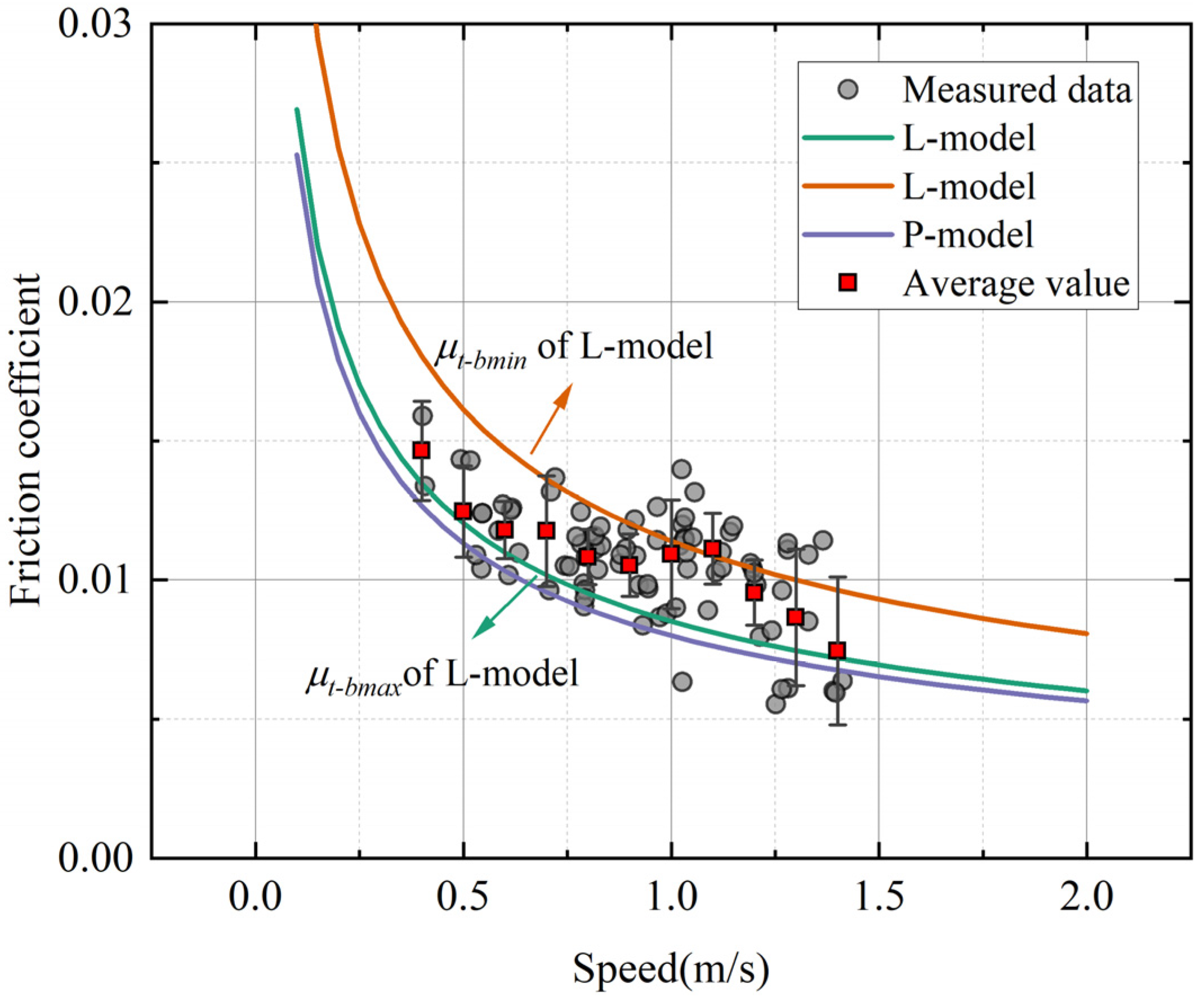

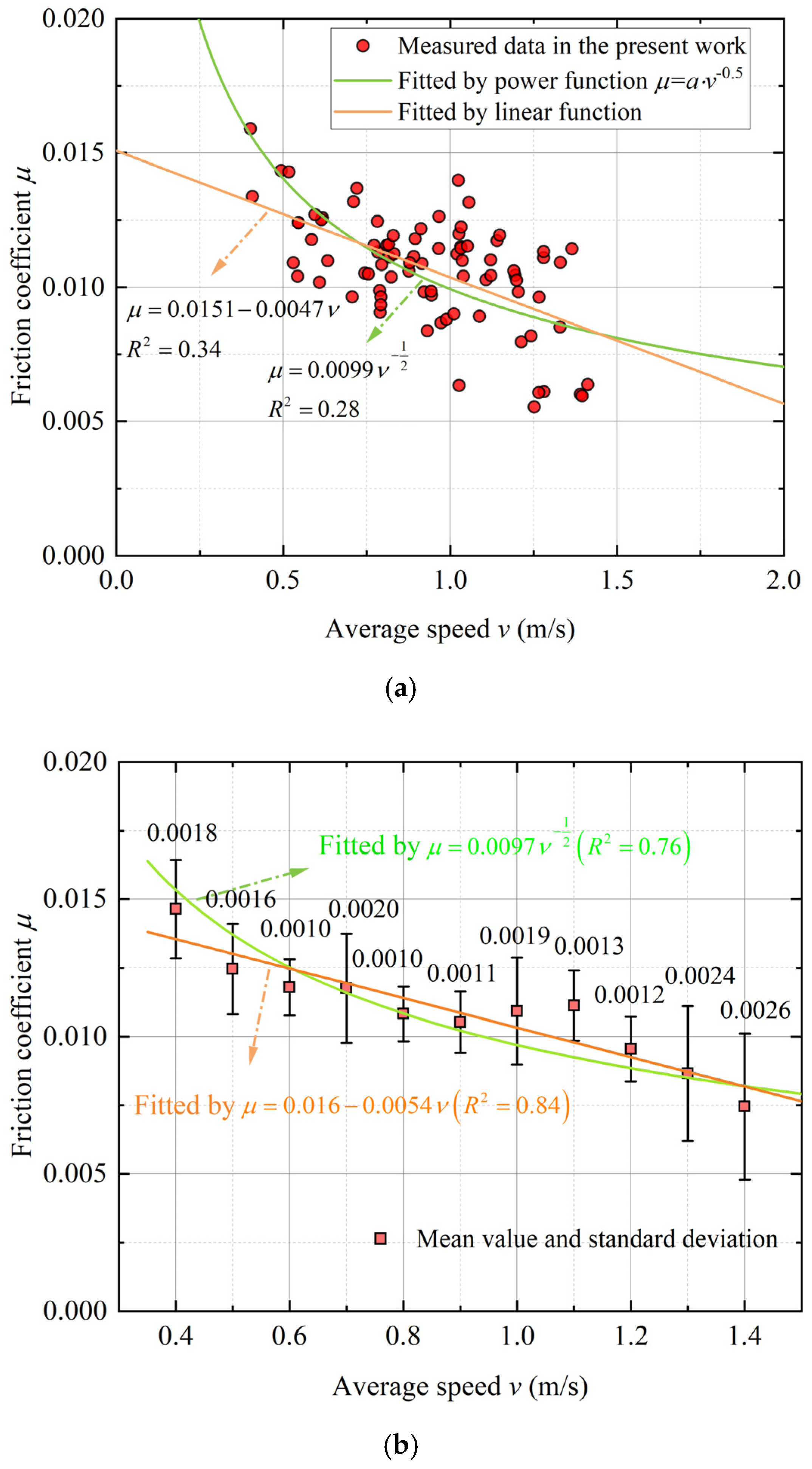

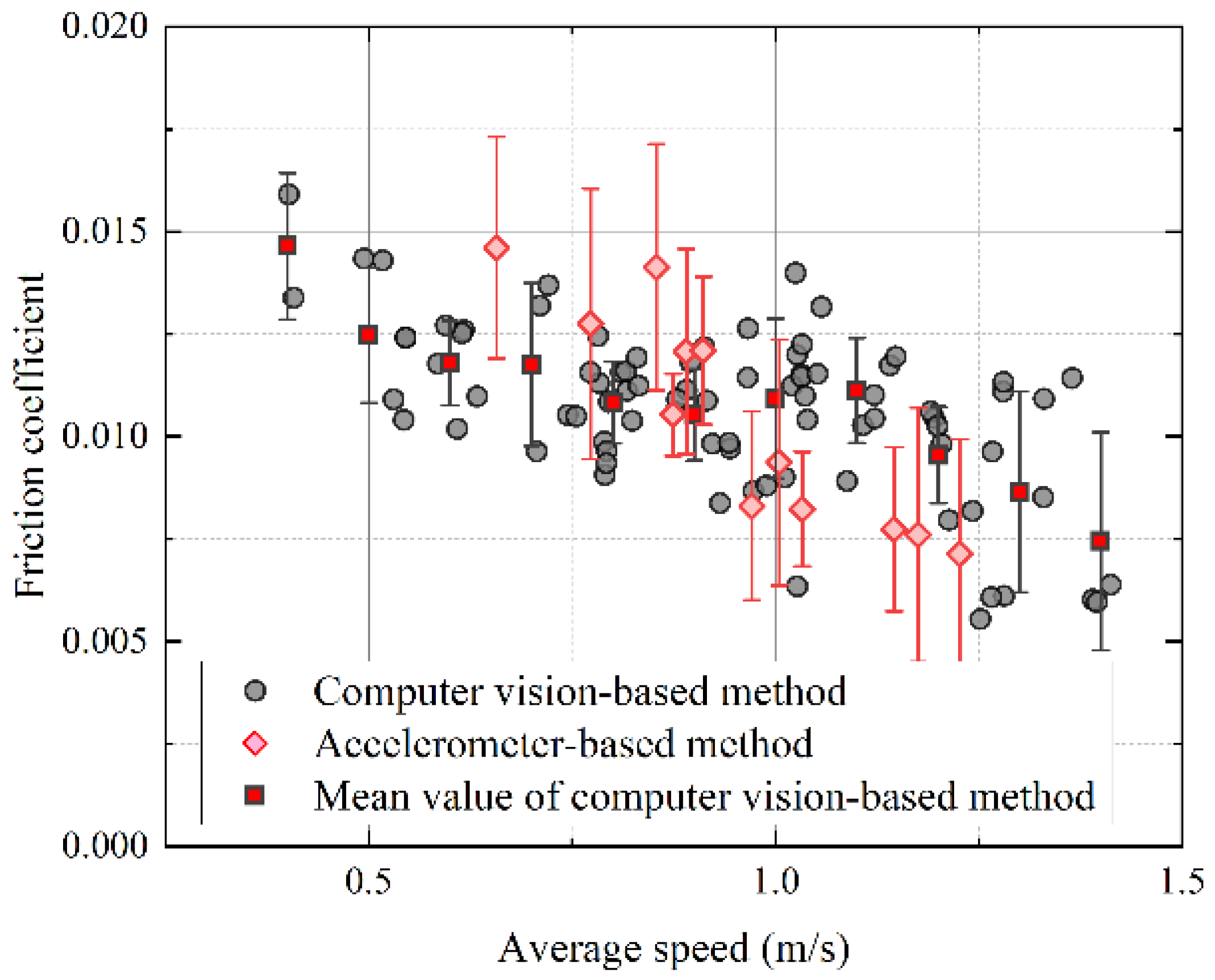

4.1. Impact of Velocity on Friction Coefficient

4.2. Assessment of the Theoretical Models for Stone–Ice Friction

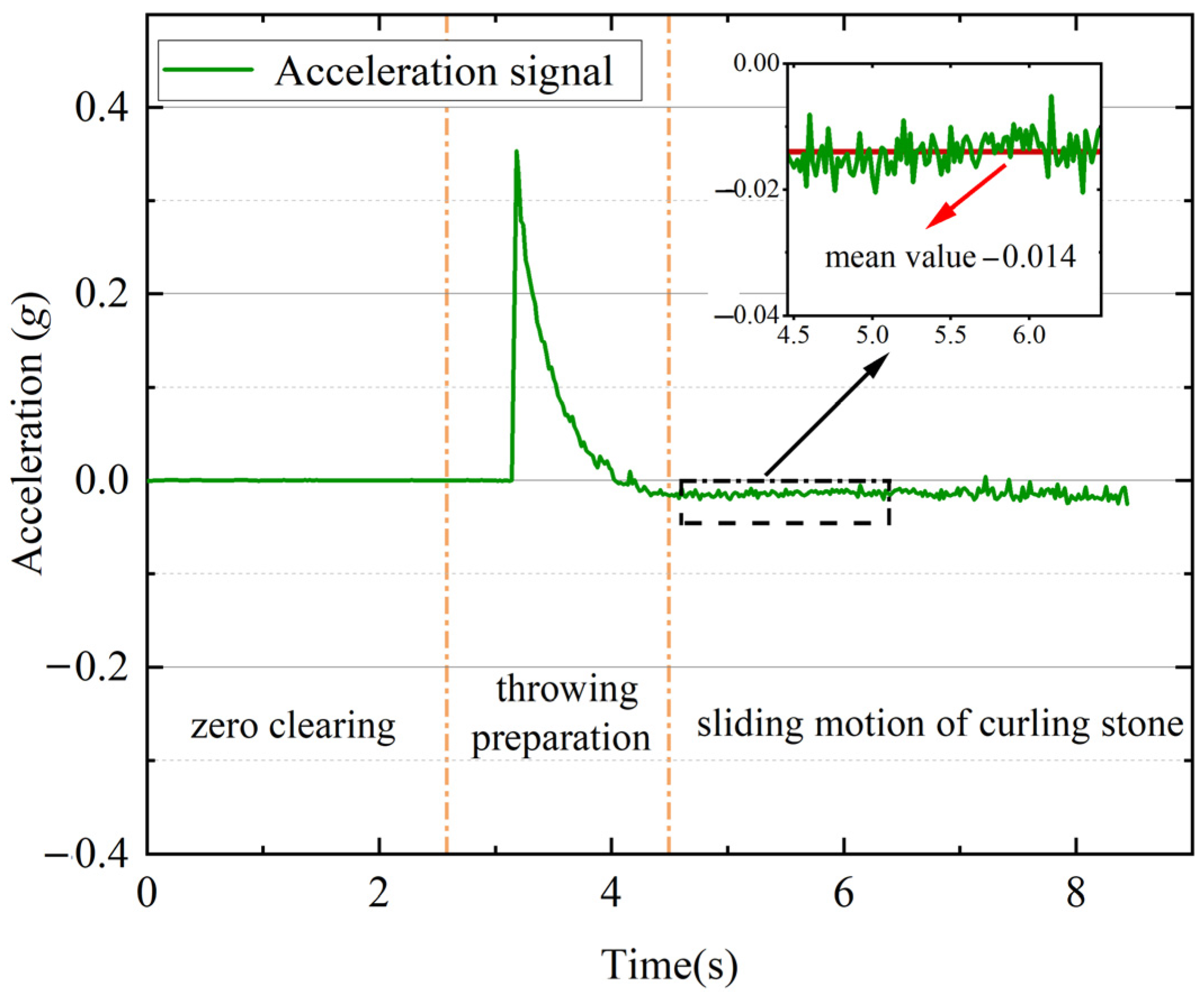

4.3. Verification of the Measured Values Using Accelerometer-Based Method

5. Limitation and Future Work

- (1)

- Only a curling stone with a linear motion trajectory was considered. The transverse motion component caused by stone rotation and ice sweeping was neglected, which is most common in ice rinks. Further studies on the friction mechanism of a curling stone following a curled trajectory are needed.

- (2)

- In this prefabricated rink for the 2022 Beijing Winter Olympics, a surface topography analysis of the pebbled ice was not conducted, due to the limitations of the experiment equipment. Further research is needed to study the influence of the surface topography characteristics of pebbled ice on the stone–ice friction coefficient to reach a more nuanced conclusion.

- (3)

- It should be noted that the friction coefficient obtained in this research is not applicable for the description of friction strength under ice-sweeping circumstances. During the ice-sweeping process, the thickness of the liquid-like layer is increased, which was ascribed to the ice temperature increasing by frictional heating and the melting point of the ice decreasing by considerable pressure. In fact, the thickness of the liquid-like layer on the ice surface has a great influence on the friction strength.

6. Conclusions

- The proposed measurement method based on computer vision technology could be used to obtain the friction coefficient of a curling stone and ice, and the obtained results were in accordance with the law of stone–ice friction, and in good agreement with the related literature data. The computer vision technology based on deep learning can be further employed to monitor the ice quality of the curling rink in real time.

- The coefficient of friction between a curling stone and ice, ranging from 0.006 to 0.016, was significantly affected by the stone sliding speed. Increasing the curling stone sliding speed resulted in lower friction coefficient values, due to the formation of a lubricating water film generated by the friction heat.

- The Lozowski model had a better performance in describing the relationship between the speed and friction. Most of our experimental results were included within the upper and lower limits predicted by the Lozowski model. Under the same ice parameters, the predicted value of the Penner model was lower than that of the Lozowski model, because it ignored the heat generated by friction transferred to the stone and melted ice.

- The accelerometer-based method was additionally employed to measure the stone–ice friction coefficient. The good agreement between the obtained values of our proposed procedure based on the YOLO-V3 deep neural network and that of the accelerometer sensor supported the effectiveness and reliability of the deep-learning-based method.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kim, T.W.; Lee, S.C.; Kil, S.K.; Choi, S.H.; Song, Y.G. A Case Study on Curling Stone and Sweeping Effect According to Sweeping Conditions. Int. J. Environ. Res. Public Health 2021, 18, 833. [Google Scholar] [CrossRef]

- Gwon, J.; Kim, H.; Bae, H.; Lee, S. Path Planning of a Sweeping Robot Based on Path Estimation of a Curling Stone Using Sensor Fusion. Electron 2020, 9, 457. [Google Scholar] [CrossRef]

- Maeno, N. Dynamics and Curl Ratio of a Curling Stone. Sport. Eng. 2014, 17, 33–41. [Google Scholar] [CrossRef]

- Zhang, W.; Li, J.; Yang, Q.; Mu, L. Practical Application of a Novel Prefabricated Curling Ice Rink Supported by Steel–Concrete Composite Floors: In Situ Measurements of Static and Dynamic Response. Structures 2021, 32, 1888–1906. [Google Scholar] [CrossRef]

- Maeno, N. Assignments and Progress of Curling Stone Dynamics. Proc. Inst. Mech. Eng. Part P J. Sport. Eng. Technol. 2016, 494–497. [Google Scholar] [CrossRef]

- Bradley, J.L. The Sports Science of Curling: A Practical Review. J. Sport. Sci. Med. 2009, 8, 495–500. [Google Scholar]

- Denny, M. Curling Rock Dynamics: Towards a Realistic Model. Can. J. Phys. 2002, 80, 1005–1014. [Google Scholar] [CrossRef]

- Jensen, E.T.; Shegelski, M.R.A. The Motion of Curling Rocks: Experimental Investigation and Semi-Phenomenological Description. Can. J. Phys. 2004, 82, 791–809. [Google Scholar] [CrossRef]

- Nyberg, H.; Hogmark, S.; Jacobson, S. Calculated Trajectories of Curling Stones Sliding under Asymmetrical Friction: Validation of Published Models. Tribol. Lett. 2013, 50, 379–385. [Google Scholar] [CrossRef]

- Kameda, T.; Shikano, D.; Harada, Y.; Yanagi, S.; Sado, K. The Importance of the Surface Roughness and Running Band Area on the Bottom of a Stone for the Curling Phenomenon. Sci. Rep. 2020, 10, 20637. [Google Scholar] [CrossRef]

- Maeno, N. Curl Mechanism of a Curling Stone on Ice Pebbles. Bull. Glaciol. Res. 2010, 28, 1–6. [Google Scholar] [CrossRef]

- Shegelski, M.R.A.; Lozowski, E. First Principles Pivot-Slide Model of the Motion of a Curling Rock: Qualitative and Quantitative Predictions. Cold Reg. Sci. Technol. 2018, 146, 182–186. [Google Scholar] [CrossRef]

- Shegelski, M.R.A.; Lozowski, E. Pivot-Slide Model of the Motion of a Curling Rock. Can. J. Phys. 2016, 94, 1305–1309. [Google Scholar] [CrossRef]

- Ziegler, M. The Split Friction Model-The Isotropic Origin of the Lateral Force in Curling. Res. Sq. 2022, 1–14. [Google Scholar] [CrossRef]

- Hattori, K.; Tokumoto, M.; Kashiwazaki, K.; Maeno, N. High-Precision Measurements of Curling Stone Dynamics: Curl Distance by Digital Image Analysis. Proc. Inst. Mech. Eng. Part P J. Sport. Eng. Technol. 2016, 1754337116679061. [Google Scholar] [CrossRef]

- Denny, M. A First-Principles Model of Curling Stone Dynamics. Tribol. Lett. 2022, 70, 84. [Google Scholar] [CrossRef]

- Denny, M. Ice Deformation Explains Curling Stone Trajectories. Tribol. Lett. 2022, 70, 41. [Google Scholar] [CrossRef]

- Braghin, F.; Cheli, F.; Melzi, S.; Sabbioni, E.; Maldifassi, S. The Engineering Approach to Winter Sports; The Engineering Approach to Winter Sports; Springer: Berlin/Heidelberg, Germany, 2016; ISBN 9781493930203. [Google Scholar]

- Penner, A.R. The Physics of Sliding Cylinders and Curling Rocks. Am. J. Phys. 2001, 69, 332. [Google Scholar] [CrossRef]

- Nyberg, H.; Alfredson, S.; Hogmark, S.; Jacobson, S. The Asymmetrical Friction Mechanism That Puts the Curl in the Curling Stone. Wear 2013, 301, 583–589. [Google Scholar] [CrossRef]

- Makkonen, L.; Tikanmäki, M. Modeling the Friction of Ice. Cold Reg. Sci. Technol. 2014, 102, 84–93. [Google Scholar] [CrossRef]

- Kietzig, A.M.; Hatzikiriakos, S.G.; Englezos, P. Physics of Ice Friction. J. Appl. Phys. 2010, 107, 4. [Google Scholar] [CrossRef]

- Spagni, A.; Berardo, A.; Marchetto, D.; Gualtieri, E.; Pugno, N.M.; Valeri, S. Friction of Rough Surfaces on Ice: Experiments and Modeling. Wear 2016, 368, 258–266. [Google Scholar] [CrossRef]

- Scherge, M.; Böttcher, R.; Spagni, A.; Marchetto, D. High-Speed Measurements of Steel-Ice Friction: Experiment vs. Calculation. Lubricants 2018, 6, 26. [Google Scholar] [CrossRef]

- The Kinetic Friction of Ice. Proc. R. Soc. London A Math. Phys. Sci. 1976, 347, 493–512. [CrossRef]

- Lozowski, E.P.; Szilder, K.; Maw, S.; Morris, A.; Poirier, L.; Kleiner, B. Towards a First Principles Model of Curling Ice Friction and Curling Stone Dynamics. In Proceedings of the International Offshore and Polar Engineering Conference, Kona, HI, USA, 21–26 June 2015. [Google Scholar]

- Marian, M.; Tremmel, S. Current Trends and Applications of Machine Learning in Tribology—A Review. Lubricants 2021, 9, 86. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Marian, M.; Profito, F.J.; Aragon, N.; Shah, R. The Use of Artificial Intelligence in Tribology—A Perspective. Lubricants 2021, 9, 2. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, B.; Chen, C.; Li, L.; Wang, X.; Jiang, B.; Zheng, T. A Test Method for Finding Early Dynamic Fracture of Rock:Using DIC and YOLOv5. Sensors 2022, 22, 6320. [Google Scholar] [CrossRef]

- Teng, S.; Liu, Z.; Li, X. Improved YOLOv3-Based Bridge Surface Defect Detection by Combining High- and Low-Resolution Feature Images. Buildings 2022, 12, 1225. [Google Scholar] [CrossRef]

- Wang, D.; Liu, Z.; Gu, X.; Wu, W.; Chen, Y. Automatic Detection of Pothole Distress in Asphalt Pavement Using Improved Convolutional Neural Networks. Remote Sens. 2022, 14, 3892. [Google Scholar] [CrossRef]

- Redmon, J.; Divvala, S.; Girshick, R.; Farhadi, A. You Only Look Once: Unified, Real-Time Object Detection. In Proceedings of the IEEE Computer Society Conference on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 26 June–1 July 2016. [Google Scholar]

- Redmon, J.; Farhadi, A. YOLOv3: An Incremental Improvement. arXiv 2018, arXiv:1804.02767. [Google Scholar]

- Li, Y.; Zhang, X.; Shen, Z. YOLO-Submarine Cable: An Improved YOLO-V3 Network for Object Detection on Submarine Cable Images. J. Mar. Sci. Eng. 2022, 10, 1143. [Google Scholar] [CrossRef]

- Kou, X.; Liu, S.; Cheng, K.; Qian, Y. Development of a YOLO-V3-Based Model for Detecting Defects on Steel Strip Surface. Meas. J. Int. Meas. Confed. 2021, 182, 109454. [Google Scholar] [CrossRef]

- Zhang, W.; Li, J.; Wang, L.; Yuan, B.; Yang, Q. Flexural Characteristics of Artificial Ice in Winter Sports Rinks: Experimental Study and Nondestructive Prediction Based on Surface Hardness Method. Arch. Civ. Mech. Eng. 2022, 22, 1–9. [Google Scholar] [CrossRef]

- Zhang, W.; Li, J.; Yuan, B.; Wang, L.; Yang, Q. Experimental Investigation of Unconfined Compressive Properties of Artificial Ice as a Green Building Material for Rinks. Buildings 2021, 11, 586. [Google Scholar] [CrossRef]

- Wang, Q.; Li, Z.; Lu, P.; Cao, X.; Leppäranta, M. In Situ Experimental Study of the Friction of Sea Ice and Steel on Sea Ice. Appl. Sci. 2018, 8, 675. [Google Scholar] [CrossRef]

- Serré, N. Numerical Modelling of Ice Ridge Keel Action on Subsea Structures. Cold Reg. Sci. Technol. 2011, 67, 107–119. [Google Scholar] [CrossRef]

- Lozowski, E.; Szilder, K.; Maw, S. A Model of Ice Friction for a Speed Skate Blade. Sport. Eng. 2013, 16, 239–253. [Google Scholar] [CrossRef]

- Dzikowski, B.; Weremczuk, J.; Pachwicewicz, M. Acceleration-Based Method of Ice Quality Assessment in the Sport of Curling. Sensors 2022, 22, 1074. [Google Scholar] [CrossRef]

- Dzikowski, B.; Pachwicewicz, M.; Weremczuk, J. Inertial Measurements of Curling Stone Movement. In Proceedings of the 2018 15th International Scientific Conference on Optoelectronic and Electronic Sensors, COE, Warsaw, Poland, 17–20 June 2018. [Google Scholar]

- Lozowski, E.; Maw, S.; Kleiner, B.; Szilder, K.; Shegelski, M.; Musilek, P.; Ferguson, D. Comparison of IMU Measurements of Curling Stone Dynamics with a Numerical Model. In Proceedings of the Procedia Engineering, Budapest, Hungary, 4–7 September 2016. [Google Scholar]

- van der Kruk, E.; den Braver, O.; Schwab, A.L.; van der Helm, F.C.T.; Veeger, H.E.J. Wireless Instrumented Klapskates for Long-Track Speed Skating. Sport. Eng. 2016, 19, 273–281. [Google Scholar] [CrossRef]

- Ovaska, M.; Tuononen, A.J. Multiscale Imaging of Wear Tracks in Ice Skate Friction. Tribol. Int. 2018, 21, 280–286. [Google Scholar] [CrossRef]

| Reference | Curling Rink | Ice Surface Temperature | Air Temperature and Relative Humidity | Sliding Velocity |

|---|---|---|---|---|

| Penner [19] | Nanaimo curling rink in Canada | −5 °C | Not available | 0.15~1 m/s |

| Nyberg et al. [20] | Curling ice prepared by Daniel Svensson at Curlingcompaniet | −3.5 °C | 6~7 °C and 55% | 0.1~2.3 m/s |

| This study | Prefabricated curling rink for Winter Olympics | −5 °C | 7~9 °C and ~39% | 0.4~1.4 m/s |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Li, S.; Zhang, W.; Wei, B.; Yang, Q. Experimental Measurement of Ice-Curling Stone Friction Coefficient Based on Computer Vision Technology: A Case Study of “Ice Cube” for 2022 Beijing Winter Olympics. Lubricants 2022, 10, 265. https://doi.org/10.3390/lubricants10100265

Li J, Li S, Zhang W, Wei B, Yang Q. Experimental Measurement of Ice-Curling Stone Friction Coefficient Based on Computer Vision Technology: A Case Study of “Ice Cube” for 2022 Beijing Winter Olympics. Lubricants. 2022; 10(10):265. https://doi.org/10.3390/lubricants10100265

Chicago/Turabian StyleLi, Junxing, Shuaiyu Li, Wenyuan Zhang, Bo Wei, and Qiyong Yang. 2022. "Experimental Measurement of Ice-Curling Stone Friction Coefficient Based on Computer Vision Technology: A Case Study of “Ice Cube” for 2022 Beijing Winter Olympics" Lubricants 10, no. 10: 265. https://doi.org/10.3390/lubricants10100265

APA StyleLi, J., Li, S., Zhang, W., Wei, B., & Yang, Q. (2022). Experimental Measurement of Ice-Curling Stone Friction Coefficient Based on Computer Vision Technology: A Case Study of “Ice Cube” for 2022 Beijing Winter Olympics. Lubricants, 10(10), 265. https://doi.org/10.3390/lubricants10100265