Effects of Laser Surface Texturing and Lubrication on the Vibrational and Tribological Performance of Sliding Contact

Abstract

:1. Introduction

2. Materials and Methods

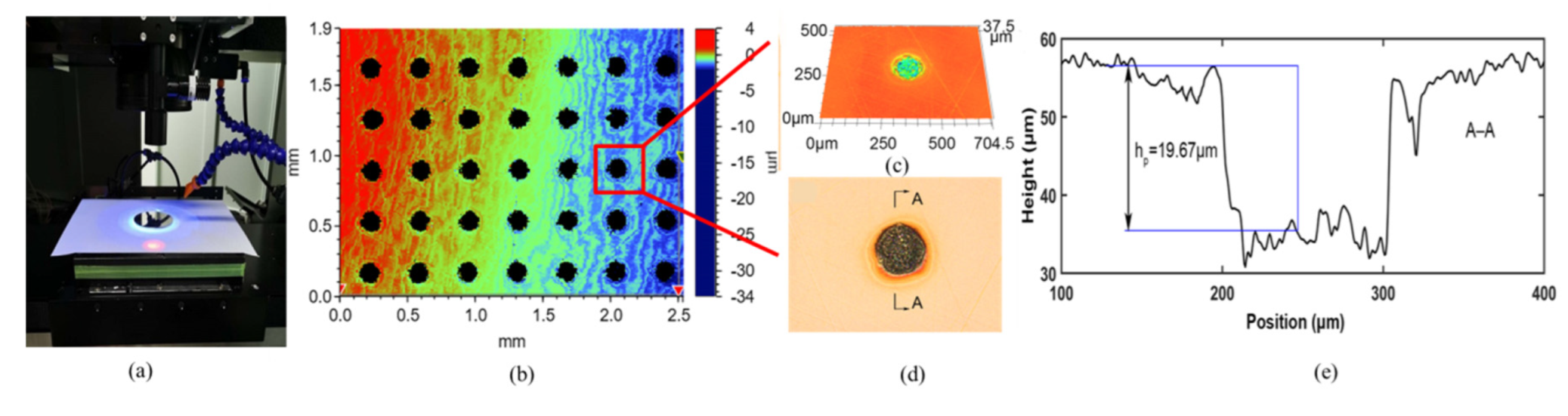

2.1. Test Specimen Preparation

2.2. Test Rig

2.3. Experimental Methodology

3. Experimental Results and Discussion

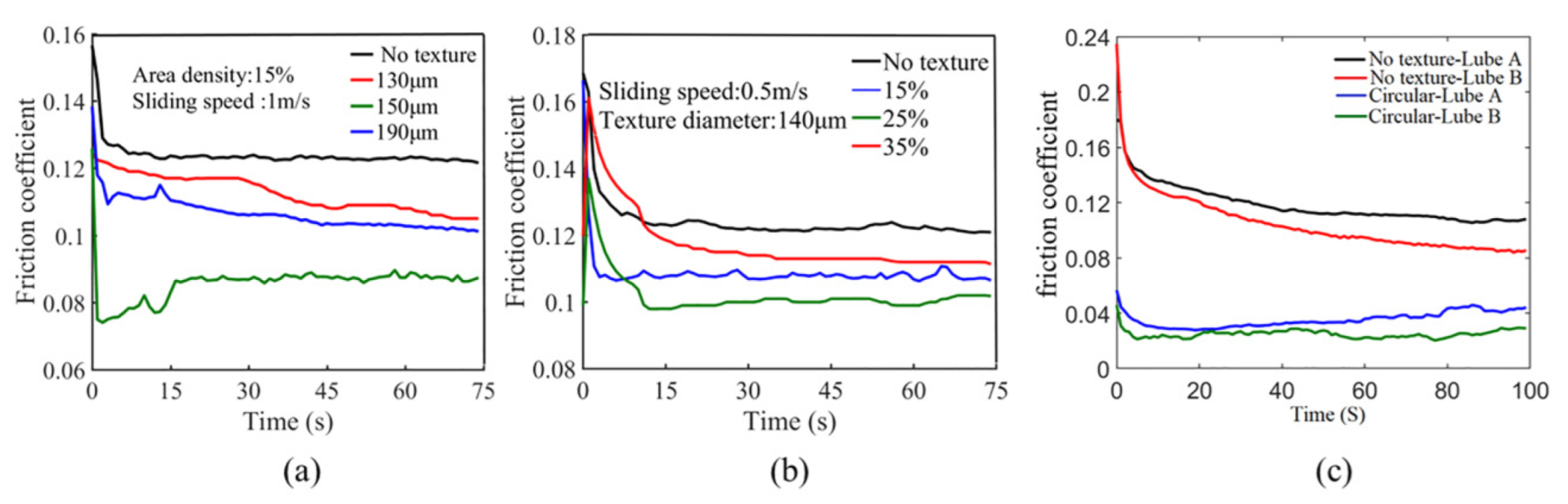

3.1. Effect of LST on COFs

3.1.1. Texture Diameter

3.1.2. Area Density

3.1.3. Lubricant

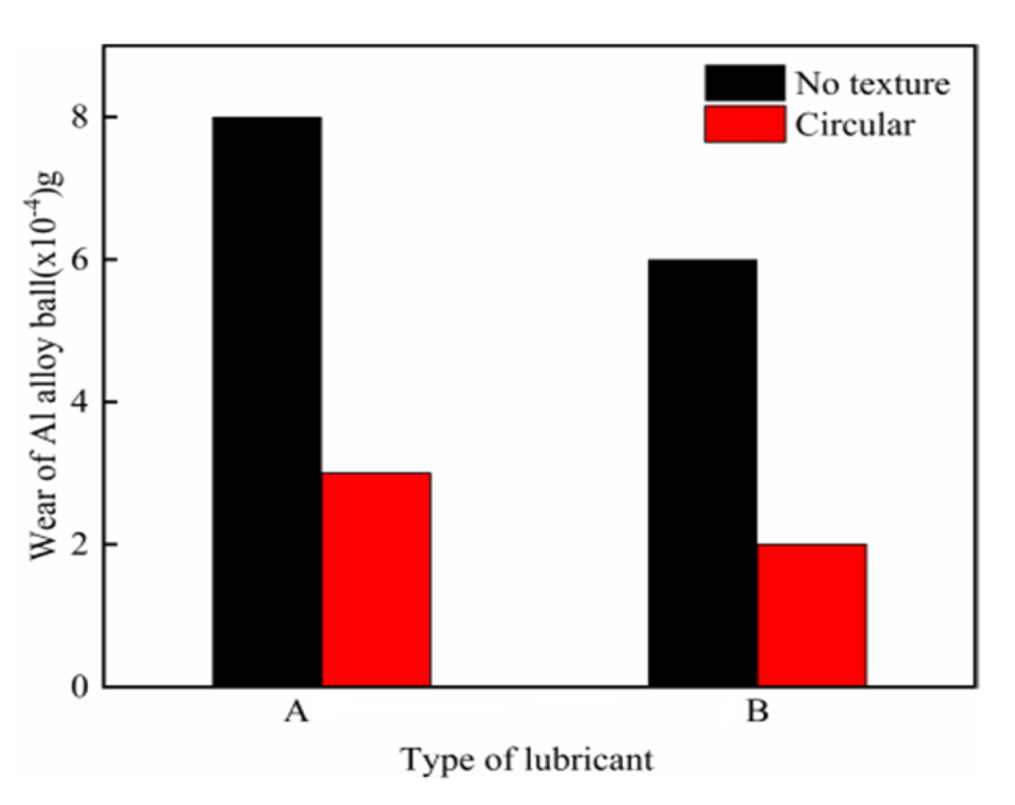

3.2. Effect of LST on Wear

3.2.1. Texture Diameter

3.2.2. Area Density

3.2.3. Lubricant

3.2.4. The Mechanism of Friction and Wear Reduction by LST

3.3. Effect of LST on Frictional Vibrations

3.3.1. Texture Diameter

3.3.2. Area Density

3.3.3. Lubricant

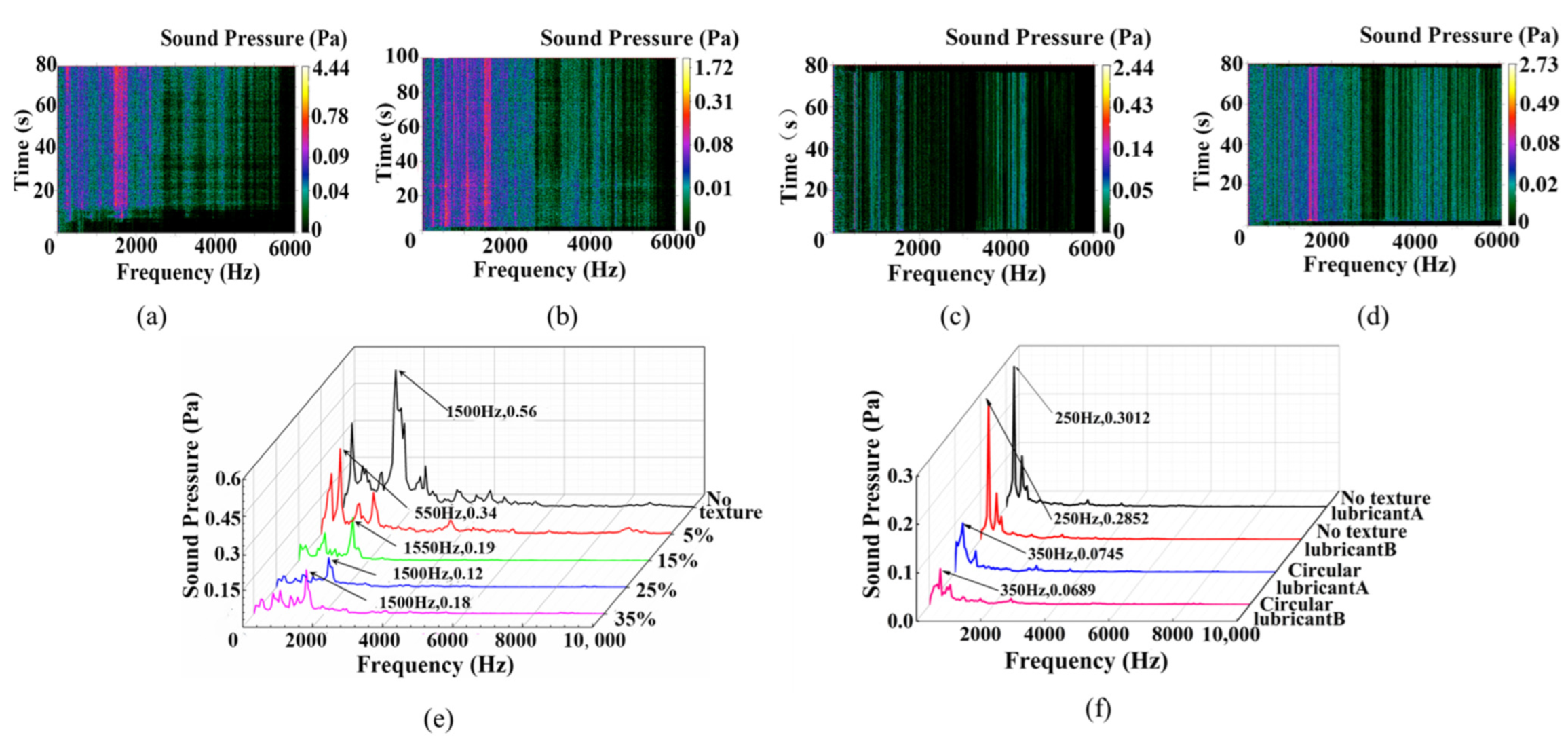

3.4. Effect of LST on Frictional Noise

3.4.1. Texture Diameter

3.4.2. Area Density

3.4.3. Lubricant

3.4.4. The Mechanism of Frictional Vibration and Noise Reduction by LST

4. Conclusions

- (1)

- Under the operation conditions in this study, the circular dimples in diameter of 150 μm have a better tribological performance than those of 130 and 190 μm, while a textured area density of 25% has a better tribological performance than those with 15% and 35% textured area densities.

- (2)

- Laser surface textures have a significant effect on the reduction of frictional vibrations and noise generated from steel-steel lubricated non-conformal sliding contacts in both the time and frequency domains. In this study, the maximum RMS reduction of frictional vibrations and noise is more than 95% and 70%, respectively, in the time and frequency domains.

- (3)

- Adding graphene to the Castrol 5W-30 fully synthetic engine oil can improve the tribological and dynamical performance of lubrication. Surface textures (circular dimples) have a more significant effect on the frictional noise and vibration reduction than the lubricants, and surface textures enhance the frictional noise reduction performance of lubrication.

- (4)

- When the upper specimen is an aluminum alloy ball, the effect of texture on the reduction of friction, vibration, and noise is more significant than the bearing steel ball upper specimen, which may be due to the more significant hydrodynamic effect generated by the surface textures sliding contact with the aluminum alloy balls. However, the mechanisms are required for further investigation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, K.Y.; Yang, X.F.; Zhang, Y.F.; Yang, H.; Lv, G.J.; Gao, Y.L. Research progress of improving surface friction properties by surface texture technology. Int. J. Adv. Manuf. Technol. 2021, 116, 1797–2821. [Google Scholar] [CrossRef]

- Shinkarenko, A.; Kligerm, Y.; Etsion, I. The effect of surface texturing in soft elasto-hydrodynamic lubrication. Tribol. Int. 2009, 42, 284–292. [Google Scholar] [CrossRef]

- Pettersson, U.; Jacobson, S. Influence of surface texture on boundary lubricated sliding contacts. Tribol. Int. 2003, 36, 857–864. [Google Scholar] [CrossRef]

- Uehara, Y.; Wakuda, M.; Yamauchi, Y.; Kanzaki, S.; Sakaguchi, S. Tribological properties of dimpled silicon nitride under oil lubrication. J. Eur. Ceram. Soc. 2004, 24, 369–373. [Google Scholar] [CrossRef]

- Yan, D.S.; Qu, N.S.; Li, H.S.; Wang, X.L. Significance of dimple parameters on the friction of sliding surfaces investigated by orthogonal experiments. Tribol. Trans. 2010, 53, 703–712. [Google Scholar] [CrossRef]

- Etsion, I.; Sher, E. Improving fuel efficiency with laser surface textured piston rings. Tribol. Int. 2009, 42, 542–547. [Google Scholar] [CrossRef]

- Ryk, G.; Etsion, I. Testing piston rings with partial laser surface texturing for friction reduction. Wear 2006, 261, 792–796. [Google Scholar] [CrossRef]

- Elo, R.; Heinrichs, J.; Jacobson, S. Surface texturing to promote formation of protective tribofilms on combustion engine valves. Proc. Inst. Mech. Eng. Part J 2018, 232, 54–61. [Google Scholar] [CrossRef]

- Wang, L.L.; Guo, S.H.; Wei, Y.L.; Yuan, G.T. Research on the influence of micropits structure on the tribological performance of friction pairs. Proc. Inst. Mech. Eng. Part J 2019, 233, 317–325. [Google Scholar] [CrossRef]

- Andersson, P.; Koskinen, J.; Varjus, S.; Gerbig, Y.; Haefke, H.; Gergiou, S.; Zhmud, B.; Buss, W. Microlubrication effect by laser-textured steel surfaces. Wear 2007, 262, 369–379. [Google Scholar] [CrossRef]

- Tang, W.; Zhou, Y.K.; Zhu, H.; Yang, H.F. The effect of surface texturing on reducing the friction and wear of steel under lubricated sliding contact. Appl. Surf. Sci. 2013, 273, 199–204. [Google Scholar] [CrossRef]

- Rapoport, L.; Moshkovich, A.; Perfilyev, V.; Gedanken, A.; Koltypin, Y.; Sominski, E.; Halperin, G.; Etsion, I. Wear life and adhesion of solid lubricant films on laser-textured steel surfaces. Wear 2009, 267, 1203–1207. [Google Scholar] [CrossRef]

- Sudeep, U.; Pandey, R.K.; Tandon, N. Effects of surface texturing on friction and vibration behaviors of sliding lubricated concentrated point contacts under linear reciprocating motion. Tribol. Int. 2013, 62, 198–207. [Google Scholar] [CrossRef]

- Segu, D.; Kim, S. Influence on friction behavior of micro-texturing under lubricated non-conformal contact. Meccanica 2014, 49, 483–492. [Google Scholar] [CrossRef]

- Duffet, G.; Sallamand, P.; Vannes, A. Improvement in friction by cw Nd:YAG laser surface treatment on cast iron cylinder bore. Appl. Surf. Sci. 2002, 205, 289–296. [Google Scholar] [CrossRef]

- Lu, P.; Wood, R.J.K.; Gee, M.G.; Wang, L.; Pfleging, W. A novel surface texture shape for directional friction control. Tribol. Lett. 2018, 66, 51. [Google Scholar] [CrossRef] [Green Version]

- Saeidi, F.; Meylan, B.; Hoffmann, P.; Wasmer, K. Effect of surface texturing on cast iron reciprocating against steel under starved lubrication conditions: A parametric study. Wear 2016, 348, 17–26. [Google Scholar] [CrossRef] [Green Version]

- Nakano, M.; Korenaga, A.; Korenaga, A.; Miyake, K.; Murakami, T.; Ando, Y.; Usami, H.; Sasaki, S. Applying micro-texture to cast iron surfaces to reduce the friction coefficient under lubricated conditions. Tribol. Lett. 2007, 28, 131–137. [Google Scholar] [CrossRef]

- Kumar, B.; Babu, P.; Marimuthu, P. Effect of laser surface texturing on tribological behaviour of grey cast iron. Int. J. Surf. Sci. Eng. 2019, 13, 220–235. [Google Scholar] [CrossRef]

- Vasumathy, D.; Meena, A. Influence of micro scale textured tools on tribological properties at tool-chip interface in turning AISI 316 austenitic stainless steel. Wear 2017, 376, 1747–1758. [Google Scholar] [CrossRef]

- Sun, Q.C.; Hu, T.C.; Fan, H.Z.; Zhang, Y.S.; Hu, L.T. Dry sliding wear behavior of TC11 alloy at 500 °C: Influence of laser surface texturing. Tribol. Int. 2015, 92, 136–145. [Google Scholar] [CrossRef]

- Kovalchenko, A.; Ajayi, O.; Erdemir, A.; Fenske, G. Friction and wear behavior of laser textured surface under lubricated initial point contact. Wear 2010, 271, 1719–1725. [Google Scholar] [CrossRef]

- Li, J.L.; Xiong, D.S.; Dai, J.H.; Huang, Z.J.; Tyagi, R. Effect of surface laser texture on friction properties of nickel-based composite. Tribol. Int. 2009, 43, 1193–1199. [Google Scholar] [CrossRef]

- Borghi, A.; Gualtieri, E.; Marchetto, D.; Moretti, L.; Valeri, S. Tribological effects of surface texturing on nitriding steel for high-performance engine applications. Wear 2008, 265, 1046–1051. [Google Scholar] [CrossRef]

- Gachot, C.; Rosenkranz, A.; Hsu, S.M.; Costa, H.L. A critical assessment of surface texturing for friction and wear improvement. Wear 2017, 372, 21–41. [Google Scholar] [CrossRef]

- Costa, H.L.; Hutchings, I.M. Hydrodynamic lubrication of textured steel surfaces under reciprocating sliding conditions. Tribol. Int. 2007, 40, 1227–1238. [Google Scholar] [CrossRef]

- Kovalchenko, A.; Ajayi, O.; Erdemir, A.; Fenske, G.; Etsion, I. The effect of laser surface texturing on transitions in lubrication regimes during unidirectional sliding contact. Tribol. Int. 2005, 38, 219–225. [Google Scholar] [CrossRef]

- Greiner, C.; Schäfer, M. Bio-inspired scale-like surface textures and their tribological properties. Bioinspir. Biomim. 2015, 10, 044001. [Google Scholar] [CrossRef]

- Zheng, L.; Wu, J.J.; Sun, S.S.; Zhang, Z.H.; Liang, S.; Liu, Z.N.; Ren, L.Q. Bionic coupling of hardness gradient to surface texture for improved anti-wear properties. J. Bionic Eng. 2016, 13, 406–415. [Google Scholar] [CrossRef]

- Sudeep, U.; Tandon, N.; Pandey, R. Friction and vibration behaviors of lubricated laser textured point contacts under reciprocating rolling motion with highlights on the used laser parameters. Procedia Technol. 2014, 14, 4–11. [Google Scholar] [CrossRef]

- Meng, F.; Shu, R.; Chen, L. Influences of operation parameters on noise of journal bearing with compound texture considering lubricant thermal effect. Proc. Inst. Mech. Eng. Part J 2020, 234, 991–1006. [Google Scholar] [CrossRef]

- Wang, S.W.; Chen, A.; Li, L.; Zhang, X.G. Tribological and vibrational effects of laser surface texturing on steel-steel sliding contact. J. Phys. Conf. Ser. 2018, 1106, 11. [Google Scholar] [CrossRef]

- Schreck, S.; Gahr, K. Laser-assisted structuring of ceramic and steel surfaces for improving tribological properties. Appl. Surf. Sci. 2005, 247, 616–622. [Google Scholar] [CrossRef]

- Kong, S.; Hu, W.J.; Li, J.S. Tribological properties of graphene in PAO base oil. China Surf. Eng. 2019, 32, 162–169. [Google Scholar]

- Yang, H.M.; Li, J.S.; Zeng, X.Q. Tribological behavior of alkylamine edge functionalized graphene oxide pickering emulsion. China Surf. Eng. 2019, 32, 151–159. [Google Scholar]

- Sarno, M.; Senatore, A.; Cirillo, C.; Petrone, V.; Ciambell, P. Oil lubricant tribological behaviour improvement through dispersion of few layer grapheme oxides. J. Nanosci. Nanotechnol. 2014, 14, 4960–4968. [Google Scholar] [CrossRef]

- Bhaumik, S.; Kamaraj, M.; Paleu, V. Tribological analyses of a new optimized gearbox biodegradable lubricant blended with reduced graphene oxide nanoparticles. Proc. Inst. Mech. Eng. Part J 2021, 235, 901–915. [Google Scholar] [CrossRef]

- Wang, S.W.; Guo, W.; Zeng, K.; Zhang, X.G. Characterization of automotive brake discs with laser-machined surfaces. Automot. Innov. 2019, 2, 190–200. [Google Scholar] [CrossRef]

- Wang, S.W.; Yan, F.Y.; Chen, A. Tribological effects of laser surface texturing and residual stress. Ind. Lubr. Tribol. 2018, 70, 126–132. [Google Scholar] [CrossRef]

- Mohmad, M.; Abdollah, M.; Tamaldin, N.; Amiruddin, H. The effect of dimple size on the tribological performances of a laser surface textured palm kernel activated carbon-epoxy composite. Ind. Lubr. Tribol. 2017, 69, 768–774. [Google Scholar] [CrossRef]

- Sudeep, U.; Tandon, N.; Pandey, R.K. Vibration studies of lubricated textured point contacts of bearing steels due to surface topographies: Simulations and experiments. Tribol. Int. 2016, 102, 265–274. [Google Scholar] [CrossRef]

| Parameter | Value | Unit |

|---|---|---|

| Laser wavelength | 1064 | nm |

| Laser output power | 100 | W |

| Acousto-optic modulation frequency | 0.5~20 | kHz |

| Maximum linear carving speed | 3000 | mm/s |

| Marking scope | 45 × 45 | mm |

| Repeated precision | 2 | μm |

| Positioning accuracy | 2 | μm |

| Marking line depth | 0.001~0.1 | mm |

| Materials | Type | Young’s Modulus (GPa) | Hardness (HB) | Density (g/cm3) |

|---|---|---|---|---|

| Steel plate | SUS304 | 193 | 205~210 | 7.93 |

| Steel ball | GCr15 | 208 | 740~860 | 7.81 |

| Al ball | 5052 | 72 | 120~160 | 2.72 |

| Parametric Study | Texture Diameter (μm) | Textured Area Density (%) | Sliding Speed (m/s) | Upper Specimen |

|---|---|---|---|---|

| Effect of texture diameter | 0 | 0 | 1.0 | Bearing steel ball |

| 130 | 15 | 1.0 | ||

| 150 | 15 | 1.0 | ||

| 190 | 15 | 1.0 | ||

| Effect of textured area density | 0 | 0 | 0.5 | Bearing steel ball |

| 140 | 15 | 0.5 | ||

| 140 | 25 | 0.5 | ||

| 140 | 35 | 0.5 | ||

| Effect of lubricant | 0 | 0 | 1.0 | Aluminum alloy ball |

| 140 | 25 | 1.0 |

| Types of Lubricants | Characteristic | Value | Unit | Test Standard |

|---|---|---|---|---|

| Lubricant A (Castrol 5w-30) | Density (ρ1 /15.6 °C) | 849 | kg/m3 | ASTM D4052 |

| Viscosity (η1/100 °C) | 0.009594 | Pa·s | ASTM D445 | |

| Flash point | 230 | °C | ASTM D92 | |

| Total base number | 11.3 | TBN | ASTM D2896 | |

| Lubricant B (Castrol 5W-30 with 0.1% graphene added) | Density (ρ2 /15.6 °C) | 860 | kg/m3 | ASTM D4052 |

| Viscosity (η2/100 °C) | 0.009718 | Pa·s | ASTM D445 | |

| Flash point | >200 | °C | ASTM D92 | |

| Total base number | 11.3 | TBN | ASTM D2896 |

| Test | RMS (Time Domain) (m/s2) | Vibration Reduction (%) | Peak Resonant Frequency/ Amplitude | ||

|---|---|---|---|---|---|

| Diameter (μm) | Area Density (%) | Speed (m/s) | Time Domain | ||

| 0 | 0 | 1 | 49.6311 | / | 700 Hz, 34.58 |

| 130 | 15 | 1 | 16.2964 | 67.2 | 550 Hz, 12.34 |

| 150 | 15 | 1 | 2.4190 | 95.1 | 500 Hz, 1.82 |

| 190 | 15 | 1 | 10.3100 | 79.2 | 750 Hz, 7.94 |

| 0 | 0 | 0.5 | 29.6885 | / | 1700 Hz,17.86 |

| 140 | 15 | 0.5 | 16.2964 | 45.1 | 500 Hz, 12.97 |

| 140 | 25 | 0.5 | 3.6681 | 87.6 | 600 Hz, 2.72 |

| 140 | 35 | 0.5 | 7.5730 | 74.5 | 550 Hz, 6.69 |

| Test | RMS (Time Domain) (m/s2) | Noise Reduction (%) | Resonant Frequency/ Amplitude | |

|---|---|---|---|---|

| Diameter (μm) | Area Density (%) | Time Domain | ||

| 0 | 0 | 1.0085 | / | 1500 Hz, 0.56 |

| 130 | 15 | 0.4870 | 52 | 1500 Hz, 0.24 |

| 150 | 15 | 0.344 | 66 | 500 Hz, 1.82 |

| 190 | 15 | 0.8524 | 15 | 750 Hz, 7.94 |

| 140 | 5 | 0.6768 | 33 | 550 Hz, 0.34 |

| 140 | 15 | 0.3124 | 69 | 1550 Hz, 0.19 |

| 140 | 25 | 0.2707 | 73 | 1500 Hz, 0.12 |

| 140 | 35 | 0.3169 | 68 | 1500 Hz, 0.18 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, S.; Sai, Q.; Wang, S.; Williams, J. Effects of Laser Surface Texturing and Lubrication on the Vibrational and Tribological Performance of Sliding Contact. Lubricants 2022, 10, 10. https://doi.org/10.3390/lubricants10010010

Liu S, Sai Q, Wang S, Williams J. Effects of Laser Surface Texturing and Lubrication on the Vibrational and Tribological Performance of Sliding Contact. Lubricants. 2022; 10(1):10. https://doi.org/10.3390/lubricants10010010

Chicago/Turabian StyleLiu, Shunchu, Qingyi Sai, Shuwen Wang, and John Williams. 2022. "Effects of Laser Surface Texturing and Lubrication on the Vibrational and Tribological Performance of Sliding Contact" Lubricants 10, no. 1: 10. https://doi.org/10.3390/lubricants10010010

APA StyleLiu, S., Sai, Q., Wang, S., & Williams, J. (2022). Effects of Laser Surface Texturing and Lubrication on the Vibrational and Tribological Performance of Sliding Contact. Lubricants, 10(1), 10. https://doi.org/10.3390/lubricants10010010