A Study on Bearing Dynamic Features under the Condition of Multiball–Cage Collision

Abstract

:1. Introduction

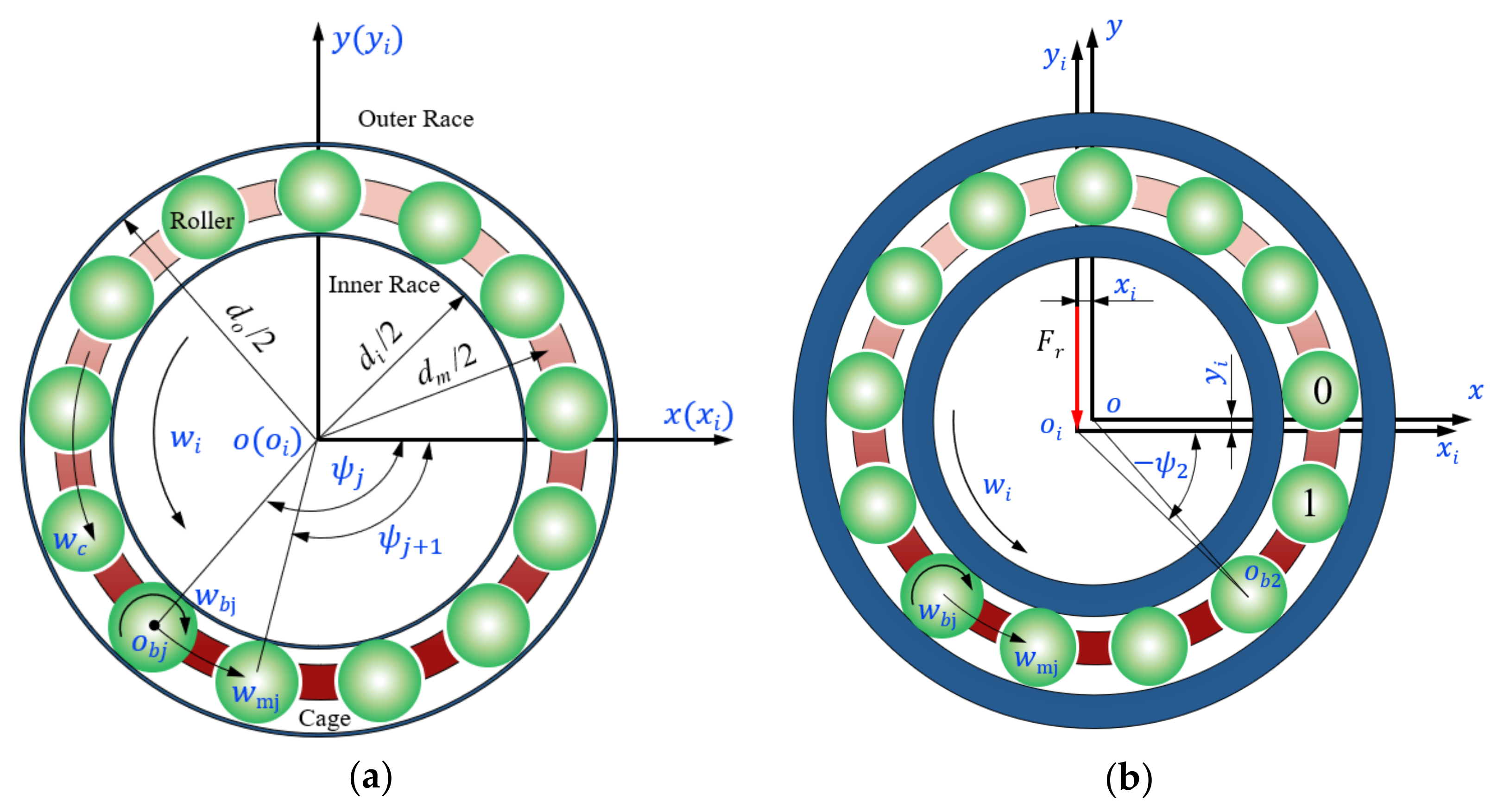

2. Bearing Dynamic Model

- The motions of the rolling elements, cage, and inner ring are limited to the radial plane of the bearing, without considering the axial movement;

- The contact between the rolling elements and the other parts satisfies the Hertz contact theory without considering plastic deformation;

- All parts are treated as rigid bodies, and the center of mass coincides with the centroid during service;

- The center of the outer ring coincides with the bearing center, which is the coordinate origin;

- A spring model is set between the rolling element and the cage pocket [19], and the inner ring rotational acceleration is always constant (100 rad/s2);

- Only one rotational degree of freedom of the cage is considered. The contact force between the ball and the pocket is considered, and the friction is ignored;

- The gap between the ball and the pocket is ignored, and the contact deformation coefficient between them is treated as a constant value.

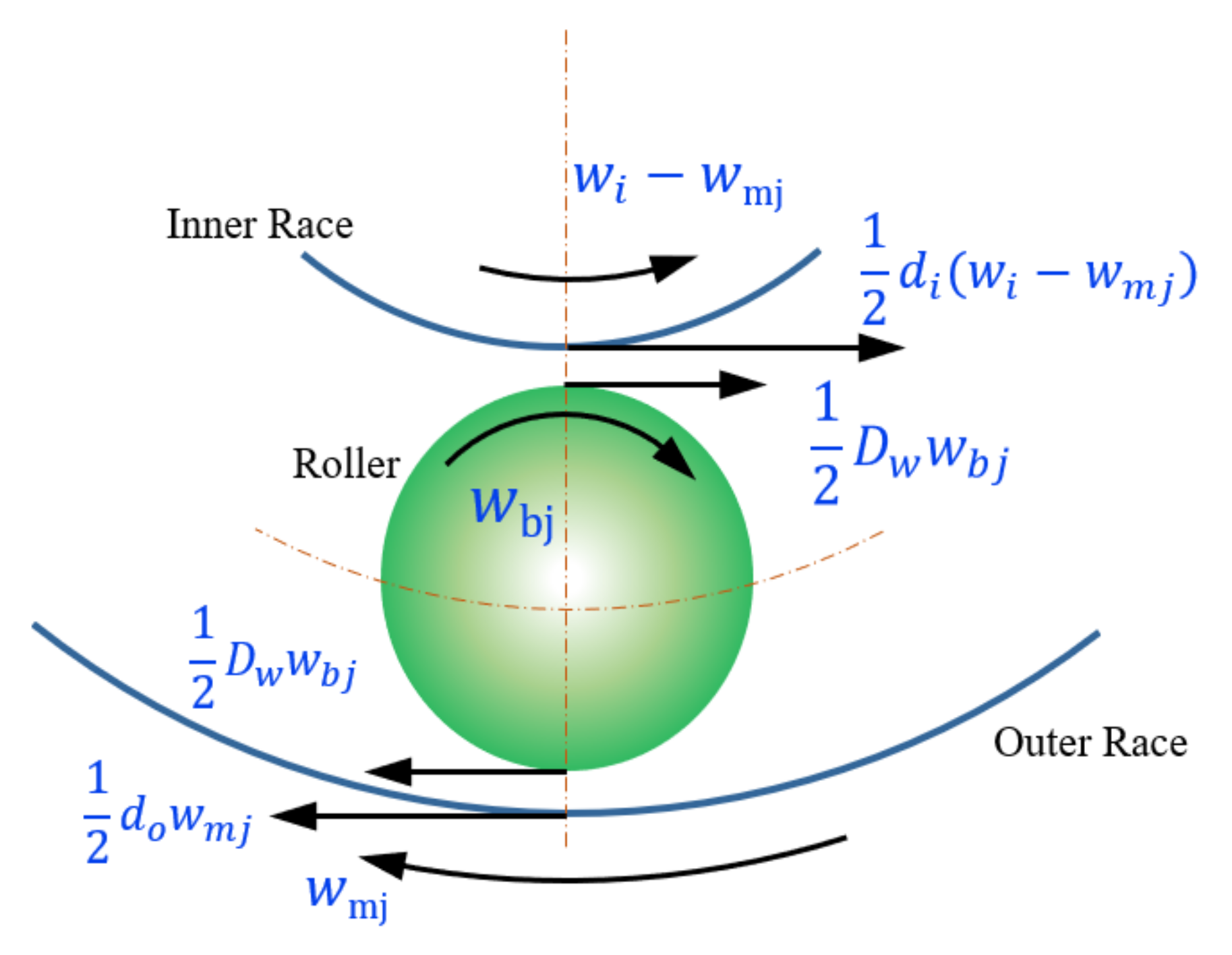

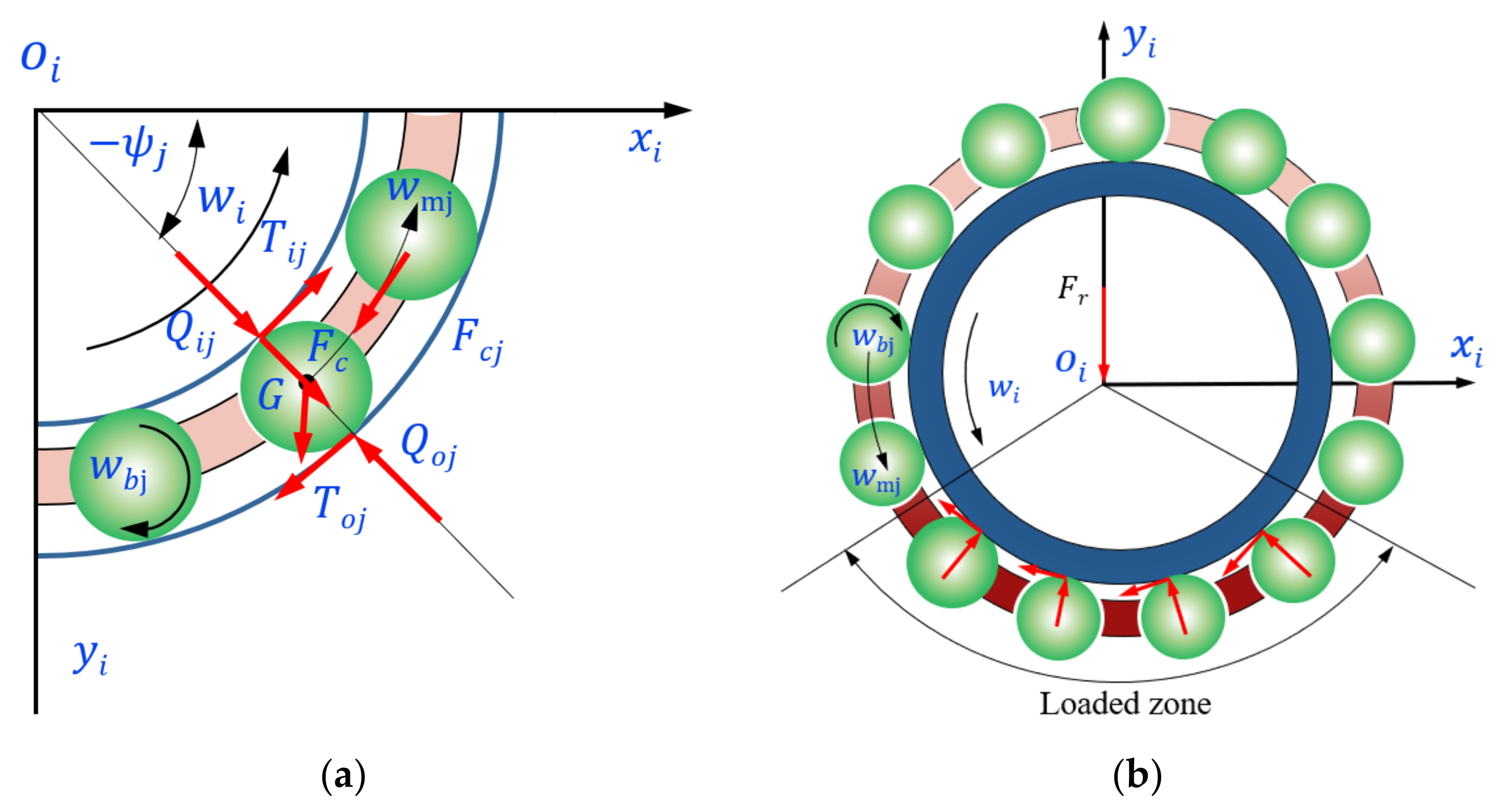

2.1. Interaction Force between Bearing Components

2.1.1. The Force between the Rolling Elements and the Rings

2.1.2. The Force between the Rolling Elements and the Cage

2.2. Mechanical Equilibrium Equations

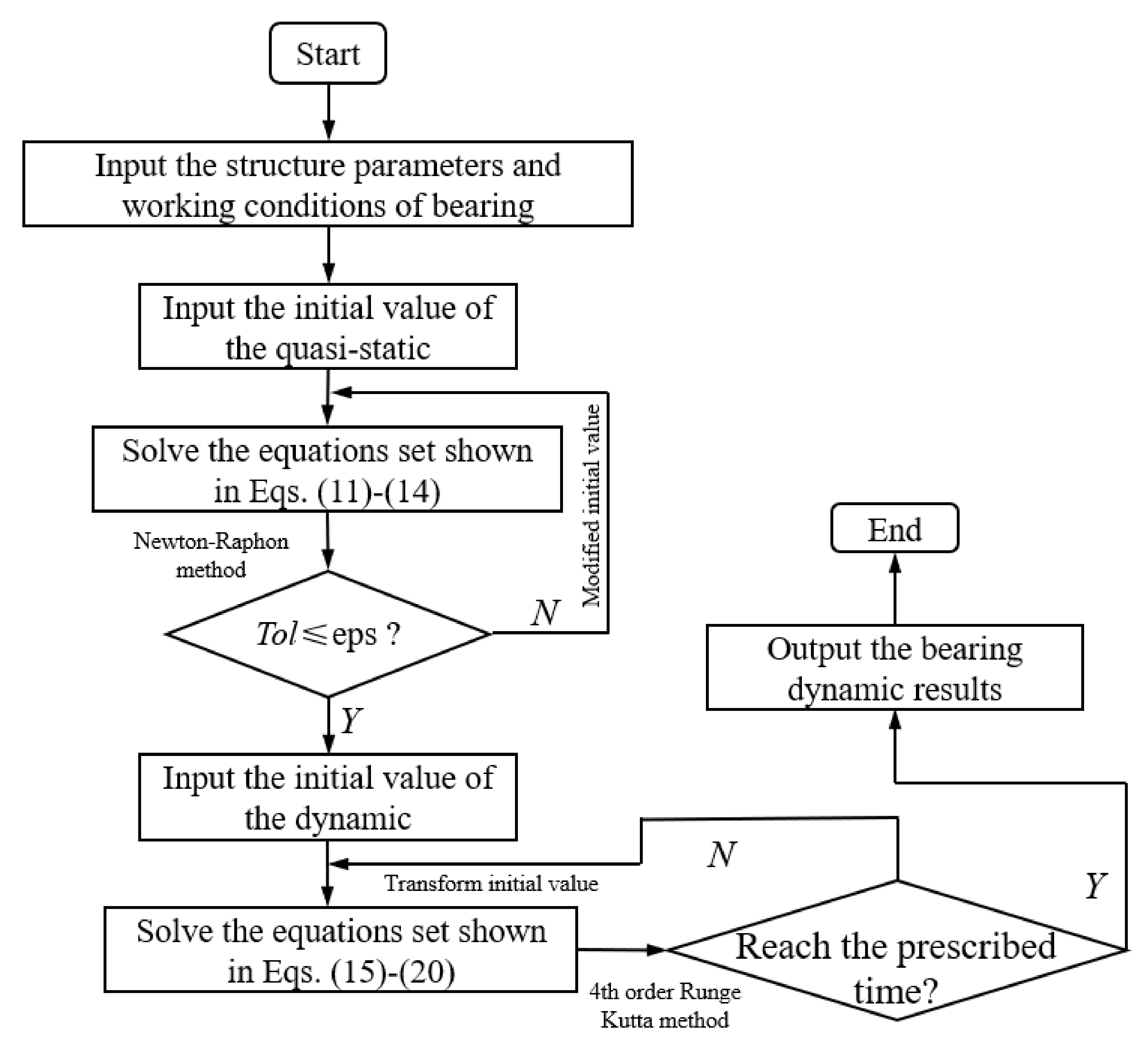

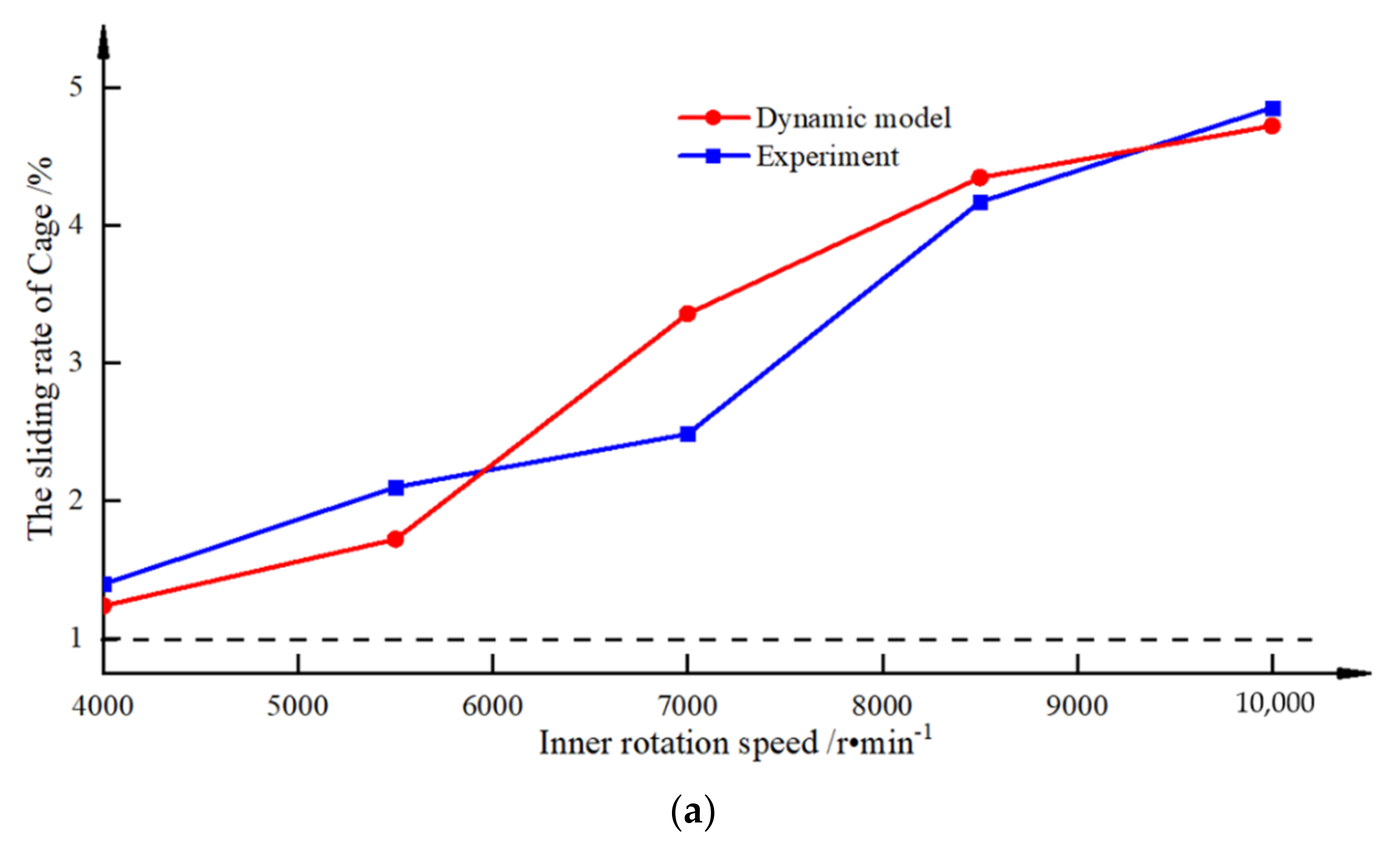

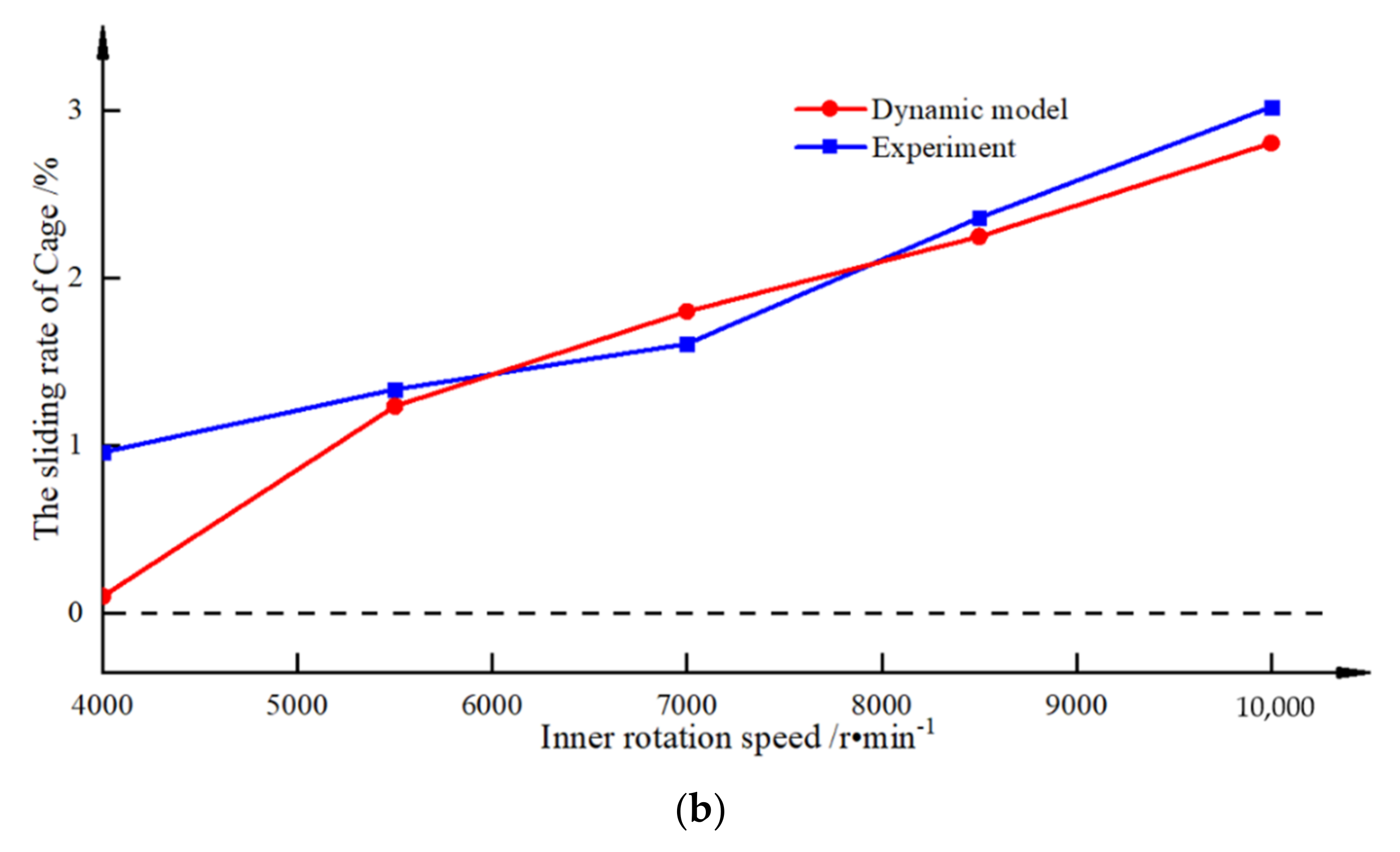

2.3. Model Solution and Verification

3. Collision Characteristics between the Ball and the Cage

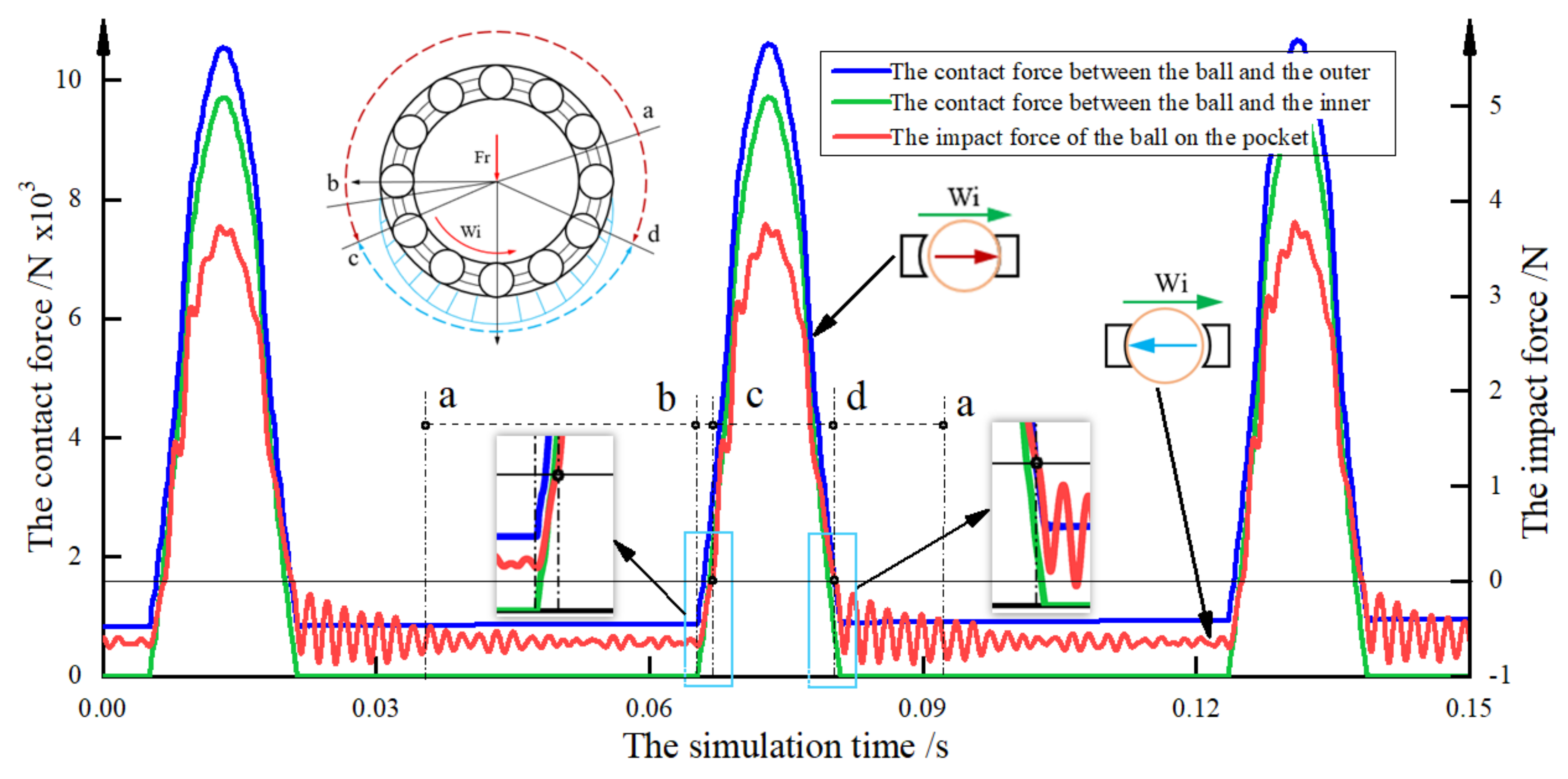

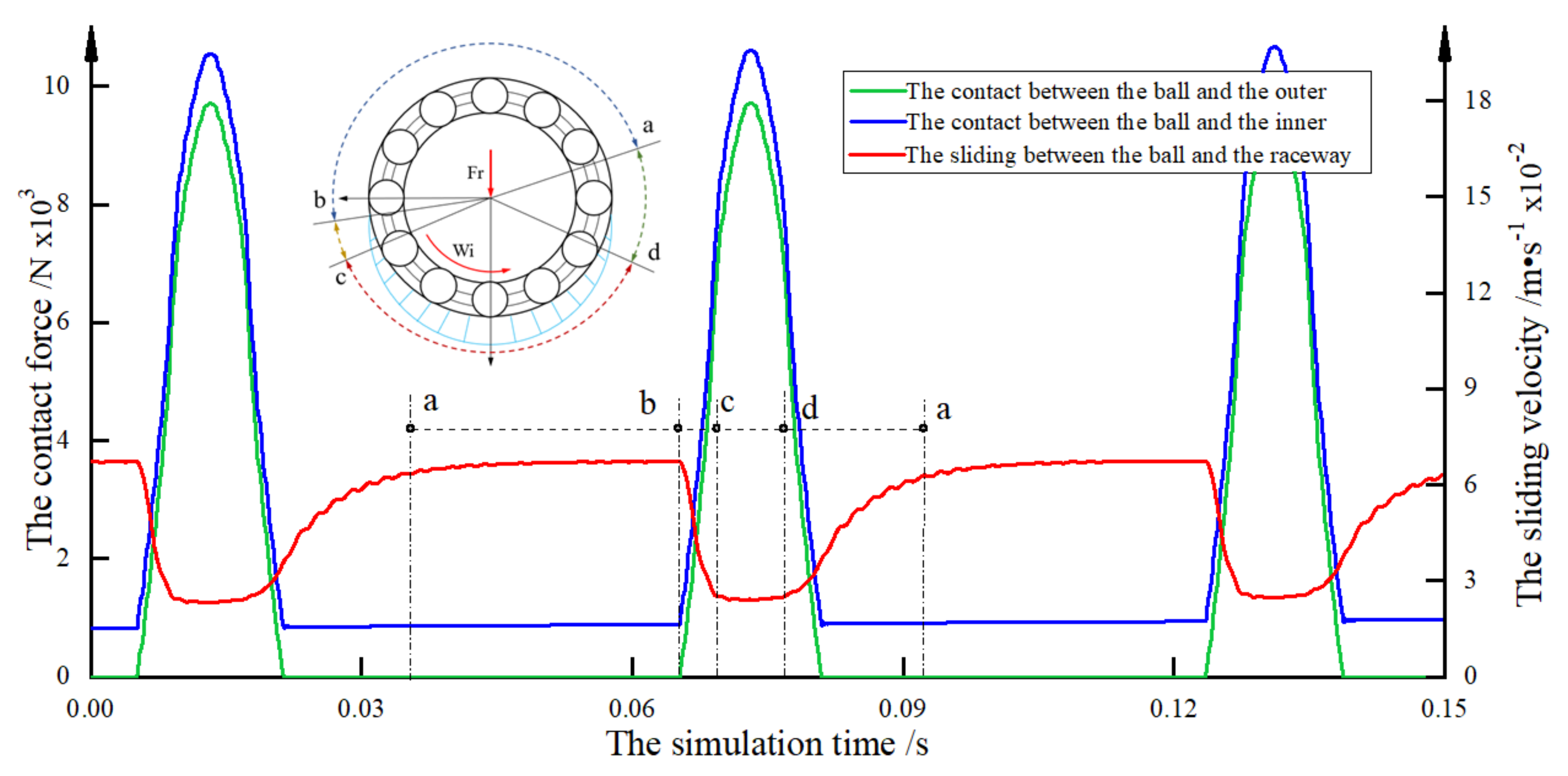

3.1. Interaction of a Single Ball and the Cage Pocket

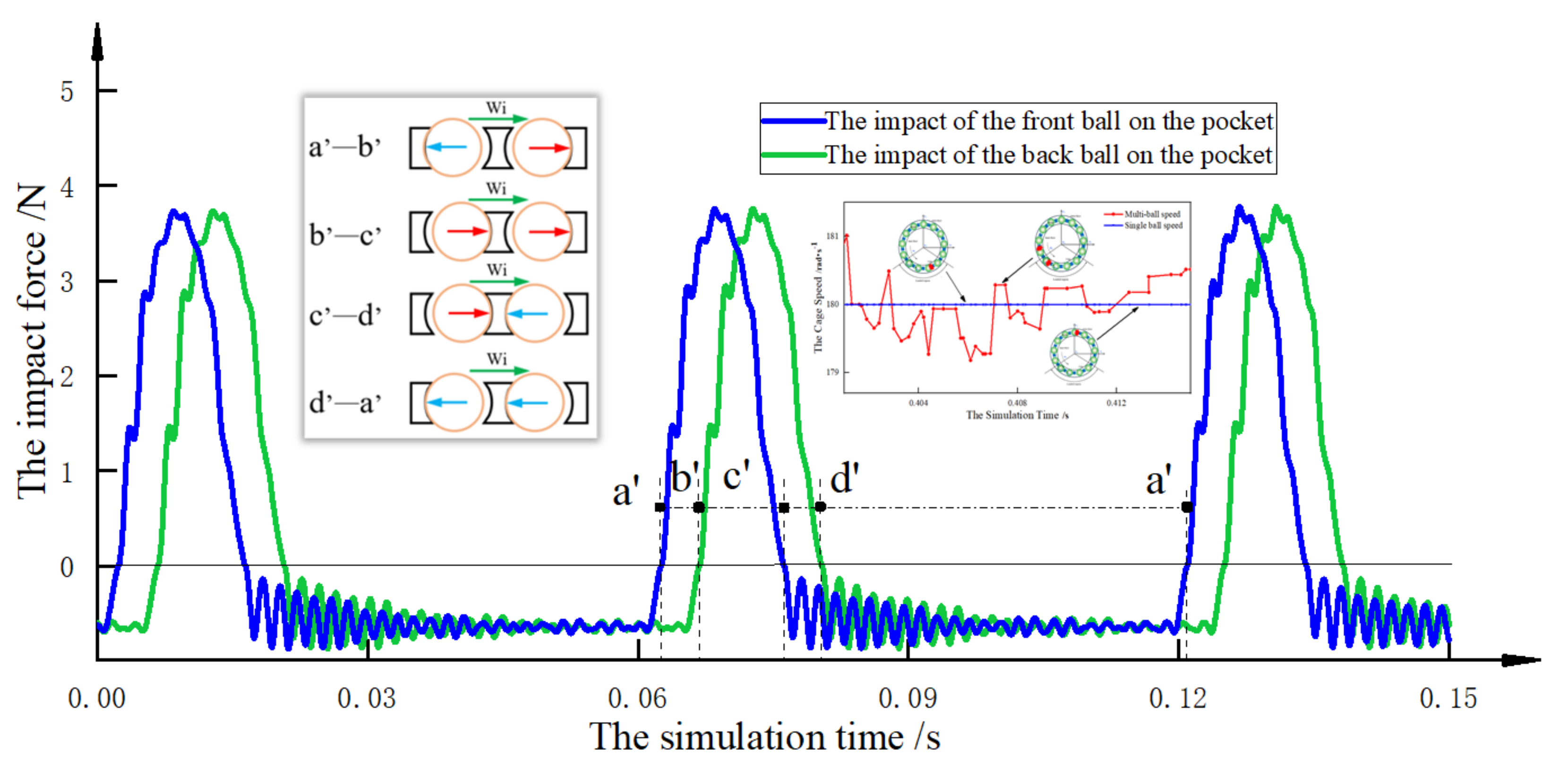

3.2. Impact Force between Two Balls and the Cage

4. Influencing Factors Analysis

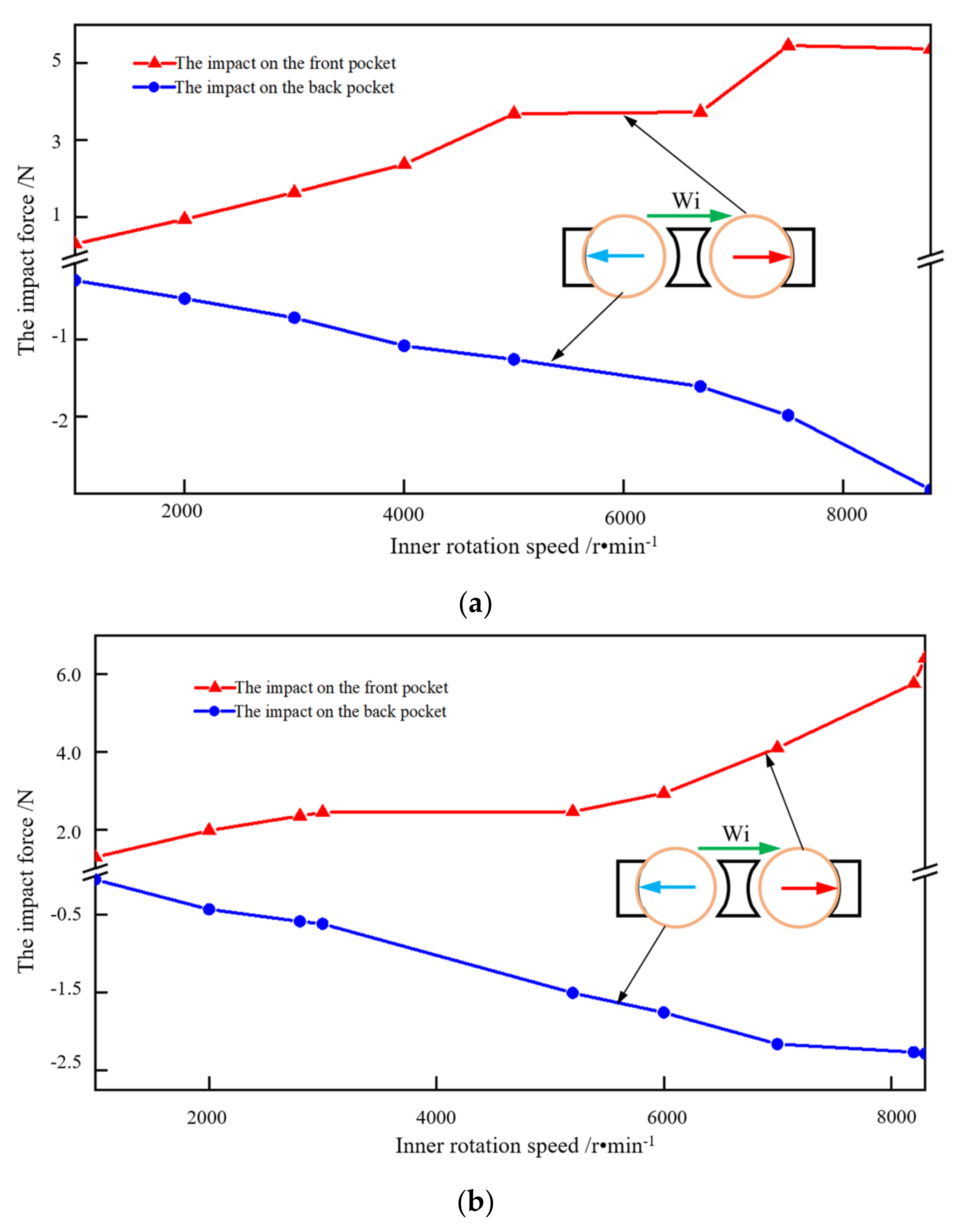

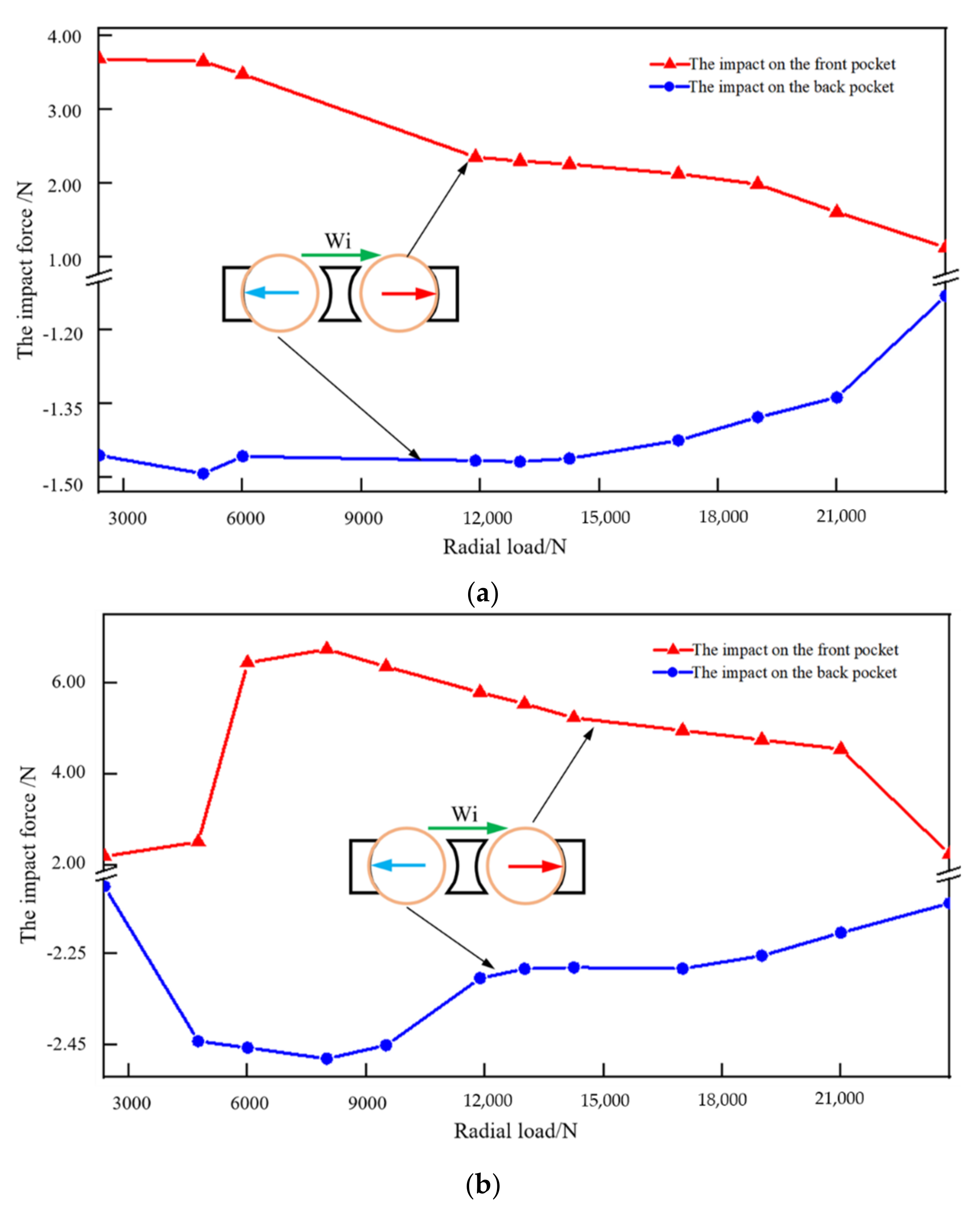

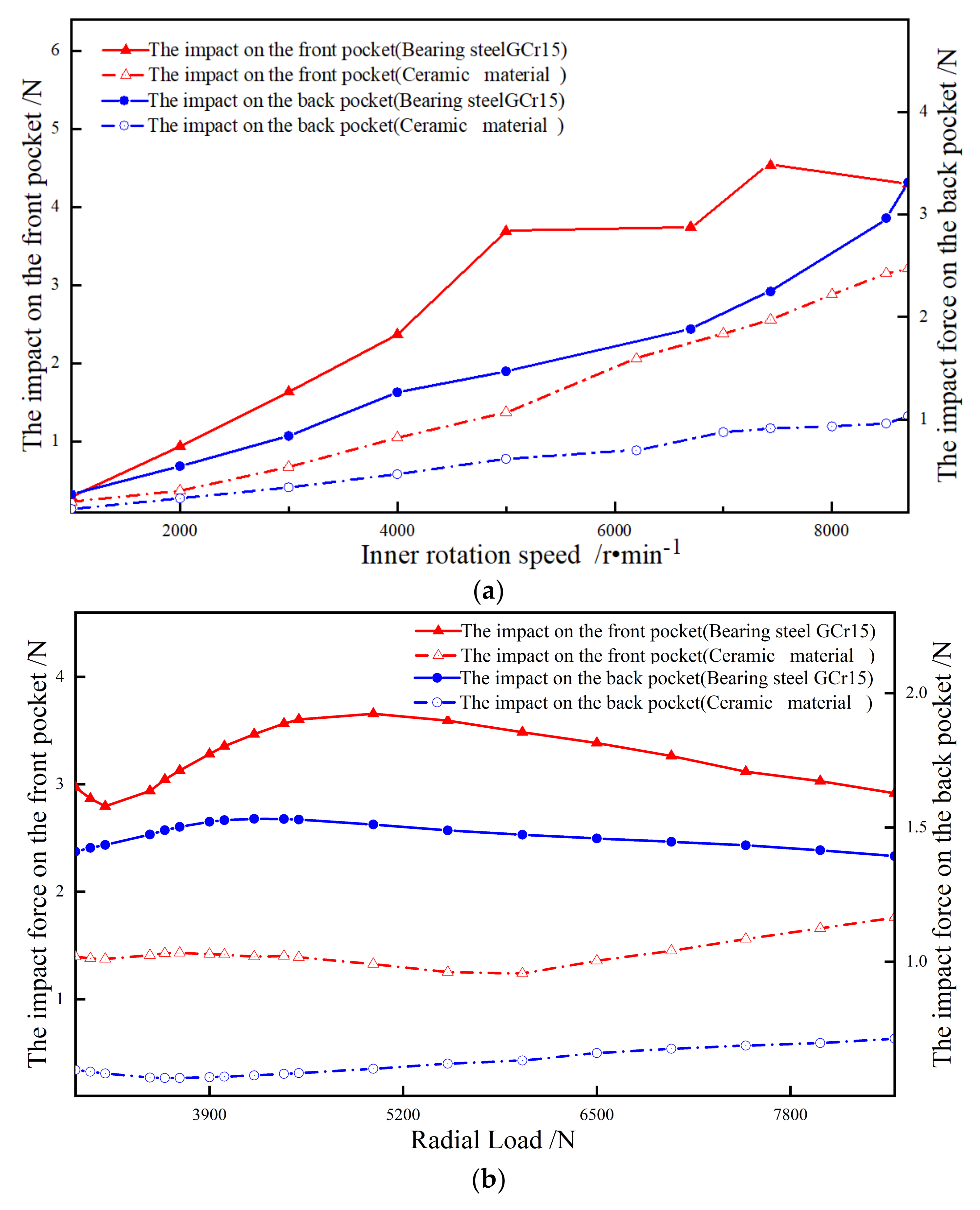

4.1. Radial Load and Rotational Speed

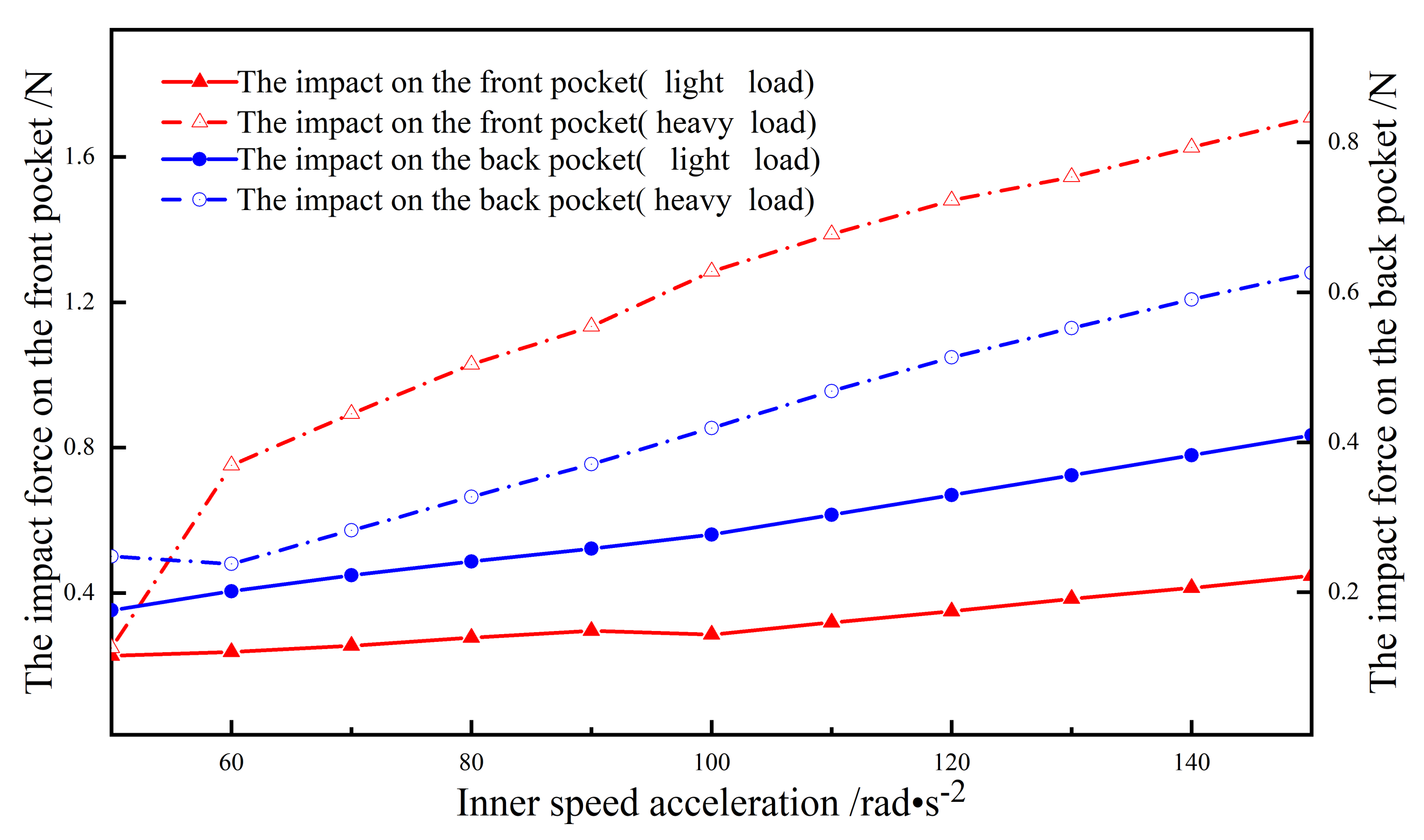

4.2. Inner Ring Speed Acceleration

4.3. Inner Ring Speed Deceleration

4.4. The Different Ball Material

5. Conclusions

- From the perspective of the relative sliding velocity between the ball and the raceway, the operation of the ball is divided into four zones. When the balls run in the a’–b’ zone and the c’–d’ zone, the multiball collision effect is obvious. The multiball collision can easily increase the stage instability because of the opposite impact directions of the adjacent two balls when the balls are in the a’–b’ zone;

- Compared to the radial force, the peak impact force is more sensitive to the rotational speed. With the increase in the rotational speed, the sliding between the balls and the raceway becomes more serious, resulting in an increase in the peak impact force;

- The influence of bearing inner ring acceleration and deceleration on the cage instability is the opposite. The peak impact force on the a’–b’ zone can easily cause the cage instability under acceleration, while the deceleration is in the c’–d’ zone because of the direction of the relative sliding velocity.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhang, T.; Chen, X.; Gu, J.; Li, Q. Progress of research on cage stability of high-speed angular contact ball bearings, Hangkong Xuebao/Acta Aeronaut. Astronaut. Sin. 2018, 39, 22026. [Google Scholar] [CrossRef]

- Sathyan, K.; Gopinath, K.; Lee, S.-H.; Hsu, H.-Y. Bearing Retainer Designs and Retainer Instability Failures in Spacecraft Moving Mechanical Systems. Tribol. Trans. 2012, 55, 503–511. [Google Scholar] [CrossRef]

- Liu, D.L.; Jiang, T.; He, Y.H. Discussion on failure problems of aero-bearing. J. Fail. Anal. Prev. 2015, 10, 324–330. [Google Scholar]

- Liu, X.H. Dynamics Analysis Model of High-Speed Rolling Bearings and Dynamic Performance of Cages. Ph.D. Thesis, Dalian University Technology, Dalian, China, 2011. [Google Scholar]

- Kingsbury, E.P. Torque variations in instrument ball bearings. ASLE Trans. 1965, 8, 435–441. [Google Scholar] [CrossRef]

- Kingsbury, E.; Walker, R. Motions of an Unstable Retainer in an Instrument Ball Bearing. J. Tribol. 1994, 116, 202–208. [Google Scholar] [CrossRef]

- Stevens, K.T. Experimental observations on torque variation caused by ball bearing cage instabilities (spin tests). In Proceedings of the Second Space Tribology Workshop, Risley, UK, 15–17 October 1980; Volume 21, pp. 101–111. [Google Scholar]

- Gentle, C.R.; Pasdari, M. Measurement of Cage and Pocket Friction in a Ball Bearing for Use in a Simulation Program. ASLE Trans. 1985, 28, 536–541. [Google Scholar] [CrossRef]

- Walters, C.T. Dynamics of ball bearings. J. Lubr. Technol. 1971, 93, 1–10. [Google Scholar] [CrossRef]

- Kannel, J.W.; Bupara, S.S. A Simplified Model of Cage Motion in Angular Contact Bearings Operating in the EHD Lubrication Regime. J. Lubr. Technol. 1978, 100, 395–403. [Google Scholar] [CrossRef]

- Gupta, P.K. Vibration Lubrication Technology of ball bearings. J. Lubr. Technol. Trans. ASME 1977, 99, 284–289. [Google Scholar] [CrossRef]

- Gupta, P.K. Frictional Instabilities in Ball Bearings. Tribol. Trans. 1988, 31, 258–268. [Google Scholar] [CrossRef]

- Gupta, P.K. On the Frictional Instabilities in a Cylindrical Roller Bearing. Tribol. Trans. 1990, 33, 395–401. [Google Scholar] [CrossRef]

- Gupta, P.K. Modeling of Instabilities Induced by Cage Clearances in Ball Bearings. Tribol. Trans. 1991, 34, 93–99. [Google Scholar] [CrossRef]

- Meeks, C.R.; Ng, K.O. The Dynamics of Ball Separators in Ball-Bearings I: Analysis. ASLE Trans. 1985, 28, 277–287. [Google Scholar] [CrossRef]

- Meeks, C.R. The Dynamics of Ball Separators in Ball Bearings—Part II: Results of Optimization Study. ASLE Trans. 1985, 28, 288–295. [Google Scholar] [CrossRef]

- Houpert, L. Piezoviscous-Rigid Rolling and Sliding Traction Forces, Application: The Rolling Element–Cage Pocket Contact. J. Tribol. 1987, 109, 363–370. [Google Scholar] [CrossRef]

- Houpert, L. CAGEDYN: A Contribution to Roller Bearing Dynamic Calculations Part I: Basic Tribology Concepts. Tribol. Trans. 2009, 53, 1–9. [Google Scholar] [CrossRef]

- Houpert, L. CAGEDYN: A Contribution to Roller Bearing Dynamic Calculations Part II: Description of the Numerical Tool and Its Outputs. Tribol. Trans. 2009, 53, 10–21. [Google Scholar] [CrossRef]

- Houpert, L. CAGEDYN: A Contribution to Roller Bearing Dynamic Calculations. Part III: Experimental Validation. Tribol. Trans. 2010, 53, 848–859. [Google Scholar] [CrossRef]

- Rivera, M.P. Bearing-Cage Frictional Instability—A Mechanical Model. Tribol. Trans. 1991, 34, 117–121. [Google Scholar] [CrossRef]

- Boesiger, E.A.; Donley, A.D.; Loewenthal, S. An Analytical and Experimental Investigation of Ball Bearing Retainer Instabilities. J. Tribol. 1992, 114, 530–538. [Google Scholar] [CrossRef]

- Nogi, T.; Maniwa, K.; Matsuoka, N. A Dynamic Analysis of Cage Instability in Ball Bearings. J. Tribol. 2018, 140, 011101. [Google Scholar] [CrossRef]

- Sakaguchi, T.; Kaoru, U. Dynamic Analysis of Cage Behavior in a Cylindrical Roller Bearing. Spec. Suppl. Ind. Mach. 2004, 71, 8–17. [Google Scholar]

- Sakaguchi, T.; Harada, K. Dynamic Analysis of Cage Behavior in a Tapered Roller Bearing. In Proceedings of the World Tribology Congress III, Washington, DC, USA, 12–16 September 2005; pp. 165–166. [Google Scholar] [CrossRef]

- Weinzapfel, N.; Sadeghi, F. A Discrete Element Approach for Modeling Cage Flexibility in Ball Bearing Dynamics Simulations. J. Tribol. 2009, 131, 021102. [Google Scholar] [CrossRef]

- Ashtekar, A.; Sadeghi, F. A New Approach for Including Cage Flexibility in Dynamic Bearing Models by Using Combined Explicit Finite and Discrete Element Methods. J. Tribol. 2012, 134, 041502. [Google Scholar] [CrossRef]

- Harris, T.A. Rolling Bearing Analysis, 5th ed.; John Wiley and Sons, Inc.: New York, NY, USA, 2006. [Google Scholar]

- Wang, Y.S. Study of Rheological Behavior of Aviation Lubricating Oil and Its Effect on Lubrication Performance. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2006. [Google Scholar]

- Tu, W.; Shao, Y.; Mechefske, C.K. An analytical model to investigate skidding in rolling element bearings during acceleration. J. Mech. Sci. Technol. 2012, 26, 2451–2458. [Google Scholar] [CrossRef]

- Wang, Y. Dynamic Analysis of Angular Contact Ball Bearing-Rotor System during Start up and Shut down. Jixie Gongcheng Xuebao/Chin. J. Mech. Eng. 2018, 54, 9–16. [Google Scholar] [CrossRef]

- Zhang, W.H. Study on the Dynamics Simulation and Semi-Physical Experiment of Cylindrical Roller Bearing. Ph.D. Thesis, Northwestern Polytechnical University, Xi’an, China, 2006. [Google Scholar]

| Name | Value |

|---|---|

| Inner diameter/mm | 80 |

| Outer diameter/mm | 125 |

| Bearing width/mm | 22 |

| Pitch diameter/mm | 102.198 |

| Cage outer diameter/mm | 108.3 |

| Cage inner diameter/mm | 102.448 |

| Cage width/mm | 18.3 |

| Number of balls | 14 |

| Ball diameter/mm | 13.474 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, S.; Zhang, X.; Yan, K.; Zhu, Y.; Hong, J. A Study on Bearing Dynamic Features under the Condition of Multiball–Cage Collision. Lubricants 2022, 10, 9. https://doi.org/10.3390/lubricants10010009

Ma S, Zhang X, Yan K, Zhu Y, Hong J. A Study on Bearing Dynamic Features under the Condition of Multiball–Cage Collision. Lubricants. 2022; 10(1):9. https://doi.org/10.3390/lubricants10010009

Chicago/Turabian StyleMa, Shuaijun, Xiaohong Zhang, Ke Yan, Yongsheng Zhu, and Jun Hong. 2022. "A Study on Bearing Dynamic Features under the Condition of Multiball–Cage Collision" Lubricants 10, no. 1: 9. https://doi.org/10.3390/lubricants10010009

APA StyleMa, S., Zhang, X., Yan, K., Zhu, Y., & Hong, J. (2022). A Study on Bearing Dynamic Features under the Condition of Multiball–Cage Collision. Lubricants, 10(1), 9. https://doi.org/10.3390/lubricants10010009