Biodigestion System Made of Polyethylene and Polystyrene Insulator for Dog Farm (on the Example of the Republic of Chile)

Abstract

1. Introduction

2. Materials and Methods

2.1. Physicochemical and Biological Analysis

2.2. Development of the Biodigester’s Dimensions

2.3. Biodigester Design

2.4. Infrastructure

2.5. Functioning

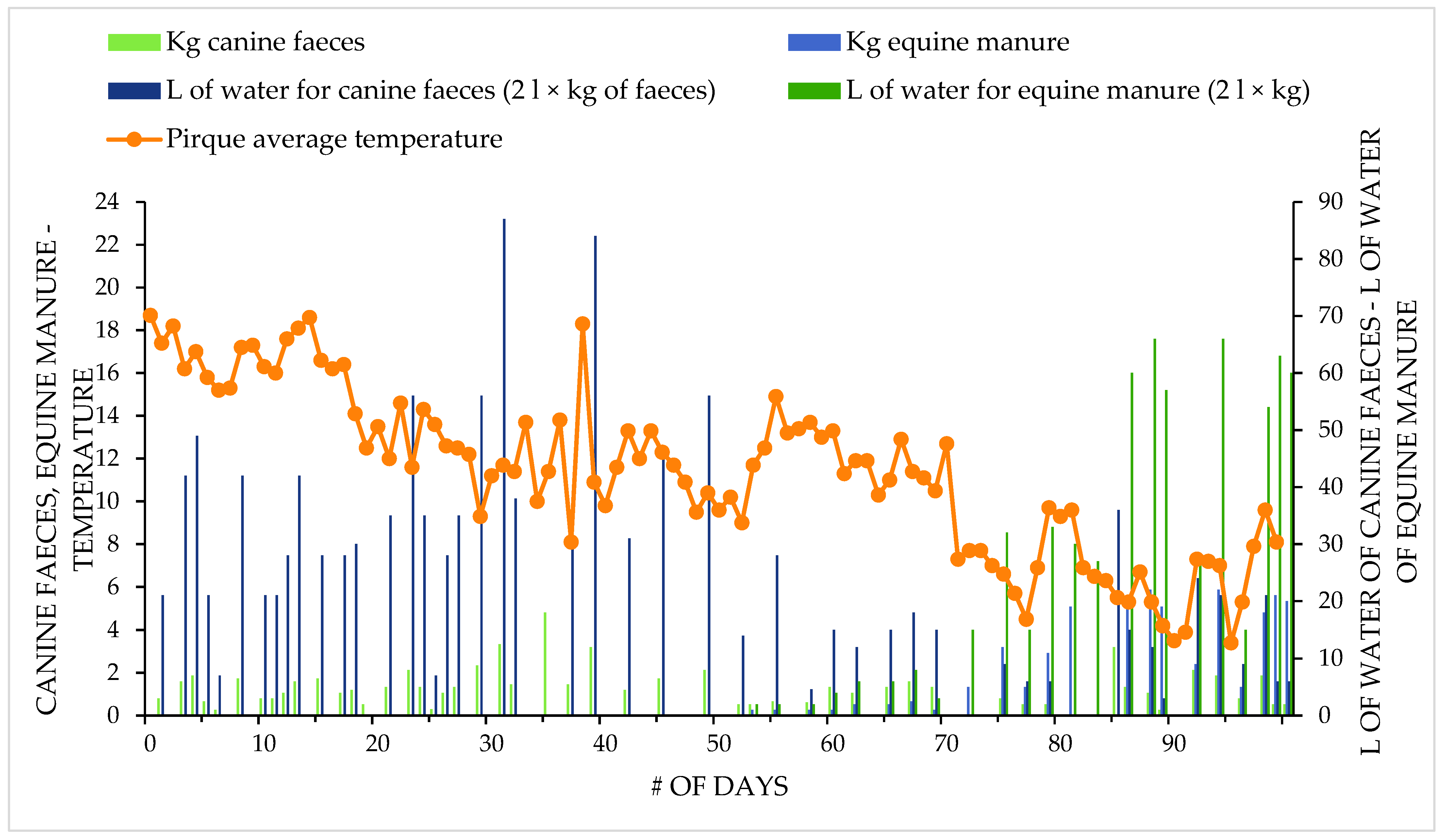

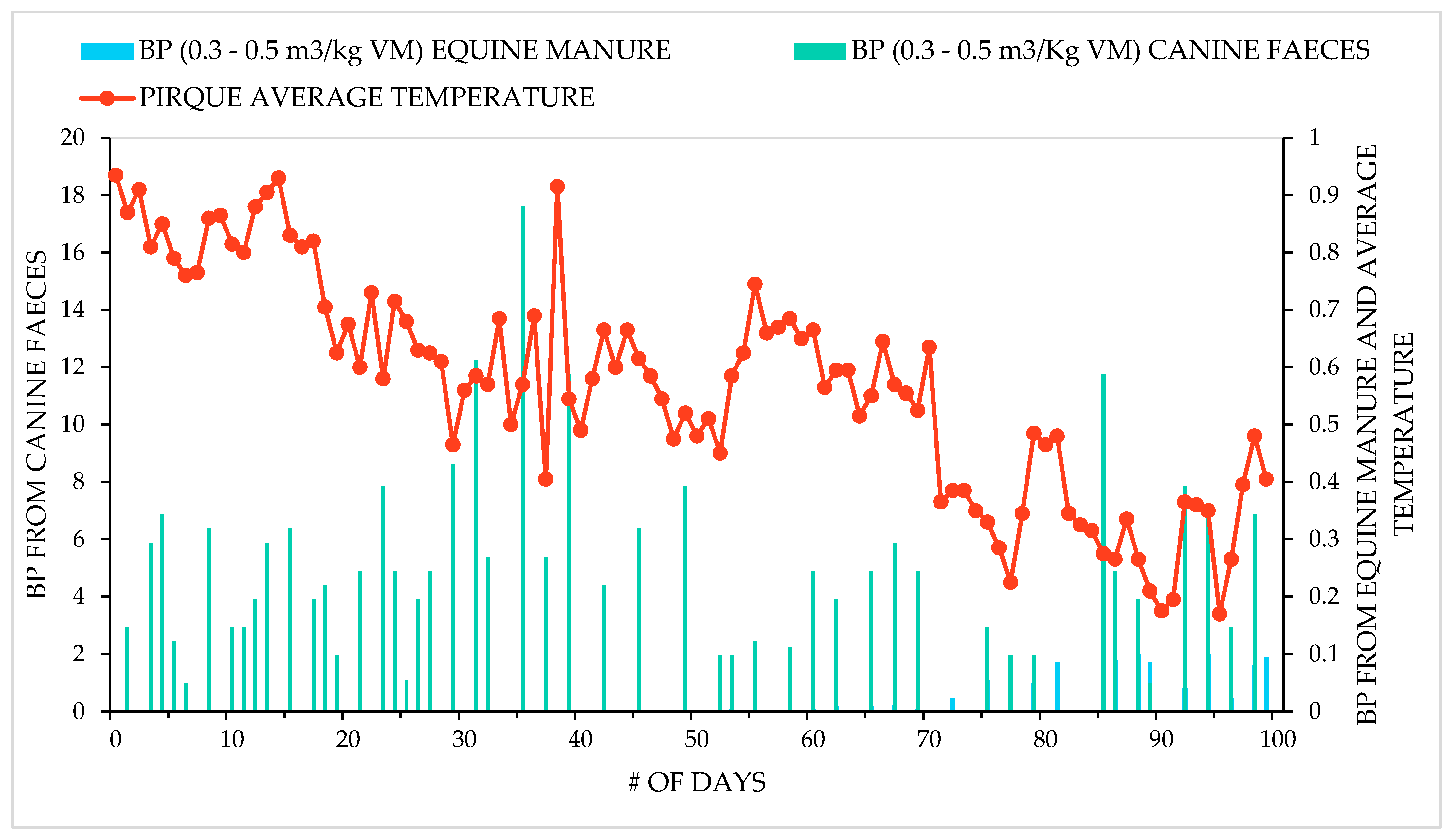

3. Results and Discussion

The Biodigester Did Not Work Completely Due to the following Factors

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Boitsenyuk, L.I.; Suslov, S.V.; Khrustaleva, M.A.; Larionov, M.V. Studying the features of the formation of the hydromorphous-bogs landscape of the Moscow region with the environmental assessment of its state. Ecol. Urban Areas 2022, 1, 47–52. [Google Scholar] [CrossRef]

- Gibadulina, I.I.; Larionov, M.V.; Maslennikova, N.N. Anatomical and morphological features of the leaves of Tilia cordata Mill. as an indicator of the adaptive capabilities of the species to the conditions of the urban environment. IOP Conf. Ser. Earth Environ. Sci. 2022, 988, 032082. [Google Scholar] [CrossRef]

- Dogadina, M.; Larionov, M.; Pravdyuk, P. Optimization of living conditions for seedlings of flowering shrubs. BIO Web. Conf. 2020, 25, 05012. [Google Scholar] [CrossRef]

- Larionov, M.V.; Larionov, N.V.; Volodkin, A.A. Research and assessment of the state of plants in artificial plant communities (on the example of the Volga and Chernozem Regions). Nat. Tech. Sci. 2021, 1, 17–20. [Google Scholar] [CrossRef]

- Mishan, E.J.; Quah, E. Compensating for environmental damage. In Cost-Benefit Analysis, 6th ed.; Routledge: Abindon, UK; New York, NY, USA, 2021; pp. 97–105. [Google Scholar]

- Wu, J.; Chang, I.-S. Compensation for Environmental Damage. In Environmental Management in China; Springer: Singapore, 2020; pp. 161–166. [Google Scholar] [CrossRef]

- Rawat, M.; Moturi, M.C.Z.; Subramanian, V. Inventory compilation and distribution of heavy metals in wastewater from small-scale industrial areas of Delhi, India. J. Environ. Monit. 2004, 5, 906–912. [Google Scholar] [CrossRef] [PubMed]

- Tsai, W.-T.; Lin, Y.-Q. Analysis of promotion policies for the valorization of food waste from industrial sources in Taiwan. Fermentation 2021, 7, 51. [Google Scholar] [CrossRef]

- Larionov, N.V.; Siraeva, I.S.; Larionov, M.V.; Gromova, T.S. The meaning of the phytotoxicity of the soils of transformational landscapes in the southeast of Russia. In Proceedings of the International Conference on Contemporary Education, Social Sciences and Ecological Studies (CESSES 2018), Moscow, Russia, 29–30 March 2018; Volume 283, pp. 930–935. [Google Scholar] [CrossRef]

- Yamada, T.; Nakao, A.; Yoshida, N. Survey and analysis on the operating status of industrial waste incineration facilities and the support for general and disaster wastes disposal. Stud. Reg. Sci. 2022, 52, 113–133. [Google Scholar] [CrossRef]

- Naderipour, A.; Abdul-Malek, Z.; Arshad, R.N.; Kamyab, H.; Chelliapan, S.; Ashokkumar, V.; Tavalaei, J. Assessment of carbon footprint from transportation, electricity, water, and waste generation: Towards utilisation of renewable energy sources. Clean Technol. Environ. Policy 2021, 23, 183–201. [Google Scholar] [CrossRef]

- Siraeva, I.S.; Larionov, M.V.; Larionov, N.V. Environmental assessment of health indicators of woody plants in natural and man-made conditions. Samara J. Sci. 2020, 1, 100–106. [Google Scholar] [CrossRef]

- Widyarsana, I.M.W.; Mulyadi, A.A.; Tambunan, S.A. Automotive hazardous waste management in automotive shops of Indonesia’s metropolitan city. Case Study: Bandung City, West Java Province. Environ. Clim. Technol. 2022, 26, 129–142. [Google Scholar] [CrossRef]

- Larionov, M.V.; Larionov, N.V.; Gromova, T.S. Factors of soil and atmospheric air degradation and their influence on the state of plants in urban and suburban ecosystems. Samara J. Sci. 2020, 2, 78–85. [Google Scholar] [CrossRef]

- Menyuka, N.N.; Sibanda, M.; Bob, U. Perceptions of the challenges and opportunities of utilising organic waste through urban agriculture in the Durban south basin. Int. J. Environ. Res. Public Health 2020, 17, 1158. [Google Scholar] [CrossRef]

- Siddiqui, M.A.; Yadav, H. Molecular characterization of bacterial community succession and analysis of physiochemical properties in a compost of solid organic waste from Gandhinagar, Gujarat, India. In Microbes in Land Use Change Management; Elsevier: Amsterdam, The Netherlands, 2021; pp. 121–136. [Google Scholar] [CrossRef]

- Gromova, T.S.; Siraeva, I.S.; Ermolenko, A.S.; Larionov, N.V.; Larionov, M.V. Vitality of woody plants as the aggregate basis of the ecological condition of urban and suburban ecosystems of the Khopyor River Region. Mod. Sci. Actual Probl. Theory Pract. Ser. Nat. Tech. Sci. 2020, 7, 20–27. [Google Scholar]

- Larionov, M.V.; Volodkin, A.A. Phytosozological study of natural monuments to determine the ecological status of specially protected natural areas. RUDN J. Ecol. Life Saf. 2022, 30, 7–27. [Google Scholar] [CrossRef]

- Volodkin, A.A.; Volodkina, O.A.; Larionov, M.V. Dynamics of reproduction of forest plantations in the forest-steppe zone of the Middle Volga Region. IOP Conf. Ser. Earth Environ. Sci. 2022, 979, 012101. [Google Scholar] [CrossRef]

- Chen, Y.; Shang, J. Disconnect analysis and influence factors of animal husbandry in China. Zhongguo Renkou Ziyuan Yu Huan Jing/ China Popul. Resour. Environ. 2014, 24, 101–107. [Google Scholar] [CrossRef]

- Larionov, M.V.; Dogadina, M.A.; Tarakin, A.V.; Minakova, I.V.; A Sentishcheva, E.; Bukreeva, T.N. Creation of artificial phytocenoses with controlled properties as a tool for managing cultural ecosystems and landscapes. IOP Conf. Ser. Earth Environ. Sci. 2021, 848, 012127. [Google Scholar] [CrossRef]

- Lukyanova, T.S.; Larionov, M.V.; Kryuchkov, S.A. Review of drinking water quality in the northern regions of the Moscow region based on data from Rospotrebnadzor and private laboratories. RUDN J. Ecol. Life Saf. 2022, 30, 357–372. [Google Scholar] [CrossRef]

- Agrawal, R.; Bhadana, B.; Mathur, A.S.; Kumar, R.; Gupta, R.P.; Satlewal, A. Improved enzymatic hydrolysis of pilot scale pretreated rice straw at high total solids loading. Front. Energy Res. 2018, 6, 115. [Google Scholar] [CrossRef]

- Buchspies, B.; Martin, K.; Junginger, M. Straw utilization for biofuel production: A consequential GHG assessment of bioethanol and biomethane provision with a focus on the time-dependency of emissions. GCB Bioenergy 2020, 12, 789–805. [Google Scholar] [CrossRef]

- Rabee, A.; Alahl, A.A.S.; Lamara, M.; Ishaq, S.L. Fibrolytic rumen bacteria of camel and sheep and their applications in the bioconversion of barley straw to soluble sugars for biofuel production. PLoS ONE 2022, 17, e0262304. [Google Scholar] [CrossRef]

- Tishler, Y.; Samach, A.; Rogachev, I.; Elbaum, R.; Levy, A.A. Analysis of wheat straw biodiversity for use as a feedstock for biofuel production. BioEnergy Res. 2015, 8, 1831–1839. [Google Scholar] [CrossRef]

- Agrawal, R.; Bhadana, B.; Chauhan, P.S.; Adsul, M.; Kumar, R.; Gupta, R.P.; Satlewal, A. Understanding the effects of low enzyme dosage and high solid loading on the enzyme inhibition and strategies to improve hydrolysis yields of pilot scale pretreated rice straw. Fuel 2022, 327, 125114. [Google Scholar] [CrossRef]

- Agu, O.S.; Tabil, L.G.; Mupondwa, E.; Emadi, B.; Dumonceaux, T. Impact of biochar addition in microwave torrefaction of camelina straw and switchgrass for biofuel production. Fuels 2022, 3, 588–606. [Google Scholar] [CrossRef]

- Passoth, V.; Sandgren, M. Biofuel production from straw hydrolysates: Current achievements and perspectives. Appl. Microbiol. Biotechnol. 2019, 103, 5105–5116. [Google Scholar] [CrossRef]

- Satlewal, A.; Agrawal, R.; Bhagia, S. Rice straw as a feedstock for biofuels: Availability, recalcitrance, and chemical properties: Rice straw as a feedstock for biofuels. Biofuels Bioprod. Biorefining 2017, 12, 83–107. [Google Scholar] [CrossRef]

- Ugolini, M.; Recchia, L.; Guandalini, G.; Manzolini, G. Novel methodology to assess advanced biofuel production at regional level: Case study for cereal straw supply chains. Energies 2022, 15, 7197. [Google Scholar] [CrossRef]

- Costantini, V.P.; Azevedo, A.C.; Li, X.; Williams, M.C.; Michel, F.C.; Saif, L.J. Effects of different animal waste treatment technologies on detection and viability of porcine enteric viruses. Appl. Environ. Microbiol. 2007, 73, 5284–5291. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Karakurt, C.; Teke, B.E.; Bülbül, B.; Alkoyak, K. Pandemics, and ecological animal husbandry. Livest. Stud. 2022, 62, 25–33. [Google Scholar] [CrossRef]

- Kumar, S.; Yadav, R.; Singh, N. Survey on Present Scenario of Biomass energy and its future prospect in Uttar Pradesh, India. In Proceedings of the CSDEEP–2017 International Conference on Challenges in Sustainable Development from Energy & Environment Perspective At: MMMUT Gorakhpur in Association with ENEA Italy, Trisaia, Italy, 24–25 March 2017; Volume 1, pp. 230–238. Available online: https://www.researchgate.net/publication/314836204_Survey_on_Present_Scenario_of_Biomass_energy_and_its_future_prospect_in_Uttar_Pradesh_India (accessed on 1 September 2022).

- Ponjavic, M.; Celebicanin, S.; Stanojevic, S.; Gazdic, M. Defining optimal locations of establishments and transportation routes for treatment and storage of animal waste. AGROFOR 2018, 3, 150–157. [Google Scholar] [CrossRef]

- Girotto, F.; Cossu, C.A. Animal waste and waste animal by-products generated along the livestock breeding and meat food chain. Waste Manag. 2017, 70, 1–2. [Google Scholar] [CrossRef]

- Issa, A.K.; Idris, M.H.; Tikau, M.I. Animal wastes as thermoplastic composite reinforcement materials for sustainable development. Int. J. Innov. Technol. Explor. Eng. 2020, 9, 62–66. [Google Scholar] [CrossRef]

- Kocaman, I.; Konukcu, F.; Ozturk, G. Measures to protect environmental problems caused by animal wastes in rural settlement areas: A case study from Western Turkey. J. Anim. Vet. Adv. 2011, 10, 1536–1542. [Google Scholar] [CrossRef]

- Muñoz, E.A.H.; Canseco, J.M.; Beltrán-Rico, A. Zoonotic parasites in dog feces from Leon, Mexico. Acta Univ. 2019, 29, 1–6. [Google Scholar] [CrossRef]

- Oa, S.-W.; Lee, Y. Nutrient runoff to watershed from land application area of animal waste. Water Pract. Technol. 2010, 5, wpt2010060. [Google Scholar] [CrossRef]

- Plavsa, N.; Jotanović, S.; Savić, Đ. Disposal of animal waste as a risk factor in the spread of zoonotic pathogens. Aгpoзнaњe 2016, 17, 219–231. [Google Scholar] [CrossRef][Green Version]

- Said, M.I. Characteristics of by-product and animal waste: A review. Large Anim. Rev. 2019, 25, 243–250. Available online: https://www.largeanimalreview.com/index.php/lar/article/view/56/57 (accessed on 14 October 2022).

- Wati, A.M.; Albab, U.R.; Azizah, S.; Adli, D.N. Pembuatan bokashi dari berbagai limbah kotoran ternak di Desa Bujel Kecamatan Mojoroto Kota Kediri Making bokashi from various animal waste in Bujel Village, Mojoroto District, Kediri City. Appl. Anim. Sci. Proceeding Ser. 2022, 3, 191–194. [Google Scholar] [CrossRef]

- Berendsen, B.J.; Wegh, R.S.; Memelink, J.; Zuidema, T.; Stolker, L.A. The analysis of animal faeces as a tool to monitor antibiotic usage. Talanta 2015, 132, 258–268. [Google Scholar] [CrossRef]

- Lazaroiu, G.; Pană, C.; Mihaescu, L.; Cernat, A.; Negurescu, N.; Mocanu, R.; Negreanu, G. Solutions for energy recovery of animal waste from leather industry. Energy Convers. Manag. 2017, 149, 1085–1095. [Google Scholar] [CrossRef]

- Gupta, P.; Singh, H.; Kumar, S. Animal waste powder utilization for Al6061/SiC composite using friction stir processing with scroll shoulder hexagonal tool. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2022. [Google Scholar] [CrossRef]

- Okafor-Elenwo, E.J.; Izevbuwa, O.E. Investigation of the suitability of animal faeces and printing papers as alternative food for the giant african land snail, archachatina marginata (Swainson). Res. J. Agric. Environ. Manag. 2020, 9, 58–65. Available online: https://apexjournal.org/rjaem/archive/2020/December/fulltext/Okafor-Elenwo%20and%20Izevbuwa.pdf (accessed on 14 October 2022).

- Parajuli, L.; Paudel, S.; Khatri, S. Design and fabrication of animal waste cleaning machine. Kathmandu Univ. J. Sci. Eng. Technol. 2021, 15, 1–4. Available online: http://old.ku.edu.np/kuset/vol15_no2/parajuli_vol_15_No_2_2021.pdf (accessed on 14 October 2022).

- Schlegel, A.J.; Assefa, Y.; Bond, H.D.; Wetter, S.M.; Stone, L.R. Soil physicochemical properties after 10 years of animal waste application. Soil Sci. Soc. Am. J. 2015, 711–719. [Google Scholar] [CrossRef]

- Suproniene, S.; Doyeni, M.O.; Viti, C.; Tilvikiene, V.; Pini, F. Characterization of the Soil Prokaryotic Community With Respect to Time and Fertilization With Animal Waste–Based Digestate in a Humid Continental Climate. Front. Environ. Sci. 2022, 10, 852241. [Google Scholar] [CrossRef]

- Abdeshahian, P.; Lim, J.S.; Ho, W.S.; Hashim, H.; Lee, C.T. Potential of biogas production from farm animal waste in Malaysia. Renew. Sustain. Energy Rev. 2016, 60, 714–723. [Google Scholar] [CrossRef]

- Jogal, K.V.; Trivedi, S.M.; Lakhlani, C.D. Adoption of improved animal husbandry practices by dairy farmers. Indian J. Anim. Sci. 2021, 91, 1115–1117. [Google Scholar] [CrossRef]

- Wang, L.; Tan, H. Economic analysis of animal husbandry based on system dynamics. Comput. Intell. Neurosci. 2022, 2022, 5641384. [Google Scholar] [CrossRef]

- Rodríguez-Monroy, C.; Mármol-Acitores, G.; Nilsson-Cifuentes, G. Electricity generation in Chile using non-conventional renewable energy sources–a focus on biomass. Renew. Sust. Energ. Rev. 2018, 81, 937–945. [Google Scholar] [CrossRef]

- Okolie, N.P.; Onifade, A.K.; Oladunmoye, M.K.; Adegunloye, D.V. Comparative study of commercial gas with biogas produced from co-digestion of corn cob, rice chaff, goat and dog dungs. Int. J. Phys. Sci. 2018, 13, 98–105. [Google Scholar] [CrossRef][Green Version]

- Arifan, F.; Abdullah, A.; Sumardiono, S. Effectiveness analysis of anaerobic digestion method in making biogas from animal manure and tofu liquid waste. J. Ilmu Dan Teknol. Has. Ternak 2021, 16, 84–94. [Google Scholar] [CrossRef]

- Lazaroiu, G.; Mihaescu, L.; Mavrodin, E.M. Combustion of biogas obtained by anaerobic fermentation of animal proteins. In Innovative Renewable Waste Conversion Technologies; Lazaroiu, G., Mihaescu, L., Eds.; Springer: Cham, Germany, 2021; Volume 17, pp. 149–178. [Google Scholar] [CrossRef]

- Li, Y.; Yan, B.; Qin, Y.; Shi, W.; Yan, J. Analysis of the types of animal husbandry and planting that influence household biogas in rural China. J. Clean. Prod. 2021, 332, 130025. [Google Scholar] [CrossRef]

- Pence, I.; Kumaş, K.; Siseci, M.C.; Akyüz, A.Ö. Environmental science and pollution research modeling of energy and emissions from animal manure using machine learning methods: The case of the Western Mediterranean Region, Turkey. Environ. Sci. Pollut. Res. 2022. [Google Scholar] [CrossRef]

- Surendra, K.C.; Takara, D.; Hashimoto, A.G.; Khanal, S. Biogas as a sustainable energy source for developing countries: Opportunities and challenges. Renew. Sust. Energ. Rev. 2014, 31, 846–859. [Google Scholar] [CrossRef]

- Tallou, A.; Haouas, A.; Jamali, Y.; Atif, K.; Amir, S.; Aziz, F. Review on cow manure as renewable energy. In Smart Village Technology: Concepts and Developments; Patnaik, S., Sen, S., Mahmoud, M.S., Eds.; Springer International Publishing: Cham, Switzerland, 2020; Volume 17, pp. 341–352. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, S.; Yin, F.; Dong, H.; Cao, Q.; Lian, T.; Zhu, J. Produce individual medium chain carboxylic acids (MCCA) from swine manure: Performance evaluation and economic analysis. Waste Manag. 2022, 144, 255–262. [Google Scholar] [CrossRef]

- Achinas, S.; Euverink, G.J.W. Rambling facets of manure-based biogas production in Europe: A briefing. Renew. Sust. Energ. Rev. 2020, 119, 109566. [Google Scholar] [CrossRef]

- Produktion Och Användning Av Biogas Och Rötrester År 2019; Arkitektkopia AB: Stockholm, Sweden, 2019; Available online: https://energimyndigheten.a-w2m.se/ResourceComment.mvc?resourceId=179401 (accessed on 1 September 2022).

- Ameen, F.; Lingam, R.; Ahsan, N.; Shankar, V. Co-digestion of microbial biomass with animal manure in three-stage anaerobic digestion. Fuel 2021, 306, 121746. [Google Scholar] [CrossRef]

- Lohani, S.P.; Havukainen, J. Anaerobic digestion: Factors affecting anaerobic digestion process. In Waste Bioremediation. Energy, Environment, and Sustainability; Springer: Singapore, 2018; pp. 343–359. [Google Scholar] [CrossRef]

- Martí-Herrero, J.; Flores, T.; Alvarez, R.; Perez, D. How to report biogas production when monitoring small-scale digesters in field. Biomass Bioenerg. 2016, 84, 31–36. [Google Scholar] [CrossRef]

- Agga, G.; Appala, K.; Kasumba, J.; Loughrin, J.H. Lagoon, anaerobic digestion, and composting of animal manure treatments impact on tetracycline resistance genes. Antibiotics 2022, 11, 391. [Google Scholar] [CrossRef]

- Lin, M.; Wang, A.; Ren, L.; Qiao, W.; Wandera, S.M.; Dong, R. Challenges of pathogen inactivation in animal manure through anaerobic digestion: A short review. Bioengineered 2022, 13, 1149–1161. [Google Scholar] [CrossRef] [PubMed]

- Mlaik, N.; Sayadi, S.; Masmoudi, M.A.; Yaacoubi, D.; Loukil, S.; Khoufi, S. Optimization of anaerobic co-digestion of fruit and vegetable waste with animal manure feedstocks using mixture design. Biomass Convers. Biorefinery 2022. [Google Scholar] [CrossRef]

- Mohan, T.; Farid, N.S.S.; Swathi, K.V.; Sowmya, A.; Ramani, K. Sustainable biological system for the removal of high strength ammoniacal nitrogen and organic pollutants in poultry waste processing industrial effluent. J. Air Waste Manag. Assoc. 2020, 70, 1236–1243. [Google Scholar] [CrossRef]

- Okoroigwe, E.C.; Ibeto, C.N.; Ezema, C.G. Experimental study of anaerobic digestion of dog waste. Sci. Res. Essays 2014, 9, 121–127. [Google Scholar] [CrossRef]

- Meidiana, C. The spatial-economic approach for determining biogas management in rural area. Int. J. Appl. Eng. Res. 2015, 10, 31–35. Available online: https://www.researchgate.net/publication/308581375_The_Spatial-economic_Approach_for_Determining_Biogas_Management_in_Rural_Area (accessed on 14 October 2022).

- Saleh, H.M.; Hassan, A. The potential of sustainable biogas production from animal waste. In Advanced Technology for the Conversion of Waste into Fuels and Chemicals; Biological Processes; Woodhead Publishing: Sawston, UK, 2021; Volume 1, pp. 115–134. [Google Scholar] [CrossRef]

- Selormey, G.K.; Barnes, B.; Kemausuor, F.; Darkwah, L. A review of anaerobic digestion of slaughterhouse waste: Effect of selected operational and environmental parameters on anaerobic biodegradability. Rev. Environ. Sci. Bio/Technol. 2021, 20, 1073–1086. [Google Scholar] [CrossRef]

- Suanggana, D.; Haryono, H.D.; Djafar, A.; Irawan, J. Potensi produksi biogas dari anaerobic digestion kotoran sapi dan kulit nanas sebagai sumber energi rice cooker biogas. G-Tech 2022, 6, 1–7. [Google Scholar] [CrossRef]

- Karaca, C. Determination of biogas production potential from animal manure and GHG emission abatement in Turkey. Int. J. Agric. Biol. Eng. 2018, 11, 205–210. [Google Scholar] [CrossRef]

- Orner, K.D.; Cornejo, P.K.; Camacho, D.R.; Alvarez, M.; Camacho-Céspedes, F. Improving life cycle economic and environmental sustainability of animal manure management in marginalized farming communities through resource recovery. Environ. Eng. Sci. 2021, 38, 310–319. [Google Scholar] [CrossRef] [PubMed]

- Ramos-Suárez, J.L.; Ritter, A.; González, J.M.; Pérez, A.C. Biogas from animal manure: A sustainable energy opportunity in the Canary Islands. Renew. Sustain. Energy Rev. 2019, 104, 137–150. [Google Scholar] [CrossRef]

- Seglah, P.A.; Wang, Y.; Wang, H.; Gao, C.; Bi, Y. Sustainable biofuel production from animal manure and crop residues in Ghana. Energies 2022, 15, 5800. [Google Scholar] [CrossRef]

- Weaver, K.H.; Harper, L.A.; De Visscher, A.; van Cleemput, O. The effect of biogas ebullition on ammonia emissions from animal manure-processing lagoons. J. Environ. Qual. 2022, 51, 632–643. [Google Scholar] [CrossRef] [PubMed]

- Zahariev, A.; Penkov, D.; Aladjadjiyan, A. Biogas from animal manure–perspectives and barriers in Bulgaria. Annu. Res. Rev. Biol. 2014, 4, 709–719. [Google Scholar] [CrossRef]

- Zheng, X.; Zou, D.; Wu, Q.; Wang, H.; Li, S.; Liu, F.; Xiao, Z. Review on fate and bioavailability of heavy metals during anaerobic digestion and composting of animal manure. Waste Manag. 2022, 150, 75–89. [Google Scholar] [CrossRef]

- Richards, D.; Yabar, H. Potential of renewable energy in Jamaica’s power sector: Feasibility analysis of biogas production for electricity generation. Sustainability 2022, 14, 6457. [Google Scholar] [CrossRef]

- Okoroigwe, E.C.; Ibeto, C.N.; Okpara, C.G. Comparative study of the potential of dog waste for biogas production. Trends Appl. Sci Res. 2010, 5, 71–77. [Google Scholar] [CrossRef]

- Limaico, S.D. Kinetic Study of Biogas Production in Tubular Biodigesters with Recycled Mobile Support and Fed with Liquid Waste from Animal Feedlots. Bachelor´s Thesis, National Polytechnic School, Quito, Ecuador, February 2018. [Google Scholar]

- Martí-Herrero, J.; Álvarez, R.; Flores, T. Evaluation of the low technology tubular digesters in the production of biogas from slaughterhouse wastewater treatment. J. Clean Prod. 2018, 199, 633–642. [Google Scholar] [CrossRef]

- Geographical Data. Available online: https://www.gobiernosantiago.cl/datos-geograficos/#:~:text=Posee%20378.444%20habitantes%2C%20con%20una,%2C%20Talagante%2C%20Melipilla%20y%20Cachapoal (accessed on 10 October 2022).

- Meteorological Directorate of Chile, Santiago, Chile, Technical Report. 2014; Unpublished Work.

- Wei, S.; Guo, Y. Comparative study of reactor performance and microbial community in psychrophilic and mesophilic biogas digesters under solid state condition. J. Biosci. Bioeng. 2018, 125, 543–551. [Google Scholar] [CrossRef]

- McAteer, P.G.; Trego, A.C.; Thorn, C.; Mahony, T.; Abram, F.; O’Flaherty, V. Reactor configuration influences microbial community structure during high-rate, low-temperature anaerobic treatment of dairy wastewater. Bioresour. Technol. 2020, 307, 123221. [Google Scholar] [CrossRef]

- Moncayo, R.G. Sizing, Design and Construction of Biodigesters and Biogas Plants–Practical Design Manual, 1st ed.; Aqualimpia Beratende Ingenieure: Hanburg, Germany, 2008; p. 486. [Google Scholar]

- Ramelli, S. (German Egineering, S.A., Santiago, Chile); Schleenstein, G. (German Egineering, S.A., Santiago, Chile). Techinal Report from Office of Agricultural Studies And Agricultural Policies, Chile. 2009. Unpublished Work. [Google Scholar]

- Ning, J.; Zhou, M.; Pan, X.; Li, C.; Lv, N.; Wang, T.; Cai, G.; Wang, R.; Li, J.; Zhu, G. Simultaneous biogas and biogas slurry production from co-digestion of pig manure and corn straw: Performance optimization and microbial community Shift. Bioresour. Technol. 2019, 282, 37–47. [Google Scholar] [CrossRef]

- Guardado Chacón, J. Design and Construction of Simple Biogas Plants; CUBASOLAR: Havana City, Cuba, 2007; p. 66. [Google Scholar]

- Garfí, M.; Herrero, J.; Garwood, A.; Ferrer, I. Household anaerobic digesters for biogas production in Latin America: A review. Renew. Sust. Energ. Rev. 2016, 60, 599–614. [Google Scholar] [CrossRef]

- Garfí, M.; Martí-Herrero, J.; Garwood, A.; Ferrer, I. Psychrophilic full scale tubular digester operating over eight years: Complete performance evaluation and microbiological population. Energies 2021, 14, 1–17. [Google Scholar]

- Ahlberg-Eliasson, K.; Westerholm, M.; Isaksson, S.; Schnürer, A. Anaerobic digestion of animal manure and influence of organic loading rate and temperature on process performance, microbiology, and methane emission from digestates. Front. Energy Res. 2021, 9, 740314. [Google Scholar] [CrossRef]

- Hupfauf, S.; Winkler, A.; Wagner, A.O.; Podmirseg, S.M.; Insam, H. Biomethanation at 45 °C offers high process efficiency and supports hygienisation. Bioresour. Technol. 2020, 300, 122671. [Google Scholar] [CrossRef] [PubMed]

- Khojastehpour, M.; Nikkhah, A.; Taheri-Rad, A. The development and evaluation of a portablepolyethylene biogas reactor. Energy Equip. Sys. 2018, 6, 61–68. [Google Scholar] [CrossRef]

- Rössel, E.; Ortiz, H. Organic mass biodigester for generation of biogas fuel. Agro-Divulg. 2022, 2, 15–18. [Google Scholar]

- Tietz, C.M.; Feiden, A.; Hillesheim, P.R. Influence of the temperature variations in the production of biogas in Bioköhler biodigesters covered with greenhouse plastic film. Acta Iguazu Cascavel. 2019, 8, 121–131. [Google Scholar]

- Díaz, C. Implementation of a Biodigester for Biogas and Biol Generation in Bogota from Canine Feces Using an Ecocatalyst as a Biological Accelerator. Bachelor´s Thesis, De La Salle University, Bogotá, Colombia, 2020. [Google Scholar]

- Sabbir, A.S.M.Y.B.; Saha, C.K.; Nandi, R.; Zaman, M.F.U.; Alam, M.M.; Sarker, S. Effects of Seasonal Temperature Variation on Slurry Temperature and Biogas Composition of a Commercial Fixed-Dome Anaerobic Digester Used in Bangladesh. Sustainability 2021, 13, 11096. [Google Scholar] [CrossRef]

- Varnero, M.T. Biogas Handbook; FAO: Santiago, Chile, 2011; p. 120. [Google Scholar]

- Ministry of Energy and Deutsche Gesellschaft für Internationale Zusammenarbeit (MINENERGÍA/GIZ). Planning Guide for Biogas Projects in Chile; MINENERGÍA/GIZ: Santiago, Chile, 2012; p. 135. [Google Scholar]

- Rojas, J. Conceptual Design of a Biodigester for Residential Biogas Production at Residential Level. Bachelor´s Thesis, University of Chile, Santiago, Chile, 2019. [Google Scholar]

- Mohammed, M.; Belkair, A.; Hamad, T.; Jirhiman, A.; Hassan, R.; Ahmeedah, A. Improving biogas production from animal manure by batch anaerobic digestion. Alger. J. Eng. Technol. 2022, 6, 79–84. Available online: https://www.jetjournal.org/index.php/ajet/article/view/199 (accessed on 1 September 2022).

- Canales-Gutiérrez, A.; Quispe-Aucca, B.J.; Romero-Loaiza, R. Design of an anaerobic biodigester model as an alternative for methane generation. J. Selva Andina Biosph. 2021, 9, 81–91. [Google Scholar] [CrossRef]

- Cerón-Vivas, A.; Cáceres, K.T.; Rincón, A.; Cajigas, Á.A. Influence of pH and the C/N ratio on the biogas production of wastewater. Rev. Fac. Ing. Univ. Antioq. 2019, 92, 70–79. [Google Scholar] [CrossRef]

- Aeberhard, R.; Bucki Wasserman, B. Obtaining biogas from dog feces, a contribution to environmental care in the city of Buenos Aires. AVERMA 2010, 14, 25–29. [Google Scholar]

- Rodríguez, D.; García, A. Design and Construction of a Biodigester for Biogas Production from Canine Feces. Bachelor´s Thesis, Francisco José de Caldas District University, Bogotá, Colombia, 2017. [Google Scholar]

- Martínez-Sabater, E.; García-Muñoz, M.; Bonete, P.; Rodriguez, M.; Sánchez-García, F.; Pérez-Murcia, M.; Bustamante, M.; López-Lluch, D.; Moral, R. Comprehensive management of dog faeces: Composting versus anaerobic digestion. J. Environ. Manag. 2019, 250, 109437. [Google Scholar] [CrossRef]

- Sharma, A.K.; Sahoo, P.K.; Mukherjee, M.; Patel, A. Assessment of sustainable biogas production from co-digestion of jatropha de-oiled cake and cattle dung using floating drum type digester under psychrophilic and mesophilic conditions. Clean Technol. 2022, 4, 529–541. [Google Scholar] [CrossRef]

- Mohanty, A.; Rout, P.R.; Dubey, B.; Meena, S.S.; Pal, P.; Goel, M. A critical review on biogas production from edible and non-edible oil cakes. Biomass Convers. Biorefin. 2022, 12, 949–966. [Google Scholar] [CrossRef]

- Elliot, B.; Moraga, A.; Quiroz, H.; Soto, P. Guide for the Installer of Medium and Large-Scale Biogas Plants; Ministry of Energy and Deutsche Gesellschaft für Internationale Zusammenarbeit (MINENERGÍA/GIZ): Santiago, Chile, 2018; 24p. [Google Scholar]

- FAO. Theoretical and Practical Guide on Biogas and Biodigesters; FAO: Buenos Aires, Argentina, 2019; 144p. [Google Scholar]

- Antle, J.M.; Ray, S. Economic Development, Sustainable Development, and Agriculture. In Sustainable Agricultural Development. Palgrave Studies in Agricultural Economics and Food Policy; Palgrave Macmillan: Cham, Switzerland, 2020; pp. 9–42. [Google Scholar] [CrossRef]

- Gromova, T.S.; Siraeva, I.S.; Ermolenko, A.S.; Larionov, N.V.; Larionov, M.V. Anthropo-technogenic load on the environment objects Khopyor River Region. Samara J. Sci. 2020, 9, 30–36. [Google Scholar] [CrossRef]

- Larionov, M.V.; Larionov, N.V.; Ermolenko, A.S. The composition and characteristics of the dendroflora in the transformed conditions of the Middle Reaches of the River Khoper. IOP Conf. Ser. Earth Environ. Sci. 2018, 115, 012009. [Google Scholar] [CrossRef]

- Larionov, M.V.; Larionov, N.V.; Siraeva, I.S. Ecological and aesthetic significance of an auto-trophic component of artificial ecosystems in ensuring of the environmental comfort and the public health protection. IOP Conf. Ser. Earth Environ. Sci. 2020, 421, 082002. [Google Scholar] [CrossRef]

- Newton, A.C.; Evans, P.M.; Watson, S.C.L.; Ridding, L.E.; Brand, S.; McCracken, M. Ecological restoration of agricultural land can improve its contribution to economic development. PLoS ONE 2021, 16, e0247850. [Google Scholar] [CrossRef]

- Truong, D.T.; Anh, N.T.Q. Policy Implications on Socio Ecological and Economic Tranformation in Vietnam’s Agriculture: Experiences from Legato Project. VNU J. Sci. Policy Manag. Stud. 2019, 35, 26–38. [Google Scholar] [CrossRef]

- Gromova, T.S.; Larionov, M.V.; Larionov, N.V.; Ermolenko, A.S. The state of woody plants of natural and anthropogenic ecosystems of the european part of Russia and their bioindication value. Proc. Int. Conf. Contemp. Educ. Soc. Sci. Ecol. Stud. (CESSES 2018) Ser. Adv. Soc. Sci. Educ. Humanit. Res. 2018, 283, 914–920. [Google Scholar] [CrossRef]

- Das, K.; Chetri, S.; Khadgawat, P.; Minocha, S.; Sengupta, A.; Sharma, B.K.; Kumar, A. An ecofriendly approach toward waste management and environmental safety through microorganisms. In Development in Wastewater Treatment Research and Processes. Innovative Microbe-Based Applications for Removal of Chemicals and Metals in Wastewater Treatment Plants; Elsevier: Amsterdam, The Netherlands, 2022; pp. 401–417. [Google Scholar] [CrossRef]

- Larionov, M.V.; Logacheva, E.A.; Larionov, N.V. An ecological analysis of the composition and condition of woody plants in urban and suburban ecosystems of the Khopyor River Region. IOP Conf. Ser. Earth Environ. Sci. 2020, 421, 062025. [Google Scholar] [CrossRef]

- Yurui, L.; Xuanchang, Z.; Zhi, C.; Liu, Z.; Zhi, L.; Liu, Y. Towards the progress of ecological restoration and economic development in China’s Loess Plateau and strategy for more sustainable development. Sci. Total Environ. 2021, 756, 143676. [Google Scholar] [CrossRef] [PubMed]

| Sample Identification | Canine Manure | Acceptance Level | ||||

|---|---|---|---|---|---|---|

| Chemical Analysis | Class A | Class B | Method | |||

| pH | 5.8 | 5.0 | 8.5 | TMECC 04.11 | ||

| Electrical conductance | dS/m | 9.4 | <3 | <8 | TMECC 04.10 | |

| Organic Matter | % | 71.0 | >20 | TMECC 05.07-A | ||

| Organic Carbon | % | 39.4 | >11 | TMECC 05.07-A | ||

| Total Nitrogen | (N) | % | 3.17 | >0.5 | TMECC 04.02-D | |

| C/N ratio | 12.4 | <25 | <30 | TMECC 05.07-A | ||

| Available Ammonium | (NH4) | mg/kg | 1330 | |||

| Available Nitrate | (NO3) | mg/kg | 539 | |||

| NH4/NO3 ratio | 2.5 | <3 | TMECC 04.02 -BC | |||

| Total Phosphorus | (P2O5) | % | 8.7 | |||

| Total Potassium | (K2O) | % | 0.43 | |||

| Total Sulfur | (S) | % | 0.22 | |||

| Total Sodium | (Na) | % | 0.54 | |||

| Total Molybdenum | (Mo) | mg/kg | <0.01 | |||

| Total Iron | (Fe) | mg/kg | 2508 | |||

| Total Manganese | (Mn) | mg/kg | 446 | |||

| Total Boron | (B) | mg/kg | 35 | |||

| Total Arsenic | (As) | mg/kg | 5.30 | 15 | 20 | TMECC 04.06 |

| Total Cadmium | (Cd) | mg/kg | <0.01 | 2 | 8 | TMECC 04.06 |

| Total Copper | (Cu) | mg/kg | 70 | 100 | 1000 | TMECC 04.06 |

| Total Chromium | (Cr) | mg/kg | 8.7 | 120 | 600 | TMECC 04.06 |

| Total Mercury | (Hg) | mg/kg | 0.950 | 1 | 4 | TMECC 04.06 |

| Total Lead | (Pb) | mg/kg | 11.1 | 100 | 300 | TMECC 04.06 |

| Total Selenium | (Se) | mg/kg | <0.01 | |||

| Total Zinc | (Zn) | mg/kg | 878 | 200 | 200 | TMECC 04.06 |

| Total Sulfur | (S) | mg/kg | 640 | |||

| Humidity | % | 77 | 30–45 | TMECC 03.09 | ||

| Dry Matter | % | 23 | 70–55 | |||

| Parameter | Units | Value |

|---|---|---|

| Average Annual Temperature | °C | 14.2 |

| Dry Matter | kg | 6.9 |

| Volatile Mass | kg | 4.899 |

| Dilution | L/day | 40 |

| Specific Volume | L | 66 |

| TRH | Days | 30 |

| Solid Retention Time (SRT) | Days | 30 |

| Charge Tank | L | 82 |

| Discharge Tank | L | 272 |

| VOC | Kg MV/m3/day | 4.9/2.5 = 1.96 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vivallos Soto, C.; Ruiz Bertín, F.; Robles Calderón, C.; Larionov, M.V.; Arias Ordóñez, P.J.; Cevallos Baque, I. Biodigestion System Made of Polyethylene and Polystyrene Insulator for Dog Farm (on the Example of the Republic of Chile). Life 2022, 12, 2039. https://doi.org/10.3390/life12122039

Vivallos Soto C, Ruiz Bertín F, Robles Calderón C, Larionov MV, Arias Ordóñez PJ, Cevallos Baque I. Biodigestion System Made of Polyethylene and Polystyrene Insulator for Dog Farm (on the Example of the Republic of Chile). Life. 2022; 12(12):2039. https://doi.org/10.3390/life12122039

Chicago/Turabian StyleVivallos Soto, Cristian, Francisco Ruiz Bertín, Carolina Robles Calderón, Maxim Viktorovich Larionov, Priscila Jackeline Arias Ordóñez, and Ivette Cevallos Baque. 2022. "Biodigestion System Made of Polyethylene and Polystyrene Insulator for Dog Farm (on the Example of the Republic of Chile)" Life 12, no. 12: 2039. https://doi.org/10.3390/life12122039

APA StyleVivallos Soto, C., Ruiz Bertín, F., Robles Calderón, C., Larionov, M. V., Arias Ordóñez, P. J., & Cevallos Baque, I. (2022). Biodigestion System Made of Polyethylene and Polystyrene Insulator for Dog Farm (on the Example of the Republic of Chile). Life, 12(12), 2039. https://doi.org/10.3390/life12122039