Abstract

The dimensioning of general-purpose machines such as manipulators involves the solution of a number of preliminary issues. The determination of reference external loads and the identification of machine configurations that give the maximum internal load for each component are two of these issues. These two problems are commonly addressed through trial-and-error procedures based on dynamic modelling, which are implemented with the support of simulation software, since static analyses are commonly considered inadequate to solve them. Despite this, here, a technique based on influence coefficients and static analyses is presented which solves them. Such technique is also able to foresee and justify dynamic issues (i.e., possible vibrations, etc.) that could heavily affect the machine behavior. The effectiveness of the proposed technique is proved by implementing it on a 3T1R parallel manipulator. The presented design method is general and applicable to any type of non-overconstrained manipulator or mechanism.

1. Introduction

The mechanical design of manipulators has mandatory steps summarizable as follows: type synthesis [1,2,3,4], dimensional synthesis [1,2,4], and machine-element design [5,6,7]. Type synthesis identifies the machine topologies that meet the motion requirements, dimensional synthesis determines the values of the geometric parameters that affect the motion tasks the machine has to perform, and, finally, machine-element design chooses materials and sizes of each component of the machine.

The third step needs, as input data, the reference external loads applied to the machine and the identification of the machine configurations that give the maximum internal loads for each component. In general-purpose machines, such as manipulators, these input data are not straightforwardly obtainable from the design requirements and their deduction becomes even more difficult when dealing with parallel manipulators (PMs) since PMs’ reachable workspace usually includes particular configurations, named “parallel” singularities [8,9,10], where the end effector cannot carry any (even infinitesimal) load without breaking down the PM.

Various performance indices were conceived for identifying PMs’ reachable-workspace regions that are free and far from singularities, where safely locating the useful workspace [11,12,13,14,15,16,17,18]. These indices well identify kinetostatic issues and can be useful to perform the dimensional synthesis and to locate the useful workspace (see, for instance, [19,20]) far from singularities. Nevertheless, they fail in relating the “distance” from singularities to the actual internal loads of the links.

Other indices take into account also robot stiffness and dynamic performances [16,17,18,21,22,23,24,25,26]. These other indices require the knowledge of data (e.g., masses, stiffness, etc.) that are available at the end of the machine design. Therefore, they are certainly suitable for comparing already-built manipulators, but their use during design is not straightforward since it requires trial-and-error procedures.

In general, all these indices can help the design procedure, but do not provide sufficient pieces of information for determining the input data of PMs’ machine-element design. This determination is commonly addressed through trial-and-error procedures based on dynamic modelling, supported by multi-body simulation software, due to the preeminent dynamic nature of the loads applied to a manipulator. This widely adopted procedure is not able to justify unforeseen/unwanted machine behaviors that come out from the simulations thus making difficult to intervene for eliminating them.

Here, an algorithm, based on influence coefficients and static analyses, is presented which provides sufficient pieces of information for determining the input data of PMs’ machine-element design. The proposed algorithm is also able to foresee and justify dynamic issues (i.e., possible vibrations, etc.) that could heavily affect the machine behavior. Its effectiveness is proved by implementing it on a 3T1R parallel manipulator. The presented design method is general and applicable to any type of non-overconstrained manipulator or mechanism.

The proposed algorithm is a novel way of computing and using influence coefficients in the design of general-purpose machines, mainly ideated for PMs, which aims at integrating the design methodologies based on performance indices and/or extended multibody simulations by solving their lacks. Indeed, it can overcome the fact that performance indices are not able to provide sufficient data for the machine-element design, and that extended multibody simulations often do not provide sufficient pieces of information for intervening when an unforeseen phenomenon comes out from the simulations.

2. Materials and Methods

Most manipulators are based on non-overconstrained architectures [27]. Non-overconstrained manipulators become isostatic structures when the actuated joints are locked. The static analysis of an isostatic structure is sufficient to relate external loads to links’ internal loads and involves the solution of a problem that is linear and homogeneous in the input (i.e., external loads) and the output (i.e., links’ internal loads) variables [28]. This solution does not need to know the materials the links are made of and links’ cross-sections, which is an ideal condition for tools to employ during design when materials and actual sizes of the links are not known since their choice/determination is the design goal. In addition, such static analyses are based only on equilibrium equations and can take into account an esteem of the dynamic loads among the known external loads thus simulating an inverse dynamic problem [27].

Problems that involve the solution of a linear system, as the above-mentioned static analyses do, can be addressed by using the superposition principle [29]. In the case of a static analysis, the linear system to solve can be put into the following canonic form

where x = (x1,…,xr)T is an r-tuple collecting all the scalar components, xi for i = 1,…,r, of the known external loads applied to the isostatic structure, y = (y1,…,ys)T is an s-tuple collecting all the scalar components, yj for j = 1,…,s, of links’ internal loads, and A is an s × r rectangular matrix of coefficients whose entries depend on the manipulator configuration.

A x = y

The linearity of system (1) allows demonstrating that (superposition principle) if x is writable as follows

where λp, for p = 1,…,n, are n scalar coefficients and up = (δ1p,…,δrp)T (where δip is the Kronecker delta defined as follows: δip = 0 for i≠p and δip = 1 for i = p), for p = 1,…,n, are n unit r-tuple, then

with for p = 1,…,n. Hereafter, vp will be named p-th influence-coefficient vector.

During the design of a manipulator, once the dimensional synthesis has been completed, Equation (3) can be exploited for the determination of the maximum internal loads of the links by implementing the following steps:

- (i).

- according to the type of motion [30] the end effector can perform, up to three independent unit forces and up to three independent unit moments are identified for characterizing the dynamic loads applied to the end effector during motion and the other dynamic loads reduced to the end effector;

- (ii).

- the unit forces/moments determined in the previous step are transformed into up r-tuples to introduce into Equation (2) for computing the input data of Equation (1);

- (iii).

- for each up determined in the previous step, the corresponding influence-coefficient vector vp is computed for a discretized set of end-effector poses inside the useful workspace of the manipulator;

- (iv).

- the so-determined vp are analyzed for finding the maximum internal loads of each link due to each unit load up together with the corresponding manipulator configurations;

- (v).

- by exploiting Equation (3), the maximum internal loads of each link determined in the previous step are combined to obtain the reference internal loads of each link to use for sizing the link in terms of material choice and cross-section.

This procedure, over providing the input data for the machine-element design, is able to highlight critical conditions due to unbalanced variable loads acting on the links, since it is a static calculus referred to dynamic loads, thus providing pieces of information that orientate the next steps of the manipulator design.

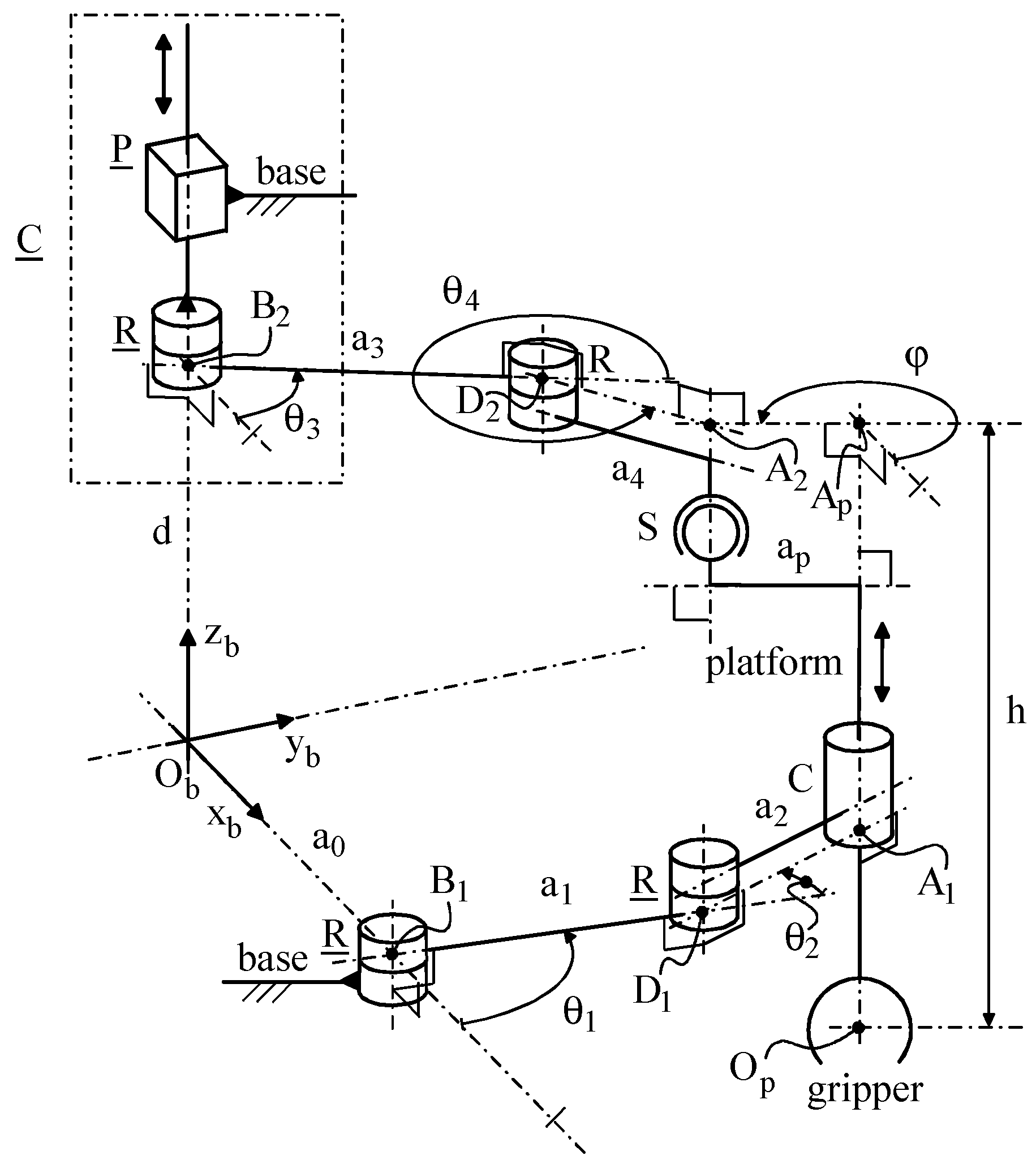

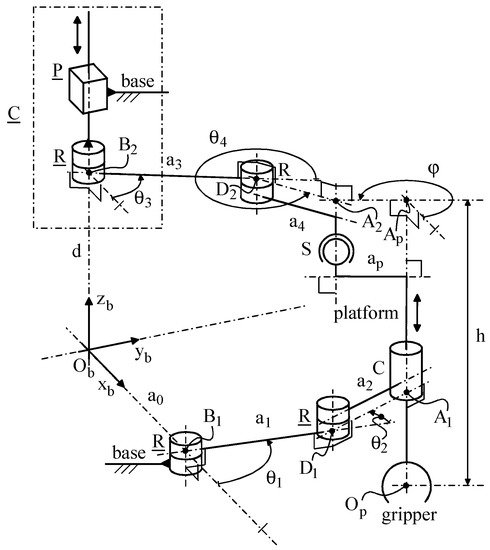

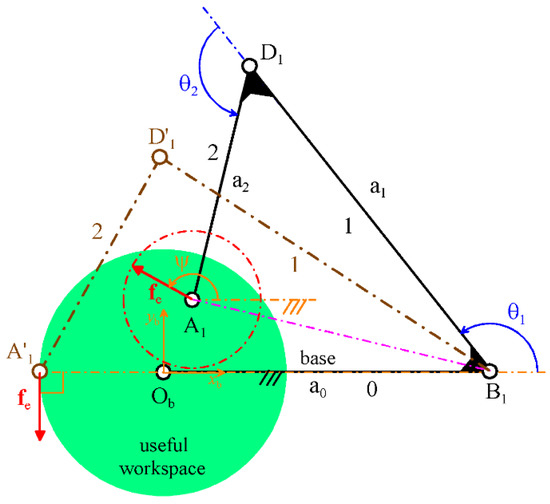

Next section exemplifies the procedure by applying it to the partially decoupled 3T1R PM shown in Figure 1.

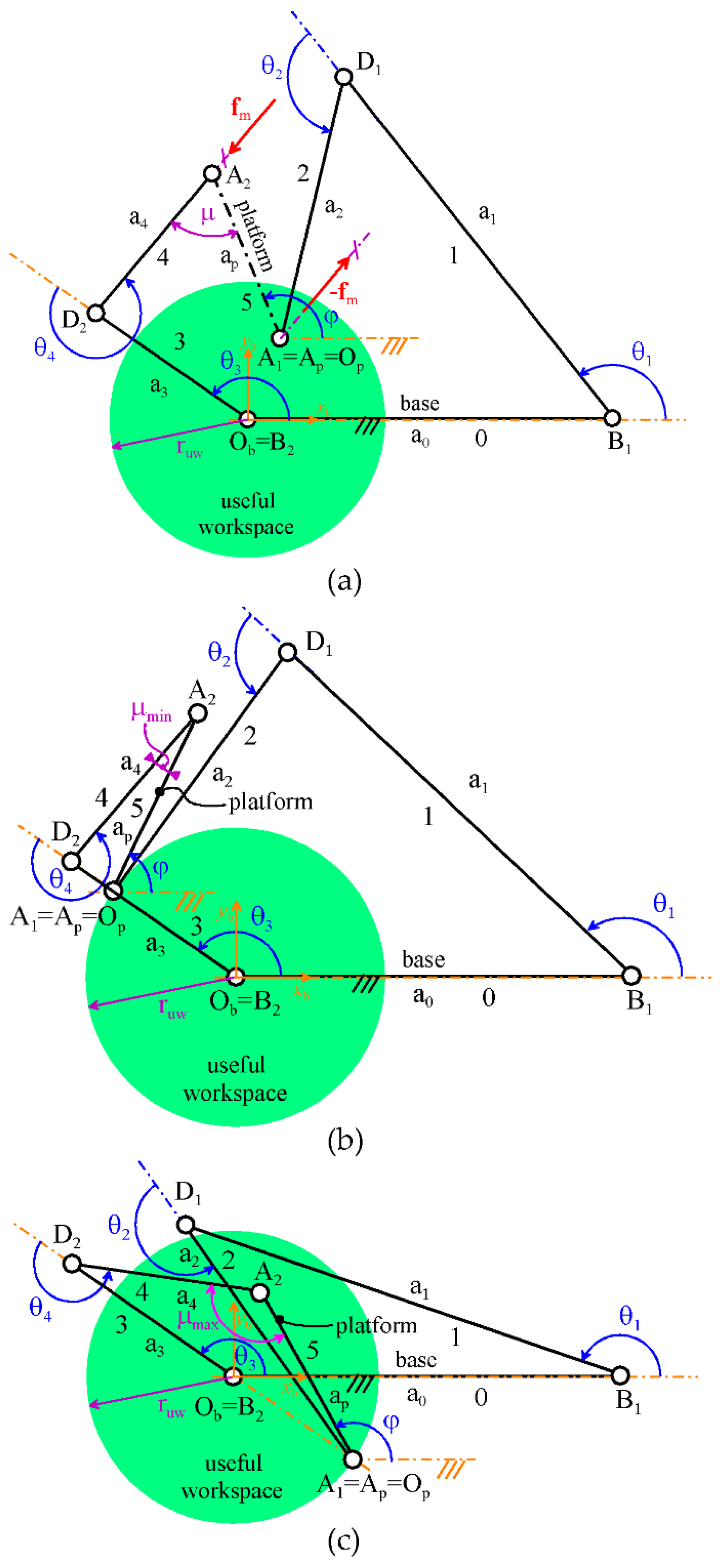

Figure 1.

The 3T1R parallel manipulator of type CRS-RRC.

3. Results

Figure 1 shows a single-loop PM in which the end effector (platform) is simultaneously connected to the frame (base) through two kinematic chains (limbs), one of type CRS1 and the other of type RRC, that is, it is a PM of type CRS-RRC. The axes of the R and C pairs are all parallel. The actuated C pair of the CRS limb is obtained by means of a PR chain with the sliding direction of the P pair parallel to the axis of the R pair. Such a PM architecture has four degrees of freedom [31] and constrains the platform to perform spatial translations (3T) plus rotations around axes with one fixed direction (1R), that is, the platform can perform only motions of 3T1R type, named Scara or Schoenflies motions [30]. This Scara PM has been ideated [20,31] at the Laboratory of Mechatronics and Virtual Prototyping (LaMaViP) of the University of Ferrara and, hereafter, for the sake of brevity, it will be named “LaMaViP’s CRS-RRC”. In the context of the Scara PMs, LaMaViP’s CRS-RRC is interesting because it can be actuated by keeping all the motors on the base and using commercial components, and it has the platform translation decoupled from the platform rotation [20,31].

The following notations/definitions are introduced (see Figure 1):

- -

- Obxbybzb is a Cartesian reference fixed to the base with the direction of the zb-coordinate axis parallel to the R and C pair axes;

- -

- Op is a point fixed to the platform whose coordinates, (xp, yp, zp)T, measured in Obxbybzb, locate the position of the platform;

- -

- B2 is a point that lies on the axis of the actuated C-pair of the CRS limb and is fixed to the output link of the C-pair;

- -

- d is the signed distance of B2 from Ob chosen as linear joint-variable of the actuated C-pair;

- -

- D2, Ap, and A2 are the intersection points between the plane parallel to the xbyb plane that passes through B2 and, respectively, the axis of the passive R-pair, the axis of the passive C-pair, and the line parallel to the zb axis that passes through the center of the S-pair;

- -

- h is a geometric constant of the platform equal to the length of the segment ApOp;

- -

- ap is a geometric constant of the platform that is equal to the length of the segment ApA2;

- -

- φ is the angle between the segment ApA2 and the line parallel to xb and passing through Ap (the angle φ uniquely determines the platform orientation);

- -

- a3 and a4 are the lengths of the segments B2D2 and D2A2, respectively;

- -

- θ3 and θ4 are the angular joint-variables of the actuated C-pair and of the passive R-pair, respectively;

- -

- θ1 and θ2 are the angular joint-variables of the two actuated R-pairs of the RRC limb;

- -

- B1, D1, and A1 are the intersection points between the xbyb coordinate plane and, respectively, the axis of the actuated R-pair adjacent to the base, the axis of the intermediate R-pair of the RRC limb and the axis of the passive C-pair;

- -

- a0, a1 and a2 are the lengths of the segments ObB1, B1D1 and D1A1, respectively.

From a kinematics point of view, the RRC limb constrains the platform to perform Schoenflies motions with rotation axis parallel to the zb-coordinate axis and controls only the xp and yp coordinates of Op (i.e., the platform translations parallel to the xbyb coordinate-plane). Moreover, the CRS limb controls the coordinate zp of point Op (i.e., the platform translation parallel to the zb-coordinate axis) through its linear joint-variable, d, and, independently, the platform orientation (i.e., the angle φ) through its angular joint-variable, θ3.

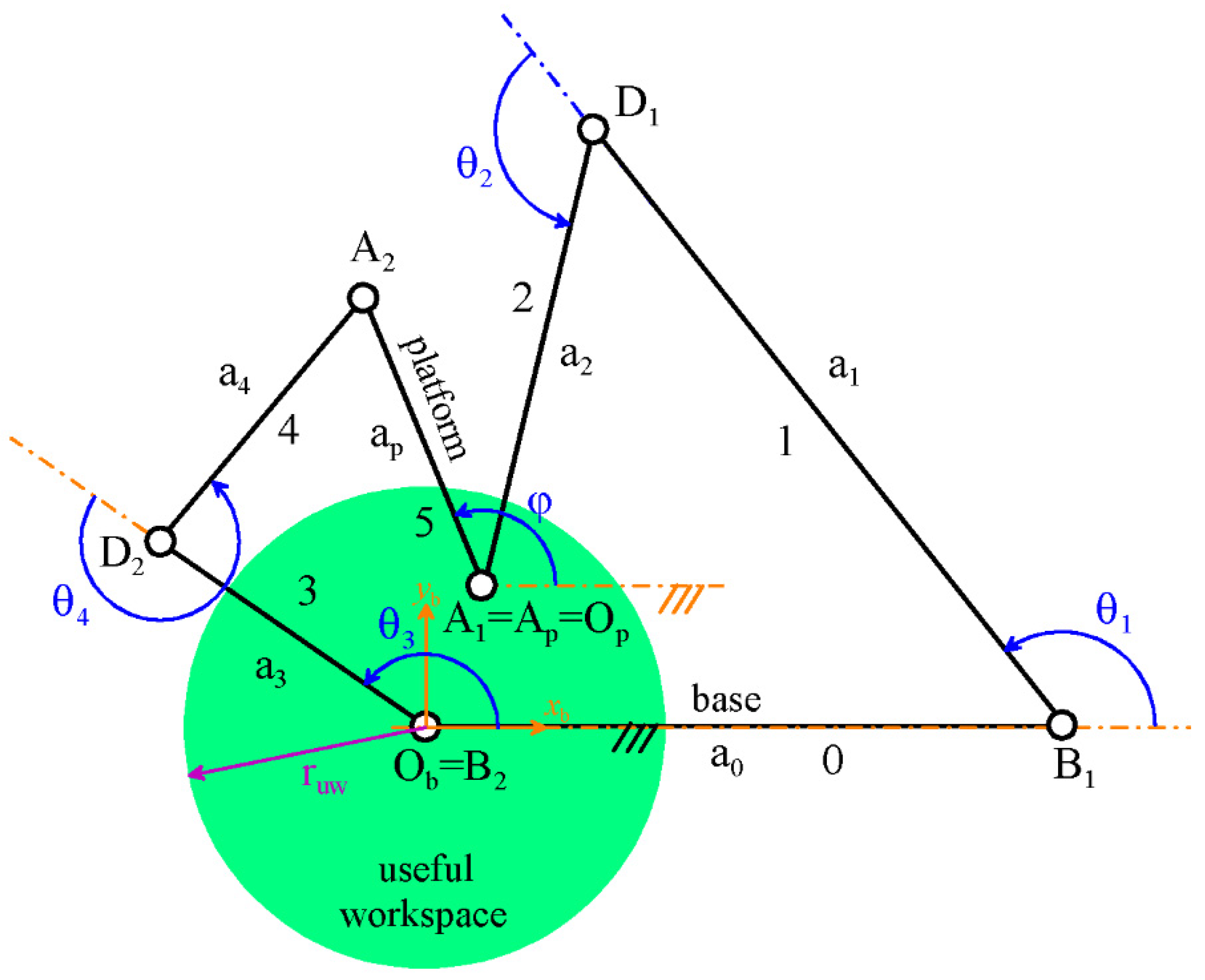

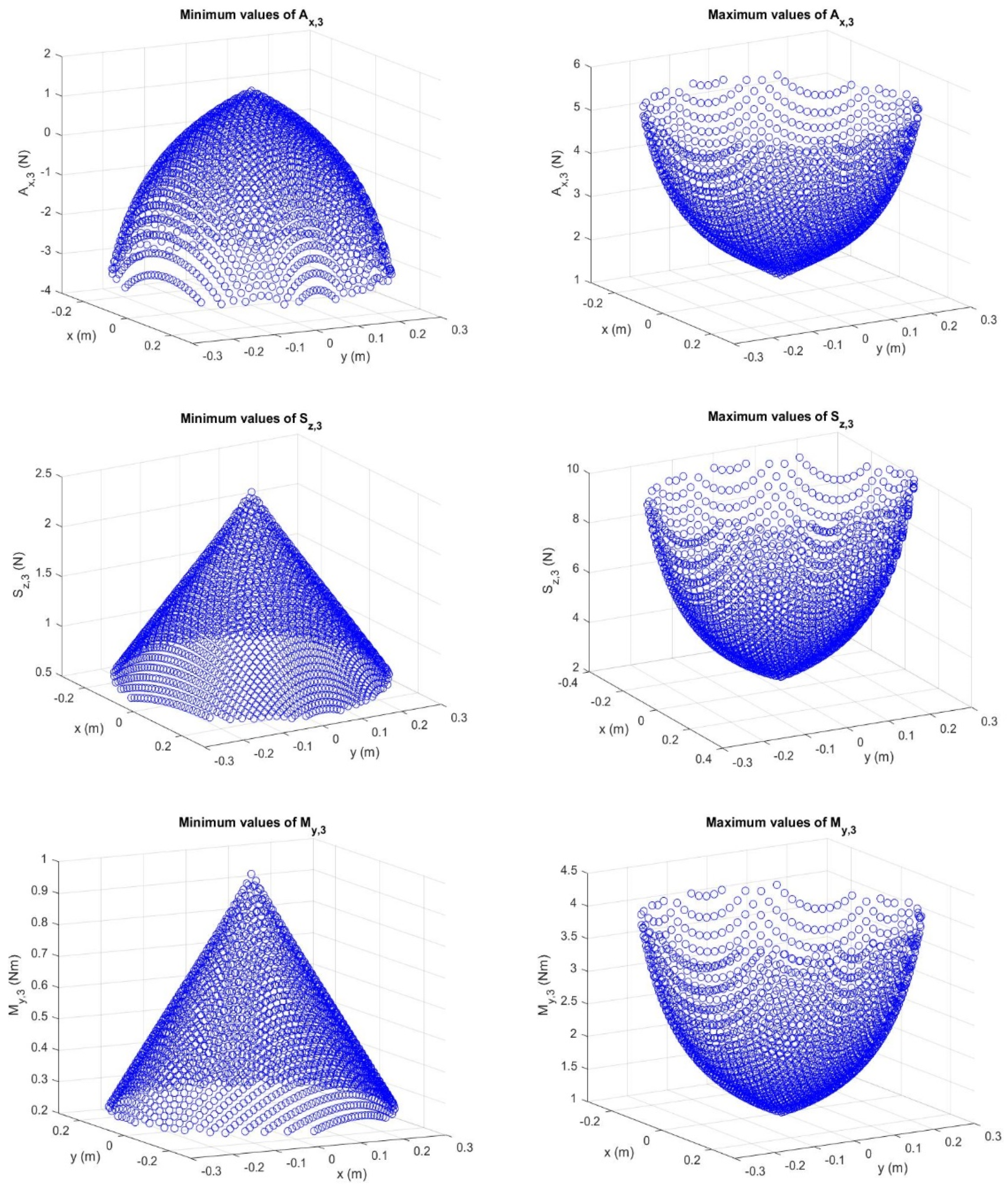

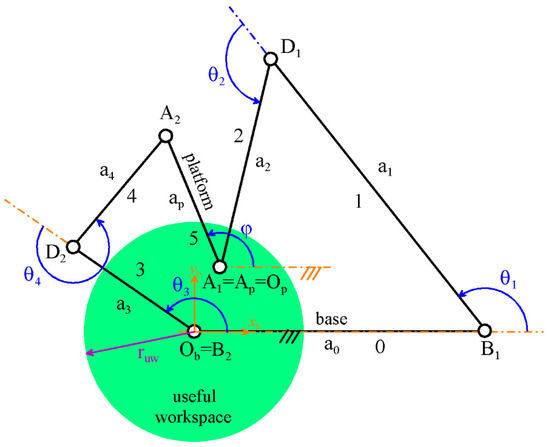

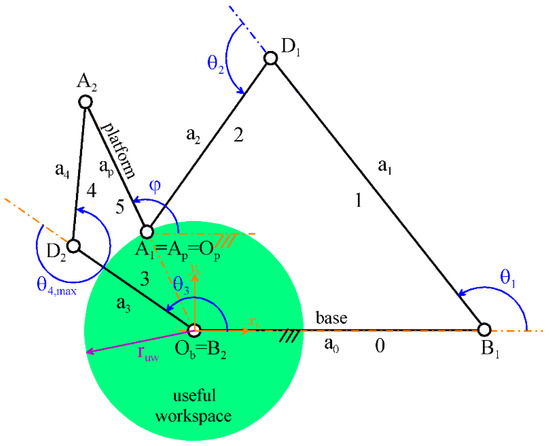

The dimensional synthesis of LaMaViP’s CRS-RRC was addressed in [19]. In [19], a useful workspace assigned as a right circular cylinder with a radius, ruw, of 300 mm and a height of 200 mm, whose axis is coincident with the zb-coordinate axis, brought to choose the following values of the geometric constants (see Figure 1): a0 = 800 mm, a1 = 950 mm, a2 = 600 mm, a3 = 400 mm, a4 = 400 mm, and ap = 400 mm. Figure 2 shows the scaled top view of a LaMaViP’s CRS-RRC sized according to this geometric data together with the position of the chosen useful workspace (the green circle in Figure 2). The analysis of Figure 2 reveals that the translation of the platform along the direction of the zb-coordinate axis is fully decoupled from the remaining platform motion. Indeed, the motion due to the prismatic pair does not appear in the top view (Figure 2) where the PM becomes a planar six-bar mechanism controlled by the actuated-joint variables θ1, θ2, and θ3. In addition, in this six-bar, θ1 and θ2 just control the position of the platform (i.e., the position of point A1), whereas θ3 fully controls the platform orientation (i.e., the angle φ) through a four-bar transmission.

Figure 2.

Scaled top view of a LaMaViP’s CRS-RRC sized according to the results of the dimensional synthesis [19].

3.1. Implementation of Steps (i) and (ii)

According to the introduced notations, the 4-tuples q = (θ1,θ2,θ3,d)T and κ = (xp,yp,zp,φ)T collect the actuated-joint (input) variables and the platform-pose (output) variables, respectively. The inspection of Figure 1 and Figure 2 reveals that the entries of q and κ must satisfy the following constraint equations

which are holonomic and time-independent.

xp = a0 + a1cosθ1 + a2cos(θ1 + θ2),

yp = a1sinθ1 + a2sin(θ1 + θ2),

zp = d − h

(xp + ap cosφ − a3 cosθ3)2 + (yp + ap sinφ − a3 sinθ3)2 = a42,

Equations (4a)–(4d) yield the following relationships between the virtual displacements δq = (δθ1, δθ2, δθ3, δd)T and δκ = (δxp, δyp, δzp, δφ)T

with

where cw and sw stand for cos(w) and sin(w), respectively, whereas, (see Figure 2)

The active-force2 system applied to LaMaViP’s CRS-RRC consists of the active external forces applied to the end effector and the generalized torques applied inside the actuated joints. The active external forces are collected into the 4-tuple γ = −(Fe,x, Fe,y, Fe,z, Me,z)T, where Fe,x, Fe,y, and Fe,z are the components, along xb, yb, and zb, respectively, of their resultant force and Me,z is the component along zb of their resultant moment about Op. In addition, the generalized torques are collected into the 4-tuple where the right subscripts indicate the actuated joint the generalized torque refers to. The virtual work principle [32] makes it possible to write

The elimination of from Equation (8) by means of Equation (5) and the consideration that the resulting expression must hold for any value of yield

where

- (a)

- Fe,x and Fe,y load only the RRC limb, their effects are coupled and do not depend on φ (i.e., on the platform orientation);

- (b)

- Fe,z loads the CRS limb through the S-pair and its static effect on links 3 and 4 (see Figure 2) depends on the limb configuration. Moreover, the static equilibrium of the platform reveals that, when Fe,z is applied at Op and the S-pair equilibrates it by applying a force −Fe,z at A2, a torque, Mp, with magnitude |Fe,z ap| (see Figure 1) and direction perpendicular to the platform plane (i.e., the plane located by the points Op, Ap and A2) arises. Mp must be equilibrated by the reaction in the passive C-pair of the RRC limb. As a consequence, Fe,z makes the RRC limb loaded, too, by the torque Mp, whose static effects on links 1 and 2 depend on the platform pose and the limb configuration;

- (c)

- Me,z loads both the limbs and all the links.

During motion, all the components of γ (= −(Fe,x, Fe,y, Fe,z, Me,z)T) are generated from the inertia forces arising in the mechanism. Therefore, the static analysis must consider all the above-mentioned cases. Regarding case (a), links’ internal loads, caused by a unit force (Fe,x, Fe,y) = (cψ, sψ) N for ψ∈[0°, 360°], corresponding to u1=(cψ, sψ, 0, 0)T N for ψ∈[0°, 360°], applied to the RRC limb at A1 (see Figure 1 and Figure 2), must be determined for a discretized set of A1 positions inside the useful workspace. Regarding case (b), links’ internal loads, caused by a unit force Fe,z (= 1 N), corresponding to u2 = (0, 0, 1, 0)T N, applied at Op (see Figure 1 and Figure 2), must be determined for a discretized set of Op positions inside the useful workspace. Regarding case (c), links’ internal loads, caused by an unit moment Me,z (=1 Nm), corresponding to u3 = (0, 0, 0, 1)T Nm, applied to the platform at Op (see Figure 1 and Figure 2), must be determined for a discretized set of Op positions inside the useful workspace.

3.2. Implementation of Steps (iii) and (iv)

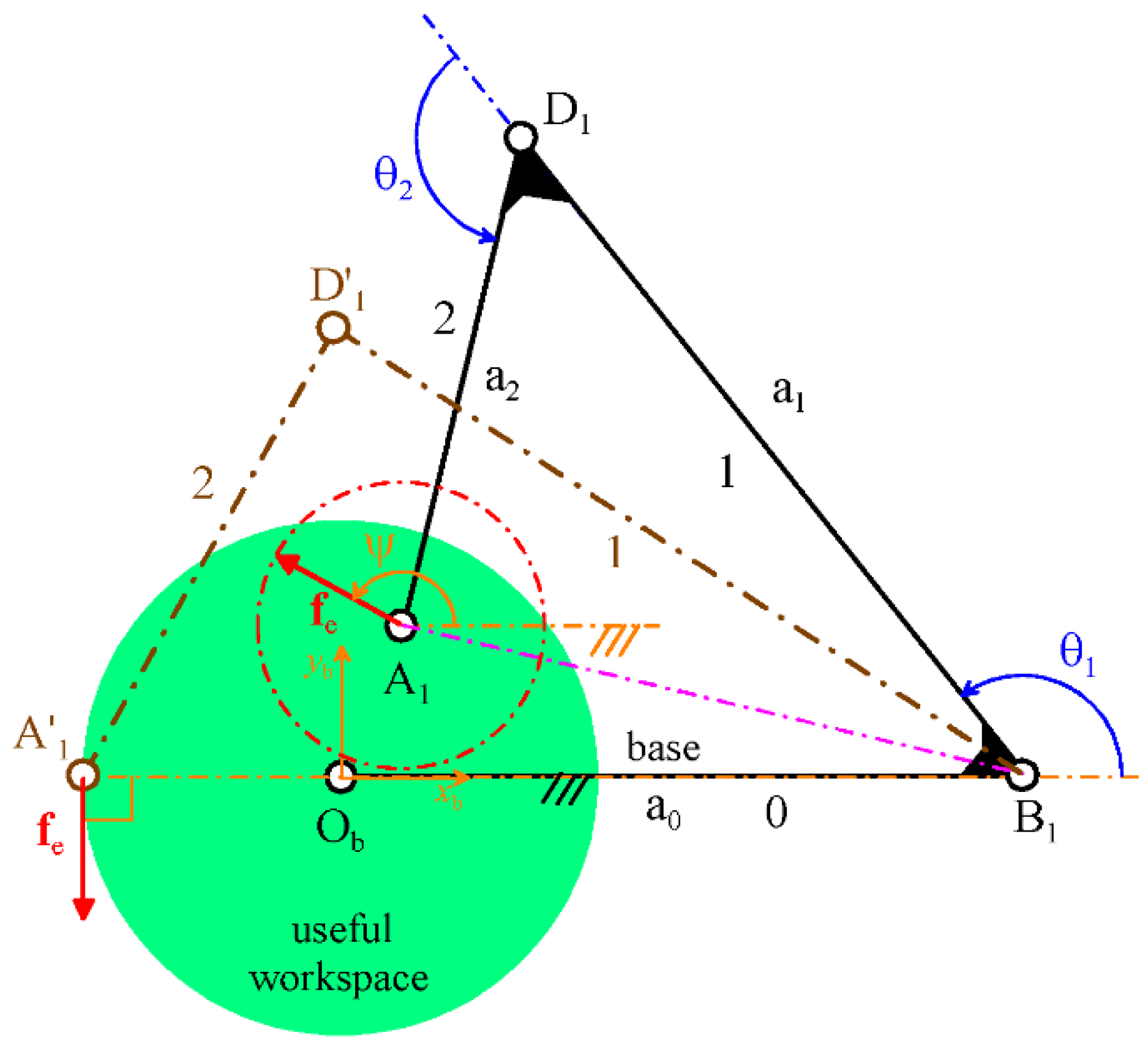

3.2.1. Case (a): Links’ Internal Loads Due to u1

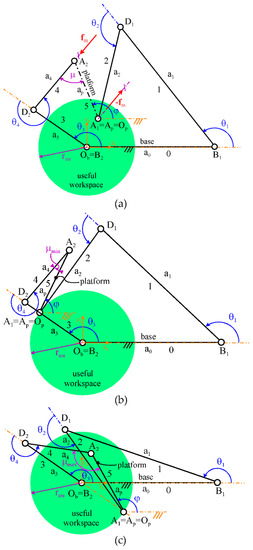

In this case, only links 1 and 2 (Figure 2) are loaded and the static problem is planar. Indeed (Figure 2 and Figure 3), it consists in computing the maximum internal loads, for each admissible RRC limb configuration (i.e., for each position of A1 in the useful workspace), in a RRC limb locked at the analyzed configuration with the planar force fe = (Fe,x, Fe,y)T = (cψ, sψ)T N for ψ∈[0°, 360°] applied at A1.

Figure 3.

Static problem to solve in case (a).

This problem is quite simple. Indeed, due to the planarity of the problem the non-null internal loads of the two links are only three: the bending moment (My), the shear force (Sz), and the axial force (Ax)3. Regarding link 2, whatever be the limb configuration, the maximum My and Sz always occur at D1 when fe is perpendicular to the link axis (i.e., when ψ = θ1 + θ2 ± 90°) and their values are My,2,max = ±|fe|a2 = ±0.6 Nm and Sz,2,max = ±|fe| = ±1 N, respectively. Further, the maximum Ax occurs when fe is aligned with the link axis (i.e., when ψ = θ1 + θ2 or ψ = θ1 + θ2 + 180°) and its value is Ax,2,max = ±|fe| = ±1 N.

Regarding link 1, at any limb configuration, the maximum My occurs either at B1 when the distance between fe’ s line of action and B1 is maximum (i.e., when fe is perpendicular to the segment A1B1 (see Figure 3)), where its value is My,1 = ±|fe||(A1 − B1)|, or, for |(A1 − B1)| < a2, at D1 where My,1 = My,2,max = ±|fe|a2 when ψ = θ1 + θ2 ± 90°. Anyway, the limb configuration with the maximum My,1 is the one where the point A1 coincides with the point A’1 shown in Figure 3. In this configuration, the maximum My occurs at B1 for ψ = ±90° and its value is My,1,max = ±|fe||(A’1 − B1)| = ±1.1 Nm. Moreover, whatever be the limb configuration, the maximum Sz (Ax) occurs when fe is perpendicular (parallel) to the link axis, that is, when ψ = θ1 ± 90° (when ψ = θ1 or ψ = θ1 + 180°), and its value is Sz,1,max = ±|fe| = ±1 N (Ax,2,max = ±|fe| = ±1 N). Table 1 summarizes the results of case (a).

Table 1.

Maximum non-null influence coefficients due to the unit force fe (Figure 3) of case (a).

3.2.2. Case (b): Links’ Internal Loads Due to u2

In this case (a unit force Fe,z (= 1 N) applied at Op (see Figure 1 and Figure 2)), the equilibrium of the platform shows that the CRS limb is loaded by the same Fe,z (=1 N) applied at the S-pair center. Moreover, it shows that the RRC limb is loaded by a torque, Mb, lying on the motion plane (i.e., the xbyb coordinate-plane) and applied at A1 (see Figure 2). In particular, Mb has magnitude |Mb| = |Fe,z ap| = 0.4 Nm and direction (φ + 90°) in the motion plane, that is, Mb =|Fe,z ap|(c(φ+90°), s(φ+90°))T = 0.4(sφ, −cφ)T Nm for φ∈[0°, 360°].

Internal Loads in the CRS Limb

In the horizontal part of link 4 (i.e., the segment A2D2 (see Figure 1 and Figure 2)), the unit force Fe,z (= 1 N) applied at the S-pair center generates a constant shear force Sy,4= Fe,z = 1 N, and a bending moment, Mz,4, that linearly grows from 0, at A2, to Mz,4,max = Fe,za4 = 0.4 Nm, at D2. Of course, in the small vertical part of link 4, only a constant axial force equal to Ax,4 = −Fe,z = −1 N is present. These values do not depend on the limb configuration.

The node equilibrium at D2 shows that link 3, at D2, is loaded by a shear force Sy,3 = Sy,4 = 1 N, a torsional moment, Mx,3, whose analytic expression is

and a bending moment, Mz,3, whose analytic expression is

Mx,3 = Mz,4,max cos(θ4 − 90°) = Fe,za4 sinθ4 = 0.4 sinθ4 Nm,

Mz,3 = Mz,4,max cosθ4 = Fe,za4 cosθ4 = 0.4 cosθ4 Nm.

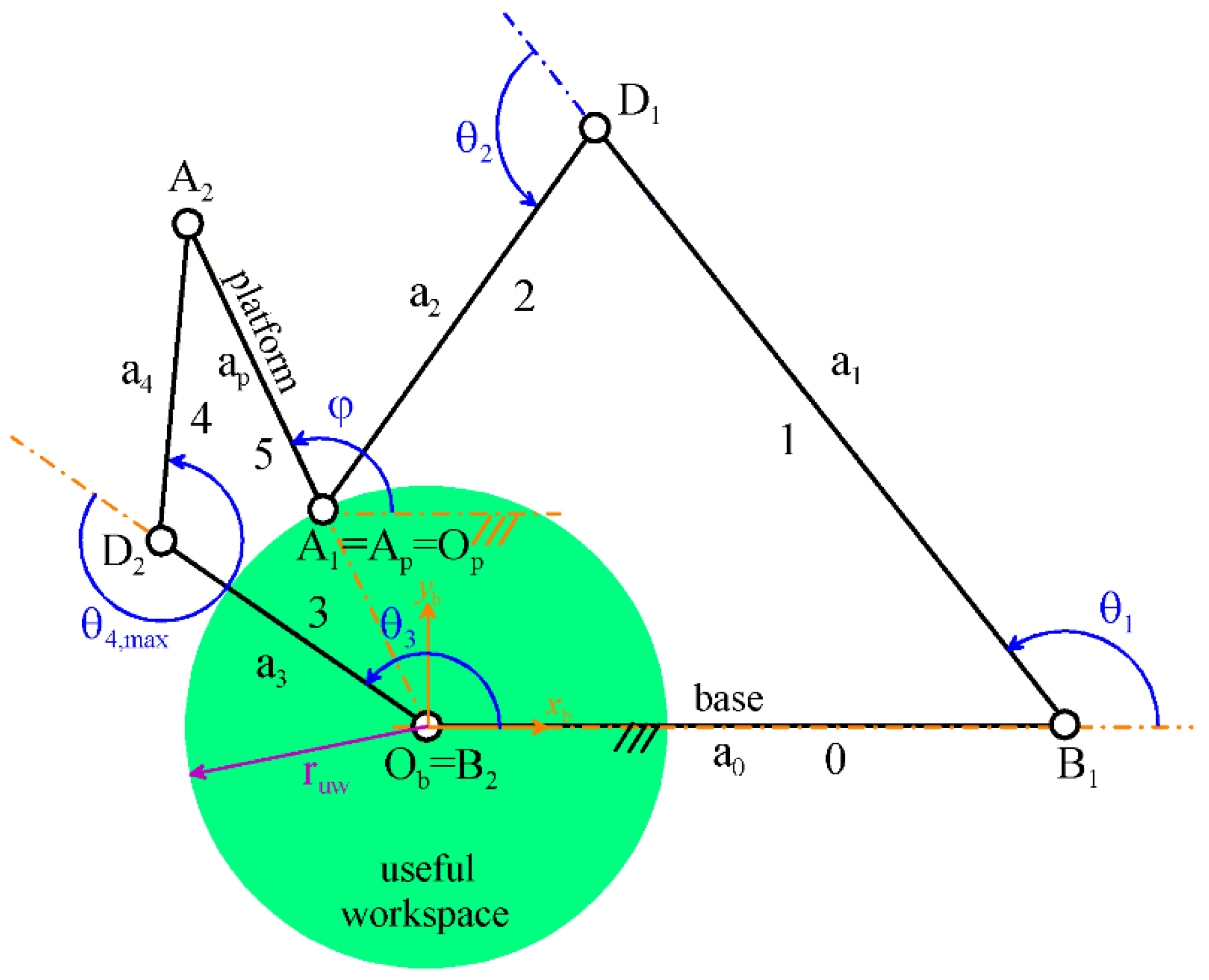

As a consequence, in link 3, the shear force Sy,3 = 1 N is constant, and the torsional moment Mx,3 (=Fe,za4 sinθ4 = 0.4 sinθ4 Nm) is constant, too, but depends on the limb configurations and its maximum Mx,3,max = ±Fe,za4 = ±0.4 Nm occurs when θ4 = ±90°. In addition, the bending moment Mz,3 linearly varies from Fe,za4cosθ4, at D2, to (Fe,za4cosθ4 + Sy,3a3), at B2, and its maximum values occurs at B2 when θ4 reaches its maximum value (see Figure 4). In the studied case (Figure 2 and Figure 4), Carnot’s theorem applied to the triangle B2A2D2 makes it possible to write

which gives θ4,min = 194.36° and θ4,max = 302.09°. As a consequence, the maximum bending moment is Mz,3,max = Fe,za4cosθ4,max + Sy,3a3 = 0.6125 Nm.

Figure 4.

Scaled top view of a LaMaViP’s CRS-RRC, sized according to the results of the dimensional synthesis [19], at the configuration where θ4 reaches its maximum value.

Internal Loads in the RRC Limb

In link 2, the torque Mb = |Fe,z ap| (sφ, −cφ)T, for φ∈[0°,360°], applied at A1, generates a constant torsional moment Mx,2 and a constant bending moment Mz,2 whose analytic expressions are (kb is the unit vector of the zb-coordinate axis (Figure 1))

and depend on the mechanism configuration. Accordingly, the maximum/minimum values of Mx,2 (Mz,2) are Mx,2,max = ±|Fe,z ap| = ±0.4 Nm (Mz,2,max = ±|Fe,z ap| = ±0.4 Nm), occur at φ = θ1 + θ2 and at φ = θ1 + θ2 + 180° (at φ = θ1 + θ2 ± 90°) and do not depend on the mechanism configuration.

In link 1, the same torque Mb = |Fe,z ap| (sφ, −cφ)T, for φ∈[0°,360°], transmitted through link 2, is applied at D1 and generates a constant torsional moment Mx,1 and a constant bending moment Mz,1 whose analytic expressions are

and depend on the mechanism configuration. Accordingly, the maximum/minimum values of Mx,1 (Mz,1) are Mx,1,max = ±|Fe,z ap| = ±0.4 Nm (Mz,1,max = ±|Fe,z ap| = ±0.4 Nm), occur at φ = θ1 and at φ = θ1 + 180° (at φ = θ1 ± 90°) and do not depend on the mechanism configuration.

Table 2 summarizes the results of case (b).

Table 2.

Maximum non-null influence coefficients due to the unit force Fe,z (= 1 N) of case (b).

3.2.3. Case (c): Links’ Internal Loads Due to u3

In this case (a unit moment Me,z (=1 Nm) applied at Op (see Figure 1 and Figure 2)), the equilibrium of the platform shows that the CRS limb is loaded by the force

which is applied at the S-pair center and is aligned with link 4 (see Figure 5a), and that the RRC limb is loaded by the force –fm applied at A1 through the C-pair (see Figure 5a).

Figure 5.

Top view of the studied LaMaViP’s CRS-RRC: (a) external loads applied to the limbs in the case Me,z = 1 Nm, (b) a mechanism configuration with the minimum value of μ, (c) a mechanism configuration with the maximum value of μ.

The maximum and minimum magnitudes of fm occur when the angle μ reaches its minimum, μmin (see Figure 5b), and maximum, μmax (see Figure 5c), values, respectively. With reference to Figure 5b,c, in the studied case, the following relationships hold

which give

Internal Loads in the CRS Limb

In link 4, the effect of the small vertical part (i.e., the one parallel to the zb-coordinate axis (Figure 1)) is minor, depends on its length, which has not been defined during the dimensional synthesis, and will be neglected in this static analysis. This assumption brings to consider the force fm directly applied at A2 (see Figure 5a) along the horizontal part of link 4. As a consequence, this load generates only an axial force Ax,4 = –|fm| whose maximum (negative) value is Ax,4,max = −10.079 N (see Equation (15)).

The node equilibrium at D2 shows that link 3, at D2, is loaded by the axial force, Ax,3, and the shear force, Sz,3, given by the relationships

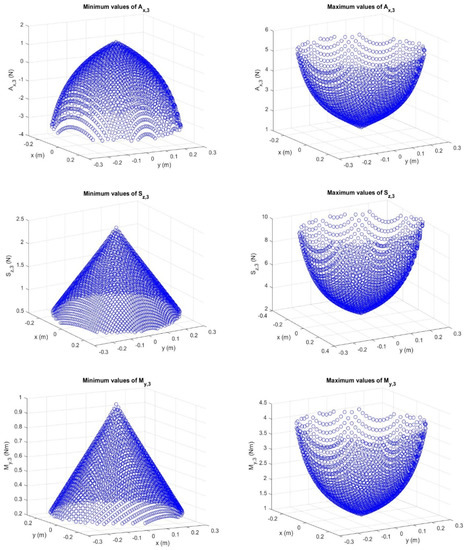

These loads, at D2, generate constant axial, Ax,3, and shear, Sz,3, forces along link 3 that only depend on the mechanism configuration, and a bending moment My,3 that linearly varies from 0, at D2, to −Sz,3a3, at B2. Since the angles μ (see Equation (14)) and θ4 that appear in Equations (17a) and (17b) are not independent (see system (4) and Equation (7)), the determination of the maximum/minimum values of Ax,3, Sz,3, and My,3 must be numerically evaluated for a sufficiently high number of mechanism configurations uniformly distributed in the useful workspace and, then, compared. A mash of 3220 positions of A1(=(xp, yp)) uniformly distributed inside the useful-workspace circle have been chosen and, at each A1 position, Equations (17a) and (17b) have been evaluated for 360 values of the angle φ spaced of 1°. The comparison of the so-computed values yields the diagrams of Figure 6 (The MatLab program that generates Figure 6 can be seen in Supplementary Materials). The analysis of these diagrams and the ranges spanned by the angles θ4 and μ (see Equations (11) and (15)) bring to the conclusion that, in link 3, the maximum values of the internal loads can be evaluated as follows

Figure 6.

Case Me,z = 1: minimum and maximum values of Ax,3, Sz,3, and My,3 computed for 3220 positions of A1(=(xp, yp)) uniformly distributed inside the useful-workspace circle.

Internal Loads in the RRC Limb

The comparison of Figure 3 and Figure 5a together with Equation (14) reveals that this is a special case of the above-discussed case (a). Consequently, the maximum values of the internal loads of links 1 and 2 are the product of the influence coefficients of Table 1 by |fm|max (see Equation (16)).

Table 3 summarizes the results of case (c).

Table 3.

Maximum non-null influence coefficients due to the unit moment Me,z (= 1 Nm) of case (c).

3.3. Implementation of Step (v)

The influence coefficients reported in Table 1, Table 2 and Table 3 must be combined by means of Equation (3) to determine the reference internal loads to use for sizing the links. In order to do this, the values of the coefficients λp appearing in Equation (3) must be deduced from the task requirements the machine has to satisfy. Assuming that the design requirements are

- -

- mass of the payload: mp = 1 kg,

- -

- gyration radius of the payload: ρ = 0.2 m,

- -

- maximum linear accelerations: ,

- -

- maximum angular acceleration: ,

- -

- global safety coefficient4: γ = 2.5,

the reference values of the external loads become Fe,x = Fe,y = Fe,z = γmp = 250 N and Me,z = γmpρ2 = 100 Nm. Accordingly, the influence coefficients of Table 1 and Table 2 must be all multiplied by λp = 250 and those of Table 3 by λp = 100; then, the resulting values must be summed. Table 4 reports the reference internal loads resulting from this computation.

Table 4.

Reference internal loads to use for sizing the links.

4. Discussion

The implementation reported in the previous section shows that the proposed method is simple and direct to apply and only in a few cases it really requires numerical evaluations. In particular, it only needs the results of the dimensional synthesis and, differently from the techniques based on global performance indices, it is able to relate directly the task requirements to the links’ internal loads.

The analysis of Table 2 reveals that the existence of decoupled motions does not imply a static decoupling between the active forces that cause those motions. Indeed, the unit force Fe,z (see Table 2) has a static effect on links 1 and 2 that belong to a limb, the RRC, that has no effect on the platform translation along the zb-coordinate axis direction. This happens without considering non-ideal phenomena (e.g., the friction in the joints). Furthermore, the found effects are difficult to compensate since the generated torsional, Mx,(1,2), and bending, Mz,(1,2), moments lie on the RRC-limb motion plane and tend to cause elastic displacements (which, in practice, are vibrations, since all the real external loads are dynamic loads that vary their magnitudes during motion) perpendicular to that plane.

Recognizing static couplings at an early stage of the design procedure with a clear identification of the causes is a peculiarity of the proposed method and is a desirable feature that can orientate the successive design choices. Other design techniques based on the extensive use of multi-body simulation software, together with a trial-and-error sizing procedure, would have found the limb vibration without giving an immediate explanation.

These results prove that the proposed algorithm integrates the design methodologies based on performance indices and/or on extended multibody simulations by solving their lacks.

5. Conclusions

A general technique based on influence coefficients and static analyses has been presented which allows the determination of the input data of the machine-element design (i.e., reference external loads and machine configurations that give the maximum internal load of each component) for non-overconstrained manipulators.

Differently from other techniques, the presented one uses only the results of the dimensional synthesis and does not need any tentative choice, about the materials, the links are made of, and links’ cross-sections, to be adjusted during the design procedure.

The proposed technique directly relates task requirements to links’ internal loads and is able to reveals dynamic phenomena (e.g., vibrations) that have a negative impact on the machine behavior.

The effectiveness of the proposed technique has been proved by implementing it on a 3T1R parallel manipulator.

Supplementary Materials

The MatLab program that generates Figure 6 is available at https://www.mdpi.com/2075-1702/9/2/27/s1.

Author Contributions

Conceptualization, R.D.G.; methodology, R.D.G.; software, E.Y.; validation, R.D.G. and E.Y.; formal analysis, R.D.G. and E.Y.; project administration, R.D.G.; funding acquisition, R.D.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was developed at the Laboratory of Mechatronics and Virtual Prototyping (LaMaViP) of Ferrara Technopole and funded by the University of Ferrara (UNIFE), grant number FAR2019.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Hartenburg, R.S.; Denavit, J. Kinematic Synthesis of Linkages; McGraw-Hill: New York, NY, USA, 1964; ISBN 9780070269101. [Google Scholar]

- Tsai, L.W. Mechanism Design: Enumeration of Kinematic Structures According to Function; CRC Press LLC: Boca Raton, FL, USA, 2001. [Google Scholar]

- Kong, X.; Gosselin, C.M. Type Synthesis of Parallel Mechanisms; Springer: Berlin/Heidelberg, Germany, 2007; ISBN 978-3-642-09118-6. [Google Scholar]

- McCarthy, J.M.; Soh, G.S. Geometric Design of Linkages; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Bhandari, V.B. Design of Machine Elements, 3rd ed.; Tata McGraw-Hill: New Delhi, India, 2010. [Google Scholar]

- Jiang, W. Analysis and Design of Machine Elements; Wiley: Singapore, 2019. [Google Scholar]

- Ashby, M.F. Materials Selection in Mechanical Design, 5th ed.; Butterworth-Heinemann: Burlington, MA, USA, 2016. [Google Scholar]

- Gosselin, C.; Angeles, J. Singularity analysis of closed-loop kinematic chains. IEEE Trans. Robot. Autom. 1990, 6, 281–290. [Google Scholar] [CrossRef]

- Zlatanov, D.; Fenton, R.G.; Benhabib, B. A Unifying Framework for Classification and Interpretation of Mechanism Singularities. J. Mech. Des. 1995, 117, 566–572. [Google Scholar] [CrossRef]

- Di Gregorio, R. A Review of the Literature on the Lower-Mobility Parallel Manipulators of 3-UPU or 3-URU Type. Robotics 2020, 9, 5. [Google Scholar] [CrossRef]

- Yoshikawa, T. Manipulability of Robotic Mechanisms. Int. J. of Rob. Res. 1985, 4, 3–9. [Google Scholar] [CrossRef]

- Klein, C.A.; Blaho, B.E. Dexterity Measures for the Design and Control of Kinematically Redundant Manipulators. Int. J. Robot. Res. 1987, 6, 72–83. [Google Scholar] [CrossRef]

- Gosselin, C.; Angeles, J. A Global Performance Index for the Kinematic Optimization of Robotic Manipulators. J. Mech. Des. 1991, 113, 220–226. [Google Scholar] [CrossRef]

- Tanev, T.; Stoyanov, B. On the performance indexes for robot manipulators. Probl. Eng. Cybern. Robot. 2000, 49, 64–71. [Google Scholar]

- Merlet, J.P. Jacobian, Manipulability, Condition Number, and Accuracy of Parallel Robots. J. Mech. Des. 2006, 128, 199–206. [Google Scholar] [CrossRef]

- Moreno, H.A.; Saltaren, R.; Carrera, I.; Puglisi, L.J.; Aracil, R. Ìndices de Desempeño de Robots Manipuladores: Una revisión del Estado del Arte. Rev. Iberoam. Automática Inf. Ind. 2012, 9, 111–122. [Google Scholar] [CrossRef]

- Patel, S.H.; Sobh, T. Manipulator Performance Measures—A Comprehensive Literature Survey. J. Intell. Robot. Syst. 2014, 77, 547–570. [Google Scholar] [CrossRef]

- Rosyid, A.; El-Khasawneh, B.; Alazzam, A. Review article: Performance measures of parallel kinematics manipulators. Mech. Sci. 2020, 11, 49–73. [Google Scholar] [CrossRef]

- Di Gregorio, R.; Cattai, M.; Simas, H. Performance-Based Design of the CRS-RRC Schoenflies-Motion Generator. Robotics 2018, 7, 55. [Google Scholar] [CrossRef]

- Simas, H.; Di Gregorio, R. Position analysis, singularity loci and workspace of a novel 2PRPU Schoenflies-motion generator. Robotics 2018, 37, 141–160. [Google Scholar] [CrossRef]

- Asada, H. A Geometrical Representation of Manipulator Dynamics and Its Application to Arm Design. J. Dyn. Syst. Meas. Control. 1983, 105, 131–142. [Google Scholar] [CrossRef]

- Yoshikawa, T. Dynamic manipulability of robot manipulators. J. Rob. Sys. 1985, 2, 113–124. [Google Scholar]

- Wiens, G.J.; Scott, R.A.; Zarrugh, M.Y. The Role of Inertia Sensitivity in the Evaluation of Manipulator Performance. J. Dyn. Syst. Meas. Control. 1989, 111, 194–199. [Google Scholar] [CrossRef]

- Chiaacchio, P.; Concilio, M. The dynamic manipulability ellipsoid for redundant manipulators. In Proceeding of the 1998 IEEE International Conference on Robotics and Automation (ICRA), Leuven, BE, 20 May 1998; IEEE: Piscataway, NJ, USA, 1998; pp. 95–100. [Google Scholar] [CrossRef]

- Di Gregorio, R.; Parenti-Castelli, V. Dynamic performance indices for 3-dof parallel manipulators. In Advances in Robot Kine-Matics; Lenarcic, J., Thomas, F., Eds.; Springer: Dordrecht, The Netherlands, 2002; pp. 11–20. [Google Scholar]

- Mo, J.; Shao, Z.; Guan, L.; Xie, F.; Tang, X. Dynamic performance analysis of the X4 high-speed pick-and-place parallel robot. Robot. Comput. Manuf. 2017, 46, 48–57. [Google Scholar] [CrossRef]

- Angeles, J. Fundamentals of Robotic Mechanical Systems, 4th ed.; Springer: New York, NY, USA, 2014. [Google Scholar]

- Wunderlich, W.; Pilkey, W.D. Mechanics of Structures: Variational and Computational Methods, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2002. [Google Scholar]

- Uicker, J.J.; Pennock, G.R.; Shigley, J.E.; McCarthy, J.M. Theory of Machines and Mechanisms, 5th ed.; Oxford University Press: New York, NY, USA, 2016. [Google Scholar]

- Hervé, J.M. The mathematical group structure of the set of displacements. Mech. Mach. Theory 1994, 29, 73–81. [Google Scholar] [CrossRef]

- Di Gregorio, R. A Novel Single-Loop Decoupled Schoenflies-Motion Generator: Concept and Kinematics Analysis. In Advances in Service and Industrial Robotics; Ferraresi, C., Quaglia, G., Eds.; Mechanisms and Machine Science Series; Springer: New York, NY, USA, 2018; Volume 49, pp. 11–18. ISBN 978-3-319-61275-1. [Google Scholar] [CrossRef]

- Salençon, J. Virtual Work Approach to Mechanical Modeling; Wiley: Hoboken, NJ, USA, 2018. [Google Scholar]

| 1 | Hereafter, R, P, U, S, and C stand for revolute pair, prismatic pair, universal joint, spherical pair, and cylindrical pair respectively. With reference to a PM, which features the frame (base) and the end effector (platform) connected to each other by a number of kinematic chains (limbs), a string of capital letters denotes the sequence of joint types that are encountered by moving from the base to the platform on a limb. The hyphen separates the strings of the limbs and the underlining indicates the actuated joints. A serial architecture has only one limb and is denoted by only one string. |

| 2 | Hereafter, the phrase “active force” indicates a force that does work when the mechanism changes its configuration. |

| 3 | Hereafter, the internal loads of a beam refer to a local Cartesian system chosen according to the convention 1 that is reported in [28]. This local system has the x axis along the beam axis, the z axis contained in the motion plane (i.e., the xbyb coordinate-plane shown in Figure 2), and the y axis perpendicular to the motion plane and pointing toward the reader (i.e., with the same direction of the zb-coordinate axis shown in Figure 1). |

| 4 | The global safety coefficient roughly takes into account the loads different from the payload that have not been considered. The designer according to his experience assigns its value. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).