Transfer of Process References between Machine Tools for Online Tool Condition Monitoring

Abstract

1. Introduction

2. Materials and Methods

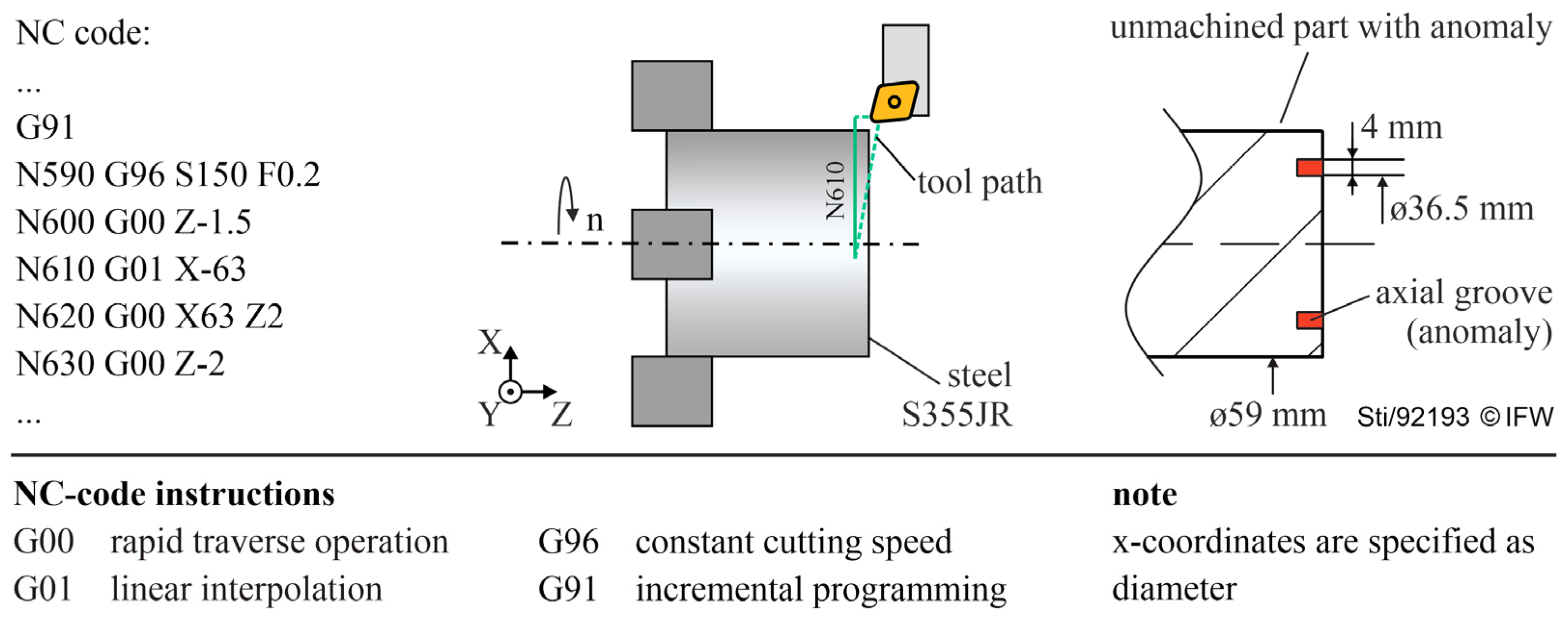

2.1. Experimental Machining

2.2. Proposed Online Monitoring Method

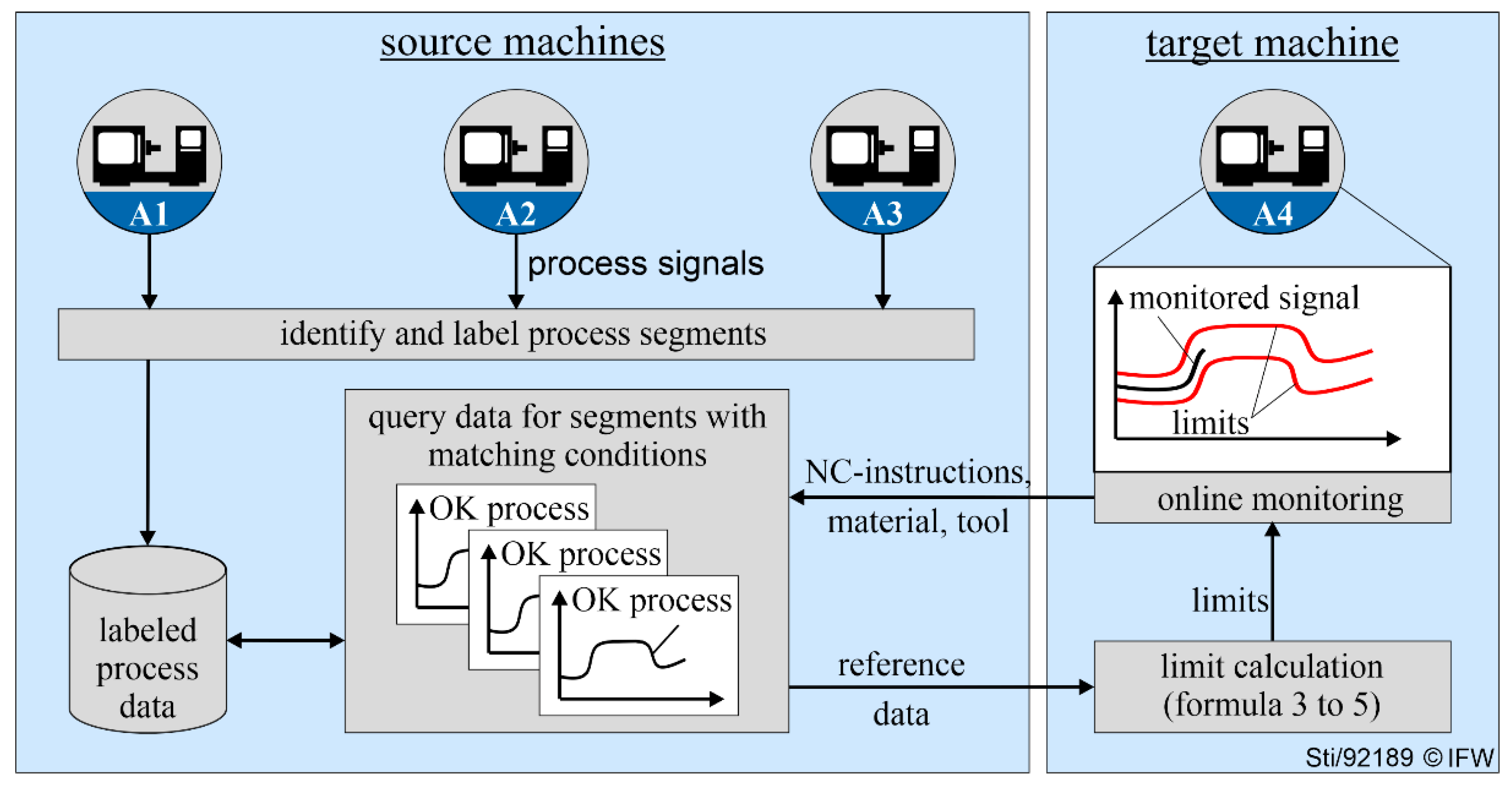

2.2.1. Monitoring with Transferred Knowledge

2.2.2. Process Segmentation

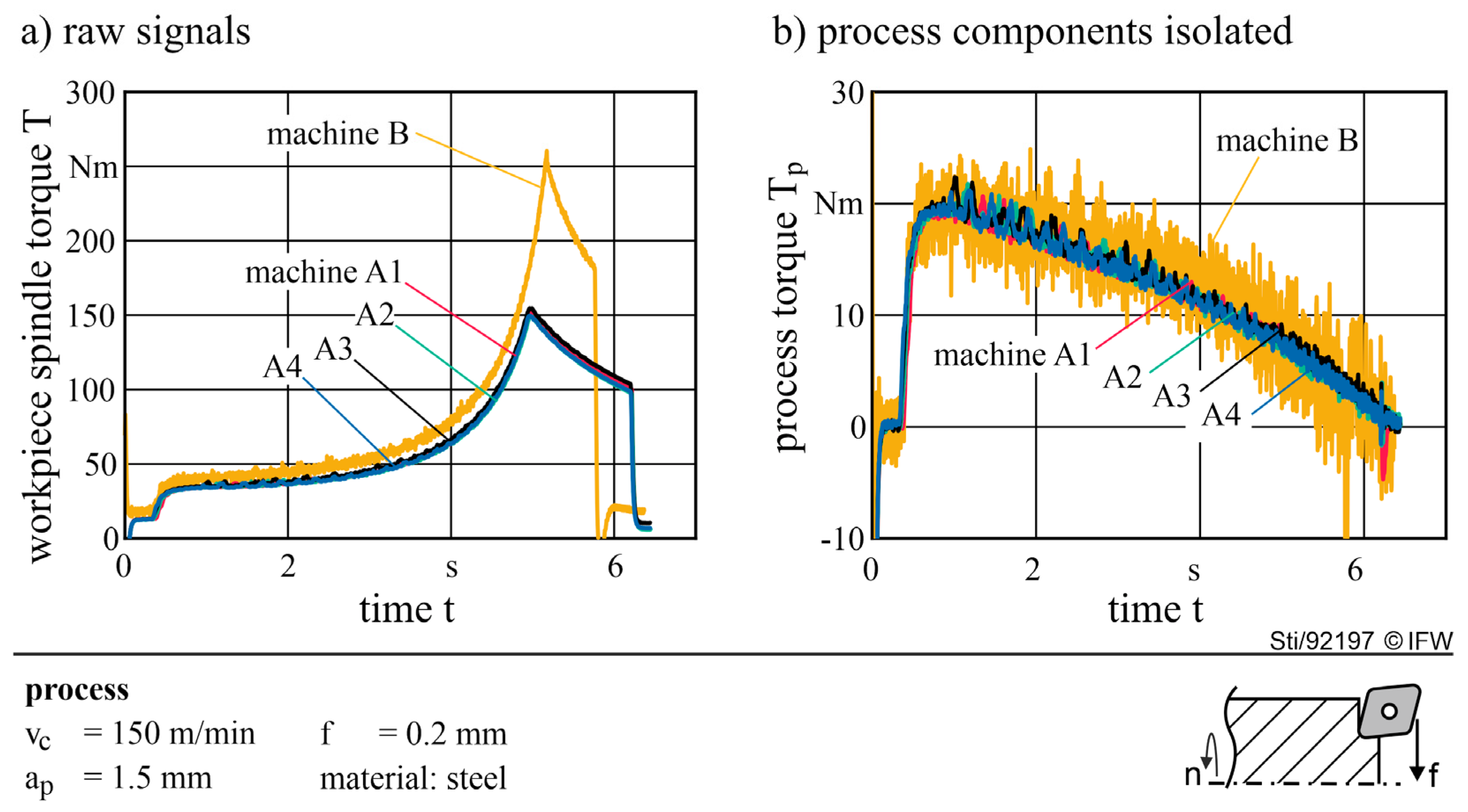

2.2.3. Process Component Isolation

2.2.4. Calculating Monitoring Limits

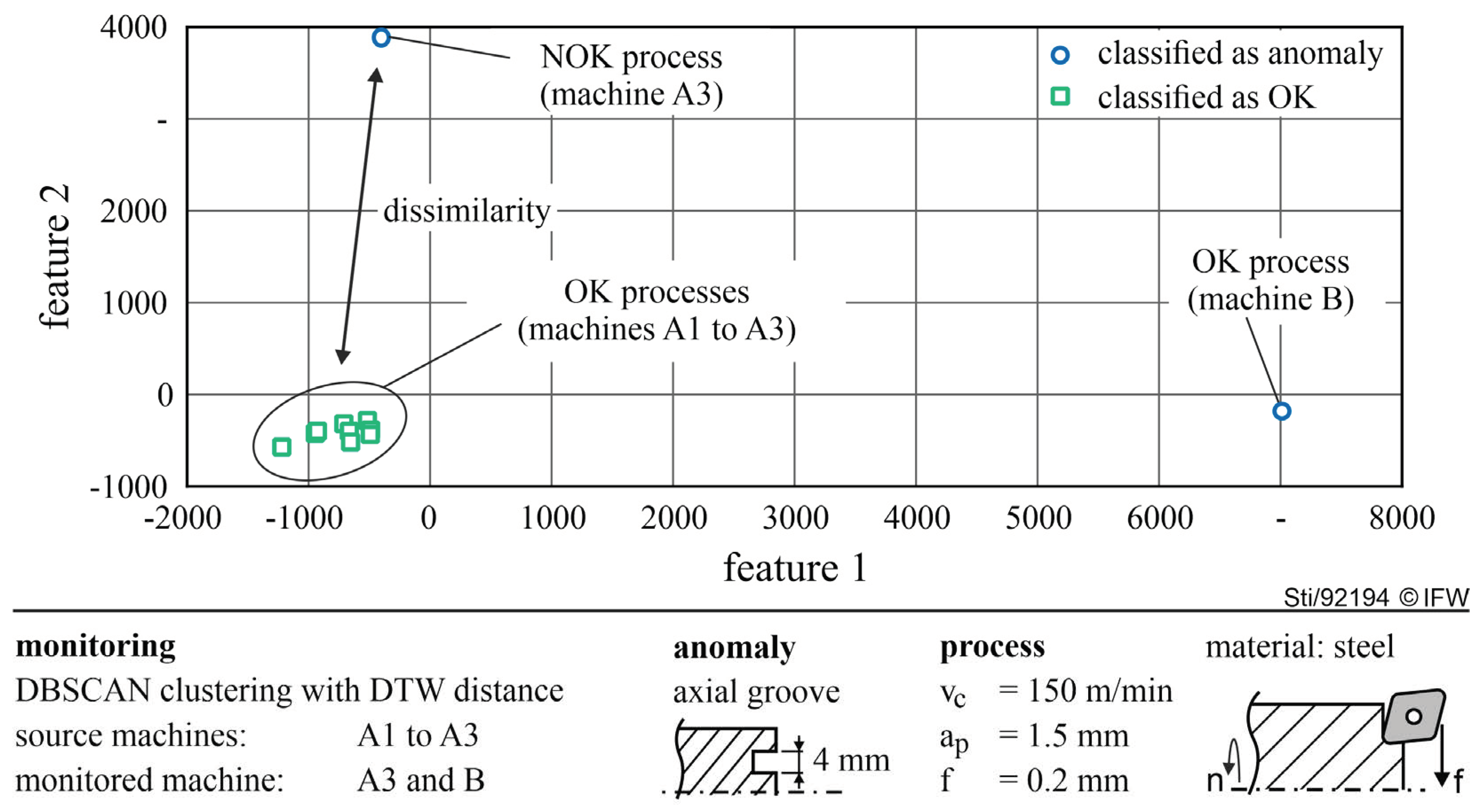

2.3. DTW-Based Anomaly Detection as a Performance Reference

3. Results and Discussion

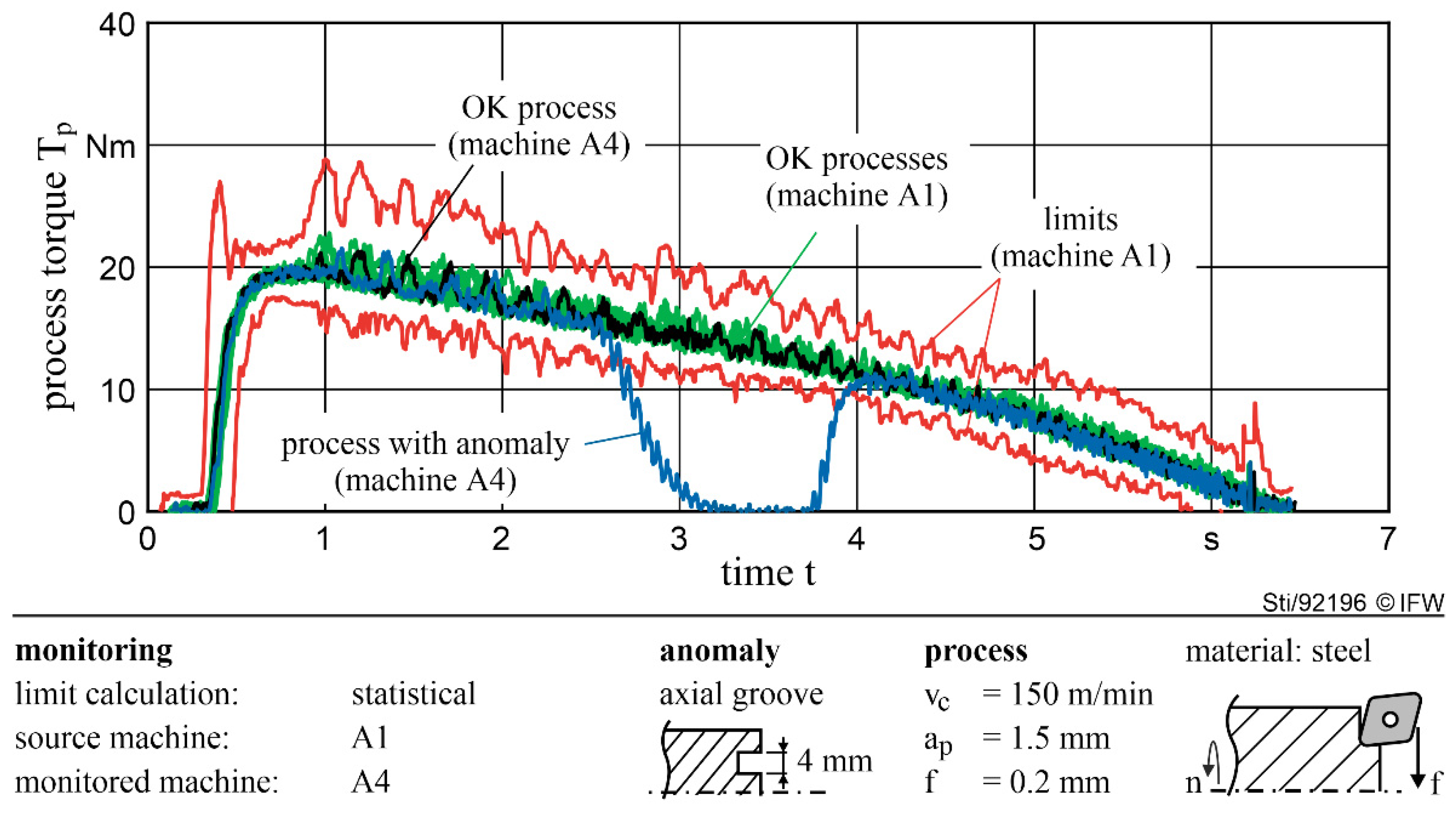

3.1. Sourcing Monitoring Limits from a Single Machine

3.2. Sourcing Monitoring Limits from Multiple Machines

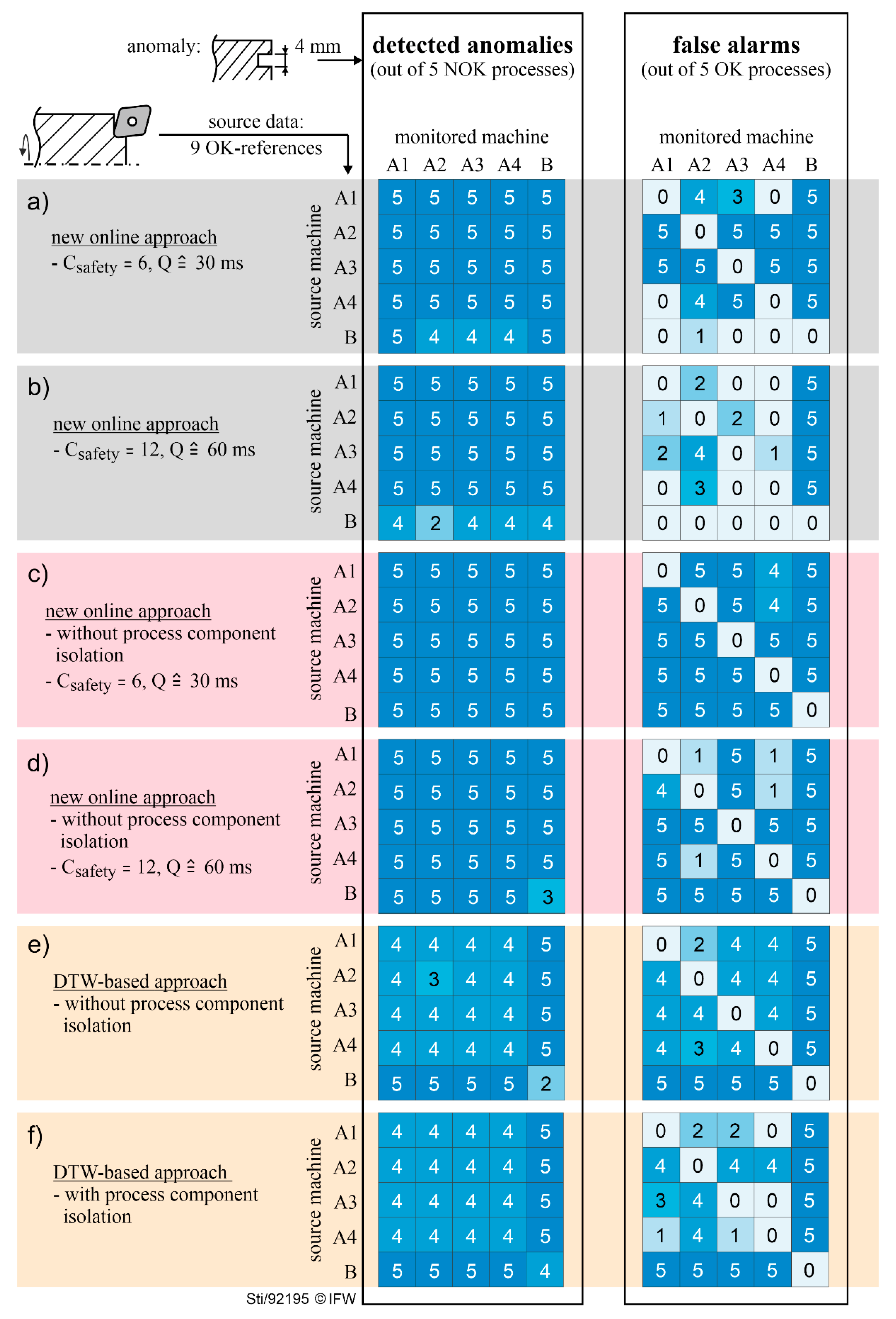

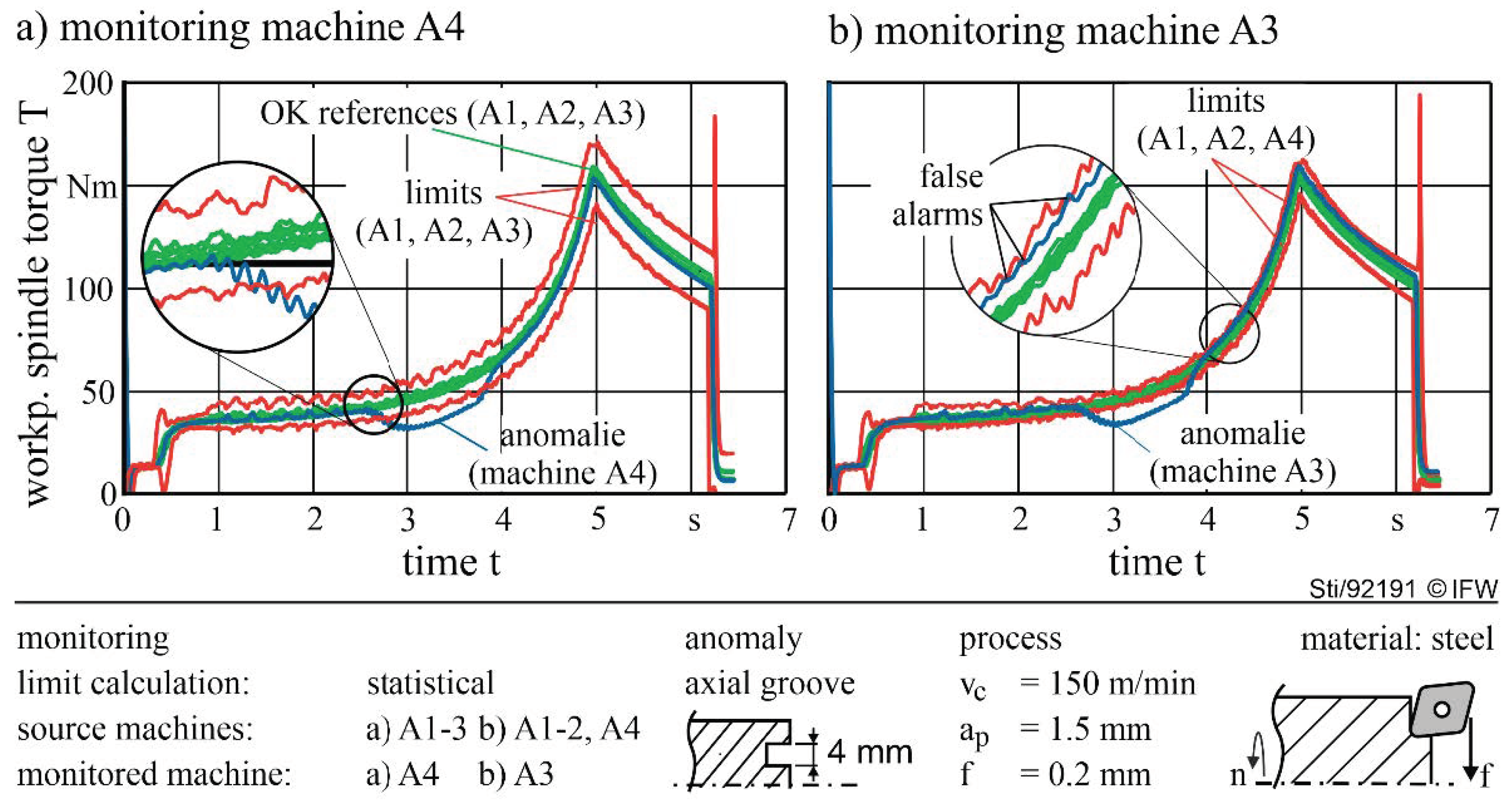

3.2.1. Transfer between Multiple Machines of the Same Model with Identical Equipment

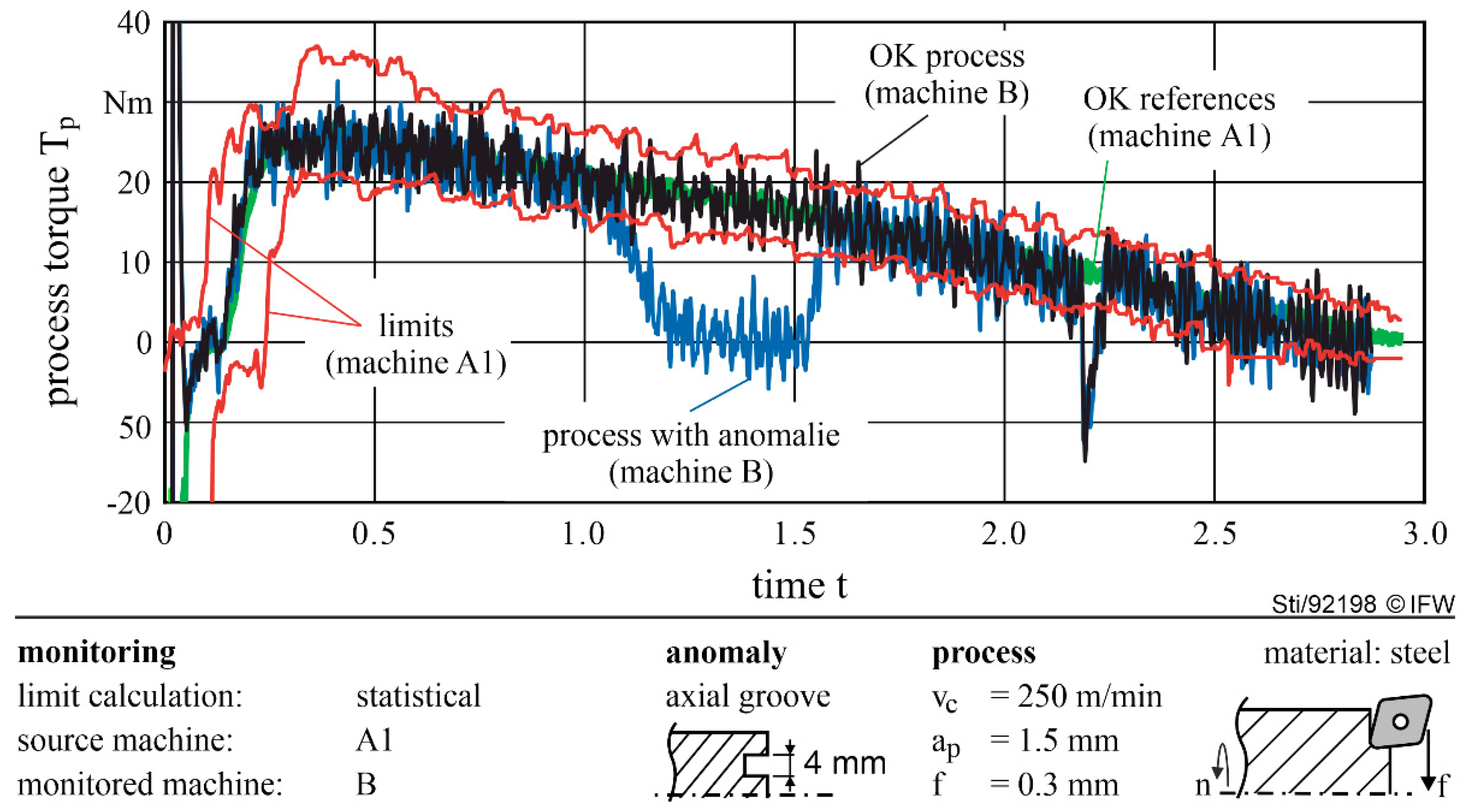

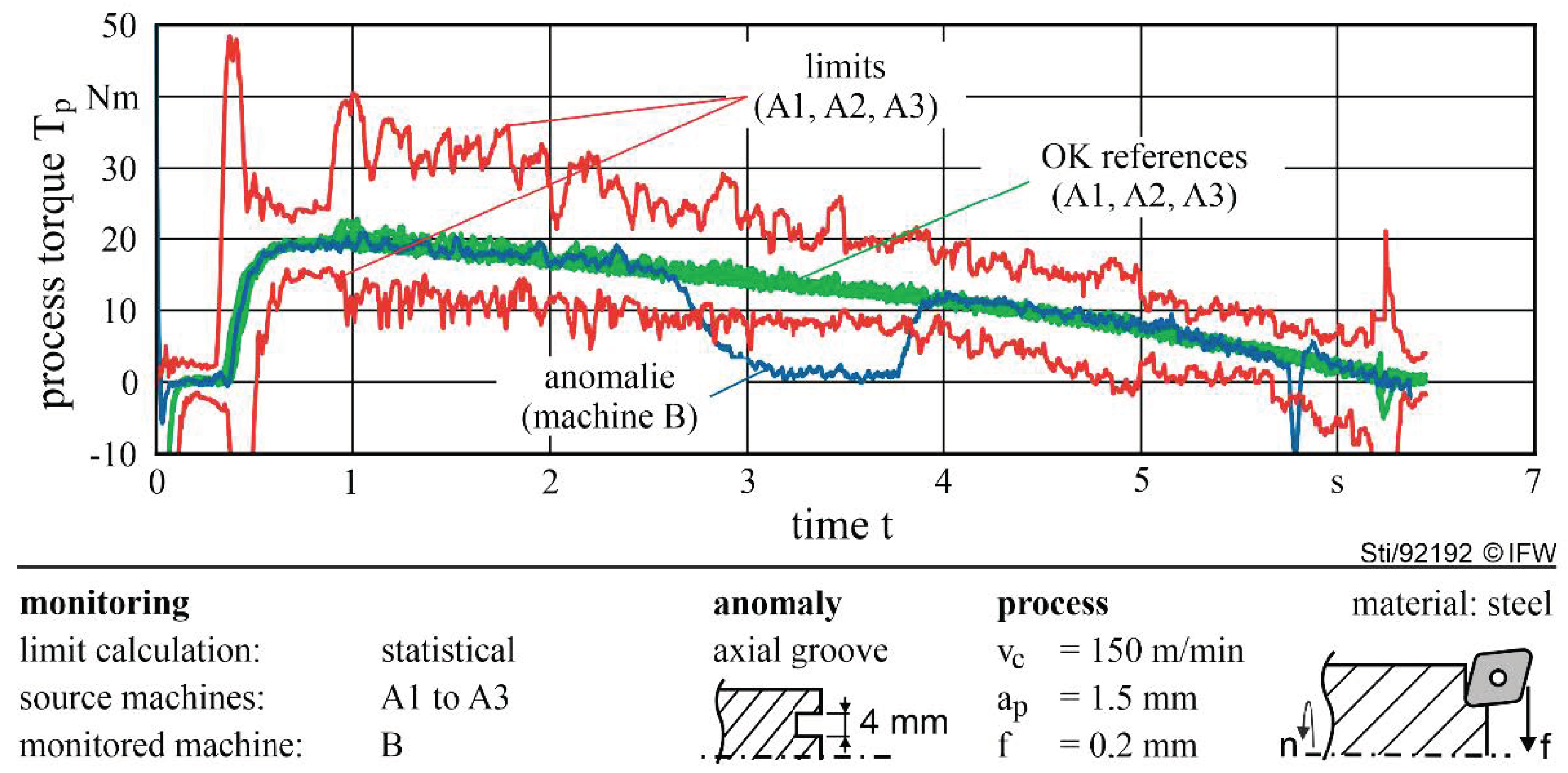

3.2.2. Transfer between Multiple Machines of Different Models

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Salgado, D.R.; Cambero, I.; Herrera Olivenza, J.M.; García Sanz-Calcedo, J.; Núnez López, P.J.; García Plaza, E. Tool wear estimation for different workpiece materials using the same monitoring system. Procedia Eng. 2013, 63, 608–615. [Google Scholar] [CrossRef][Green Version]

- Lee, J.Y.; Shin, Y.J.; Kim, M.-S.; Kim, E.S.; Yoon, H.S.; Kim, S.Y.; Yoon, Y.C.; Ahn, S.H.; Min, S. A Simplified Machine-Tool Power-Consumption Measurement Procedure and Methodology for Estimating Total Energy Consumption. J. Manuf. Sci. Eng. 2016, 138, 51004. [Google Scholar] [CrossRef]

- Altintas, Y.; Kersting, P.; Biermann, D.; Budak, E.; Denkena, B.; Lazoglu, I. Virtual process systems for part machining operations. CIRP Ann.-Manuf. Technol. 2014, 63, 585–605. [Google Scholar] [CrossRef]

- Hassan, M.; Damir, A.; Attia, H.; Thomson, V. Benchmarking of Pattern Recognition Techniques for Online Tool Wear Detection. Procedia CIRP 2018, 72, 1451–1456. [Google Scholar] [CrossRef]

- Wang, P.; Liu, Z.; Gao, R.X.; Guo, Y. Heterogeneous data-driven hybrid machine learning for tool condition prognosis. CIRP Ann.-Manuf. Technol. 2019, 68, 455–458. [Google Scholar] [CrossRef]

- Cai, W.; Zhang, W.; Hu, X.; Liu, Y. A hybrid information model based on long short-term memory network for tool condition monitoring. J. Intell. Manuf. 2020, 31, 1497–1510. [Google Scholar] [CrossRef]

- Li, W.D.; Liang, Y.C. Deep transfer learing based diagnosis for machining process lifecycle. Procedia CIRP 2020, 90, 642–647. [Google Scholar] [CrossRef]

- Kan, C.; Yang, H.; Kumara, S. Parallel computing and network analytics for fast Industrial Internet-of-Things (IIoT) machine information processing and condition monitoring. J. Manuf. Syst. 2018, 46, 282–293. [Google Scholar] [CrossRef]

- Rudlf, T.; Brecher, C.; Possel-Dolken, F. Contact-based collision detection—A new approach to avoid hard collision in machine tools. In Proceedings of the International Conference on Smart Machining Systems, Gaithersburg, MD, USA, 13–15 March 2007. [Google Scholar]

- Abele, E.; Brecher, C.; Gsell, S.C.; Hassis, A.; Korff, D. Steps towards a protection system for machine tool main spindles against crash-caused damages. Prod. Eng. 2012, 6, 631–642. [Google Scholar] [CrossRef]

- Denkena, B.; Fischer, R.; Euhus, D.; Neff, T. Simulation based process monitoring for single item production without machine external sensors. Procedia Technol. 2014, 15, 341–348. [Google Scholar] [CrossRef]

- Denkena, B.; Dahlmann, D.; Damm, J. Self-adjusting Process Monitoring System in Series Production. Procedia CIRP 2015, 33, 233–238. [Google Scholar] [CrossRef]

- Bombinski, A.; Blazejak, K.; Nejman, M.; Jemielniak, K. Sensor signal segmentation for tool condtion monitoring. Procedia CIRP 2016, 46, 155–160. [Google Scholar] [CrossRef]

- Bergmann, B.; Witt, M. Feeling machine for material-specific machining. CIRP Ann.-Manuf. Technol. 2020, 63, 353–356. [Google Scholar] [CrossRef]

- Denkena, B.; Bergmann, B.; Witt, M. Feeling Machine for Process Monitoring of Turning Hybrid Solid Components. Metals 2020, 10, 930. [Google Scholar] [CrossRef]

- Ester, M.; Kriegel, H.-P.; Sander, J.; Xu, X. A density-based algorithm for discovering clusters in large spatial databases with noise. In Proceedings of the Second International Conference on Knowledge Discovery in Databases and Data Mining; AAAI Press: Portland, OR, USA, 1996; pp. 226–231. [Google Scholar]

| ID | Process | Parameter |

|---|---|---|

| 1 | face turning | f = 0.2 mm, ap = 1 mm, vc = 250 m/min |

| 2 | face turning | f = 0.3 mm, ap = 1 mm, vc = 150 m/min |

| 3 | face turning | f = 0.2 mm, ap = 1.5 mm, vc = 150 m/min |

| 4 | face turning | f = 0.3 mm, ap = 1.5 mm, vc = 250 m/min |

| 5 | face turning | f = 0.25 mm, ap = 1.25 mm, vc = 200 m/min |

| ID | Type of Lath | Control | Number Examined |

|---|---|---|---|

| A1 to A4 | DMG Mori CTX 1250 TC | Sinumerik 840D sl | 4 |

| B | DMG Mori CTX beta 800 | Sinumerik 840D sl | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Denkena, B.; Bergmann, B.; Stiehl, T.H. Transfer of Process References between Machine Tools for Online Tool Condition Monitoring. Machines 2021, 9, 282. https://doi.org/10.3390/machines9110282

Denkena B, Bergmann B, Stiehl TH. Transfer of Process References between Machine Tools for Online Tool Condition Monitoring. Machines. 2021; 9(11):282. https://doi.org/10.3390/machines9110282

Chicago/Turabian StyleDenkena, Berend, Benjamin Bergmann, and Tobias H. Stiehl. 2021. "Transfer of Process References between Machine Tools for Online Tool Condition Monitoring" Machines 9, no. 11: 282. https://doi.org/10.3390/machines9110282

APA StyleDenkena, B., Bergmann, B., & Stiehl, T. H. (2021). Transfer of Process References between Machine Tools for Online Tool Condition Monitoring. Machines, 9(11), 282. https://doi.org/10.3390/machines9110282