The Research and Experiments on Contact Sealing Theory of the Underwater Clamp Connector

Abstract

:1. Introduction

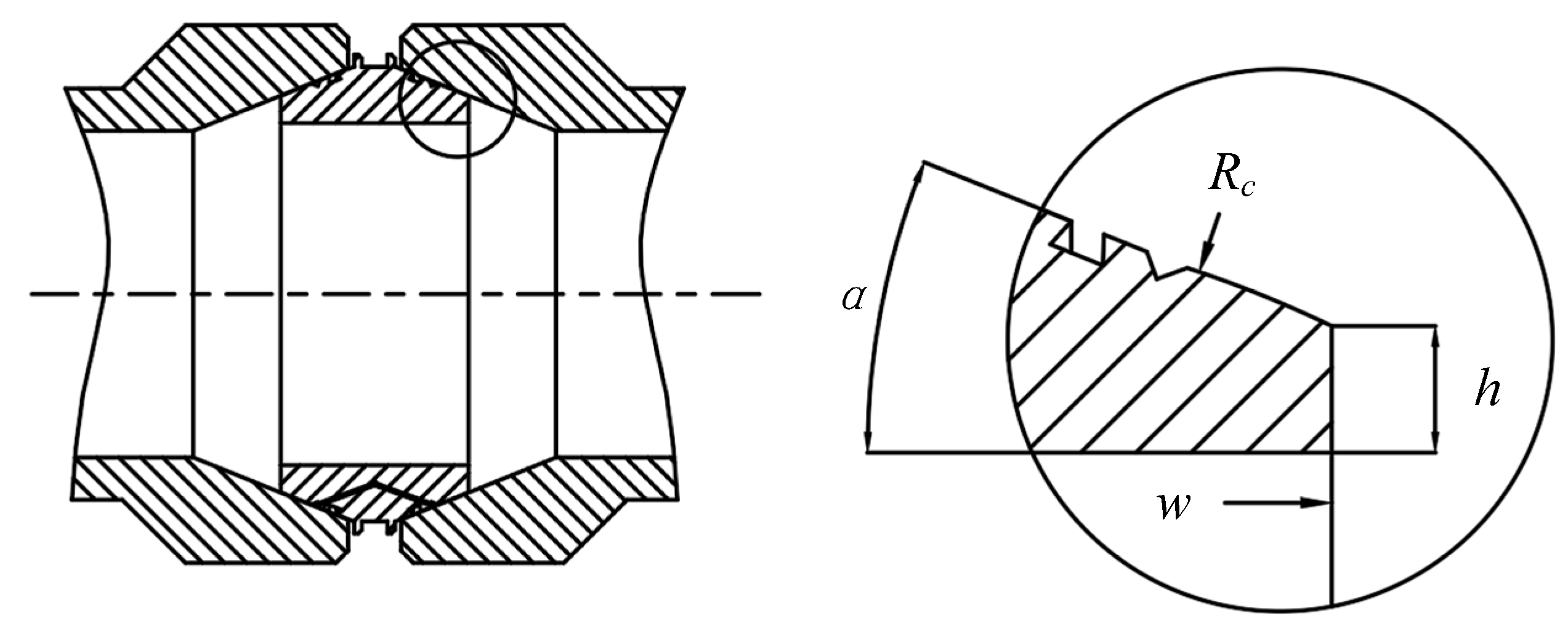

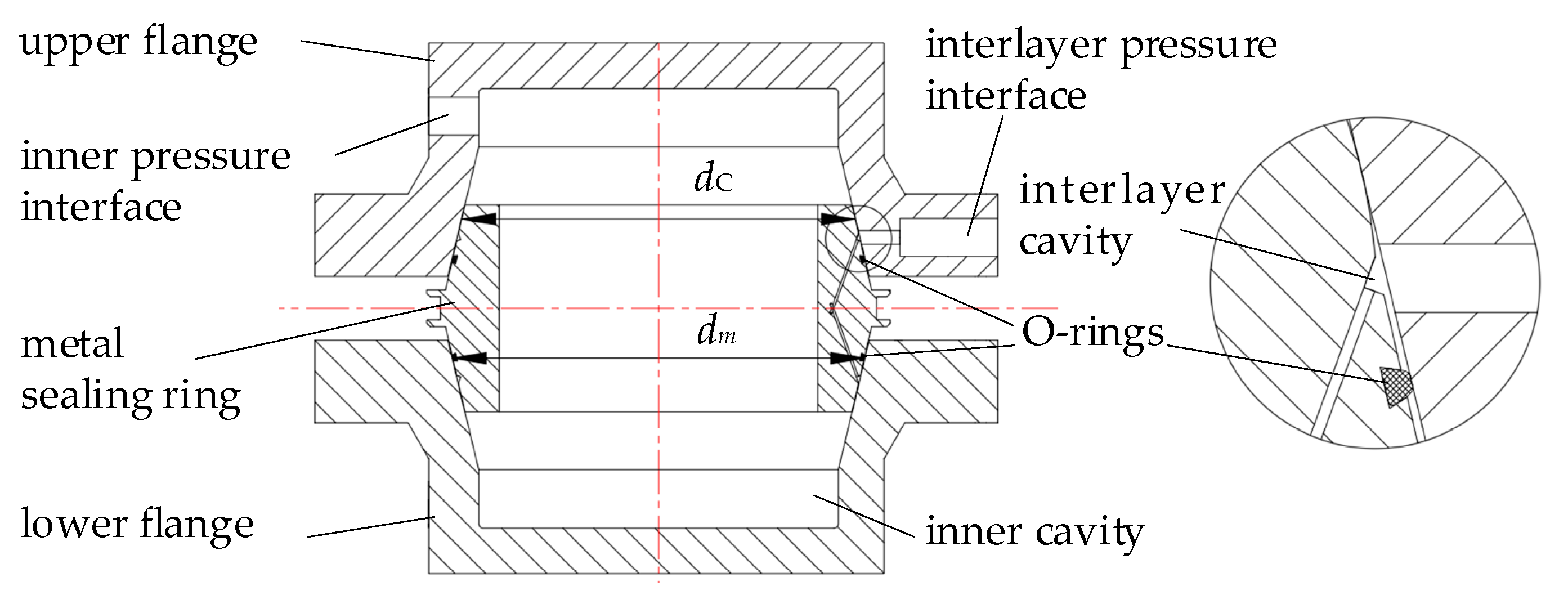

2. The Structure and Sealing Force of the Underwater Clamp Connector

3. Research on Contact Sealing Theory of Underwater Clamp Connector

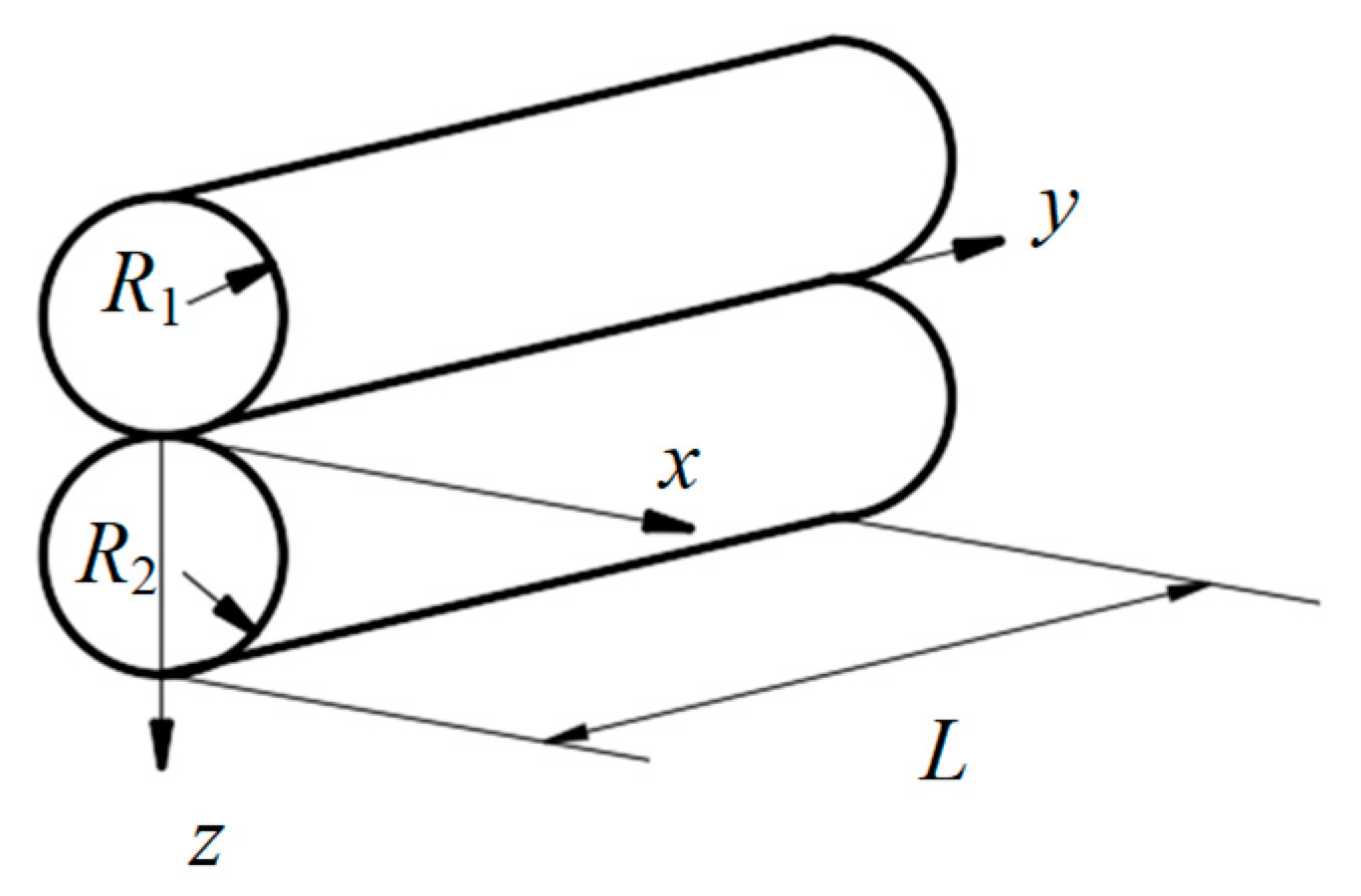

3.1. Comparison of Differences between Hertz Contact and Connector Contact Models

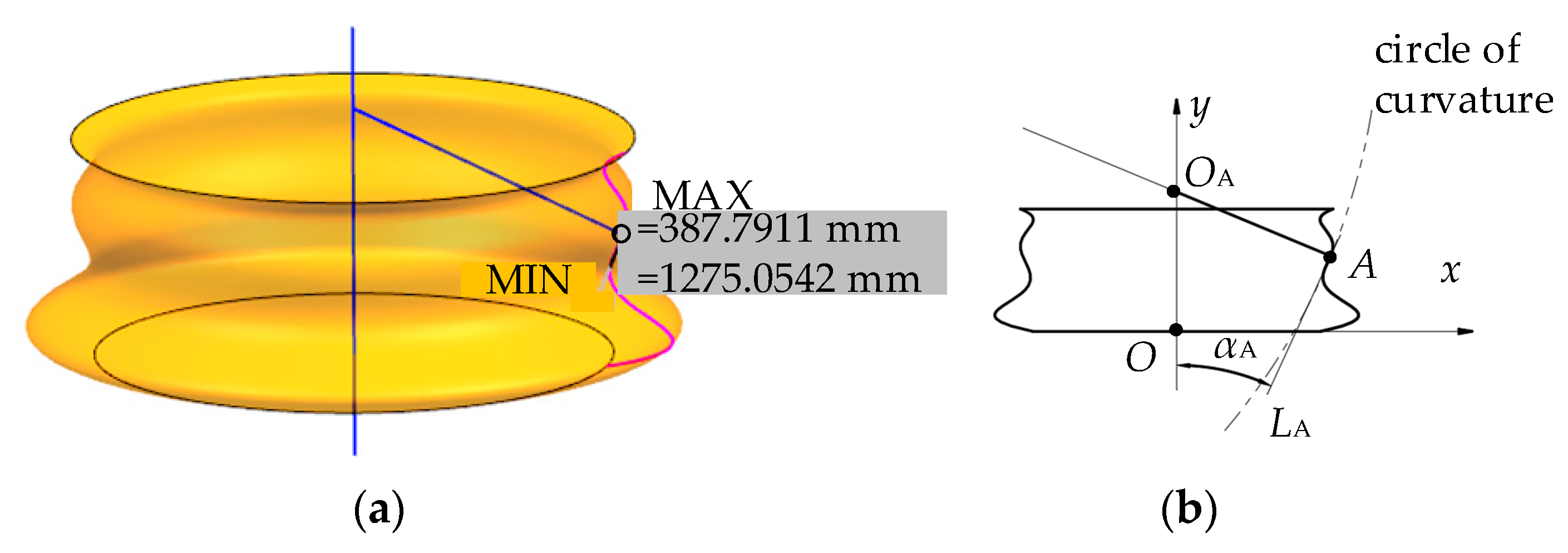

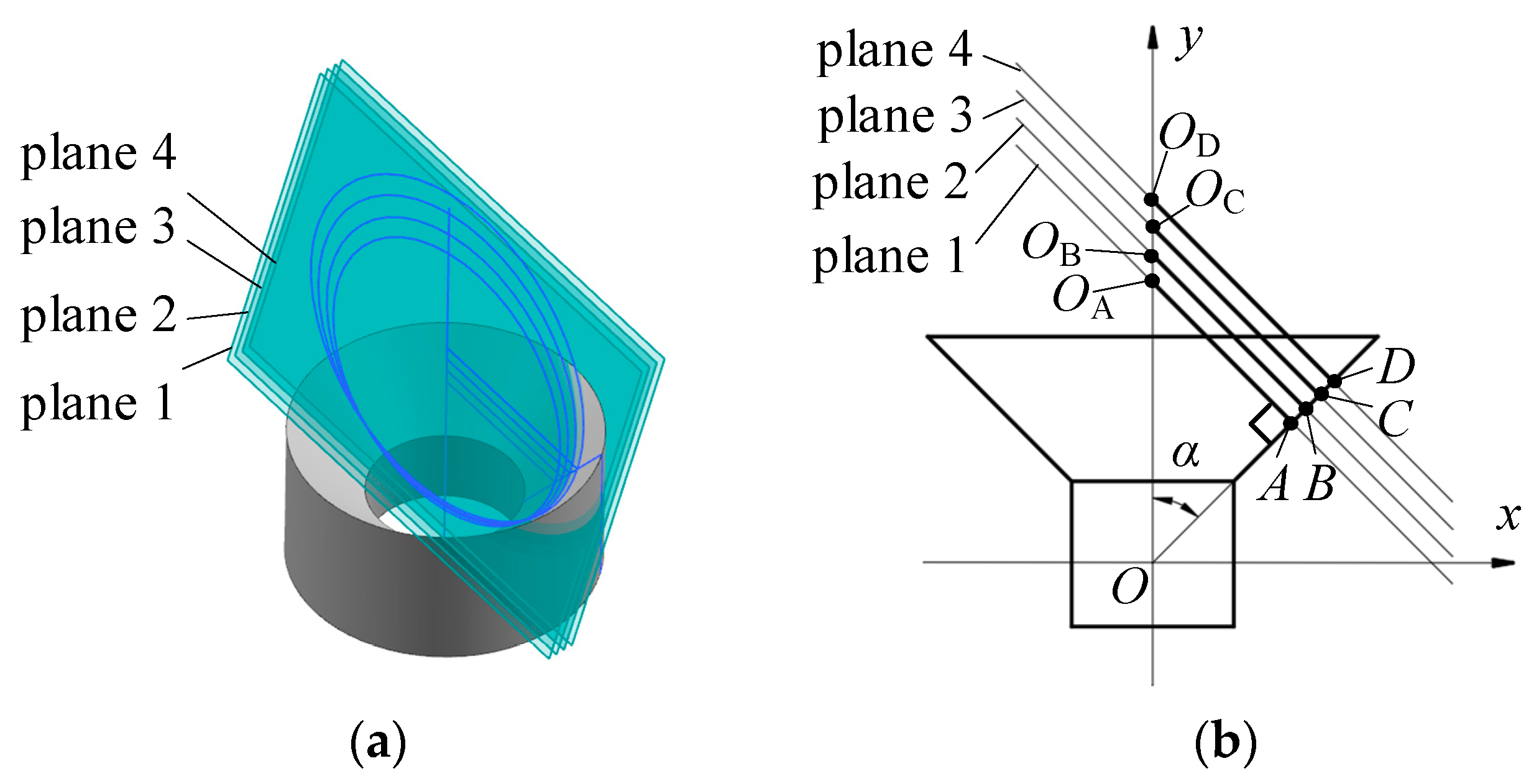

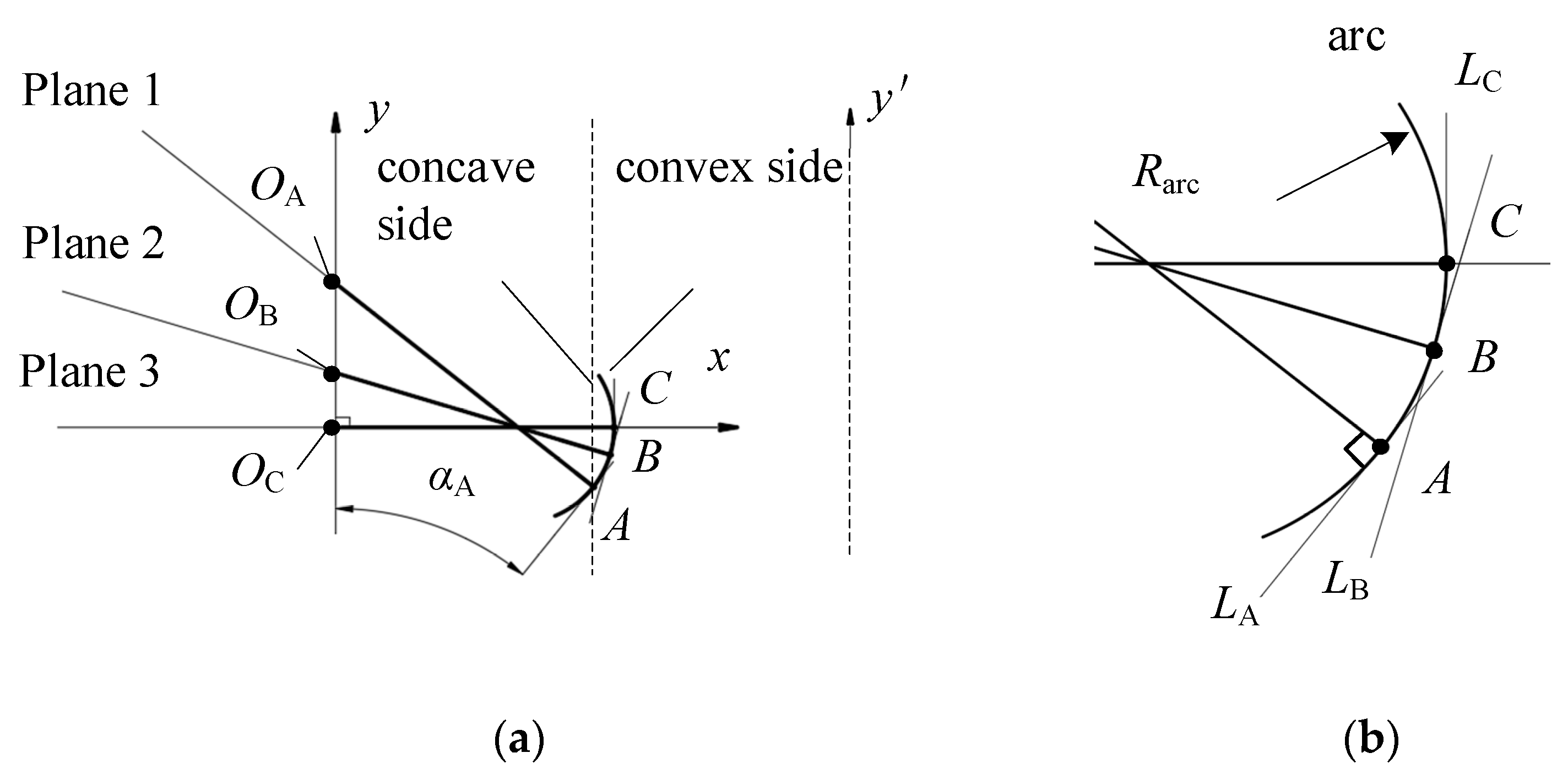

3.2. Research on the Radius of Curvature Extreme Value of the Sealing Contact Point of the Underwater Clamp Connector

3.2.1. The Extreme Value of the Radius of Curvature at Any Point on the Flange Cone

3.2.2. The Extreme Value of the Radius of Curvature at Any Point on the Contact Point of the Metal Sealing Gasket

3.3. Application of Hertz Contact in Underwater Clamp Connector

3.4. Derivation of Contact Sealing Theory of Underwater Clamp Connector

4. Simulation Research on Metal Contact Sealing Theory of Underwater Clamp Connector

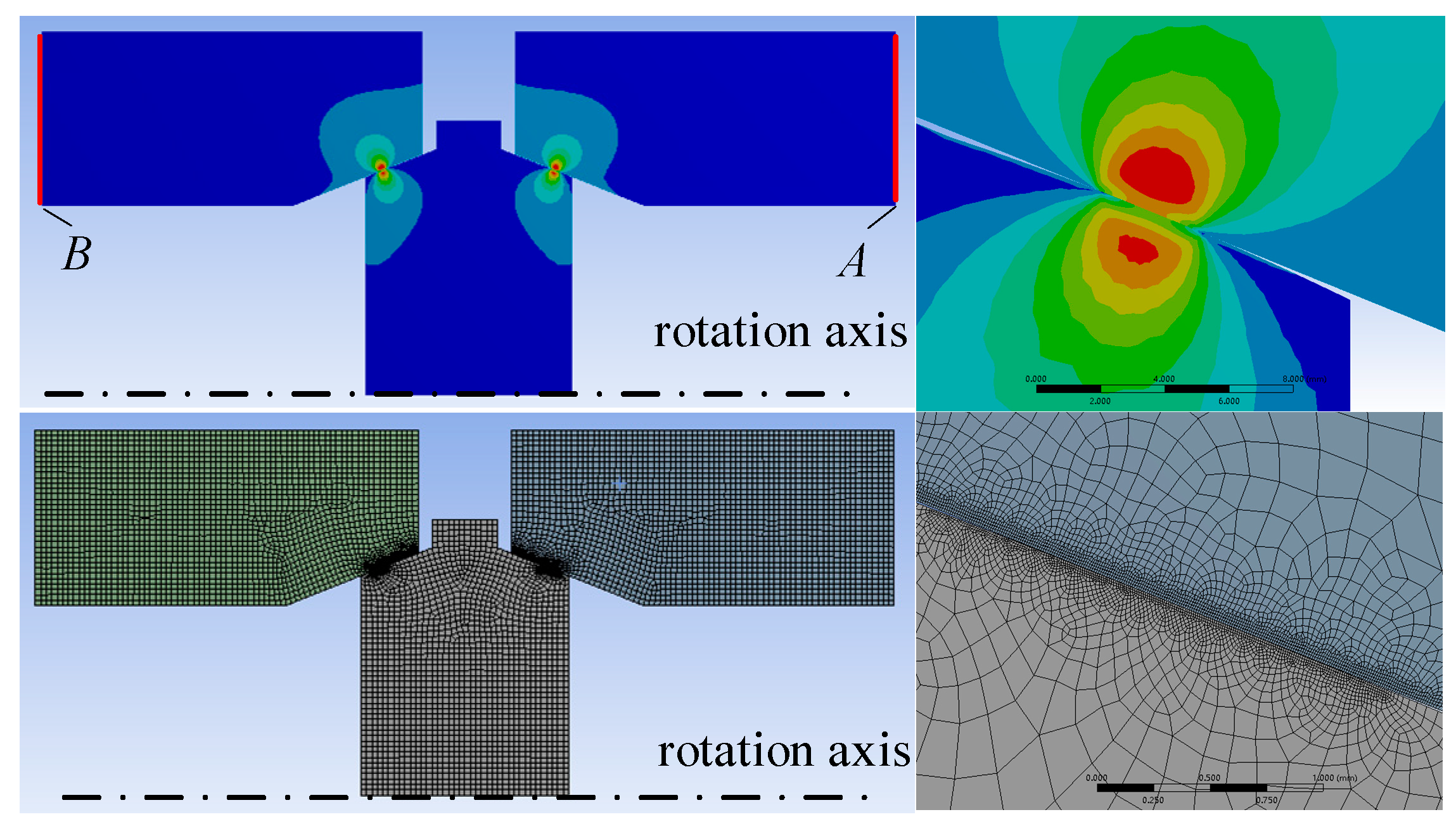

4.1. Establishment of Contact Model between Flange and Metal Sealing Gasket

4.2. Establishment of Finite Element Model of Sealing Structure

4.3. Solution and Errors of Data Analysis

- When the axial force is used as the known maximum contact stress, the deviation in the simulation value is 3.86% to 4.63% lower than the theoretical value;

- The error decreases with the axial force showing a decreasing trend;

- The maximum contact stress is the power function of the axial force. The data near the edge below the minimum preload pressure and above the yield strength basically meet the above conclusions.

- The theoretical calculation is more in line with the model in which the sealing gasket is a full circle which rotated into an approximate sphere (the arc center is a sphere on the axis of rotation). The metal sealing gasket axis in the simulation model cuts off two parts at both ends, which is closer to the actual situation. As shown in Figure 9, when the other errors have the same influence, when Fa = 51,990 N, the ends cut off model is about 12% lower than the full circle rotation model. The maximum contact stress is about 6.5% lower. The maximum contact stress is lower than the overall maximum stress, which is more beneficial for sealing higher pressure before the material yields;

- The theoretical calculation model is more in line with the infinite radius of curvature of the contact point. The smaller the radius of curvature, the greater the errors;

- There is an error in the method of solving the equivalent radius of curvature used for theoretical calculation.

5. Revision and Experimental Research on Contact Sealing Theory of Underwater Clamp Connector

5.1. Correction Coefficient of Contact Sealing Theory of Underwater Clamp Connector

5.2. Correction Coefficient under Different Oil Pressure and Water Depth

5.3. Verification Test of Contact Sealing Theory of Underwater Clamp Connector

5.3.1. Inner Cavity Pressure Sealing Test

- Preparation of test equipment: metal sealing gasket, inner flange, outer flange, O-rings, 200 t press (including control box and pressure indicator), electric pressure pump (including valve, pressure gauge, water tank), oil pipes, and joints;

- According to the schematic diagram of the inner cavity pressure shown in Figure 11, build a test bench, check the oil circuit interface connection, check the sealing gasket, clean the sealing surface, and test pressure and the oil circuit tightness;

- The initial pressure of the press is 60 t;

- Turn on the electric pump and observe the leakage between the two flanges and the pressure indicator. When the pressure indicator does not rise significantly or there is visible leakage, stop the pressure and observe the rate of decrease in the pressure indicator. When it is less than 5% per hour and less than 3.45 MPa per hour, hold for 15 min, and record the pressure. According to API Spec 6A [24], the acceptable pressure drop in the test is the same as the rate of decrease;

- Increase the pressure of the press by 10 t;

- Repeat step 4 and step 5, the test does not end until the holding pressure exceeds 41.4 MPa after timing.

- The sealing pressure error before correction is between −17.6% and −28.8%, and it is between −9.24% and 5.56% after correction. Therefore, the error after correction is significantly reduced;

- The error before and after correction fluctuates greatly.

- The error between the pressure indication of the press and the actual provided pressure;

- The error between the indicator in hydraulic gauge of the pressure pump and the actual liquid pressure;

- The pressure drop of the hydraulic oil circuit;

- The experimental error fluctuates greatly. The main reason is that the liquid pressure shares most of the press pressure when the inner cavity is pressed. The axial force acting on the sealing gasket only accounts for 4% to 8% of the axial force provided by the press. The error fluctuation of the test measurement data will amplify the Fa error fluctuation obtained by Equation (23).

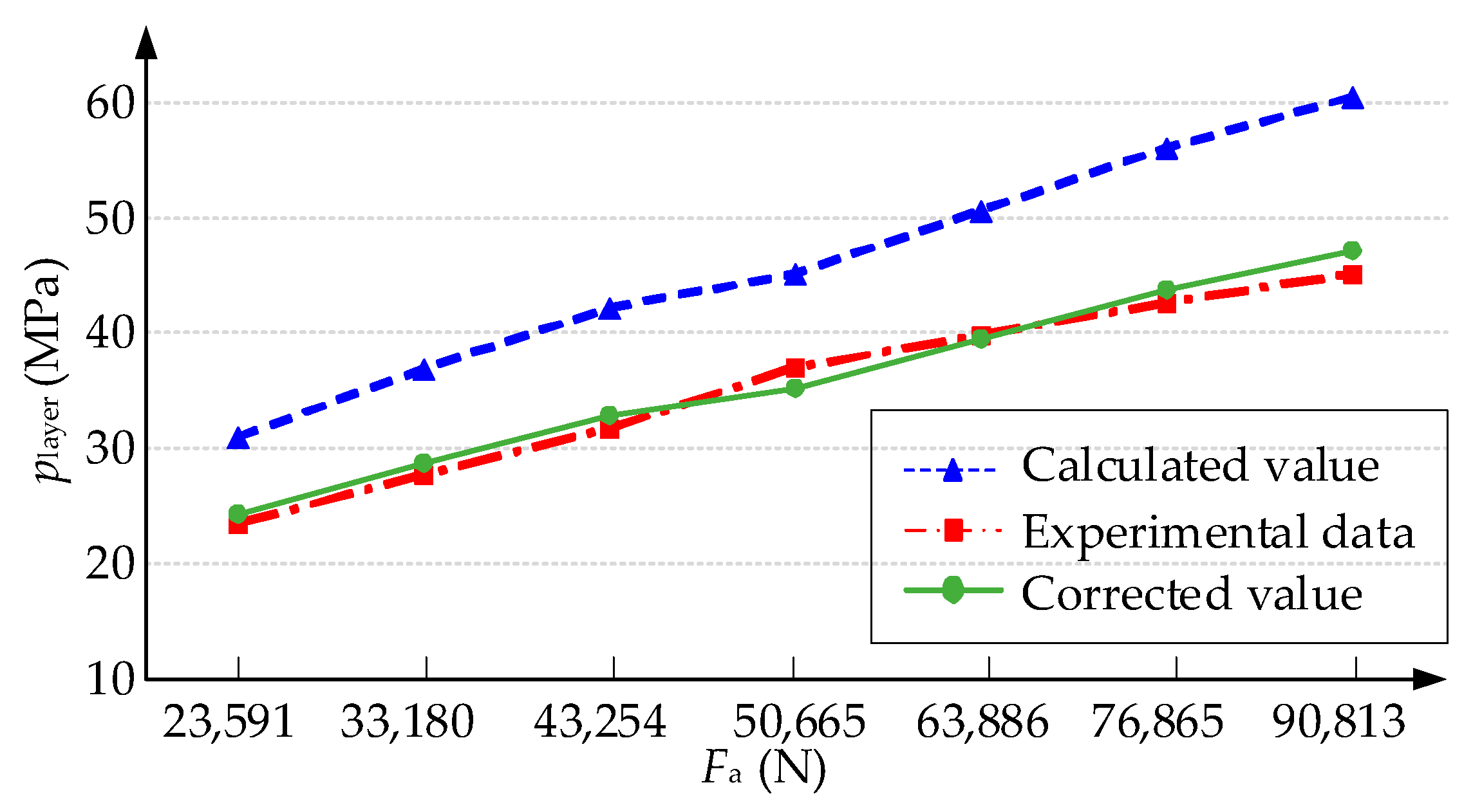

5.3.2. Interlayer Cavity Pressure Sealing Test

- The sealing pressure error before correction is between −18.2% and −25.3%, and the sealing pressure error after correction is between −4.55% and 4.83%. Therefore, the error after correction is significantly reduced;

- Compared to before and after correction in Section 4.3, the error fluctuation is reduced.

6. Conclusions

- A method for solving the radius of curvature of rotating parts such as metal sealing gaskets and flanges is proposed. This method is extended to solve the problem of the extreme value of the radius of curvature at any point on the arbitrary curved surface;

- It is verified that the Hertz contact theory is applicable to the contact calculation model of the clamp connector, and the error is within 6%. Analytical equations obtained in this article can be used in future engineering design and the simulation, and tests are not needed anymore;

- It can be seen that the theory, simulation, and experiment are highly consistent, which proves that the error correction coefficient, khw (in this article is 0.78), of the six-inch connector can greatly improve the accuracy of theoretical calculation in practical application, which is a great innovation and breakthrough. The accuracy of the analytical results is good enough to be used in the engineering application.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Yong, B.; Qiang, B. Subsea Pipelines and Risers; Elsevier: Amsterdam, The Netherlands, 2014; pp. 809–812. [Google Scholar]

- Wang, Z.; Li, Y.J.; Zhang, B.; Zhang, W.; Liu, F.K. Analysis of Flanges Mechanics and Sealing on Horizontal Pipes Connector in Deep Sea. In Applied Mechanics and Materials; Zhang, H., Jin, D., Eds.; Trans Tech Publications, Ltd.: Stafa-Zurich, Switzerland, 2012; Volume 164, pp. 326–329. ISBN 978-3-03785-410-5. [Google Scholar]

- Yun, F.; Wang, L.; Yao, S.; Liu, J.; Liu, T.; Wang, R. Analytical and experimental study on sealing contact characteristics of subsea collet connectors. Adv. Mech. Eng. 2017, 9, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Zhao, H.; Wang, D.; Xu, Y. Metal sealing mechanism and experimental study of the subsea wellhead connector. J. Braz. Soc. Mech. Sci. Eng. 2019, 42, 1–17. [Google Scholar] [CrossRef]

- Zhao, H.; Chen, R.; Luo, X.; Duan, M.; Lu, Y.; Fu, G.; Tian, H.; Ye, D. Metal sealing performance of subsea X-tree wellhead connector sealer. Chin. J. Mech. Eng. 2015, 28, 649–656. [Google Scholar] [CrossRef]

- Wang, L.-Q.; Wei, Z.-L.; Yao, S.-M.; Guan, Y.; Li, S.-K. Sealing Performance and Optimization of a Subsea Pipeline Mechanical Connector. Chin. J. Mech. Eng. 2018, 31, 1–14. [Google Scholar] [CrossRef]

- Wei, Z.; Wang, L.; Guan, Y.; Yao, S.; Li, S. Static metal sealing mechanism of a subsea pipeline mechanical connector. Adv. Mech. Eng. 2016, 8, 1687814016654821. [Google Scholar] [CrossRef] [Green Version]

- Zhang, K.; Huang, H.; Duan, M.; Hong, Y.; Estefen, S.F. Theoretical investigation of the compression limits of sealing structures in complex load transferring between subsea connector components. J. Nat. Gas Sci. Eng. 2017, 44, 202–213. [Google Scholar] [CrossRef]

- Liu, M.; Zhang, L.; Wang, L.; Liu, H.; Sun, Y.; Wang, Y. The leakage analysis of submarine pipeline connecter based on a new fractal porous media model. Desalin, Water Treat. 2020, 188, 390–399. [Google Scholar] [CrossRef]

- Krishna, M.M.; Shunmugam, M.; Prasad, N.S. A study on the sealing performance of bolted flange joints with gaskets using finite element analysis. Int. J. Press. Vessel. Pip. 2007, 84, 349–357. [Google Scholar] [CrossRef]

- Murtagian, G.R.; Fanelli, V.; Villasante, J.A.; Johnson, D.H.; Ernst, H.A. Sealability of Stationary Metal-to-Metal Seals. J. Tribol. 2004, 126, 591–596. [Google Scholar] [CrossRef]

- Strozzi, A.; Lugli, R. Design of a pressure vessel shell-bottom closure achieved via a segmented locking ring. Int. J. Press. Vessel. Pip. 2020, 188, 104240. [Google Scholar] [CrossRef]

- Liu, T.; Li, X.; Liu, S.; Tian, Y.; Long, J.; Xu, C.; Sun, K. Analysis of Wedge-Shaped Contact Seal in Deep-Sea Sampler of the chapter. In Analysis of Wedge-Shaped Contact Seal in Deep-Sea Sampler; IEEE: Piscataway, NJ, USA, 2019. [Google Scholar]

- Zhao, B.; Zhang, S.; Li, T.; Hao, J.; Wang, T. The Sealing Technology in Pipeline Repair Clamp. J. Coast. Res. 2020, 104, 872–881. [Google Scholar] [CrossRef]

- Zhao, B.J.; Zhu, H.W.; Zhang, J.Y.; Zhang, S.L. Circumferential Sealing Structure of a Subsea Oil and Gas Pipeline Repair Clamp. Strength Mater. 2020, 52, 59–70. [Google Scholar] [CrossRef]

- Yang, Y.; Zhu, H.; He, D.; Du, C.; Xu, L.; He, Y.; Zheng, Y.; Ye, Z. Contact mechanical behaviors of radial metal seal for the interval control valve in intelligent well: Modeling and theoretical study. Energy Sci. Eng. 2019, 8, 1337–1352. [Google Scholar] [CrossRef]

- Shintaku, T.; Nagase, R.; Sugita, E. Connection mechanism of physical-contact optical fiber connectors with spherical convex polished ends. Appl. Opt. 1991, 30, 5260–5265. [Google Scholar] [CrossRef] [PubMed]

- Johnson, K. Contact Mechanics; Cambridge University Press: Cambridge, UK, 1978; pp. 12–119, 451–481. [Google Scholar]

- Olukoko, O.A.; Becker, A.; Fenner, R.T. Three benchmark examples for frictional contact modelling using finite element and boundary elements methods. J. Strain Anal. Eng. Des. 1993, 28, 293–301. [Google Scholar] [CrossRef]

- Menga, N. Rough frictional contact of elastic thin layers: The effect of geometrical coupling. Int. J. Solids Struct. 2019, 164, 212–220. [Google Scholar] [CrossRef]

- Menga, N.; Afferrante, L.; Demelio, G.; Carbone, G. Rough contact of sliding viscoelastic layers: Numerical calculations and theoretical predictions. Tribol. Int. 2018, 122, 67–75. [Google Scholar] [CrossRef]

- Popov, V.L. Contact Mechanics and Friction: Physical Principles and Applications; Springer: Berlin, Heidelberg, 2017; pp. 55–67. [Google Scholar]

- Yun, F.; Wang, G.; Yan, Z.; Jia, P.; Xu, X.; Wang, L.; Sun, H.; Liu, W. Analysis of Sealing and Leakage Performance of the Subsea Collet Connector with Lens-Type Sealing Structure. J. Mar. Sci. Eng. 2020, 8, 444. [Google Scholar] [CrossRef]

- API SPEC 6A. In Specification for Wellhead and Tree Equipment; American Petroleum Institute: Washington, DC, UAS, 2018.

- Sawaryn, S.J. A Generalised Solution to the Point to Target Problem Using the Minimum Curvature Method. In Proceedings of the SPE/IADC International Drilling Conference and Exhibition, London, UK, 17–19 March 2021. [Google Scholar]

| Name | Flange | Metal Sealing Gasket |

|---|---|---|

| Material | F22 | Incoloy 825 |

| Yield strength (MPa) | 515 | 220 |

| Elastic modulus (MPa) | 2.1 × 105 | 2.05 × 105 |

| Poisson ratio | 0.3 | 0.25 |

| Equivalent elastic modulus E* (MPa) | 1.126 × 105 | |

| Equivalent radius of curvature Re (mm) | 92.94 | |

| Rotary diameter of contact point dc (mm) | 167.54 | |

| Angle between flange bell mouth and axis α (°) | 22 | |

| No | Displacement Loading (mm) | Maximum Stress of Sealing Gasket/Flange (MPa) | Axial Force Fa (N) | Simulation pmax (MPa) | Theoretical Calculation pmax (MPa) | Differential Value (MPa) | Error (%) |

|---|---|---|---|---|---|---|---|

| 1 | 0.01 | 65/64 | 7492 | 113 | 120 | −7 | −5.83 |

| 2 | 0.02 | 95/95 | 15,692 | 165 | 174 | −9 | −5.17 |

| 3 | 0.03 | 119/119 | 24,196 | 206 | 216 | −10 | −4.63 |

| 4 | 0.04 | 139/140 | 32,911 | 241 | 252 | −11 | −4.37 |

| 5 | 0.05 | 157/159 | 41,789 | 272 | 284 | −12 | −4.23 |

| 6 | 0.06 | 174/176 | 50,801 | 300 | 313 | −13 | −4.15 |

| 7 | 0.07 | 189/193 | 59,928 | 326 | 340 | −14 | −4.12 |

| 8 | 0.08 | 203/207 | 69,154 | 350 | 365 | −15 | −4.11 |

| 9 | 0.09 | 216/222 | 78,472 | 374 | 389 | −15 | −3.86 |

| 10 | 0.10 | 229/236 | 87,868 | 396 | 412 | −16 | −3.88 |

| 11 | 0.11 | 242/250 | 97,342 | 417 | 433 | −16 | −3.69 |

| Equivalent Radius of Curvature Re | Rotary Diameter of Contact Point dc | Angle between Flange Bell Mouth and Axis α |

|---|---|---|

| 104.5 mm | 173.14 mm | 13° |

| pin/MPa(psi) | Fa/N | Simulation pmax/MPa | Theoretical Calculation pmax/MPa | khw |

|---|---|---|---|---|

| 41.4 (6000) | 67,000 | 343 | 430 | 0.798 |

| 37.9 (5500) | 56,230 | 314 | 394 | 0.797 |

| 34.5 (5000) | 47,098 | 286 | 361 | 0.792 |

| 31.0 (4500) | 38,838 | 257 | 328 | 0.784 |

| 27.6 (4000) | 31,245 | 228 | 294 | 0.776 |

| 24.1 (3500) | 23,429 | 199 | 255 | 0.781 |

| 20.7 (3000) | 17,520 | 171 | 220 | 0.777 |

| Depth of Water/m | σmax/MPa | Axial Displacement of Flange | Fa/N | Simulation pmax/MPa | Theoretical pmax/MPa | khw |

|---|---|---|---|---|---|---|

| 0 | 219.51 | 0.07 | 78,848 | 357.11 | 467.00 | 0.765 |

| 500 | 220.68 | 0.16 | 86,289 | 371.62 | 488.54 | 0.761 |

| 1000 | 220.81 | 0.24 | 91,911 | 386.77 | 504.21 | 0.767 |

| 1500 | 220.11 | 0.31 | 95,707 | 397.27 | 514.51 | 0.772 |

| 2000 | 219.32 | 0.37 | 97,659 | 402.42 | 519.74 | 0.774 |

| 2500 | 219.49 | 0.43 | 99,632 | 407.38 | 524.96 | 0.776 |

| 3000 | 221.17 | 0.49 | 101,630 | 411.76 | 530.20 | 0.777 |

| Fpress (N) | Initial pin (MPa) | Pressurization Value in 15 min pin (MPa) | Pressure Drop in 15 min (MPa) | Conversion to Hourly Pressure Drop (MPa) | Fa (N) |

|---|---|---|---|---|---|

| 600,000 | 24.4 | 24.3 | 0.1 | 0.4 (1.6%) | 28,172 |

| 700,000 | 28.7 | 28.5 | 0.2 | 0.8 (2.8%) | 29,338 |

| 800,000 | 32.3 | 32.1 | 0.2 | 0.8 (2.5%) | 44,623 |

| 900,000 | 36.4 | 36.1 | 0.3 | 1.2 (3.3%) | 50,495 |

| 1,000,000 | 39.5 | 39.3 | 0.2 | 0.8 (2.0%) | 75,192 |

| 1,100,000 | 43.7 | 43.6 | 0.1 | 0.4 (0.9%) | 74,005 |

| 1,200,000 | 47.9 | 47.5 | 0.4 | 1.6 (3.3%) | 82,230 |

| Experimental Data | Theoretical Calculation and Error | ||||

|---|---|---|---|---|---|

| Calculated Value | Corrected Value | ||||

| pin (MPa) | Fa (N) | pin (MPa) | Error (%) | pin (MPa) | Error (%) |

| 24.3 | 28,172 | 33.9 | −28.3 | 26.5 | −8.30 |

| 28.5 | 29,338 | 34.6 | −17.6 | 27.0 | 5.56 |

| 32.1 | 44,623 | 42.7 | −24.8 | 33.3 | −3.60 |

| 36.1 | 50,495 | 45.5 | −20.7 | 35.5 | 1.69 |

| 39.3 | 75,192 | 55.5 | −28.8 | 43.3 | −9.24 |

| 43.6 | 74,005 | 55.0 | −20.7 | 42.9 | 1.63 |

| 47.5 | 82,230 | 57.9 | −18.0 | 45.2 | 5.09 |

| Fpress (N) | Initial player (MPa) | Pressurization Value in 15 min player (MPa) | Pressure Drop in 15 min (MPa) | Conversion to Hourly Pressure Drop (MPa) | Fa (N) |

|---|---|---|---|---|---|

| 80,000 | 23.4 | 23.3 | 0.1 | 0.4 (1.7%) | 23,591 |

| 100,000 | 27.8 | 27.6 | 0.2 | 0.8 (2.9%) | 33,180 |

| 120,000 | 31.8 | 31.7 | 0.1 | 0.4 (1.3%) | 43,254 |

| 140,000 | 37.0 | 36.9 | 0.1 | 0.4 (1.1%) | 50,665 |

| 160,000 | 39.9 | 39.7 | 0.2 | 0.8 (2.0%) | 63,886 |

| 180,000 | 42.8 | 42.6 | 0.2 | 0.8 (1.9%) | 76,865 |

| 200,000 | 45.4 | 45.1 | 0.3 | 1.2 (2.7%) | 90,813 |

| Experimental Data | Theoretical Calculation and Error | ||||

|---|---|---|---|---|---|

| Calculated Value | Corrected Value | ||||

| player (MPa) | Fa (N) | player (MPa) | Error (%) | player (MPa) | Error (%) |

| 23.3 | 23,591 | 30.9 | −24.6 | 24.2 | −4.55 |

| 27.6 | 33,180 | 36.8 | −25.0 | 28.7 | −3.83 |

| 31.7 | 43,254 | 42.1 | −24.7 | 32.8 | −3.35 |

| 36.9 | 50,665 | 45.1 | −18.2 | 35.2 | 4.83 |

| 39.7 | 63,886 | 50.6 | −21.5 | 39.5 | 0.68 |

| 42.6 | 76,865 | 56.0 | −23.9 | 43.7 | −2.52 |

| 45.1 | 90,813 | 60.4 | −25.3 | 47.1 | −4.25 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Yun, F.; Sun, H.; Wang, L.; Yan, Z.; Wang, G.; Gong, H.; Jiao, K.; Liu, D.; Hao, X. The Research and Experiments on Contact Sealing Theory of the Underwater Clamp Connector. Machines 2021, 9, 262. https://doi.org/10.3390/machines9110262

Wang W, Yun F, Sun H, Wang L, Yan Z, Wang G, Gong H, Jiao K, Liu D, Hao X. The Research and Experiments on Contact Sealing Theory of the Underwater Clamp Connector. Machines. 2021; 9(11):262. https://doi.org/10.3390/machines9110262

Chicago/Turabian StyleWang, Wuchao, Feihong Yun, Haiting Sun, Liquan Wang, Zheping Yan, Gang Wang, Haixia Gong, Kefeng Jiao, Dong Liu, and Xiaoquan Hao. 2021. "The Research and Experiments on Contact Sealing Theory of the Underwater Clamp Connector" Machines 9, no. 11: 262. https://doi.org/10.3390/machines9110262

APA StyleWang, W., Yun, F., Sun, H., Wang, L., Yan, Z., Wang, G., Gong, H., Jiao, K., Liu, D., & Hao, X. (2021). The Research and Experiments on Contact Sealing Theory of the Underwater Clamp Connector. Machines, 9(11), 262. https://doi.org/10.3390/machines9110262