1. Introduction

With the continuous development of computer technology, product design patterns and methods are changing. In order to meet the increasing demand of personalized product design, it has become the development trend of new product design mode to further shorten the product design cycle, reduce product cost, and improve product performance [

1]. In the face of complex products, design companies often consider two design ideas: Top-down and bottom-up. Since the top-down design method is more in line with the designer’s design thinking process, it is more natural to adopt the top-down design method for the design of complex products [

2,

3,

4].

The top-down design process is usually divided into three design phases: Requirements’ analysis, conceptual design, and detailed design. In the process of product design, the functional requirements are first analyzed and the preliminary conceptual models are proposed. Then, through the evaluation of the design scheme, the best conceptual model is determined. Finally, each part in the design scheme is designed in detail [

5]. However, the current CAD (Computer Aided Design) software cannot effectively support the whole process of top-down product design, especially in the transition phase between conceptual design and detailed design. Most product design systems based on CAD software (Creo, SolidWorks) are mainly determined by a skeleton model of the main components and the overall layout of the product by the designer [

6]. According to the model, the parts are designed in detail, and the finished parts are finally assembled into the initial skeleton model to complete the assembly model of a product [

6].

In order to stay competitive in the industry, enterprises should reduce the manufacturing cost while maintaining the product quality [

7]. However, the proportion of enterprises’ payment for purchased parts accounts for more than 50% of the total product cost [

8]. Therefore, choosing the right supplier can significantly reduce product cost, improve product competitiveness, and improve customer satisfaction. It is reviewed that in recent years, most of the optimization models for supplier selection are established based on each indicator of the supplier, and different algorithms are applied to get a reasonable plan [

9,

10]. At present, most product design systems basically use a database to store the functions, specifications, dimensions, and other information of different suppliers for purchased parts. The designer completes the selection of each component according to the functional requirements, and the combination of different series’ numbers of different parts’ suppliers also plays an important role in the decision of the final plan.

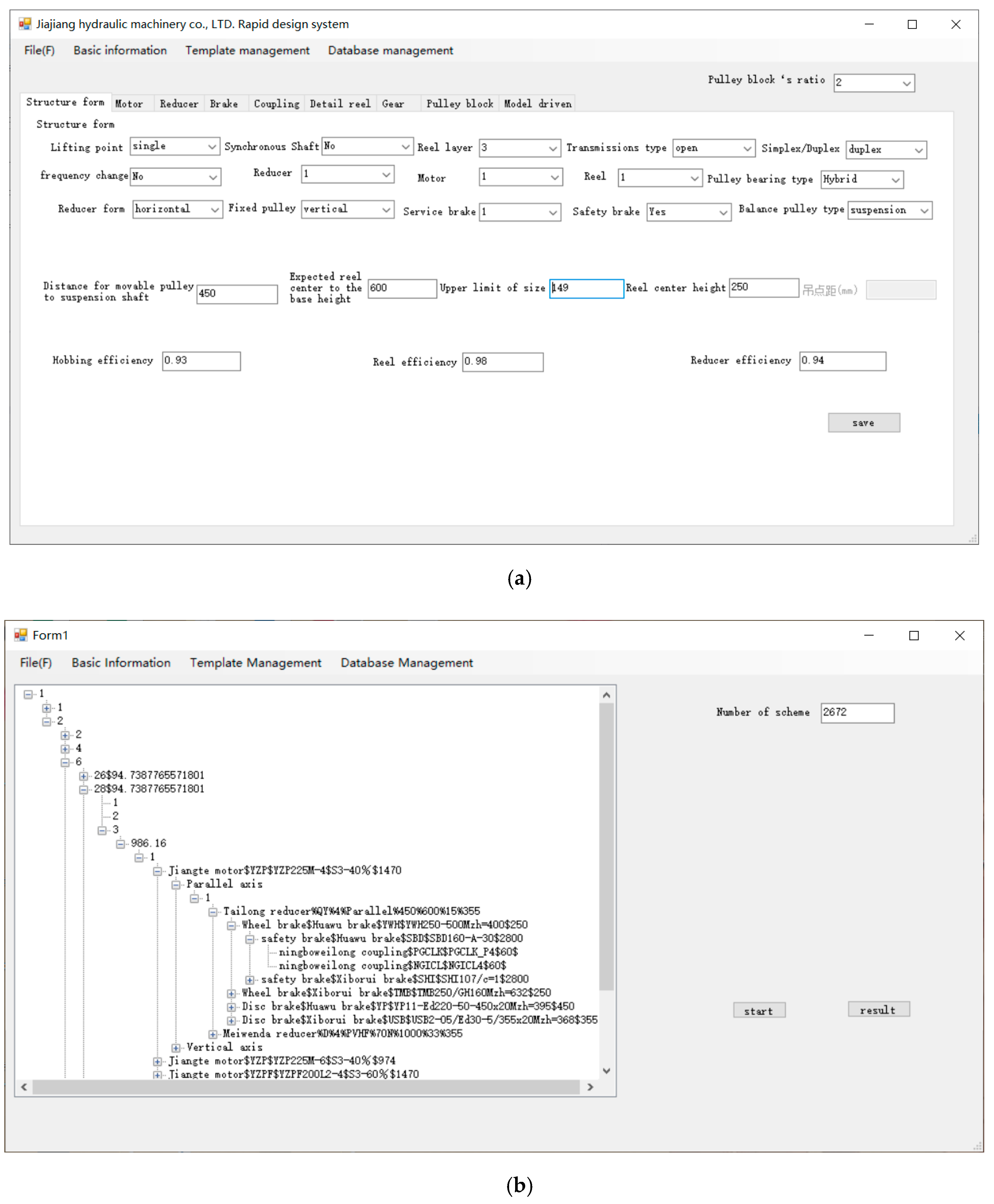

The work of this paper is divided into two parts. A design model based on multi-way tree structure was proposed. The design scheme is represented by a set of product attributes that are the main structural parameters of the product and the number and type of each component. The conceptual design and detailed design of the product are combined by using the principle of multi-way tree to form a pattern of combining the principles and designing the parts at the same time. After the design is completed, the product solutions are integrated as a feature of multi-way tree. A certain number of design schemes can be obtained by traversing multiple trees.

Analytic hierarchy process (AHP) is a decision-making method that decomposes elements related to decision making into objective, criteria, and plan for qualitative and quantitative analysis at three levels [

11]. Technique for order preference by similarity to an ideal solution (TOPSIS) is a sorting method that approximates the ideal solution, which evaluates the relative merits and demerits of the existing objects according to the degree of similarity between the limited evaluation objects and the ideal target [

11]. AHP and TOPSIS are used to evaluate the design scheme. In the second part, a recommendation method of optimizing component supplier combination based on learning-to-rank was proposed. According to the preference demand of the designer, the training set is constructed by the user’s operation log. The learning-to-rank algorithm is used to sort the list of recommended schemes twice.

The novelty of this paper is as follows:

The design scheme included not only the principle synthesis of the product but also the selection and structure information of the corresponding parts. At the same time, the conceptual design of the product was done by a computer.

A simplified and efficient recommendation method was proposed to evaluate design schemes.

In this paper,

Section 2 describes previous research and background in top-down product design and combination of suppliers, and then the proposed method is explained in

Section 3. This paper presents a recommendation method of product design schemes based on multi-way tree and learning-to-rank. Then, a case study was performed with a hoist to demonstrate the feasibility and usefulness of the proposed method in

Section 4. A conclusion of this study is described in

Section 5.

2. Related Research

In the development history of product design, top-down product design has always been an important issue, and the support of top-down design of a computer aided system is absolutely necessary. This section outlines some important research work on both top-down product design and supplier portfolio selection.

Most 3D CAD software can only provide a geometric modeling function for the design/drawing operation, which cannot completely replace the top-down design process of the product by the computer [

12]. Therefore, many researchers hope to replace CAD systems with more automated, knowledge-based, and intelligent design systems by expanding CAD systems.

Aleixo et al. [

13] combined the conceptual design with the final product modeling, and verified the method by testing two CAD software conceptual design tools. He et al. [

14] proposed an original understanding integrated modeling method based on physical quantity model, which connected functional design, principle concept design, and structure concept design. Nahm et al. [

15] combined the practice of SBD (Schottky Barrier Diode) with parametric modeling and proposed a design model based on preference set to make the early design stage more flexible. In order to improve the efficiency of design/redesign, Sharma and Gao [

16] proposed a method that combines sequential flowchart logic with expert system, uses user-defined feature tree as input for analysis, and takes flange as an example to verify the effectiveness of the method. Kong et al. [

17] developed a 3D injection mold design system integrated with SolidWorks by using Visual C++. Varela et al. [

18] proposed a C++ rapid parameterization system for ship structure based on 3D CAD software. Lin et al. [

19] developed a mold parametric design system based on Pro/engineer. Yang et al. [

20] developed a blade modeling system. On Creo platform, Zhang et al. [

21] established a feature information model based on part feature description by using CAD technology, parametric design, and part model library technology. Li et al. [

22] proposed a full-parameter correlation modeling design system for standard CAMs (Computer Aided Manufacturing) with different working angles, which simplified the steps of CAM modeling.

In recent years, scholars have carried out a lot of research on supplier portfolio selection. Most of the suppliers involved in the product design process are as a multi-objective decision problem. Therefore, analytic hierarchy process (AHP), mathematical programming, linear programming, data envelope analysis (DEA), genetic algorithm, and other methods have been proposed. Benyoucef et al. [

23] proposed a supplier selection system based on analytic hierarchy process (AHP) which integrates fuzzy concepts and empirical data. Balakrishnan et al. [

24] constructed a product component portfolio design scheme and a multi-objective optimization model of suppliers, which was optimized by mathematical programming method to achieve the optimal product design, which takes both tangible and intangible factors into consideration when selecting the best supplier, so as to determine the optimal supplier and order quantity. Toloo et al. [

25] constructed a comprehensive data enveloping analysis (DEA) model that can identify the most effective suppliers from the cardinal and ordinal data, and illustrated the applicability of the method by taking the specification data of 18 suppliers as an example. Cao et al. [

26] established an optimization model of integrating product family design and supplier selection based on multiple logit consumer selection rules and using genetic algorithm, which further saved costs and improved production efficiency.

According to the literature, three problems were identified in terms of computer-aided product design and supplier portfolio. First of all, it is seldom considered to combine conceptual design and detailed design, and most product design systems only realize one or the other of computer-aided product conceptual design or detailed design. Second, the previous product design system requires designers to interact with the system to determine certain design parameters and parts’ selection by experience, so the number of design schemes obtained is very few and the schemes are not optimal. Finally, most supplier combinations need to collect a lot of information to establish mathematical models to solve problems, which is a complex process. In the next section, we will discuss in detail how to recommend product design solutions based on multi-way tree and learning-to-rank.

3. The Recommendation Method

3.1. Product Design Model Based on Multi-Way Tree Structure

The design scheme can be represented by the attributes of the product. Since the attributes of a product are limited, the number of design schemes is also limited by permutation and combination [

27]. At the same time, the principle for designers to judge the advantages and disadvantages of a scheme is to weigh whether the values of several important attributes of the scheme are better on the basis of meeting the design requirements. Therefore, given a set of attributes, S = {A1,…,An} describes a design scheme.

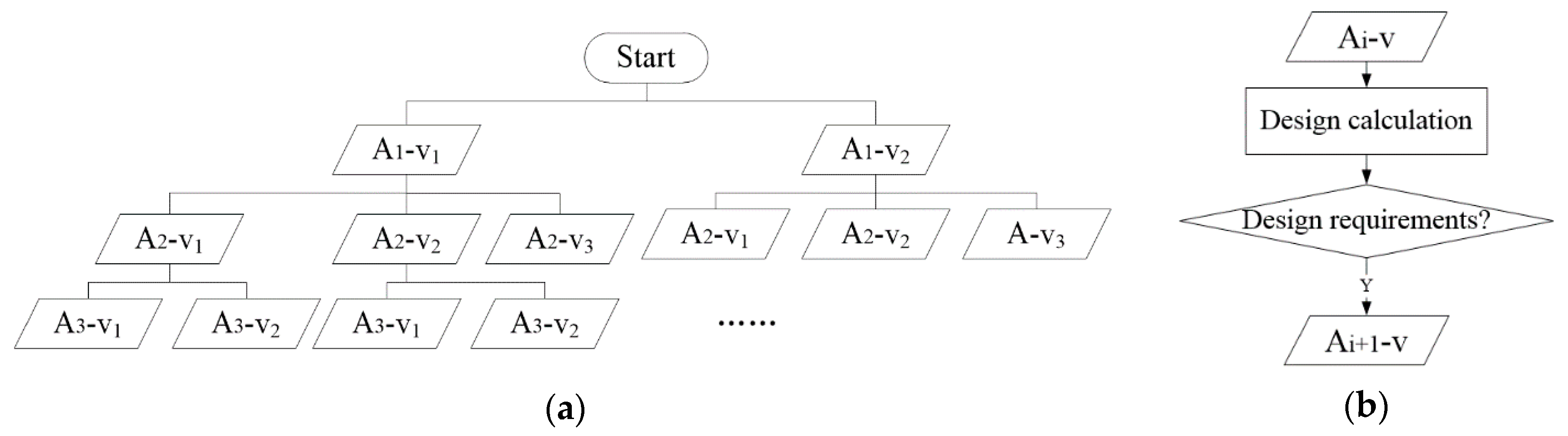

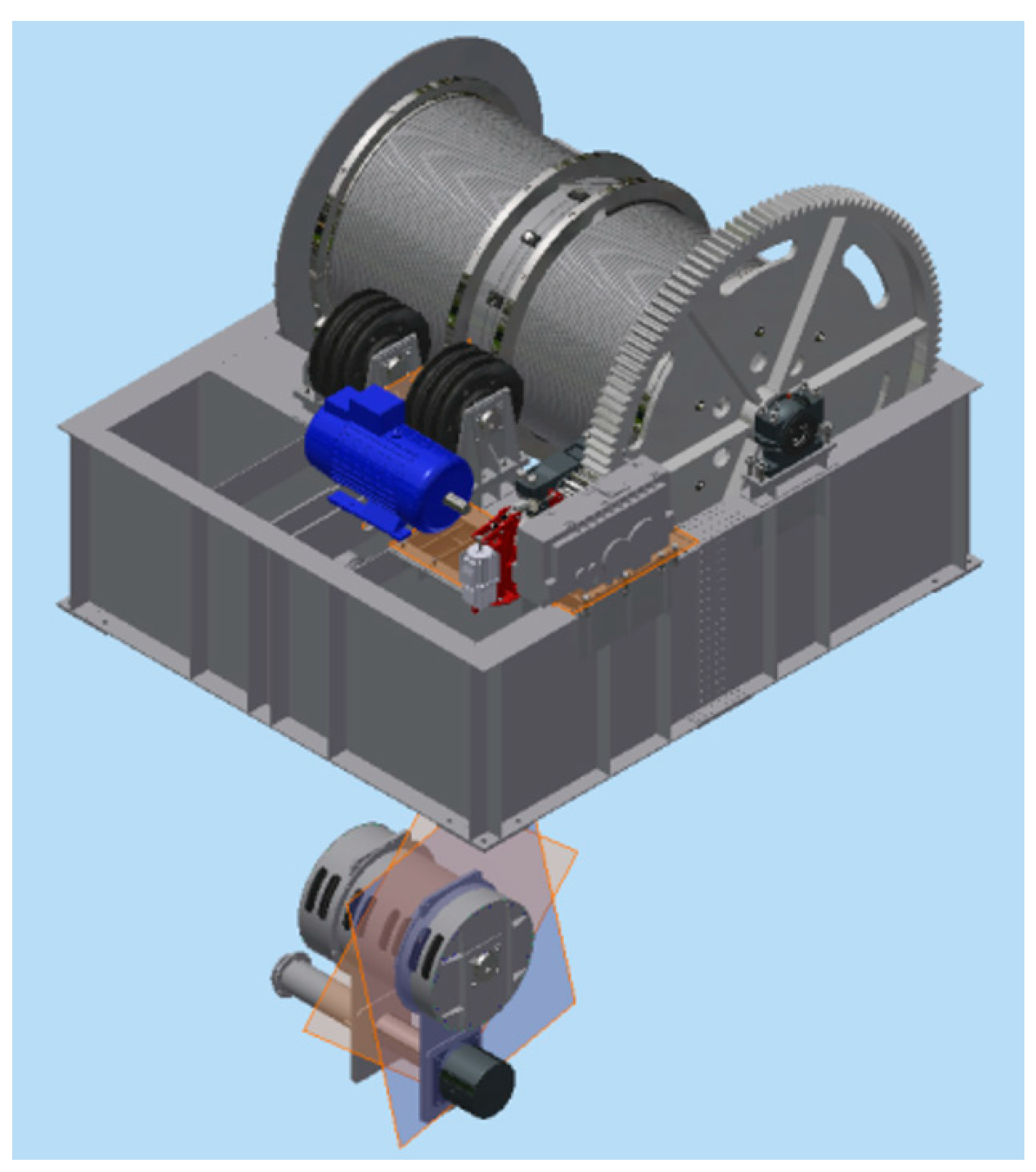

In order to make the design process of the scheme have a clear structure, the product design system adopts the multi-way tree structure to establish the model, and attributes generate the multi-way tree nodes in each layer in order of the design process requirements. Among them, the nodes in this model are divided into two categories: Inherent nodes and generated nodes. The inherent node corresponds to the inherent attribute that will remain unchanged while design requirements are changed. The generated node corresponds to the generated attribute that is calculated from the inherent attribute and other design parameters. A complete path of the structure is a design scheme for the product. After the design is completed, the structure can be traversed to generate all possible solutions (alternatives). All possible solutions (alternatives) can be obtained by traversing the structure, after the design is completed. The attribute structure table is shown in

Table 1, and the multi-way tree structure is shown in

Figure 1.

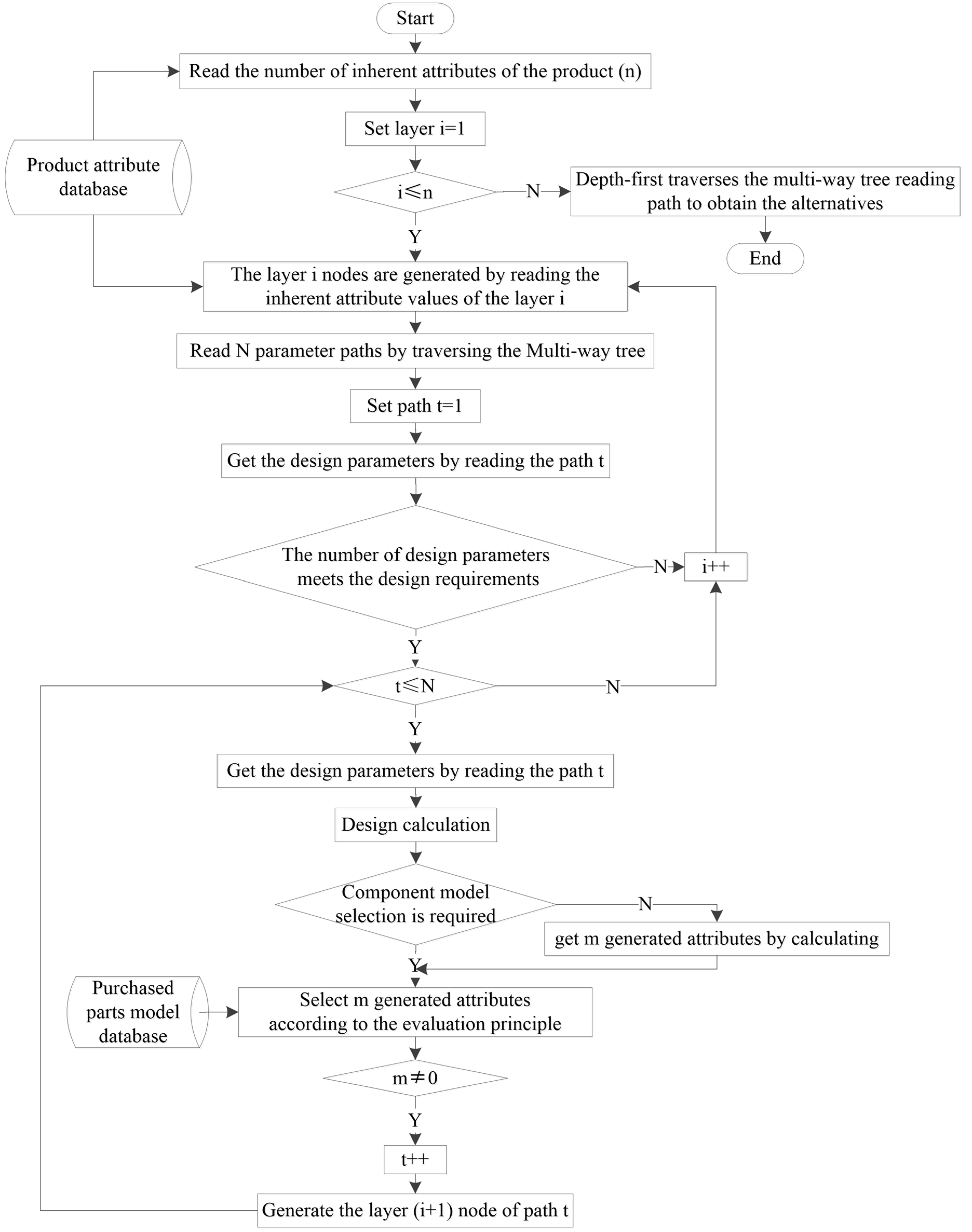

The specific process of multi-way tree model is shown in

Figure 2.

Step 1: Multi-way tree model initialization.

Get the total number of inherent attributes n by reading the number of the product inherent attributes from product attribute database; set layer i = 1, and start the system.

Step 2: Generation of lower level nodes.

In order to obtain sufficient parameter values, the current multi-way tree model needs to be judged. If the number of nodes in the node path t that reads the current number of layers meets the required design parameters, the component design is started; otherwise, the next layer node is loaded: Layer i = i + 1.

Step 3: The component design.

When the design parameters meet the requirements, the path t is read (t = 1). If the component is purchased from abroad, the selection is required. According to the evaluation rules, the lower level nodes are generated from the purchased parts model database; otherwise, the lower level nodes are generated by calculating. If m ≠ 0, t = t + 1 and generate the layer (i + 1) of path t; otherwise, the path t ends.

Step 4: Acquisition of alternatives.

When the multi-way tree model is complete (i > n), alternatives were obtained by depth-first traversal [

28].

3.2. Design Scheme Ordering Based on AHP-TOPSIS Method

3.2.1. AHP-TOPSIS Method

The analytic hierarchy process (AHP) proposed by Saaty, an American operations research scientist, in the 1970s, is a decision analysis method combining qualitative and quantitative analysis, which is widely applicable to the decision analysis of various types of problems. It is decomposed into the problem of complex constituent factors. These factors will govern how formation is grouped with hierarchical structure, through comparing the two ways to determine the relative importance of various factors in the hierarchy, relative weights under single criterion, and the consistency check, Then human judgment is integrated to decide the total sorts of the relative importance of various factors. The disadvantage of AHP is that when the judgment matrix is constructed in a qualitative way, the judgment may be too subjective due to human factors [

29]. The basic idea of TOPSIS is to determine the ideal solution and the negative ideal solution, according to the elements of the decision-making problem, and to rank each scheme according to the relative closeness degree of the ideal solution of its elements. That is, the scheme closest to the ideal solution and furthest from the negative ideal solution is the optimal scheme. The disadvantage of TOPSIS method is that it adopts a one-dimensional qualitative method to determine the index weight, so it is difficult to determine the index weight in the case of multi-factor analysis [

29].

This paper, on the basis of summarizing the previous research results, applied AHP and TOPSIS in the evaluation and ranking of design schemes [

30]. First, it used AHP to divide all factors into ordered levels and scientifically assign weights. Then, it constructed the AHP-TOPSIS comprehensive evaluation model by combining with TOPSIS. TOPSIS can rank the evaluation objects according to how close they are to the ideal target, but in the case of multi-factor analysis, it is difficult to determine the index weight, and AHP can effectively overcome this disadvantage to some extent. TOPSIS can comprehensively consider more than 10 factors of program evaluation, and AHP can objectively give the weight of each influencing factor. The combination of the two can create conditions for improving the accuracy of program ranking.

Product life cycle cost includes design phase cost, manufacturing phase cost, sales phase cost, use and maintenance cost, and recovery and scrap cost [

31]. Since more than 70% of the total cost of product life cycle is borne in the initial stage of design, designers can fully consider the impact of design decisions on the life cycle, thus greatly reducing the product life cycle cost [

32]. Therefore, it is very important to estimate and optimize the cost as early as possible and as accurately as possible. In order to achieve the above goals, this part mainly uses typical parameters in the product concept design phase to estimate the cost of alternative solutions and to sort the solution set. In order to achieve the above purposes, this part mainly uses typical parameters [

33] of the product concept design stage to estimate the cost of alternative schemes and to sort the scheme set. Typical parameters mainly refer to the cost of each component that affects the product cost. Sometimes the cost of the product parts is not clear, and other parameters of the parts can be used to group the evaluation indicators for the evaluation of the scheme. According to the evaluation objects, the role of each indicator in the comprehensive evaluation is not equally important, and the weight of traditional TOPSIS is generally set artificially to take the average value, which cannot reflect the preference and personality of experts [

34]. Therefore, according to the characteristics and requirements of the product, experts establish the evaluation index system. In order to calculate the overall cost of the product scientifically, the weight of components is taken as the evaluation index, and AHP is applied to determine the weight of each index in the evaluation index system of the product. TOPSIS is used to determine the relative proximity of each index value of the alternative solution to the ideal solution, so as to rank the advantages and disadvantages of the product design alternatives for subsequent processing by comparing the relative proximity [

35].

3.2.2. Scheme Ranking Process

The sequence of design schemes based on AHP-TOPSIS is as follows [

36] (AHP is summarized in step 1, TOPSIS is summarized in steps 2–8):

Step 1: Experts select m typical parameters C

1, C

2, …, C

m from the program attributes based on empirical knowledge to establish the evaluation index system of the product. AHP method was used to calculate the weight of each evaluation index ω. The five-scale method was adopted to compare and assign values, and then the corresponding judgment matrix A was constructed according to the assignment criteria, as shown in

Table 2.

Step 2: Set the scheme S = {S

1, S

2, …, S

n) and each scheme evaluation index R = {r

1, r

2, …, r

m}. The evaluation index r

ij represents the j evaluation index of the i scheme, where i∈[1, n], j∈[1, m]. The initial judgment matrix can be expressed as:

Step 3: The initial judgment matrix S = (r

ij)

n × m is normalized to get the matrix Z = (z

ij)

n × m, where the elements are:

Step 4: By multiplying the column vectors of the matrix and the weights of evaluation indicators determined by AHP method, the weighted standardized decision matrix

B = (

bij)

n × m can be obtained, where the elements are:

Step 5: The positive and negative ideal solutions are obtained. That is, the optimal value and the worst value of each index constitute the positive ideal solution

B+ and the negative ideal solution

B−:

Step 6: Calculate the n-dimensional Euclidean distance

Qi+ and

Qj+ of each design scheme from

B+ and

B− using the following equations:

Step 7: Calculate the relative proximity of each design scheme to the ideal solution

Di:

Step 8: Sort each design scheme according to the size order of Di, and select the first n1 schemes for the designer to choose.

3.3. Optimization of Component Supplier Combination Based on Learning-to-Rank

The list of solutions generated based on AHP-TOPSIS did not reflect the designer’s preference for the component supplier combination. In order to solve this problem, a component supplier combination recommendation algorithm based on user behavior feedback was proposed to further optimize the recommendation list.

3.3.1. Problem Statement

Our problem can be formalized as follows: Given a set of product suppliers and serial numbers S = {S1, S2, …, Sn} describing these products’ attributes’ combination based on the designer’s preference, our goal was to induce a function f that scored design schemes in S according to the degree to which they satisfy the specific requirements of a designer, given as an n-tuple (s1, s2, …, sn)

3.3.2. Formulation as a Learning-to-Rank Problem

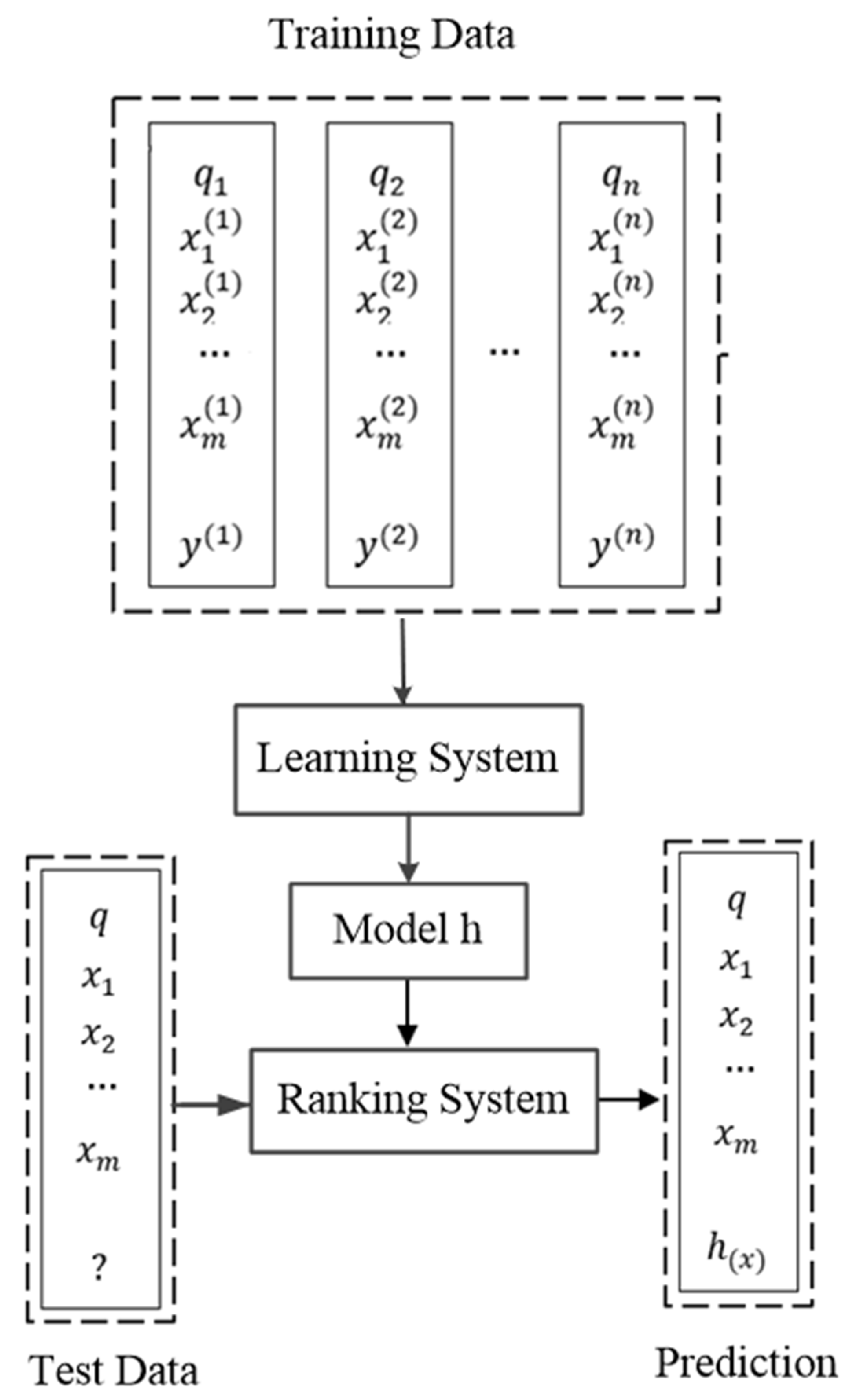

Learning-to-rank [

37] method uses machine learning method in an information retrieval problem to automatically learn the final sorting function for retrieval based on feature set. The classic learning-to-rank framework is shown in

Figure 3.

In this framework, first extract the characteristics of the document to get eigenvector xj(i). The eigenvector and annotation constitute a training example of the document pair (xj(i), y(i)). Then, choose the appropriate ranking algorithm to learn and get the ranking model h. Finally, a new query q (test data) outputs the relevance score of the query and the documents to be sorted according to the ranking model h and then outputs according to the score. Its formal description is as follows:

Suppose the eigenvector space of the ranking object is X = {x1,x2,…,xm} ⊆ Rn, where n is the dimension of the eigenvector xi and m is the number of samples in the training data set. Each eigenvector corresponds to a label yi ∈ Y and dimspace Y = {y1,y2,…,ym}. Y consists of discrete variables and there is an order relationship between them. The purpose of learning-to-rank is to find an optimal rank function f* from the solution space F = {f : Rn →Y} to minimize the risk function, R(f) = ∫X × Yl(x, y, f(x))dp(x, y). Then, rank function f* for all of the output Y′ of the training data sample (X, Y) maximum close to mark Y.

RankSVM [

38] is an effective learning-to-rank algorithm. It uses pair-wised samples as training samples. The optimization objective of learning is that, in the sorting function of samples, the number of reverse pairs of samples is the least.

Following Joachims [

39], we formalized the task as a ranking problem. We defined a designer requirement as a tuple r = (

s1,

s2, …,

sn), and, if

si was more in line with the requirements specified in r than

sj, then

si >

sj. Then, our goal was to induce a ranking function

f shown in Equation (12):

We approached this problem using the framework of RankSVM provided by Joachims [

39]. The function

f was assumed a linear model parametrized by a weight vector

ω that assigned a weight to all features shown in Equation (13):

The loss function of RankSVM algorithm is shown in Equation (14).

The ω is the parameter of the hyperplane, εij is the slack variable in the case that there is an outlier in the training set, and C is the error penalty factor. The larger C is, the fewer outliers can be tolerated, that is, the higher the requirement for error reduction.

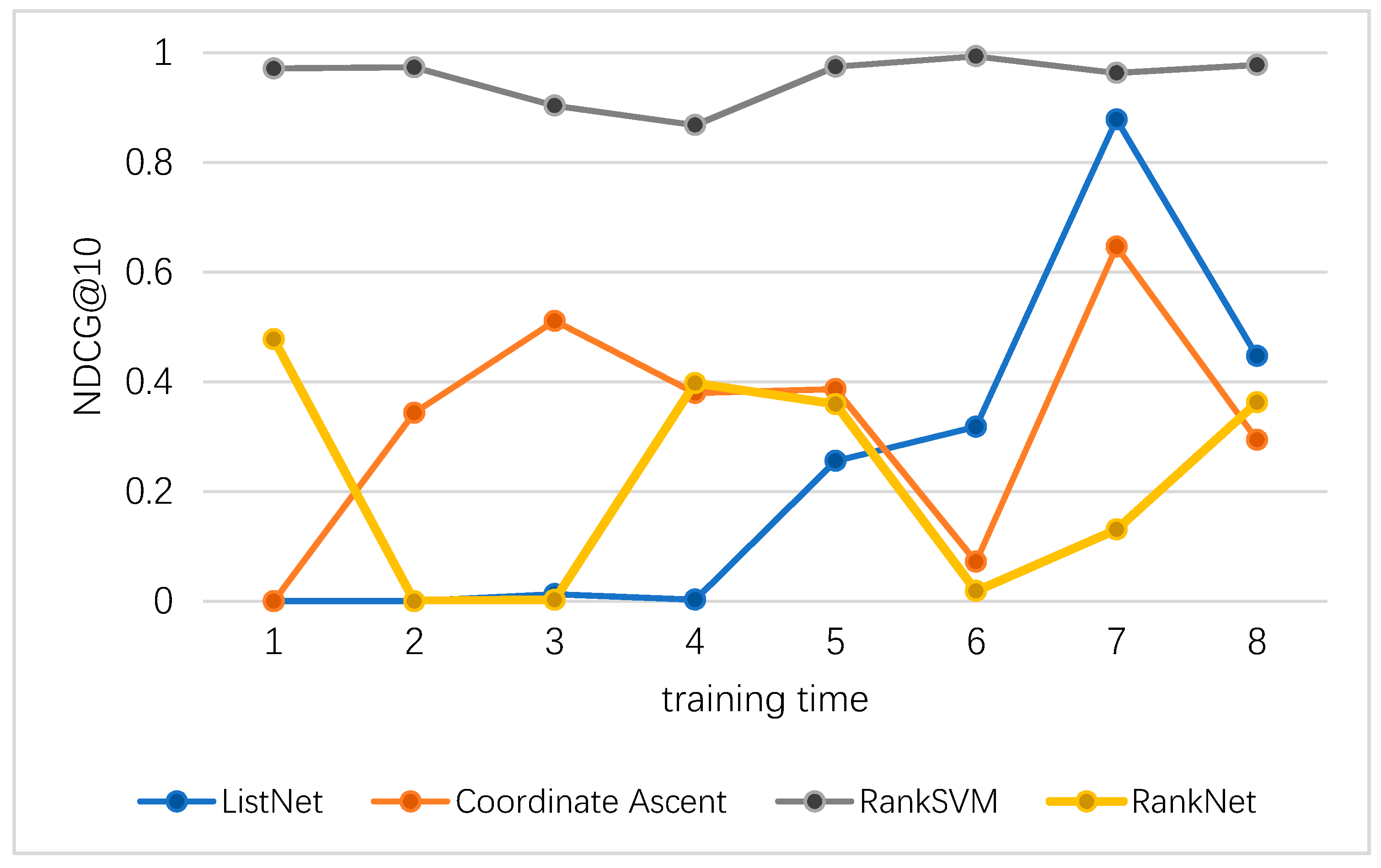

3.3.3. Evaluation Method

Because the ultimate goal of the algorithm was to make the predicted project ranking as close as possible to the preference of experts, rather than the rating prediction, the evaluation method selected NDCG (normalized discounted cumulative gain) [

40] as the measurement. NDCG is often used as an evaluation index to evaluate the ranking accuracy. NDCG@K refers to taking Top K recommended projects for effect evaluation. The value range was between 0 and 1. The larger the result is, the more the ranking conforms to the expectation.

NDCG is more sensitive to the ranking of higher ranked items [

38].

In recent years,

NDCG has been widely used in information retrieval. First of all, the calculation formula of

DCGK (discounted cumulative gain) is shown as follows:

The

reli is the correlation of the recommendation results at position

i, and

k is the size of the list of recommendations to be examined. In order to normalize

DCG, we need to compare DCG with ideal

DCG as follows:

3.3.4. Construction Method of Training Data

This algorithm requires users to mark the query results according to the positive or negative correlation between the scheme result returned by the system and the user’s design intention, and then the system uses the user’s feedback information to improve the scheme sorting. However, most users are unwilling to spend the time and energy to give feedback to the system, so it is difficult for the system to obtain sufficient user feedback [

41]. Therefore, in order to obtain sufficient user feedback to construct training data, user clicking and browsing are regarded as implicit user feedback [

42]. By referring to the usage of the existing shopping software, the system will refer to the user feedback behavior, as shown in

Table 3:

The recommended system constructed training data as follows: Through the collection of the designer’s behavior of browsing the scheme interface, the scheme set was reordered according to the following priority rules, and then the training data needed by the algorithm were constructed.

The priority rules are as follows:

Finally determine plan > alternative plan > clicked plan > unclicked plan > deleted plan (“>” means priority over, the same as later).

Alternatives of the same level are further prioritized by reading the detailed page time of the scheme, that is, the scheme with a long reading time has a high priority.

Click schemes of the same level are further prioritized by the number of clicks, that is, the schemes with more clicks have higher priority.

3.3.5. Optimization of Component Supplier Combination Process

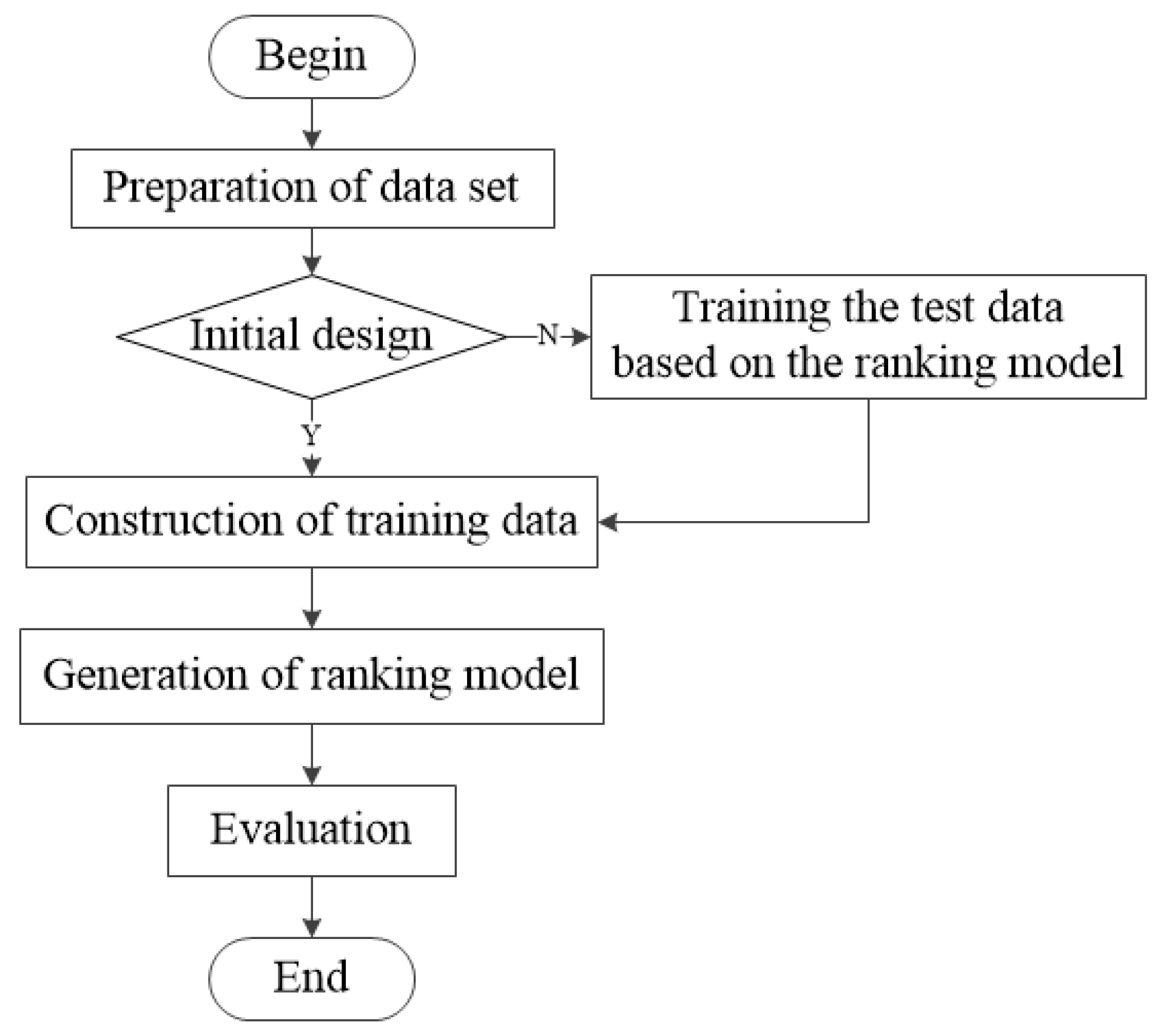

The specific process of optimization of component supplier combination is shown in

Figure 4.

Step 1: Preparation of data set.

Select the first n alternatives sorted by AHP-TOPSIS. The eigenvector space (data set) of the ranking object is formed by extracting the manufacturer, series number, and other features of the parts in the scheme. The data set of the ranking object is obtained by selecting the first n alternatives sorted by AHP-TOPSIS, which is formed by extracting the manufacturer, series number, and other features of the parts in the scheme.

Step 2: Construction of training data.

If it is the first time to design, the designer will choose the best design scheme based on experience. According to the above priority rules, the data set is reordered to form the training data. If not, the data set is sorted by a trained sorting model, and then the above operation is performed.

Step 3: Generation of ranking model.

An appropriate learning-to-rank algorithm is selected to train the data set to obtain the model.

Step 4: Evaluation.

In order to evaluate the effect of different algorithms on this problem, the metric of NDCG is adopted to evaluate the ranking result.