Condition-Based Maintenance—An Extensive Literature Review

Abstract

1. Introduction

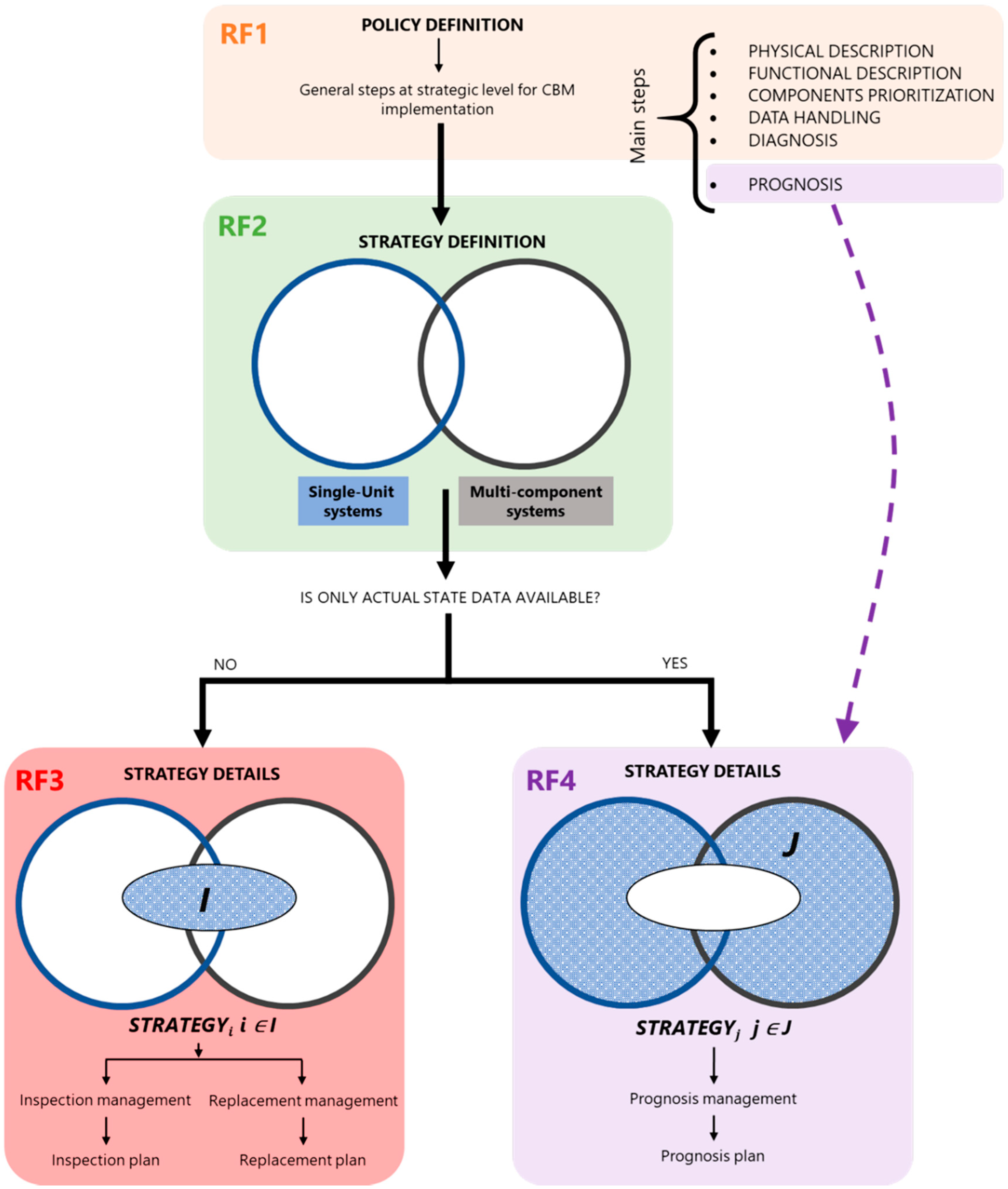

- MAINTENANCE POLICY—all management activities that set requirements, objectives, strategies and responsibilities for maintenance and implement them using management approach (i.e., planning, control, supervision and improvement). Policies refer to a set of rules made by the organization to ensure rational decision making.

- MAINTENANCE STRATEGY—management direction used to achieve maintenance objectives, achieving a competitive and effective position in the market.

- MAINTENANCE PLAN—structured and documented set of commitments including activities, procedures, resources and time required to perform maintenance activities.

Structure of the Paper

- the overall structure of the paper reflects the actual path followed by the authors for the implementation of the presented literature review

- the presentation of the extracted research factors (RFs) follows what the authors consider to be the logical path within CBM.

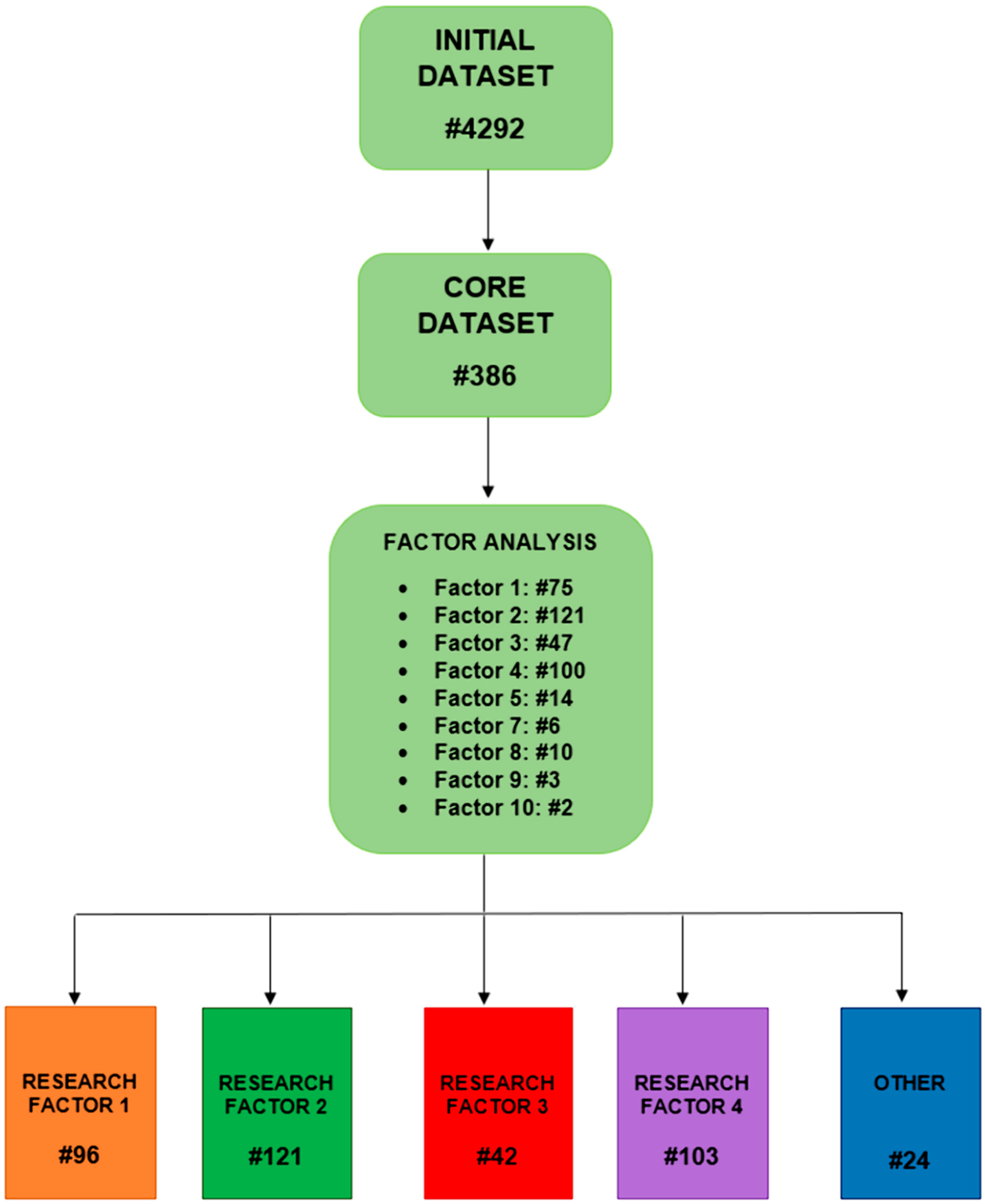

2. Methodology

3. Findings from a Systematic Literature Search and Factor Analysis

- Research factor 1: The fundamentals of CBM and its implementation

- Research factor 2: CBM strategies

- Research factor 3: Replacement and inspections management and plan and actual machinery health state

- Research factor 4: Prognosis management and plan

- Factor 5, factor 7 and factor 9 are presented in Section 4.5 respectively as CBM for electrical components, Maintenance scheduling for wind farms and Lot-sizing optimization for maintenance

- Factor 8 and factor 10 were relocated within one of the four RFs presented in the paper, that is, RF1, RF2, RF3 and RF4. Factor 6 has been excluded due to the lack of articles attributed to this factor.

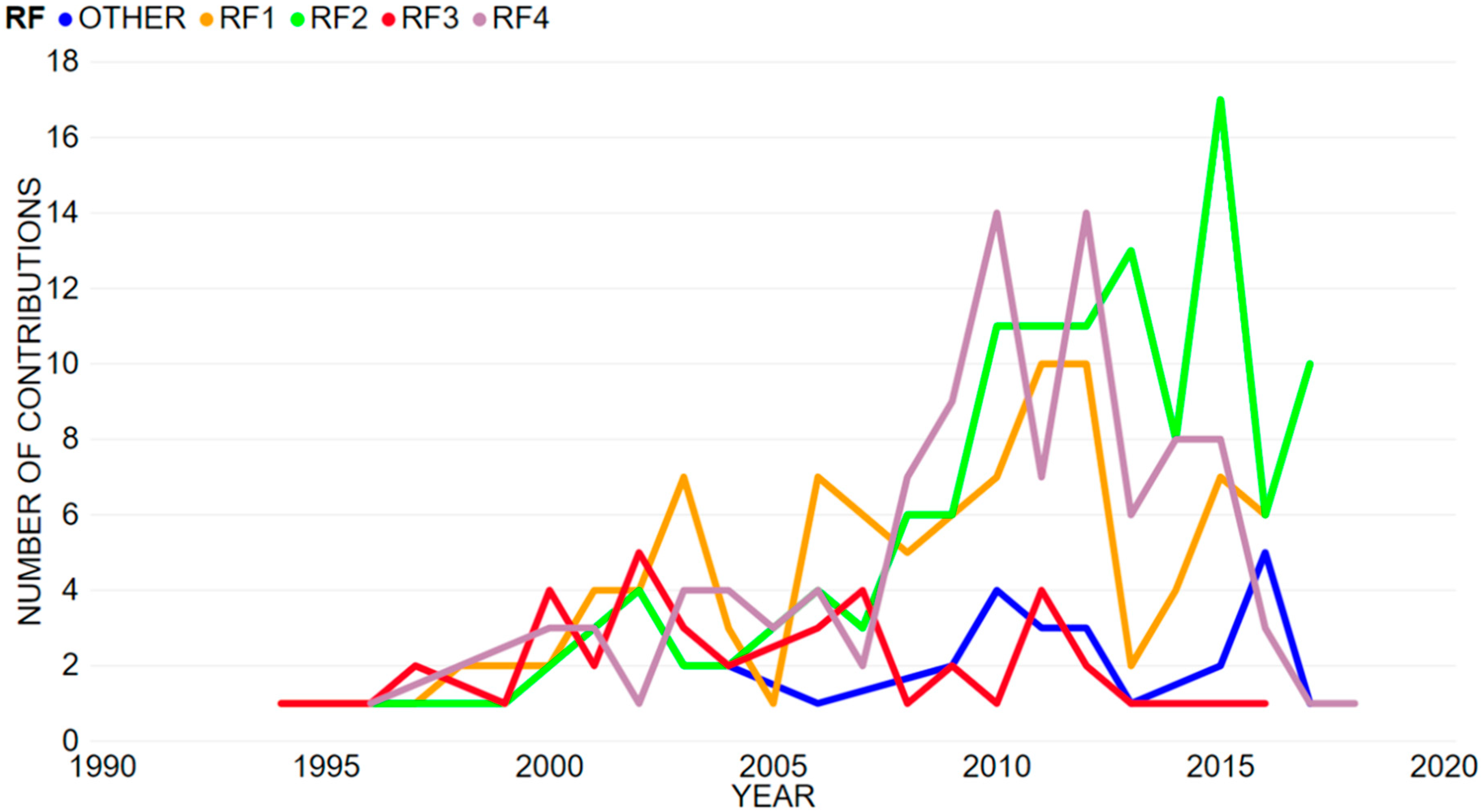

- Besides the initial interest on standard themes about CBM (RF1 and RF3), there is a common ground interest on these topics over the years

- RF2 is one of the most examined research themes, with a significant increase around 2008 and 2015 and opposite tendency over more recent years

- RF3 can be considered a saturated RF, as for only three contributions belong to it over the last three years

- After 2008, RF4 raised significantly, becoming one of the most investigated CBM research areas in terms of number of contributions

- “Other” research topics seem to be attracting increasing interest in recent years

4. Research Factors

4.1. The Fundamentals of CBM and Its Implementation

4.1.1. Domain-Based CBM Fundamentals

4.1.2. Meta-Dimensions of CBM Fundamentals

4.2. CBM Strategies

4.2.1. Single-Unit Systems

4.2.2. Multi-Component Systems

4.2.3. About Dependencies

4.3. Replacement and Inspections Management and Plan and Actual Machinery Health State

4.3.1. About Inspection

4.3.2. About Replacement

4.4. Prognosis Management and Plan

4.5. Other

4.5.1. Maintenance Scheduling for Wind Farms

4.5.2. Lot-Sizing Optimization for Maintenance

4.5.3. CBM for Electrical Components

5. Discussion

5.1. Bibliometric-Driven Discussion

5.2. Future Research

6. Conclusions

Funding

Conflicts of Interest

Abbreviations

| Abbreviation | Meaning |

| ABR | Age-Based Replacement |

| AHP | Analytic Hierarchy Process |

| CBM | Condition-Based Maintenance |

| CM | Condition Monitoring |

| HMM | Hidden Markov Model |

| HSMM | Hidden Semi-Markov Model |

| ICT | Information And Communication Technology |

| LAD | Logical Analysis Of Data |

| PCA | Principal Component Analysis |

| RCM | Reliability-Centered Maintenance |

| RF | Research Factor |

| RUL | Remaining Useful Life |

| TBM | Time-Based Maintenance |

References

- Lee, J.; Ghaffari, M.; Elmeligy, S. Self-maintenance and engineering immune systems: Towards smarter machines and manufacturing systems. Annu. Rev. Control 2011, 35, 111–122. [Google Scholar] [CrossRef]

- Jardine, A.K.S.; Lin, D.; Banjevic, D. A review on machinery diagnostics and prognostics implementing condition-based maintenance. Mech. Syst. Signal Process. 2006, 20, 1483–1510. [Google Scholar] [CrossRef]

- Baldin, A.E. Global approach to plant maintenance. In Proceedings of the AIPE Conference, Montreal, QC, Cananda, 1 June 1976. [Google Scholar]

- Baldin, A.E. Condition based maintenance: A powerful tool for modern plant management. Terotechnica 1979, 1, 119–129. [Google Scholar]

- Hirani, J.A.; Varadrajan, R. Condition-Based Maintenance. Indian Text. J. 1985, 95, 43–50. [Google Scholar]

- Henry, T.A. The simple approach to condition monitoring. Terotechnical 1979, 1, 131. [Google Scholar]

- Baldin, A.E. Condition-based maintenance. Chem. Eng. 1981, 88, 89–95. [Google Scholar]

- Harrou, F.; Sun, Y.; Madakyaru, M. Kullback-Leibler distance-based enhanced detection of incipient anomalies. J. Loss Prev. Process Ind. 2016, 44, 73–87. [Google Scholar] [CrossRef]

- Wiboonrat, M. Developing diagnostics and prognostics of data center systems implementing with condition-based maintenance. In Proceedings of the IECON 2018—44th Annual Conference of the IEEE Industrial Electronics Society, Washington, DC, USA, 21–23 October 2018; pp. 4901–4906. [Google Scholar]

- Harrou, F.; Sun, Y.; Khadraoui, S. Amalgamation of anomaly-detection indices for enhanced process monitoring. J. Loss Prev. Process Ind. 2016, 40, 365–377. [Google Scholar] [CrossRef]

- Martin, K.F. A review by discussion of condition monitoring and fault diagnosis in machine tools. Int. J. Mach. Tools Manuf. 1994, 34, 527–551. [Google Scholar] [CrossRef]

- Tsang, A.H.C. Condition-based maintenance: Tools and decision making. J. Qual. Maint. Eng. 1995, 1, 3–17. [Google Scholar] [CrossRef]

- Campos, J. Development in the application of ICT in condition monitoring and maintenance. Comput. Ind. 2009, 60, 1–20. [Google Scholar] [CrossRef]

- Si, X.-S.; Wang, W.; Hu, C.-H.; Zhou, D.-H. Remaining useful life estimation—A review on the statistical data driven approaches. Eur. J. Oper. Res. 2011, 213, 1–14. [Google Scholar] [CrossRef]

- Guillén, A.J.; Crespo, A.; Macchi, M.; Gómez, J. On the role of Prognostics and Health Management in advanced maintenance systems. Prod. Plan. Control 2016, 27, 991–1004. [Google Scholar] [CrossRef]

- Kothamasu, R.; Huang, S.H.; Verduin, W.H. System health monitoring and prognostics—A review of current paradigms and practices. Int. J. Adv. Manuf. Technol. 2006, 28, 1012–1024. [Google Scholar] [CrossRef]

- Dragomir, O.E.; Gouriveau, R.; Dragomir, F.; Minca, E.; Zerhouni, N. Review of prognostic problem in condition-based maintenance. In Proceedings of the 2009 European Control Conference, ECC 2009, Budapest, Hungary, 23–26 August 2009; pp. 1587–1592. [Google Scholar]

- Benedettini, O.; Baines, T.S.; Lightfoot, H.W.; Greenough, R.M. State-of-the-art in integrated vehicle health management. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2009, 223, 157–170. [Google Scholar] [CrossRef]

- Jaw, L.C. Recent advancements in aircraft Engine Health Management (EHM) technologies and recommendations for the next step. In Proceedings of the ASME Turbo Expo, Reno-Tahoe, NV, USA, 6–9 June 2005; Volume 1, pp. 683–695. [Google Scholar]

- Klingenberg, W.; de Boer, T.W. Condition-based maintenance in punching/blanking of sheet metal. Int. J. Mach. Tools Manuf. 2008, 48, 589–598. [Google Scholar] [CrossRef]

- Olde Keizer, M.C.A.; Flapper, S.D.P.; Teunter, R.H. Condition-based maintenance policies for systems with multiple dependent components: A review. Eur. J. Oper. Res. 2017, 261, 405–420. [Google Scholar] [CrossRef]

- Heng, A.; Zhang, S.; Tan, A.C.C.; Mathew, J. Rotating machinery prognostics: State of the art, challenges and opportunities. Mech. Syst. Signal Process. 2009, 23, 724–739. [Google Scholar] [CrossRef]

- UNI EN 13306:2018 - Maintenance—Maintenance Terminology. 2018. Available online: http://store.uni.com/catalogo/uni-en-13306-2018?josso_back_to=http://store.uni.com/josso-security-check.php&josso_cmd=login_optional&josso_partnerapp_host=store.uni.com (accessed on 7 June 2020).

- Elsevier, Scopus, An Eye on Global Research. 2018. Available online: https://www.elsevier.com/solutions/scopus (accessed on 7 June 2020).

- Shafique, M. Thinking inside the box? Intellectual structure of the knowledge base of innovation research (1988–2008). Strateg. Manag. J. 2013, 34, 62–93. [Google Scholar] [CrossRef]

- Di Stefano, G.; Gambardella, A.; Verona, G. Technology push and demand pull perspectives in innovation studies: Current findings and future research directions. Res. Policy 2012, 41, 1283–1295. [Google Scholar] [CrossRef]

- Patriarca, R.; Bergström, J.; Di Gravio, G.; Costantino, F. Resilience engineering: Current status of the research and future challenges. Saf. Sci. 2018, 102, 79–100. [Google Scholar] [CrossRef]

- Al-Douri, Y.K.; Tretten, P.; Karim, R. Improvement of railway performance: A study of Swedish railway infrastructure. J. Mod. Transp. 2016, 24, 22–37. [Google Scholar] [CrossRef]

- Guillén, A.J.; Crespo, A.; Gómez, J.F.; Sanz, M.D. A framework for effective management of condition based maintenance programs in the context of industrial development of E-Maintenance strategies. Comput. Ind. 2016, 82, 170–185. [Google Scholar] [CrossRef]

- Coraddu, A.; Oneto, L.; Ghio, A.; Savio, S.; Anguita, D.; Figari, M. Machine learning approaches for improving condition-based maintenance of naval propulsion plants. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2016, 230, 136–153. [Google Scholar] [CrossRef]

- Arts, R.H.P.M.; Knapp, G.M.; Mann, L. Some aspects of measuring maintenance performance in the process industry. J. Qual. Maint. Eng. 1998, 4, 6–11. [Google Scholar] [CrossRef]

- Horner, R.M.W.; El-Haram, M.A.; Munns, A.K. Building maintenance strategy: A new management approach. J. Qual. Maint. Eng. 1997, 3, 273–280. [Google Scholar] [CrossRef]

- Edwards, D.J.; Holt, G.D.; Harris, F.C. Predictive maintenance techniques and their relevance to construction plant. J. Qual. Maint. Eng. 1998, 4, 25–37. [Google Scholar] [CrossRef]

- Galar, D.; Kumar, U.; Villarejo, R.; Johansson, C.-A. Hybrid prognosis for railway health assessment: An information fusion approach for PHM deployment. Chem. Eng. Trans. 2013, 33, 769–774. [Google Scholar]

- Su, Z.; Núñez, A.; Jamshidi, A.; Baldi, S.; Li, Z.; Dollevoet, R.; De Schutter, B. Model Predictive Control for Maintenance Operations Planning of Railway Infrastructures. In Proceedings of the 6th International Conference on Computational Logistics, ICCL 2015, Delft, The Netherlands, 23–25 September 2015; Volume 9335, ISBN 9783319242637. [Google Scholar]

- Berdinyazov, A.; Camci, F.; Baskan, S.; Sevkli, M.; Eldemir, F. Economic analysis of condition based maintenance. Int. J. Ind. Eng. Theory Appl. Pract. 2011, 18, 386–403. [Google Scholar]

- Basurko, O.C.; Uriondo, Z. Condition-based maintenance for medium speed diesel engines used in vessels in operation. Appl. Therm. Eng. 2015, 80, 404–412. [Google Scholar] [CrossRef]

- Kacprzynski, G.J.; Gumina, M.; Roemer, M.J.; Caguiat, D.E.; Galie, T.R.; McGroarty, J.J. A prognostic modeling approach for predicting recurring maintenance for shipboard propulsion systems. In Proceedings of the ASME Turbo Expo, New Orleans, LA, USA, 4–7 June 2001; Volume 1. [Google Scholar]

- Altosole, M.; Campora, U.; Martelli, M.; Figari, M. Performance decay analysis of a marine gas turbine propulsion system. J. Ship Res. 2014, 58, 117–129. [Google Scholar] [CrossRef]

- Bond, L.J.; Doctor, S.R.; Griffin, J.W.; Hull, A.B.; Malik, S.N. Damage assessment technologies for prognostics and proactive management of materials degradation. Nucl. Technol. 2011, 173, 46–55. [Google Scholar] [CrossRef]

- Jarrell, D.B.; Sisk, D.R.; Bond, L.J. Prognostics and condition-based maintenance: A new approach to precursive metrics. Nucl. Technol. 2004, 145, 275–286. [Google Scholar] [CrossRef]

- Dunsdon, J.; Harrington, M. The application of Open system architecture for condition based maintenance to complete IVHM. In Proceedings of the IEEE Aerospace Conference Proceedings, Big Sky, MT, USA, 1–8 March 2008. [Google Scholar]

- Luo, J.; Namburu, M.; Pattipati, K.; Qiao, L.; Kawamoto, M.; Chigusa, S. Model-based Prognostic Techniques. In Proceedings of the AUTOTESTCON (Proceedings), Anaheim, CA, USA, 22–25 September 2003; pp. 330–340. [Google Scholar]

- Ogaji, S.O.T.; Singh, R. Advanced engine diagnostics using artificial neural networks. Appl. Soft Comput. J. 2003, 3, 259–271. [Google Scholar] [CrossRef]

- Greenough, R.M.; Grubic, T. Modelling condition-based maintenance to deliver a service to machine tool users. Int. J. Adv. Manuf. Technol. 2011, 52, 1117–1132. [Google Scholar] [CrossRef]

- Tsoutsanis, E.; Meskin, N.; Benammar, M.; Khorasani, K. A dynamic prognosis scheme for flexible operation of gas turbines. Appl. Energy 2016, 164, 686–701. [Google Scholar] [CrossRef]

- Wiggelinkhuizen, E.; Verbruggen, T.; Braam, H.; Rademakers, L.; Xiang, J.; Watson, S. Assessment of condition monitoring techniques for offshore wind farms. J. Sol. Energy Eng. Trans. ASME 2008, 130, 0310041–0310049. [Google Scholar] [CrossRef]

- Zhou, D.; Zhang, H.; Weng, S. A novel prognostic model of performance degradation trend for power machinery maintenance. Energy 2014, 78, 740–746. [Google Scholar] [CrossRef]

- Veldman, J.; Klingenberg, W.; Wortmann, H. Managing condition-based maintenance technology: A multiple case study in the process industry. J. Qual. Maint. Eng. 2011, 17, 40–62. [Google Scholar] [CrossRef]

- Waeyenbergh, G.; Pintelon, L. Maintenance concept development: A case study. Int. J. Prod. Econ. 2004, 89, 395–405. [Google Scholar] [CrossRef]

- Niu, G.; Yang, B.-S.; Pecht, M. Development of an optimized condition-based maintenance system by data fusion and reliability-centered maintenance. Reliab. Eng. Syst. Saf. 2010, 95, 786–796. [Google Scholar] [CrossRef]

- Lehtonen, M. On the optimal strategies of condition monitoring and maintenance allocation in distribution systems. In Proceedings of the 2006 9th International Conference on Probabilistic Methods Applied to Power Systems, PMAPS, Stockholm, Sweden, 11–15 June 2006. [Google Scholar]

- Moore, W.J.; Starr, A.G. An intelligent maintenance system for continuous cost-based prioritisation of maintenance activities. Comput. Ind. 2006, 57, 595–606. [Google Scholar] [CrossRef]

- Wang, L.; Chu, J.; Wu, J. Selection of optimum maintenance strategies based on a fuzzy analytic hierarchy process. Int. J. Prod. Econ. 2007, 107, 151–163. [Google Scholar] [CrossRef]

- Arunraj, N.S.; Maiti, J. Risk-based maintenance policy selection using AHP and goal programming. Saf. Sci. 2010, 48, 238–247. [Google Scholar] [CrossRef]

- Bevilacqua, M.; Braglia, M. Analytic hierarchy process applied to maintenance strategy selection. Reliab. Eng. Syst. Saf. 2000, 70, 71–83. [Google Scholar] [CrossRef]

- Ly, C.; Tom, K.; Byington, C.S.; Patrick, R.; Vachtsevanos, G.J. Fault diagnosis and failure prognosis for engineering systems: A global perspective. In Proceedings of the 2009 IEEE International Conference on Automation Science and Engineering, CASE 2009, Bangalore, India, 22–25 August 2009; pp. 108–115. [Google Scholar]

- Mortada, M.-A.; Yacout, S.; Lakis, A. Diagnosis of rotor bearings using logical analysis of data. J. Qual. Maint. Eng. 2011, 17, 371–397. [Google Scholar] [CrossRef]

- Bennane, A.; Yacout, S. LAD-CBM; New data processing tool for diagnosis and prognosis in condition-based maintenance. J. Intell. Manuf. 2012, 23, 265–275. [Google Scholar] [CrossRef]

- Mortada, M.-A.; Carroll III, T.; Yacout, S.; Lakis, A. Rogue components: Their effect and control using logical analysis of data. J. Intell. Manuf. 2012, 23, 289–302. [Google Scholar] [CrossRef]

- Kothamasu, R.; Huang, S.H. Adaptive Mamdani fuzzy model for condition-based maintenance. Fuzzy Sets Syst. 2007, 158, 2715–2733. [Google Scholar] [CrossRef]

- Ciarapica, F.E.; Giacchetta, G. Managing the condition-based maintenance of a combined-cycle power plant: An approach using soft computing techniques. J. Loss Prev. Process Ind. 2006, 19, 316–325. [Google Scholar] [CrossRef]

- Yam, R.C.M.; Tse, P.W.; Li, L.; Tu, P. Intelligent predictive decision support system for condition-based maintenance. Int. J. Adv. Manuf. Technol. 2001, 17, 383–391. [Google Scholar] [CrossRef]

- Wu, F.; Wang, T.; Lee, J. An online adaptive condition-based maintenance method for mechanical systems. Mech. Syst. Signal Process. 2010, 24, 2985–2995. [Google Scholar] [CrossRef]

- Garga, A.K.; McClintic, K.T.; Campbell, R.L.; Yang, C.-C.; Lebold, M.S.; Hay, T.A.; Byington, C.S. Hybrid reasoning for prognostic learning in CBM systems. IEEE Aerosp. Conf. Proc. 2001, 6, 62957–62969. [Google Scholar]

- Tsang, A.H.C.; Yeung, W.K.; Jardine, A.K.S.; Leung, B.P.K. Data management for CBM optimization. J. Qual. Maint. Eng. 2006, 12, 37–51. [Google Scholar] [CrossRef]

- Fumagalli, L.; Macchi, M.; Rapaccini, M. Computerized maintenance management systems in SMEs: A survey in Italy and some remarks for the implementation of Condition Based Maintenance. IFAC Proc. Vol. (IFAC-PapersOnline) 2009, 13, 1615–1619. [Google Scholar] [CrossRef]

- Campos, J.; Jantunen, E.; Prakash, O. A web and mobile device architecture for mobile e-maintenance. Int. J. Adv. Manuf. Technol. 2009, 45, 71–80. [Google Scholar] [CrossRef]

- Goyal, D.; Pabla, B.S. Condition based maintenance of machine tools–A review. CIRP J. Manuf. Sci. Technol. 2015, 10, 24–35. [Google Scholar] [CrossRef]

- Galar, D.; Palo, M.; Van Horenbeek, A.; Pintelon, L. Integration of disparate data sources to perform maintenance prognosis and optimal decision making. Insight Non-Destr. Test. Cond. Monit. 2012, 54, 440–445. [Google Scholar] [CrossRef]

- Prajapati, A.; Bechtel, J.; Ganesan, S. Condition based maintenance: A survey. J. Qual. Maint. Eng. 2012, 18, 384–400. [Google Scholar] [CrossRef]

- Koochaki, J.; Bokhorst, J.; Wortmann, H.; Klingenberg, W. Evaluating condition based maintenance effectiveness for two processes in series. J. Qual. Maint. Eng. 2011, 17, 398–414. [Google Scholar] [CrossRef]

- Do, P.; Voisin, A.; Levrat, E.; Iung, B. A proactive condition-based maintenance strategy with both perfect and imperfect maintenance actions. Reliab. Eng. Syst. Saf. 2015, 133, 22–32. [Google Scholar] [CrossRef]

- Rasmekomen, N.; Parlikad, A.K. Condition-based maintenance of multi-component systems with degradation state-rate interactions. Reliab. Eng. Syst. Saf. 2016, 148, 1–10. [Google Scholar] [CrossRef]

- Tian, Z.; Liao, H. Condition based maintenance optimization for multi-component systems using proportional hazards model. Reliab. Eng. Syst. Saf. 2011, 96, 581–589. [Google Scholar] [CrossRef]

- Huynh, K.T.; Barros, A.; Bérenguer, C.; Castro, I.T. A periodic inspection and replacement policy for systems subject to competing failure modes due to degradation and traumatic events. Reliab. Eng. Syst. Saf. 2011, 96, 497–508. [Google Scholar] [CrossRef]

- Deloux, E.; Castanier, B.; Bérenguer, C. Predictive maintenance policy for a gradually deteriorating system subject to stress. Reliab. Eng. Syst. Saf. 2009, 94, 418–431. [Google Scholar] [CrossRef][Green Version]

- Berrade, M.D.; Scarf, P.A.; Cavalcante, C.A.V.; Dwight, R.A. Imperfect inspection and replacement of a system with a defective state: A cost and reliability analysis. Reliab. Eng. Syst. Saf. 2013, 120, 80–87. [Google Scholar] [CrossRef]

- Liu, B.; Liang, Z.; Parlikad, A.K.; Xie, M.; Kuo, W. Condition-based maintenance for systems with aging and cumulative damage based on proportional hazards model. Reliab. Eng. Syst. Saf. 2017, 168, 200–209. [Google Scholar] [CrossRef]

- Olde Keizer, M.C.A.; Teunter, R.H.; Veldman, J. Joint condition-based maintenance and inventory optimization for systems with multiple components. Eur. J. Oper. Res. 2017, 257, 209–222. [Google Scholar] [CrossRef]

- Bouvard, K.; Artus, S.; Bérenguer, C.; Cocquempot, V. Condition-based dynamic maintenance operations planning & grouping. Application to commercial heavy vehicles. Reliab. Eng. Syst. Saf. 2011, 96, 601–610. [Google Scholar]

- Alaswad, S.; Xiang, Y. A review on condition-based maintenance optimization models for stochastically deteriorating system. Reliab. Eng. Syst. Saf. 2017, 157, 54–63. [Google Scholar] [CrossRef]

- Flage, R.; Coit, D.W.; Luxhøj, J.T.; Aven, T. Safety constraints applied to an adaptive Bayesian condition-based maintenance optimization model. Reliab. Eng. Syst. Saf. 2012, 102, 16–26. [Google Scholar] [CrossRef]

- Tian, Z.; Jin, T.; Wu, B.; Ding, F. Condition based maintenance optimization for wind power generation systems under continuous monitoring. Renew. Energy 2011, 36, 1502–1509. [Google Scholar] [CrossRef]

- Shi, H.; Zeng, J. Real-time prediction of remaining useful life and preventive opportunistic maintenance strategy for multi-component systems considering stochastic dependence. Comput. Ind. Eng. 2016, 93, 192–204. [Google Scholar] [CrossRef]

- Nguyen, K.-A.; Do, P.; Grall, A. Multi-level predictive maintenance for multi-component systems. Reliab. Eng. Syst. Saf. 2015, 144, 83–94. [Google Scholar] [CrossRef]

- Shafiee, M.; Finkelstein, M.; Bérenguer, C. An opportunistic condition-based maintenance policy for offshore wind turbine blades subjected to degradation and environmental shocks. Reliab. Eng. Syst. Saf. 2015, 142, 463–471. [Google Scholar] [CrossRef]

- Castanier, B.; Grall, A.; Bérenguer, C. A condition-based maintenance policy with non-periodic inspections for a two-unit series system. Reliab. Eng. Syst. Saf. 2005, 87, 109–120. [Google Scholar] [CrossRef]

- Li, H.; Deloux, E.; Dieulle, L. A condition-based maintenance policy for multi-component systems with Lévy copulas dependence. Reliab. Eng. Syst. Saf. 2016, 149, 44–55. [Google Scholar] [CrossRef]

- Van, P.D.; Bérenguer, C. Condition based maintenance model for a production deteriorating system. In Proceedings of the Conference on Control and Fault-Tolerant Systems, SysTol’10—Final Program and Book of Abstracts, Nice, France, 6–8 October 2010; pp. 424–429. [Google Scholar]

- Van, P.D.; Bérenguer, C. Condition-based maintenance with imperfect preventive repairs for a deteriorating production system. Qual. Reliab. Eng. Int. 2012, 28, 624–633. [Google Scholar] [CrossRef]

- Wang, L.; Chu, J.; Mao, W. A condition-based order-replacement policy for a single-unit system. Appl. Math. Model. 2008, 32, 2274–2289. [Google Scholar] [CrossRef]

- Huynh, K.T.; Barros, A.; Bérenguer, C. Maintenance decision-making for systems operating under indirect condition monitoring: Value of online information and impact of measurement uncertainty. IEEE Trans. Reliab. 2012, 61, 410–425. [Google Scholar] [CrossRef][Green Version]

- Huynh, T.K.; Barros, A.; Bérenguer, C. A reliability-based opportunistic predictive maintenance model for k-out-of-n deteriorating systems. Chem. Eng. Trans. 2013, 33, 493–498. [Google Scholar]

- Chouikhi, H.; Khatab, A.; Rezg, N. A condition-based maintenance policy for a production system under excessive environmental degradation. J. Intell. Manuf. 2014, 25, 727–737. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhou, Y.; Sun, Y.; Ma, L. Condition-based maintenance optimisation without a predetermined strategy structure for a two-component series system | Optymalizacja zależnego od stanu technicznego utrzymania urza{ogonek}dzeń dla dwuskładnikowego systemu szeregowego nie wymagaja{ogonek}. Eksploat. Niezawodn. 2012, 14, 120–129. [Google Scholar]

- Huynh, K.T.; Barros, A.; Bérenguer, C. Multi-level decision-making for the predictive maintenance of k-out-of-n:F deteriorating systems. IEEE Trans. Reliab. 2015, 64, 94–117. [Google Scholar] [CrossRef]

- Verbert, K.; De Schutter, B.; Babuška, R. Timely condition-based maintenance planning for multi-component systems. Reliab. Eng. Syst. Saf. 2017, 159, 310–321. [Google Scholar] [CrossRef]

- Zhu, Q.; Peng, H.; van Houtum, G.-J. A condition-based maintenance policy for multi-component systems with a high maintenance setup cost. OR Spectr. 2015, 37, 1007–1035. [Google Scholar] [CrossRef]

- Koochaki, J.; Bokhorst, J.A.C.; Wortmann, H.; Klingenberg, W. The influence of condition-based maintenance on workforce planning and maintenance scheduling. Int. J. Prod. Res. 2013, 51, 2339–2351. [Google Scholar] [CrossRef]

- Asadzadeh, S.M.; Azadeh, A. An integrated systemic model for optimization of condition-based maintenance with human error. Reliab. Eng. Syst. Saf. 2014, 124, 117–131. [Google Scholar] [CrossRef]

- Van Horenbeek, A.; Pintelon, L. A dynamic predictive maintenance policy for complex multi-component systems. Reliab. Eng. Syst. Saf. 2013, 120, 39–50. [Google Scholar] [CrossRef]

- Huynh, K.T.; Castro, I.T.; Barros, A.; Berenguer, C. On the use of mean residual life as a condition index for condition-based maintenance decision-making. IEEE Trans. Syst. Man Cybern. Syst. 2014, 44, 877–893. [Google Scholar] [CrossRef]

- Huynh, K.T.; Grall, A.; Bérenguer, C. Assessment of diagnostic and prognostic condition indices for efficient and robust maintenance decision-making of systems subject to stress corrosion cracking. Reliab. Eng. Syst. Saf. 2017, 159, 237–254. [Google Scholar] [CrossRef]

- de Jonge, B.; Teunter, R.; Tinga, T. The influence of practical factors on the benefits of condition-based maintenance over time-based maintenance. Reliab. Eng. Syst. Saf. 2017, 158, 21–30. [Google Scholar] [CrossRef]

- Kim, M.J.; Makis, V. Joint optimization of sampling and control of partially observable failing systems. Oper. Res. 2013, 61, 777–790. [Google Scholar] [CrossRef]

- Marseguerra, M.; Zio, E.; Podofillini, L. Condition-based maintenance optimization by means of genetic algorithms and Monte Carlo simulation. Reliab. Eng. Syst. Saf. 2002, 77, 151–165. [Google Scholar] [CrossRef]

- Barata, J.; Soares, C.G.; Marseguerra, M.; Zio, E. Simulation modelling of repairable multi-component deteriorating systems for “on condition” maintenance optimisation. Reliab. Eng. Syst. Saf. 2002, 76, 255–264. [Google Scholar] [CrossRef]

- Byon, E.; Ding, Y. Season-dependent condition-based maintenance for a wind turbine using a partially observed markov decision process. IEEE Trans. Power Syst. 2010, 25, 1823–1834. [Google Scholar] [CrossRef]

- Zhao, X.; Fouladirad, M.; Bérenguer, C.; Bordes, L. Condition-based inspection/replacement policies for non-monotone deteriorating systems with environmental covariates. Reliab. Eng. Syst. Saf. 2010, 95, 921–934. [Google Scholar] [CrossRef]

- Wang, L.; Zheng, E.; Li, Y.; Wang, B.; Wu, J. Maintenance optimization of generating equipment based on a condition-based maintenance policy for multi-unit systems. In Proceedings of the 2009 Chinese Control and Decision Conference, CCDC 2009, Guilin, China, 17–19 June 2009; pp. 2440–2445. [Google Scholar]

- Naderkhani, Z.G.F.; Makis, V. Optimal condition-based maintenance policy for a partially observable system with two sampling intervals. Int. J. Adv. Manuf. Technol. 2015, 78, 795–805. [Google Scholar] [CrossRef]

- Liao, H.; Elsayed, E.A.; Chan, L.-Y. Maintenance of continuously monitored degrading systems. Eur. J. Oper. Res. 2006, 175, 821–835. [Google Scholar] [CrossRef]

- Tan, L.; Cheng, Z.; Guo, B.; Gong, S. Condition-based maintenance policy for gamma deteriorating systems. J. Syst. Eng. Electron. 2010, 21, 57–61. [Google Scholar] [CrossRef]

- Feng, Q.; Bi, X.; Zhao, X.; Chen, Y.; Sun, B. Heuristic hybrid game approach for fleet condition-based maintenance planning. Reliab. Eng. Syst. Saf. 2017, 157, 166–176. [Google Scholar] [CrossRef]

- Camci, F. System maintenance scheduling with prognostics information using genetic algorithm. IEEE Trans. Reliab. 2009, 58, 539–552. [Google Scholar] [CrossRef]

- Wang, L.; Chu, J.; Mao, W. A condition-based replacement and spare provisioning policy for deteriorating systems with uncertain deterioration to failure. Eur. J. Oper. Res. 2009, 194, 184–205. [Google Scholar] [CrossRef]

- El-Thalji, I.; Jantunen, E. On the development of condition based maintenance strategy for offshore wind farm: Requirement elicitation process. Energy Procedia 2012, 24, 328–339. [Google Scholar] [CrossRef]

- Caballé, N.C.; Castro, I.T.; Pérez, C.J.; Lanza-Gutiérrez, J.M. A condition-based maintenance of a dependent degradation-threshold-shock model in a system with multiple degradation processes. Reliab. Eng. Syst. Saf. 2015, 134, 98–109. [Google Scholar] [CrossRef]

- Castro, I.T.; Caballé, N.C.; Pérez, C.J. A condition-based maintenance for a system subject to multiple degradation processes and external shocks. Int. J. Syst. Sci. 2015, 46, 1692–1704. [Google Scholar] [CrossRef]

- Li, W.; Pham, H. An inspection-maintenance model for systems with multiple competing processes. IEEE Trans. Reliab. 2005, 54, 318–327. [Google Scholar] [CrossRef]

- Chen, D.; Trivedi, K.S. Closed-form analytical results for condition-based maintenance. Reliab. Eng. Syst. Saf. 2002, 76, 43–51. [Google Scholar] [CrossRef]

- Liu, X.; Li, J.; Al-Khalifa, K.N.; Hamouda, A.S.; Coit, D.W.; Elsayed, E.A. Condition-based maintenance for continuously monitored degrading systems with multiple failure modes. IIE Trans. 2013, 45, 422–435. [Google Scholar] [CrossRef]

- Olde Keizer, M.C.A.; Teunter, R.H.; Veldman, J. Clustering condition-based maintenance for systems with redundancy and economic dependencies. Eur. J. Oper. Res. 2016, 251, 531–540. [Google Scholar] [CrossRef]

- Do, P.; Scarf, P.; Lung, B. Condition-based maintenance for a two-component system with dependencies. IFAC-PapersOnLine 2015, 28, 946–951. [Google Scholar] [CrossRef]

- Nguyen, K.-A.; Do, P.; Grall, A. Condition-based maintenance for multi-component systems using importance measure and predictive information. Int. J. Syst. Sci. Oper. Logist. 2014, 1, 228–245. [Google Scholar] [CrossRef]

- Qian, X.; Wu, Y. Dynamic control-limit policy of condition based maintenance for the hydroelectricity generating unit. Int. J. Secur. Appl. 2014, 8, 95–106. [Google Scholar] [CrossRef]

- De Smidt-Destombes, K.S.; Van der Heijden, M.C.; Van Harten, A. On the availability of a k-out-of-N system given limited spares and repair capacity under a condition based maintenance strategy. Reliab. Eng. Syst. Saf. 2004, 83, 287–300. [Google Scholar] [CrossRef]

- Hong, H.P.; Zhou, W.; Zhang, S.; Ye, W. Optimal condition-based maintenance decisions for systems with dependent stochastic degradation of components. Reliab. Eng. Syst. Saf. 2014, 121, 276–288. [Google Scholar] [CrossRef]

- Shafiee, M.; Finkelstein, M. A proactive group maintenance policy for continuously monitored deteriorating systems: Application to offshore wind turbines. Proc. Inst. Mech. Eng. Part O J. Risk Reliab. 2015, 229, 373–384. [Google Scholar] [CrossRef]

- Liang, Z.; Parlikad, A.K. A tiered modelling approach for condition-based maintenance of industrial assets with load sharing interaction and fault propagation. IMA J. Manag. Math. 2015, 26, 125–144. [Google Scholar] [CrossRef]

- Zhang, Z.; Wu, S.; Lee, S.; Ni, J. Modified iterative aggregation procedure for maintenance optimisation of multi-component systems with failure interaction. Int. J. Syst. Sci. 2014, 45, 2480–2489. [Google Scholar] [CrossRef]

- Golmakani, H.R. Optimal age-based inspection scheme for condition-based maintenance using A* search algorithm. Int. J. Prod. Res. 2012, 50, 7068–7080. [Google Scholar] [CrossRef]

- Jardine, A.K.S. Optimizing condition based maintenance decisions. In Proceedings of the Annual Reliability and Maintainability Symposium, Seattle, WA, USA, 28–31 January 2002; pp. 90–97. [Google Scholar]

- Chen, A.; Wu, G.S. Real-time health prognosis and dynamic preventive maintenance policy for equipment under aging Markovian deterioration. Int. J. Prod. Res. 2007, 45, 3351–3379. [Google Scholar] [CrossRef]

- Yang, S.K. An experiment of state estimation for predictive maintenance using Kalman filter on a DC motor. Reliab. Eng. Syst. Saf. 2002, 75, 103–111. [Google Scholar] [CrossRef]

- Saranga, H.; Knezevic, J. Reliability prediction for condition-based maintained systems. Reliab. Eng. Syst. Saf. 2001, 71, 219–224. [Google Scholar] [CrossRef]

- Hontelez, J.A.M.; Burger, H.H.; Wijnmalen, D.J.D. Optimum condition-based maintenance policies for deteriorating systems with partial information. Reliab. Eng. Syst. Saf. 1996, 51, 267–274. [Google Scholar] [CrossRef]

- Ghasemi, A.; Esmaeili, S.; Yacout, S. Development of equipment failure prognostics model based on Logical Analysis of Data (LAD). Eng. Lett. 2013, 21, 256–263. [Google Scholar]

- Lin, D.; Makis, V. Filters and parameter estimation for a partially observable system subject to random failure with continuous-range observations. Adv. Appl. Probab. 2004, 36, 1212–1230. [Google Scholar] [CrossRef]

- Lin, D.; Makis, V. On-line parameter estimation for a failure-prone system subject to condition monitoring. J. Appl. Probab. 2004, 41, 211–220. [Google Scholar] [CrossRef]

- Lin, D.; Banjevic, D.; Jardine, A.K.S. Using principal components in a proportional hazards model with applications in condition-based maintenance. J. Oper. Res. Soc. 2006, 57, 910–919. [Google Scholar] [CrossRef]

- Banjevic, D.; Jardine, A.K.S.; Makis, V.; Ennis, M. A control-limit policy and software for condition-based maintenance optimization. INFOR 2001, 39, 32–50. [Google Scholar] [CrossRef]

- Ohnishi, M.; Morioka, T.; Ibaraki, T. Optimal minimal-repair and replacement problem of discrete-time Markovian deterioration system under incomplete state information. Comput. Ind. Eng. 1994, 27, 409–412. [Google Scholar] [CrossRef]

- Makis, V.; Jiang, X. Optimal replacement under partial observations. Math. Oper. Res. 2003, 28, 382–394. [Google Scholar] [CrossRef]

- Grall, A.; Bérenguer, C.; Dieulle, L. A condition-based maintenance policy for stochastically deteriorating systems. Reliab. Eng. Syst. Saf. 2002, 76, 167–180. [Google Scholar] [CrossRef]

- Golmakani, H.R.; Pouresmaeeli, M. Optimal replacement policy for condition-based maintenance with non-decreasing failure cost and costly inspection. J. Qual. Maint. Eng. 2014, 20, 51–64. [Google Scholar] [CrossRef]

- Wang, W. A model to determine the optimal critical level and the monitoring intervals in condition-based maintenance. Int. J. Prod. Res. 2000, 38, 1425–1436. [Google Scholar] [CrossRef]

- Li, L.; You, M.; Ni, J. Reliability-based dynamic maintenance threshold for failure prevention of continuously monitored degrading systems. J. Manuf. Sci. Eng. Trans. ASME 2009, 131, 0310101–0310109. [Google Scholar] [CrossRef]

- Castanier, B.; Bérenguer, C.; Grall, A. A sequential condition-based repair/replacement policy with non-periodic inspections for a system subject to continuous wear. Appl. Stoch. Model. Bus. Ind. 2003, 19, 327–347. [Google Scholar] [CrossRef]

- Golmakani, H.R. Condition-based inspection scheme for condition-based maintenance. Int. J. Prod. Res. 2012, 50, 3920–3935. [Google Scholar] [CrossRef]

- Golmakani, H.R.; Fattahipour, F. Age-based inspection scheme for condition-based maintenance. J. Qual. Maint. Eng. 2011, 17, 93–110. [Google Scholar] [CrossRef]

- Vlok, P.J.; Coetzee, J.L.; Banjevic, D.; Jardine, A.K.S.; Makis, V. Optimal component replacement decisions using vibration monitoring and the proportional-hazards model. J. Oper. Res. Soc. 2002, 53, 193–202. [Google Scholar] [CrossRef]

- Lei, Y.; Li, N.; Guo, L.; Li, N.; Yan, T.; Lin, J. Machinery health prognostics: A systematic review from data acquisition to RUL prediction. Mech. Syst. Signal Process. 2018, 104, 799–834. [Google Scholar] [CrossRef]

- Ray, A.; Tangirala, S. Stochastic modeling of fatigue crack dynamics for on-line failure prognostics. IEEE Trans. Control Syst. Technol. 1996, 4, 443–451. [Google Scholar] [CrossRef]

- Le Son, K.; Fouladirad, M.; Barros, A.; Levrat, E.; Lung, B. Remaining useful life estimation based on stochastic deterioration models: A comparative study. Reliab. Eng. Syst. Saf. 2013, 112, 165–175. [Google Scholar] [CrossRef]

- Medjaher, K.; Tobon-Mejia, D.A.; Zerhouni, N. Remaining useful life estimation of critical components with application to bearings. IEEE Trans. Reliab. 2012, 61, 292–302. [Google Scholar] [CrossRef]

- Tobon-Mejia, D.A.; Medjaher, K.; Zerhouni, N.; Tripot, G. A data-driven failure prognostics method based on mixture of gaussians hidden markov models. IEEE Trans. Reliab. 2012, 61, 491–503. [Google Scholar] [CrossRef]

- Liu, Q.; Dong, M.; Peng, Y. A novel method for online health prognosis of equipment based on hidden semi-Markov model using sequential Monte Carlo methods. Mech. Syst. Signal Process. 2012, 32, 331–348. [Google Scholar] [CrossRef]

- Ben Ali, J.; Chebel-Morello, B.; Saidi, L.; Malinowski, S.; Fnaiech, F. Accurate bearing remaining useful life prediction based on Weibull distribution and artificial neural network. Mech. Syst. Signal Process. 2015, 56, 150–172. [Google Scholar] [CrossRef]

- Pan, Y.; Chen, J.; Li, X. Bearing performance degradation assessment based on lifting wavelet packet decomposition and fuzzy c-means. Mech. Syst. Signal Process. 2010, 24, 559–566. [Google Scholar] [CrossRef]

- Pan, Y.N.; Chen, J.; Dong, G.M. A hybrid model for bearing performance degradation assessment based on support vector data description and fuzzy c-means. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2009, 223, 2687–2695. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, B.; Vachtsevanos, G.; Orchard, M. Machine condition prediction based on adaptive neuro-fuzzy and high-order particle filtering. IEEE Trans. Ind. Electron. 2011, 58, 4353–4364. [Google Scholar] [CrossRef]

- Caesarendra, W.; Niu, G.; Yang, B.-S. Machine condition prognosis based on sequential Monte Carlo method. Expert Syst. Appl. 2010, 37, 2412–2420. [Google Scholar] [CrossRef]

- Barraza-Barraza, D.; Tercero-Gómez, V.G.; Beruvides, M.G.; Limón-Robles, J. An adaptive ARX model to estimate the RUL of aluminum plates based on its crack growth. Mech. Syst. Signal Process. 2017, 82, 519–536. [Google Scholar] [CrossRef]

- Camci, F.; Chinnam, R.B. Health-state estimation and prognostics in machining processes. IEEE Trans. Autom. Sci. Eng. 2010, 7, 581–597. [Google Scholar] [CrossRef]

- Sun, J.; Zuo, H.; Wang, W.; Pecht, M.G. Application of a state space modeling technique to system prognostics based on a health index for condition-based maintenance. Mech. Syst. Signal Process. 2012, 28, 585–596. [Google Scholar] [CrossRef]

- Lei, Y.; Li, N.; Lin, J. A New Method Based on Stochastic Process Models for Machine Remaining Useful Life Prediction. IEEE Trans. Instrum. Meas. 2016, 65, 2671–2684. [Google Scholar] [CrossRef]

- Singleton, R.K.; Strangas, E.G.; Aviyente, S. Extended kalman filtering for remaining-useful-life estimation of bearings. IEEE Trans. Ind. Electron. 2015, 62, 1781–1790. [Google Scholar] [CrossRef]

- Carr, M.J.; Wang, W. An approximate algorithm for prognostic modelling using condition monitoring information. Eur. J. Oper. Res. 2011, 211, 90–96. [Google Scholar] [CrossRef]

- Hong, S.; Zhou, Z.; Zio, E.; Hong, K. Condition assessment for the performance degradation of bearing based on a combinatorial feature extraction method. Digit. Signal Process. A Rev. J. 2014, 27, 159–166. [Google Scholar] [CrossRef]

- Loutas, T.H.; Roulias, D.; Georgoulas, G. Remaining useful life estimation in rolling bearings utilizing data-driven probabilistic E-support vectors regression. IEEE Trans. Reliab. 2013, 62, 821–832. [Google Scholar] [CrossRef]

- Yaqub, M.F.; Gondal, I.; Kamruzzaman, J. Multi-step support vector regression and optimally parameterized wavelet packet transform for machine residual life prediction. JVC/J. Vib. Control 2013, 19, 963–974. [Google Scholar] [CrossRef]

- Wang, D.; Miao, Q.; Kang, R. Robust health evaluation of gearbox subject to tooth failure with wavelet decomposition. J. Sound Vib. 2009, 324, 1141–1157. [Google Scholar] [CrossRef]

- Kim, H.-E.; Tan, A.C.C.; Mathew, J.; Choi, B.-K. Bearing fault prognosis based on health state probability estimation. Expert Syst. Appl. 2012, 39, 5200–5213. [Google Scholar] [CrossRef]

- Tran, V.T.; Thom Pham, H.; Yang, B.-S.; Tien Nguyen, T. Machine performance degradation assessment and remaining useful life prediction using proportional hazard model and support vector machine. Mech. Syst. Signal Process. 2012, 32, 320–330. [Google Scholar] [CrossRef]

- Tang, S.-J.; Guo, X.-S.; Yu, C.-Q.; Zhou, Z.-J.; Zhou, Z.-F.; Zhang, B.-C. Real time remaining useful life prediction based on nonlinear Wiener based degradation processes with measurement errors. J. Cent. South Univ. 2014, 21, 4509–4517. [Google Scholar] [CrossRef]

- Camci, F.; Chinnam, R.B. Hierarchical HMMs for autonomous diagnostics and prognostics. In Proceedings of the IEEE International Conference on Neural Networks—Conference Proceedings, Vancouver, BC, Canada, 16–21 July 2006; pp. 2445–2452. [Google Scholar]

- Dong, M.; Yang, Z.-B. Dynamic Bayesian network based prognosis in machining processes. J. Shanghai Jiaotong Univ. 2008, 13E, 318–322. [Google Scholar] [CrossRef]

- Carr, M.J.; Wang, W. Modeling failure modes for residual life prediction using stochastic filtering theory. IEEE Trans. Reliab. 2010, 59, 346–355. [Google Scholar] [CrossRef]

- Heng, A.; Tan, A.C.C.; Mathew, J.; Montgomery, N.; Banjevic, D.; Jardine, A.K.S. Intelligent condition-based prediction of machinery reliability. Mech. Syst. Signal Process. 2009, 23, 1600–1614. [Google Scholar] [CrossRef]

- Guo, L.; Gao, H.; Huang, H.; He, X.; Li, S. Multifeatures Fusion and Nonlinear Dimension Reduction for Intelligent Bearing Condition Monitoring. Shock Vib. 2016, 2016, 1–10. [Google Scholar] [CrossRef]

- Niu, G.; Yang, B.-S. Intelligent condition monitoring and prognostics system based on data-fusion strategy. Expert Syst. Appl. 2010, 37, 8831–8840. [Google Scholar] [CrossRef]

- Tian, Z. An artificial neural network method for remaining useful life prediction of equipment subject to condition monitoring. J. Intell. Manuf. 2012, 23, 227–237. [Google Scholar] [CrossRef]

- Mahamad, A.K.; Saon, S.; Hiyama, T. Predicting remaining useful life of rotating machinery based artificial neural network. Comput. Math. Appl. 2010, 60, 1078–1087. [Google Scholar] [CrossRef]

- Tian, Z.; Zuo, M.J. Health condition prediction of gears using a recurrent neural network approach. IEEE Trans. Reliab. 2010, 59, 700–705. [Google Scholar] [CrossRef]

- Wang, P.; Vachtsevanos, G. Fault prognostics using dynamic wavelet neural networks. Artif. Intell. Eng. Des. Anal. Manuf. AIEDAM 2001, 15, 349–365. [Google Scholar] [CrossRef]

- Baruah, P.; Chinnam, R.B. HMMs for diagnostics and prognostics in machining processes. Int. J. Prod. Res. 2005, 43, 1275–1293. [Google Scholar] [CrossRef]

- Liu, Q.; Dong, M.; Lv, W.; Geng, X.; Li, Y. A novel method using adaptive hidden semi-Markov model for multi-sensor monitoring equipment health prognosis. Mech. Syst. Signal Process. 2015, 64–65, 217–232. [Google Scholar] [CrossRef]

- Yu, J. Health condition monitoring of machines based on hidden markov model and contribution analysis. IEEE Trans. Instrum. Meas. 2012, 61, 2200–2211. [Google Scholar] [CrossRef]

- Zhou, Z.-J.; Hu, C.-H.; Xu, D.-L.; Chen, M.-Y.; Zhou, D.-H. A model for real-time failure prognosis based on hidden Markov model and belief rule base. Eur. J. Oper. Res. 2010, 207, 269–283. [Google Scholar] [CrossRef]

- Chinnam, R.B.; Baruah, P. Autonomous diagnostics and prognostics in machining processes through competitive learning-driven HMM-based clustering. Int. J. Prod. Res. 2009, 47, 6739–6758. [Google Scholar] [CrossRef]

- Dong, M.; He, D. A segmental hidden semi-Markov model (HSMM)-based diagnostics and prognostics framework and methodology. Mech. Syst. Signal Process. 2007, 21, 2248–2266. [Google Scholar] [CrossRef]

- Dong, M.; He, D. Hidden semi-markov models for machinery health diagnosis and prognosis. Trans. N. Am. Manuf. Res. Inst. SME 2004, 32, 199–206. [Google Scholar]

- Jiang, R.; Kim, M.J.; Makis, V. Maximum likelihood estimation for a hidden semi-markov model with multivariate observations. Qual. Reliab. Eng. Int. 2012, 28, 783–791. [Google Scholar] [CrossRef]

- Dong, M.; Peng, Y. Equipment PHM using non-stationary segmental hidden semi-Markov model. Robot. Comput. Integr. Manuf. 2011, 27, 581–590. [Google Scholar] [CrossRef]

- Saxena, A.; Celaya, J.; Balaban, E.; Goebel, K.; Saha, B.; Saha, S.; Schwabacher, M. Metrics for evaluating performance of prognostic techniques. In Proceedings of the 2008 International Conference on Prognostics and Health Management, PHM 2008, Denver, CO, USA, 6–9 October 2008. [Google Scholar]

- Saxena, A.; Celaya, J.; Saha, B.; Saha, S.; Goebel, K. Evaluating algorithm performance metrics tailored for prognostics. In Proceedings of the IEEE Aerospace Conference Proceedings, Big Sky, MT, USA, 7–14 March 2009. [Google Scholar]

- Wang, W.; Zhang, W. An asset residual life prediction model based on expert judgments. Eur. J. Oper. Res. 2008, 188, 496–505. [Google Scholar] [CrossRef]

- Elghazel, W.; Bahi, J.; Guyeux, C.; Hakem, M.; Medjaher, K.; Zerhouni, N. Dependability of wireless sensor networks for industrial prognostics and health management. Comput. Ind. 2015, 68, 1–15. [Google Scholar] [CrossRef]

- Lee, J.; Wu, F.; Zhao, W.; Ghaffari, M.; Liao, L.; Siegel, D. Prognostics and health management design for rotary machinery systems—Reviews, methodology and applications. Mech. Syst. Signal Process. 2014, 42, 314–334. [Google Scholar] [CrossRef]

- Andrawus, J.A.; Watson, J.F.; Kishk, M.; Adam, A. The selection of a suitable maintenance strategy for wind turbines. Wind Eng. 2006, 30, 471–486. [Google Scholar] [CrossRef]

- Sørensen, J.D. Framework for risk-based planning of operation and maintenance for offshore wind turbines. Wind Energy 2009, 12, 493–506. [Google Scholar] [CrossRef]

- Wu, Y.-R.; Zhao, H.-S. Optimization maintenance of wind turbines using Markov decision processes. In Proceedings of the 2010 International Conference on Power System Technology: Technological Innovations Making Power Grid Smarter, POWERCON2010, Hangzhou, China, 24–28 October 2010. [Google Scholar]

- Byon, E.; Pérez, E.; Ding, Y.; Ntaimo, L. Simulation of wind farm operations and maintenance using discrete event system specification. Simulation 2011, 87, 1093–1117. [Google Scholar] [CrossRef]

- Yildirim, M.; Sun, X.A.; Gebraeel, N.Z. Sensor-Driven Condition-Based Generator Maintenance Scheduling—Part I: Maintenance Problem. IEEE Trans. Power Syst. 2016, 31, 4253–4262. [Google Scholar] [CrossRef]

- Yildirim, M.; Sun, X.A.; Gebraeel, N.Z. Sensor-Driven Condition-Based Generator Maintenance Scheduling—Part II: Incorporating Operations. IEEE Trans. Power Syst. 2016, 31, 4263–4271. [Google Scholar] [CrossRef]

- Bouslah, B.; Gharbi, A.; Pellerin, R. Joint economic design of production, continuous sampling inspection and preventive maintenance of a deteriorating production system. Int. J. Prod. Econ. 2016, 173, 184–198. [Google Scholar] [CrossRef]

- Jafari, L.; Makis, V. Optimal lot-sizing and maintenance policy for a partially observable production system. Comput. Ind. Eng. 2016, 93, 88–98. [Google Scholar] [CrossRef]

- Cheng, G.Q.; Zhou, B.H.; Li, L. Joint optimization of lot sizing and condition-based maintenance for multi-component production systems. Comput. Ind. Eng. 2017, 110, 538–549. [Google Scholar] [CrossRef]

- Xu, B.; Han, X.; Li, Y.; Zhang, Y.; Li, M.; Huang, H. Opportunistic maintenance decision-making model for power equipment. Zhongguo Dianji Gongcheng Xuebao/Proc. Chin. Soc. Electr. Eng. 2016, 36, 6379–6388. [Google Scholar]

- Yuan, Z.; Sun, C.; Li, J.; Du, L.; Liao, R. Study on condition-based maintenance policy of transformer based on fuzzy multiple expert and multiple attribute group decision making. Dianli Xitong Zidonghua/Autom. Electr. Power Syst. 2004, 28, 66–70. [Google Scholar]

- Tian, L.; Xing, J.-G. Discussion on making decision about electric equipment for condition based maintenance. Power Syst. Technol. 2004, 28, 60–63. [Google Scholar]

- Li, M.; Han, X.; Yang, M.; Guo, Z. Basic concept and theoretical study of condition-based maintenance for power transmission system. Zhongguo Dianji Gongcheng Xuebao/Proc. Chin. Soc. Electr. Eng. 2011, 31, 43–52. [Google Scholar]

- Pan, L.; Lu, G.; Zhang, Y.; Yu, G.; Zhu, D. Decision-making optimization of equipment condition-based maintenance according to risk comprehensive evaluation. Dianli Xitong Zidonghua/Autom. Electr. Power Syst. 2010, 34, 28–32. [Google Scholar]

- Li, M.; Han, X.; Wang, Y.; Guo, Z.; Liu, G. Decision-making model and solution of condition-based maintenance for substation. Zhongguo Dianji Gongcheng Xuebao/Proc. Chin. Soc. Electr. Eng. 2012, 32, 196–202. [Google Scholar]

- Pan, L.; Zhang, Y.; Yu, G.; Du, C. Prediction of electrical equipment failure rate for condition-based maintenance decision-making. Dianli Zidonghua Shebei/Electr. Power Autom. Equip. 2010, 30, 91–94. [Google Scholar]

- Sun, P.; Chen, S.-H.; Zhang, C.-Q. Assessment of failure rate for substation equipment life cycle based on Marquardt parameter estimation method. Dianli Xitong Baohu yu Kongzhi/Power Syst. Prot. Control 2012, 40, 85–90. [Google Scholar]

- Meeker, W.Q.; Hong, Y. Reliability meets big data: Opportunities and challenges. Qual. Eng. 2014, 26, 102–116. [Google Scholar] [CrossRef]

- Scarf, P.A. On the application of mathematical models in maintenance. Eur. J. Oper. Res. 1997, 99, 493–506. [Google Scholar] [CrossRef]

- Katipamula, S.; Brambley, M.R. Review article: Methods for fault detection, diagnostics, and prognostics for building systems—A review, part I. HVAC R Res. 2005, 11, 3–25. [Google Scholar] [CrossRef]

- Wang, W. A two-stage prognosis model in condition based maintenance. Eur. J. Oper. Res. 2007, 182, 1177–1187. [Google Scholar] [CrossRef]

- Goh, K.M.; Tjahjono, B.; Baines, T.; Subramaniam, S. A review of research in manufacturing prognostics. In Proceedings of the 2006 IEEE International Conference on Industrial Informatics, INDIN’06, Singapore, 16–18 August 2006; pp. 417–422. [Google Scholar]

- Mechefske, C.K.; Wang, Z. Using fuzzy linguistics to select optimum maintenance and condition monitoring strategies. Mech. Syst. Signal Process. 2001, 15, 1129–1140. [Google Scholar] [CrossRef]

- De Jonge, B.; Klingenberg, W.; Teunter, R.; Tinga, T. Reducing costs by clustering maintenance activities for multiple critical units. Reliab. Eng. Syst. Saf. 2016, 145, 93–103. [Google Scholar] [CrossRef]

- Peng, H.; Van Houtum, G.-J. Joint optimization of condition-based maintenance and production lot-sizing. Eur. J. Oper. Res. 2016, 253, 94–107. [Google Scholar] [CrossRef]

- Shin, J.-H.; Jun, H.-B. On condition based maintenance policy. J. Comput. Des. Eng. 2015, 2, 119–127. [Google Scholar] [CrossRef]

- Wang, W. Condition-Based Maintenance Modelling. Springer Ser. Reliab. Eng. 2008, 8, 111–131. [Google Scholar]

- Neves, M.L.; Santiago, L.P.; Maia, C.A. A condition-based maintenance policy and input parameters estimation for deteriorating systems under periodic inspection. Comput. Ind. Eng. 2011, 61, 503–511. [Google Scholar] [CrossRef]

- Ji, G.; Wu, W.; Zhang, B.; Liu, S.; Jiang, W. A time-varying component outage model for power system condition-based maintenance. Zhongguo Dianji Gongcheng Xuebao/Proc. Chin. Soc. Electr. Eng. 2013, 33, 139–146. [Google Scholar]

- Zuashkiani, A.; Banjevic, D.; Jardine, A.K.S. Estimating parameters of proportional hazards model based on expert knowledge and statistical data. J. Oper. Res. Soc. 2009, 60, 1621–1636. [Google Scholar] [CrossRef]

- Galar, D.; Gustafson, A.; Tormos, B.; Berges, L. Maintenance decision making based on different types of data fusion | Podejmowanie decyzji eksploatacyjnych w oparciu o fuzje{ogonek} różnego typu danych. Eksploat. Niezawodn. 2012, 14, 135–144. [Google Scholar]

- Creveling, C.J. Increasing the Reliability of Electronic Equipment by the Use of Redundant Circuits. Proc. IRE 1956, 44, 509–515. [Google Scholar] [CrossRef]

- Jafari, L.; Makis, V. Joint optimal lot sizing and preventive maintenance policy for a production facility subject to condition monitoring. Int. J. Prod. Econ. 2015, 169, 156–168. [Google Scholar] [CrossRef]

| Factor | Value | Percent | Cum% | Ratio |

|---|---|---|---|---|

| 1 | 138.902 | 36.0 | 36.0 | 1.403 |

| 2 | 98.884 | 25.6 | 61.6 | 2.991 |

| 3 | 34.007 | 8.8 | 70.4 | 1.889 |

| 4 | 18.004 | 4.7 | 75.1 | 1.495 |

| 5 | 12.043 | 3.1 | 78.2 | 1.275 |

| 6 | 9.443 | 2.4 | 80.7 | 1.181 |

| 7 | 7.9955 | 2.1 | 82.7 | 1.441 |

| 8 | 547 | 1.4 | 84.2 | 1.182 |

| 9 | 4.694 | 1.2 | 85.4 | 1.162 |

| 10 | 4.040 | 1.0 | 86.4 | 1.093 |

| Rf | Minimum Number of Citations | Maximum Number of Citations | Average Number of Citations |

|---|---|---|---|

| 1 | 3 | 543 | 56.75 |

| 2 | 3 | 253 | 51.50 |

| 3 | 3 | 307 | 48.41 |

| 4 * | 5 | 772 | 85.57 |

| other | 7 | 99 | 24.75 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Quatrini, E.; Costantino, F.; Di Gravio, G.; Patriarca, R. Condition-Based Maintenance—An Extensive Literature Review. Machines 2020, 8, 31. https://doi.org/10.3390/machines8020031

Quatrini E, Costantino F, Di Gravio G, Patriarca R. Condition-Based Maintenance—An Extensive Literature Review. Machines. 2020; 8(2):31. https://doi.org/10.3390/machines8020031

Chicago/Turabian StyleQuatrini, Elena, Francesco Costantino, Giulio Di Gravio, and Riccardo Patriarca. 2020. "Condition-Based Maintenance—An Extensive Literature Review" Machines 8, no. 2: 31. https://doi.org/10.3390/machines8020031

APA StyleQuatrini, E., Costantino, F., Di Gravio, G., & Patriarca, R. (2020). Condition-Based Maintenance—An Extensive Literature Review. Machines, 8(2), 31. https://doi.org/10.3390/machines8020031